Frequency-Decoupled Dual-Stage Inverse Lithography Optimization via Hierarchical Sampling and Morphological Enhancement

Abstract

:1. Introduction

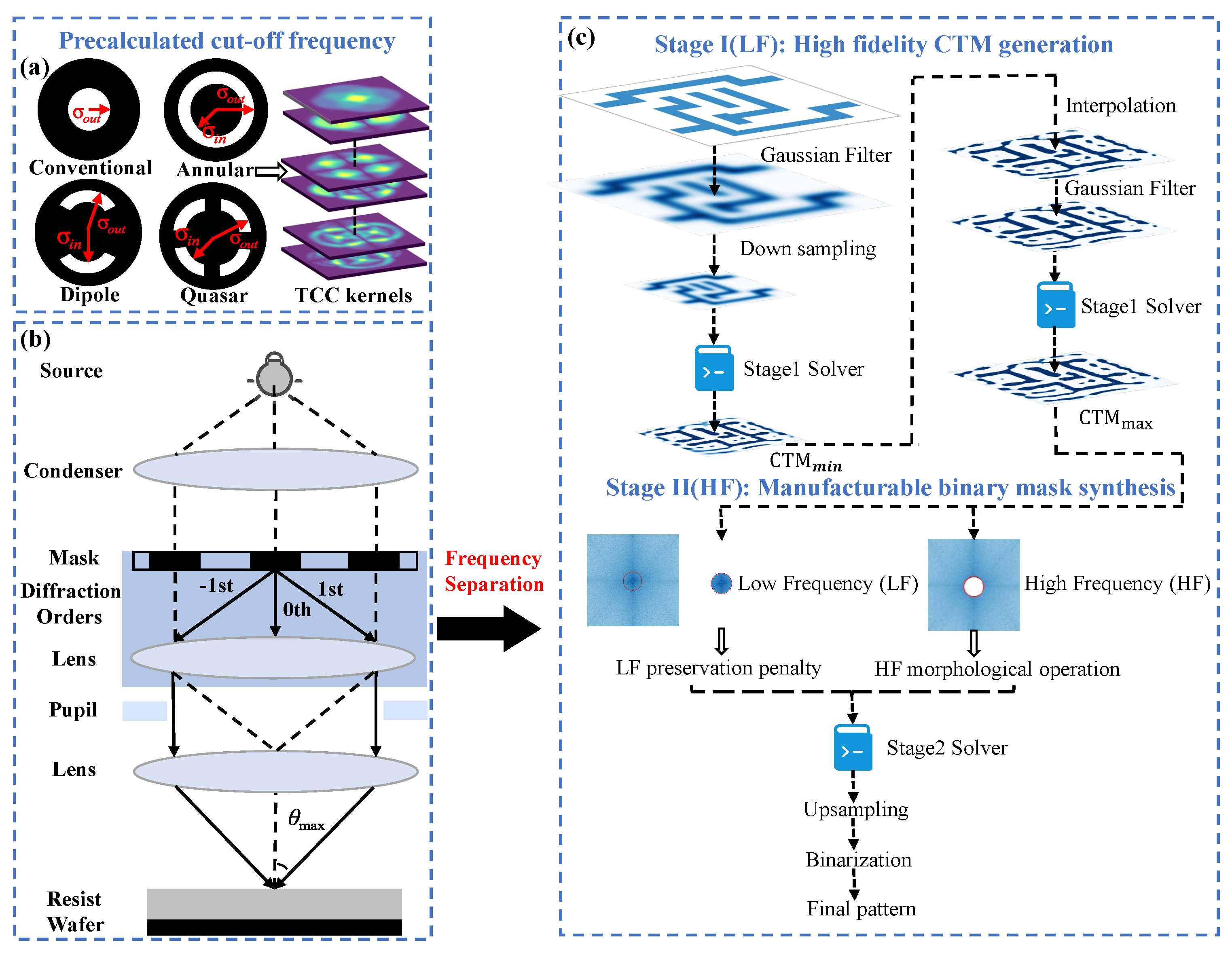

2. Fundamentals of Gradient-Based ILT Optimization Framework

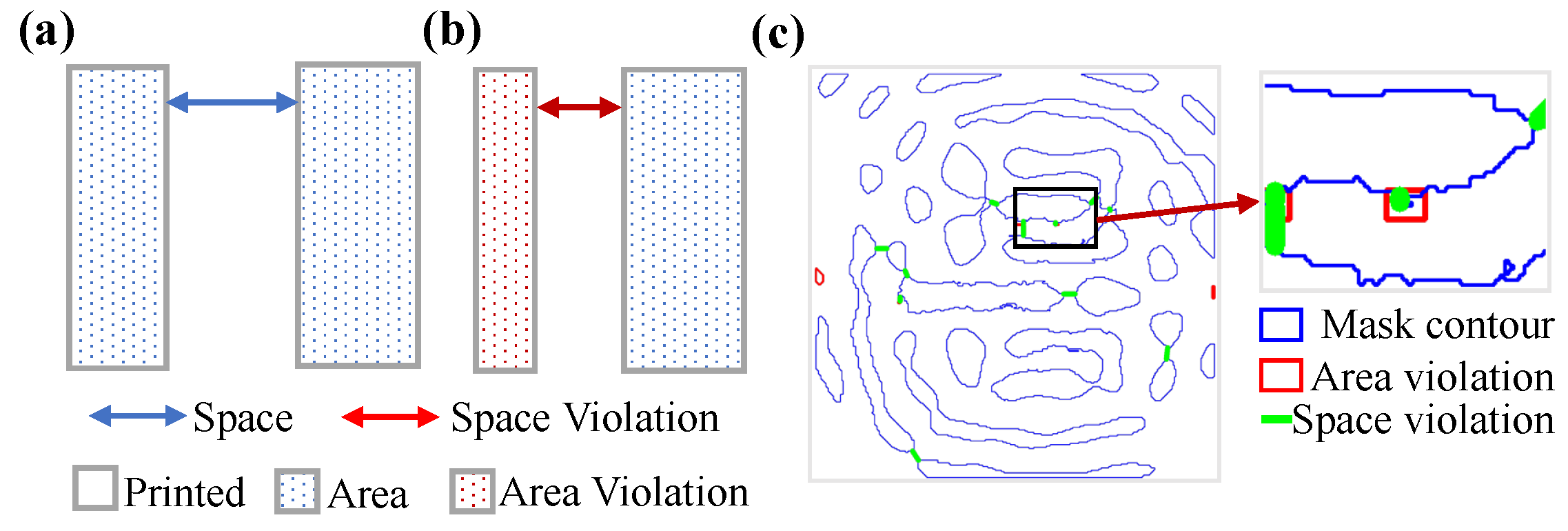

2.1. Forward Lithography Imaging Model

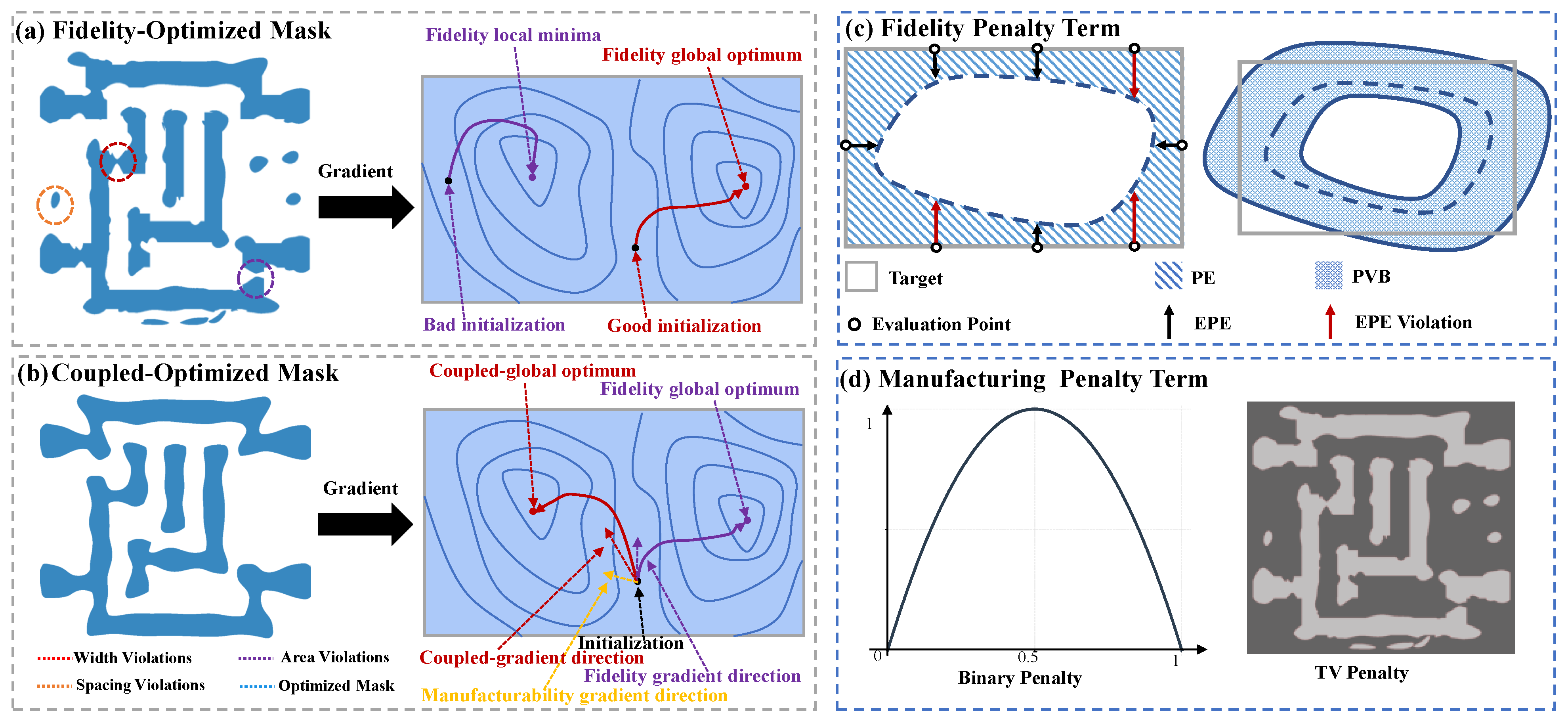

2.2. Inverse Lithography Optimization Framework

3. Frequency-Decoupled Dual-Stage ILT Optimization Algorithm

3.1. High-Fidelity CTM Generation

| Algorithm 1 High-fidelity CTM Generation |

| Require: Target pattern , optical parameters (NA, , ), desired resolution n, maximum iterations Ensure: Optimized CTM

|

3.2. Manufacturable Binary Mask Synthesis

| Algorithm 2 Manufacturable Binary Mask Synthesis |

| Require: Optimized CTM , max iterations Ensure: Binary mask

|

4. Experiments

4.1. Experimental Setup

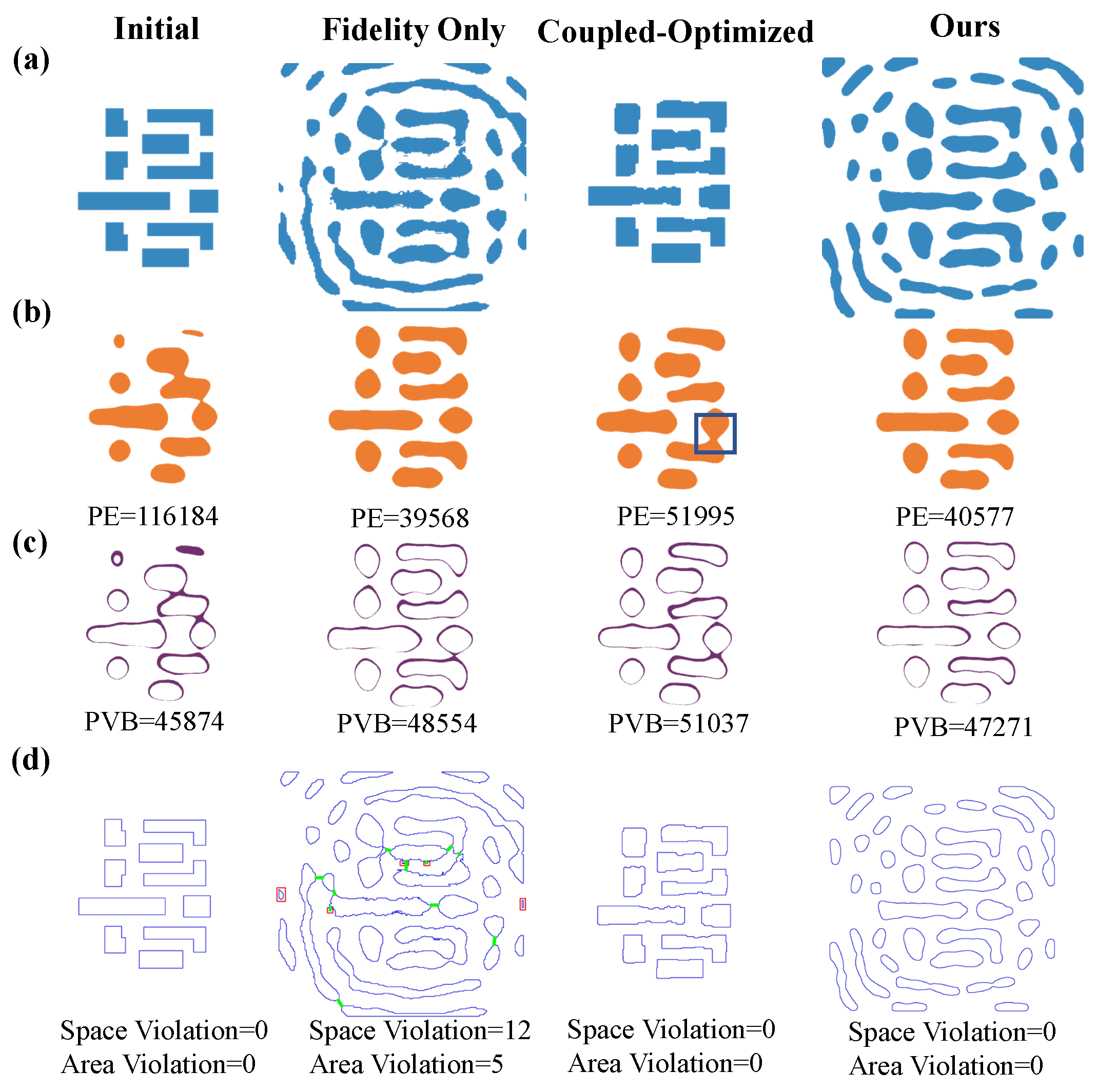

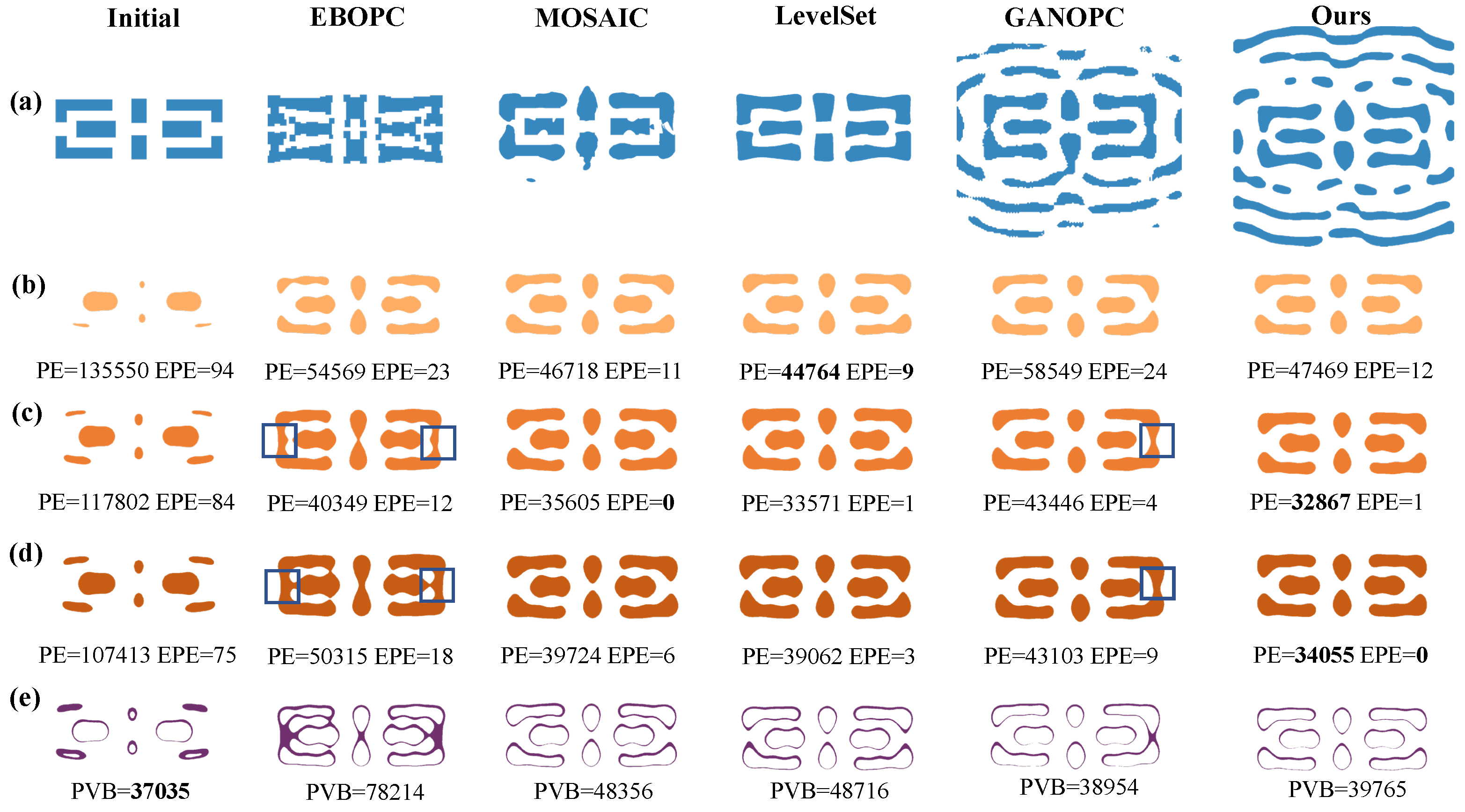

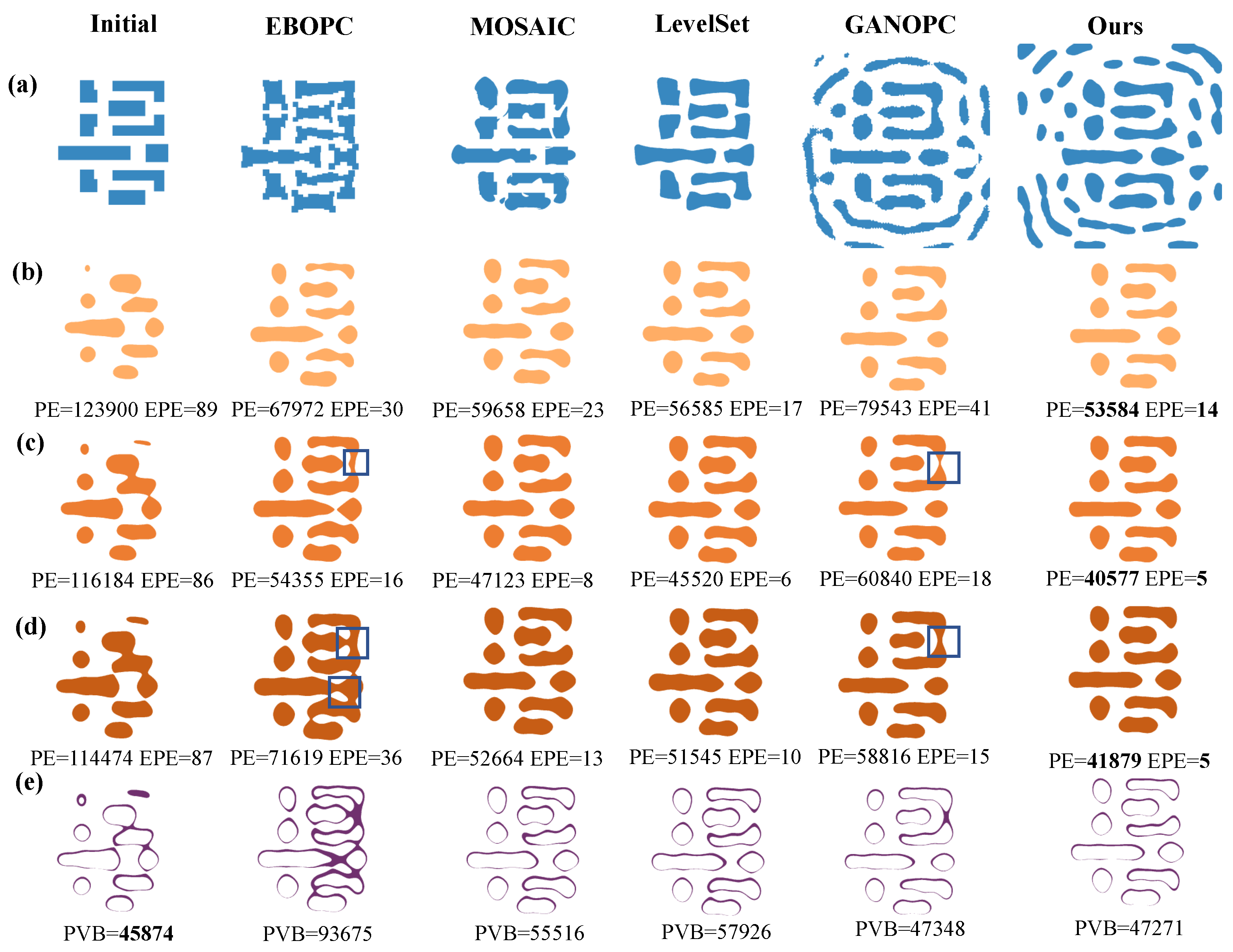

4.2. Different Cost Function Simulation Result Analysis

4.3. Simulation Results for Mask Fidelity Analysis

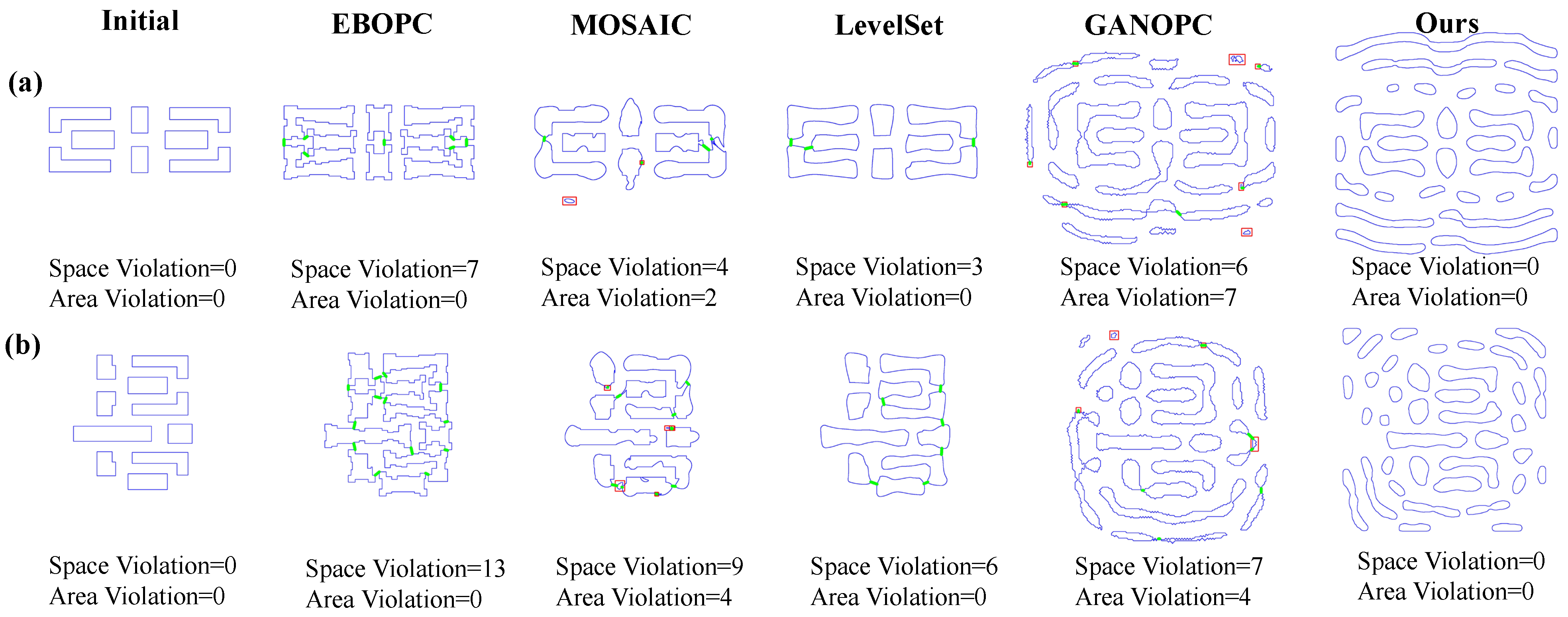

4.4. Simulation Results for Mask Manufacturability Analysis

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wei, Y. Advanced Lithography Theory and Applications for Ultra-Large Scale Integrated Circuits; Science Press: New York, NY, USA, 2016. [Google Scholar]

- Mack, C.A. Fifty years of Moore’s law. IEEE Trans. Semicond. Manuf. 2011, 24, 202–207. [Google Scholar] [CrossRef]

- Wong, A.K.K. Optical Imaging in Projection Microlithography; SPIE Press: Bellingham, WA, USA, 2005; Volume 66. [Google Scholar]

- Ma, X.; Arce, G.R. Computational Lithography; John Wiley & Sons: Hoboken, NJ, USA, 2011. [Google Scholar]

- Villaret, A.; Tritchkov, A.; Entradas, J.; Yesilada, E. Inverse lithography technique for advanced CMOS nodes. In Proceedings of the Optical Microlithography XXVI, San Jose, CA, USA, 26–28 February 2013; SPIE: Bellingham, WA, USA, 2013; Volume 8683, pp. 97–108. [Google Scholar]

- Pang, L. Inverse lithography technology: 30 years from concept to practical, full-chip reality. J. Micro/Nanopatterning Mater. Metrol. 2021, 20, 030901. [Google Scholar] [CrossRef]

- Poonawala, A.; Milanfar, P. Mask design for optical microlithography—an inverse imaging problem. IEEE Trans. Image Process. 2007, 16, 774–788. [Google Scholar] [CrossRef] [PubMed]

- Abrams, D.S.; Pang, L. Fast inverse lithography technology. In Proceedings of the Optical Microlithography XIX, San Jose, CA, USA, 21–24 February 2006; SPIE: Bellingham, WA, USA, 2006; Volume 6154, pp. 534–542. [Google Scholar]

- Schenker, R.; Bollepalli, S.; Hu, B.; Toh, K.; Singh, V.; Yung, K.; Cheng, W.h.; Borodovsky, Y. Integration of pixelated phase masks for full-chip random logic layers. In Proceedings of the Optical Microlithography XXI, San Jose, CA, USA, 26–29 February 2008; SPIE: Bellingham, WA, USA, 2008; Volume 6924, pp. 163–173. [Google Scholar]

- Granik, Y.; Sakajiri, K.; Shang, S. On objectives and algorithms of inverse methods in microlithography. In Proceedings of the Photomask Technology 2006, Monterey, CA, USA, 18–22 September 2006; SPIE: Bellingham, WA, USA, 2006; Volume 6349, pp. 1402–1409. [Google Scholar]

- Lv, W.; Lam, E.Y.; Wei, H.; Liu, S. Cascadic multigrid algorithm for robust inverse mask synthesis in optical lithography. J. Micro/Nanolithography MEMS MOEMS 2014, 13, 023003. [Google Scholar] [CrossRef]

- Sun, S.; Yang, F.; Yu, B.; Shang, L.; Zeng, X. Efficient ilt via multi-level lithography simulation. In Proceedings of the 2023 60th ACM/IEEE Design Automation Conference (DAC), San Francisco, CA, USA, 9–13 July 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 1–6. [Google Scholar]

- Chen, W.; Ma, X.; Zhang, S. Bandwidth-aware fast inverse lithography technology using Nesterov accelerated gradient. Opt. Express 2024, 32, 42639–42651. [Google Scholar] [CrossRef]

- Chen, G.; Li, S.; Wang, X. Efficient optical proximity correction based on virtual edge and mask pixelation with two-phase sampling. Opt. Express 2021, 29, 17440–17463. [Google Scholar] [CrossRef] [PubMed]

- Yu, Z.; Chen, G.; Ma, Y.; Yu, B. A GPU-enabled level-set method for mask optimization. IEEE Trans. Comput.-Aided Des. Integr. Circuits Syst. 2022, 42, 594–605. [Google Scholar] [CrossRef]

- Yu, J.C.; Yu, P. Impacts of cost functions on inverse lithography patterning. Opt. Express 2010, 18, 23331–23342. [Google Scholar] [CrossRef] [PubMed]

- Ungar, P.J.; Torunoglu, I.H. Lithography Mask Design Through Mask Functional Optimization and Spatial Frequency Analysis. US Patent 7,856,612, 21 December 2010. [Google Scholar]

- Jia, N.; Lam, E.Y. Pixelated source mask optimization for process robustness in optical lithography. Opt. Express 2011, 19, 19384–19398. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Shi, Z.; Geng, Z.; Yang, Y.; Yan, X. A new algorithm of inverse lithography technology for mask complexity reduction. J. Semicond. 2012, 33, 045009. [Google Scholar] [CrossRef]

- Shen, S.; Yu, P.; Pan, D.Z. Enhanced DCT2-based inverse mask synthesis with initial SRAF insertion. In Proceedings of the Photomask Technology 2008, Monterey, CA, USA, 7–10 October 2008; SPIE: Bellingham, WA, USA, 2008; Volume 7122, pp. 1269–1281. [Google Scholar]

- Lv, W.; Xia, Q.; Liu, S. Mask-filtering-based inverse lithography. J. Micro/Nanolithography Mems, Moems 2013, 12, 043003. [Google Scholar] [CrossRef]

- He, P.; Liu, J.; Gu, H.; Jiang, H.; Liu, S. Linearized EUV mask optimization based on the adjoint method. Opt. Express 2024, 32, 8415–8424. [Google Scholar] [CrossRef] [PubMed]

- Chen, K.y.; Lan, A.; Yang, R.; Chen, V.; Wang, S.; Zhang, S.; Xu, X.; Yang, A.; Liu, S.; Shi, X.; et al. Full-chip application of machine learning SRAFs on DRAM case using auto pattern selection. In Proceedings of the Optical Microlithography XXXII, San Jose, CA, USA, 26–27 February 2019; SPIE: Bellingham, WA, USA, 2019; Volume 10961, pp. 35–46. [Google Scholar]

- Wang, S.; Su, J.; Zhang, Q.; Fong, W.; Sun, D.; Baron, S.; Zhang, C.; Lin, C.; Chen, B.D.; Howell, R.C.; et al. Machine learning assisted SRAF placement for full chip. In Proceedings of the Photomask Technology 2017, Monterey, CA, USA, 11–14 September 2017; SPIE: Bellingham, WA, USA, 2017; Volume 10451, pp. 95–101. [Google Scholar]

- Xu, D.; Zhang, S.; Zhang, H.; Mandic, D.P. Convergence of the RMSProp deep learning method with penalty for nonconvex optimization. Neural Netw. 2021, 139, 17–23. [Google Scholar] [CrossRef] [PubMed]

- Hopkins, H.H. The concept of partial coherence in optics. Proc. R. Soc. London. Ser. Math. Phys. Sci. 1951, 208, 263–277. [Google Scholar]

- Adam, K.; Granik, Y.; Torres, A.; Cobb, N.B. Improved modeling performance with an adapted vectorial formulation of the Hopkins imaging equation. In Proceedings of the Optical Microlithography XVI, Santa Clara, CA, USA, 25–28 February 2003; SPIE: Bellingham, WA, USA, 2003; Volume 5040, pp. 78–91. [Google Scholar]

- Wu, X.; Fühner, T.; Erdmann, A.; Lam, E.Y. Levet-set-based inverse lithography under random field shape uncertainty in a vector Hopkins imaging model. In Proceedings of the Computational Optical Sensing and Imaging; Optica Publishing Group: Washington, DC, USA, 2017; paper CW1B–4. [Google Scholar]

- Cobb, N. Sum of Coherent Systems Decomposition by SVD; University of California at Berkeley: Berkeley, CA, USA, 1995; p. 94720. [Google Scholar]

- Goodman, J.W. Introduction to Fourier Optics; Roberts and Company Publishers: Greenwood Village, CO, USA, 2005. [Google Scholar]

- Mack, C. Fundamental Principles of Optical Lithography: The Science of Microfabrication; John Wiley & Sons: Hoboken, NJ, USA, 2007. [Google Scholar]

- Ma, X.; Arce, G.R. Generalized inverse lithography methods for phase-shifting mask design. Opt. Express 2007, 15, 15066–15079. [Google Scholar] [CrossRef] [PubMed]

- Ungar, P.J.; Torunoglu, I.H. Solution-Dependent Regularization Method for Quantizing Continuous-Tone Lithography Masks. US Patent 7,716,627, 11 May 2010. [Google Scholar]

- Zhao, X.; Chu, C. Line Search-Based Inverse Lithography Technique for Mask Design. VLSI Des. 2012, 2012, 589128. [Google Scholar] [CrossRef]

- Gao, J.R.; Xu, X.; Yu, B.; Pan, D.Z. MOSAIC: Mask optimizing solution with process window aware inverse correction. In Proceedings of the 51st Annual Design Automation Conference, San Francisco, CA, USA, 1–5 June 2014; pp. 1–6. [Google Scholar]

- Gonzales, R.C.; Wintz, P. Digital Image Processing; Addison-Wesley Longman Publishing Co., Inc.: St. Boston, MA, USA, 1987. [Google Scholar]

- Fühner, T. Artificial Evolution for the Optimization of Lithographic Process Conditions. Ph.D. Thesis, Friedrich-Alexander-Universität Erlangen-Nürnberg (FAU), Erlangen, Germany, 2014. [Google Scholar]

- Banerjee, S.; Li, Z.; Nassif, S.R. ICCAD-2013 CAD contest in mask optimization and benchmark suite. In Proceedings of the 2013 IEEE/ACM International Conference on Computer-Aided Design (ICCAD), San Jose, CA, USA, 18–21 November 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 271–274. [Google Scholar]

- Kato, K.; Taniguchi, Y.; Nishizawa, K.; Endo, M.; Inoue, T.; Hagiwara, R.; Yasaka, A. Mask rule check using priority information of mask patterns. In Proceedings of the Photomask Technology 2007, Monterey, CA, USA, 11–14 September 2017; SPIE: Bellingham, WA, USA, 2007; Volume 6730, pp. 1420–1429. [Google Scholar]

- Zheng, S.; Ma, Y.; Zhu, B.; Chen, G.; Zhao, W.; Yin, S.; Yu, Z.; Yu, B. OpenILT: An Open-Source Platform for Inverse Lithography Technique Research. 2023. Available online: https://github.com/OpenOPC/OpenILT/ (accessed on 26 March 2023).

- Yang, H.; Li, S.; Ma, Y.; Yu, B.; Young, E.F. GAN-OPC: Mask optimization with lithography-guided generative adversarial nets. In Proceedings of the 55th Annual Design Automation Conference, San Francisco, CA, USA, 24–29 June 2018; pp. 1–6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Zhang, Q.; Sun, H.; Jin, C.; Zhou, J.; Liu, J. Frequency-Decoupled Dual-Stage Inverse Lithography Optimization via Hierarchical Sampling and Morphological Enhancement. Micromachines 2025, 16, 515. https://doi.org/10.3390/mi16050515

Zhou J, Zhang Q, Sun H, Jin C, Zhou J, Liu J. Frequency-Decoupled Dual-Stage Inverse Lithography Optimization via Hierarchical Sampling and Morphological Enhancement. Micromachines. 2025; 16(5):515. https://doi.org/10.3390/mi16050515

Chicago/Turabian StyleZhou, Jie, Qingyan Zhang, Haifeng Sun, Chuan Jin, Ji Zhou, and Junbo Liu. 2025. "Frequency-Decoupled Dual-Stage Inverse Lithography Optimization via Hierarchical Sampling and Morphological Enhancement" Micromachines 16, no. 5: 515. https://doi.org/10.3390/mi16050515

APA StyleZhou, J., Zhang, Q., Sun, H., Jin, C., Zhou, J., & Liu, J. (2025). Frequency-Decoupled Dual-Stage Inverse Lithography Optimization via Hierarchical Sampling and Morphological Enhancement. Micromachines, 16(5), 515. https://doi.org/10.3390/mi16050515