Characterization of Micro-Holes Drilled Using a UV Femtosecond Laser in Modified Polyimide Flexible Circuit Boards

Abstract

1. Introduction

2. Materials and Methods

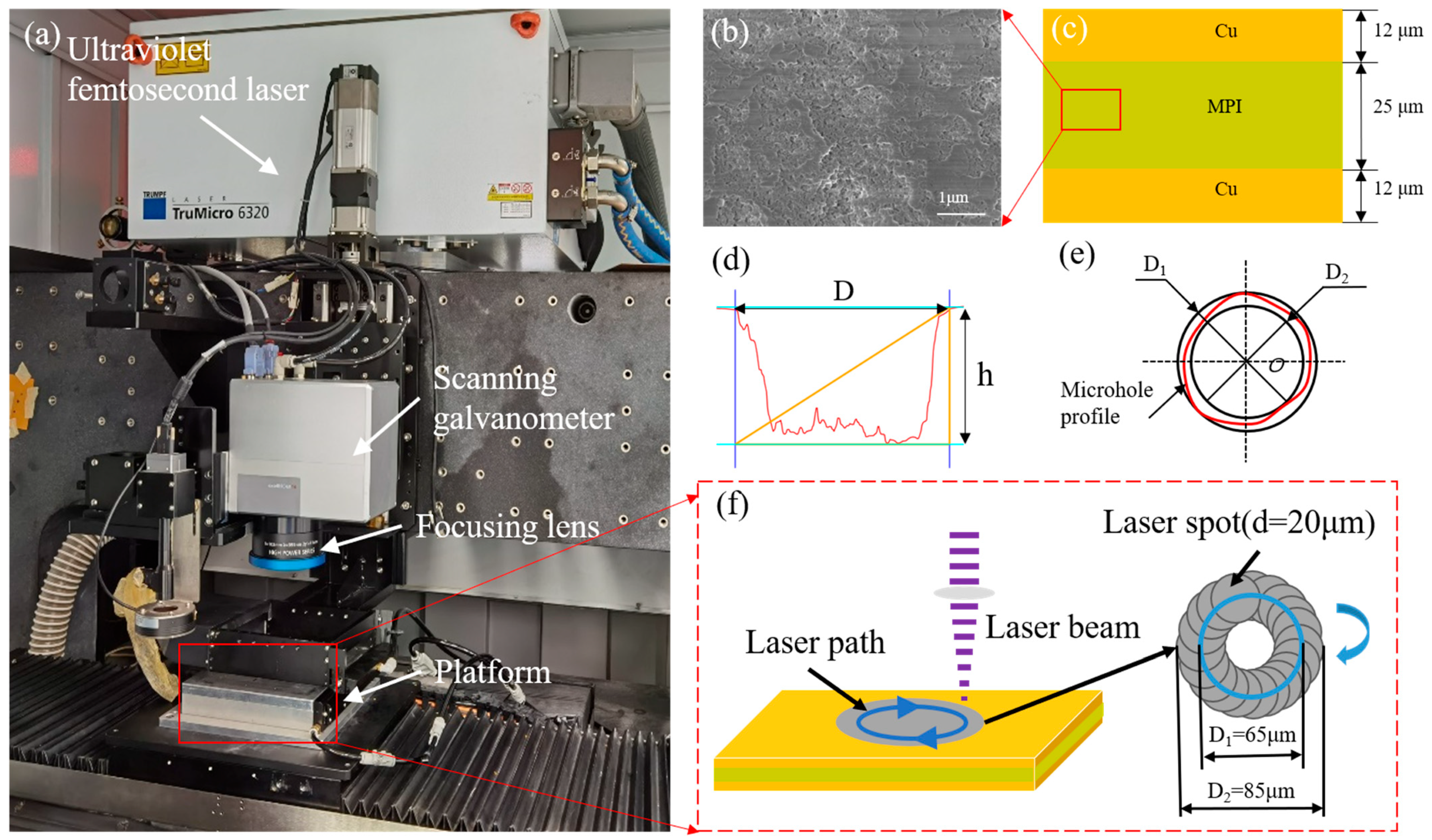

2.1. Experimental Equipment and Materials

2.2. Experimental Design

2.3. Experimental Testing Methods

3. Results and Discussion

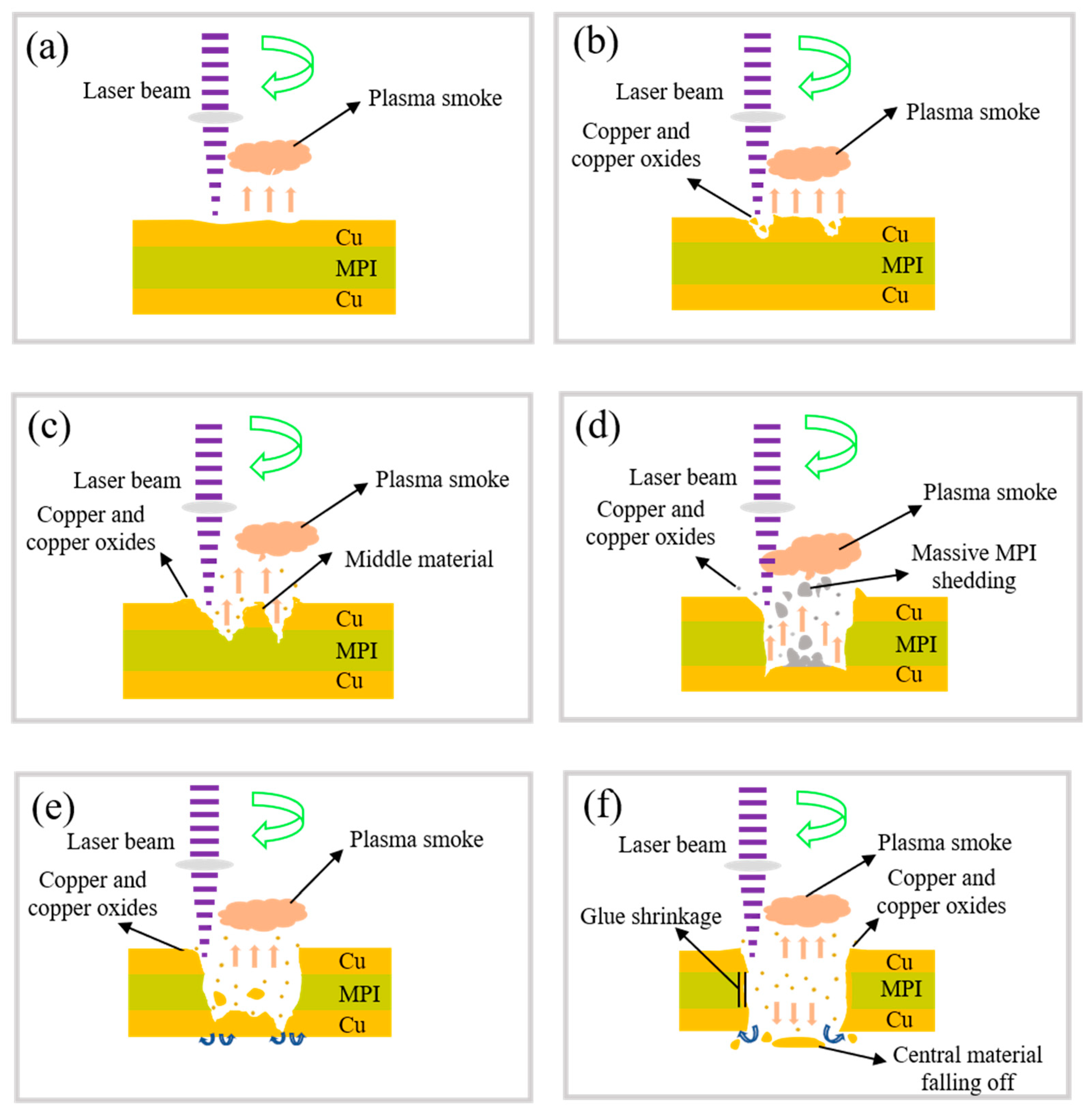

3.1. Morphology Analysis of Micro-Hole Formation in Phase Field Crystal Processed Using a Femtosecond Laser

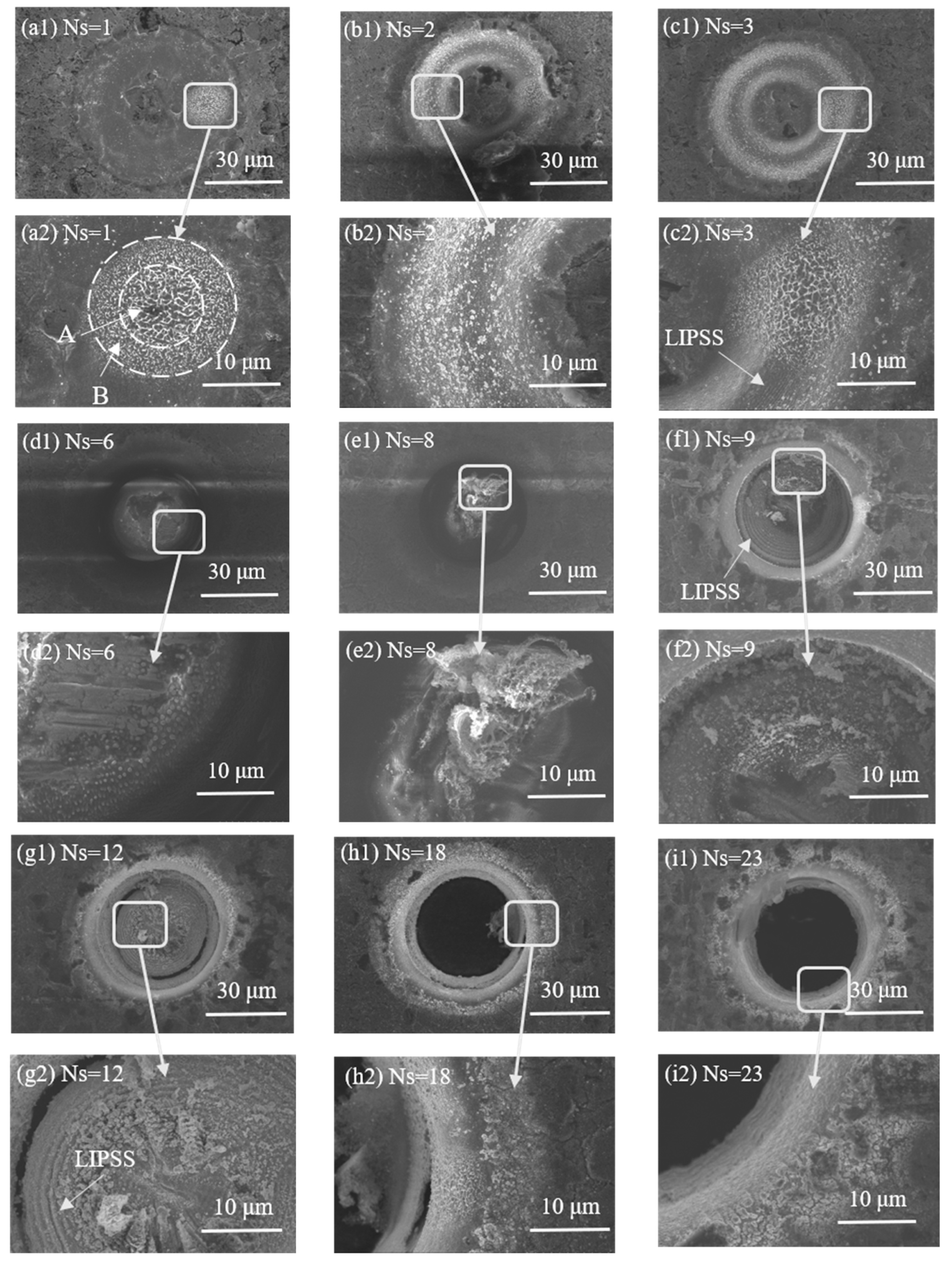

3.1.1. Analysis of the Micro-Hole Surface Morphology Characteristics of FPCs Processed Using a Femtosecond Laser

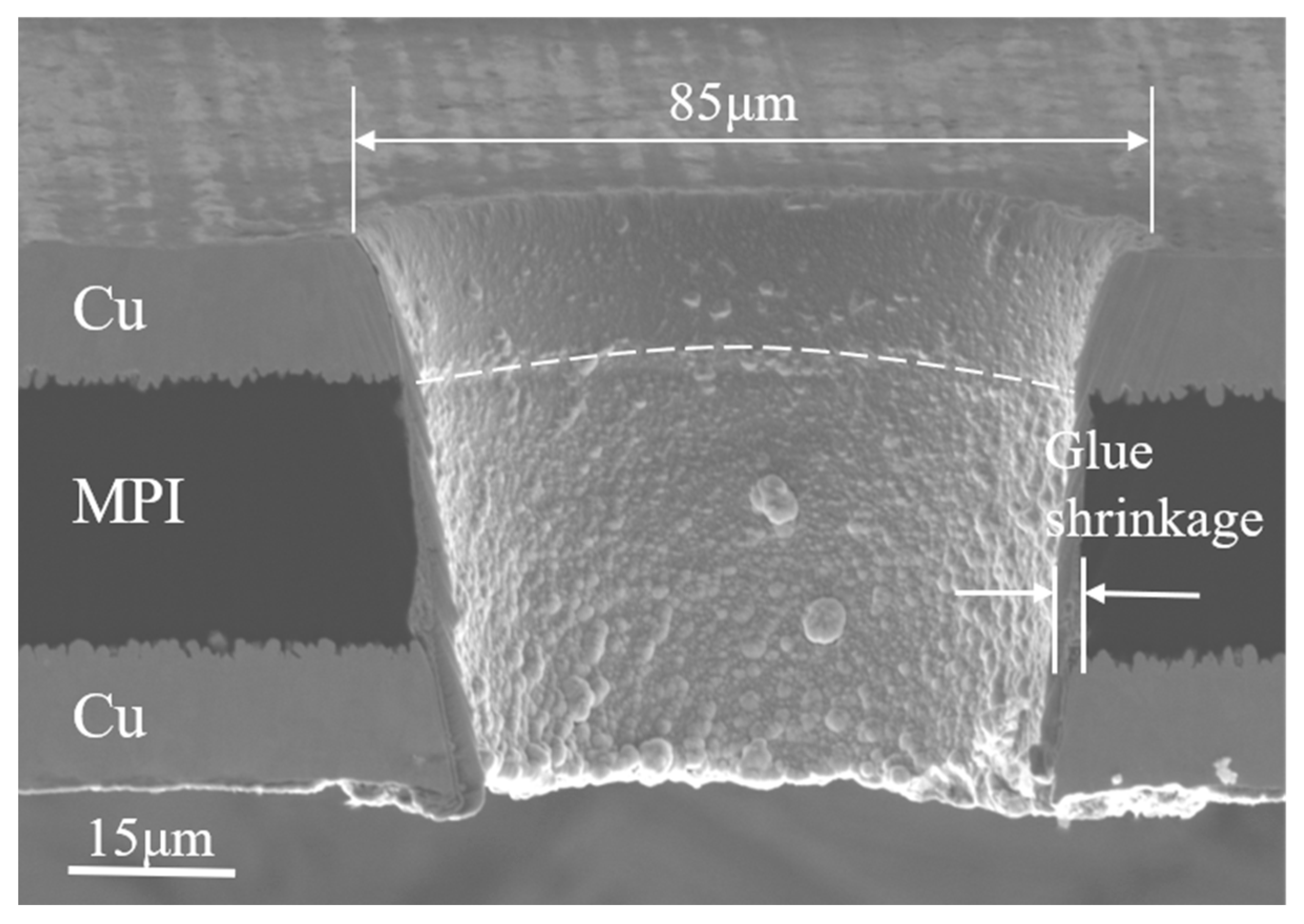

3.1.2. Cross-Sectional Morphology Characteristics of FPC Micro-Holes Processed Using a Femtosecond Laser

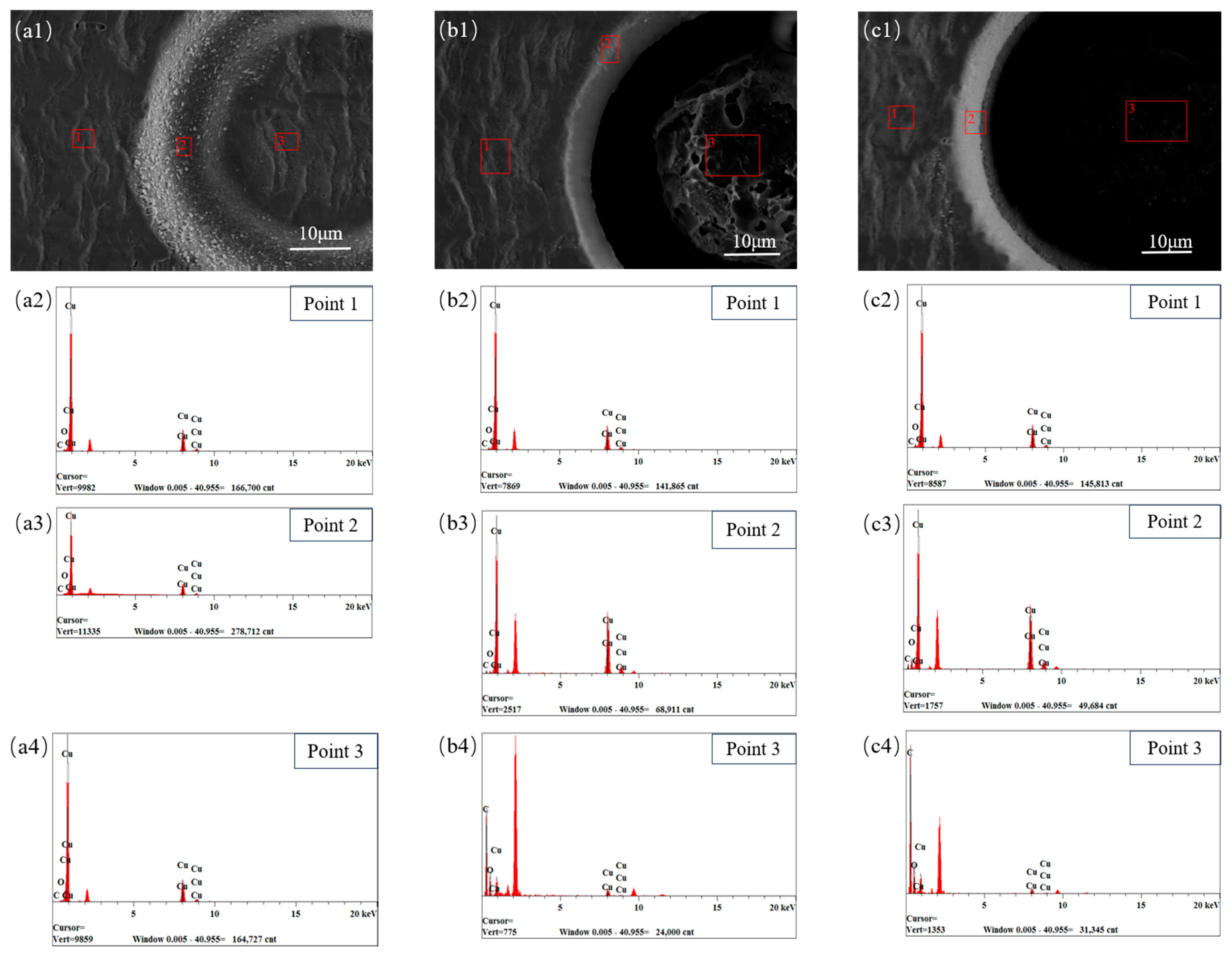

3.1.3. Material Composition Analysis of Femtosecond Laser Micro-Holes in FPC

3.2. Characterization of Micro-Holes in FPC Femtosecond Laser Processing

3.3. Effect of Femtosecond Laser Processing Parameters on FPC Micro-Hole Quality

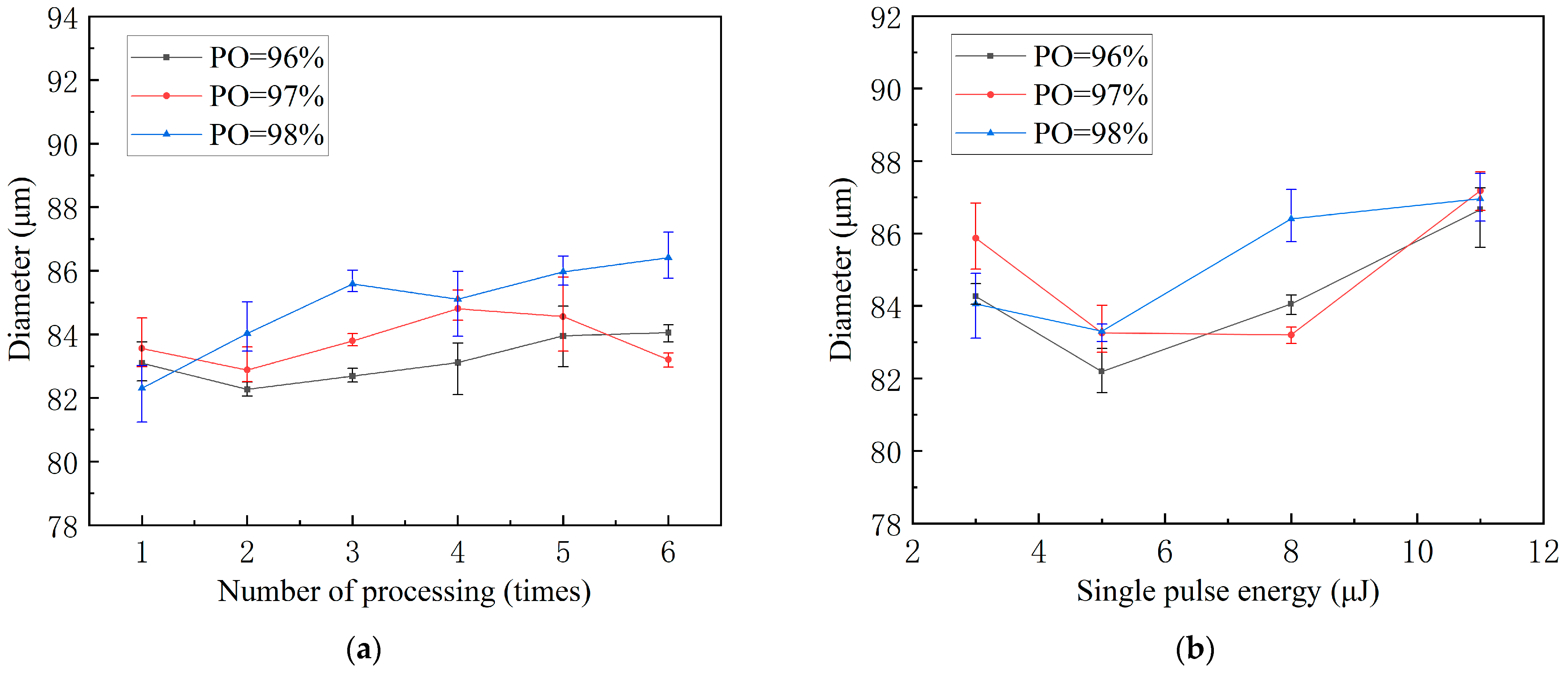

3.3.1. Effect of Femtosecond Laser Processing Parameters on Micro-Hole Size in FPC

- (1)

- Effect of laser parameters on the diameters of the micro-holes.

- (2)

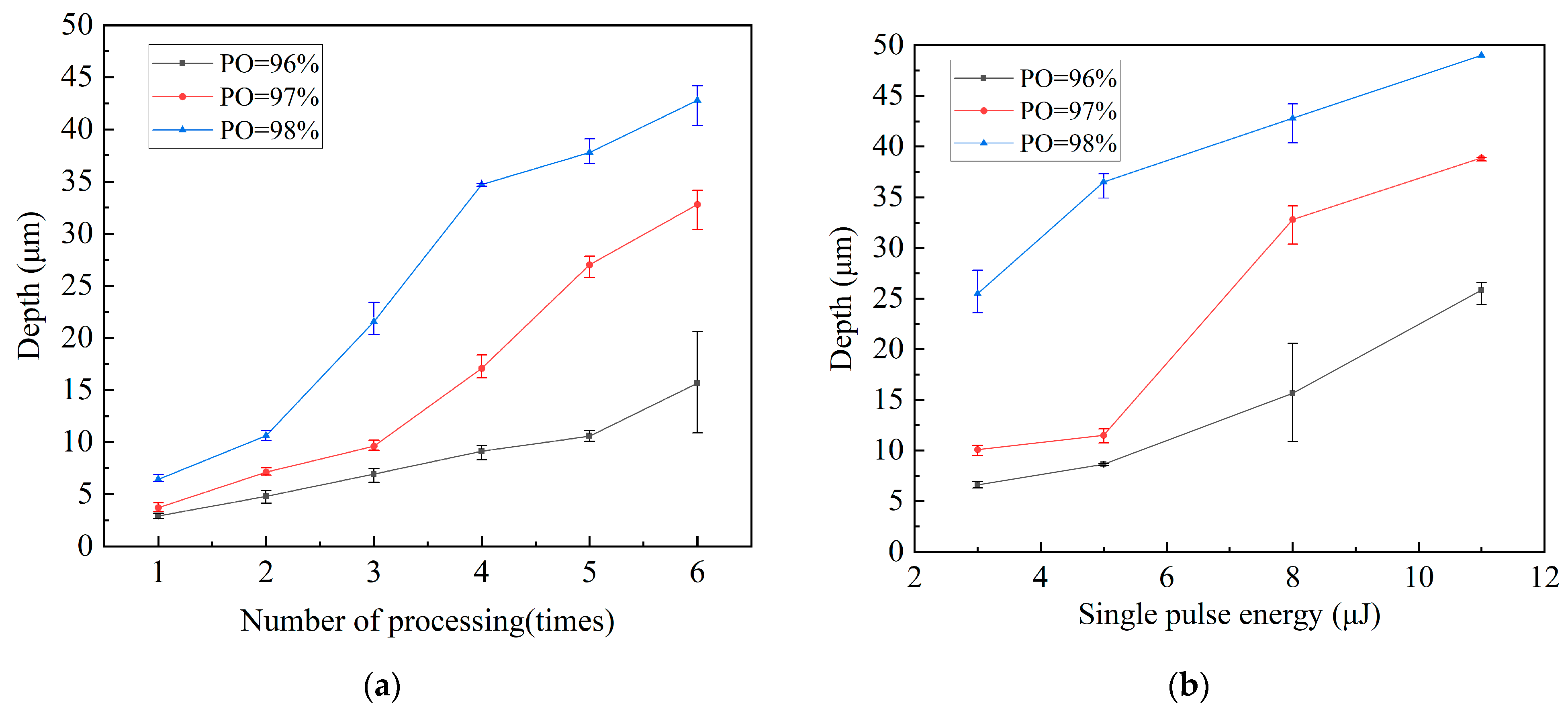

- Effect of laser parameters on the depth of micro-holes

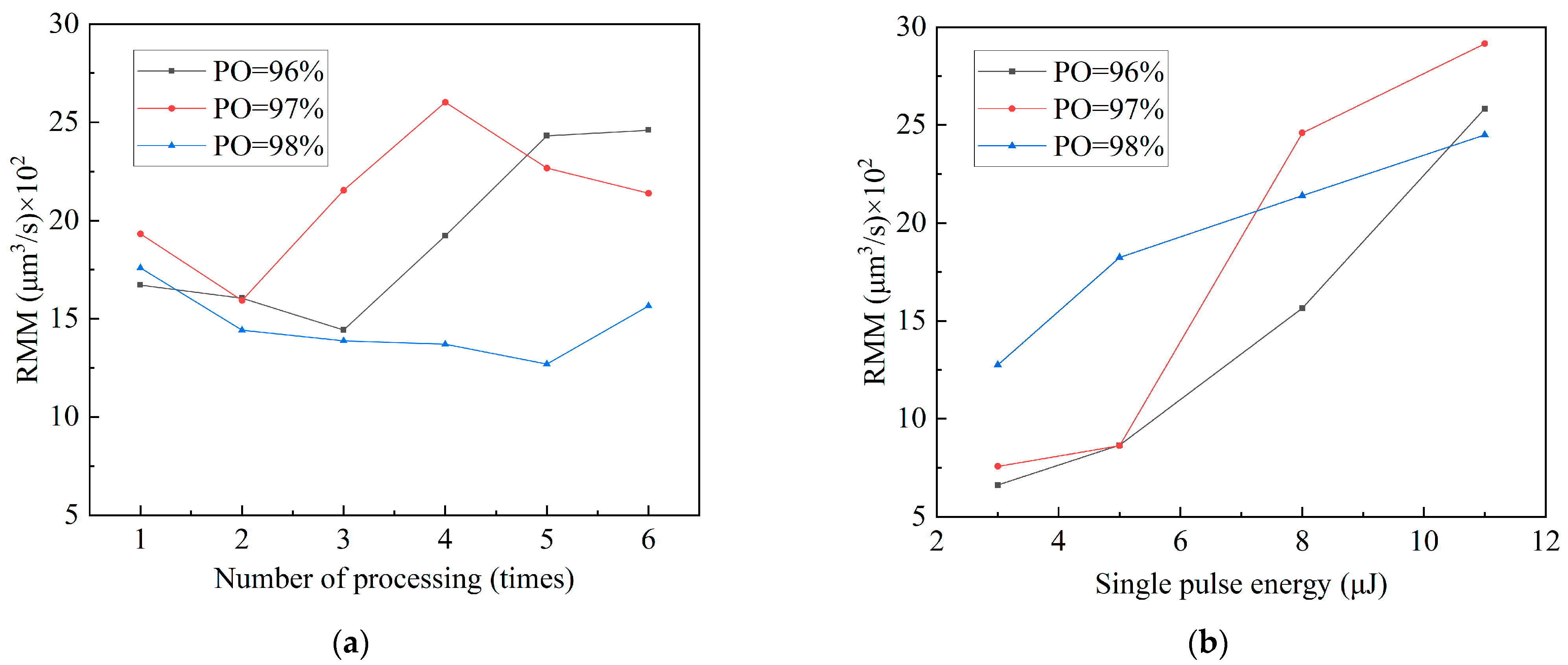

3.3.2. Processing Parameters of Femtosecond Lasers and Effects on MRR

4. Conclusions

- (1)

- Laser energy affects the surface morphology of copper. During the processing of the surface layer of copper, melting and solidification occur at the end of the laser path owing to the delay in turning the laser on and off, which disappears after the MPI resin layer has been processed. Throughout the entire process, the copper surface exhibited a periodic structure under the influence of laser energy, and its position remained constant.

- (2)

- Cu reacted with airborne oxygen, thereby undergoing oxidation during laser processing. During processing, tiny oxide particles adhered to the copper surface layer. The oxides and molten MPI co-adhered to the copper surface layer during MPI processing. The MPI layer melted and ablated more quickly than the copper because of the disparate quality of the materials. The MPI formed significant amounts of flocs upon heating. The MPI generated debris that adhered to the hole wall as the processing time increased.

- (3)

- Changes in the processing parameters did not significantly alter the diameter of the micro-holes, which was controlled by the spot size and processing path. The processing diameter of the material was affected by the outer ring of the laser spot and exhibited a Gaussian distribution, with less power transmitted at lower energies. The depth of micro-holes was directly proportional to the laser single-pulse energy, number of passes, and PO rate, which are all affected by laser processing parameters. As MPI had a lower melting point and absorbed more heat, the rate of depth change increased rapidly during processing.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, W.; Wang, L. Microdrilling of Through-Holes in Flexible Printed Circuits Using Picosecond Ultrashort Pulse Laser. Polymers 2018, 10, 1390. [Google Scholar] [CrossRef] [PubMed]

- Li, Z.Y.; Zheng, L.J.; Wang, C.Y.; Huang, X.; Xie, J.C. Investigation of burr formation and its influence in micro-drilling hole of flexible printed circuit board. Circuit World 2020, 46, 221–228. [Google Scholar] [CrossRef]

- Zheng, L.J.; Wang, C.Y.; Zhang, X.; Song, Y.X.; Zhang, L.Q.; Wang, K.F. The entry drilling process of flexible printed circuit board and its influence on hole quality. Circuit World 2015, 41, 147–153. [Google Scholar] [CrossRef]

- Zhai, Z.S.; Guo, Z.; Wang, Y.T.; Lv, Q.H.; Chen, L.; Lou, D.Y.; Yang, Q.B.; Liu, D. Research on perforation characteristics of FPC by femtosecond laser under different polarization states. Appl. Laser 2017, 37, 262–267. (In Chinese) [Google Scholar]

- Wang, C.Y.; Zheng, L.J.; Li, S.; Liao, B.M.; Huang, X.; Tang, H.Q.; Wang, B.; Yang, L.P. Research on printed circuit board mechanical drilling. Mech. Process. Technol. 2015, 23, 51–59. (In Chinese) [Google Scholar]

- Yang, W. Micro Blind Via Forming Technology of Packaging Substrate. Electron. Process Technol. 2022, 43, 338–341. (In Chinese) [Google Scholar]

- Li, Y.Z.; Pan, J.Y.; Yan, C.X.; Li, J.X.; Xin, W.; Zhang, Y.T.; Liu, W.Z.; Liu, X.F.; Xu, H.Y.; Liu, Y.C. Efficient Carrier Multiplication in Self-Powered Near-Ultraviolet γ InSe/Graphene Heterostructure Photodetector with External Quantum Efficiency Exceeding 161%. Nano Lett. 2024, 24, 7252–7260. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.C.; Wang, M.D.; Zhang, S.J.; Lin, Y.; Wang, X.Y.; Yin, Z.H.; Wang, X.B. Techniques for Femtosecond Laser Processing of Micro-Holes in FR-4 Copper Clad Laminate. Chin. J. Lasers 2020, 47, 135–143. (In Chinese) [Google Scholar]

- Lu, Z.; Wang, M.; Zhang, P.; Li, C. Femtosecond Laser machining of flexible printed circuit boards. In Proceedings of the International Conference on Advanced Technologies and Applications of Modern Industry, Wuhan, China, 19–21 November 2021. [Google Scholar]

- Biswas, S.; Ghosh, A.; Odusanya, A.; Kietzig, A.M. Effect of irradiation wavelength on femtosecond laser-induced homogenous surface structures. Appl. Surf. Sci. 2019, 493, 375–383. [Google Scholar] [CrossRef]

- Anderson, M.; Ediger, A.; Tsubaki, A.; Zuhlke, C.; Alexander, D.; Gogos, G.; Shield, J.E. Surface and microstructure investigation of picosecond versus femtosecond laser pulse processed copper. Surf. Coat. Technol. 2021, 409, 126872. [Google Scholar] [CrossRef]

- Han, Y.J.; Zhang, J.J.; Wang, X.H.; Sun, T. Parametric optimization of hole taper control in ultraviolet nanosecond laser micro-drilling of copper foil. Opt. Laser Technol. 2023, 167, 109706. [Google Scholar] [CrossRef]

- Balachninaite, O.; Tamuliene, V.; Eicas, L.; Vaicaitis, V. Laser micromachining of steel and copper using femtosecond laser pulses in GHz burst mode. Results Phys. 2021, 8, 103847. [Google Scholar] [CrossRef]

- Lorenz, P.; Ehrhardt, M.; Zimmer, K. High Pore Density Polyimide Membrane Production by PS Laser Pulses. J. Laser Micro Nanoeng. 2022, 17, 6–11. [Google Scholar]

- Zhang, T.; Wu, C.Y.; Rong, Y.M.; Li, M.; Huang, Y.; Zhang, G.J. Laser ablation behavior and mechanism of polyimide by UV irradiation. Mater. Manuf. Process. 2022, 37, 809–815. [Google Scholar] [CrossRef]

- Hu, X.J.; Yang, F.; Guo, M.Z.; Pei, J.Y.; Zhao, H.Y.; Wang, Y.J. Fabrication of polyimide microfluidic devices by laser ablation based additive manufacturing. Microsyst. Technol. 2020, 26, 1573–1583. [Google Scholar] [CrossRef]

- Lu, H.J.; Ou, Z.D.; Huang, B.; Huang, X.; Wang, C.Y.; Zheng, L.J. Research Progress on the Induction Mechanism of Graphitization Phase Transition of Diamond Materials. J. Mech. Sci. Technol. 2022, 41, 536–546. (In Chinese) [Google Scholar]

| Project | Parameters | Units |

|---|---|---|

| Wavelength | 343 | nm |

| Pulse Width | 500 | fs |

| Frequency | 1200 | kHz |

| Cooling mode | thermostatic water cooling | / |

| Spot Diameter | 20 | μm |

| Focal length of the field lens | 103 | mm |

| Laser Processing Parameters | Abbreviation | Experimental Parameters | Units |

|---|---|---|---|

| Single pulse energy | E | 3, 5, 8, 11 | μJ |

| Pulse overlap rate | PO | 96, 97, 98 | % |

| Number of scans | Ns | 1, 2, 3, 4, 5, 6 | times |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, L.; Lin, S.; Lu, H.; Huang, B.; Liu, Y.; Wang, J.; Wei, X.; Wang, J.; Wang, C. Characterization of Micro-Holes Drilled Using a UV Femtosecond Laser in Modified Polyimide Flexible Circuit Boards. Micromachines 2024, 15, 1078. https://doi.org/10.3390/mi15091078

Zheng L, Lin S, Lu H, Huang B, Liu Y, Wang J, Wei X, Wang J, Wang C. Characterization of Micro-Holes Drilled Using a UV Femtosecond Laser in Modified Polyimide Flexible Circuit Boards. Micromachines. 2024; 15(9):1078. https://doi.org/10.3390/mi15091078

Chicago/Turabian StyleZheng, Lijuan, Shuzhan Lin, Huijuan Lu, Bing Huang, Yu Liu, Jun Wang, Xin Wei, Jun Wang, and Chengyong Wang. 2024. "Characterization of Micro-Holes Drilled Using a UV Femtosecond Laser in Modified Polyimide Flexible Circuit Boards" Micromachines 15, no. 9: 1078. https://doi.org/10.3390/mi15091078

APA StyleZheng, L., Lin, S., Lu, H., Huang, B., Liu, Y., Wang, J., Wei, X., Wang, J., & Wang, C. (2024). Characterization of Micro-Holes Drilled Using a UV Femtosecond Laser in Modified Polyimide Flexible Circuit Boards. Micromachines, 15(9), 1078. https://doi.org/10.3390/mi15091078