Size-Effect-Based Dimension Compensations in Wet Etching for Micromachined Quartz Crystal Microstructures

Abstract

:1. Introduction

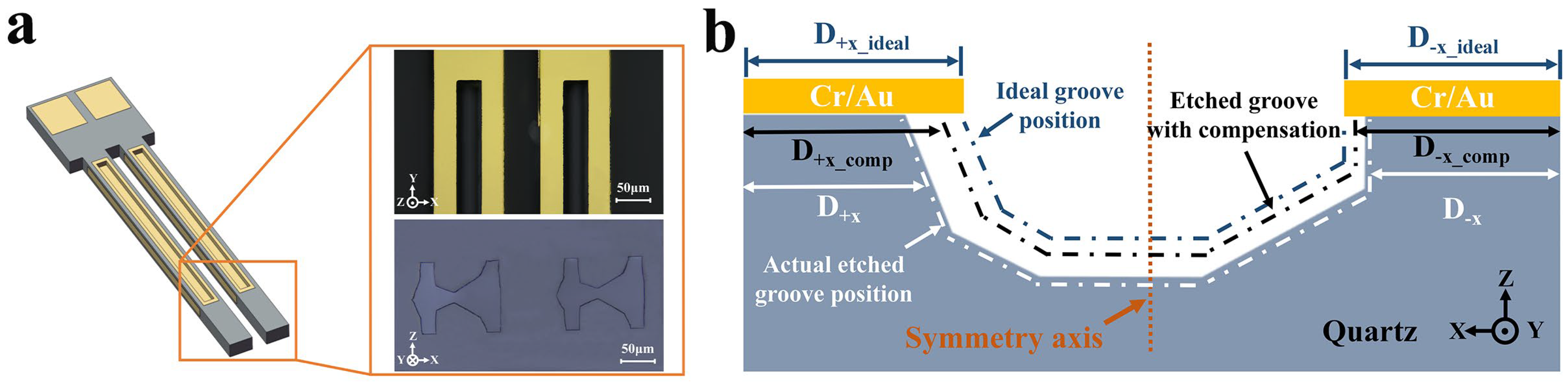

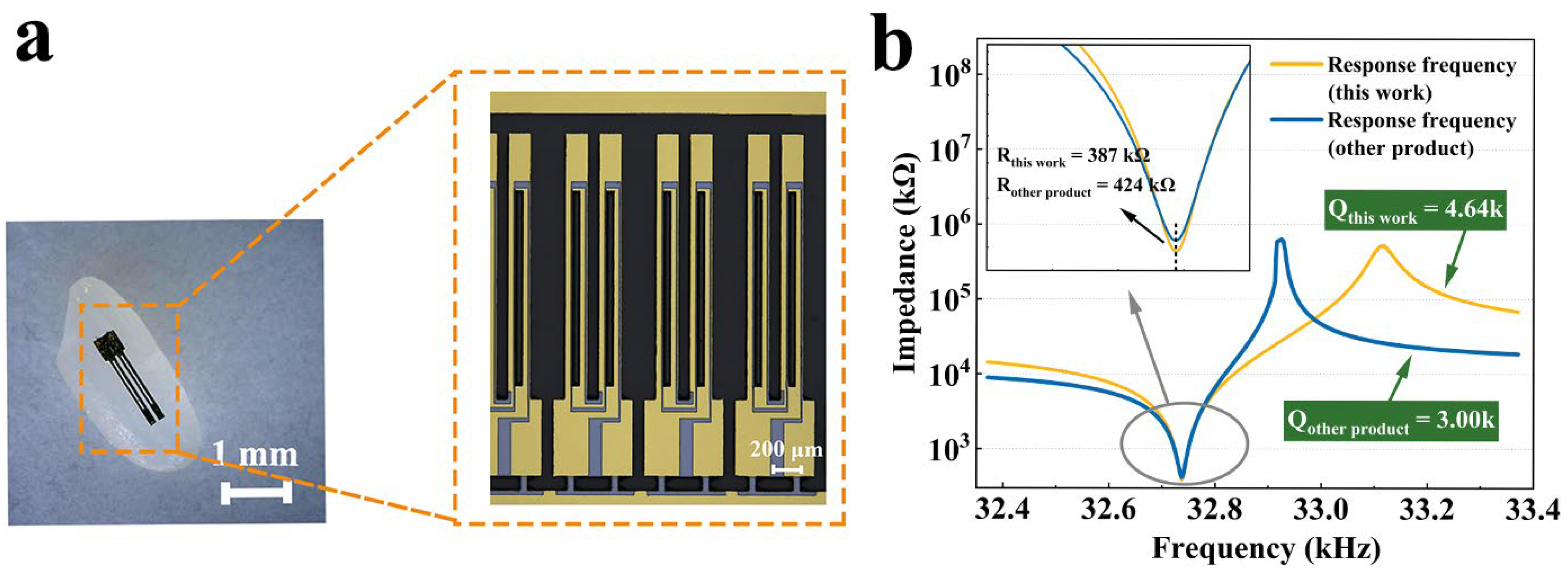

2. Materials and Methods

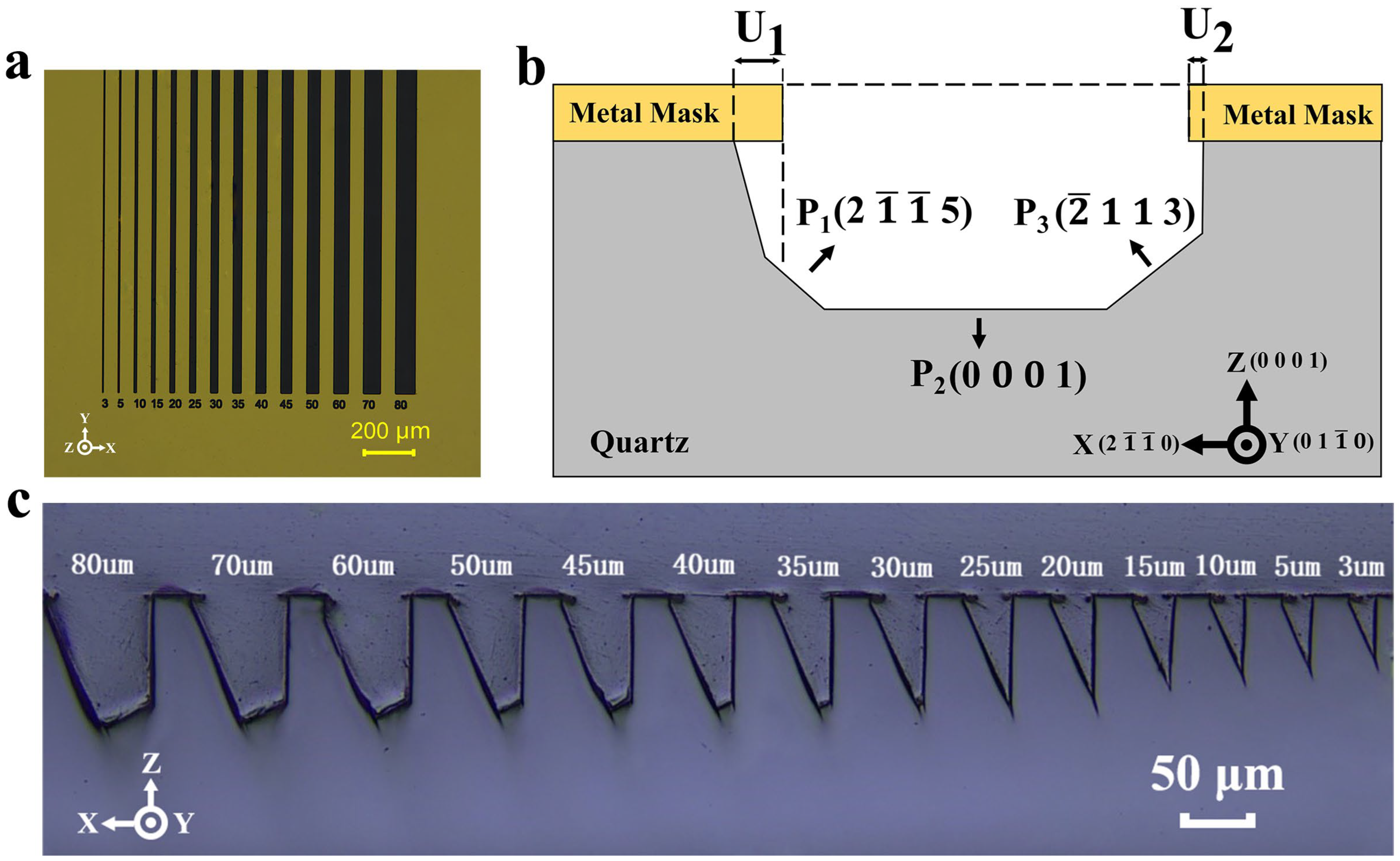

2.1. Pattern Design

2.2. Sample Preparation

2.3. Profile Definition

2.4. Measurement

3. Results and Discussion

3.1. Evolution of Bilateral Etching Profiles

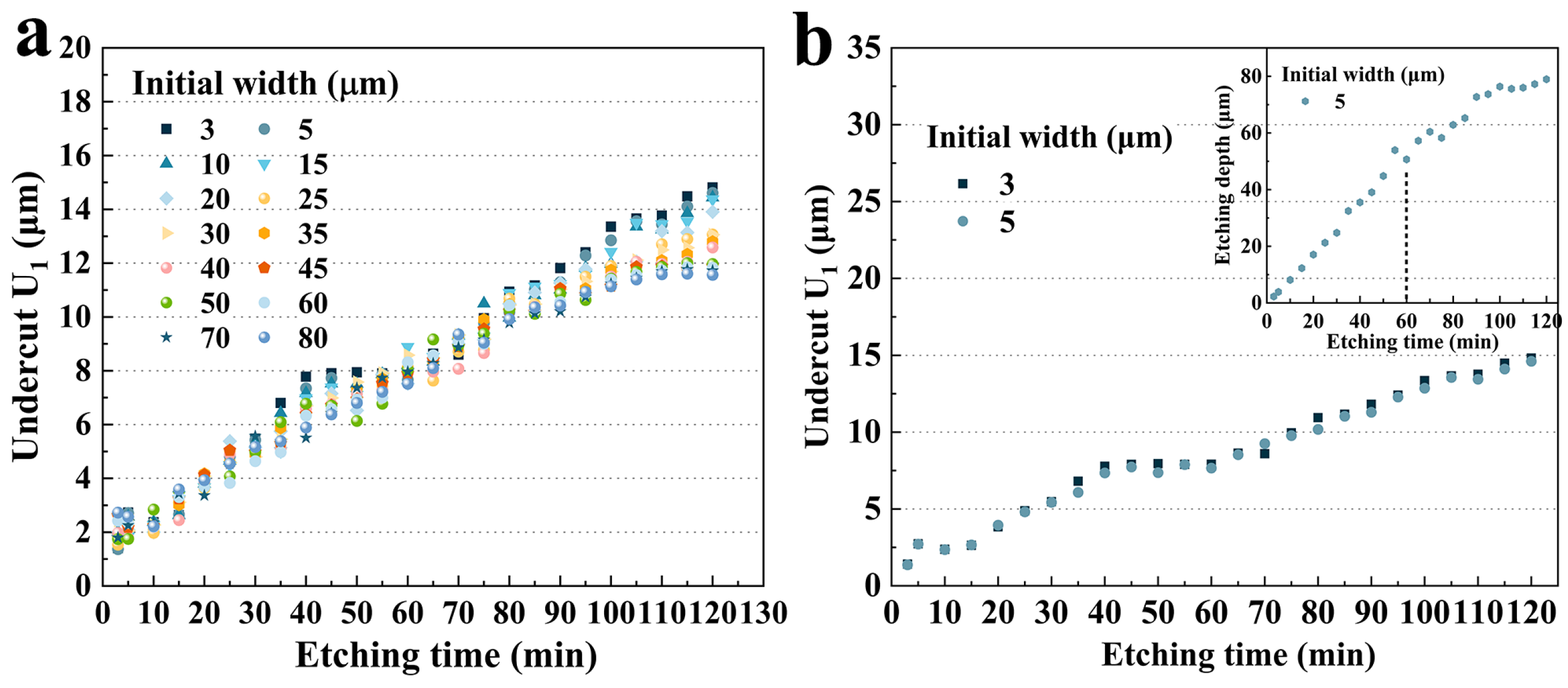

3.2. Effect of the Hard Mask Width on the U1

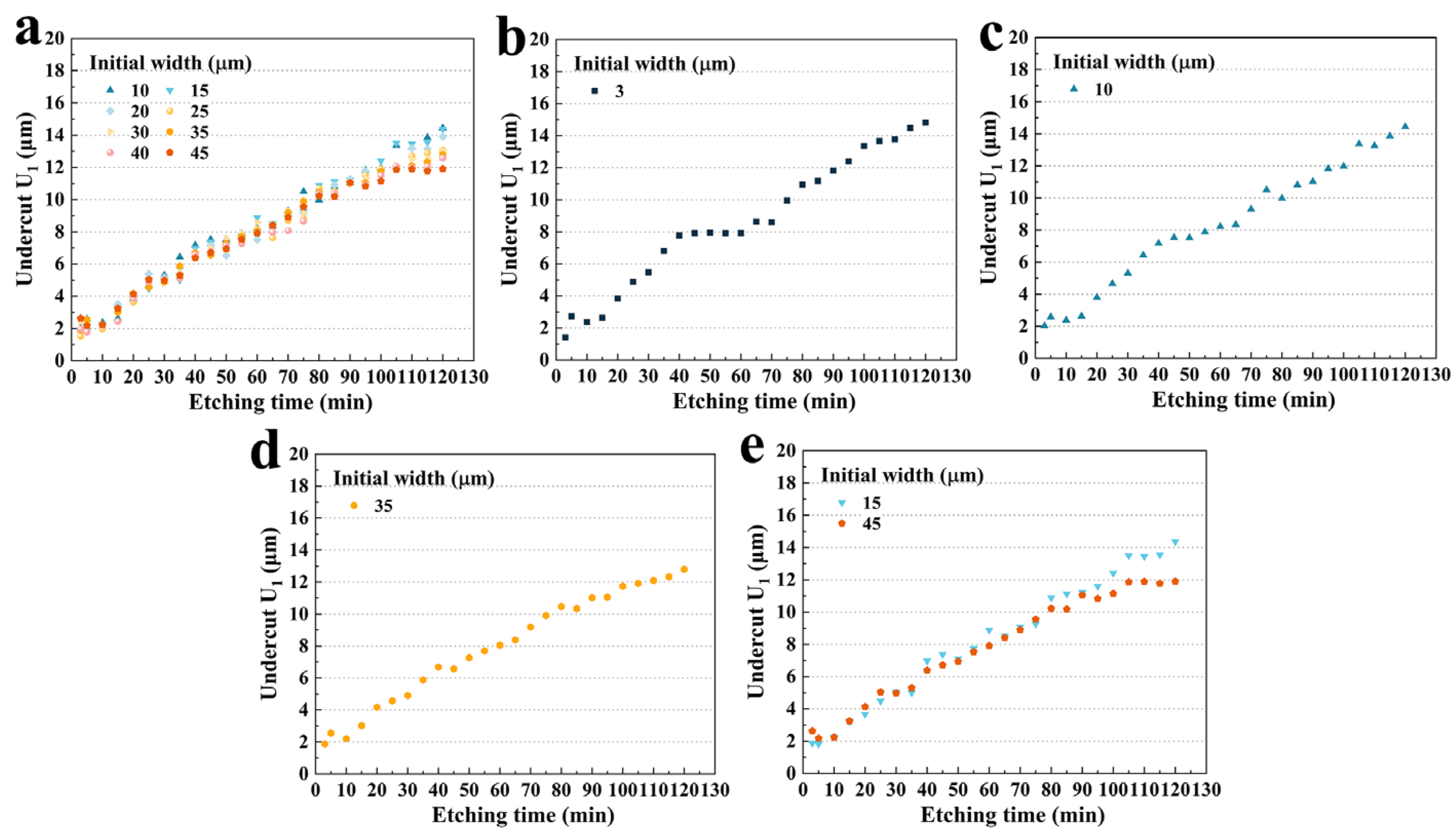

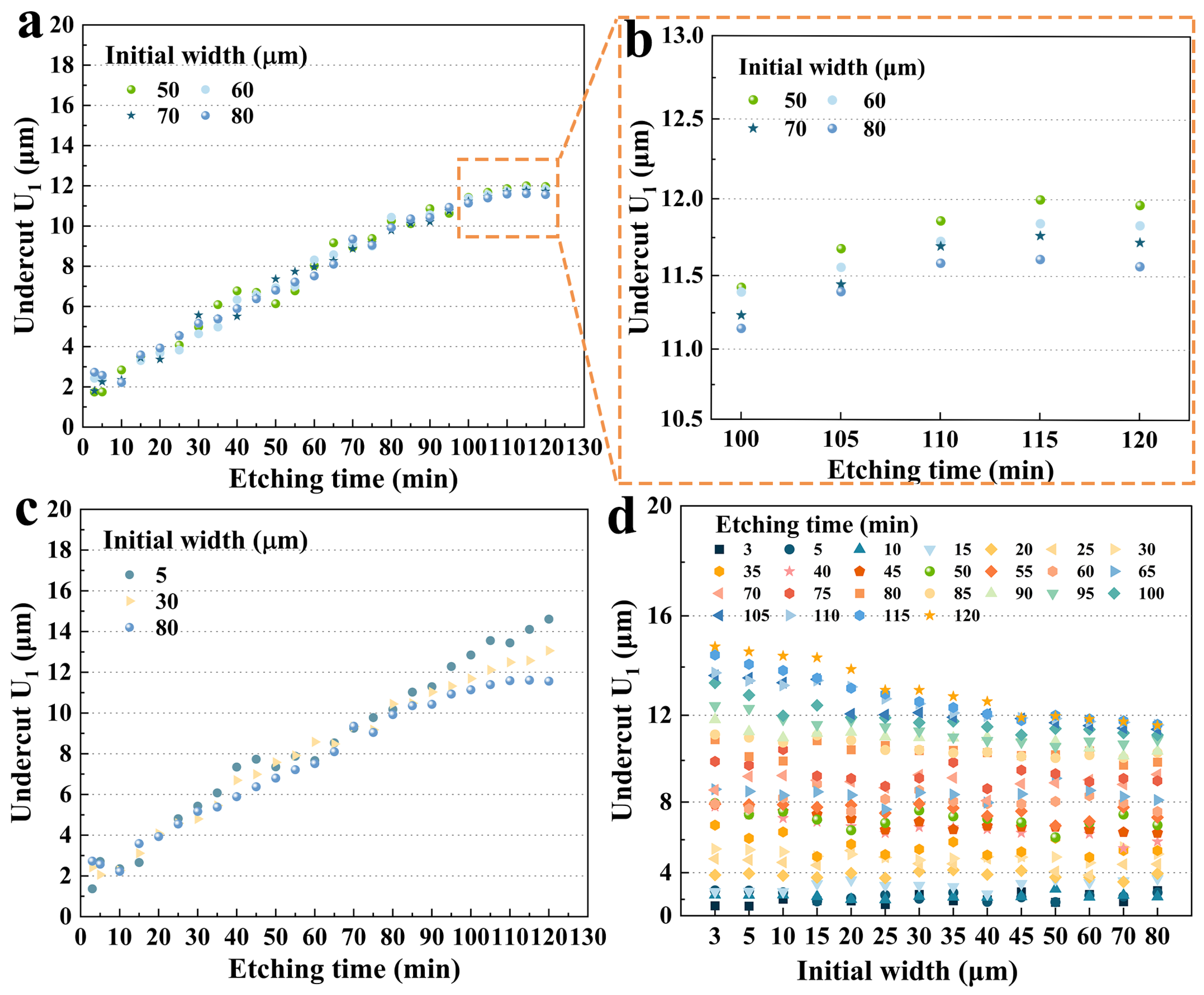

3.2.1. Size Effect on U1

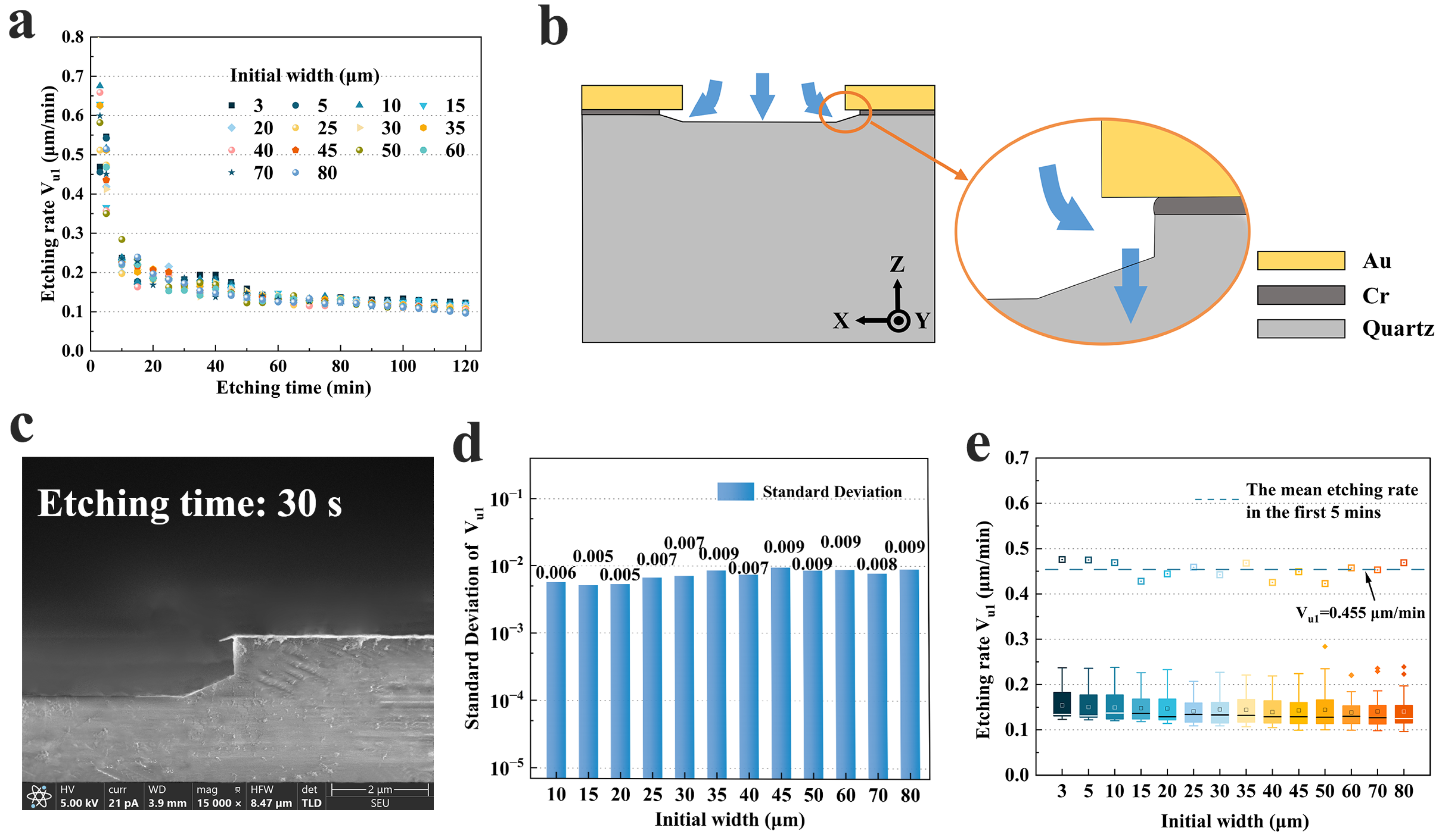

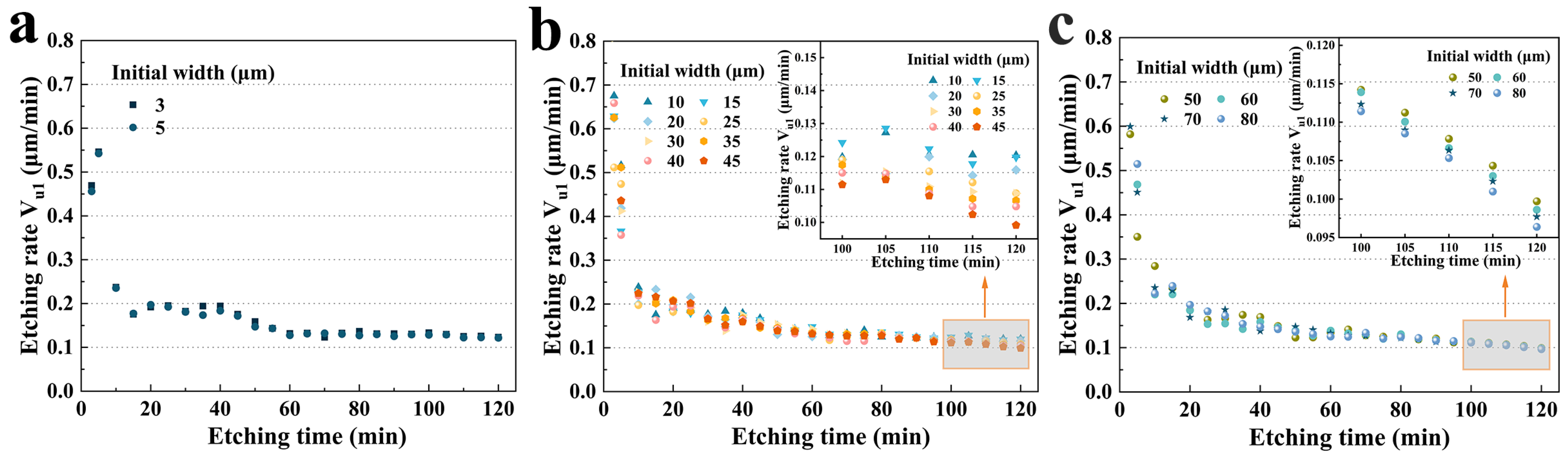

3.2.2. Size Effect on Etching Rate Vu1

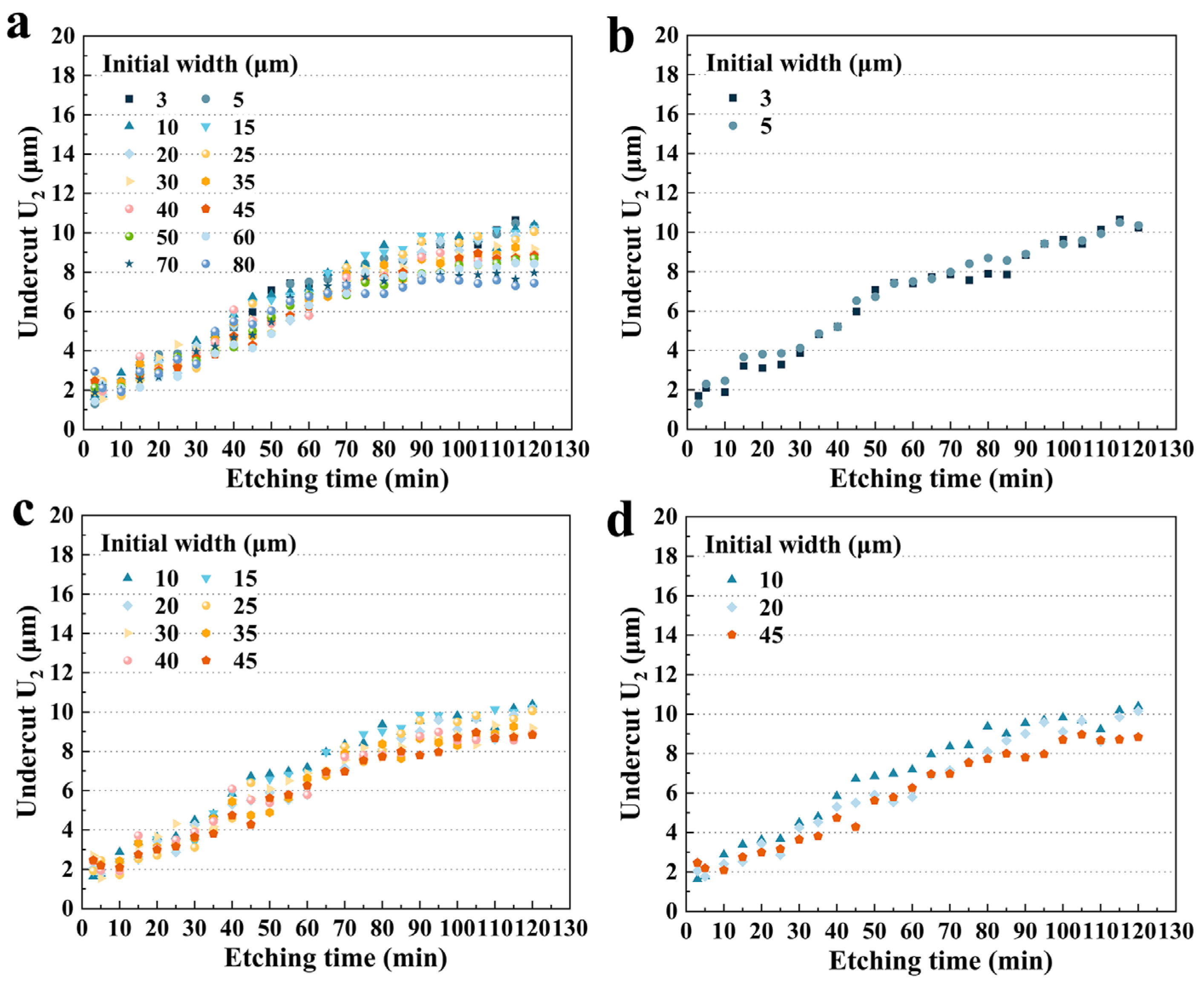

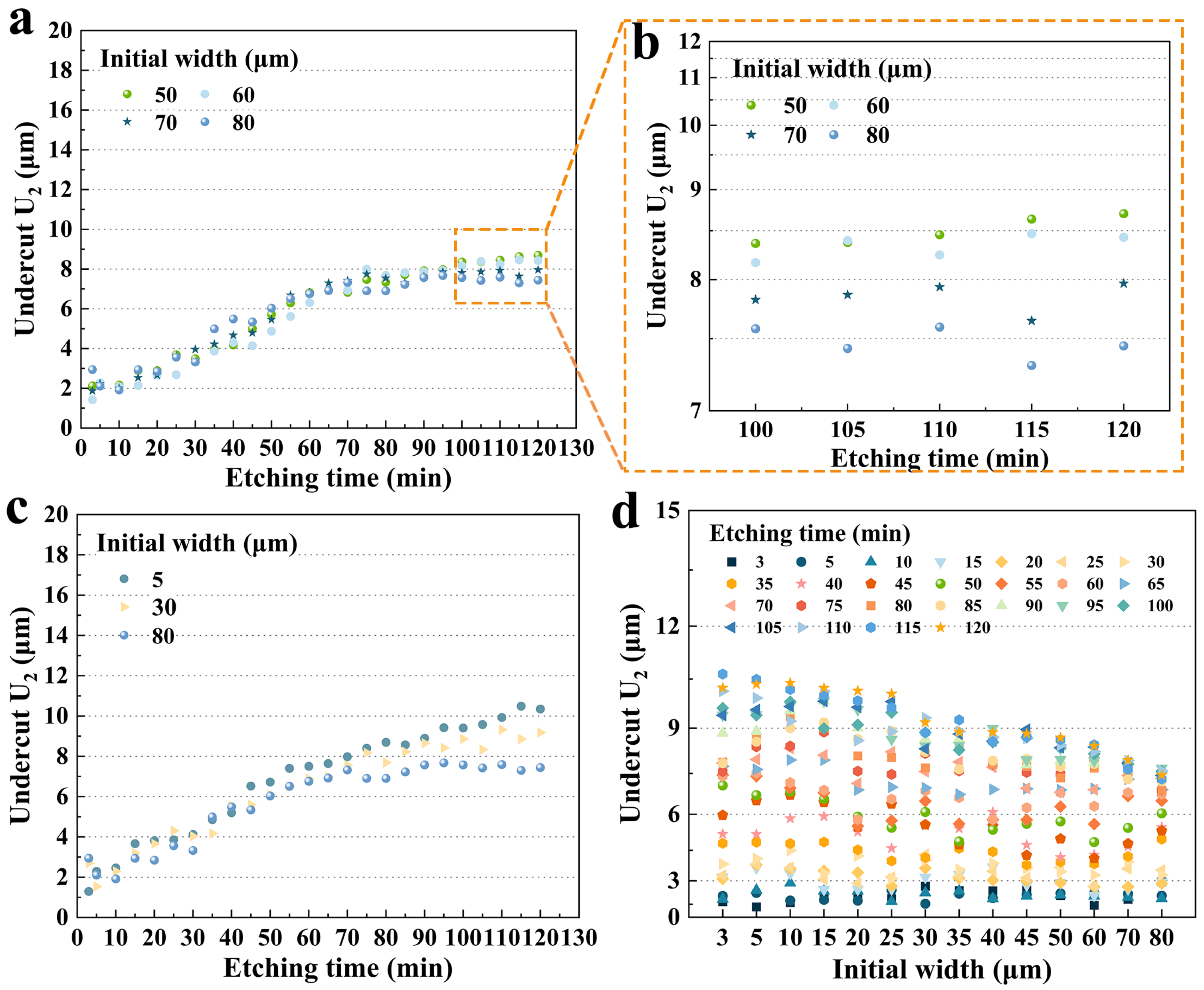

3.3. Effect of the Hard Mask Width on the U2

3.3.1. Size Effect on U2

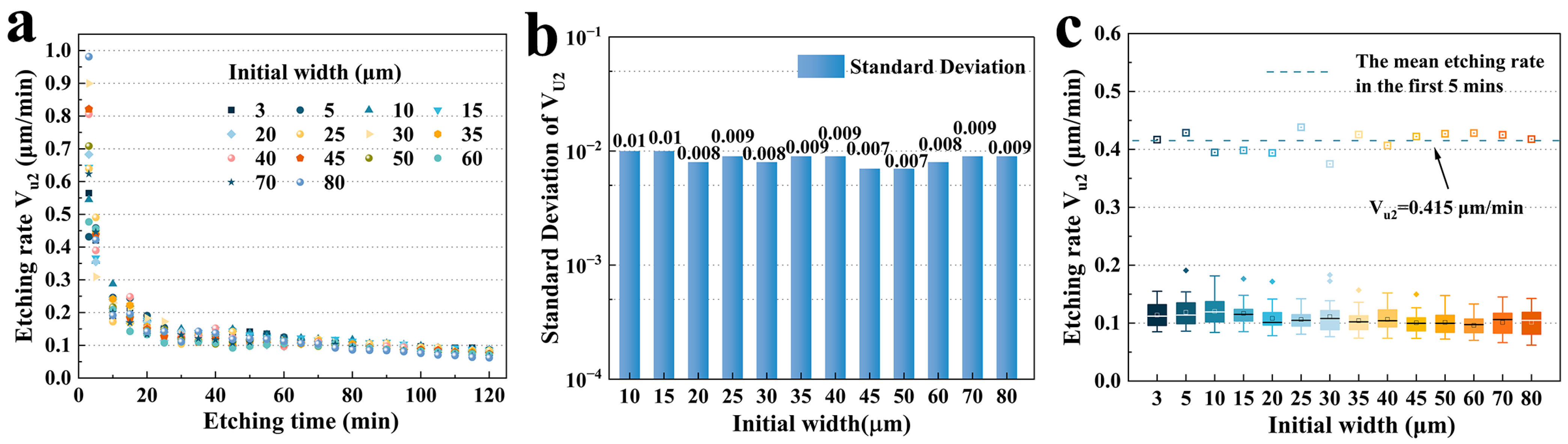

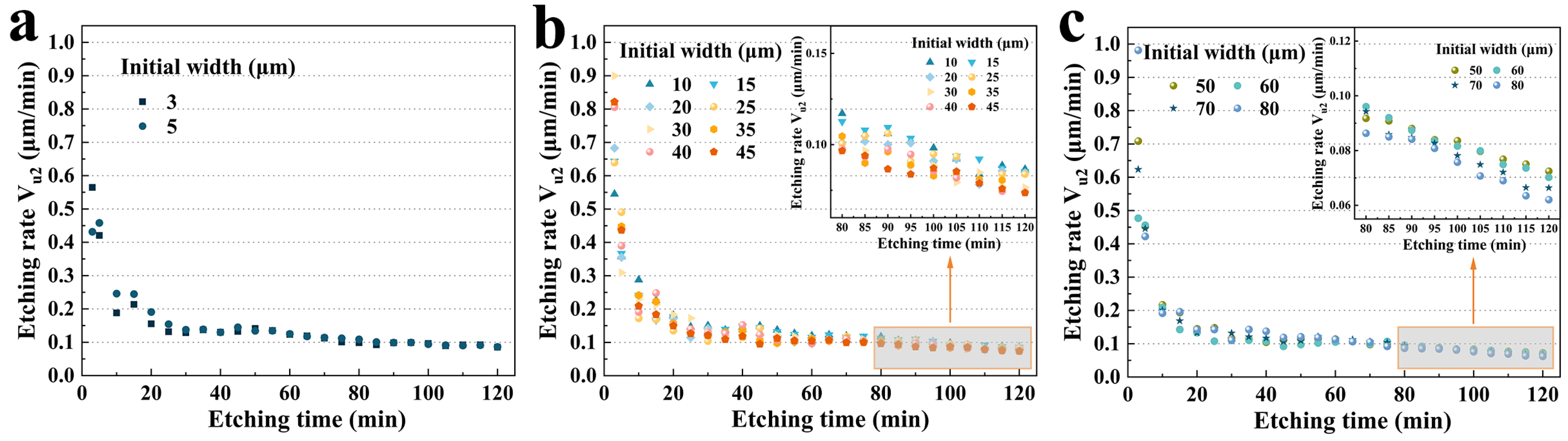

3.3.2. Size Effect on Etching Rate Vu2

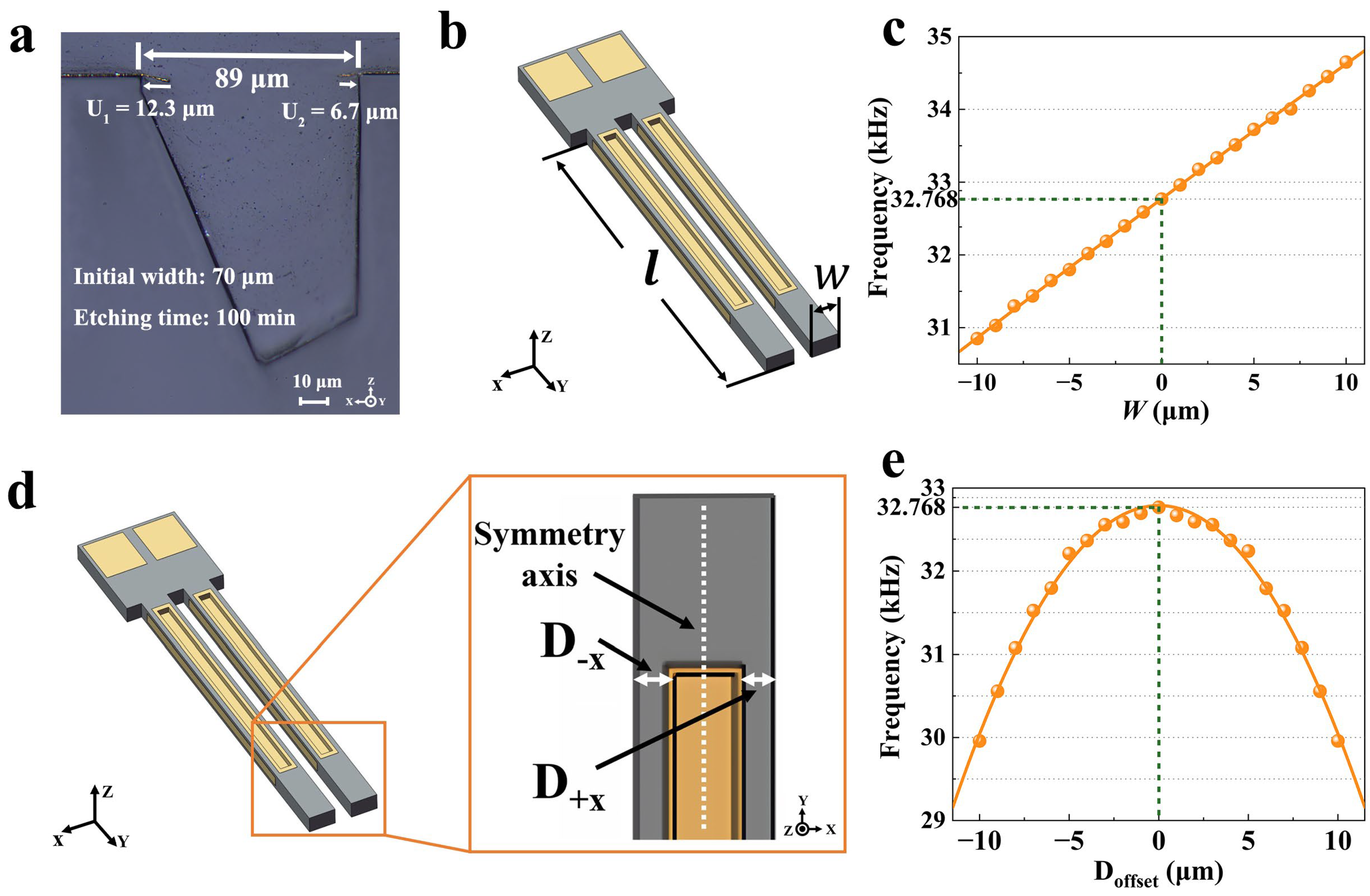

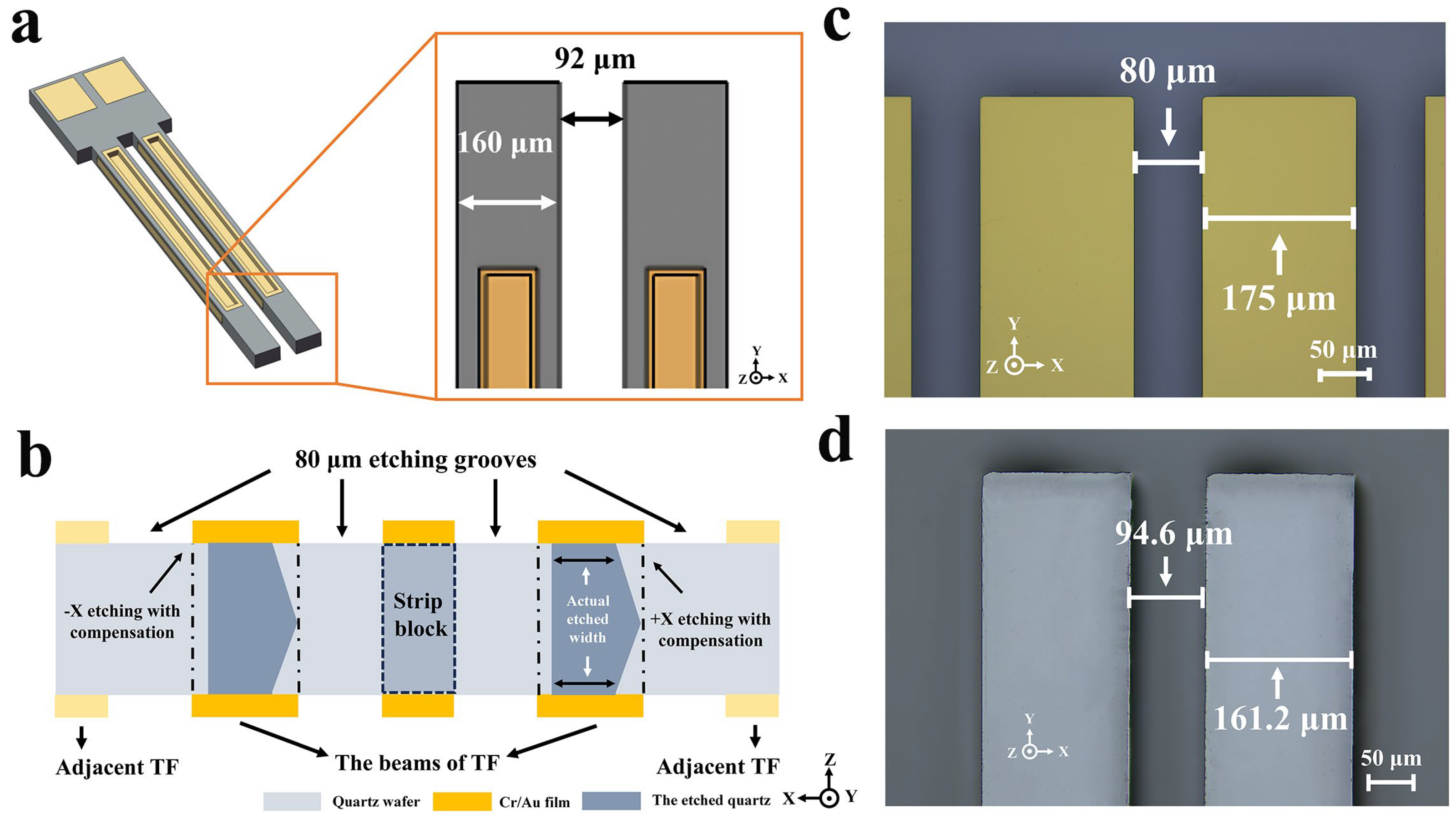

3.4. Size-Effect Dimensional Compensation for Quartz MEMS Tuning Fork

3.4.1. Etching Width Dimension Compensation

3.4.2. Etching Position Compensation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bottom, V.E. Introduction to Quartz Crystal Unit Design; Van Nostrand Reinhold Company: New York, NY, USA, 1982. [Google Scholar]

- Danel, J.S.; Delapierre, G. Quartz: A material for microdevices. J. Micromech. Microeng. 1991, 1, 187. [Google Scholar] [CrossRef]

- Osipov, A.A.; Iankevich, G.A.; Alexandrov, S.E. Monocrystalline Quartz ICP Etching: Road to High-Temperature Dry Etching. Plasma Chem. Plasma Process. 2020, 40, 423–431. [Google Scholar] [CrossRef]

- Traon, O.L.; Deyzac, F.; Janiaud, D.; Muller, S. The VIA vibrating beam accelerometer: A new quartz micromachined sensor. In Proceedings of the 1999 Joint Meeting of the European Frequency and Time Forum and the IEEE International Frequency Control Symposium (Cat. No.99CH36313), Besancon, France, 13–16 April 1999; pp. 1041–1044. [Google Scholar]

- Xie, X.; Zhou, C.; Wei, X.; Hu, W.; Ren, Q. Laser machining of transparent brittle materials: From machining strategies to applications. Opto-Electron. Adv. 2019, 2, 180017. [Google Scholar] [CrossRef]

- Staudte, J.H. Subminiature Quartz Tuning Fork Resonator. In Proceedings of the 27th Annual Symposium on Frequency Control, Cherry Hill, NJ, USA, 12–14 June 1973; pp. 50–54. [Google Scholar]

- Bai, B.; Li, C.; Zhao, Y. Development of V-Shaped Beam on the Shock Resistance and Driving Frequency of Micro Quartz Tuning Forks Resonant Gyroscope. Micromachines 2020, 11, 1012. [Google Scholar] [CrossRef]

- Bai, B.; Li, C.; Zhao, Y. Development of an effective method to reduce mechanical coupling error in a micro quartz tuning fork gyroscope. Sens. Actuators A 2021, 332, 113058. [Google Scholar] [CrossRef]

- Feng, L.; Zhao, K.; Sun, Y.; Cui, J.; Cui, F.; Yang, A. A Multi-Fork Z-Axis Quartz Micromachined Gyroscope. Sensors 2013, 13, 12482–12496. [Google Scholar] [CrossRef]

- Inoue, T.; Yoshimatsu, M.; Okazaki, M. Miniaturization of angular rate sensor element using bonded quartz tuning fork. In Proceedings of the IEEE International Frequency Control Symposium and PDA Exhibition/17th European Frequency and Time Forum, Tampa, FL, USA, 4–8 May 2003; pp. 1007–1011. [Google Scholar]

- Du, L.; Wu, C.; Peng, H.; Zou, L.; Zhao, L.; Huang, L.; Wang, P. Piezoelectric olfactory receptor biosensor prepared by aptamer-assisted immobilization. Sens. Actuators B 2013, 187, 481–487. [Google Scholar] [CrossRef]

- Han, C.; Li, C.; Zhao, Y.; Li, B. High-Stability Quartz Resonant Accelerometer With Micro-Leverages. J. Microelectromech. Syst. 2021, 30, 184–192. [Google Scholar] [CrossRef]

- Li, B.; Zhao, Y.; Li, C.; Cheng, R.; Sun, D.; Wang, S. A Differential Resonant Accelerometer with Low Cross-Interference and Temperature Drift. Sensors 2017, 17, 178. [Google Scholar] [CrossRef]

- Liang, J.; Zhang, L.; Wang, L.; Dong, Y.; Ueda, T. Flip Chip Bonding of a Quartz MEMS-Based Vibrating Beam Accelerometer. Sensors 2015, 15, 22049–22059. [Google Scholar] [CrossRef]

- Han, C.; Li, C.; Zhao, Y.L.; Li, B.; Wei, X.Y. Research on a Micro-Processing Technology for Fabricating Complex Structures in Single-Crystal Quartz. Micromachines 2020, 11, 337. [Google Scholar] [CrossRef]

- Hunt, J.R.; Smythe, R.C. Chemically Milled VHF and UHF AT-Cut Resonators. In Proceedings of the 39th Annual Symposium on Frequency Control, Philadelphia, PA, USA, 29–31 May 1985; pp. 292–300. [Google Scholar]

- Iwata, H. Multistage chemical etching for high-precision frequency adjustment in ultrahigh-frequency fundamental quartz resonators. IEEE Trans. Sonics Ultrason. 2005, 52, 1435–1442. [Google Scholar] [CrossRef]

- Dong, Y.; Zhou, Y.; Huang, H.; Zhang, B.; Li, X.; Chen, K.; Sun, L.; Dou, G. Etching of quartz crystals in liquid phase environment: A review. Nanotechnol. Precis. Eng. 2024, 7, 025001. [Google Scholar] [CrossRef]

- Clower, W.; Kaajakari, V.; Wilson, C.G. Laser-Assisted Wet Etching of Quartz Crystal Resonators. J. Microelectromech. Syst. 2018, 27, 22–24. [Google Scholar] [CrossRef]

- Li, B.; Li, C.; Zhao, Y.; Han, C.; Zhang, Q. Deep Reactive Ion Etching of Z-Cut Alpha Quartz for MEMS Resonant Devices Fabrication. Micromachines 2020, 11, 724. [Google Scholar] [CrossRef]

- Zhang, H.; Xing, Y.; Zhang, J.; Li, Y. The Microscopic Activation Energy Etching Mechanism in Anisotropic Wet Etching of Quatrz. In Proceedings of the 31st IEEE International Conference on Micro Electro Mechanical Systems (MEMS), Belfast, North Ireland, 21–25 January 2018; pp. 471–474. [Google Scholar]

- Liang, J.; Kohsaka, F.; Matsuo, T.; Ueda, T. Wet etched high aspect ratio microstructures on quartz for MEMS applications. IEEJ Trans. Sens. Micromach. 2007, 127, 337–342+1. [Google Scholar] [CrossRef]

- Liu, J.; Fedder, G.K. Silicon Undercut Characterization in a CMOS-MEMS Process. In Proceedings of the TRANSDUCERS 2007—2007 International Solid-State Sensors, Actuators and Microsystems Conference, Lyon, France, 10–14 June 2007; pp. 505–508. [Google Scholar]

- Rangsten, P.; Hedlund, C.; Katardjiev, I.V.; Backlund, Y. Etch rates of crystallographic planes in Z-cut quartz—Experiments and simulation. J. Micromech. Microeng. 1998, 8, 1–6. [Google Scholar] [CrossRef]

- Forrer, M.P. A Flexure-Mode Quartz for an Electronic Wrist-Watch. In Proceedings of the 23rd Annual Symposium on Frequency Control, Atlantic City, NJ, USA, 6–8 May 1969; pp. 157–162. [Google Scholar]

- Li, S.; Lu, J.; Shang, Z.; Zeng, X.; Yuan, Y.; Wu, H.; Pan, Y.; Sampaolo, A.; Patimisco, P.; Spagnolo, V.; et al. Compact quartz-enhanced photoacoustic sensor for ppb-level ambient NO2 detection by use of a high-power laser diode and a grooved tuning fork. Photoacoustics 2022, 25, 100325. [Google Scholar] [CrossRef]

- Masayuki, K. Tuning Fork Type Piezoelectric Oscillator and a Method for Manufacturing Thereof, Piezoelectric Device. Japan Patent CN03123302.3, 8 October 2003. [Google Scholar]

- Zhang, Q.; Feng, L.; Cui, J.; Tang, Y.; Yao, Y. Design of A New Structure Quartz MEMS Gyroscope with High Sensitivity. IOP Conf. Ser. Mater. Sci. Eng. 2018, 382, 042036. [Google Scholar] [CrossRef]

- Ueda, T.; Kohsaka, F.; Iino, T.; Yamazaki, D. Theory to Predict Etching Shapes in Quartz Crystal and Its Application to Design Devices. Trans. Soc. Instrum. Control Eng. 1987, 23, 1233–1238. [Google Scholar] [CrossRef]

- Hedlund, C.; Lindberg, U.; Bucht, U.; Soderkvist, J. Anisotropic etching of Z-cut quartz. J. Micromech. Microeng. 1993, 3, 65. [Google Scholar] [CrossRef]

- Tellier, C.R. A 3-Dimensional Kinematic Model for the Dissolution of Crystals. J. Cryst. Growth 1989, 96, 450–452. [Google Scholar] [CrossRef]

- Tellier, C. CAD design of mask compensation patterns. In Proceedings of the 2nd IEEE International Conference on Sensors, Toronto, ON, Canada, 22–24 October 2003; pp. 517–522. [Google Scholar]

- Giessibl, F.J. The qPlus sensor, a powerful core for the atomic force microscope. Rev. Sci. Instrum. 2019, 90, 011101. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Dou, G.; Wei, Z.; Ji, S.; Dai, H.; Tang, K.; Sun, L. Size-Effect-Based Dimension Compensations in Wet Etching for Micromachined Quartz Crystal Microstructures. Micromachines 2024, 15, 784. https://doi.org/10.3390/mi15060784

Dong Y, Dou G, Wei Z, Ji S, Dai H, Tang K, Sun L. Size-Effect-Based Dimension Compensations in Wet Etching for Micromachined Quartz Crystal Microstructures. Micromachines. 2024; 15(6):784. https://doi.org/10.3390/mi15060784

Chicago/Turabian StyleDong, Yide, Guangbin Dou, Zibiao Wei, Shanshan Ji, Huihui Dai, Kaiqin Tang, and Litao Sun. 2024. "Size-Effect-Based Dimension Compensations in Wet Etching for Micromachined Quartz Crystal Microstructures" Micromachines 15, no. 6: 784. https://doi.org/10.3390/mi15060784

APA StyleDong, Y., Dou, G., Wei, Z., Ji, S., Dai, H., Tang, K., & Sun, L. (2024). Size-Effect-Based Dimension Compensations in Wet Etching for Micromachined Quartz Crystal Microstructures. Micromachines, 15(6), 784. https://doi.org/10.3390/mi15060784