Research on the Influence of Carbon Sources and Buffer Layers on the Homogeneous Epitaxial Growth of 4H-SiC

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Effect of C Source

3.1.1. Effect of C Source on Growth Rate and Uniformity

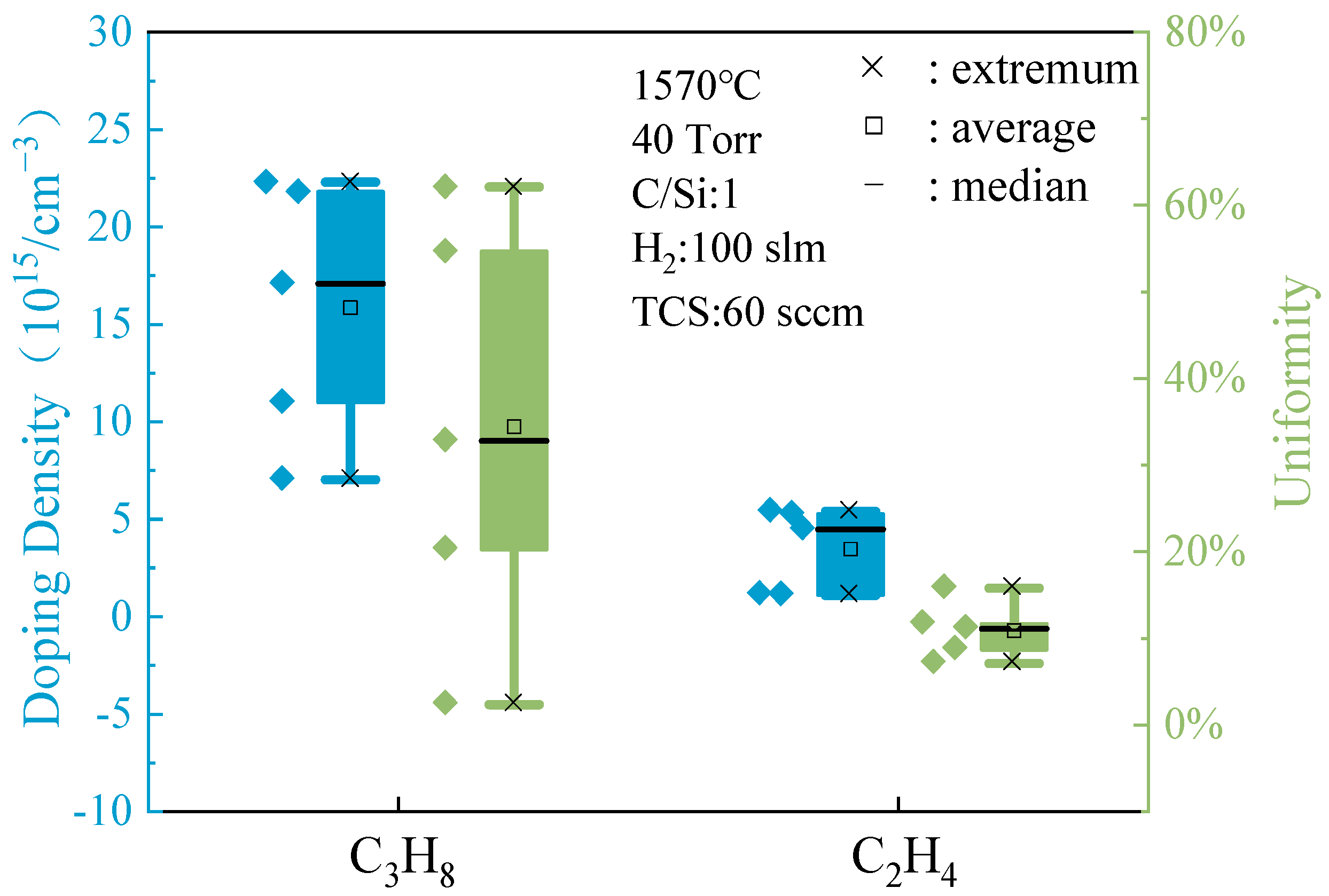

3.1.2. Effect of C Source on Doping Concentration and Uniformity

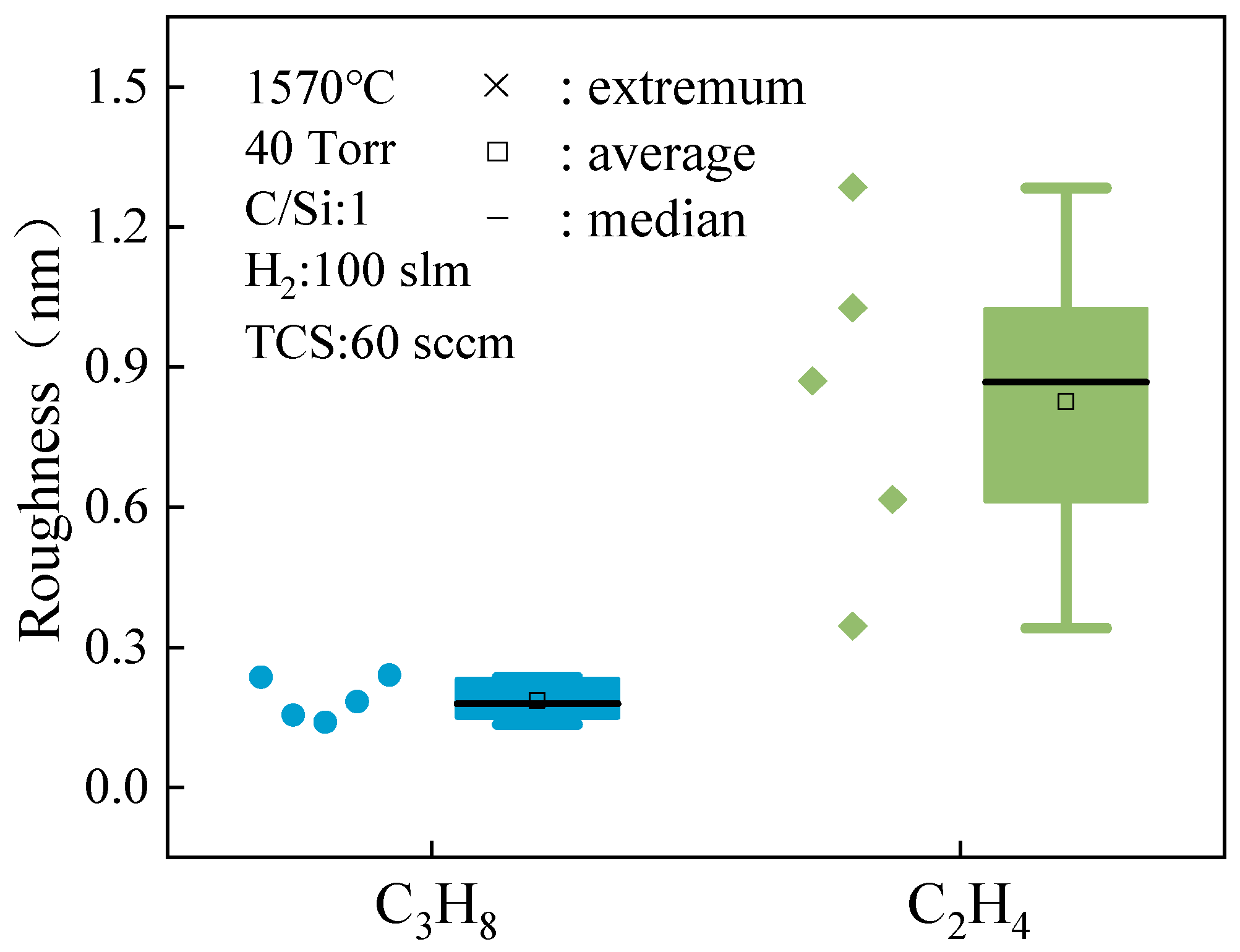

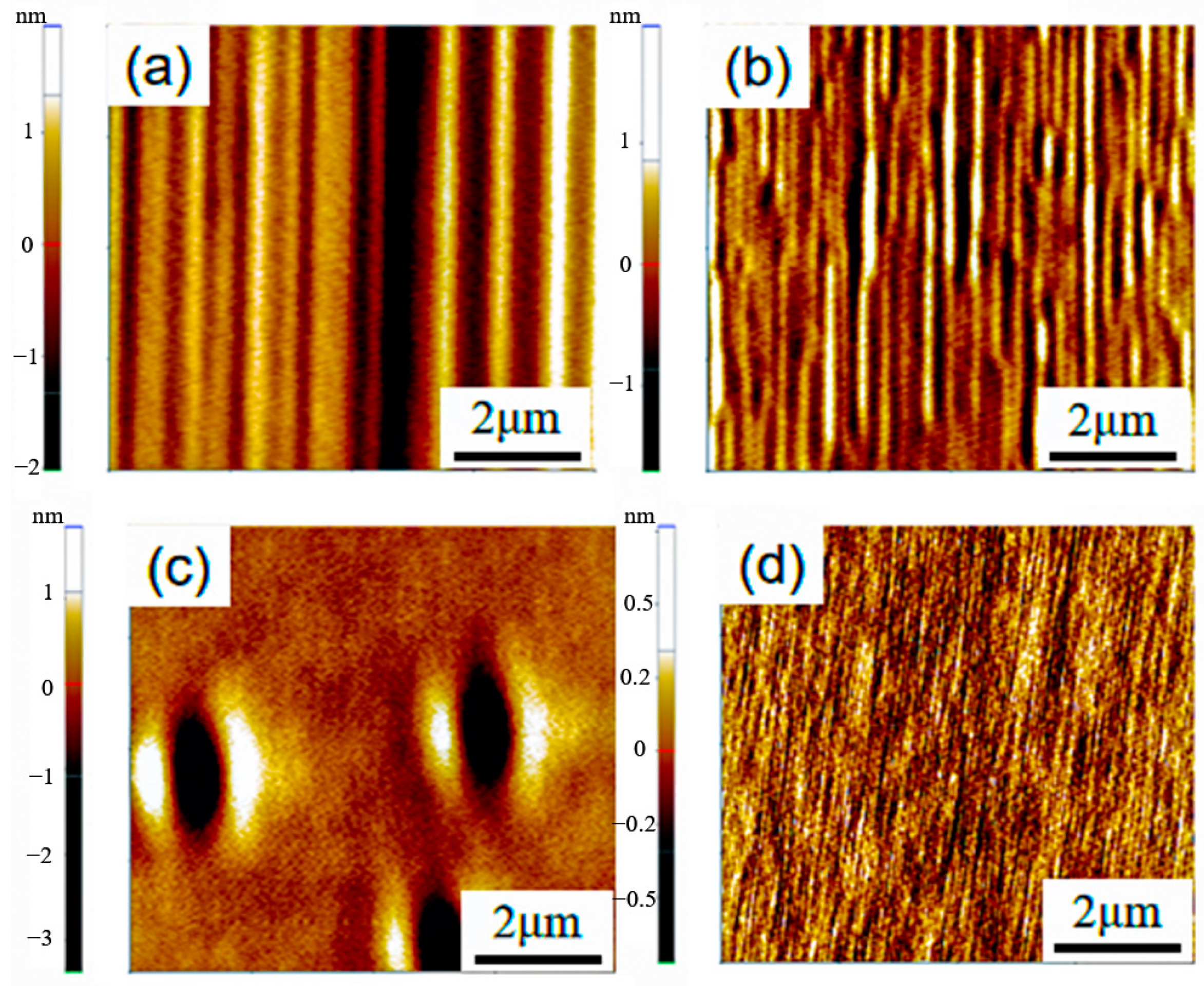

3.1.3. Effect of C Source on Roughness

3.2. Effect of Growth Pressure

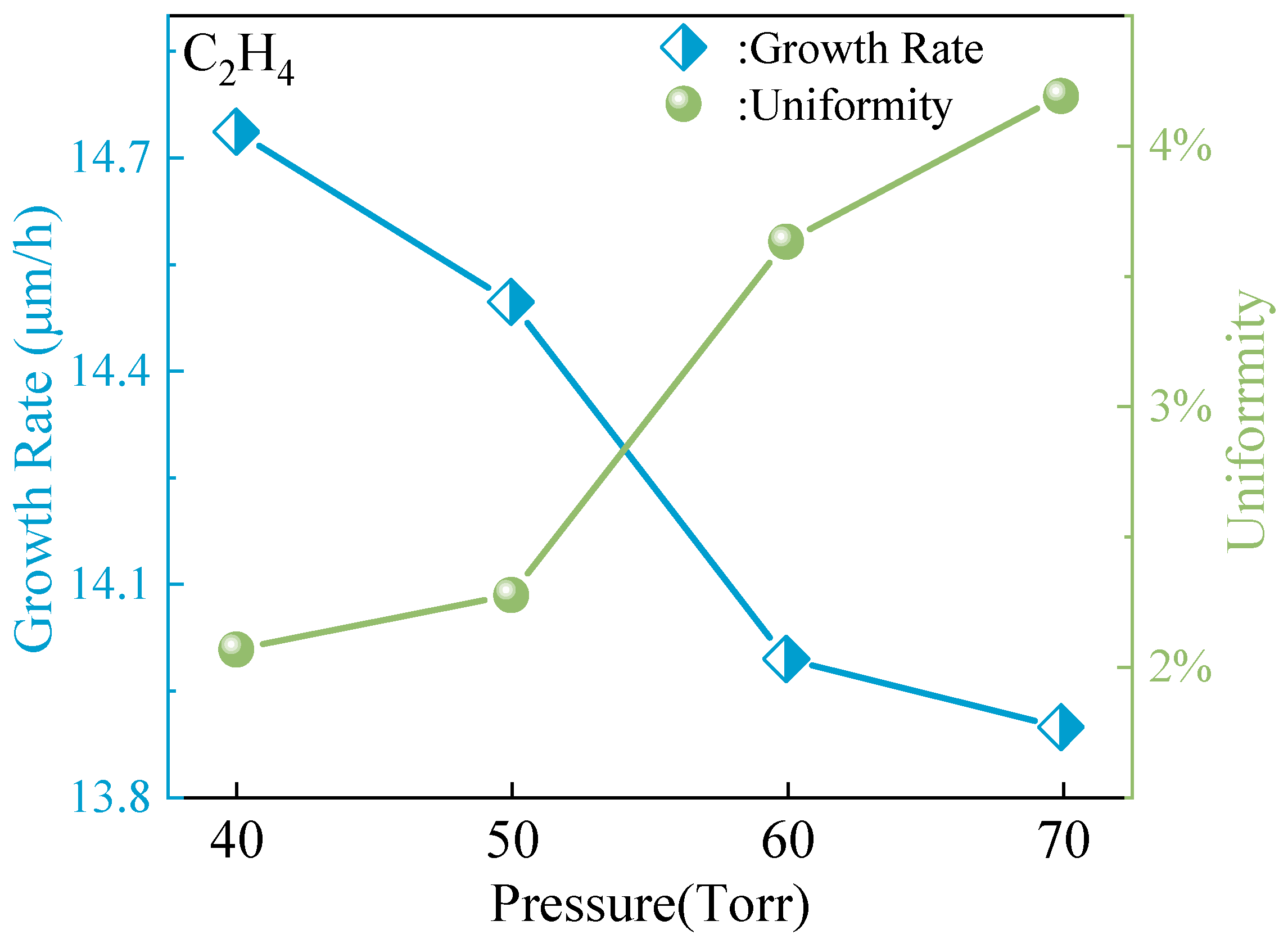

3.2.1. Effect of Growth Pressure on Growth Rate and Uniformity

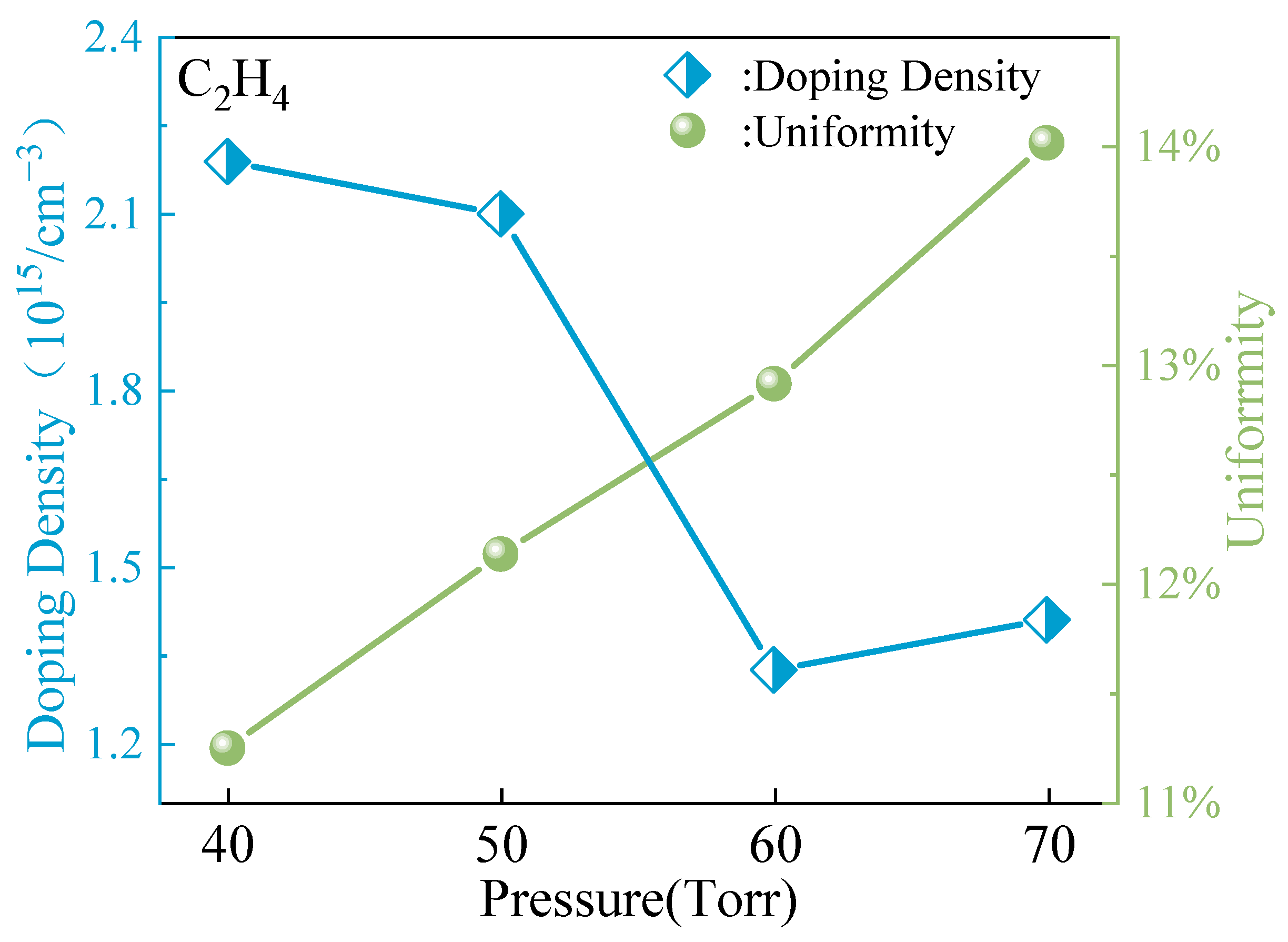

3.2.2. Effect of Growth Pressure on Doping Concentration and Uniformity

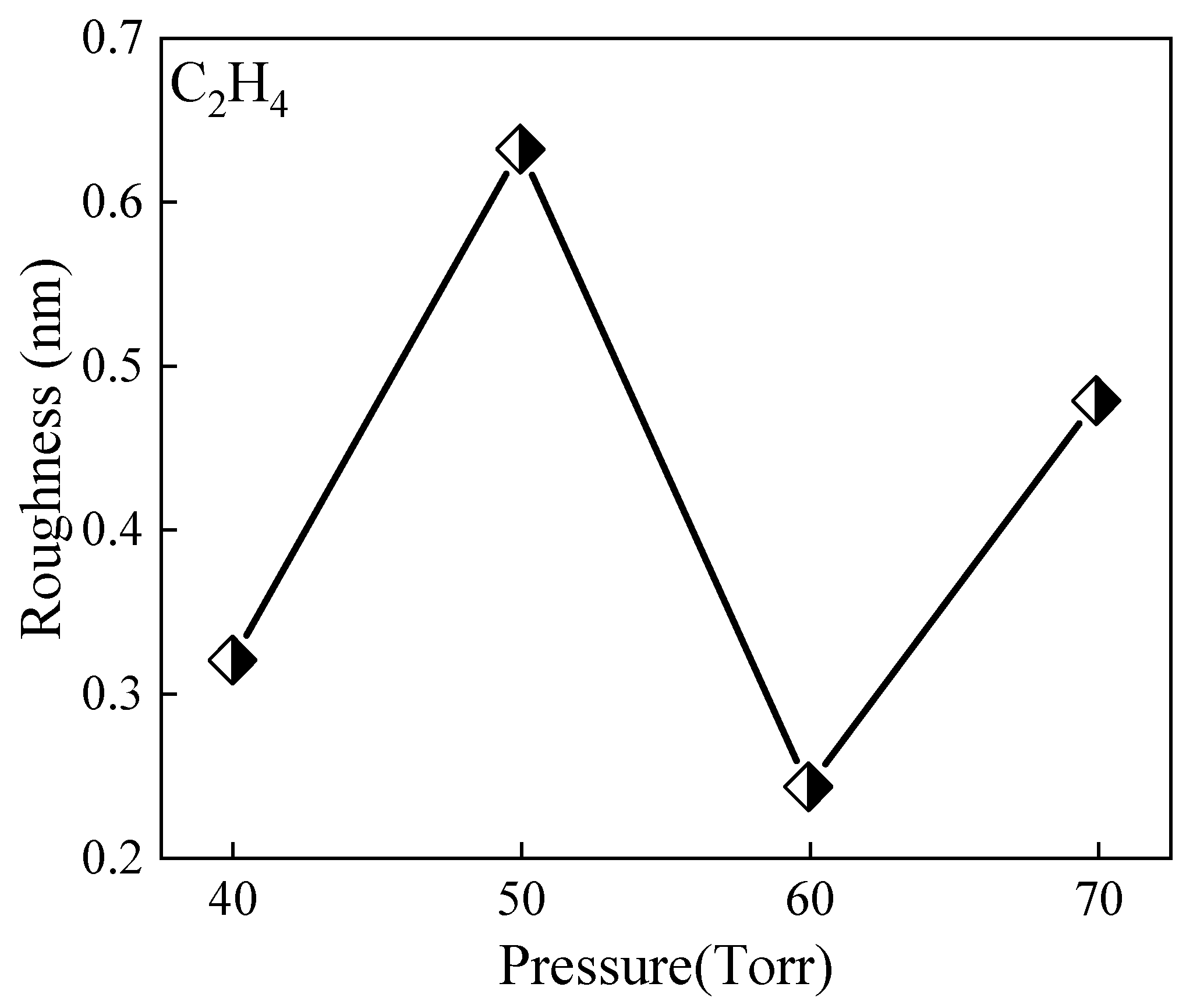

3.2.3. Effect of Growth Pressure on Roughness

3.3. Effect of Buffer Layer Growth

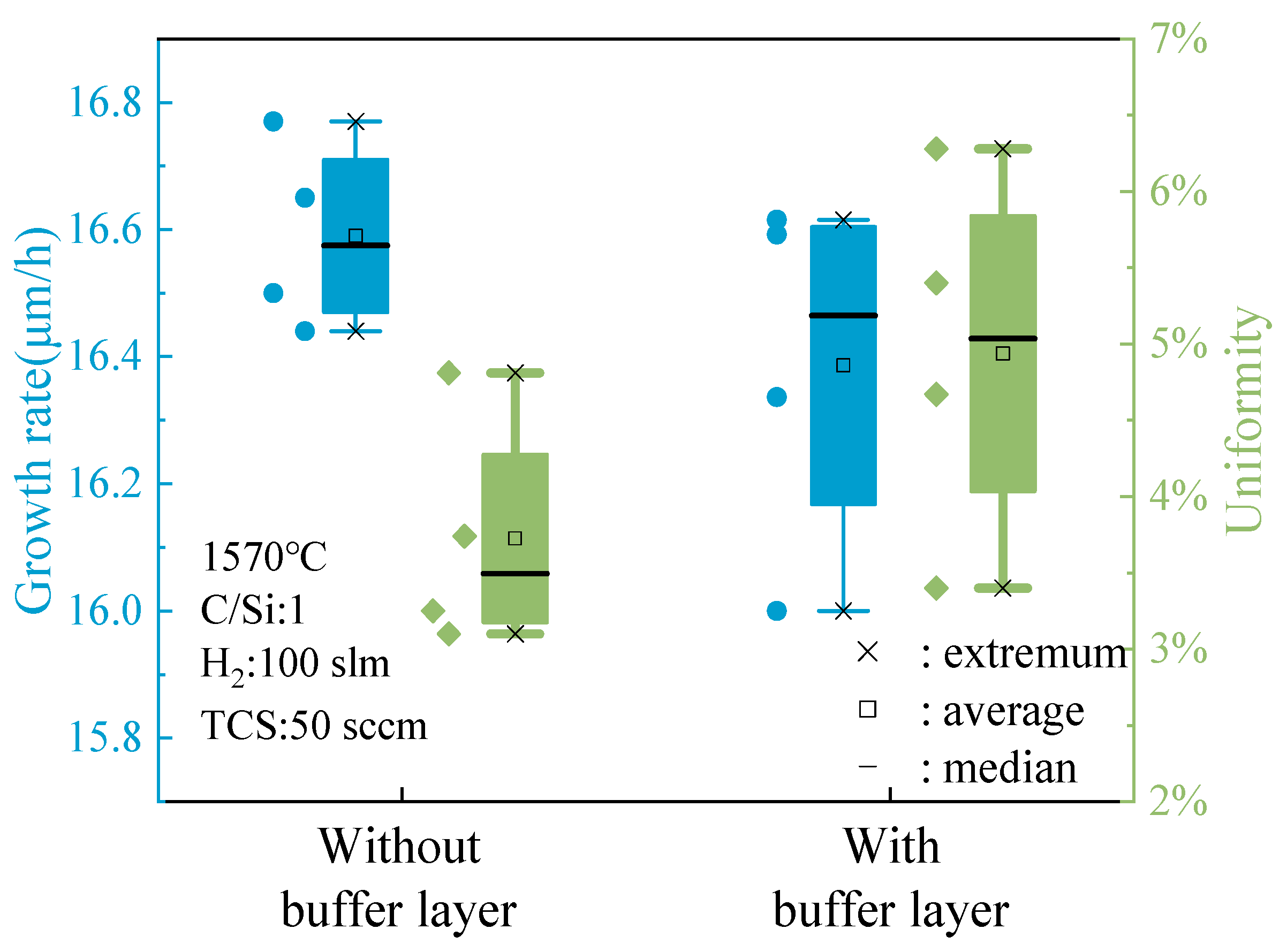

3.3.1. Effect of Buffer Layer Growth on Growth Rate and Uniformity

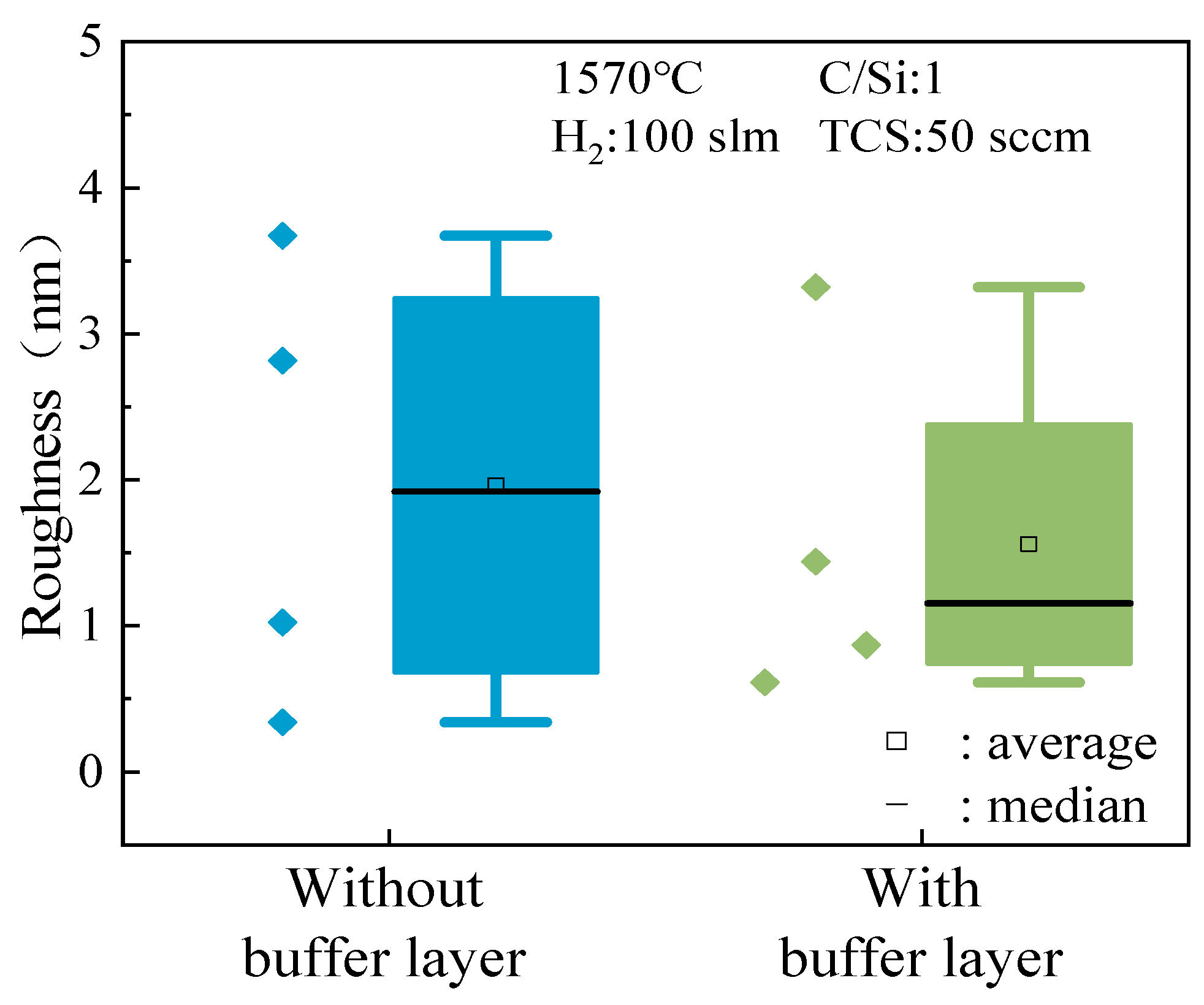

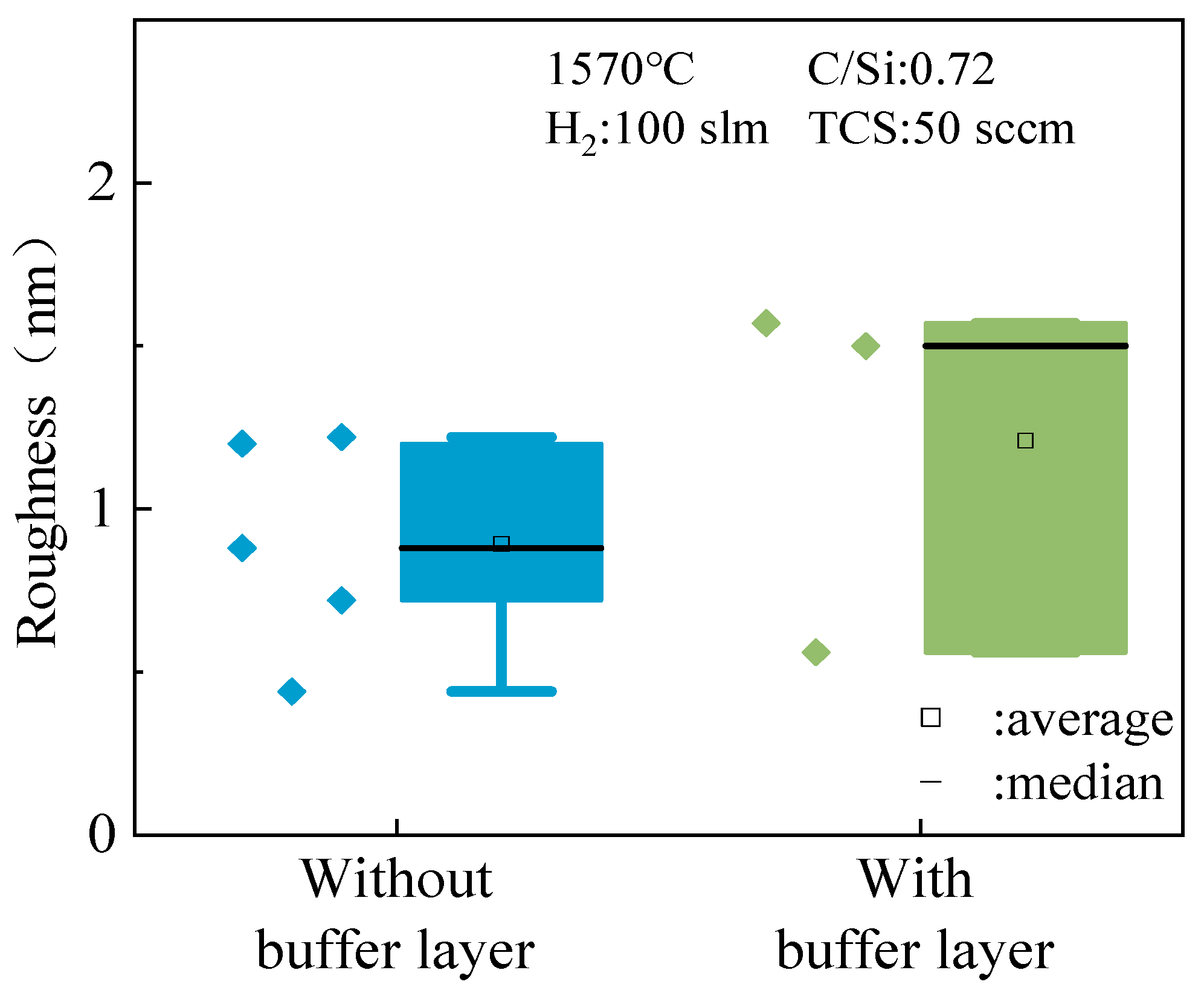

3.3.2. Effect of Buffer Layer Growth on Roughness

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Tang, Z.; Gu, L.; Jin, L.; Dai, K.; Mao, C.; Wu, S.; Zhang, R.; Yang, J.; Ying, J.; Fan, J.; et al. Insights into the Effect of Susceptor Rotational Speed in CVD Reactor on the Quality of 4H-SiC Epitaxial Layer on Homogeneous Substrates. Mater. Today Commun. 2024, 38, 108037. [Google Scholar] [CrossRef]

- Chen, J.; Guan, M.; Yang, S.; Zhao, S.; Yan, G.; Shen, Z.; Zhao, W.; Wang, L.; Liu, X.; Sun, G.; et al. Characterization of Epitaxial Layers Grown on 4H-SiC (000-1) Substrates. J. Cryst. Growth 2023, 604, 127048. [Google Scholar] [CrossRef]

- Matsunami, H. Fundamental Research on Semiconductor SiC and Its Applications to Power Electronics. Proc. Jpn. Acad. Ser. B 2020, 96, 235–254. [Google Scholar] [CrossRef] [PubMed]

- Utsumi, K.; Tanaka, H.; Mori, N. Theoretical Analysis of Electron Scattering by Step-Terrace Structures at SiC Metal-Oxide-Semiconductor Interface. Jpn. J. Appl. Phys. 2024, 63, 02SP75. [Google Scholar] [CrossRef]

- Hu, Y.; Liu, F.; Liu, X. A Simulator for Investigation of Breakdown Characteristics of SiC MOSFETs. Appl. Sci. 2024, 14, 983. [Google Scholar] [CrossRef]

- Hassan, J.U.; Bergman, P.; Palisaitis, J.; Henry, A.; McNally, P.J.; Anderson, S.; Janzén, E. Growth and Properties of SiC On-Axis Homoepitaxial Layers. Mater. Sci. Forum 2010, 645–648, 83–88. [Google Scholar] [CrossRef]

- Suo, H.; Eto, K.; Osawa, H.; Kato, T.; Okumura, H. Threading Dislocation Increase in the Initial Stage of Growth of Nitrogen and Boron Co-Doped 4H-SiC by Physical Vapor Transport. J. Cryst. Growth 2022, 598, 126876. [Google Scholar] [CrossRef]

- Odesanya, K.O.; Ahmad, R.; Andriyana, A.; Bingol, S.; Wong, Y.H. Review—Gate Oxide Thin Films Based on Silicon Carbide. ECS J. Solid-State Sci. Technol. 2022, 11, 083004. [Google Scholar] [CrossRef]

- Zhu, B.; Zhao, D.; Niu, Y.; Zhao, H. Atomic Study on Deformation Behavior and Anisotropy Effect of 4C–SiC during Nanoindentation. Mater. Sci. Semicond. Process. 2023, 163, 107580. [Google Scholar] [CrossRef]

- Zhang, J.; Ellison, A.; Henry, A. Nitrogen Incorporation during 4H-SiC Epitaxy in a Chimney CVD Reactor. J. Cryst. Growth 2001, 226, 267–276. [Google Scholar] [CrossRef]

- Mannen, Y.; Shimada, K.; Taniguchi, C.; Ohtani, N. Stability of Multiple Shockley Type Basal Plane Stacking Faults in Heavily Nitrogen-Doped 4H-SiC Crystals. J. Cryst. Growth 2018, 498, 328–335. [Google Scholar] [CrossRef]

- Shenai, K.; Dudley, M.; Davis, R.F. Current Status and Emerging Trends in Wide Bandgap (WBG) Semiconductor Power Switching Devices. Ecs J. Solid-State Sci. Technol. 2013, 2, N3055–N3063. [Google Scholar] [CrossRef]

- La Via, F.; Alquier, D.; Giannazzo, F.; Kimoto, T.; Neudeck, P.; Ou, H.; Roncaglia, A.; Saddow, S.E.; Tudisco, S. Emerging SiC Applications beyond Power Electronic Devices. Micromachines 2023, 14, 1200. [Google Scholar] [CrossRef] [PubMed]

- An, Y.; Zhang, W.; Tang, X.; Niu, X.; Wang, L.; Yang, X.; Shen, Z.; Sun, J.; Sang, L.; Liu, R.; et al. Effects of Constant Voltage Stress on Bipolar Degradation in 4H-SiC IGBT. J. Cryst. Growth 2023, 605, 127083. [Google Scholar] [CrossRef]

- Ul Hassan, J.; Karhu, R.; Lilja, L.; Janzén, E. Wafer Scale On-Axis Homoepitaxial Growth of 4H-SiC (0001) for High-Power Devices: Influence of Different Gas Phase Chemistries and Growth Rate Limitations. Cryst. Growth Des. 2019, 19, 3288–3297. [Google Scholar] [CrossRef]

- Wang, R.; Huang, Y.; Yang, D.; Pi, X. Impurities and Defects in 4H Silicon Carbide. Appl. Phys. Lett. 2023, 122, 180501. [Google Scholar] [CrossRef]

- Song, B.; Gao, B.; Han, P.; Yu, Y. Surface Kinetic Mechanisms of Epitaxial Chemical Vapour Deposition of 4H Silicon Carbide Growth by Methyltrichlorosilane-H2 Gaseous System. Materials 2022, 15, 3768. [Google Scholar] [CrossRef]

- Stuchlikova, T.H.; Stuchlik, J.; Remes, Z.; Taylor, A.; Mortet, V.; Ashcheulov, P.; Gregora, I.; Krivyakin, G.; Volodin, V. High-Temperature PIN Diodes Based on Amorphous Hydrogenated Silicon-Carbon Alloys and Boron-Doped Diamond Thin Films. Phys. Status Solidi (b) 2020, 257, 1900247. [Google Scholar] [CrossRef]

- Cooper, J.A.; Agarwal, A. SiC Power-Switching Devices-the Second Electronics Revolution? Proc. IEEE 2002, 90, 956–968. [Google Scholar] [CrossRef]

- Hassan, J.; Bergman, J.P.; Henry, A.; Janzén, E. In-Situ Surface Preparation of Nominally on-Axis 4H-SiC Substrates. J. Cryst. Growth 2008, 310, 4430–4437. [Google Scholar] [CrossRef]

- Yang, S.; Zhao, S.; Chen, J.; Yan, G.; Shen, Z.; Zhao, W.; Wang, L.; Zhang, Y.; Liu, X.; Sun, G.; et al. Growth of 4H-SiC Epitaxial Layers at Temperatures below 1500 °C Using Trichlorosilane (TCS). J. Cryst. Growth 2023, 612, 127058. [Google Scholar] [CrossRef]

- Kimoto, T. Bulk and Epitaxial Growth of Silicon Carbide. Prog. Cryst. Growth Charact. Mater. 2016, 62, 329–351. [Google Scholar] [CrossRef]

- Zhao, L.X.; Yang, L.; Wu, H.W. High Quality 4H-SiC Homo-Epitaxial Wafer Using the Optimal C/Si Ratio. J. Cryst. Growth 2020, 530, 125302. [Google Scholar] [CrossRef]

- Zhao, S.; Chen, J.; Yang, S.; Yan, G.; Shen, Z.; Zhao, W.; Wang, L.; Liu, X.; Sun, G.; Zeng, Y. Effect of Temperature on Growth of Epitaxial Layer on Semi-Insulating 4H-SiC Substrate. J. Cryst. Growth 2023, 603, 127008. [Google Scholar] [CrossRef]

- Zhao, L.; Wu, H. A Correlation Study of Substrate and Epitaxial Wafer with 4H-N Type Silicon Carbide. J. Cryst. Growth 2019, 507, 109–112. [Google Scholar] [CrossRef]

- Valente, G.; Cavallotti, C.; Masi, M.; Carra, S. Reduced Order Model for the CVD of Epitaxial Silicon from Silane and Chlorosilanes. J. Cryst. Growth 2001, 230, 247–257. [Google Scholar] [CrossRef]

- La Via, F.; Galvagno, G.; Foti, G.; Mauceri, M.; Leone, S.; Pistone, G.; Abbondanza, G.; Veneroni, A.; Masi, M.; Valente, G.L.; et al. 4H SiC Epitaxial Growth with Chlorine Addition. Chem. Vap. Depos. 2006, 12, 509–515. [Google Scholar] [CrossRef]

- Yan, G.G.; He, Y.W.; Shen, Z.W.; Cui, Y.X.; Li, J.T.; Zhao, W.S.; Wang, L.; Liu, X.F.; Zhang, F.; Sun, G.S.; et al. Effect of C/Si Ratio on Growth of 4H-SiC Epitaxial Layers on on-Axis and 4° off-Axis Substrates. J. Cryst. Growth 2020, 531, 125362. [Google Scholar] [CrossRef]

- Liu, X.F.; Yan, G.G.; Liu, B.; Shen, Z.W.; Wen, Z.X.; Chen, J.; Zhao, W.S.; Wang, L.; Zhang, F.; Sun, G.S.; et al. Process Optimization for Homoepitaxial Growth of Thick 4H-SiC Films via Hydrogen Chloride Chemical Vapor Deposition. J. Cryst. Growth 2018, 504, 7–12. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, Y.; Xia, X.; Wang, Y.; Zhou, P.; Li, Z. Growth of High-Quality 4H-SiC Epitaxial Layers on 4° off-Axis C-Face 4H-SiC Substrates. J. Cryst. Growth 2020, 531, 125355. [Google Scholar] [CrossRef]

- Bah, M.; Alquier, D.; Lesecq, M.; Defrance, N.; Valente, D.; Ngo, T.H.; Frayssinet, E.; Portail, M.; De Jaeger, J.-C.; Cordier, Y. Highlighting the Role of 3C–SiC in the Performance Optimization of (Al,Ga)N-based High-Electron Mobility Transistors. Mater. Sci. Semicond. Process. 2024, 171, 107977. [Google Scholar] [CrossRef]

- Roccaforte, F.; Fiorenza, P.; Greco, G.; Lo Nigro, R.; Giannazzo, F.; Iucolano, F.; Saggio, M. Emerging Trends in Wide Band Gap Semiconductors (SiC and GaN) Technology for Power Devices. Microelectron. Eng. 2018, 187, 66–77. [Google Scholar] [CrossRef]

- Tang, X.; Sang, L.; Li, Y.; Kong, L.; Tian, L.; Tian, H.; Wu, P.; Jia, R.; Yang, F.; Wu, J.; et al. The Influence of Temperature on the Silicon Droplet Evolution in the Homoepitaxial Growth of 4H-SiC. J. Cryst. Growth 2018, 504, 37–40. [Google Scholar]

- Daigo, Y.; Takada, Y.; Kurashima, K.; Watanabe, T.; Ishiguro, A.; Ishii, S.; Moriyama, Y.; Mizushima, I. Influence of Residual Dopants to Net Doping Concentration in N-Type 4H-SiC Films Grown Using High-Speed Wafer Rotation Vertical CVD Method. Jpn. Jpn. J. Appl. Phys. 2022, 61, SC1041. [Google Scholar] [CrossRef]

- Mochizuki, K.; Mishima, T. Analysis of Surface Diffusion of Carbon- and Nitrogen-Containing Molecules during Homoepitaxial Growth of 4H-SiC (0001) under Silicon-Rich Conditions. Jpn. J. Appl. Phys. 2021, 60, 018001. [Google Scholar] [CrossRef]

- Saitoh, Y.; Itoh, H.; Wada, K.; Sakai, M.; Horii, T.; Hiratsuka, K.; Tanaka, S.; Mikamura, Y. 150 A SiC V-Groove Trench Gate MOSFET with 6 x 6 Mm (2) Chip Size on a 150 Mm C-Face In-House Epitaxial Wafer. Jpn. J. Appl. Phys. 2016, 55, 04ER05. [Google Scholar] [CrossRef]

- Peng, J.; Jolly, B.; Mitchell, D.J.; Haynes, J.A.; Shin, D. Computational Thermodynamic Study of SiC Chemical Vapor Deposition from MTS-H 2 *. J. Am. Ceram. Soc. 2021, 104, 3726–3737. [Google Scholar] [CrossRef]

- Daigo, Y.; Ishiguro, A.; Moriyama, Y.; Mizushima, I. Structure and Reduction of Large Bumps Formed on 4H-SiC Epitaxial Film Originated from Dislocations in Substrate. J. Cryst. Growth 2021, 574, 126329. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, W.; Pei, Y.; Li, Y.; Guo, N.; Zhang, X.; Liu, X. Research on the Influence of Carbon Sources and Buffer Layers on the Homogeneous Epitaxial Growth of 4H-SiC. Micromachines 2024, 15, 600. https://doi.org/10.3390/mi15050600

Yuan W, Pei Y, Li Y, Guo N, Zhang X, Liu X. Research on the Influence of Carbon Sources and Buffer Layers on the Homogeneous Epitaxial Growth of 4H-SiC. Micromachines. 2024; 15(5):600. https://doi.org/10.3390/mi15050600

Chicago/Turabian StyleYuan, Weilong, Yicheng Pei, Yunkai Li, Ning Guo, Xiuhai Zhang, and Xingfang Liu. 2024. "Research on the Influence of Carbon Sources and Buffer Layers on the Homogeneous Epitaxial Growth of 4H-SiC" Micromachines 15, no. 5: 600. https://doi.org/10.3390/mi15050600

APA StyleYuan, W., Pei, Y., Li, Y., Guo, N., Zhang, X., & Liu, X. (2024). Research on the Influence of Carbon Sources and Buffer Layers on the Homogeneous Epitaxial Growth of 4H-SiC. Micromachines, 15(5), 600. https://doi.org/10.3390/mi15050600