Experimental Investigation on Ultra-Thin Vapor Chamber with Composite Wick for Electronics Thermal Management

Abstract

:1. Introduction

2. Experimental Section

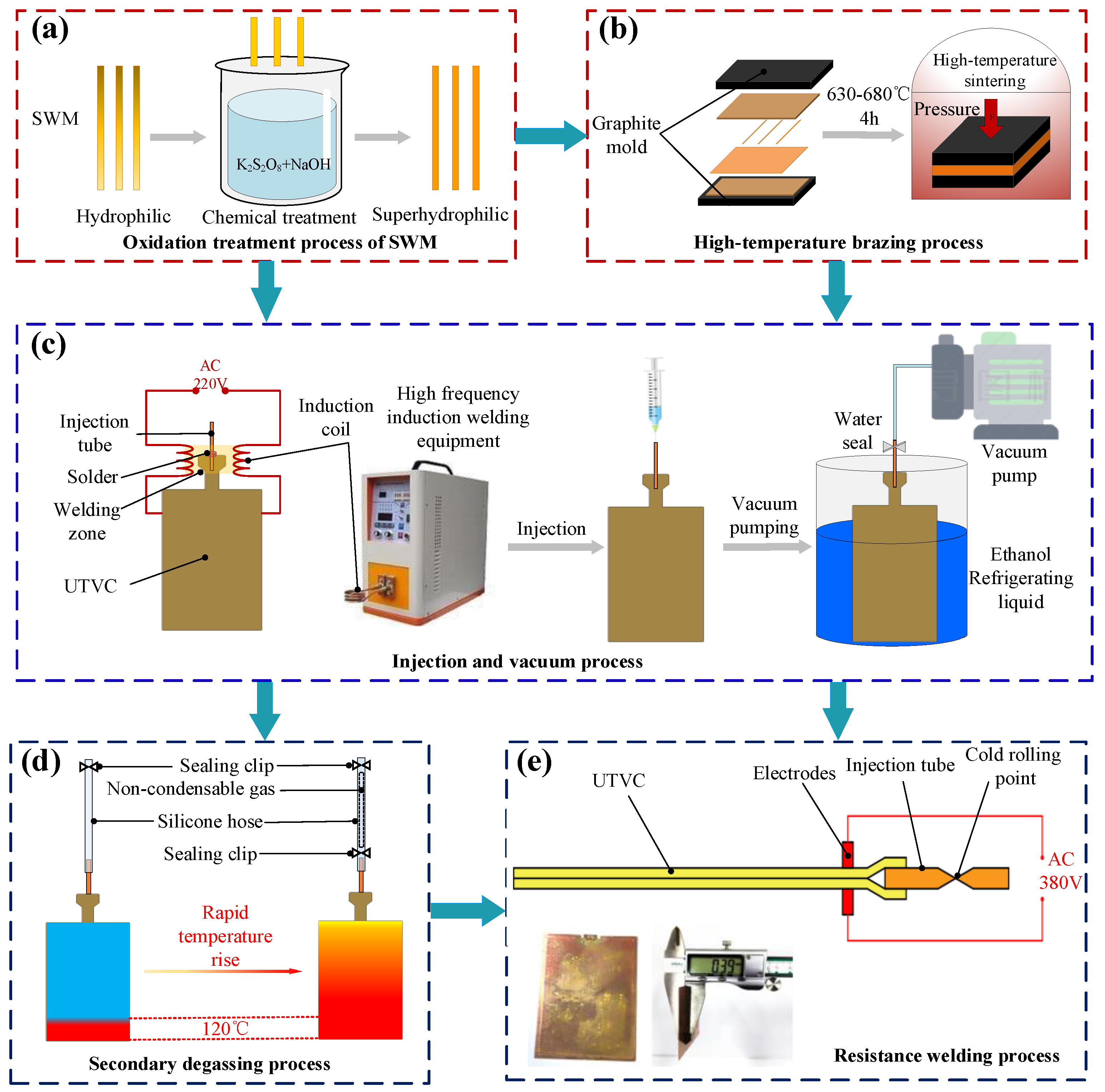

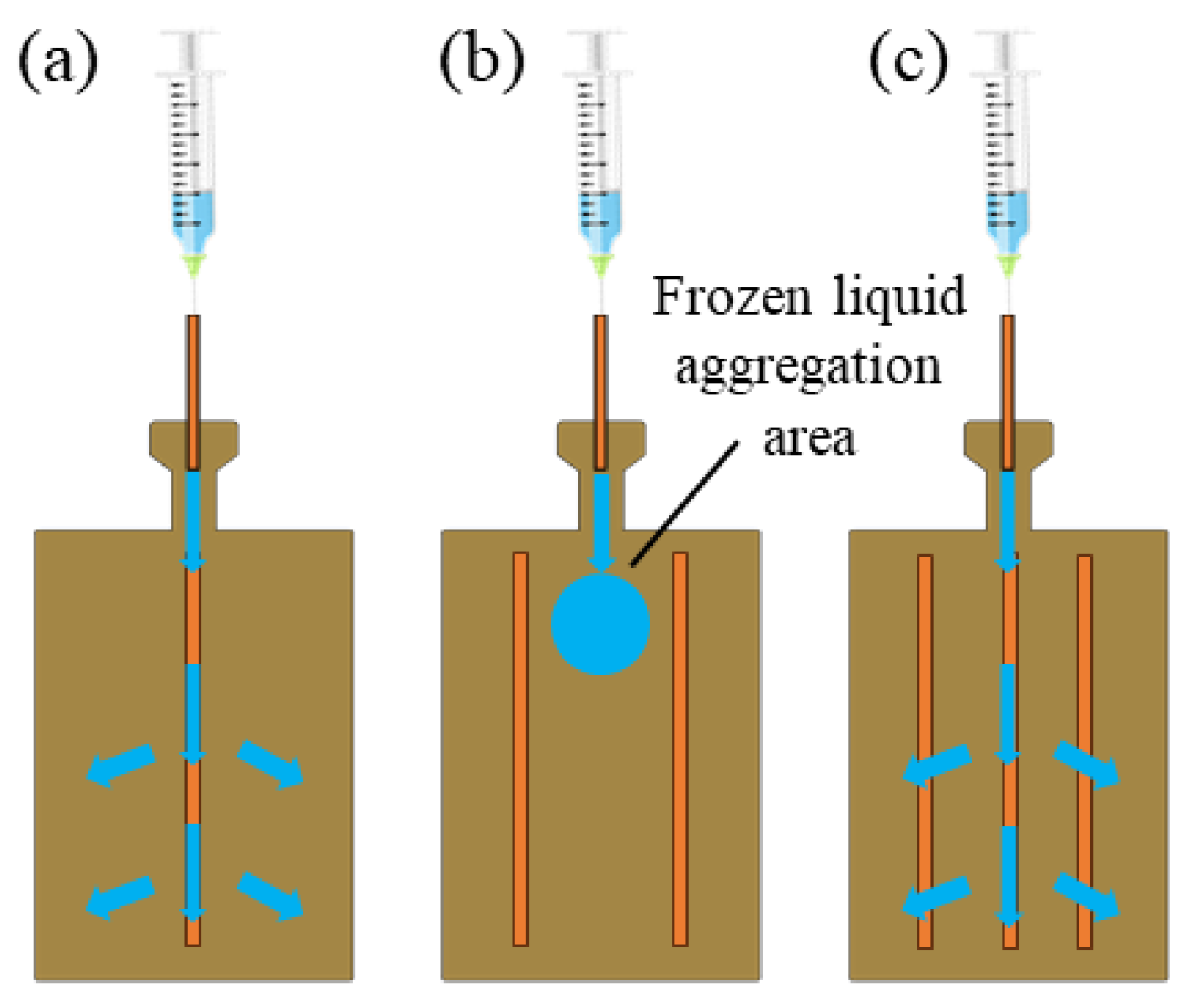

2.1. Design and Manufacturing of UTVC

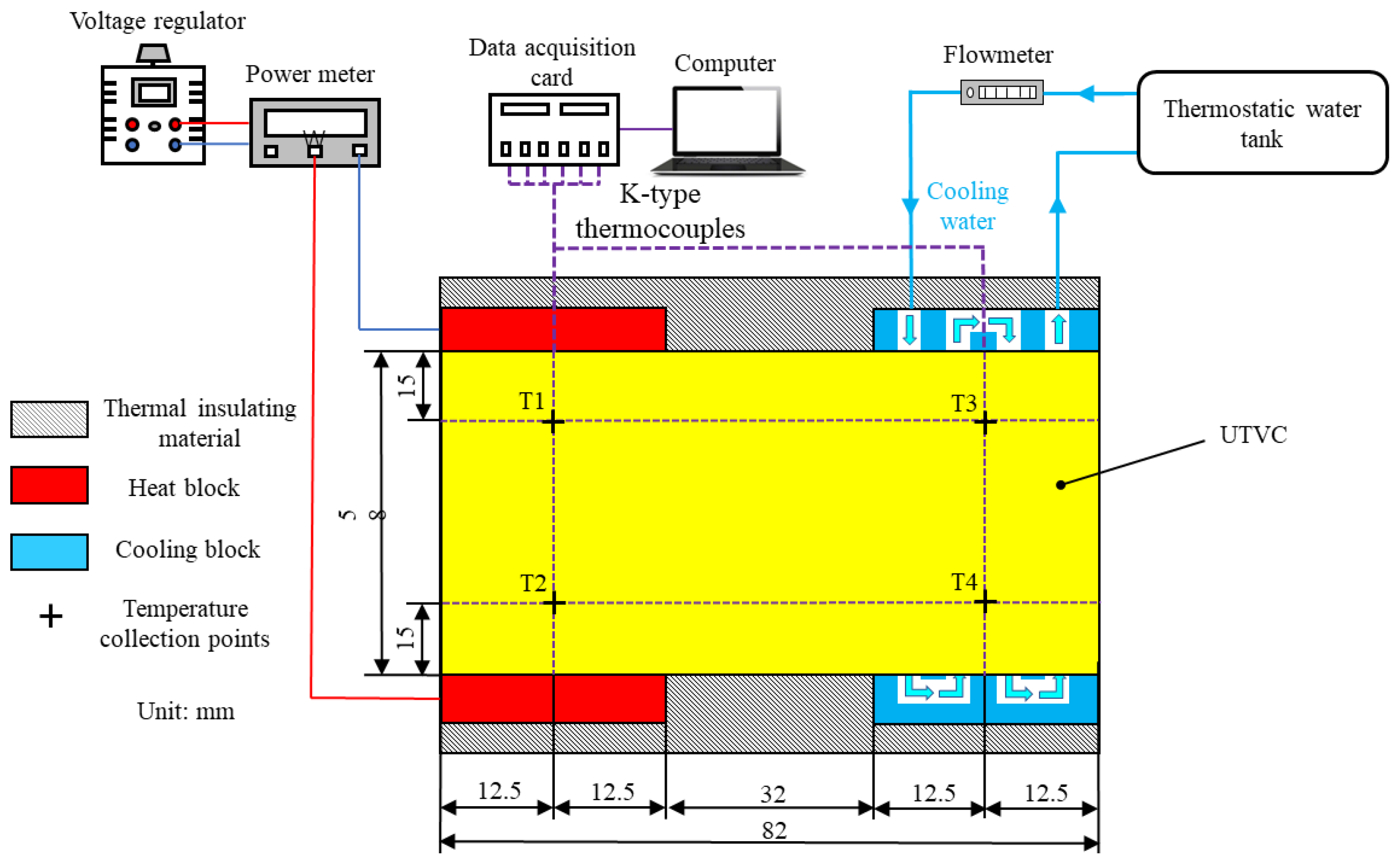

2.2. Heat Transfer Performance Test

2.3. Characterization of Wettability of Wick

2.4. Data Processing and Uncertainty

3. Results and Discussion

3.1. Wettability of Wick

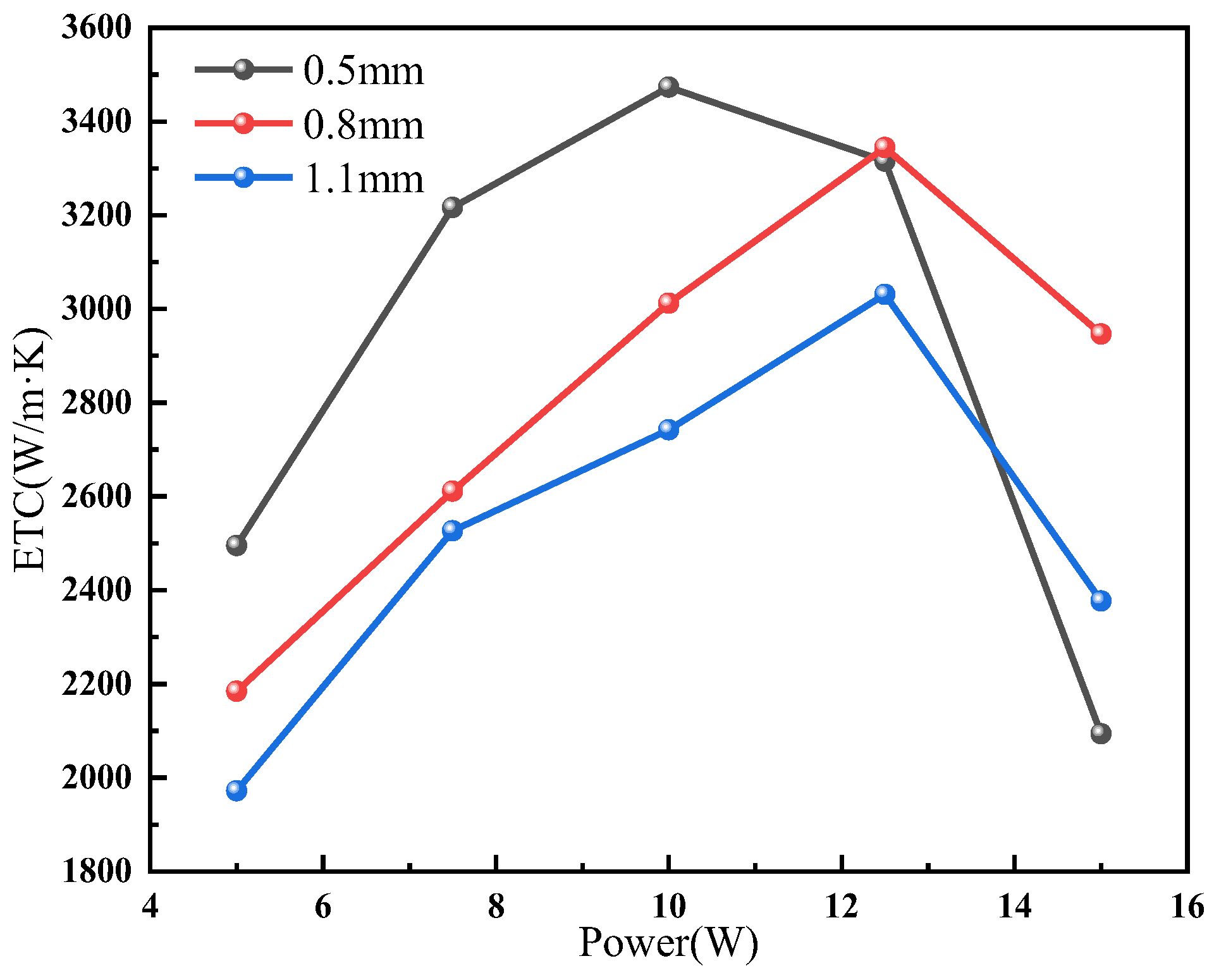

3.2. Effect of Support Column Diameter

3.3. Effect of Different FRs

3.4. Effect of Wick Structure

3.5. Comparison with Reported Studies

4. Conclusions

- (1)

- The ETC with support column diameters of 0.5 mm, 0.8 mm, and 1.1 mm are compared under the condition of 30% FR and 0 SWMs. The UTVC with 0.5 mm support column diameter has the highest ETC of 3473 W/(m·K). By comparison, the UTVCs with 0.8 mm and 1.1 mm support column diameters have the ETC of 3344 W/(m·K) and 3031 W/(m·K), respectively. The ETC of UTVC with 0.5 mm support column is improved by 3.9% and 14.6% compared with that of 0.8 mm and 1.1 mm support column, the ETC decreases as the diameter of the support column increases.

- (2)

- The effect of FRs on UTVCs with different numbers of SWMs (0 SWMs, 1 SWM, 2 SWMs, 3 SWMs) is consistent, the ETC of 30% FR is the highest, and the highest ETC is about 3473 W/(m·K), 3565 W/(m·K), 3350 W/(m·K) and 3837 W/(m·K), respectively. Compared with 20% FR, the ETC of 30% FR increased by 16%, 54.5%, 6.3%, and 26.1%, respectively, and compared with 40% FR, the ETC of 30% FR improved by 14.2%, 2.8%, 2.4%, and 7.3%, respectively.

- (3)

- The increased number of SWMs can significantly improve the ultimate power of the UTVCs; under the condition of optimal 30% FR, the ultimate power of UTVCs with 0, 1, 2, and 3 SWMs are 15 W, 18 W, 26 W, and 26 W, respectively. an increase in the number of SWMs can slightly promote the maximum ETC of UTVCs, the maximum ETC of UTVCs with 0, 1, 2, and 3 SWMs are 3490 W/(m·K), 3565 W/(m·K), 3432 W/(m·K), and 3837 W/(m·K), respectively, indicating that the UTVC with the 3 SWMs has the highest ultimate power of 26 W. Moreover, the maximum ETC of UTVC with 0, 1, 2, and 3 SWMs shows slight improvement.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Symbols | |

| and Temperatures of evaporation section, °C | and Temperatures of condensation section, °C |

| Average temperature of evaporating section, °C | Average temperature of condensing section, °C |

| Temperature difference, °C | Total thermal resistance, °C/W |

| Input power, W | Equivalent thermal conductivity, W/(m·K) |

| Cross-sectional area, m2 | Effective length, m |

| Length of evaporating section, m | Length of adiabatic section, m |

| Length of condensing section, m | |

| Abbreviations | |

| UTVC Ultra-thin vapor chamber | SWM Spiral-woven mesh |

| FR Filling ratio | ETC Equivalent thermal conductivity |

| UTHP Ultra-thin heat pipe | SSGW Single arched sintered groove wick |

| BSGW Double-sided arched sintered groove wick | MGW Mesh groove wick |

References

- Arshad, A.; Jabbal, M.; Shi, L.; Yan, Y. Thermophysical characteristics and enhancement analysis of carbon-additives phase change mono and hybrid materials for thermal management of electronic devices. J. Energy Storage 2021, 34, 102231. [Google Scholar] [CrossRef]

- Garimella, S.V.; Fleischer, A.S.; Murthy, J.Y.; Keshavarzi, A.; Prasher, R.; Patel, C.; Bhavnani, S.H.; Venkatasubramanian, R.; Mahajan, R.; Joshi, Y.; et al. Thermal Challenges in Next-Generation Electronic Systems. IEEE Trans. Compon. Packag. Technol. 2008, 31, 801–815. [Google Scholar] [CrossRef]

- Wang, H.-L.; Wu, H.-C.; Wang, S.K.; Hung, T.-C.; Yang, R.-J. A study of mini-channel thermal module design for achieving high stability and high capability in electronic cooling. Appl. Therm. Eng. 2013, 51, 1144–1153. [Google Scholar] [CrossRef]

- Yuan, T.; Teng, Q.; Li, C.; Li, J.; Su, W.; Song, X.; Shi, Y.; Xu, H.; Han, Y.; Wei, S.; et al. The emergence and prospects of carbon dots with solid-state photoluminescence for light-emitting diodes. Mater. Horiz. 2024, 11, 102–112. [Google Scholar] [CrossRef] [PubMed]

- Garimella, S.V. Advances in mesoscale thermal management technologies for microelectronics. Microelectron. J. 2006, 37, 1165–1185. [Google Scholar] [CrossRef]

- Chen, G.; Jia, M.; Zhang, S.; Tang, Y.; Wan, Z. Pool boiling enhancement of novel interconnected microchannels with reentrant cavities for high-power electronics cooling. Int. J. Heat Mass Transfer 2020, 156, 119836. [Google Scholar] [CrossRef]

- Sun, Y.; Chen, G.; Zhang, S.; Tang, Y.; Zeng, J.; Yuan, W. Pool boiling performance and bubble dynamics on microgrooved surfaces with reentrant cavities. Appl. Therm. Eng. 2017, 125, 432–442. [Google Scholar] [CrossRef]

- Wang, H.; Wang, F.; Li, Z.; Tang, Y.; Yu, B.; Yuan, W. Experimental investigation on the thermal performance of a heat sink filled with porous metal fiber sintered felt/paraffin composite phase change material. Appl. Energy 2016, 176, 221–232. [Google Scholar] [CrossRef]

- Koukoravas, T.P.; Damoulakis, G.; Megaridis, C.M. Experimental investigation of a vapor chamber featuring wettability-patterned surfaces. Appl. Therm. Eng. 2020, 178, 115522. [Google Scholar] [CrossRef]

- Huang, J.; Zhou, W.; Xiang, J.; Liu, C.; Gao, Y.; Li, S.; Ling, W. Development of novel flexible heat pipe with multistage design inspired by structure of human spine. Appl. Therm. Eng. 2020, 175, 115392. [Google Scholar] [CrossRef]

- Ling, W.; Zhou, W.; Yu, W.; Liu, R.; Hui, K.S. Thermal performance of loop heat pipes with smooth and rough porous copper fiber sintered sheets. Energy Convers. Manag. 2017, 153, 323–334. [Google Scholar] [CrossRef]

- Tang, Y.; Tang, H.; Wang, Z.; Yuan, W.; Lu, L. Research status and development trends of ultra-thin micro heat pipes. Chin. J. Mech. Eng. 2017, 53, 131–144. [Google Scholar] [CrossRef]

- Ming, T.; Li, Z.; Zhao, S.; Zhi, C.; Liu, D.; Shi, C.; Yuan, Y.; Tan, G.; Wu, Y. Heat transfer enhancement of the ultra-thin flat heat pipe integrated with copper-fiber bundle wicks. Appl. Therm. Eng. 2024, 236, 121676. [Google Scholar] [CrossRef]

- Li, X.B.; Shi, Z.; Wang, S.; Hu, Q.; Bao, L.; Zhang, H.J.K.E.M. Analysis of structural parameters of grooved-wicksin micro heat pipes based on capillary limits. Key Eng. Mater. 2012, 499, 21–26. [Google Scholar] [CrossRef]

- Zhou, W.J.; Li, Y.; Chen, Z.S.; Deng, L.Q.; Gan, Y.H. A novel ultra-thin flattened heat pipe with biporous spiral woven mesh wick for cooling electronic devices. Energy Convers. Manag. 2019, 180, 769–783. [Google Scholar] [CrossRef]

- Sanhan, W.; Vafai, K.; Kammuang-Lue, N.; Terdtoon, P.; Sakulchangsatjatai, P. Numerical simulation of flattened heat pipe with double heat sources for CPU and GPU cooling application in laptop computers. J. Comput. Des. Eng. 2021, 8, 524–535. [Google Scholar] [CrossRef]

- Zhou, W.; Li, Y.; Chen, Z.; Deng, L.; Gan, Y. Ultra-thin flattened heat pipe with a novel band-shape spiral woven mesh wick for cooling smartphones. Int. J. Heat Mass Transfer 2020, 146, 118792. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, W.J.; He, J.B.; Yan, Y.Y.; Li, B.; Zeng, Z.X. Thermal performance of ultra-thin flattened heat pipes with composite wick structure. Appl. Therm. Eng. 2016, 102, 487–499. [Google Scholar] [CrossRef]

- Velardo, J.; Date, A.; Singh, R.; Nihill, J.; Date, A.; Thanh Long, P.; Takahashi, M. Experimental investigation of a vapour chamber heat spreader with hybrid wick structure. Int. J. Therm. Sci. 2019, 140, 28–35. [Google Scholar] [CrossRef]

- Rezk, K.; Abdelrahman, M.A.; Attia, A.A.A.; Emam, M. Thermal control of temperature-sensitive electronic components using a vapor chamber integrated with a straight fins heat sink: An experimental investigation. Appl. Therm. Eng. 2022, 217, 119147. [Google Scholar] [CrossRef]

- Lu, Z.; Bai, P.; Huang, B.; Henzen, A.; Coehoorn, R.; Liao, H.; Zhou, G. Experimental investigation on the thermal performance of three-dimensional vapor chamber for LED automotive headlamps. Appl. Therm. Eng. 2019, 157, 113478. [Google Scholar] [CrossRef]

- Luo, X.; Hu, R.; Guo, T.; Zhu, X.; Chen, W.; Mao, Z.; Liu, S. In Low thermal resistance LED light source with vapor chamber coupled fin heat sink. In Proceedings of the 60th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 1–4 June 2010; pp. 1347–1352. [Google Scholar]

- Huang, G.; Liu, W.; Luo, Y.; Li, Y. A novel ultra-thin vapor chamber for heat dissipation in ultra-thin portable electronic devices. Appl. Therm. Eng. 2020, 167, 114726. [Google Scholar] [CrossRef]

- Lim, H.T.; Kim, S.H.; Im, H.D.; Oh, K.H.; Jeong, S.H. Fabrication and evaluation of a copper flat micro heat pipe working under adverse-gravity orientation. J. Micromech. Microeng. 2008, 18, 105013. [Google Scholar] [CrossRef]

- Ding, C.; Soni, G.; Bozorgi, P.; Piorek, B.D.; Meinhart, C.D.; MacDonald, N.C. A Flat Heat Pipe Architecture Based on Nanostructured Titania. J. Microelectromech. Syst. 2010, 19, 878–884. [Google Scholar] [CrossRef]

- Shi, B.; Zhang, H.; Zhang, P.; Yan, L. Performance test of an ultra-thin flat heat pipe with a 0.2 mm thick vapor chamber. J. Micromech. Microeng. 2019, 29, 115019. [Google Scholar] [CrossRef]

- Tang, H.; Tang, Y.; Yuan, W.; Peng, R.; Lu, L.; Wan, Z. Fabrication and capillary characterization of axially micro-grooved wicks for aluminium flat-plate heat pipes. Appl. Therm. Eng. 2018, 129, 907–915. [Google Scholar] [CrossRef]

- Chen, L.; Deng, D.X.; Huang, Q.S.; Xu, X.H.; Xie, Y.X. Development and thermal performance of a vapor chamber with multi-artery reentrant microchannels for high-power LED. Appl. Therm. Eng. 2020, 166, 114686. [Google Scholar] [CrossRef]

- Li, Y.; He, J.; He, H.; Yan, Y.; Zeng, Z.; Li, B. Investigation of ultra-thin flattened heat pipes with sintered wick structure. Appl. Therm. Eng. 2015, 86, 106–118. [Google Scholar] [CrossRef]

- Groll, M. Principles and applications of heat pipes. Die Naturwissenschaften 1980, 67, 72–79. [Google Scholar] [CrossRef]

- Huang, X.; Franchi, G. Design and fabrication of hybrid bi-modal wick structure for heat pipe application. J. Porous Mater. 2008, 15, 635–642. [Google Scholar] [CrossRef]

- Sun, Y.; Zhao, Z.; Li, X.; Hu, H.; Ji, Z.; Qi, H. A novel aerogels/porous Si3N4 ceramics composite with high strength and improved thermal insulation property. Ceram. Int. 2018, 44, 5233–5237. [Google Scholar] [CrossRef]

- Xin, G.; Zhang, P.; Chen, Y.; Cheng, L.; Huang, T.; Yin, H. Development of composite wicks having different thermal conductivities for loop heat pipes. Appl. Therm. Eng. 2018, 136, 229–236. [Google Scholar] [CrossRef]

- Kline, S.J.; Mcclintock, F.A. Describing Uncertainties in Single-Sample Experiments. Mech. Eng. 1953, 75, 3–8. [Google Scholar]

- Zhang, S.W.; Liu, D.R.; Huang, H.Z.; Nie, C.; Tang, Y.; Yuan, W.; Chen, G. High performance and reliable ultra-thin vapor chamber via an optimised second vacuuming and sealing process. Appl. Therm. Eng. 2024, 241, 122318. [Google Scholar] [CrossRef]

| Structure/Parameters | Material/Dimensions (mm) |

|---|---|

| Shells and tube materials | Copper (C5191) |

| Working fluid | Deionized water |

| UTVC dimension (length × width × thickness) | 58 × 82 × 0.4 |

| Cavity dimension (length × width × thickness) | 54 × 78 × 0.2 |

| Wick structure | Copper mesh + SWM |

| Literature | Thickness (mm) | Ultimate Power (W) | Minimum Thermal Resistance (°C/W) | Maximum ETC (W/(m·K)) |

|---|---|---|---|---|

| Zhou et al. [15] | 1.5 | 24 | 0.092 | / |

| Li et al. [18] | 1 | 14 | 0.05 | / |

| Huang et al. [23] | 0.5 | 7.58 | / | 25,200 |

| Lim et al. [24] | 1.5 | 13 | 5.45 | / |

| Shi et al. [26] | 0.65 | 13.7 | 1.15 | 800 |

| Zhang et al. [35] | 0.32 | 3 | 1.701 | / |

| This work | 0.39 | 26 | 0.56 | 3837 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Huang, H.; Bai, J.; Yan, C.; Qiu, H.; Tang, Y.; Luo, F. Experimental Investigation on Ultra-Thin Vapor Chamber with Composite Wick for Electronics Thermal Management. Micromachines 2024, 15, 627. https://doi.org/10.3390/mi15050627

Zhang S, Huang H, Bai J, Yan C, Qiu H, Tang Y, Luo F. Experimental Investigation on Ultra-Thin Vapor Chamber with Composite Wick for Electronics Thermal Management. Micromachines. 2024; 15(5):627. https://doi.org/10.3390/mi15050627

Chicago/Turabian StyleZhang, Shiwei, Haoyi Huang, Jingjing Bai, Caiman Yan, Huarong Qiu, Yong Tang, and Fangqiong Luo. 2024. "Experimental Investigation on Ultra-Thin Vapor Chamber with Composite Wick for Electronics Thermal Management" Micromachines 15, no. 5: 627. https://doi.org/10.3390/mi15050627

APA StyleZhang, S., Huang, H., Bai, J., Yan, C., Qiu, H., Tang, Y., & Luo, F. (2024). Experimental Investigation on Ultra-Thin Vapor Chamber with Composite Wick for Electronics Thermal Management. Micromachines, 15(5), 627. https://doi.org/10.3390/mi15050627