Abstract

The search for renewable energy resources has attracted considerable research interests in electrochemical reactions of hydrogen evolution reaction (HER) and oxygen reduction reaction (ORR) that are essential for fuel cells. Earth-abundant, eco-friendly and cost-effective transition metal compounds are emerging candidates as electrocatalysts in these reactions. Herein, we report the growth of manganese sulfide nanoparticles on three-dimensional graphene, through an easy, progressive successive ionic layer adsorption and reaction (SILAR) method, where manganese sulfide nanoparticles (MnS-NPs), diameter of 4–5 nm are homogeneously decorated on the 3D graphene matrix. The formed hybrid shows improved HER activity in 0.1 M KOH when compared to bulk MnS. Moreover, MnS-NPs@3DG is also active in catalyzing ORR, qualifying it as a new type of bifunctional electrocatalyst in alkaline media.

1. Introduction

The ongoing depletion of fossil fuels has demanded an urgent development in more sustainable renewable energy sources. In particular, molecular hydrogen is short-listed as an eco-friendly energy conveyer to potentially meet the over-expanding energy needs [1,2]. The hydrogen evolution reaction (HER) is pivotal to electrochemical splitting of water into H2 and O2 as an inexpensive and viable route to subsequent hydrogen fuels [3,4,5,6]. Normally, catalysts are required to reduce the overpotential (η) to drive HER at a relatively low potential with an appreciable rate. To date, Pt remains as the most efficient HER electrocatalyst, but the price and scarcity of Pt seriously limit its practical applications [7,8,9,10]. Therefore, finding alternative cost-effective electrocatalysts from earth-abundant elements is of the utmost importance [11]. Recently, transition metals and their compounds including borides, carbides, nitrides, phosphides, oxides, sulfides and selenides emerged as efficient electrocatalysts for HER [12,13,14,15,16,17,18]. In particular, Mn-based compounds have attracted considerable interests owing to their low cost and relatively high abundance. Generally, electrocatalytic activities can be manipulated on two aspects, i.e., chemical compositional tuning by doping and morphology control for a judiciously designed nanostructurized electrode [19,20,21,22,23]. For example, Li et al. solvothermally synthesized hexagram nanosheets of bimetallic cobalt manganese sulfide (CMS) supported by a three-dimensional (3D) Ni foam and this free-standing electrode possessed an overpotential (η) of 210 mV at 100 mA cm−2 in the HER [24]. Tang et al. reported hydrothermally synthesized nanosheets of Co-Mn carbonate hydroxide on a 3D nickel foam and the hybrid catalyst featured an overpotential of 180 mV at 10 mA cm−2 [20]. Meanwhile, Miao et al. set a scalable pathway to synthesize Ni-Mn-Co spinel ternary sulfide on the reduced graphene oxide (RGO), and the nanocomposite had an insignificant η of 151 mV at 10 mA cm−2 [25]. Moreover, catalytic activity of MnS has been enhanced unusually by supporting interconnected porous sheets into a 3D framework. Graphene has been demonstrated to be a suitable support for catalysts due to its high surface area and excellent conductivity [26,27,28]. To profit the electrocatalytic activity of MnS nanoparticles (Mn-NPs) in a 3D scenario, we herein report a hybrid catalyst of MnS nanoparticles supported on the porous 3D graphene foam (MnS-NPs@3DG) prepared via a convenient SILAR method. SILAR has been proven to be a facile, low-cost and eco-friendly method to grow nanomaterials on 3D conductive supports [29,30], and it is clearly different from previous MnS synthetic routes such as spray pyrolysis, microwave irradiation, chemical bath deposition, solvothermal and hydrothermal that required time-consuming procedures and harsh conditions [31,32,33,34]. Meanwhile, the 3D graphene network provides a large surface area with enriched catalytic sites to anchor MnS-NPs for efficient HER, while cordial contact of MnS-NPs with 3D conductive support ensures a facile electron transport at MnS-NPs/3DG interface, eliminating barriers for electron transport across highly resistive MnS. On the other hand, catalytic active sites are electronically connected through the underlying 3D graphene network, simultaneously permitting facile diffusion of gaseous molecules and electrolyte species for high HER performance. As a result, the MnS-NPs@3DG showed a catalytic performance of 274 mV (η) at 10 mA cm−2. To the best of our knowledge, this material is reported for the first time for HER. Additionally, the MnS-NPs@3DG nanohybrid also actively participated in catalyzing the oxygen reduction reaction (ORR), making it a new kind of bifunctional electrocatalyst in alkaline media.

2. Results and Discussion

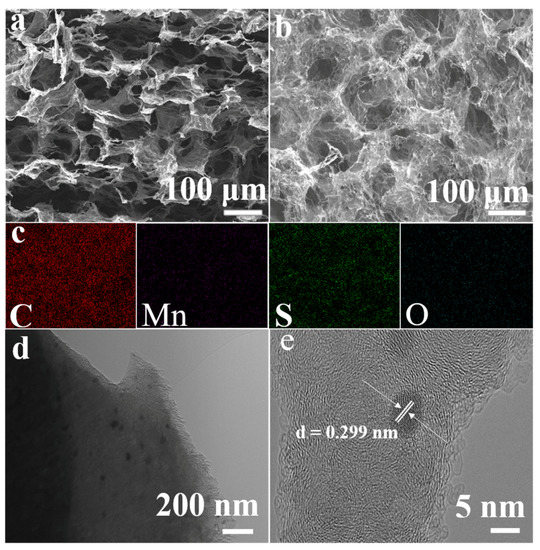

The morphology of the resulted MnS-NPs@3DG was viewed by scanning electron microscopy (SEM). The SEM image in Figure 1a reveals the interconnecting cross-linked feature of graphene sheets into a three-dimensional monolith, which was rich in pores of different sizes ranging from sub-micrometer to several micrometers. For nanoparticle loading by the SILAR process, the time of dipping/drying and the number of SILAR cycles were strictly controlled to ensure even distribution of nanoparticles on the graphene foam. As presented in Figure 1b, the surface of the 3D graphene framework became rougher after the deposition of MnS-NPs, and element mapping in Figure 1c endorses the subsistence of carbon, manganese, sulfur and oxygen in the as-prepared nanocomposite. MnS-NPs were further characterized by transmission electron microscopy (TEM, Figure 1d). Owing to the transparent nature of thin graphene sheets in the composite, MnS-NPs can be well resolved on surface of graphene. The HRTEM images in Figure 1e revealed that the size of nanoparticles was around 4-5 nm with 0.299 nm d-spacing paralleled to (101) plane of MnS [35]. In order to optimize the catalytic activity of the hybrid catalyst, SILAR cycles of 1, 3, 5 and 10 were applied to yield samples denoted as SILSR-1, SILAR-3, SILAR-5 and SILAR-10. It is found that the number of SILAR cycles is a crucial parameter to control aggregation of MnS-NPs on the 3DG network, and formation of MnS-NPs aggregates on the surface of the graphene framework may block pores of the graphene foam (Figure S1). Therefore, the number of SILAR cycles was optimized as 5, where sufficient MnS-NPs could be anchored on the 3DG network without interfering electron transport or electrolyte diffusion through the nanocomposite toward efficiently catalyzing the HER [36].

Figure 1.

The SEM images of 3DG (a) and MnS-NPs@3DG (b); corresponding elemental mapping of MnS-NPs@3DG (c); TEM (d) and HRTEM (e) image of typical MnS-NPs on graphene sheet.

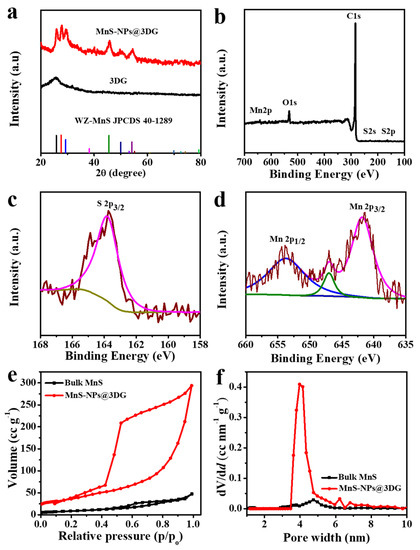

The structure of the MnS-NPs@3DG was probed by the x-ray diffraction technique. Figure 2a compares XRD configurations of the as-prepared composite with the 3DG. A typical diffraction peak at 2θ of ~26° was observed in the 3DG, corresponding to the diffraction between the (002) plane of the graphene. In addition, the MnS-NPs@3DG also shows other characteristic peaks at 2θ of 27.6°, 29.4°, 45.7°, 49.5° and 54.1°, confirming the formation of γ-MnS (JPCD: 40-1289). XPS was further carried out to evaluate the bonding characteristics of MnS-NPs@3DG. The atomic ratio of Mn to S is 1.02: 1 (Figure 2b), well matching the stoichiometric ratio of MnS. Additionally, the high-resolution S spectrum in Figure 2c shows distinctive S2p3/2 peak at the binding energy of 163.6 eV, which originated from the sulfur in MnS [37] and high-resolution Mn spectrum exhibits two main peaks of Mn2p3/2 and Mn2p1/2 at 641.8 eV and 653.7 eV, respectively, with a satellite feature of Mn2+ situated at 647 eV in Figure 2d [38,39]. Furthermore, N2 adsorption and desorption experiments were conducted (Figure 2e) and the Brunauer–Emmett–Teller (BET) specific surface area of MnS-NP@3DG was determined as 134.3 m2 g−1, which was significantly larger than that of the bulk MnS (32.5 m2 g−1) due to the benefit of porous 3D support to improve the specific surface area. Meanwhile, MnS-NPs@3DG has a pore size of 4 nm (Figure 2f), which may cause an easy flow of electrolytic species during the HER process.

Figure 2.

(a) XRD pattern of the MnS-NPs@3DG, 3DG and γ-MnS (JCPDS no. 40-1289); (b) XPS spectral data of MnS-NPs@3DG and high resolution XPS spectral data of S2p (c)and Mn2p (d); (e) N2 adsorption and desorption isotherms and (f) corresponding pore size distribution of as-prepared bulk MnS and MnS-NPs@3DG, respectively.

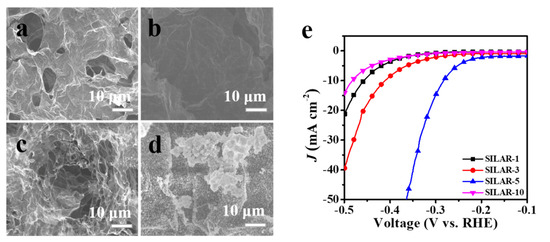

The electrocatalytic HER activity of catalysts was conducted in alkaline solution (0.1 M KOH) with a typical three-electrode system. SEM images in Figure 3a−d reveal that the morphology of the catalyst changed from slightly rough to large aggregates with the increased number of SILAR cycles, and such a morphological change significantly influenced the catalytic performance in HER. As shown in Figure 3e, as the loading amount of electrocatalytically active MnS-NPs increased, the value of the electrocatalytic current density (Jcat) dramatically improved until SILAR cycles reached 5. Interestingly, a poor catalytic current was observed in SILAR-10, and this could be attributed to the excessive stackings of the highly resistive MnS-NPs that impede electron flow across the electrode to the catalyst/electrolyte interface. While the number of SILAR cycles was optimized as 5, the effect of mass loading was further studied in Figure S2, and an optimal catalyst loading of ~0.28 mg cm−2 was obtained. The observed inferior performance with a larger catalytic loading may be attributed to impeded electron transport through a thicker catalyst layer and/or agglomeration of catalytic mesopores with inefficient electrolytic flow through the catalyst on the electrode surface.

Figure 3.

SEM images of MnS@3DG with different SILAR cycles: (a) SILAR-1, (b) SILAR-3, (c) SILAR-5 and (d) SILAR-10; (e) the polarization curves of MnS-NPs@3DG with different SILAR cycles.

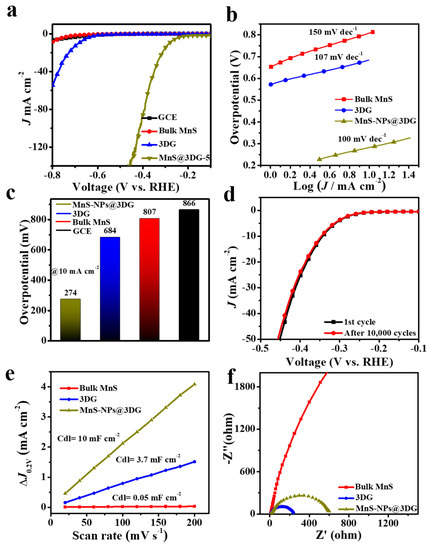

Figure 4a plots comparative polarization curves for bulk MnS, 3DG and MnS-NPs@3DG, respectively. The current density for bulk MnS was 8.8 mA cm−2 at an over-potential of 800 mV, and its poor HER catalytic activity may be attributed to lack of catalytic surface area and conductivity. In comparison, cathodic catalytic current for MnS-NPs@3DG initiated at −230 mV (Figure S3), and after this potential, Jcat sharply increased to about 142 mA cm−2 at an overpotential of 490 mV. Such an improvement in catalytic activity is a result of electrical coupling of catalytic active sites with 3D interconnected graphene sheets, thus enlarging the catalyst/electrolyte interface to promote HER and avoiding electron transport directly through intrinsically less-conductive MnS to the electrode [40]. The kinetics of the catalyzed HER were analyzed by measuring Tafel plots. As shown in Figure 4b, the calculated Tafel slope of MnS-NPs@3DG was 100 mV dec−1 approximately, while higher Tafel slopes were found for 3DG (107 mV dec−1) and bulk MnS (150 mV dec−1), implying that the effective use of a large interfacial surface area and rapid electron transportation were responsible for the better HER observed in the MnS-NPs@3DG. Meanwhile, as Tafel slope is associated with the rate-limiting step in HER, the measured Tafel slope value (100 mVdec−1) for MnS-NPs@3DG suggested a Volmer-Heyrosky mechanism [41]. In general, an over-potential of 274 mV was required to achieve a benchmark Jcat of 10 mA cm−2. In contrast, much higher overpotentials of 684 and 807 mV were required for 3DG and bulk MnS to generate a current density of 10 mA cm−2 (Figure 4c). Catalytic durability is another indispensable factor for effective practical usage of non-precious electrocatalysts for long-duration hydrogen production. All samples were measured by continuous cyclic voltammetric (CV) sweeps with a scan rate of 50 mV s−1 for 10,000 cycles at a selected potential range of 0.1 and −0.6 V. Figure 4d shows that the polarization curves of the MnS-NP@3DG in Cycle 1 and Cycle 10,000 were almost identical, confirming its excellent stability in catalyzing HER. Furthermore, double layer capacitance (Cdl) was estimated for bulk MnS, 3DG and MnS-NPs@3DG (Figure 4e) [42], and a potential range was selected as 0.15 to −0.25 V due to the presence of non-faradaic current [43]. In comparison to both 3DG (3.7 mF cm−2) and bulk MnS (0.05 mF cm−2), a larger Cdl (10 mF cm−2) was found for the MnS-NPs@3DG, proving that it exposed more active sites for electrocatalytic activity in HER. Additionally, the electrochemical impedance spectroscopy (EIS) results in Figure 4f reveal that MnS-NPs@3DG possessed smaller faradaic impedance than bulk MnS, implying that the existence of the graphene support enhanced the interfacial surface area for rapid charge transfer in HER.

Figure 4.

(a) Hydrogen evolution reaction (HER) polarization curves of bulk MnS, 3DG and MnS-NPs@3DG at scan rate of 5 mV s−1 in 0.1 M KOH; (b) Tafel plots of the bulk MnS, 3DG and MnS-NPs@3DG; (c) the overpotential at 10 mA cm−2 for bulk MnS, 3DG and MnS-NPs@3DG; (d) durability of MnS-NPs@3DG catalyst descript negligible HER activity loss even after 10,000 cyclic voltammetric (CV) cycles within 0.1 to −0.6 V at 50 mVs−1; (e) capacitive current measurements for bulk MnS, 3DG and MnS-NPs@3DG ΔJ0 = Ja − Jc); (f) Nyquist plots of bulk MnS, 3DG and MnS-NPs@3DG.

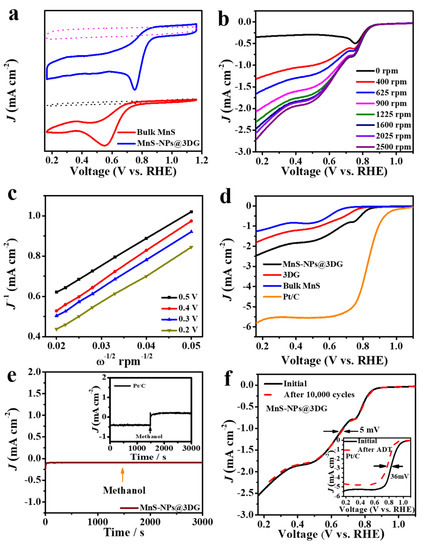

The prepared hybrid was also active for catalyzing ORR in 0.1 M KOH solution. As depicted in Figure 5a, featureless CV response of MnS-NP@3DG was noticed in nitrogen saturated electrolyte, while a strong cathodic reductive peak appeared in oxygen saturated electrolyte, indicating that the as-prepared hybrid has potential for electrocatalytic reduction in oxygen. ORR for MnS-NPs@3DG started at ~ 0.9 V, with well resolved reductive loop bulging at ~ 0.75 V. In contrast, bulk MnS showed inferior ORR activity as compared to Mn-NPs@3DG, which again suggests the improved ORR catalytic activity of the as-prepared hybrid originated from good compatibility between MnS-NPs and the underlying 3DG network. For further confirmation, ORR kinetics of MnS-NP@3DG was also noted in oxygen saturated alkaline solution (0.1 M KOH) by using the rotating disk electrode (RDE) system as presented in Figure 5b. At various potentials, Koutecky−Levich (K-L) plots possessed good linearity which imply a similar electron transfer number for ORR (Figure 5c). For ORR phenomena, the slope of Koutecky–Levich plots was used to obtain the number of electrons (n) required to reduce one O2 molecule. A value of n = 2 was calculated for MnS-NPs@3DG within the potential range of 0.2–0.5 V, signifying a specific two-electron transfer ORR process. Moreover, the MnS-NPs@3DG nanohybrid catalyst exhibited the most positive ORR onset potential of 0.9 V and a current density of 2.5 mA cm−2 at 1600 rpm (Figure 5d). The methanol crossover effect was tested in oxygen saturated alkaline solution (0.1 M KOH) to investigate the methanol tolerance of the resulting MnS-NPs@3DG catalyst. No apparent changes were observed for as-prepared MnS-NPs@3DG after adding methanol (10 vol%) showing its good methanol tolerance potential (Figure 5e). In contrast, the Pt/C catalyst showed an obvious oxidation peak under the same condition (inset of Figure 5e), further proving that the MnS-NPs@3DG nanohybrid exhibited superior methanol tolerance compared to a standard platinum-based catalyst. The CV measurements were further conducted to investigate the durability of the electrocatalyst in alkaline solution at a 50 mV s−1 scan rate. As shown in Figure 5f, polarization curves after 10,000 cycles negatively shifted 5 and 40 mV for Mns-NPs@3DG and Pt/C, respectively, highlighting the durability of the MnS-NPs@3DG catalyst in the ORR.

Figure 5.

(a) CV measurements of MnS-NPs@3DG and bulk MnS in alkaline solution at 10 mV s−1, where the solid line and dash line represents the CV curves in oxygen saturated and nitrogen saturated alkaline solution, respectively; (b) the RDE measurements for MnS-NPs@3DG in alkaline solution at different rotating speeds; (c) K–L plots attain at 0.5 to 0.2 V from the RDE measurements; (d) polarization curves for MnS-NPs@3DG, 3DG, bulk MnS and Pt catalyst in oxygen saturated alkaline solution at 10 mV s−1 on a RDE (1600 rpm); (e) the crossover toleration test of MnS-NPs@3DG and Pt catalyst (inset) in the oxygen saturated alkaline solution at −0.2 V; (f) oxygen reduction reaction (ORR) polarization curves of the MnS-NPs@3DG and Pt/C after 10,000 cycles.

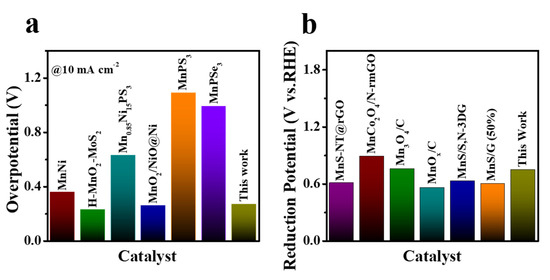

Performance-based comparative study for various Mn-based catalysts have been narrated in Figure 6a,b. Owing to bifunctional electrocatalysts (HER, ORR), the tailored nanocomposite was proven to excel over other Mn-based catalysts (Figure 6; Tables S1 and S2 Supplementary Materials). In a nut shell, well-tailored nanocomposite (MnS-NPs@3DG) showed impressive (HER, ORR) functionalities that though not comparable to Pt-based expensive catalysts yet, may helpful to curtail the expense of such an expensive metal-based catalyst as alternatives for the same purposes.

Figure 6.

(a) Comparison of recently reported highly active Mn-based HER electrocatalysts and (b) ORR electrocatalysts in the literature, respectively.

3. Materials and Method

3.1. Reagents

Manganese chloride tetra hydrate (MnCl2·4H2O) was received from Fuchen Chemical Reagents Factory (Tianjin, China), sodium sulfide (Na2S·9H2O) from Guangfu Fine Chemical industry (Tianjin China), and 5 wt% Nafion solution (Aladdin, Shanghai, China). All reagents were utilized with no further refining.

3.2. Synthesis of GO

The modified Hummer’s method was adopted to synthesize graphene oxide (GO) by oxidation leading exfoliation of natural graphite flakes [44].

3.3. Synthesis of 3DG

Our previously reported method was adopted for synthesis of 3DG. In nut shell, 3 mL 6 mg mL−1 GO aqueous solution with 0.25 mL 100 mg mL−1 sodium dodecyl sulfate (SDS) aqueous solution homogenized in a 20 mL propylene isotopic vial (internal diameter 22) at 3000 rpm stirring rate for 60s. Then, in this pre-homogenized solution, 0.4 mL Nonidet P-40 (NP-40 in 10% octylphenoxypolyethanol in aqueous media, Aladdin, Shanghai, China) was added. Then, direct quenching in liquid N2 for almost 30 min was required to solidify this solution then subjected to freeze-drying for several hours to obtain GO foam (GOF) with subsequent calcination on 1000 °C for 2h in inert (Ar) environment with 5 °C/min heating rate.

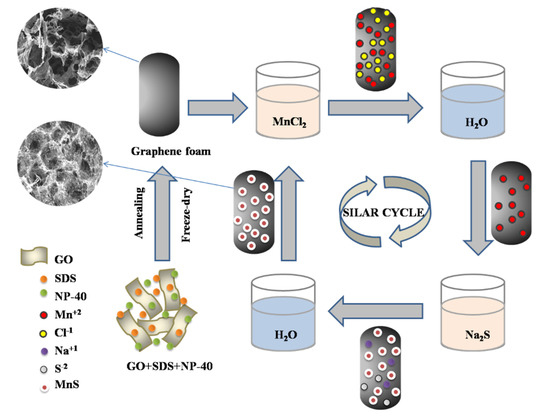

3.4. Synthesis of MnS-NPs@3DG

In the present work, MnS-NPs were formed in-situ on the 3D graphene network via the SILAR method. Briefly, for the deposition of MnS-NPs, 0.1 M MnCl2·4H2O solution (pH = 5.5) was used as a cationic precursor, and 0.05 M Na2S·9H2O solution (pH = 12) was used as an anionic precursor. After cleaning by using ethanol-water (1:1 by volume), graphene foam was desiccated in an inert environment at 60 °C for several hours. After graphene foam became completely dried, MnS-NPs were loaded as depicted in Scheme 1 by the SILAR cycle. Here, the SILAR cycle was completed successfully for the required outcomes in four steps: (1) Mn2+ uptake: the 3DG substrate was immersed into the MnCl2·4H2O solution for 30 s for Mn2+ ions adsorption. (2) 1st washing: washing of substrate for 50 s was required to remove detached Mn2+. (3) S2− uptake: 30 s complete immersion of substrate in Na2S·9H2O solution for ionic attachment of S2− with ante-adsorbed Mn2+ ions to form MnS-NPs. (4) 2nd washing: washing of substrate for 50 s was required to drench as well as to remove unreacted S2− ions on the surface of Mn2+ embellished 3DG. Lastly, before characterization of the sample, the as-formed samples were desiccated at 60 °C for 3 h. For comparison, the SILAR process was repeated 1, 3, 5 and 10 times to yield control samples of SILAR-1, SILAR-3, SILAR-5 and SILAR-10, respectively, to optimize the size of MnS-NPs and the catalytic activity of the electrocatalyst.

Scheme 1.

Synthetic procedure for MnS-NPs@3DG by the SILAR method.

3.5. Material Characterization

Scanning electron microscope (SEM, JSM-7500F, Hitachi, Tokyo, Japan) and transmission electron microscope (TEM, 7650B, Hitachi, Tokyo, Japan) were applied in order to confirm morphology of the as-formed product. For X-ray analysis, Rigaku Smart Lab, X-ray Diffractometer, Tokyo, Japan was used to record data. While for X-ray photoelectron spectroscopy (XPS), an ESCALab220i-XL electron spectrometer (VG Scientific, Waltham, MA, USA) using 300 W Al Ka radiations was used to record data.

3.6. Electrochemical Characterization

For electrochemical characterization of the as-formed nanohybrid, standard three-electrode set-up (glassy carbon, graphite rod and Ag/AgCl) was used with potentiostat (CHI 760D working station). To prepare catalytic ink of MnS-NP@3DG as a working electrode, a 20 mg sample with 3.6 mL solvent mixture (ethanol-isopropanol 3:1 by volume) and 0.4 mL nafion solution (5 wt%) was subjected to ultrasonic treatment till homogeneous ink formation. The catalyst ink (4 µL) was deposited on 3mm diametric glassy carbon electrode (GCE) (loading quantity ≈ 0.283 mg cm−2). Alkaline electrolyte (0.1 M KOH) was used for linear sweep voltammetry (LSV). Moreover, all data were in a reversed hydrogen electrode, and IR drop corrected polarization curves were recorded. Catalytic resistance was measured within the frequency range 0.1–100 kHz by electrochemical impedance spectroscopy (EIS). By using the following Equation (1), the potential was converted to the RHE scale, where ERHE is the potential vs. RHE, while EAg/AgCl is the potential referring to Ag/AgCl. The overpotential (η) was attained by the intersection of the tangents of LSV current and the polarization curve baseline.

In order to test our as-formed catalyst for ORR, 5 µL catalytic ink was deposited onto another GCE (loading quantity ≈ 0.1 mg cm−2). The CV measurements were recorded in alkaline solution at 10 mV s−1, and RDE measurements were pursued at different rotating speeds (0–2500 rpm). For comparative view, the standard Pt based catalyst was also studied. The transferred electron number (n) was calculated from the Koutecky–Levich (K–L) equation [45,46].

Mathematically, relation between current and electrode rotating speed is as follows:

Where jk is the kinetic current, ω rotation rate speed of the electrode and B is the Levich slope, which is given by:

Here, n describes the electron number for the reduction in one O2 molecule, F is the Faraday constant (F = 96,485 C mol−1), is the diffusion coefficient of O2 in 0.1 M KOH ( = 1.9 × 10−5 cm2 s−1), ν is the kinematics viscosity (v = 0.01 cm2 s−1) and is O2 concentration in solution ( = 1.2 × 10−6 mol cm−3). When the rotating speed of the electrode is expressed in rpm, the constant 0.2 has been used.

4. Conclusions

In summary, MnS nanoparticles were synthesized and loaded on 3D graphene foam in one step by a cost-effective and eco-friendly SILAR method for catalyzing HER and ORR. Taking advantage of the three-dimensional structure of graphene as a superior current acquirer and catalyst carrier, the MnS-NPs@3D graphene featured much lower overpotential than analogues of bulk MnS. Additionally, its ORR activity was well proved, enabling it as a new kind of bifunctional catalyst. The current work may pave a new way for other metal chalcogenide-based low-cost bifunctional catalyst alternatives to noble metal compounds for electrochemical applications.

Supplementary Materials

The following are available online at https://www.mdpi.com/2073-4344/10/10/1141/s1, Figure S1: (a,b) SEM images of SILAR-1 and SILAR-10; Figure S2: the polarization curves of MnS-NPs@3DG with different loading weights; Figure S3: the Tafel plot of the MnS-NPs@3DG; Figure S4: (a–c) CV curves of bulk MnS, 3DG and MnS-NPs@3DG from 0.15 to −0.25 V vs. RHE at different scan rates; Table S1: comparison of recently reported highly active Mn-based HER electrocatalyst in the literature; Table S2: comparison of recently reported highly active Mn-based ORR electrocatalyst in the literature.

Author Contributions

K.u.R. conceived the conceptualization; S.A., L.S., J.G., Q.G., Y.X. participated in the software; and Z.Z. supervised the project. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Chinese Scholarship Council, grant number: [2016GXZF80; 2017GXZ019672].

Acknowledgments

Khalil ur Rehman and Shaista Airam thank Chinese Scholarship Council (No. 2016GXZF80, 2017GXZ019672) for financial support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Turner, J.; Sverdrup, G.; Mann, M.K.; Maness, P.-C.; Kroposki, B.; Ghirardi, M.; Evans, R.J.; Blake, D. Renewable hydrogen production. Int. J. Energy Res. 2008, 32, 379–407. [Google Scholar] [CrossRef]

- Dunn, S. Hydrogen futures: Toward a sustainable energy system. Int. J. Hydrogen Energy 2002, 27, 235–264. [Google Scholar] [CrossRef]

- Holladay, J.D.; Hu, J.; King, D.L.; Wang, Y. An overview of hydrogen production technologies. Catal. Today 2009, 139, 244–260. [Google Scholar] [CrossRef]

- Kudo, A.; Miseki, Y. Heterogeneous photocatalyst materials for water splitting. Chem. Soc. Rev. 2009, 38, 253–278. [Google Scholar] [CrossRef]

- Lewis, N.S.; Nocera, D.G. Powering the planet: Chemical challenges in solar energy utilization. Proc. Natl. Acad. Sci. USA 2006, 103, 15729–15735. [Google Scholar] [CrossRef]

- Greeley, J.; Jaramillo, T.F.; Bonde, J.; Chorkendorff, I.B.; Nørskov, J.K. Computational high-throughput screening of electrocatalytic materials for hydrogen evolution. In Materials for Sustainable Energy; Co-Published with Macmillan Publishers Ltd.: London, UK, 2010; pp. 280–284. ISBN 978-981-4317-64-1. [Google Scholar]

- Bai, S.; Wang, C.; Deng, M.; Gong, M.; Bai, Y.; Jiang, J.; Xiong, Y. Surface Polarization Matters: Enhancing the Hydrogen-Evolution Reaction by Shrinking Pt Shells in Pt–Pd–Graphene Stack Structures. Angew. Chem. Int. Ed. 2014, 53, 12120–12124. [Google Scholar] [CrossRef]

- Subbaraman, R.; Tripkovic, D.; Strmcnik, D.; Chang, K.-C.; Uchimura, M.; Paulikas, A.P.; Stamenkovic, V.; Markovic, N.M. Enhancing Hydrogen Evolution Activity in Water Splitting by Tailoring Li+-Ni(OH)-Pt Interfaces. Science 2011, 334, 1256–1260. [Google Scholar] [CrossRef]

- Stephens, I.E.L.; Chorkendorff, I. Minimizing the Use of Platinum in Hydrogen-Evolving Electrodes. Angew. Chem. Int. Ed. 2011, 50, 1476–1477. [Google Scholar] [CrossRef]

- Hou, D.; Zhou, W.; Liu, X.; Zhou, K.; Xie, J.; Li, G.; Chen, S. Pt nanoparticles/MoS2 nanosheets/carbon fibers as efficient catalyst for the hydrogen evolution reaction. Electrochim. Acta 2015, 166, 26–31. [Google Scholar] [CrossRef]

- Kong, D.; Cha, J.J.; Wang, H.; Lee, H.R.; Cui, Y. First-row transition metal dichalcogenide catalysts for hydrogen evolution reaction. Energy Environ. Sci. 2013, 6, 3553–3558. [Google Scholar] [CrossRef]

- Chen, W.-F.; Sasaki, K.; Ma, C.; Frenkel, A.I.; Marinkovic, N.; Muckerman, J.T.; Zhu, Y.; Adzic, R.R. Hydrogen-Evolution Catalysts Based on Non-Noble Metal Nickel–Molybdenum Nitride Nanosheets. Angew. Chem. Int. Ed. 2012, 51, 6131–6135. [Google Scholar] [CrossRef]

- Kong, D.; Wang, H.; Cha, J.J.; Pasta, M.; Koski, K.J.; Yao, J.; Cui, Y. Synthesis of MoS2 and MoSe2 Films with Vertically Aligned Layers. Nano Lett. 2013, 13, 1341–1347. [Google Scholar] [CrossRef]

- Merki, D.; Hu, X. Recent developments of molybdenum and tungsten sulfides as hydrogen evolution catalysts. Energy Environ. Sci. 2011, 4, 3878–3888. [Google Scholar] [CrossRef]

- Zou, X.; Zhang, Y. Noble metal-free hydrogen evolution catalysts for water splitting. Chem. Soc. Rev. 2015, 44, 5148–5180. [Google Scholar] [CrossRef]

- Faber, M.S.; Jin, S. Earth-abundant inorganic electrocatalysts and their nanostructures for energy conversion applications. Energy Environ. Sci. 2014, 7, 3519–3542. [Google Scholar] [CrossRef]

- Wang, J.; Cui, W.; Liu, Q.; Xing, Z.; Asiri, A.M.; Sun, X. Recent Progress in Cobalt-Based Heterogeneous Catalysts for Electrochemical Water Splitting. Adv. Mater. 2016, 28, 215–230. [Google Scholar] [CrossRef]

- Cui, W.; Cheng, N.; Liu, Q.; Ge, C.; Asiri, A.M.; Sun, X. Mo2C Nanoparticles Decorated Graphitic Carbon Sheets: Biopolymer-Derived Solid-State Synthesis and Application as an Efficient Electrocatalyst for Hydrogen Generation. ACS Catal. 2014, 4, 2658–2661. [Google Scholar] [CrossRef]

- Li, J.; Wei, G.; Zhu, Y.; Xi, Y.; Pan, X.; Ji, Y.; Zatovsky, I.V.; Han, W. Hierarchical NiCoP nanocone arrays supported on Ni foam as an efficient and stable bifunctional electrocatalyst for overall water splitting. J. Mater. Chem. A 2017, 5, 14828–14837. [Google Scholar] [CrossRef]

- Tang, T.; Jiang, W.-J.; Niu, S.; Liu, N.; Luo, H.; Chen, Y.-Y.; Jin, S.-F.; Gao, F.; Wan, L.-J.; Hu, J.-S. Electronic and Morphological Dual Modulation of Cobalt Carbonate Hydroxides by Mn Doping toward Highly Efficient and Stable Bifunctional Electrocatalysts for Overall Water Splitting. J. Am. Chem. Soc. 2017, 139, 8320–8328. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, W.; Rao, Y.; Li, Z.; Tsubaki, N.; Wu, M. Cation modulating electrocatalyst derived from bimetallic metal–organic frameworks for overall water splitting. J. Mater. Chem. A 2017, 5, 6170–6177. [Google Scholar] [CrossRef]

- Fang, L.; Li, W.; Guan, Y.; Feng, Y.; Zhang, H.; Wang, S.; Wang, Y. Tuning Unique Peapod-Like Co(SxSe1–x)2 Nanoparticles for Efficient Overall Water Splitting. Adv. Funct. Mater. 2017, 27, 1701008. [Google Scholar] [CrossRef]

- Wang, X.-D.; Chen, H.-Y.; Xu, Y.-F.; Liao, J.-F.; Chen, B.-X.; Rao, H.-S.; Kuang, D.-B.; Su, C.-Y. Self-supported NiMoP2 nanowires on carbon cloth as an efficient and durable electrocatalyst for overall water splitting. J. Mater. Chem. A 2017, 5, 7191–7199. [Google Scholar] [CrossRef]

- Li, J.; Xu, W.; Luo, J.; Zhou, D.; Zhang, D.; Wei, L.; Xu, P.; Yuan, D. Synthesis of 3D Hexagram-Like Cobalt–Manganese Sulfides Nanosheets Grown on Nickel Foam: A Bifunctional Electrocatalyst for Overall Water Splitting. Nano-Micro Lett. 2017, 10, 6. [Google Scholar] [CrossRef]

- Miao, R.; He, J.; Sahoo, S.; Luo, Z.; Zhong, W.; Chen, S.-Y.; Guild, C.; Jafari, T.; Dutta, B.; Cetegen, S.A.; et al. Reduced Graphene Oxide Supported Nickel–Manganese–Cobalt Spinel Ternary Oxide Nanocomposites and Their Chemically Converted Sulfide Nanocomposites as Efficient Electrocatalysts for Alkaline Water Splitting. ACS Catal. 2017, 7, 819–832. [Google Scholar] [CrossRef]

- Huang, C.; Li, C.; Shi, G. Graphene based catalysts. Energy Environ. Sci. 2012, 5, 8848–8868. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, Y.; Zhang, Z. A porous graphene/cobalt phosphate composite as an efficient oxygen evolving catalyst. Electrochem. Commun. 2014, 48, 35–39. [Google Scholar] [CrossRef]

- Zhao, S.; Yin, H.; Du, L.; Yin, G.; Tang, Z.; Liu, S. Three dimensional N-doped graphene/PtRu nanoparticle hybrids as high performance anode for direct methanol fuel cells. J. Mater. Chem. A 2014, 2, 3719–3724. [Google Scholar] [CrossRef]

- Bulakhe, R.N.; Sahoo, S.; Nguyen, T.T.; Lokhande, C.D.; Roh, C.; Lee, Y.R.; Shim, J.-J. Chemical synthesis of 3D copper sulfide with different morphologies for high performance supercapacitors application. RSC Adv. 2016, 6, 14844–14851. [Google Scholar] [CrossRef]

- Kumbhar, V.S.; Lee, Y.R.; Ra, C.S.; Tuma, D.; Min, B.-K.; Shim, J.-J. Modified chemical synthesis of MnS nanoclusters on nickel foam for high performance all-solid-state asymmetric supercapacitors. RSC Adv. 2017, 7, 16348–16359. [Google Scholar] [CrossRef]

- Zhang, X.; Shi, F.; Niu, J.; Jiang, Y.; Wang, Z. Superhydrophobic surfaces: From structural control to functional application. J. Mater. Chem. 2008, 18, 621–633. [Google Scholar] [CrossRef]

- Wang, S.; Li, K.; Zhai, R.; Wang, H.; Hou, Y.; Yan, H. Synthesis of metastable γ-manganese sulfide crystallites by microwave irradiation. Mater. Chem. Phys. 2005, 91, 298–300. [Google Scholar] [CrossRef]

- Lokhande, C.D.; Ennaoui, A.; Patil, P.S.; Giersig, M.; Muller, M.; Diesner, K.; Tributsch, H. Process and characterisation of chemical bath deposited manganese sulphide (MnS) thin films. Thin Solid Films 1998, 330, 70–75. [Google Scholar] [CrossRef]

- Jandová, J.; Lisá, K.; Vu, H.; Vranka, F. Separation of copper and cobalt-nickel sulphide concentrates during processing of manganese deep ocean nodules. Hydrometallurgy 2005, 77, 75–79. [Google Scholar] [CrossRef]

- Beltran-Huarac, J.; Resto, O.; Carpena-Nuñez, J.; Jadwisienczak, W.M.; Fonseca, L.F.; Weiner, B.R.; Morell, G. Single-Crystal γ-MnS Nanowires Conformally Coated with Carbon. ACS Appl. Mater. Interfaces 2014, 6, 1180–1186. [Google Scholar] [CrossRef] [PubMed]

- Ji, J.; Zhang, L.L.; Ji, H.; Li, Y.; Zhao, X.; Bai, X.; Fan, X.; Zhang, F.; Ruoff, R.S. Nanoporous Ni(OH)2 Thin Film on 3D Ultrathin-Graphite Foam for Asymmetric Supercapacitor. ACS Nano 2013, 7, 6237–6243. [Google Scholar] [CrossRef]

- Pu, J.; Cui, F.; Chu, S.; Wang, T.; Sheng, E.; Wang, Z. Preparation and Electrochemical Characterization of Hollow Hexagonal NiCo2S4 Nanoplates as Pseudocapacitor Materials. ACS Sustain. Chem. Eng. 2014, 2, 809–815. [Google Scholar] [CrossRef]

- Wang, Z.; Xiao, S.; An, Y.; Long, X.; Zheng, X.; Lu, X.; Tong, Y.; Yang, S. Co(II)1–xCo(0)x/3Mn(III)2x/3S Nanoparticles Supported on B/N-Codoped Mesoporous Nanocarbon as a Bifunctional Electrocatalyst of Oxygen Reduction/Evolution for High-Performance Zinc-Air Batteries. ACS Appl. Mater. Interfaces 2016, 8, 13348–13359. [Google Scholar] [CrossRef]

- Fujiwara, M.; Matsushita, T.; Ikeda, S. Evaluation of Mn3s X-ray photoelectron spectroscopy for characterization of manganese complexes. J. Electron Spectros. Relat. Phenomena 1995, 74, 201–206. [Google Scholar] [CrossRef]

- Li, Y.; Wang, H.; Xie, L.; Liang, Y.; Hong, G.; Dai, H. MoS2 Nanoparticles Grown on Graphene: An Advanced Catalyst for the Hydrogen Evolution Reaction. J. Am. Chem. Soc. 2011, 133, 7296–7299. [Google Scholar] [CrossRef]

- Wang, X.; Kolen’ko, Y.V.; Bao, X.-Q.; Kovnir, K.; Liu, L. One-Step Synthesis of Self-Supported Nickel Phosphide Nanosheet Array Cathodes for Efficient Electrocatalytic Hydrogen Generation. Angew. Chem. Int. Ed. 2015, 54, 8188–8192. [Google Scholar] [CrossRef]

- Zheng, Y.; Jiao, Y.; Zhu, Y.; Li, L.H.; Han, Y.; Chen, Y.; Du, A.; Jaroniec, M.; Qiao, S.Z. Hydrogen evolution by a metal-free electrocatalyst. Nat. Commun. 2014, 5, 3783. [Google Scholar] [CrossRef] [PubMed]

- Lukowski, M.A.; Daniel, A.S.; Meng, F.; Forticaux, A.; Li, L.; Jin, S. Enhanced Hydrogen Evolution Catalysis from Chemically Exfoliated Metallic MoS2 Nanosheets. J. Am. Chem. Soc. 2013, 135, 10274–10277. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Cheng, H.; Zhao, Y.; Hu, Y.; Liu, Y.; Dai, L.; Qu, L. Newly-Designed Complex Ternary Pt/PdCu Nanoboxes Anchored on Three-Dimensional Graphene Framework for Highly Efficient Ethanol Oxidation. Adv. Mater. 2012, 24, 5493–5498. [Google Scholar] [CrossRef] [PubMed]

- Gong, K.; Du, F.; Xia, Z.; Durstock, M.; Dai, L. Nitrogen-Doped Carbon Nanotube Arrays with High Electrocatalytic Activity for Oxygen Reduction. Science 2009, 323, 760–764. [Google Scholar] [CrossRef] [PubMed]

- Qu, L.; Liu, Y.; Baek, J.-B.; Dai, L. Nitrogen-Doped Graphene as Efficient Metal-Free Electrocatalyst for Oxygen Reduction in Fuel Cells. ACS Nano 2010, 4, 1321–1326. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).