Composite Magnetic Filaments: From Fabrication to Magnetic Hyperthermia Application

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Composite Filaments

2.2.2. 3D Printouts

Mechanical Tests

Magnetic Hyperthermia

3. Results

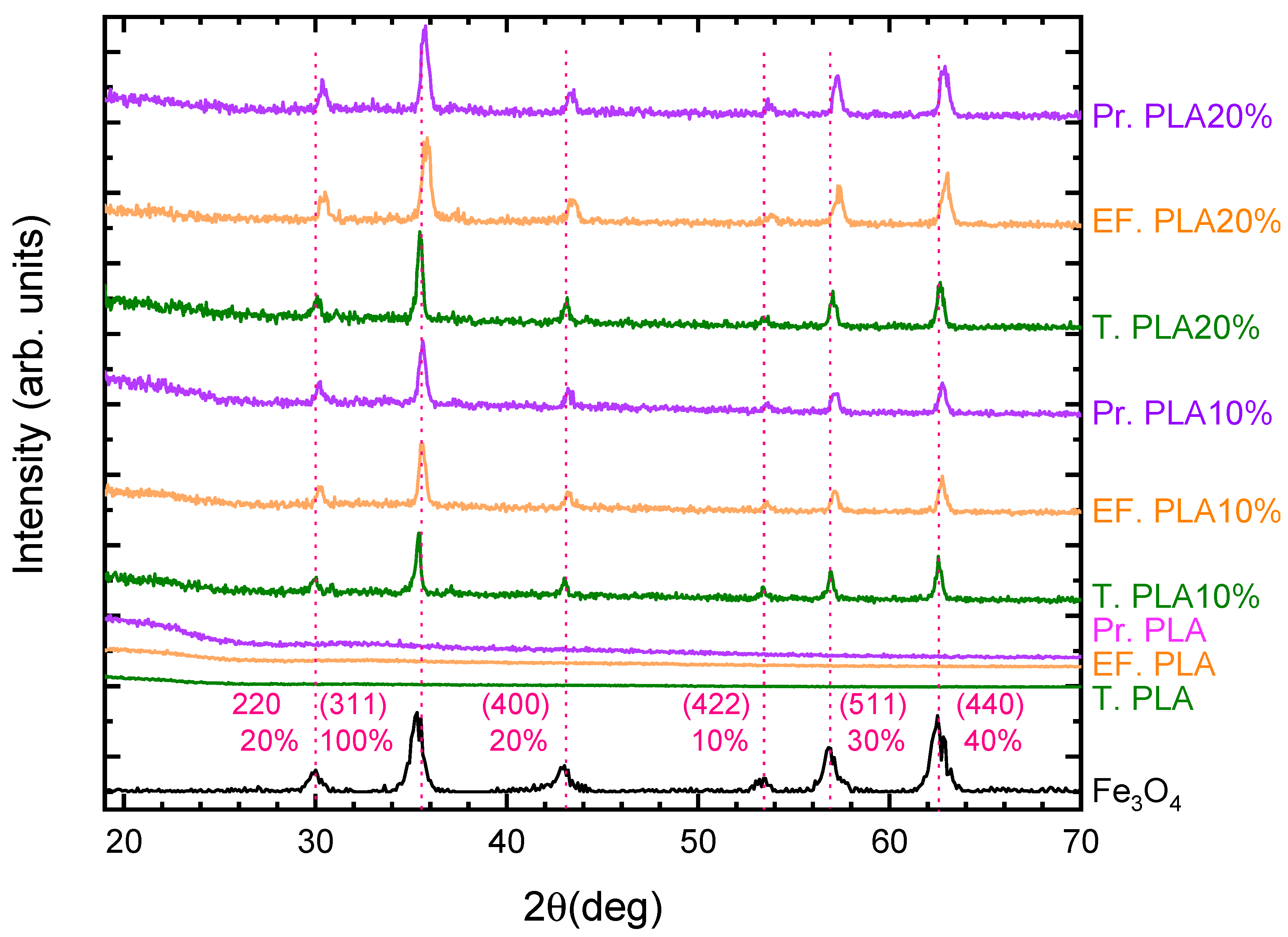

3.1. Filament Features

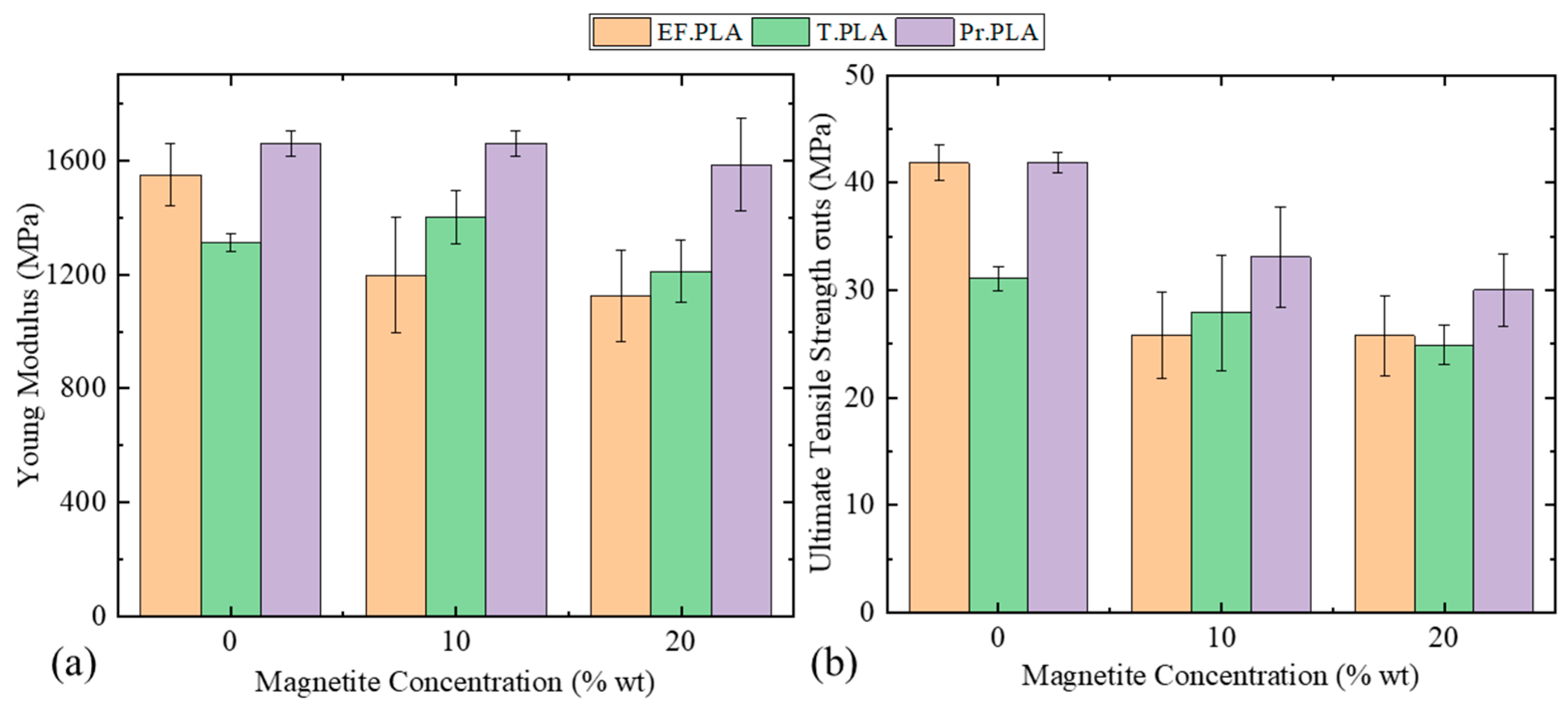

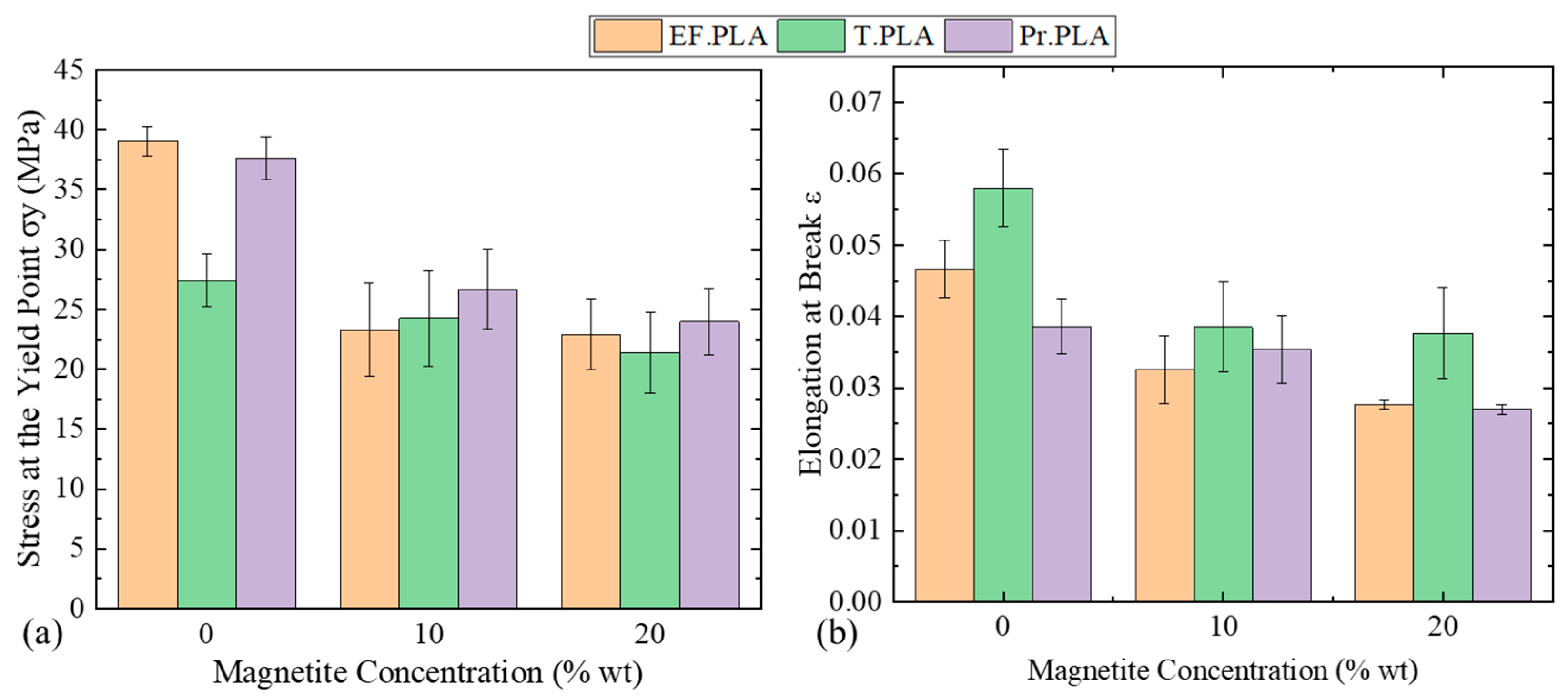

3.2. Mechanical Evaluation

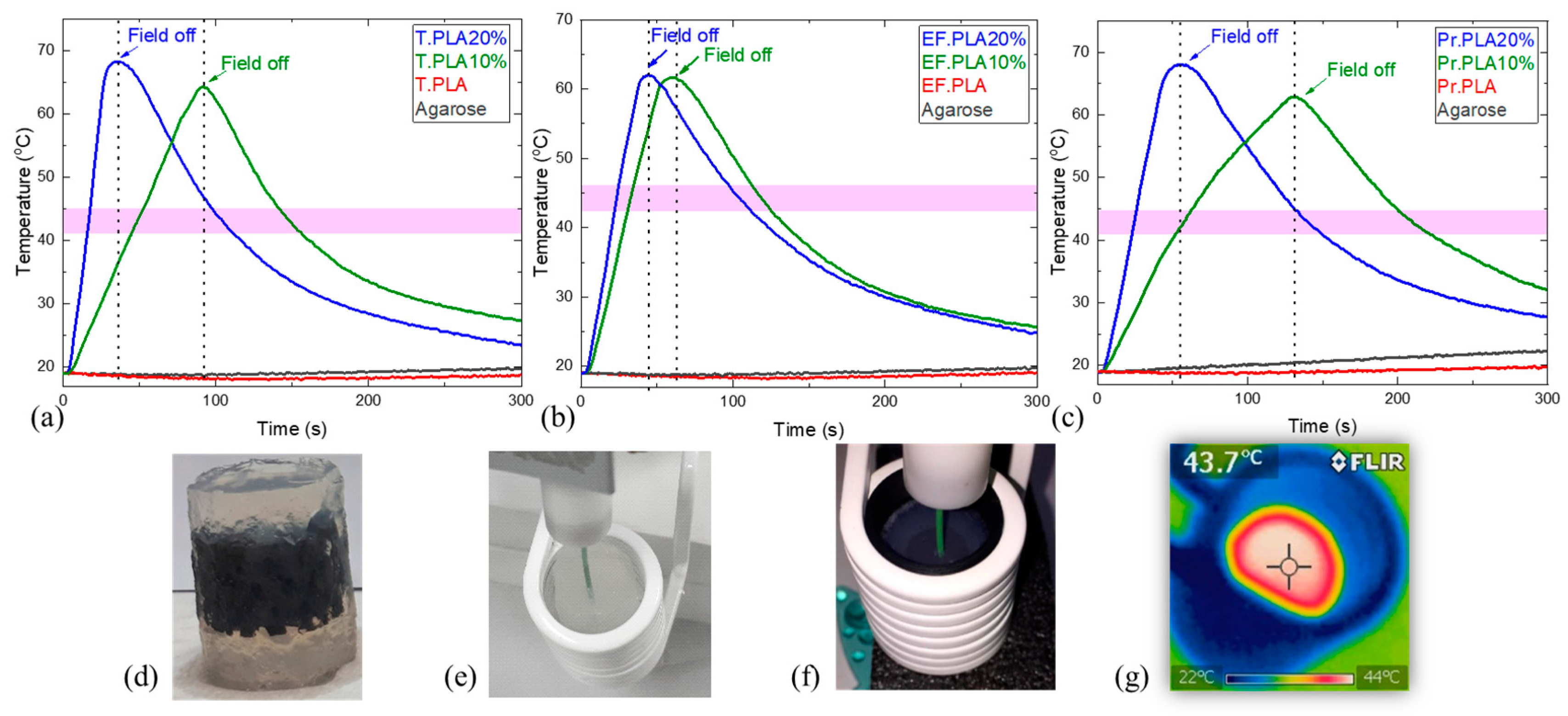

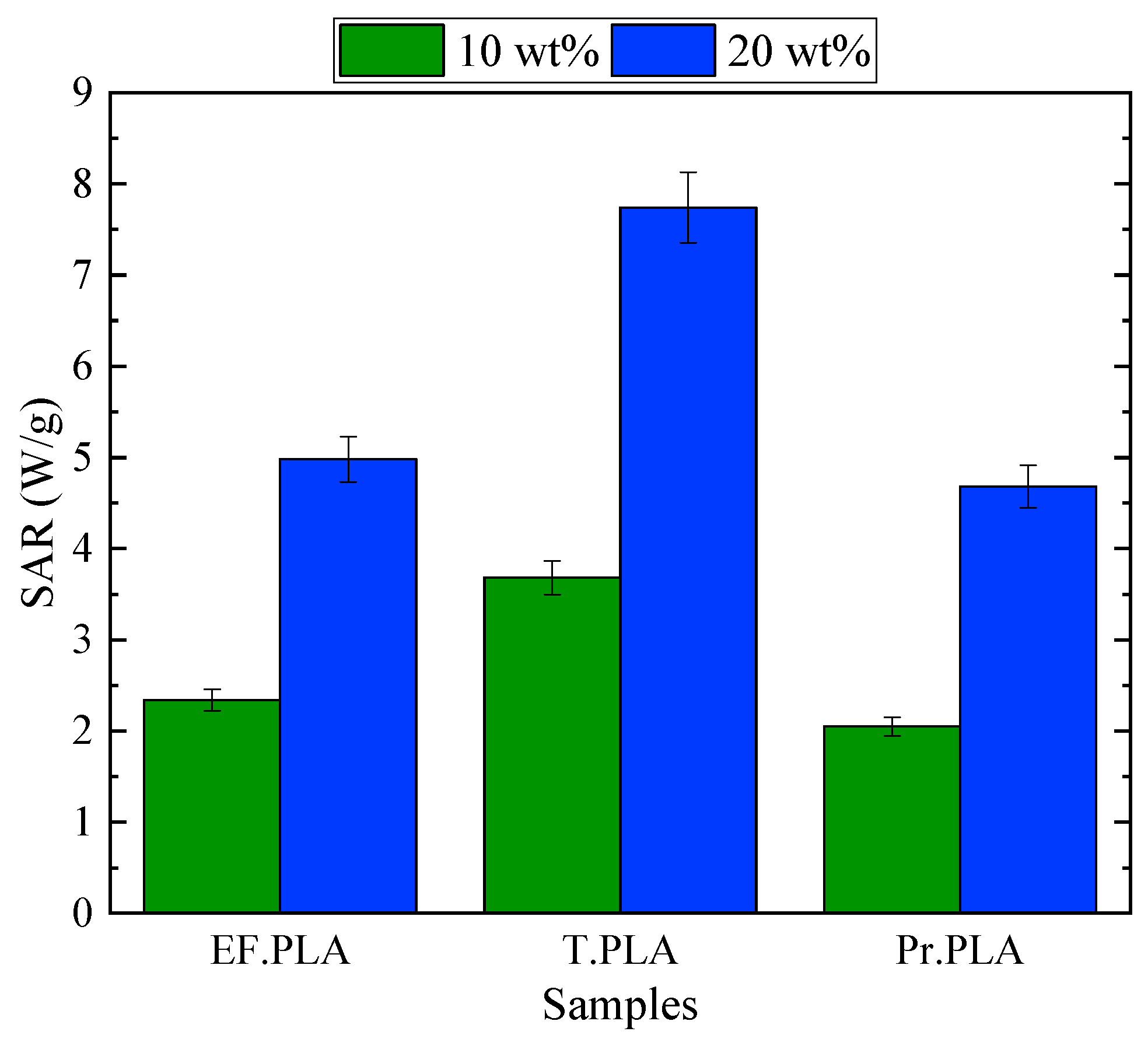

3.3. Magnetic Hyperthermia Evaluation

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| MNPs | Magnetic nanoparticles |

| PLA | Polylactic acid |

| 3D | 3-dimensional |

| 4D | 4-dimensional |

| FDM | Fused Deposition Modeling |

| XRD | X-ray diffraction |

| Pr. PLA | Premium PLA |

| EF. PLA | EasyFil PLA |

| T. PLA | Tough PLA |

References

- Kumar, A.; Kumar, D.; Faisal, N.; Sharma, A.; Kumar, A.A.; Goyal, A.; Saxena, K.K.; Prakash, C.; Kumar, D. Application of 3D printing technology for medical implants: A state-of-the-art review. Adv. Mater. Process. Technol. 2024, 10, 357–372. [Google Scholar] [CrossRef]

- He, Q.; Tang, T.; Zeng, Y.; Iradukunda, N.; Bethers, B.; Li, X.; Yang, Y. Review on 3D Printing of Bioinspired Structures for Surface/Interface Applications. Adv. Funct. Mater. 2024, 34, 2309323. [Google Scholar] [CrossRef]

- Peng, Y.; Unluer, C. Development of alternative cementitious binders for 3D printing applications: A critical review of progress, advantages and challenges. Compos. B Eng. 2023, 252, 110492. [Google Scholar] [CrossRef]

- Gao, Y.; Lalevée, J.; Simon-Masseron, A. An overview on 3D printing of structured porous materials and their applications. Adv. Mater. Technol. 2023, 8, 2300377. [Google Scholar] [CrossRef]

- Rodrigo-Navarro, A.; Sankaran, S.; Dalby, M.J.; del Campo, A.; Salmeron-Sanchez, M. Engineered living biomaterials. Nat. Rev. Mater. 2021, 6, 1175–1190. [Google Scholar] [CrossRef]

- Cao, D.; Ding, J. Recent advances in regenerative biomaterials. Regen. Biomater. 2022, 9, rbac098. [Google Scholar] [CrossRef]

- Klębowski, B.; Depciuch, J.; Parlińska-Wojtan, M.; Baran, J. Applications of noble metal-based nanoparticles in medicine. Int. J. Mol. Sci. 2018, 19, 4031. [Google Scholar] [CrossRef] [PubMed]

- Yetisgin, A.A.; Cetinel, S.; Zuvin, M.; Kosar, A.; Kutlu, O. Therapeutic nanoparticles and their targeted delivery applications. Molecules 2020, 25, 2193. [Google Scholar] [CrossRef]

- Saroia, J.; Wang, Y.; Wei, Q.; Lei, M.; Li, X.; Guo, Y.; Zhang, K. A review on 3D printed matrix polymer composites: Its potential and future challenges. J. Adv. Manuf. Technol. 2020, 106, 1695–1721. [Google Scholar] [CrossRef]

- Bekas, D.G.; Hou, Y.; Liu, Y.; Panesar, A. 3D printing to enable multifunctionality in polymer-based composites: A review. Compos. B Eng. 2019, 179, 107540. [Google Scholar] [CrossRef]

- Materón, E.M.; Miyazaki, C.M.; Carr, O.; Joshi, N.; Picciani, P.H.; Dalmaschio, C.J.; Davis, F.; Shimizu, F.M. Magnetic nanoparticles in biomedical applications: A review. Appl. Surf. Sci. 2021, 6, 100163. [Google Scholar] [CrossRef]

- Rezaei, B.; Yari, P.; Sanders, S.M.; Wang, H.; Chugh, V.K.; Liang, S.; Mostufa, S.; Xu, K.; Wang, J.P.; Gómez-Pastora, J.; et al. Magnetic nanoparticles: A review on synthesis, characterization, functionalization, and biomedical applications. Small 2024, 20, 2304848. [Google Scholar] [CrossRef] [PubMed]

- Fan, D.; Wang, Q.; Zhu, T.; Wang, H.; Liu, B.; Wang, Y.; Liu, Z.; Liu, X.; Fan, D.; Wang, X. Recent advances of magnetic nanomaterials in bone tissue repair. Front. Chem. 2020, 8, 745. [Google Scholar] [CrossRef]

- Amirov, A.; Omelyanchik, A.; Murzin, D.; Kolesnikova, V.; Vorontsov, S.; Musov, I.; Musov, K.; Khashirova, S.; Rodionova, V. 3D printing of PLA/magnetic ferrite composites: Effect of filler particles on magnetic properties of filament. Processes 2022, 10, 2412. [Google Scholar] [CrossRef]

- Makridis, A.; Okkalidis, N.; Trygoniaris, D.; Kazeli, K.; Angelakeris, M. Composite magnetic 3D-printing filament fabrication protocol opens new perspectives in magnetic hyperthermia. J. Phys. D Appl. Phys. 2023, 56, 285002. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; de Vicente, J.; Skårman, B.; Vidarsson, H.; Larsson, P.O.; Bollero, A. Effect of particle size distribution on obtaining novel MnAlC-based permanent magnet composites and flexible filaments for 3D-printing. Addit. Manuf. 2020, 33, 101179. [Google Scholar] [CrossRef]

- Pigliaru, L.; Rinaldi, M.; Ciccacci, L.; Norman, A.; Rohr, T.; Ghidini, T.; Nanni, F. 3D printing of high performance polymer-bonded PEEK-NdFeB magnetic composite materials. Funct. Compos. Mater. 2020, 1, 4. [Google Scholar] [CrossRef]

- Lodi, M.B.; Makridis, A.; Carboni, N.M.; Kazeli, K.; Curreli, N.; Samaras, T.; Angelakeris, M.; Mazzarella, G.; Fanti, A. Design and characterization of magnetic scaffolds for bone tumor hyperthermia. IEEE Access 2022, 10, 19768–19779. [Google Scholar] [CrossRef]

- Lodi, M.B.; Makridis, A.; Kazeli, K.; Samaras, T.; Angelakeris, M.; Mazzarella, G.; Fanti, A. On the Evaluation of the Hyperthermic Efficiency of Magnetic Scaffolds. IEEE Open J. Eng. Med. Biol. 2023, 5, 88–98. [Google Scholar] [CrossRef]

- Makridis, A.; Kazeli, K.; Kyriazopoulos, P.; Maniotis, N.; Samaras, T.; Angelakeris, M. An accurate standardization protocol for heating efficiency determination of 3D printed magnetic bone scaffolds. J. Phys. D Appl. Phys. 2022, 55, 435002. [Google Scholar] [CrossRef]

- Formfutura. Available online: https://formfutura.com/ (accessed on 28 January 2025).

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2014.

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Lei, M.; Wei, Q.; Li, M.; Zhang, J.; Yang, R.; Wang, Y. Numerical simulation and experimental study the effects of process parameters on filament morphology and mechanical properties of FDM 3D printed PLA/GNPs nanocomposite. Polymers 2022, 14, 3081. [Google Scholar] [CrossRef] [PubMed]

- Yao, T.; Deng, Z.; Zhang, K.; Li, S. A method to predict the ultimate tensile strength of 3D printing polylactic acid (PLA) materials with different printing orientations. Compos. B Eng. 2019, 163, 393–402. [Google Scholar] [CrossRef]

- Syrlybayev, D.; Zharylkassyn, B.; Seisekulova, A.; Akhmetov, M.; Perveen, A.; Talamona, D. Optimisation of strength properties of FDM printed parts—A critical review. Polymers 2021, 13, 1587. [Google Scholar] [CrossRef]

- Kim, W.; Suh, C.Y.; Cho, S.W.; Roh, K.M.; Kwon, H.; Song, K.; Shon, I.J. A new method for the identification and quantification of magnetite–maghemite mixture using conventional X-ray diffraction technique. Talanta 2012, 94, 348–352. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Li, B.; Wan, G.; Zhao, G.; Zhang, A. Strong and thermal-resistance glass fiber-reinforced polylactic acid (PLA) composites enabled by heat treatment. Int. J. Biol. Macromol. 2019, 129, 448–459. [Google Scholar] [CrossRef]

- Rodríguez-Panes, A.; Claver, J.; Camacho, A.M. The influence of manufacturing parameters on the mechanical behaviour of PLA and ABS pieces manufactured by FDM: A comparative analysis. Materials 2018, 11, 1333. [Google Scholar] [CrossRef] [PubMed]

- Luo, F.; Fortenberry, A.; Ren, J.; Qiang, Z. Recent progress in enhancing poly (lactic acid) stereocomplex formation for material property improvement. Front. Chem. 2020, 8, 688. [Google Scholar] [CrossRef]

- Tsige, M.; Lorenz, C.D.; Stevens, M.J. Role of network connectivity on the mechanical properties of highly cross-linked polymers. Macromolecules 2004, 37, 8466–8472. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D printing biocompatible polyurethane/poly (lactic acid)/graphene oxide nanocomposites: Anisotropic properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef]

- Ghozali, M.; Fahmiati, S.; Triwulandari, E.; Restu, W.K.; Farhan, D.; Wulansari, M.; Fatriasari, W. PLA/metal oxide biocomposites for antimicrobial packaging application. Polym.-Plast. Technol. Mater. 2020, 59, 1332–1342. [Google Scholar] [CrossRef]

- Krishnamoorti, R. Strategies for dispersing nanoparticles in polymers. MRS Bull. 2007, 32, 341–347. [Google Scholar] [CrossRef]

- Lv, H.; Song, S.; Sun, S.; Ren, L.; Zhang, H. Enhanced properties of poly (lactic acid) with silica nanoparticles. Polym. Adv. Technol. 2016, 27, 1156–1163. [Google Scholar] [CrossRef]

- Gao, Y.; Picot, O.T.; Bilotti, E.; Peijs, T. Influence of filler size on the properties of poly (lactic acid)(PLA)/graphene nanoplatelet (GNP) nanocomposites. Eur. Polym. J. 2017, 86, 117–131. [Google Scholar] [CrossRef]

- Zhang, S.; Liang, Y.; Qian, X.; Hui, D.; Sheng, K. Pyrolysis kinetics and mechanical properties of poly (lactic acid)/bamboo particle biocomposites: Effect of particle size distribution. Nanotechnol. Rev. 2020, 9, 524–533. [Google Scholar] [CrossRef]

- Piekarska, K.; Piorkowska, E.; Bojda, J. The influence of matrix crystallinity, filler grain size and modification on properties of PLA/calcium carbonate composites. Polym. Test. 2017, 62, 203–209. [Google Scholar] [CrossRef]

- Papadopoulos, L.; Klonos, P.A.; Terzopoulou, Z.; Psochia, E.; Sanusi, O.M.; Hocine, N.A.; Benelfellah, A.; Giliopoulos, D.; Triantafyllidis, K.; Kyritsis, A.; et al. Comparative study of crystallization, semicrystalline morphology, and molecular mobility in nanocomposites based on polylactide and various inclusions at low filler loadings. Polymer 2021, 217, 123457. [Google Scholar] [CrossRef]

- Ashraf, M.A.; Peng, W.; Zare, Y.; Rhee, K.Y. Effects of size and aggregation/agglomeration of nanoparticles on the interfacial/interphase properties and tensile strength of polymer nanocomposites. Nanoscale Res. Lett. 2018, 13, 214. [Google Scholar] [CrossRef]

- Jancar, J.; Douglas, J.F.; Starr, F.W.; Kumar, S.K.; Cassagnau, P.; Lesser, A.J.; Sternstein, S.S.; Buehler, M.J. Current issues in research on structure–property relationships in polymer nanocomposites. Polymer 2010, 51, 3321–3343. [Google Scholar] [CrossRef]

- Zhang, K.; Li, G.H.; Shi, Y.D.; Chen, Y.F.; Zeng, J.B.; Wang, M. Crystallization kinetics and morphology of biodegradable poly (ε-caprolactone) with chain-like distribution of ferroferric oxide nanoparticles: Toward mechanical enhancements. Polymer 2017, 117, 84–95. [Google Scholar] [CrossRef]

- Zhao, W.; Su, Y.; Wen, X.; Wang, D. Manipulating crystallization behavior of poly (ethylene oxide) by functionalized nanoparticle inclusion. Polymer 2019, 165, 28–38. [Google Scholar] [CrossRef]

- Cheng, S.; Carroll, B.; Lu, W.; Fan, F.; Carrillo, J.M.; Martin, H.; Holt, A.P.; Kang, N.G.; Bocharova, V.; Mays, J.W.; et al. Interfacial properties of polymer nanocomposites: Role of chain rigidity and dynamic heterogeneity length scale. Macromolecules 2017, 50, 2397–2406. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Korlos, A.; Fischer-Griffiths, P.E.; Grammatikos, S. On the mechanical response of silicon dioxide nanofiller concentration on fused filament fabrication 3D printed isotactic polypropylene nanocomposites. Polymers 2021, 13, 2029. [Google Scholar] [CrossRef]

- Petousis, M.; Moutsopoulou, A.; Korlos, A.; Papadakis, V.; Mountakis, N.; Tsikritzis, D.; Ntintakis, I.; Vidakis, N. The effect of nano zirconium dioxide (ZrO2)-optimized content in polyamide 12 (PA12) and polylactic acid (PLA) matrices on their thermomechanical response in 3D printing. Nanomaterials 2023, 13, 1906. [Google Scholar] [CrossRef]

- Shah, M.; Ullah, A.; Azher, K.; Ur Rehman, A.; Akturk, N.; Juan, W.; Tüfekci, C.S.; Salamci, M.U. The influence of nanoparticle dispersions on mechanical and thermal properties of polymer nanocomposites using SLA 3D printing. Crystals 2023, 13, 285. [Google Scholar] [CrossRef]

- Sanida, A.; Velmachos, T.G.; Stavropoulos, S.G.; Psarras, G.C.; Tsonos, C.; Kanapitsas, A.; Soin, N.; Siores, E. Thermomechanical response of Fe3O4/PVDF nanocomposites. Procedia Struct. Integr. 2018, 10, 91–96. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Defersha, F.; Yang, S. Expanding poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs) applications: A review on modifications and effects. Polymers 2021, 13, 4271. [Google Scholar] [CrossRef] [PubMed]

- Hozdić, E.; Hasanagić, R. Analysis of the Impact of Cooling Lubricants on the Tensile Properties of FDM 3D Printed PLA and PLA+ CF Materials. Polymers 2024, 16, 2228. [Google Scholar] [CrossRef]

- Li, F.J.; Liang, J.Z.; Zhang, S.D.; Zhu, B. Tensile properties of polylactide/poly (ethylene glycol) blends. J. Polym. Environ. 2015, 23, 407–415. [Google Scholar] [CrossRef]

- Constant-Mandiola, B.; Aguilar-Bolados, H.; Geshev, J.; Quíjada, R. Study of the influence of magnetite nanoparticles supported on thermally reduced graphene oxide as filler on the mechanical and magnetic properties of polypropylene and polylactic acid nanocomposites. Polymers 2021, 13, 1635. [Google Scholar] [CrossRef]

- Yousefi, M.A.; Rahmatabadi, D.; Baniassadi, M.; Bodaghi, M.; Baghani, M. 4D Printing of Multifunctional and Biodegradable PLA-PBAT-Fe3O4 Nanocomposites with Supreme Mechanical and Shape Memory Properties. Macromol. Rapid Commun. 2024, 46, 2400661. [Google Scholar] [CrossRef] [PubMed]

| Sample | Filament Type | MNP Concentration (wt% MNPs) | Scaffold Dimensions (mm) | Dog Bone Dimensions (mm) |

|---|---|---|---|---|

| Pr. PLA | Pr. PLA | 0 | 16 (H) × 19 (D) | |

| Pr. PLA10% | 10 | 63.5 (L) × 9.53 (G) | ||

| Pr. PLA20% | 20 | |||

| EF. PLA | EF. PLA | 0 | 16 (H) × 19 (D) | |

| EF. PLA10% | 10 | 63.5 (L) × 9.53 (G) | ||

| EF. PLA20% | 20 | |||

| T. PLA | T. PLA | 0 | 16 (H) × 19 (D) | |

| T. PLA10% | 10 | 63.5 (L) × 9.53 (G) | ||

| T. PLA20% | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alexandridis, A.; Argyros, A.; Kyriazopoulos, P.; Genitseftsis, I.; Okkalidis, N.; Michailidis, N.; Angelakeris, M.; Makridis, A. Composite Magnetic Filaments: From Fabrication to Magnetic Hyperthermia Application. Micromachines 2025, 16, 328. https://doi.org/10.3390/mi16030328

Alexandridis A, Argyros A, Kyriazopoulos P, Genitseftsis I, Okkalidis N, Michailidis N, Angelakeris M, Makridis A. Composite Magnetic Filaments: From Fabrication to Magnetic Hyperthermia Application. Micromachines. 2025; 16(3):328. https://doi.org/10.3390/mi16030328

Chicago/Turabian StyleAlexandridis, Athanasios, Apostolos Argyros, Pavlos Kyriazopoulos, Ioannis Genitseftsis, Nikiforos Okkalidis, Nikolaos Michailidis, Makis Angelakeris, and Antonios Makridis. 2025. "Composite Magnetic Filaments: From Fabrication to Magnetic Hyperthermia Application" Micromachines 16, no. 3: 328. https://doi.org/10.3390/mi16030328

APA StyleAlexandridis, A., Argyros, A., Kyriazopoulos, P., Genitseftsis, I., Okkalidis, N., Michailidis, N., Angelakeris, M., & Makridis, A. (2025). Composite Magnetic Filaments: From Fabrication to Magnetic Hyperthermia Application. Micromachines, 16(3), 328. https://doi.org/10.3390/mi16030328