Structure and Properties of Bioactive Titanium Dioxide Surface Layers Produced on NiTi Shape Memory Alloy in Low-Temperature Plasma

Abstract

:1. Introduction

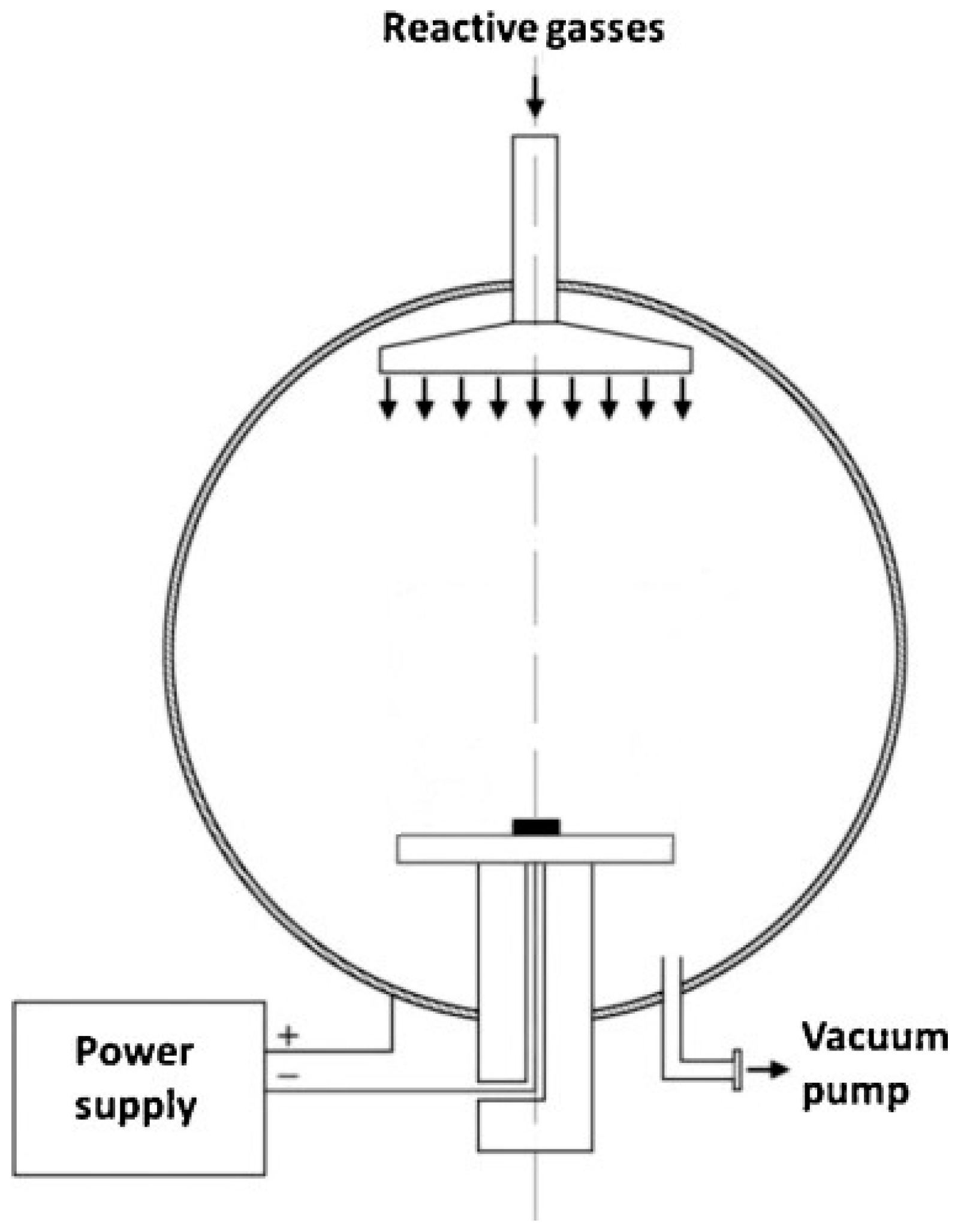

2. Materials and Methods

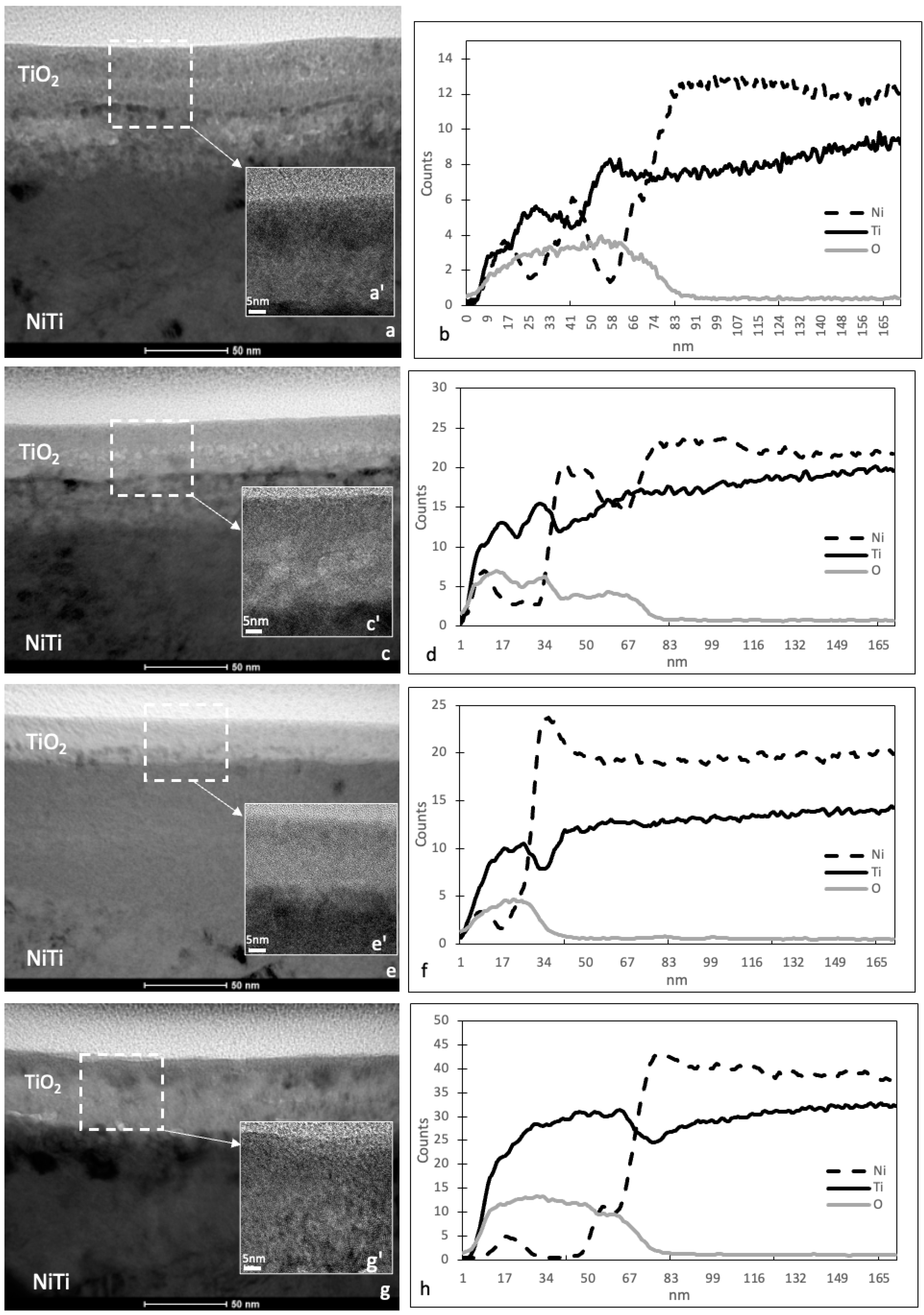

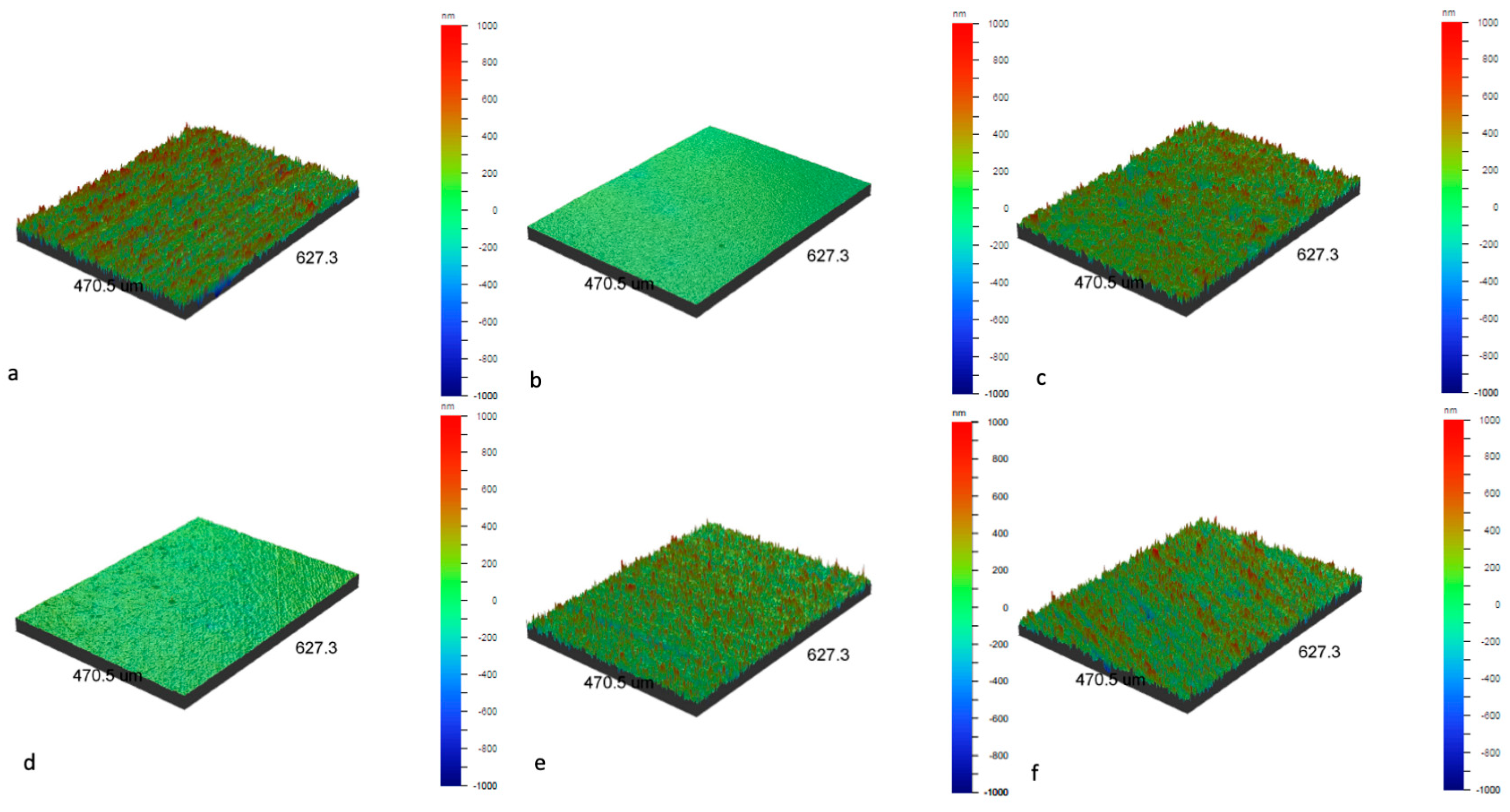

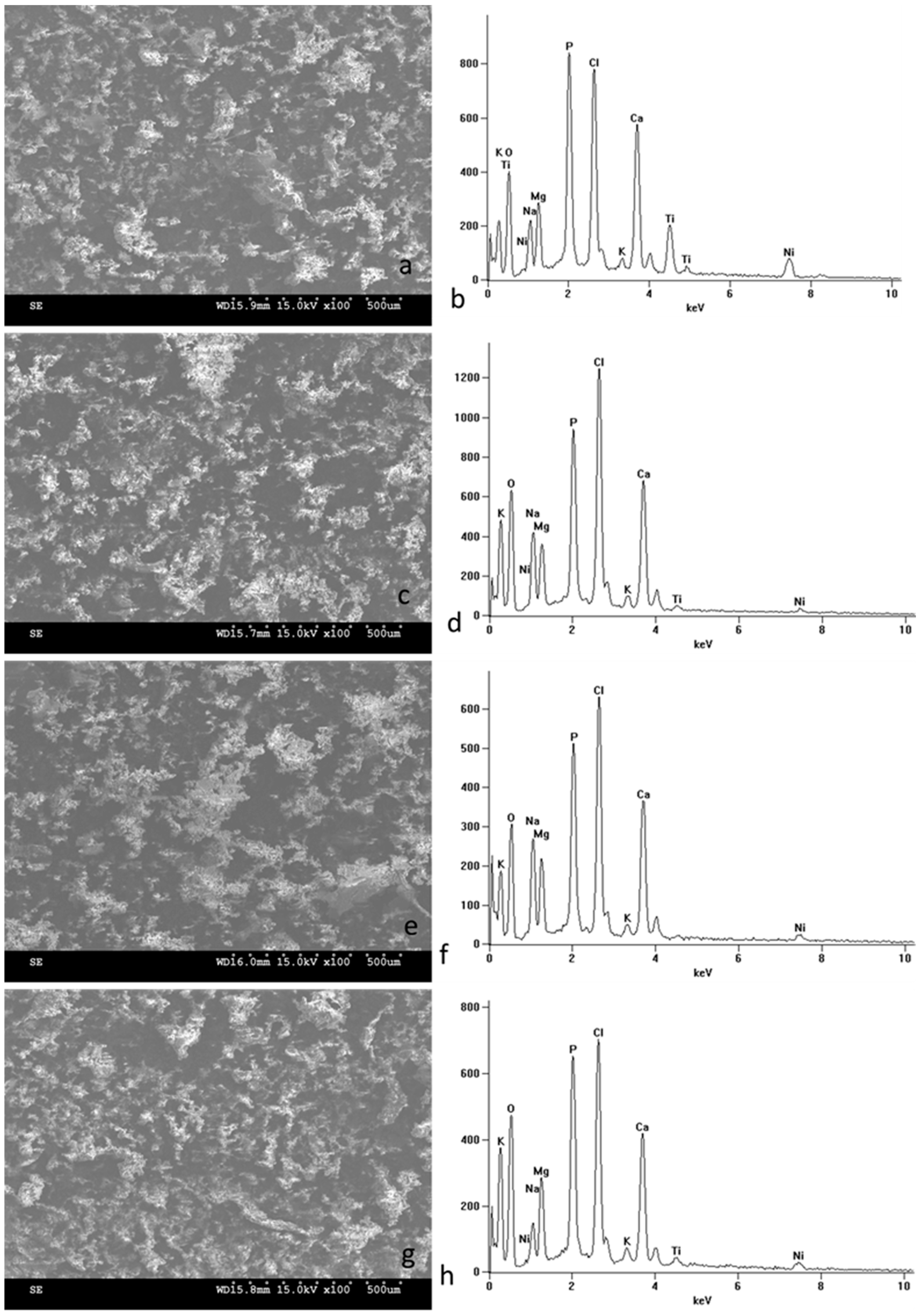

3. Results and Discussion

4. Conclusions

- Variations in the temperature of the oxidation process in low-temperature glow discharge plasma, while maintaining consistent process duration, significantly impact the thickness and structure of the resulting titanium oxide layers.

- The nature of the titanium oxide layer and the nickel-enriched transition zone beneath the oxidized layer is also influenced by the surface preparation, such as mechanical polishing or mechanical grinding.

- Oxidized layers exhibit increased bioactivity compared to the alloy in its initial state.

- The distinct structure of these layers results in a varied composition of biomimetic deposits composed of calcium phosphates.

- The surface preparation before the process did not significantly affect the level of bioactivity in the layers but did influence the phase composition of calcium phosphates. The precise identification of compounds in the future will enable the accurate association of a specific phase composition with a given type of layer.

- All tested materials, including those in their initial state, display a high level of bioactivity in the long term (30 days).

- The expedited formation of biomimetic calcium phosphates may contribute to the potentially enhanced osseointegration of the material when used for bone implants. Increased bioactivity is thus promising in the context of broadening the application of NiTi alloys in medicine. Consequently, oxidation processes in low-temperature plasma can be regarded as a crucial aspect of material solutions for constructing biocompatible NiTi alloy implants. As this study has a preliminary character, further investigations are planned to comprehensively assess the long-term effectiveness of our surface treatment.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biesiekierski, A.; Wang, J.; Abdel-Hady Gepreel, M.; Wen, C. A new look at biomedical Ti-based shape memory alloys. Acta Biomater. 2012, 8, 1661–1669. [Google Scholar] [CrossRef]

- Morgan, N. Medical shape memory alloy applications—The market and its products. Mater. Sci. Eng. A 2004, 378, 16–23. [Google Scholar] [CrossRef]

- Brunette, D.M.; Tengvall, P.; Textor, M.; Thomsen, P. Titanium in Medicine: Material Science, Surface Science, Engineering, Biological Responses and Medical Applications; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Rondelli, G.; Torricelli, P.; Fini, M.; Rimondini, L.; Giardino, R. In vitro corrosion study by EIS of an equiatomic NiTi alloy and an implant quality AISI 316 stainless steel. J. Biomed. Mater. Res. Part B Appl. Biomater. 2006, 79, 320–324. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Wu, S.K.; Lin, S.J.; Lin, T.H. Biocompatibility and mechanical properties of Ti–Ni–Cu shape memory alloy fabricated by powder metallurgy. Mater. Sci. Eng. C 2017, 72, 446–452. [Google Scholar]

- Liu, X.; Chu, P.K.; Ding, C. Surface modification of titanium, titanium alloys, and related materials for biomedical applications. Mater. Sci. Eng. R Rep. 2005, 47, 49–121. [Google Scholar] [CrossRef]

- Zainal, M.A.; Sahlan, S.; Ali, M.S.M. Micromachined Shape-Memory-Alloy Microactuators and Their Application in Biomedical Devices. Micromachines 2015, 6, 879–901. [Google Scholar] [CrossRef]

- Benard, W.; Kahn, H.; Heuer, A.; Huff, M. Thin-film shape-memory alloy actuated micropumps. J. Microelectromechanical Syst. 1998, 7, 245–251. [Google Scholar] [CrossRef]

- Fu, Y.Q.; Huang, W.M.; Chung, C.Y. TiNi thin film shape memory alloys for optical sensing applications. In Thin Film Shape Memory Alloys: Fundamentals and Device Applications; Miyazaki, S., Fu, Y.Q., Huang, W.M., Eds.; Cambridge University Press: Cambridge, UK, 2009; pp. 437–456. [Google Scholar]

- Lai, B.-K.; Kahn, H.; Phillips, S.M.; Heuer, A.H. A Comparison of PZT-Based and TiNi Shape Memory Alloy-Based MEMS Microactuators. Ferroelectrics 2004, 306, 221–226. [Google Scholar] [CrossRef]

- Kim, M.; Heo, J.; Rodrigue, H.; Lee, H.; Pané, S.; Han, M.; Ahn, S. Shape Memory Alloy (SMA) Actuators: The Role of Material, Form, and Scaling Effects. Adv. Mater. 2023, 35, 2208517. [Google Scholar] [CrossRef]

- Hanawa, T. Metal ion release from metal implants. Mater. Sci. Eng. C 2004, 24, 745–752. [Google Scholar] [CrossRef]

- Arndt, M.; Brück, A.; Scully, T.; Jäger, A.; Bourauel, C. Nickel ion release from orthodontic NiTi wires under simulation of realistic in-situ conditions. J. Mater. Sci. 2005, 40, 3659–3667. [Google Scholar] [CrossRef]

- Denkhaus, E.; Salnikow, K. Nickel essentiality, toxicity, and carcinogenicity. Crit. Rev. Oncol. 2002, 42, 35–56. [Google Scholar] [CrossRef]

- Eliaz, N.; Sridhar, T.M. Biocompatibility of Nickel and its Alloys. In Nickel and Chromium Nanoparticles; Springer: Berlin/Heidelberg, Germany, 2018; pp. 247–266. [Google Scholar]

- Chen, M.; Yang, X.; Hu, R.; Cui, Z.; Man, H. Bioactive NiTi shape memory alloy used as bone bonding implants. Mater. Sci. Eng. C 2004, 24, 497–502. [Google Scholar] [CrossRef]

- Huang, T.T.; Liu, X. The effect of a TiN coating on the biocompatibility of NiTi shape memory alloy. J. Alloys Compd. 2019, 805, 1148–1157. [Google Scholar]

- Gong, H.; Wang, Y.; Wang, J.; Zhang, Z. Improvement of corrosion resistance, bioactivity and cell response of NiTi alloy by graphene oxide/hydroxyapatite coating. RSC Adv. 2016, 6, 95965–95973. [Google Scholar]

- Sui, J.; Cai, W. Effect of diamond-like carbon (DLC) on the properties of the NiTi alloys. Diam. Relat. Mater. 2006, 15, 1720–1726. [Google Scholar] [CrossRef]

- Lelątko, J.; Goryczka, T.; Wierzchoń, T.; Ossowski, M.; Łosiewicz, B.; Rówiński, E.; Morawiec, H. Structure of Low Temperature Nitrided/Oxidized Layer Formed on NiTi Shape Memory Alloy. Solid State Phenom. 2010, 163, 127–130. [Google Scholar] [CrossRef]

- Chlanda, A.; Witkowska, J.; Morgiel, J.; Nowińska, K.; Choińska, E.; Swieszkowski, W.; Wierzchoń, T. Multi-scale characterization and biological evaluation of composite surface layers produced under glow discharge conditions on NiTi shape memory alloy for potential cardiological application. Micron 2018, 114, 14–22. [Google Scholar] [CrossRef]

- Czarnowska, E.; Borowski, T.; Sowińska, A.; Lelątko, J.; Oleksiak, J.; Kamiński, J.; Tarnowski, M.; Wierzchoń, T. Structure and properties of nitrided surface layer produced on NiTi shape memory alloy by low temperature plasma nitriding. Appl. Surf. Sci. 2015, 334, 24–31. [Google Scholar] [CrossRef]

- Witkowska, J.; Sowińska, A.; Czarnowska, E.; Płociński, T.; Kamiński, J.; Wierzchoń, T. Hybrid a-CNH+TiO2 +TiN-type surface layers produced on NiTi shape memory alloy for cardiovascular applications. Nanomedicine 2017, 12, 2233–2244. [Google Scholar] [CrossRef]

- Forsgren, J.; Svahn, F.; Jarmar, T.; Engqvist, H. Formation and adhesion of biomimetic hydroxyapatite deposited on titanium substrates. Acta Biomater. 2007, 3, 980–984. [Google Scholar] [CrossRef]

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef]

- Dalby, M.J.; Gadegaard, N.; Tare, R.; Andar, A.; Riehle, M.O.; Herzyk, P.; Wilkinson, C.D.W.; Oreffo, R.O.C. The control of human mesenchymal cell differentiation using nanoscale symmetry and disorder. Nat. Mater. 2014, 6, 170–174. [Google Scholar] [CrossRef]

- Amini, A.R.; Laurencin, C.T.; Nukavarapu, S.P. Bone tissue engineering: Recent advances and challenges. Crit. Rev. Biomed. Eng. 2013, 40, 363–408. [Google Scholar] [CrossRef]

- Olivares-Navarrete, R.; Hyzy, S.L.; Hutton, D.L.; Dunn, G.R.; Appert, C.; Boyan, B.D.; Schwartz, Z. Role of non-canonical Wnt signaling in osteoblast maturation on microstructured titanium surfaces. Acta Biomater. 2019, 99, 677–687. [Google Scholar] [CrossRef]

- Coelho, P.G.; Suzuki, M.; Guimaraes, M.V.; Marin, C.; Granato, R.; Gil, J.N.; Miller, R.J. Early bone healing around different implant bulk designs and surgical techniques: A study in dogs. J. Clin. Periodontol. 2019, 46, 199–209. [Google Scholar] [CrossRef]

- Zhang, Y.; Fan, Z.; Xing, Y.; Jia, S.; Mo, Z.; Gong, H. Effect of microtopography on osseointegration of implantable biomaterials and its modification strategies. Front. Bioeng. Biotechnol. 2022, 10, 981062. [Google Scholar] [CrossRef]

- Meyer, F.; Amaechi, B.T.; Fabritius, H.-O.; Enax, J. Overview of Calcium Phosphates used in Biomimetic Oral Care. Open Dent. J. 2018, 12, 406–423. [Google Scholar] [CrossRef]

- Dorozhkin, S.V. Calcium orthophosphates: Occurrence, properties, biomineralization, pathological calcification and biomimetic applications. Biomatter 2011, 1, 121–164. [Google Scholar] [CrossRef]

- Nancollas, G.H.; Wu, W. Biomineralization mechanisms: A kinetics and interfacial energy approach. J. Cryst. Growth 2000, 211, 137–142. [Google Scholar] [CrossRef]

- Wan, B.; Ruan, Y.; Shen, C.; Xu, G.; Forouzanfar, T.; Lin, H.; Wu, G. Biomimetically precipitated nanocrystalline hydroxyapatite. Nano TransMed 2022, 1, e9130008. [Google Scholar] [CrossRef]

- Hu, T.; Chu, C.-L.; Yin, L.-H.; Pu, Y.-P.; Dong, Y.-S.; Guo, C.; Sheng, X.-B.; Chung, J.-C.; Chu, P.-K. In vitro biocompatibility of titanium-nickel alloy with titanium oxide film by H2O2 oxidation. Trans. Nonferrous Met. Soc. China 2007, 17, 553–557. [Google Scholar] [CrossRef]

- Ponomarev, V.A.; Popova, A.D.; Sheveyko, A.N.; Permyakova, E.S.; Kuptsov, K.A.; Ilnitskaya, A.S.; Slukin, P.V.; Ignatov, S.G.; Gloushankova, N.A.; Subramanian, B.; et al. Microstructure and biological properties of titanium dioxide coatings doped with bioactive and bactericidal elements. Appl. Surf. Sci. 2022, 575, 151755. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Qiao, Y.; Zhu, H.; Li, J.; Cui, T.; Ding, C. Enhanced bioactivity and bacteriostasis effect of TiO2 nanofilms with favorable biomimetic architectures on titanium surface. RSC Adv. 2013, 3, 11214–11225. [Google Scholar] [CrossRef]

- Wang, X.X.; Hayakawa, S.; Tsuru, K.; Osaka, A. Bioactive titania gel layers formed by chemical treatment of Ti substrate with a H2O2/HCl solution. Biomaterials 2002, 23, 1353. [Google Scholar] [CrossRef]

- Mendes, S.C.; Van Den Brink, I.; De Bruijn, J.D.; Van Blitterswijk, C.A. In vivo bone formation by human bone marrow cells: Effect of osteogenic culture supplements and cell densities. J. Mater. Sci. Mater. Med. 1998, 9, 855–858. [Google Scholar] [CrossRef]

| NiTi (Ground Surface) | NiTi (Polished Surface) | NiTi + TiO2 (290 °C, Ground Surface) | NiTi + TiO2 (290 °C, Polished Surface) | NiTi + TiO2 (190 °C, Ground Surface) | NiTi + TiO2 (390 °C, Ground Surface) | |

|---|---|---|---|---|---|---|

| Ra [nm] | 197.1 ± 6.6 | 20.5 ± 4.3 | 170.0 ± 6.3 | 30.1 ± 1.9 | 145.4 ± 2.3 | 172.9 ± 5.8 |

| Rq [nm] | 254.8 ± 9.9 | 25.9 ± 5.1 | 221.9 ± 6.7 | 39.7 ± 2.3 | 192.9 ± 2.5 | 223.3 ± 7.8 |

| Rz [nm] | 2567.1 ± 294.5 | 336.2 ± 58.4 | 2301.6 ± 67.3 | 690.4 ± 53.6 | 2222.0 ± 54.3 | 2596.7 ± 137.5 |

| Rt [nm] | 3279.4 ± 664.5 | 580.6 ± 180.0 | 2829.5 ± 224.6 | 954.5 ± 140.4 | 2650.1 ± 248.5 | 3647.5 ± 478.9 |

| 14 Days in SBF | Ca (%at.) | P (%at.) | O (%at.) | Ca/P | ||||

|---|---|---|---|---|---|---|---|---|

| Place of Analysis | Image Area | Point | Image Area | Point | Image Area | Point | Image Area | Point |

| NiTi (mechanically ground surface) | 0.14 | 0.44 ± 0.05 | 0.33 | 0.14 ± 0.02 | 20.79 | 2.42 ± 0.09 | 0.42 | 3.14 |

| NiTi (mechanically polished surface) | - | - | 0.32 | 1.57 ± 0.09 | 15.96 | 29.94 ± 0.56 | - | - |

| NiTi + TiO2 (290 °C, mechanically ground surface) | 16.67 | 17.06 ± 0.49 | 12.48 | 11.67 ± 0.35 | 36.68 | 19.08 ± 1.29 | 1.34 | 1.46 |

| NiTi + TiO2 (290 °C, mechanically polished surface) | 18.25 | 27.48 ± 0.15 | 13.73 | 21.10 ± 0.12 | 32.93 | 35.81 ± 0.67 | 1.33 | 1.30 |

| NiTi + TiO2 (190 °C, mechanically ground surface) | 20.22 | 27.39 ± 0.18 | 24.70 | 22.36 ± 0.14 | 37.30 | 21.28 ± 0.83 | 0.81 | 1.23 |

| NiTi + TiO2 (390 °C, mechanically ground surface) | 0.13 | 0.54 ± 0.02 | 0.34 | 0.02 ± 0.02 | 21.81 | 0.70 ± 0.07 | 0.10 | - |

| 30 Days in SBF | Ca (%at.) | P (%at.) | O (%at.) | Ca/P | ||||

|---|---|---|---|---|---|---|---|---|

| Place of Analysis | Image Area | Point | Image Area | Point | Image Area | Point | Image Area | Point |

| NiTi (mechanically ground surface) | 12.89 | 20.88 ± 0.48 | 12.16 | 18.52 ± 0.59 | 38.41 | 37.92 ± 1.33 | 1.06 | 1.13 |

| NiTi + TiO2 (290 °C, mechanically ground surface) | 12.63 | 17.15 ± 0.32 | 11.01 | 17.97 ± 0.24 | 44.38 | 43.38 ± 1.07 | 1.15 | 0.95 |

| NiTi + TiO2 (190 °C, mechanically ground surface) | 13.03 | 33.63 ± 0.42 | 11.65 | 18.94 ± 0.27 | 42.16 | 27.49 ± 1.47 | 1.12 | 1.78 |

| NiTi + TiO2 (390 °C, mechanically ground surface) | 10.59 | 35.61 ± 0.41 | 10.77 | 20.13 ± 0.26 | 40.15 | 23.81 ± 1.32 | 0.98 | 1.76 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Witkowska, J.; Borowski, T.; Kulikowski, K.; Wunsch, K.; Morgiel, J.; Sobiecki, J.; Wierzchoń, T. Structure and Properties of Bioactive Titanium Dioxide Surface Layers Produced on NiTi Shape Memory Alloy in Low-Temperature Plasma. Micromachines 2024, 15, 886. https://doi.org/10.3390/mi15070886

Witkowska J, Borowski T, Kulikowski K, Wunsch K, Morgiel J, Sobiecki J, Wierzchoń T. Structure and Properties of Bioactive Titanium Dioxide Surface Layers Produced on NiTi Shape Memory Alloy in Low-Temperature Plasma. Micromachines. 2024; 15(7):886. https://doi.org/10.3390/mi15070886

Chicago/Turabian StyleWitkowska, Justyna, Tomasz Borowski, Krzysztof Kulikowski, Karol Wunsch, Jerzy Morgiel, Jerzy Sobiecki, and Tadeusz Wierzchoń. 2024. "Structure and Properties of Bioactive Titanium Dioxide Surface Layers Produced on NiTi Shape Memory Alloy in Low-Temperature Plasma" Micromachines 15, no. 7: 886. https://doi.org/10.3390/mi15070886