Micro-Opto-Electro-Mechanical Systems for High-Precision Displacement Sensing: A Review

Abstract

1. Introduction

2. Definition of MOEMS Displacement Sensing

3. Performance Indexes

4. Classifications

4.1. Guided-Wave Based Techniques

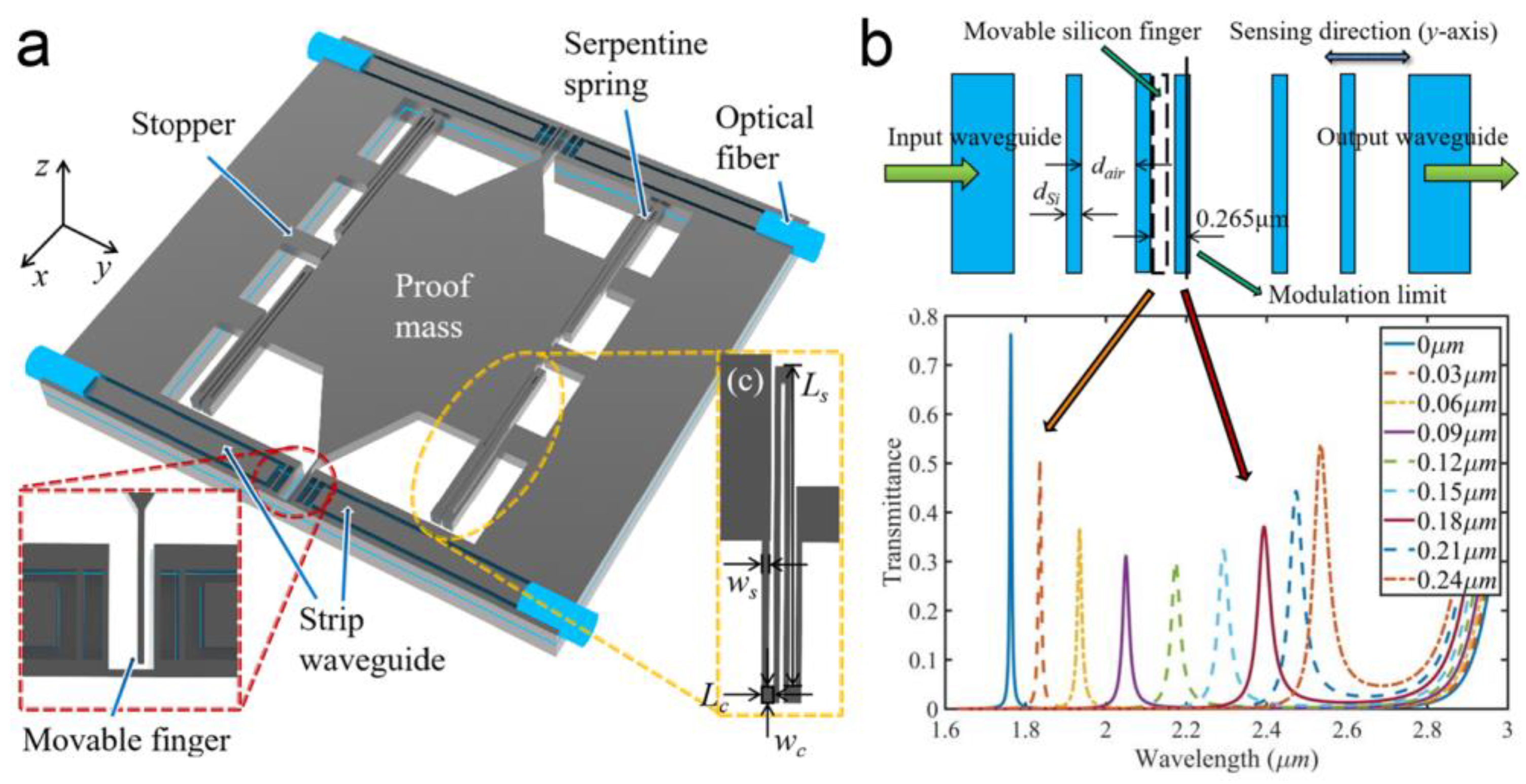

4.1.1. Evanescent Coupling Scheme

4.1.2. Interference Scheme

4.1.3. Bandgap Modulation Scheme

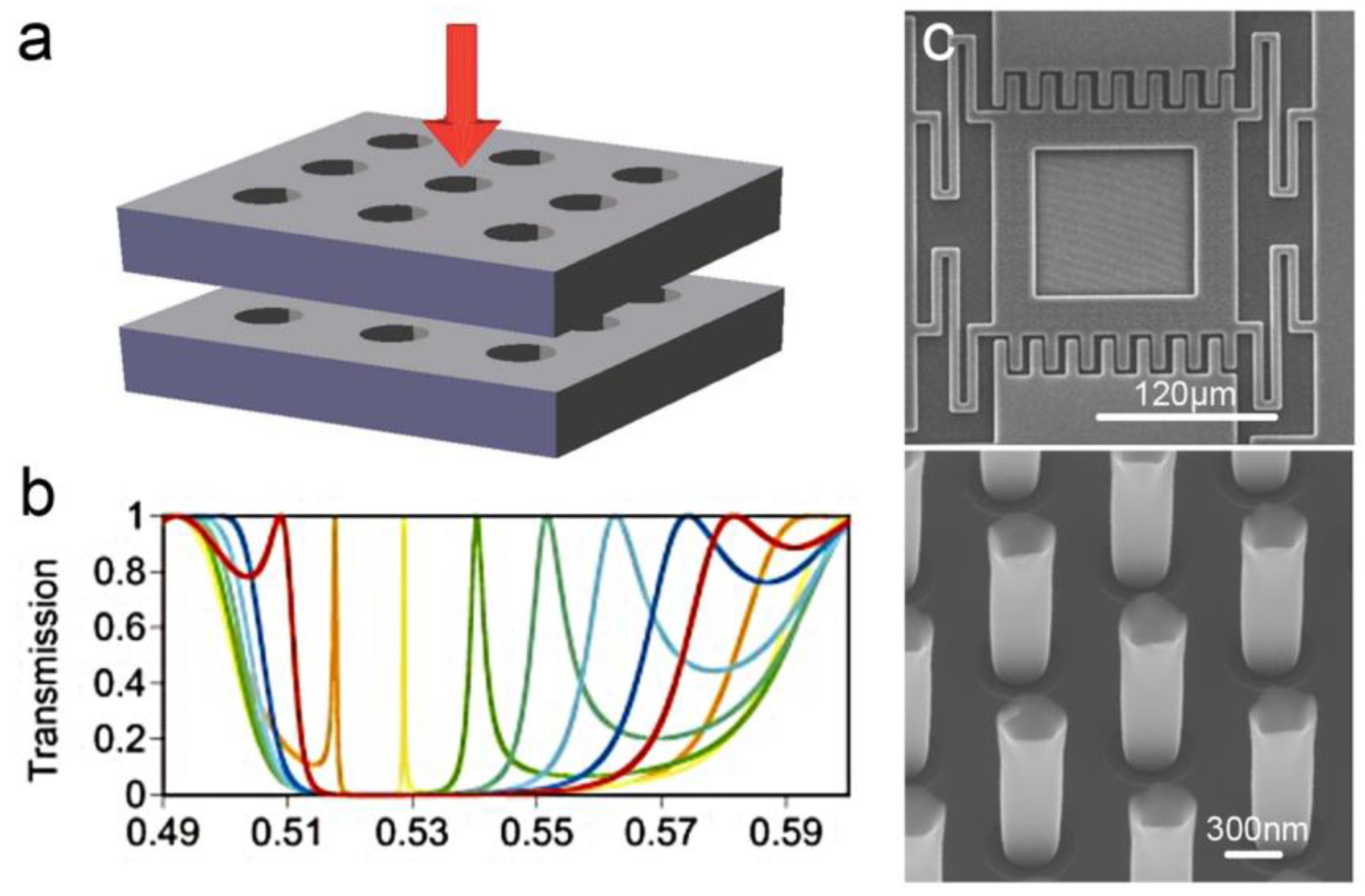

4.2. Figures, Tables and Schemes

4.2.1. Transmission Scheme

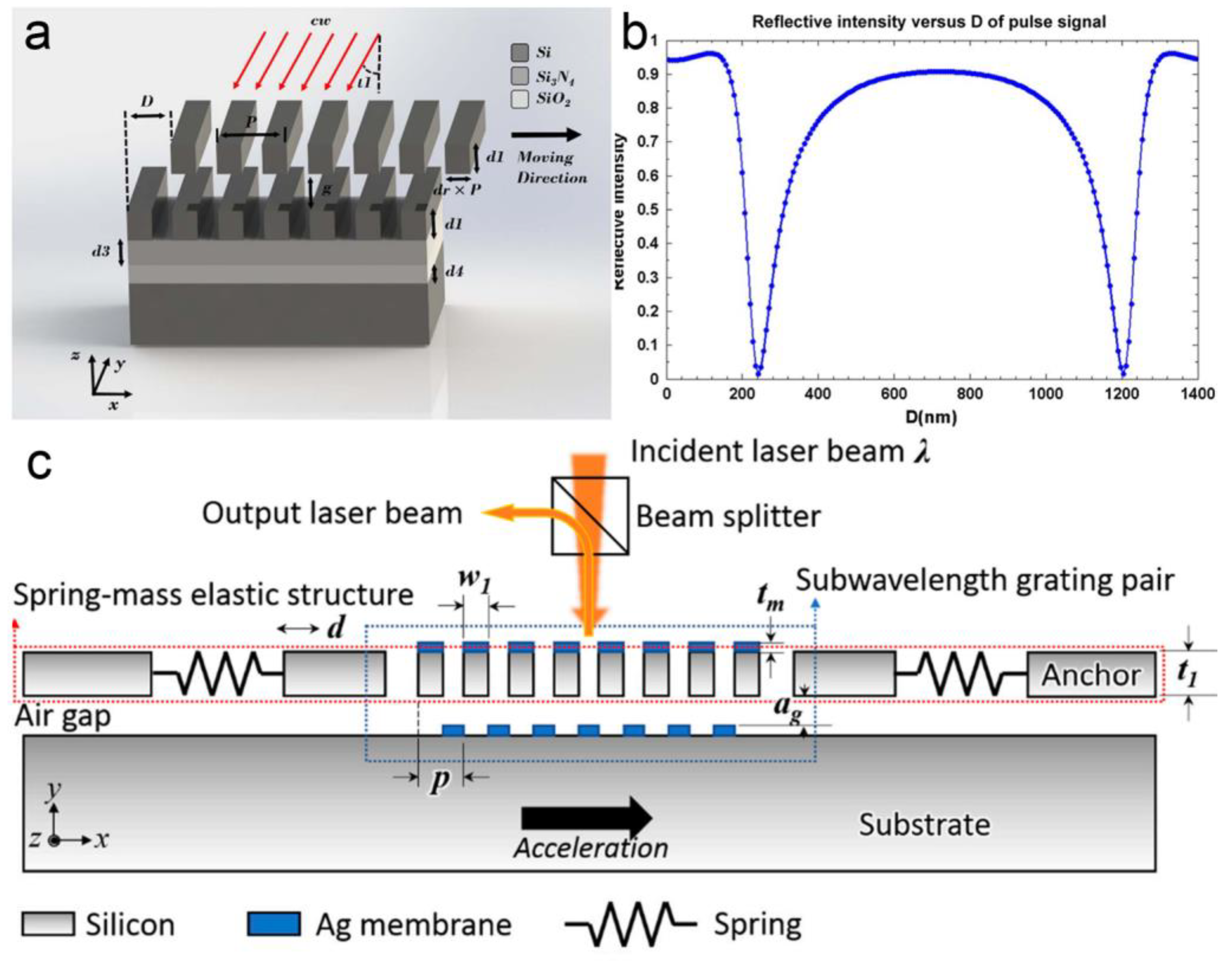

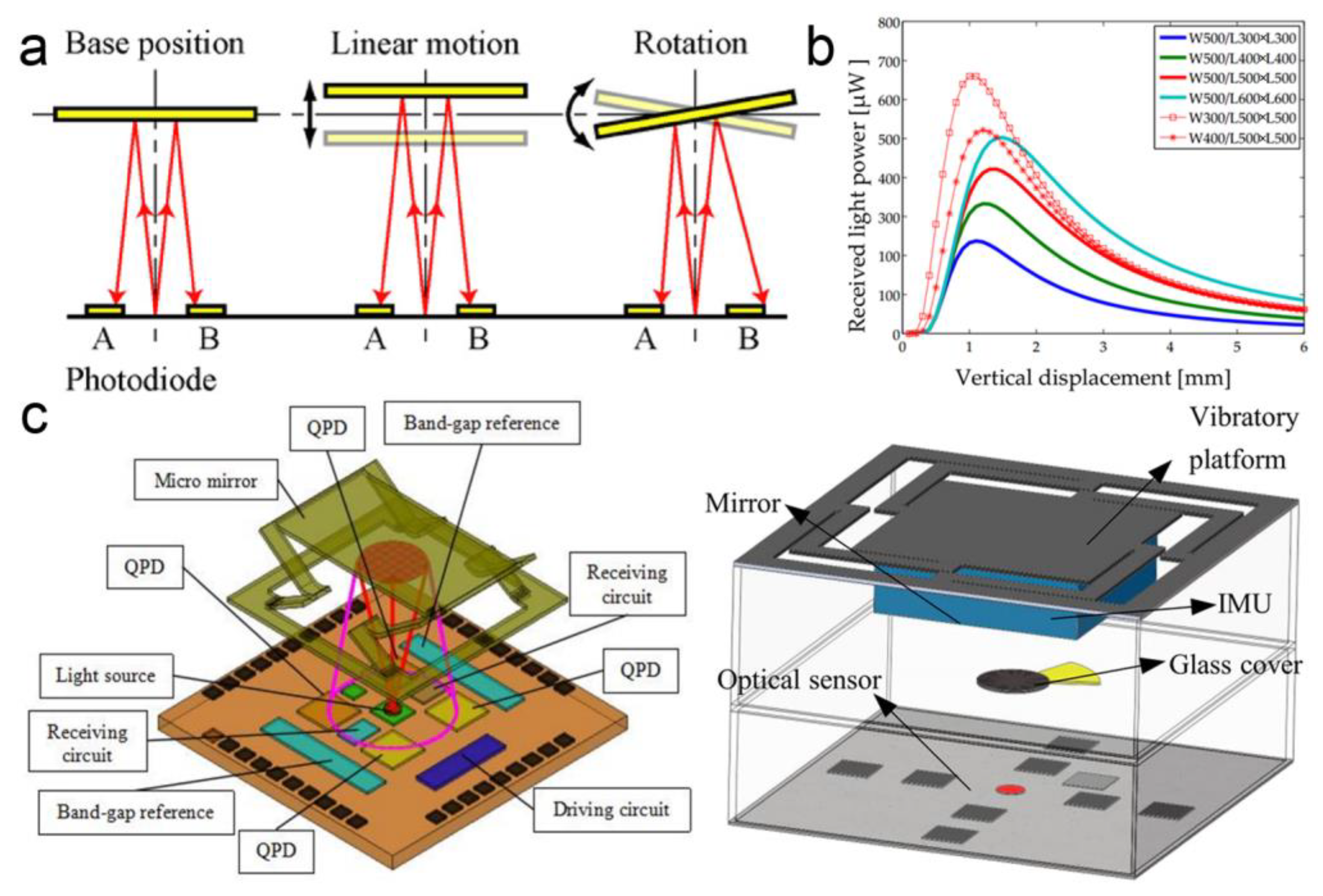

4.2.2. Reflection Scheme

5. Conclusions and Outlook

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Rakich, P.T.; Popovic, M.A.; Soljacic, M.; Ippen, E.P. Trapping, corralling and spectral bonding of optical resonances through optically induced potentials. Nat. Photonics 2007, 1, 658–665. [Google Scholar] [CrossRef]

- Gao, W.; Kim, S.W.; Bosse, H.; Haitjema, H.; Chena, Y.L.; Lu, X.D.; Knapp, W.; Weckenmann, A.; Estler, W.T.; Kunzmann, H. Measurement technologies for precision positioning. Cirp Ann.-Manuf. Technol. 2015, 64, 773–796. [Google Scholar] [CrossRef]

- Gao, W.; Haitjema, H.; Fang, F.Z.; Leach, R.K.; Cheung, C.F.; Savio, E.; Linares, J.M. On-machine and in-process surface metrology for precision manufacturing. Cirp Ann.-Manuf. Technol. 2019, 68, 843–866. [Google Scholar] [CrossRef]

- Lei, Y.-J.; Li, R.-J.; Zhang, L.-S.; Hu, P.-H.; Huang, Q.-X. Optical Accelerometers for Detecting Low-Frequency Micro-Vibrations. Appl. Sci. 2022, 12, 3994. [Google Scholar] [CrossRef]

- Berkovic, G.; Shafir, E. Optical methods for distance and displacement measurements. Adv. Opt. Photonics 2012, 4, 441–471. [Google Scholar] [CrossRef]

- Tseng, V.F.G.; Xie, H. Simultaneous piston position and tilt angle sensing for large vertical displacement micromirrors by frequency detection inductive sensing. Appl. Phys. Lett. 2015, 107, 214102. [Google Scholar] [CrossRef]

- Tseng, V.F.-G.; Xie, H. Resonant Inductive Coupling-Based Piston Position Sensing Mechanism for Large Vertical Displacement Micromirrors. J. Microelectromechanical Syst. 2016, 25, 207–216. [Google Scholar] [CrossRef]

- Ye, Y.; Zhang, C.; He, C.; Wang, X.; Huang, J.; Deng, J. A Review on Applications of Capacitive Displacement Sensing for Capacitive Proximity Sensor. IEEE Access 2020, 8, 45325–45342. [Google Scholar] [CrossRef]

- Hu, P.-C.; Chang, D.; Tan, J.-B.; Yang, R.-T.; Yang, H.-X.; Fu, H.-J. Displacement measuring grating interferometer: A review. Front. Inf. Technol. Electron. Eng. 2019, 20, 631–654. [Google Scholar] [CrossRef]

- Motamedi, E.; Kubby, J.; Oden, P.; Piyawattanametha, W. Emerging MOEMS Technology and Applications. J. Micro-Nanolithography Mems Moems 2014, 13, 011101. [Google Scholar] [CrossRef][Green Version]

- Lu, Q.; Wang, Y.; Wang, X.; Yao, Y.; Wang, X.; Huang, W. Review of micromachined optical accelerometers: From mg to sub-μg. Opto-Electron. Adv. 2021, 4, 200045. [Google Scholar] [CrossRef]

- Algamili, A.S.; Khir, M.H.M.; Dennis, J.O.; Ahmed, A.Y.; Alabsi, S.S.; Ba Hashwan, S.S.; Junaid, M.M. A Review of Actuation and Sensing Mechanisms in MEMS-Based Sensor Devices. Nanoscale Res. Lett. 2021, 16, 16. [Google Scholar] [CrossRef] [PubMed]

- Wu, Y.; Zeng, X.; Rao, Y.-J.; Gong, Y.; Hou, C.-L.; Yang, G.-G. MOEMS Accelerometer Based on Microfiber Knot Resonator. IEEE Photonics Technol. Lett. 2009, 21, 1547–1549. [Google Scholar] [CrossRef]

- Pang, C.; Bae, H.; Gupta, A.; Bryden, K.; Yu, M. MEMS Fabry-Perot sensor interrogated by optical system-on-a-chip for simultaneous pressure and temperature sensing. Opt. Express 2013, 21, 21829–21839. [Google Scholar] [CrossRef] [PubMed]

- Jindal, S.K.; Raghuwanshi, S.K.; Kumar, A. Realization of MOEMS pressure sensor using mach zehnder interferometer. J. Mech. Sci. Technol. 2015, 29, 3831–3839. [Google Scholar] [CrossRef]

- Huang, J.; Wen, Q.; Nie, Q.; Chang, F.; Zhou, Y.; Wen, Z. Miniaturized NIR Spectrometer Based on Novel MOEMS Scanning Tilted Grating. Micromachines 2018, 9, 478. [Google Scholar] [CrossRef] [PubMed]

- el Ahdab, R.; Sharma, S.; Nabki, F.; Menard, M. Wide-band silicon photonic MOEMS spectrometer requiring a single photodetector. Opt. Express 2020, 28, 31345–31359. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Li, C.; Shi, X.; Wu, Z.; Fan, S.; Wan, Z.; Han, S. High-Sensitivity Graphene MOEMS Resonant Pressure Sensor. ACS Appl. Mater. Interfaces 2023, 15, 30479–30485. [Google Scholar] [CrossRef] [PubMed]

- Mireles, J., Jr.; Sauceda, A.; Jimenez, A.; Ramos, M.; Gonzalez-Landaeta, R. Design and Development of a MOEMS Accelerometer Using SOI Technology. Micromachines 2023, 14, 231. [Google Scholar] [CrossRef]

- Yang, X.; Xia, D.; Fu, B.; Li, J.; Zhao, J.; Chu, Q. High-Sensitivity MOEMS Gyroscope Based on Photonic Crystal Wavelength Modulation. IEEE Sens. J. 2024, 24, 9489–9497. [Google Scholar] [CrossRef]

- Van Gorp, B.; Onaran, A.G.; Degertekin, F.L. Integrated dual grating method for extended range interferometric displacement detection in probe microscopy. Appl. Phys. Lett. 2007, 91, 2772114. [Google Scholar] [CrossRef]

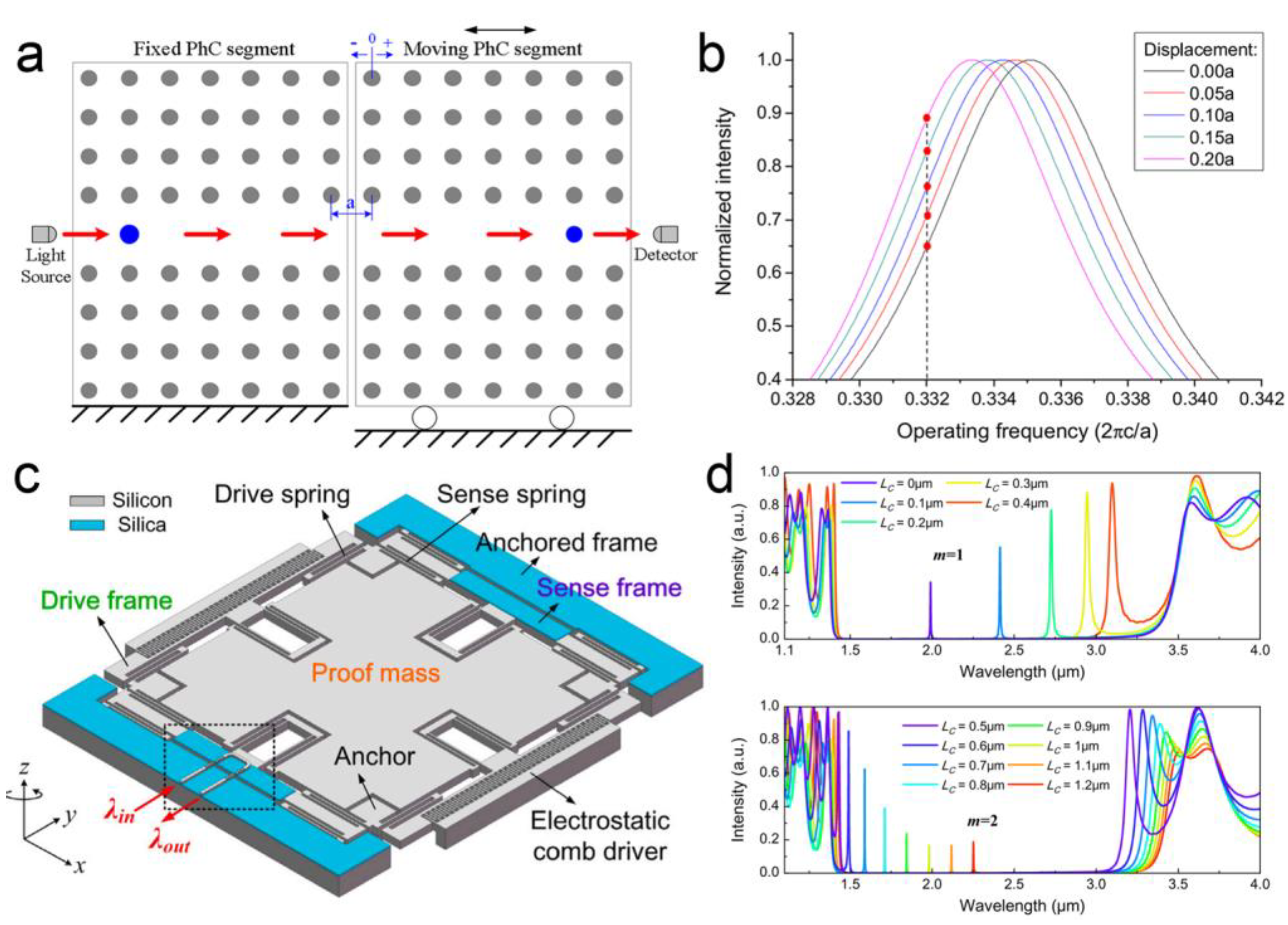

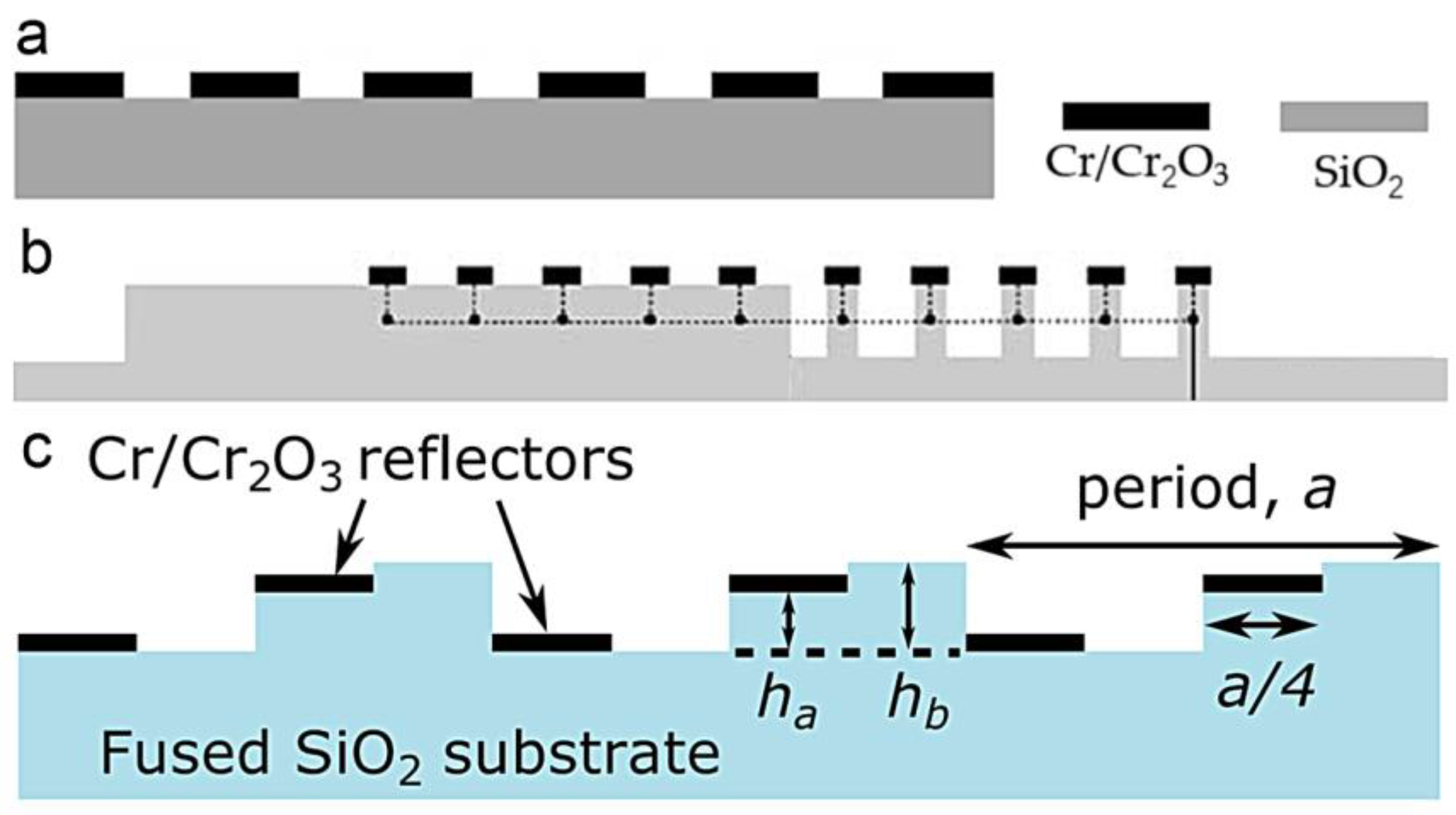

- Hadzialic, S.; Kim, S.; Sarioglu, A.F.; Sudbo, A.S.; Solgaard, O. Displacement Sensing with a Mechanically Tunable Photonic Crystal. IEEE Photonics Technol. Lett. 2010, 22, 1196–1198. [Google Scholar] [CrossRef]

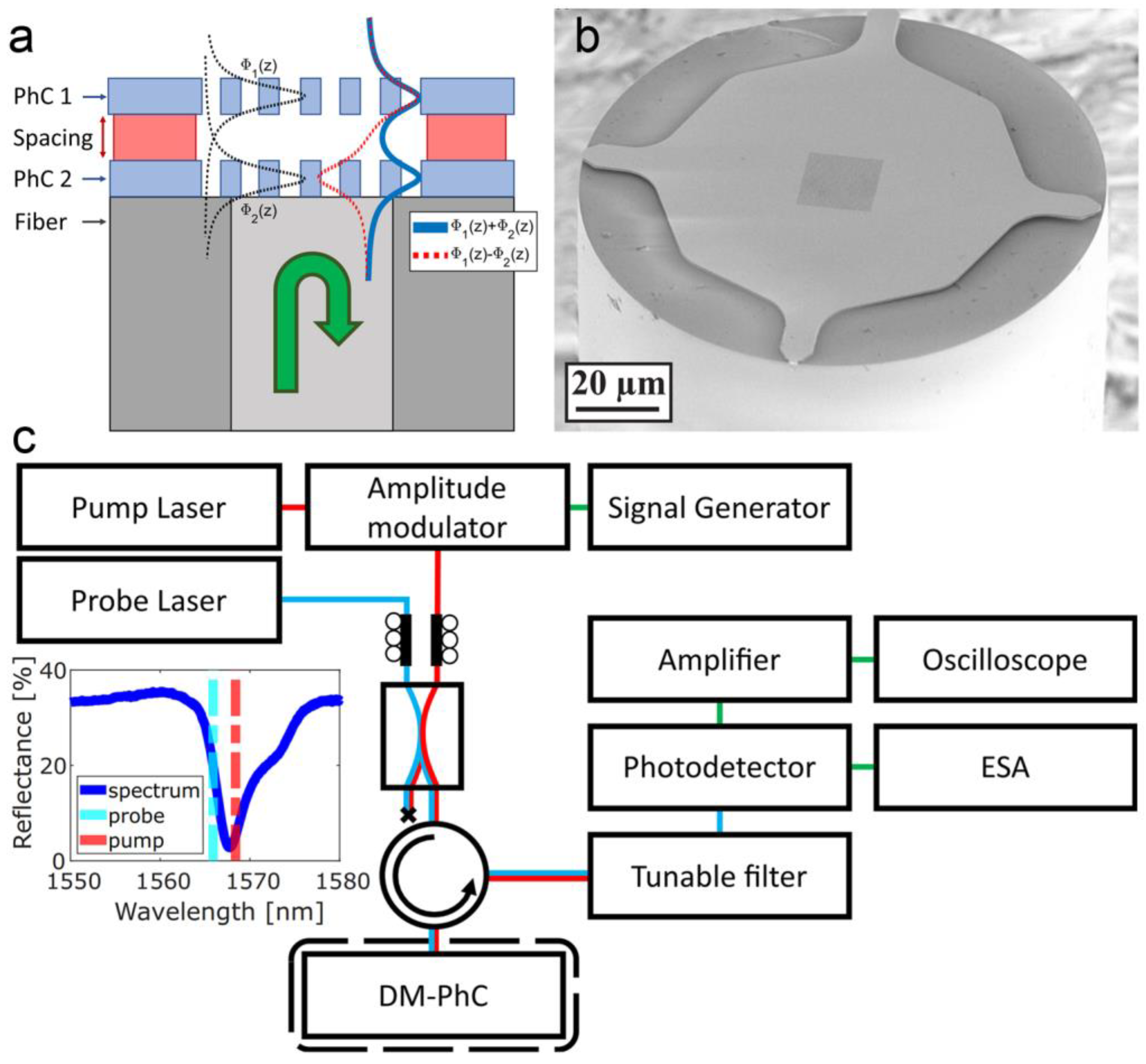

- Miao, H.; Srinivasan, K.; Aksyuk, V. A microelectromechanically controlled cavity optomechanical sensing system. New J. Phys. 2012, 14, 075015. [Google Scholar] [CrossRef]

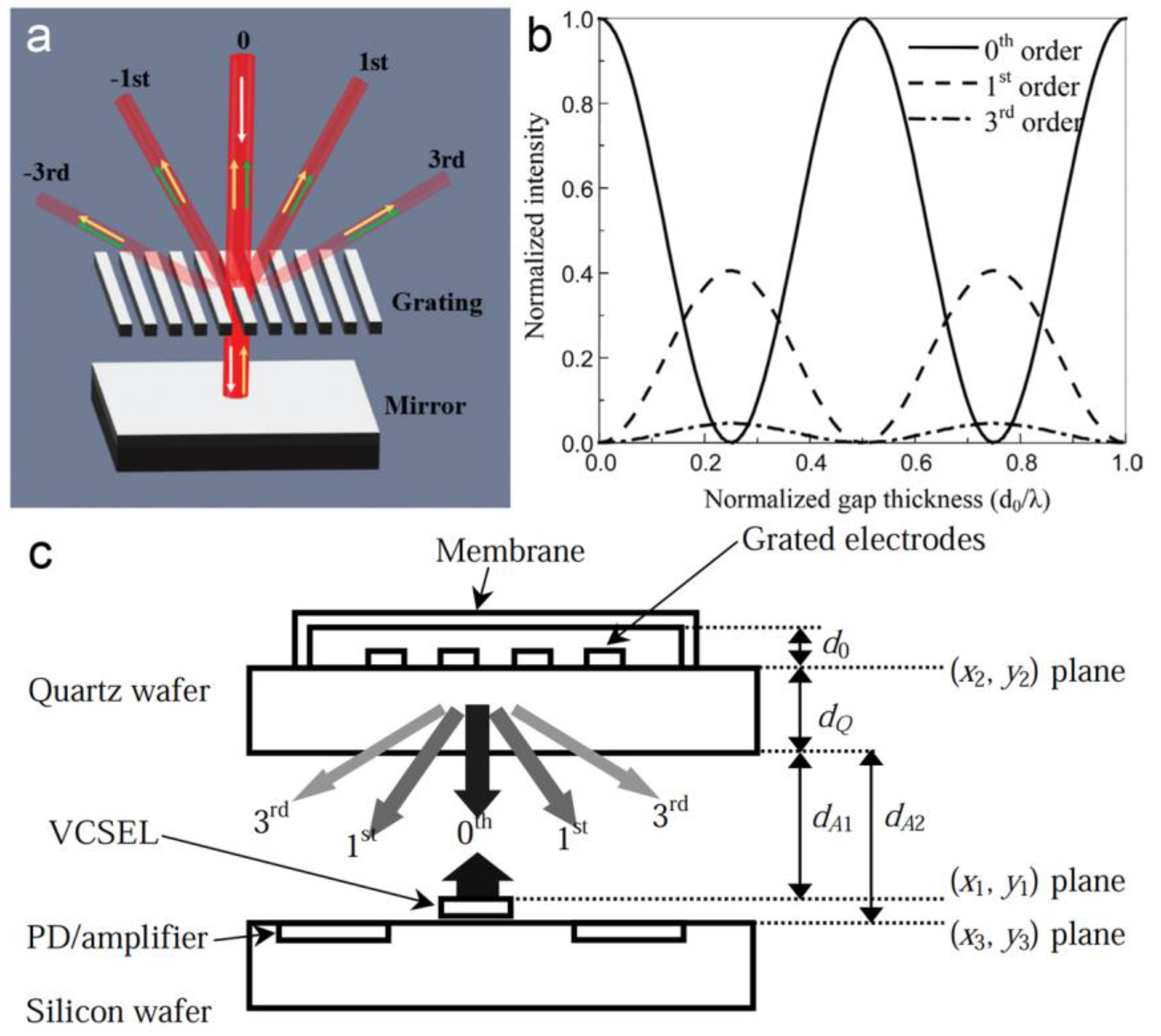

- Williams, R.P.; Hord, S.K.; Hall, N.A. Optically read displacement detection using phase-modulated diffraction gratings with reduced zeroth-order reflections. Appl. Phys. Lett. 2017, 110, 151104. [Google Scholar] [CrossRef]

- Sun, P.; She, X.; Yao, J.; Chen, K.; Bi, R.; Wang, L.; Shu, X. Monolithic Integrated Micro-Opto-Electromechanical Accelerometer Based on Michelson Interferometer Structure. J. Light. Technol. 2022, 40, 4364–4372. [Google Scholar] [CrossRef]

- Zhu, J.; Liu, X.; Shi, Q.; He, T.; Sun, Z.; Guo, X.; Liu, W.; Bin Sulaiman, O.; Dong, B.; Lee, C. Development Trends and Perspectives of Future Sensors and MEMS/NEMS. Micromachines 2020, 11, 7. [Google Scholar] [CrossRef] [PubMed]

- Liu, T.; Pagliano, F.; van Veldhoven, R.; Pogoretskiy, V.; Jiao, Y.; Fiore, A. Integrated nano-optomechanical displacement sensor with ultrawide optical bandwidth. Nat. Commun. 2020, 11, 2407. [Google Scholar] [CrossRef] [PubMed]

- Schilling, R.; Schutz, H.; Ghadimi, A.H.; Sudhir, V.; Wilson, D.J.; Kippenberg, T.J. Near-Field Integration of a SiN Nanobeam and a SiO2 Microcavity for Heisenberg-Limited Displacement Sensing. Phys. Rev. Appl. 2016, 5, 054019. [Google Scholar] [CrossRef]

- Hortschitz, W.; Steiner, H.; Sachse, M.; Stifter, M.; Kohl, F.; Schalko, J.; Jachimowicz, A.; Keplinger, F.; Sauter, T. An Optical In-Plane MEMS Vibration Sensor. IEEE Sens. J. 2011, 11, 2805–2812. [Google Scholar] [CrossRef]

- Taghavi, M.; Latifi, H.; Parsanasab, G.M.; Abedi, A.; Nikbakht, H.; Poorghadiri, M.H. A Dual-Axis MOEMS Accelerometer. IEEE Sens. J. 2021, 21, 13156–13164. [Google Scholar] [CrossRef]

- Hosseinzadeh Sani, M.; Saghaei, H.; Mehranpour, M.A.; Asgariyan Tabrizi, A. A Novel All-Optical Sensor Design Based on a Tunable Resonant Nanocavity in Photonic Crystal Microstructure Applicable in MEMS Accelerometers. Photonic Sens. 2021, 11, 457–471. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Fan, C.; Jin, L.; Li, M.; Xin, C. Design and simulation of a waveguiding MOEMS gyroscope with ultrawide optical bandwidth based on tunable cascaded Fabry-Perot cavities. Opt. Commun. 2024, 556, 130268. [Google Scholar] [CrossRef]

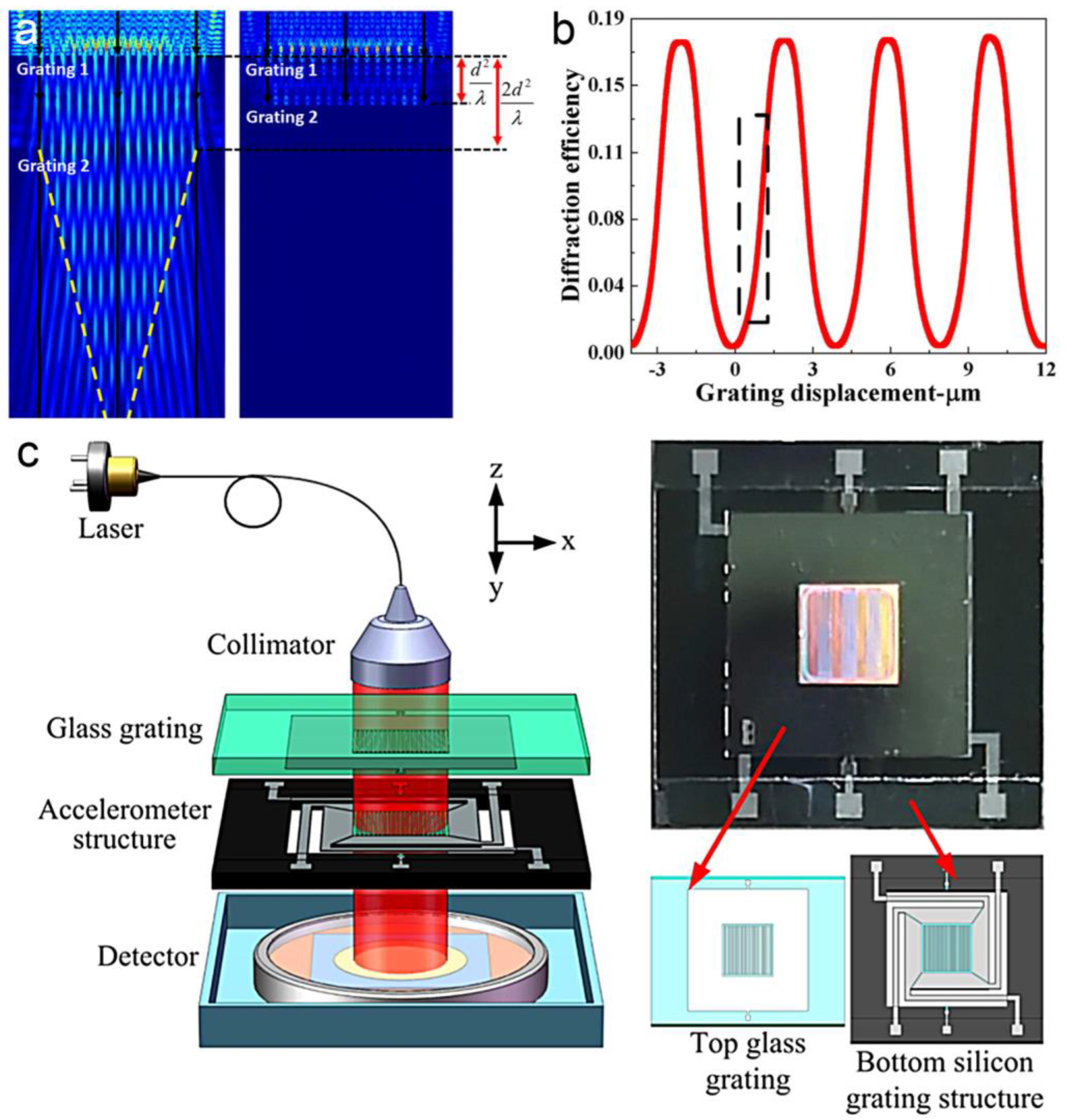

- Chen, W.; Jin, L.; Wang, Z.; Peng, H.; Li, M. Design and Demonstration of an in-Plane Micro-Optical-Electro-Mechanical-System Accelerometer Based on Talbot Effect of Dual-Layer Gratings. Micromachines 2023, 14, 1301. [Google Scholar] [CrossRef] [PubMed]

- Yao, Y.; Pan, D.; Wang, J.; Dong, T.; Guo, J.; Wang, C.; Geng, A.; Fang, W.; Lu, Q. Design and Modification of a High-Resolution Optical Interferometer Accelerometer. Sensors 2021, 21, 2070. [Google Scholar] [CrossRef] [PubMed]

- Takeshita, T.; Iwasaki, T.; Harisaki, K.; Ando, H.; Higurashi, E.; Sawada, R. Development of a Piezo-driven Mechanical Stage Integrated Microdisplacement Sensor for Calibration of Displacements. Sens. Mater. 2014, 26, 547–557. [Google Scholar]

- Huang, W.; Yan, X.; Zhang, S.; Li, Z.; Hassan, J.N.A.; Chen, D.; Wen, G.; Chen, K.; Deng, G.; Huang, Y. MEMS and MOEMS Gyroscopes: A Review. Photonic Sens. 2023, 13, 230419. [Google Scholar] [CrossRef]

- Qu, H. CMOS MEMS Fabrication Technologies and Devices. Micromachines 2016, 7, 14. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Chen, X.; Liu, C.; Cai, G.; Wang, W. A survey on the grating based optical position encoder. Opt. Laser Technol. 2021, 143, 107352. [Google Scholar] [CrossRef]

- Mohd-Yasin, F.; Nagel, D.J.; Korman, C.E. Noise in MEMS. Meas. Sci. Technol. 2010, 21, 012001. [Google Scholar] [CrossRef]

- Pooser, R.C.; Lawrie, B. Ultrasensitive measurement of microcantilever displacement below the shot-noise limit. Optica 2015, 2, 393–399. [Google Scholar] [CrossRef]

- Li, M.; Pernice, W.H.P.; Xiong, C.; Baehr-Jones, T.; Hochberg, M.; Tang, H.X. Harnessing optical forces in integrated photonic circuits. Nature 2008, 456, 480–484. [Google Scholar] [CrossRef] [PubMed]

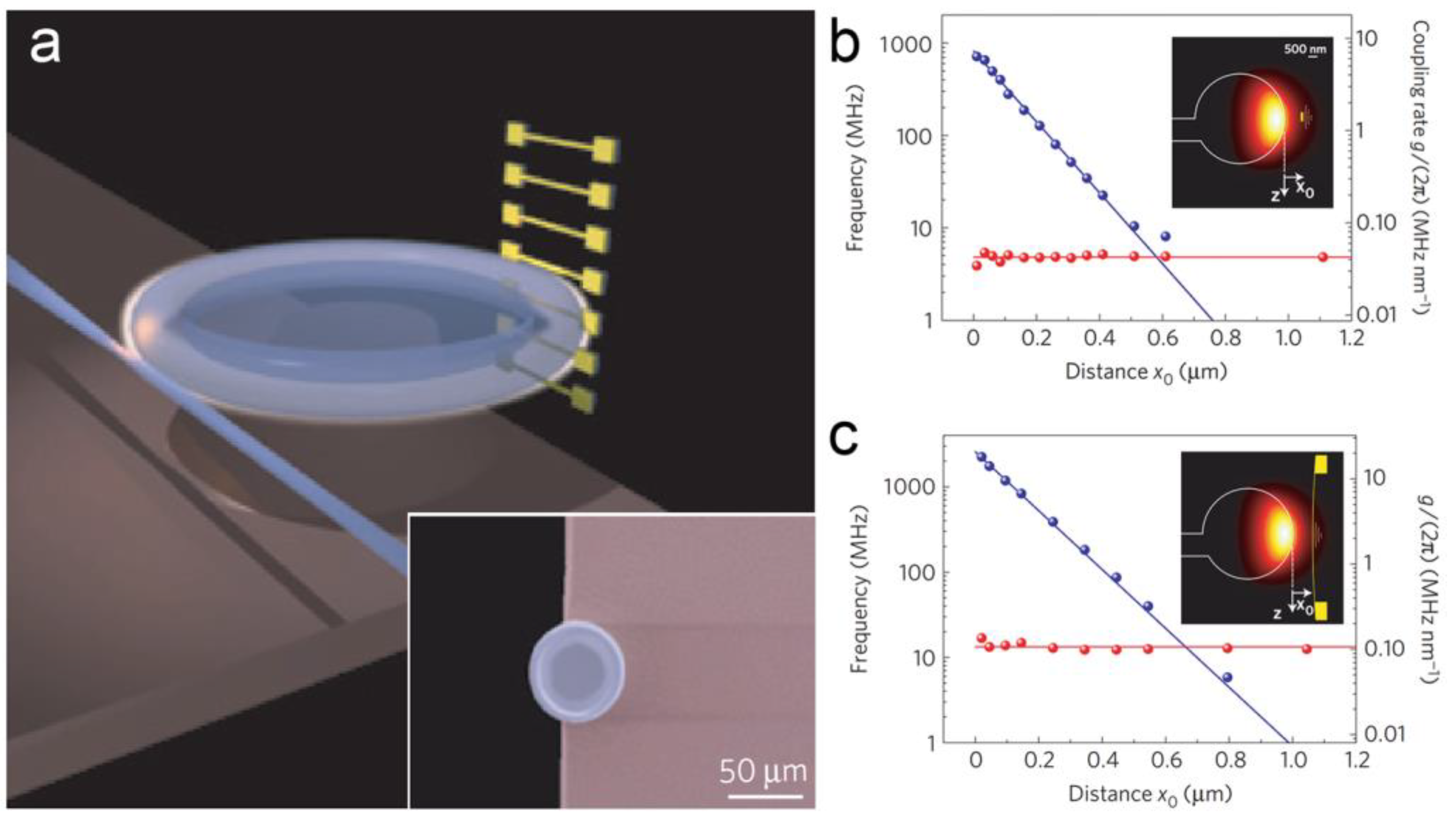

- Anetsberger, G.; Arcizet, O.; Unterreithmeier, Q.P.; Riviere, R.; Schliesser, A.; Weig, E.M.; Kotthaus, J.P.; Kippenberg, T.J. Near-field cavity optomechanics with nanomechanical oscillators. Nat. Phys. 2009, 5, 909–914. [Google Scholar] [CrossRef]

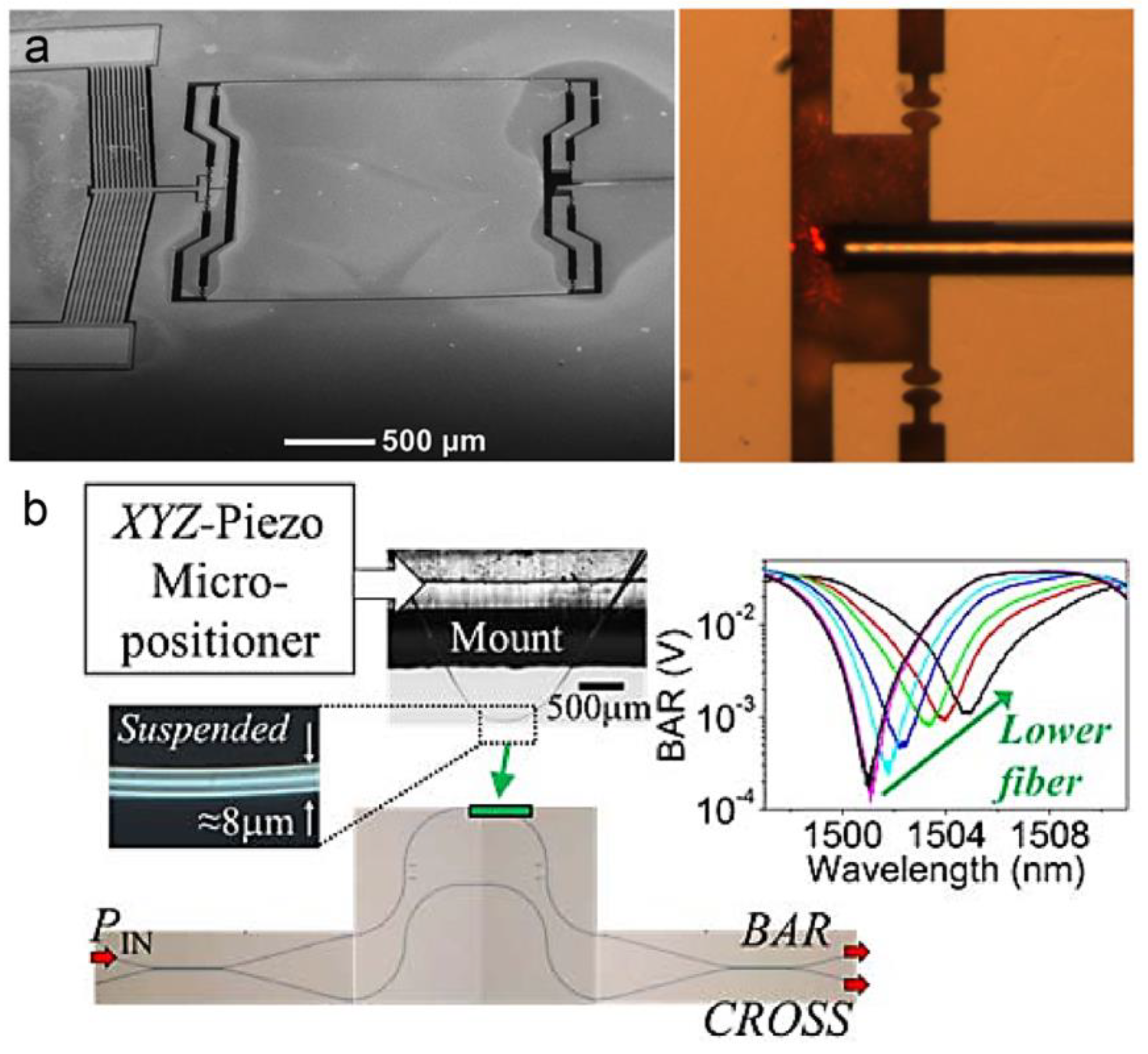

- Li, M.; Pernice, W.H.P.; Tang, H.X. Broadband all-photonic transduction of nanocantilevers. Nat. Nanotechnol. 2009, 4, 377–382. [Google Scholar] [CrossRef] [PubMed]

- Hendriks, A.L.; Picelli, L.; van Veldhoven, R.P.J.; Verhagen, E.; Fiore, A. Nano-optomechanical fiber-tip sensing. Nanophotonics 2024, 1, 10. [Google Scholar] [CrossRef]

- Hall, N.A.; Lee, W.; Degertekin, F.L. Capacitive micromachined ultrasonic transducers with diffraction-based integrated optical displacement detection. IEEE Trans. Ultrason. Ferroelectr. Freq. Control. 2003, 50, 1570–1580. [Google Scholar] [CrossRef] [PubMed]

- Savran, C.A.; Sparks, A.W.; Sihler, J.; Li, J.; Wu, W.-C.; Berlin, D.E.; Burg, T.P.; Fritz, J.; Schmidt, M.A.; Manalis, S.R. Fabrication and Characterization of a Micromechanical Sensor for Differential Detection of Nanoscale Motions. J. Microelectromechanical Syst. 2002, 11, 703–708. [Google Scholar] [CrossRef]

- Pruessner, M.W.; Park, D.; Stievater, T.H.; Kozak, D.A.; Rabinovich, W.S. An Optomechanical Transducer Platform for Evanescent Field Displacement Sensing. IEEE Sens. J. 2014, 14, 3473–3481. [Google Scholar] [CrossRef]

- Orlowska, K.; Swiatkowski, M.; Kunicki, P.; Kopiec, D.; Gotszalk, T. High-resolution and wide-bandwidth light intensity fiber optic displacement sensor for MEMS metrology. Appl. Opt. 2016, 55, 5960–5966. [Google Scholar] [CrossRef] [PubMed]

- Steiner, H.; Hortschitz, W.; Kainz, A.; Stifter, M.; Jachimowicz, A.; Schalko, J.; Keplinger, F.; Kohl, F. MOEMS transducer with a non-linear transfer characteristic for static displacement measurement applications on the example of an inclination sensor. Sens. Actuators A Phys. 2017, 263, 727–732. [Google Scholar] [CrossRef]

- Tong, L.; Lou, J.; Mazur, E. Single-mode guiding properties of subwavelength-diameter silica and silicon wire waveguides. Opt. Express 2004, 12, 1025–1035. [Google Scholar] [CrossRef]

- Zhang, J.B.; Fang, H.B.; Wang, P.; Zhang, L.; Guo, X.; Tong, L. Optical microfiber or nanofiber: A miniature fiber-optic platform for nanophotonics. Photonics Res. 2024, 3, R02. [Google Scholar] [CrossRef]

- Huang, K.; Yang, S.; Tong, L. Modeling of evanescent coupling between two parallel optical nanowires. Appl. Opt. 2007, 46, 1429–1434. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.L.; Barker, R.F. Characterization and Testing of a Micro-g Whispering Gallery Mode Optomechanical Accelerometer. J. Light. Technol. 2018, 36, 3919–3926. [Google Scholar] [CrossRef]

- Kilic, O.; Ra, H.; Akkaya, O.C.; Digonnet, M.J.F.; Solgaard, O. Haltere-like Optoelectromechanical Gyroscope. IEEE Sens. J. 2016, 16, 4274–4280. [Google Scholar] [CrossRef]

- Wu, X.; Tong, L. Optical microfibers and nanofibers. Nanophotonics 2013, 2, 407–428. [Google Scholar] [CrossRef]

- Povinelli, M.L.; Loncar, M.; Ibanescu, M.; Smythe, E.J.; Johnson, S.G.; Capasso, F.; Joannopoulos, J.D. Evanescent-wave bonding between optical waveguides. Opt. Lett. 2005, 30, 3042–3044. [Google Scholar] [CrossRef] [PubMed]

- Chen, B.; Wu, H.; Xin, C.; Dai, D.; Tong, L. Flexible integration of free-standing nanowires into silicon photonics. Nat. Commun. 2017, 8, 20. [Google Scholar] [CrossRef] [PubMed]

- Xin, C.; Zhang, Z.; Wang, X.; Fan, C.; Li, M. Ultracompact single-layer optical MEMS accelerometer based on evanescent coupling through silicon nanowaveguides. Sci. Rep. 2022, 12, 21697. [Google Scholar] [CrossRef]

- Xu, Z.; Cao, L.; Su, P.; He, Q.; Jin, G.; Gu, G. Micro-displacement sensor with large dynamic range based on photonic crystal co-directional coupler. IEEE J. Quantum Electron. 2007, 43, 182–187. [Google Scholar] [CrossRef]

- Krause, A.G.; Winger, M.; Blasius, T.D.; Lin, Q.; Painter, O. A high-resolution microchip optomechanical accelerometer. Nat. Photonics 2012, 6, 768–772. [Google Scholar] [CrossRef]

- Soltanian, E.; Jafari, K.; Abedi, K. A Novel Differential Optical MEMS Accelerometer Based on Intensity Modulation, Using an Optical Power Splitter. IEEE Sens. J. 2019, 19, 12024–12030. [Google Scholar] [CrossRef]

- Karabacak, D.M.; Ekinci, K.L.; Gan, C.H.; Gbur, G.J.; Ünlü, M.S.; Ippolito, S.B.; Goldberg, B.B.; Carney, P.S. Diffraction of evanescent waves and nanomechanical displacement detection. Opt. Express 2007, 32, 1881–1883. [Google Scholar] [CrossRef] [PubMed]

- Ab Razak, M.Z.; Reduan, S.A.; Sharbirin, A.S.; Jamaludin, N.; Zulkifli, M.Z.; Ahmad, H. Noncontact Optical Displacement Sensor Using an Adiabatic U-Shaped Tapered Fiber. IEEE Sens. J. 2015, 15, 5388–5392. [Google Scholar] [CrossRef]

- Schliesser, A.; Anetsberger, G.; Riviere, R.; Arcizet, O.; Kippenberg, T.J. High-sensitivity monitoring of micromechanical vibration using optical whispering gallery mode resonators. New J. Phys. 2008, 10, 095015. [Google Scholar] [CrossRef]

- Wilson, D.J.; Sudhir, V.; Piro, N.; Schilling, R.; Ghadimi, A.; Kippenberg, T.J. Measurement-based control of a mechanical oscillator at its thermal decoherence rate. Nature 2015, 524, 325–329. [Google Scholar] [CrossRef] [PubMed]

- Kolli, V.R.; Dudla, P.; Talabattula, S. Integrated optical MEMS serially coupled double racetrack resonator based accelerometer. Optik 2021, 236, 166583. [Google Scholar] [CrossRef]

- Gholamzadeh, R.; Salarieh, H.; Parsanasab, G.M.; Akbari, J. A high sensitive, low foot print, SU-8 material-based, light intensity modulated MOMS accelerometer. Opt. Eng. 2022, 61, 055103. [Google Scholar] [CrossRef]

- Feng, Y.; Yang, W.; Zou, X. Design and Simulation Study of an Optical Mode-Localized MEMS Accelerometer. Micromachines 2023, 14, 39. [Google Scholar] [CrossRef] [PubMed]

- Basumallick, N.; Biswas, P.; Dasgupta, K.; Bandyopadhyay, S. Design optimization of fiber Bragg grating accelerometer for maximum sensitivity. Sens. Actuators A Phys. 2013, 194, 31–39. [Google Scholar] [CrossRef]

- Tosi, D.; Perrone, G.; Vallan, A. Performance Analysis of a Noncontact Plastic Fiber Optical Fiber Displacement Sensor with Compensation of Target Reflectivity. J. Sens. 2013, 2013, 781548. [Google Scholar] [CrossRef]

- Orlowska, K.; Slupski, P.; Swiatkowski, M.; Kunicki, P.; Sankowska, A.; Gotszalk, T. Light Intensity Fibre Optic Sensor for MEMS displacement and vibration metrology. Opt. Laser Technol. 2015, 65, 159–163. [Google Scholar] [CrossRef]

- Favero, I.; Stapfner, S.; Hunger, D.; Paulitschke, P.; Reichel, J.; Lorenz, H.; Weig, E.M.; Karrai, K. Fluctuating nanomechanical system in a high finesse optical microcavity. Opt. Express 2009, 17, 12813–12820. [Google Scholar] [CrossRef] [PubMed]

- Kim, Y.-S.; Dagalakis, N.G.; Choi, Y.-M. Optical fiber Fabry-Perot micro-displacement sensor for MEMS in-plane motion stage. Microelectron. Eng. 2018, 187, 6–13. [Google Scholar] [CrossRef]

- Malayappan, B.; Lakshmi, U.P.; Rao, B.V.V.S.N.P.; Ramaswamy, K.; Pattnaik, P.K. Sensing Techniques and Interrogation Methods in Optical MEMS Accelerometers: A Review. IEEE Sens. J. 2022, 22, 6232–6246. [Google Scholar] [CrossRef]

- Qu, Z.; Ouyang, H.; Xiong, W.; Xu, Q.; Wang, Y.; Liu, H. A Nano-g MOEMS Accelerometer Featuring Electromagnetic Force Balance with 157-dB Dynamic Range. IEEE Trans. Ind. Electron. 2024, 71, 6418–6426. [Google Scholar] [CrossRef]

- Rahimi, M.; Malekmohammad, M.; Taghavi, M.; Noori, M.; Parsanasab, G.-M.M. Design and Fabrication of a Differential MOEMS Accelerometer Based on Fabry-Perot Micro-Cavities. IEEE Sens. J. 2022, 22, 14779–14785. [Google Scholar] [CrossRef]

- Zandi, K.; Belanger, J.A.; Peter, Y.-A. Design and Demonstration of an In-Plane Silicon-on-Insulator Optical MEMS Fabry-Perot-Based Accelerometer Integrated with Channel Waveguides. J. Microelectromechanical Syst. 2012, 21, 1464–1470. [Google Scholar] [CrossRef]

- Trigona, C.; Ando, B.; Baglio, S. Fabrication and Characterization of an MOEMS Gyroscope Based on Photonic Bandgap Materials. IEEE Trans. Instrum. Meas. 2016, 65, 2840–2852. [Google Scholar] [CrossRef]

- Di Falco, A.; O’Faolain, L.; Krauss, T.F. Photonic crystal slotted slab waveguides. Photonics Nanostructures-Fundam. Appl. 2008, 6, 38–41. [Google Scholar] [CrossRef]

- Wu, C.J.; Wang, Z.H. Properties of defect modes in one-dimensional photonic crystals. Prog. Electromagn. Res.-PIER 2010, 103, 169–184. [Google Scholar] [CrossRef]

- Sheikhaleh, A.; Jafari, K.; Abedi, K. Design and Analysis of a Novel MOEMS Gyroscope Using an Electrostatic Comb-Drive Actuator and an Optical Sensing System. IEEE Sens. J. 2019, 19, 144–150. [Google Scholar] [CrossRef]

- Suh, W.; Solgaard, O.; Fan, S. Displacement sensing using evanescent tunneling between guided resonances in photonic crystal slabs. J. Appl. Phys. 2005, 98, 033102. [Google Scholar] [CrossRef]

- Xu, Z.F.; Cao, L.C.; Gu, C.; He, Q.S.; Jin, G.F. Micro displacement sensor based on line-defect resonant cavity in photonic crystal. Opt. Express 2006, 14, 298–305. [Google Scholar] [CrossRef] [PubMed]

- Suh, W.; Yanik, M.F.; Solgaard, O.; Fan, S. Displacement-sensitive photonic crystal structures based on guided resonance in photonic crystal slabs. Appl. Phys. Lett. 2003, 82, 1999. [Google Scholar] [CrossRef]

- Levy, O.; Steinberg, B.Z.; Nathan, M.; Boag, A. Ultrasensitive displacement sensing using photonic crystal waveguides. Applied Phys. Lett. 2005, 86, 104102. [Google Scholar] [CrossRef]

- Huang, K.; Yu, M.; Cheng, L.; Liu, J.; Cao, L. A Proposal for an Optical MEMS Accelerometer with High Sensitivity Based on Wavelength Modulation System. J. Light. Technol. 2019, 37, 5474–5478. [Google Scholar] [CrossRef]

- Huang, K.; Cao, L.; Zhai, P.; Liu, P.; Cheng, L.; Liu, J. High sensitivity sensing system theoretical research base on waveguide-nano DBRs one dimensional photonic crystal microstructure. Opt. Commun. 2020, 470, 125392. [Google Scholar] [CrossRef]

- Sheikhaleh, A.; Abedi, K.; Jafari, K. A Proposal for an Optical MEMS Accelerometer Relied on Wavelength Modulation with One Dimensional Photonic Crystal. J. Light. Technol. 2016, 34, 5244–5249. [Google Scholar] [CrossRef]

- Lee, C.K.; Radhakrishnan, R.; Chen, C.C.; Li, J.; Thillaigovindan, J.; Balasubramanian, N. Design and Modeling of a Nanomechanical Sensor Using Silicon Photonic Crystals. J. Light. Technol. 2008, 26, 839–846. [Google Scholar] [CrossRef]

- Ahrnadian, M.; Jafari, K.; Sharifi, M.J. Novel graphene-based optical MEMS accelerometer dependent on intensity modulation. ETRI J. 2018, 40, 794–801. [Google Scholar] [CrossRef]

- Afunadian, M.; Jafari, K. A Graphene-Based Wide-Band MEMS Accelerometer Sensor Dependent on Wavelength Modulation. IEEE Sens. J. 2019, 19, 6226–6232. [Google Scholar] [CrossRef]

- Nie, Y.; Huang, K.; Yang, J.; Cao, L.; Cheng, L.; Wang, Q.; Tian, H.; Peihua, W.; Heng, L. A Proposal to Enhance High-Frequency Optical MEMS Accelerometer Sensitivity Based on a One-Dimensional Photonic Crystal Wavelength Modulation System. IEEE Sens. J. 2020, 20, 14639–14645. [Google Scholar] [CrossRef]

- Huang, K.; Nie, Y.; Liu, Y.; Liu, P.; Cao, L.; Wang, Q.; Cheng, L.; Cui, J.; Gao, X.; Li, J. A Proposal for a High-Sensitivity Optical MEMS Accelerometer with a Double-Mode Modulation System. J. Light. Technol. 2021, 39, 303–309. [Google Scholar] [CrossRef]

- Sheikhaleh, A.; Abedi, K.; Jafari, K. An Optical MEMS Accelerometer Based on a Two-Dimensional Photonic Crystal Add-Drop Filter. J. Light. Technol. 2017, 35, 3029–3034. [Google Scholar] [CrossRef]

- Beyaz, M.I.; McCarthy, M.; Ghalichechian, N.; Ghodssi, R. Closed-loop control of a long-range micropositioner using integrated photodiode sensors. Sens. Actuators A Phys. 2009, 151, 187–194. [Google Scholar] [CrossRef]

- Abozyd, S.; Toraya, A.; Gaber, N. Design and Modeling of Fiber-Free Optical MEMS Accelerometer Enabling 3D Measurements. Micromachines 2022, 13, 343. [Google Scholar] [CrossRef] [PubMed]

- Xin, C.; Yang, Z.; Qi, J.; Niu, Q.; Ma, X.; Fan, C.; Li, M. Ultra-compact displacement and vibration sensor with a sub-nanometric resolution based on Talbot effect of optical microgratings. Opt. Express 2022, 30, 40009–40017. [Google Scholar] [CrossRef] [PubMed]

- Kim, M.-S.; Scharf, T.; Menzel, C.; Rockstuhl, C.; Herzig, H.P. Talbot images of wavelength-scale amplitude gratings. Opt. Express 2012, 20, 4903–4920. [Google Scholar] [CrossRef] [PubMed]

- Cao, B.; Zhang, R.; Niu, Q.; Ma, X.; Yang, Z.; Li, M.; Xin, C. Out-of-plane displacement sensor based on the Talbot effect in angular-modulated double-layer optical gratings. Appl. Opt. 2022, 61, 9873–9878. [Google Scholar] [CrossRef]

- Zhang, M.; Yang, H.; Niu, Q.; Zhang, X.; Yang, J.; Lai, J.; Fan, C.; Li, M.; Xin, C. Combined Displacement and Angle Sensor with Ultra-High Compactness Based on Self-Imaging Effect of Optical Microgratings. Sensors 2024, 24, 908. [Google Scholar] [CrossRef]

- Yang, Z.; Ma, X.; Yu, D.; Cao, B.; Niu, Q.; Li, M.; Xin, C. An Ultracompact Angular Displacement Sensor Based on the Talbot Effect of Optical Microgratings. Sensors 2023, 23, 1091. [Google Scholar] [CrossRef] [PubMed]

- Li, M.; Geng, H.; Wu, Q.; Zhang, R.; Han, Y.; Wang, G. Application of double metal/dielectric gratings in optical displacement detection. Appl. Opt. 2018, 57, 3438–3443. [Google Scholar] [CrossRef]

- Jin, L.; Wang, C.; Jin, L.; Chen, W.; Xu, H.; Cui, M.; Li, M. Micro-opto-electro-mechanical systems accelerometer based on the Talbot effect of double-layer diffraction gratings. Appl. Opt. 2022, 61, 5386–5391. [Google Scholar] [CrossRef] [PubMed]

- Jin, L.; Xie, K.; Du, Y.; Li, M. Linearization signal conditioning circuit for tri-axial micro-grating MOEMS accelerometer. Opt. Express 2024, 32, 10241–10251. [Google Scholar] [CrossRef] [PubMed]

- Jourlin, Y.; Jay, J.; Parriaux, O. Compact diffractive interferometric displacement sensor in reflection. Precis. Eng. 2002, 26, 1–6. [Google Scholar] [CrossRef]

- Fourmen, S.; Arguel, P.; Noullet, J.L.; Lozes, F.; Bonnefont, S.; Sarrabayrouse, G.; Jourlin, Y.; Parriaux, O. A silicon integrated opto-electro-mechanical displacement sensor. Sens. Actuators A Phys. 2004, 110, 294–300. [Google Scholar] [CrossRef]

- Lee, W.; Hall, N.A.; Degertekin, F.L. A grating-assisted resonant-cavity-enhanced optical displacement detection method for micromachined sensors. Appl. Phys. Lett. 2004, 85, 3032–3034. [Google Scholar] [CrossRef] [PubMed]

- Bicen, B.; Jolly, S.; Jeelani, K.; Garcia, C.T.; Hall, N.A.; Degertekin, F.L.; Su, Q.; Cui, W.; Miles, R.N. Integrated Optical Displacement Detection and Electrostatic Actuation for Directional Optical Microphones with Micromachined Biomimetic Diaphragms. IEEE Sens. J. 2009, 9, 1933–1941. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, J.; Hou, C.; Bai, J.; Yang, G. Optical accelerometer based on grating interferometer with phase modulation technique. Appl. Opt. 2012, 51, 7005–7010. [Google Scholar] [CrossRef]

- Lu, Q.; Wang, C.; Bai, J.; Wang, K.; Lou, S.; Jiao, X.; Han, D.; Yang, G.; Liu, D.; Yang, Y. Minimizing cross-axis sensitivity in grating-based optomechanical accelerometers. Opt. Express 2016, 24, 9094–9111. [Google Scholar] [CrossRef]

- Lu, Q.; Bai, J.; Wang, K.; He, S. Design, Optimization, and Realization of a High-Performance MOEMS Accelerometer from a Double-Device-Layer SOI Wafer. J. Microelectromechanical Syst. 2017, 26, 859–869. [Google Scholar] [CrossRef]

- Li, C.; Yang, B.; Zheng, X.; Sun, Z.; Zhou, L.; Huang, X.; Guo, X. An Optical Interferometry Based MEMS Accelerometer Applicable to Seismic-Grade Measurement. IEEE Trans. Instrum. Meas. 2022, 71, 7503810. [Google Scholar] [CrossRef]

- Gao, S.; Zhou, Z.; Zhang, Y.; Deng, K.; Feng, L. High-resolution micro-grating accelerometer based on a gram-scale proof mass. Opt. Express 2019, 27, 34299–34312. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Cai, C.; Zhang, Y.; Deng, X.; Lin, L.; Xiao, W. High Sensitivity Optical MEMS Accelerometer Based on a Metal Fabry-Prot Microcavities Wavelength Modulation System. IEEE Sens. J. 2024, 24, 4304–4314. [Google Scholar] [CrossRef]

- Li, M.; Liang, Z.; Zhang, R.; Wu, Q.; Xin, C.; Jin, L.; Xie, K.; Zhao, H. Large-scale range diffraction grating displacement sensor based on polarization phase-shifting. Appl. Opt. 2020, 59, 469–473. [Google Scholar] [CrossRef] [PubMed]

- Zhou, G.Y.; Chau, F.S. Grating-Assisted Optical Microprobing of In-Plane and Out-of-Plane Displacements of Microelectromechanical Devices. J. Microelectromechanical Syst. 2006, 15, 388–395. [Google Scholar] [CrossRef]

- Wood, R. Anomalous Diffraction Gratings. Phys. Rev. 1935, 48, 928–936. [Google Scholar] [CrossRef]

- Hessel, A.; Oliner, A.A. A New Theory of Wood’s Anomalies on Optical Gratings. Appl. Opt. 1965, 4, 1275–1297. [Google Scholar] [CrossRef]

- Wang, C.; Lu, Q.; Bai, J.; Yang, G.; Wang, K.; Liu, D.; Yang, Y. Highly sensitive lateral deformable optical MEMS displacement sensor: Anomalous diffraction studied by rigorous coupled-wave analysis. Appl. Opt. 2015, 54, 8935–8943. [Google Scholar] [CrossRef]

- Lu, Q.; Bai, J.; Wang, K.; Chen, P.; Fang, W.; Wang, C. Single Chip-Based Nano-Optomechanical Accelerometer Based on Subwavelength Grating Pair and Rotated Serpentine Springs. Sensors 2018, 18, 2036. [Google Scholar] [CrossRef]

- Li, M.; Wang, Z.; Geng, H.; Wu, Q.; Zhang, R.; Cui, Z.; Wang, X.; Wang, G. Structural design and simulation of a micro-gyroscope based on nano-grating detection. Microsyst. Technol. 2019, 25, 1627–1637. [Google Scholar] [CrossRef]

- Ishikawa, I.; Sawada, R.; Higurashi, E.; Sanada, S.; Chino, D. Integrated micro-displacement sensor that measures tilting angle and linear movement of an external mirror. Sens. Actuators A Phys. 2007, 138, 269–275. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, Y.; Sun, X.; Zhu, L.; Cheng, X.; Chen, Q.; Liu, Y.; Xie, H. Integrated tilt angle sensing for large displacement scanning MEMS mirrors. Opt. Express 2018, 26, 25736–25749. [Google Scholar] [CrossRef] [PubMed]

- Cheng, X.; Sun, X.; Liu, Y.; Zhu, L.; Zhang, X.; Zhou, L.; Xie, H. Integrated Optoelectronic Position Sensor for Scanning Micromirrors. Sensors 2018, 18, 982. [Google Scholar] [CrossRef] [PubMed]

- Iwasaki, T.; Takeshita, T.; Arinaga, Y.; Uemura, K.; Ando, H.; Takeuchi, S.; Furue, M.; Higurashi, E.; Sawada, R. Shearing force measurement device with a built-in integrated micro displacement sensor. Sens. Actuators A Phys. 2015, 221, 1–8. [Google Scholar] [CrossRef]

- Du, Y.-J.; Yang, T.-T.; Gong, D.-D.; Wang, Y.-C.; Sun, X.-Y.; Qin, F.; Dai, G. High Dynamic Micro Vibrator with Integrated Optical Displacement Detector for In-Situ Self-Calibration of MEMS Inertial Sensors. Sensors 2018, 18, 2055. [Google Scholar] [CrossRef]

- Zhan, H.; Zhou, W.; Ran, L.; Yu, H.; Peng, B.; Hao, R. A High-Resolution Optical Displacement Detection Method for Piezoelectric Microvibratory Stage. IEEE Trans. Ind. Electron. 2020, 67, 10897–10904. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, C.; Xu, Y.; Zhang, Z.; Li, M. Micro-Opto-Electro-Mechanical Systems for High-Precision Displacement Sensing: A Review. Micromachines 2024, 15, 1011. https://doi.org/10.3390/mi15081011

Xin C, Xu Y, Zhang Z, Li M. Micro-Opto-Electro-Mechanical Systems for High-Precision Displacement Sensing: A Review. Micromachines. 2024; 15(8):1011. https://doi.org/10.3390/mi15081011

Chicago/Turabian StyleXin, Chenguang, Yingkun Xu, Zhongyao Zhang, and Mengwei Li. 2024. "Micro-Opto-Electro-Mechanical Systems for High-Precision Displacement Sensing: A Review" Micromachines 15, no. 8: 1011. https://doi.org/10.3390/mi15081011

APA StyleXin, C., Xu, Y., Zhang, Z., & Li, M. (2024). Micro-Opto-Electro-Mechanical Systems for High-Precision Displacement Sensing: A Review. Micromachines, 15(8), 1011. https://doi.org/10.3390/mi15081011