Ru-Promoted Ni/Al2O3 Fluidized Catalyst for Biomass Gasification

Abstract

1. Introduction

2. Biomass Gasification Reaction Network

3. Results and Discussion

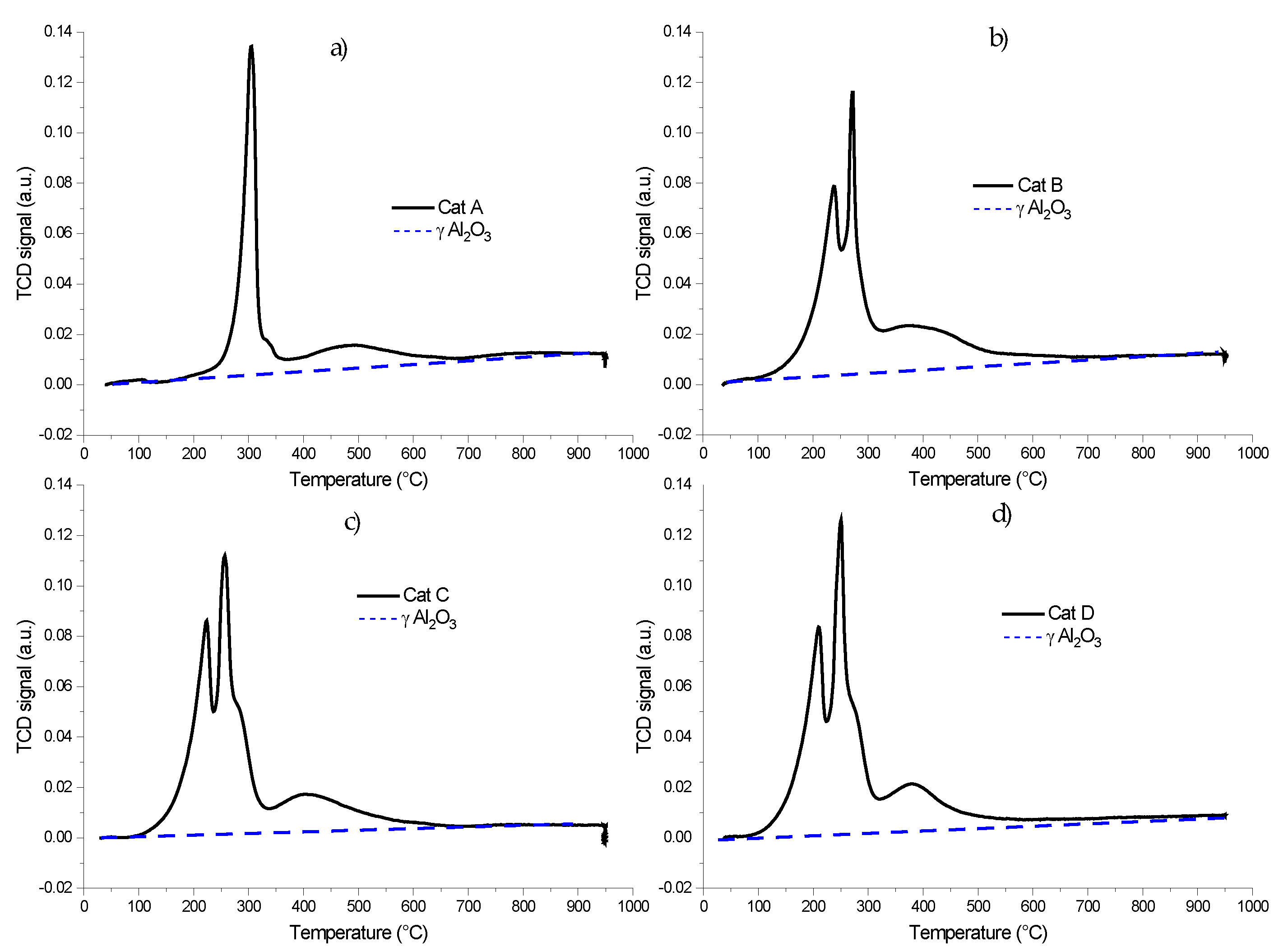

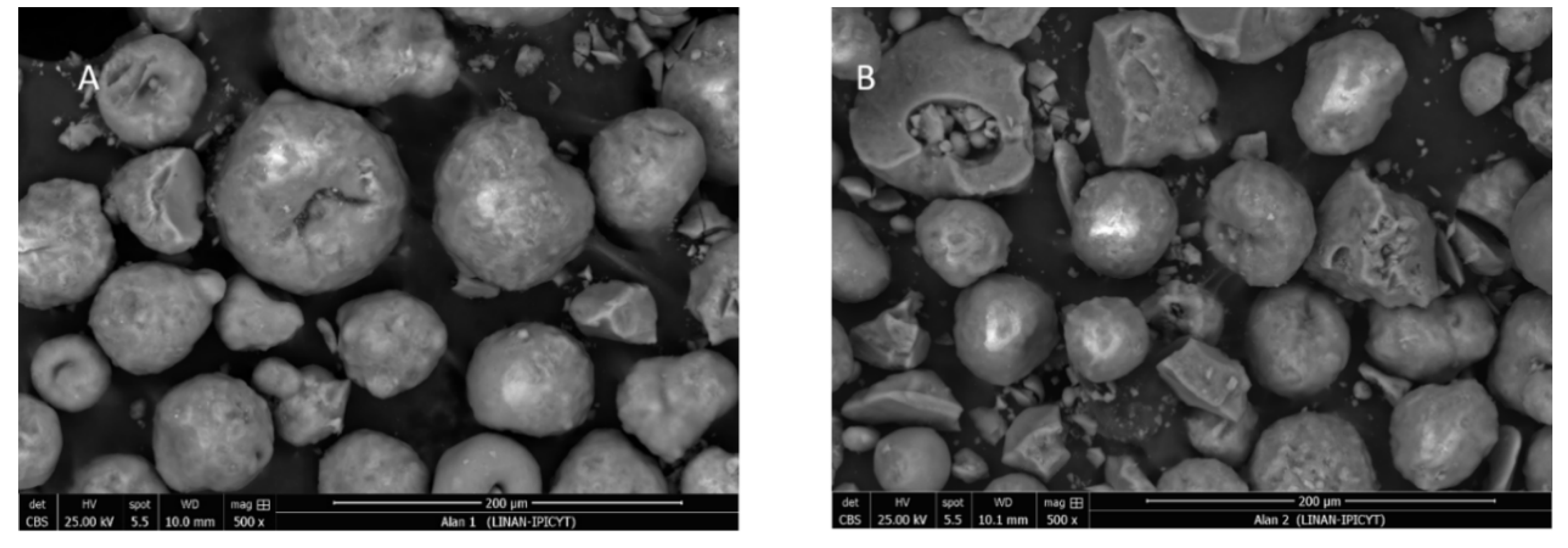

3.1. Catalyst Characterization

3.2. Gasification Results

4. Materials and Methods

4.1. Catalysts Preparation

4.2. Catalyst Characterization

4.3. CREC Riser Simulator

5. Conclusions

- (a)

- The Ru-promoted Ni catalyst supported on γAl2O3 of the present study is suitable for lignin surrogate steam gasification, displaying an 80% 2M4MP conversion at 600 °C in a CREC Riser Simulator;

- (b)

- The 5% Ni-0.25% Ru/γAl2O3 catalyst displays adequate physicochemical properties in terms of specific surface areas (larger than 190 m2/g), reducible nickel (bigger than 3%), reducible ruthenium (bigger than 3%) and a decrease of acidity by 6%, with metal addition;

- (c)

- The addition of Ru increases Ni reducibility (34%) on the catalyst and promotes, as a result, an Ni spillover;

- (d)

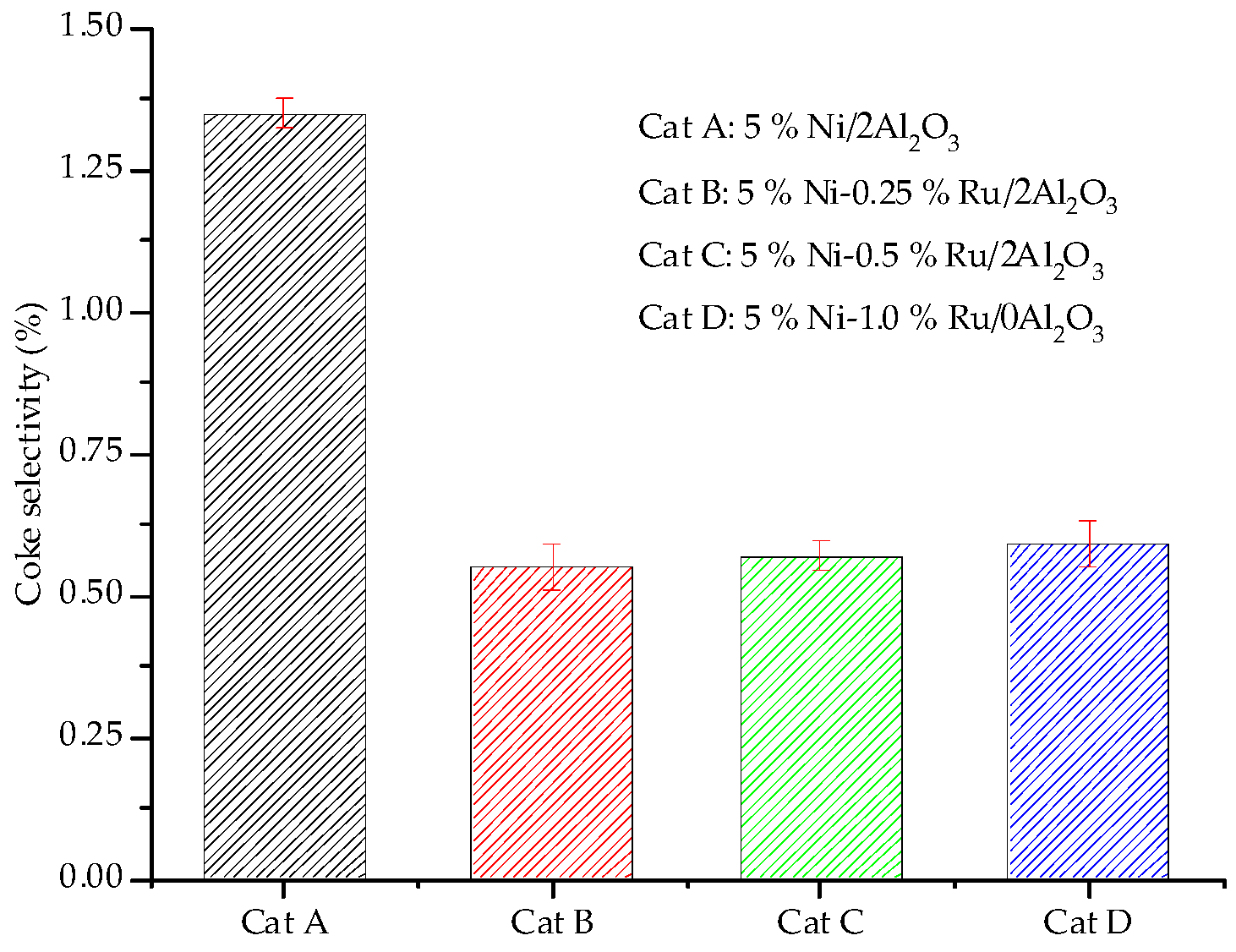

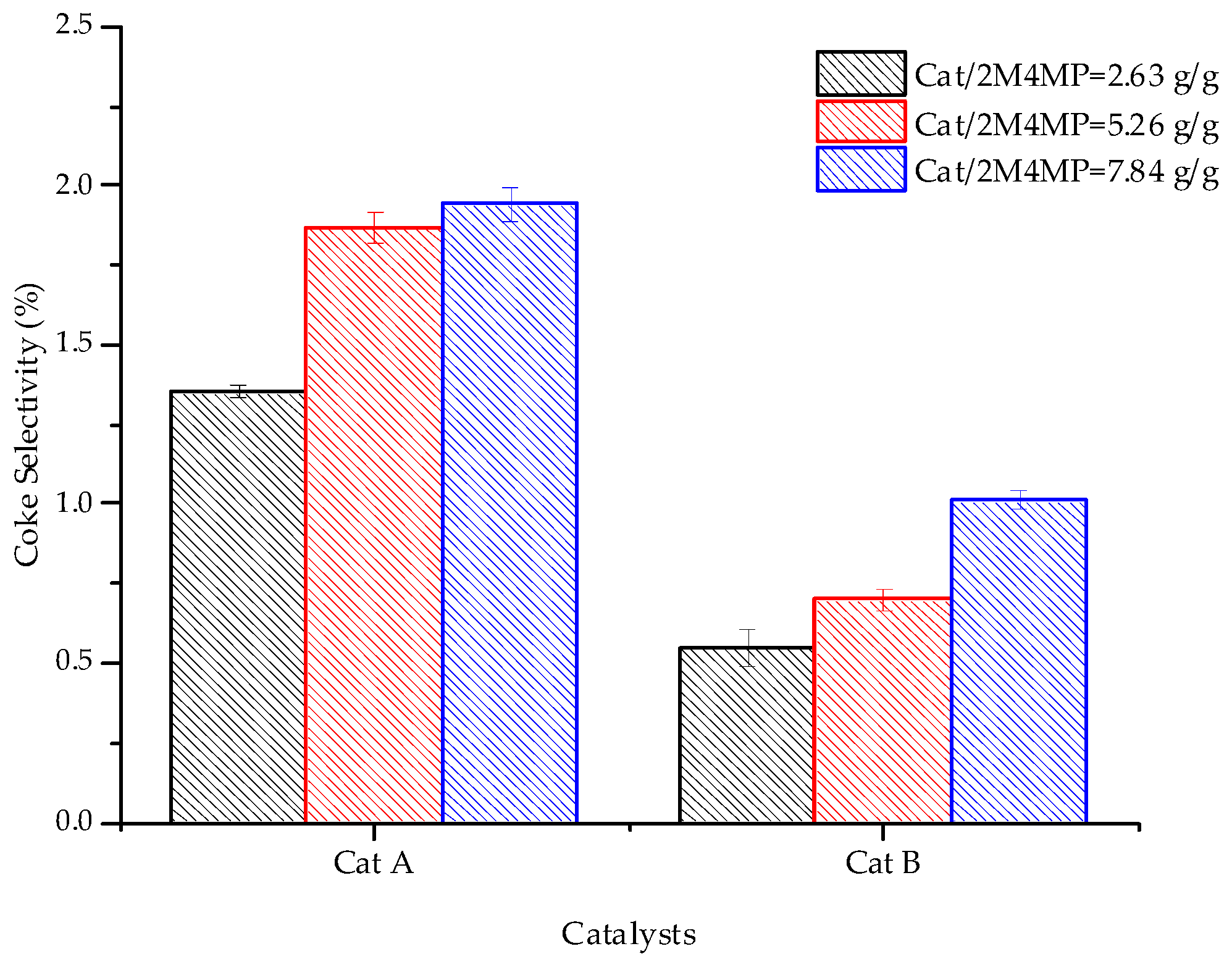

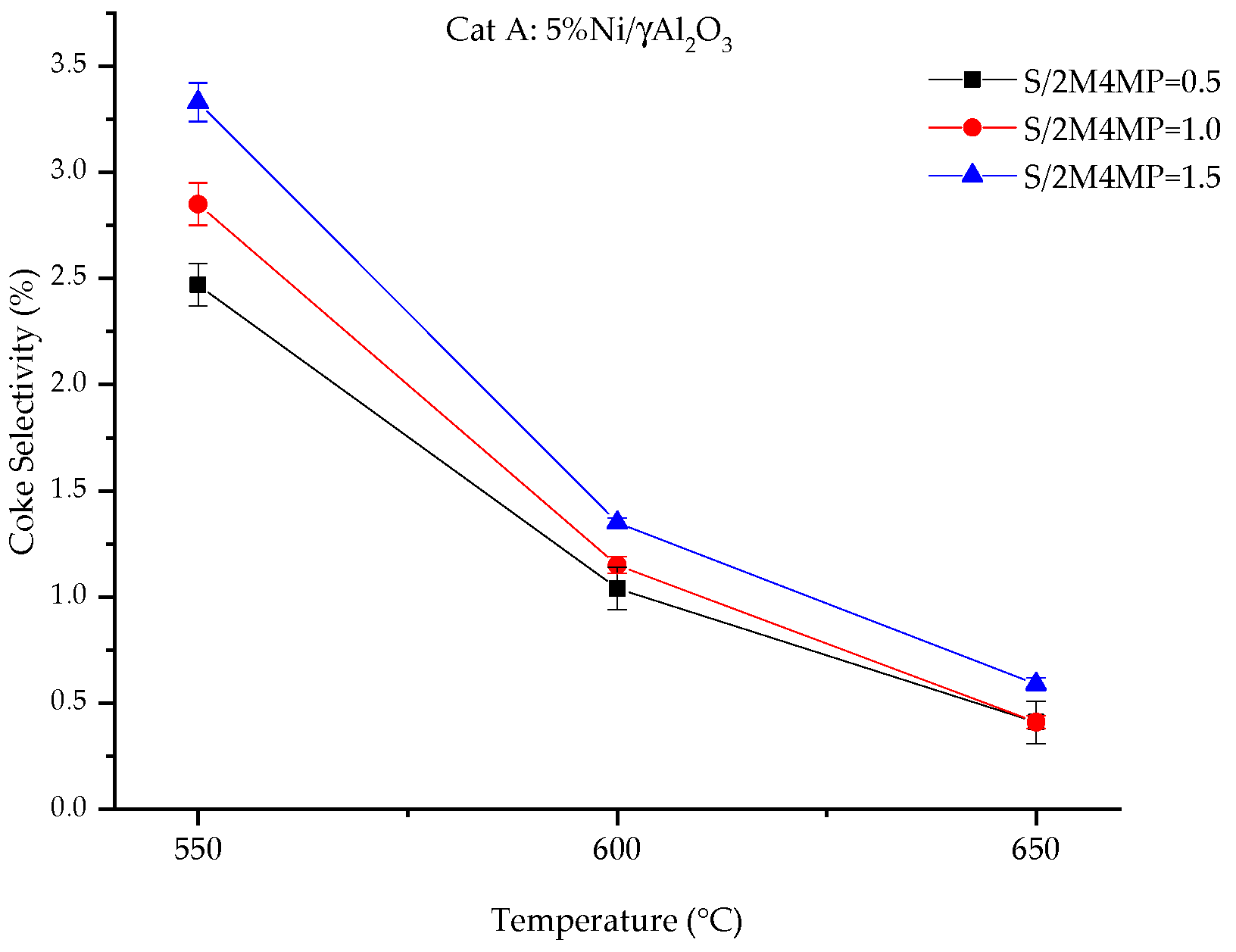

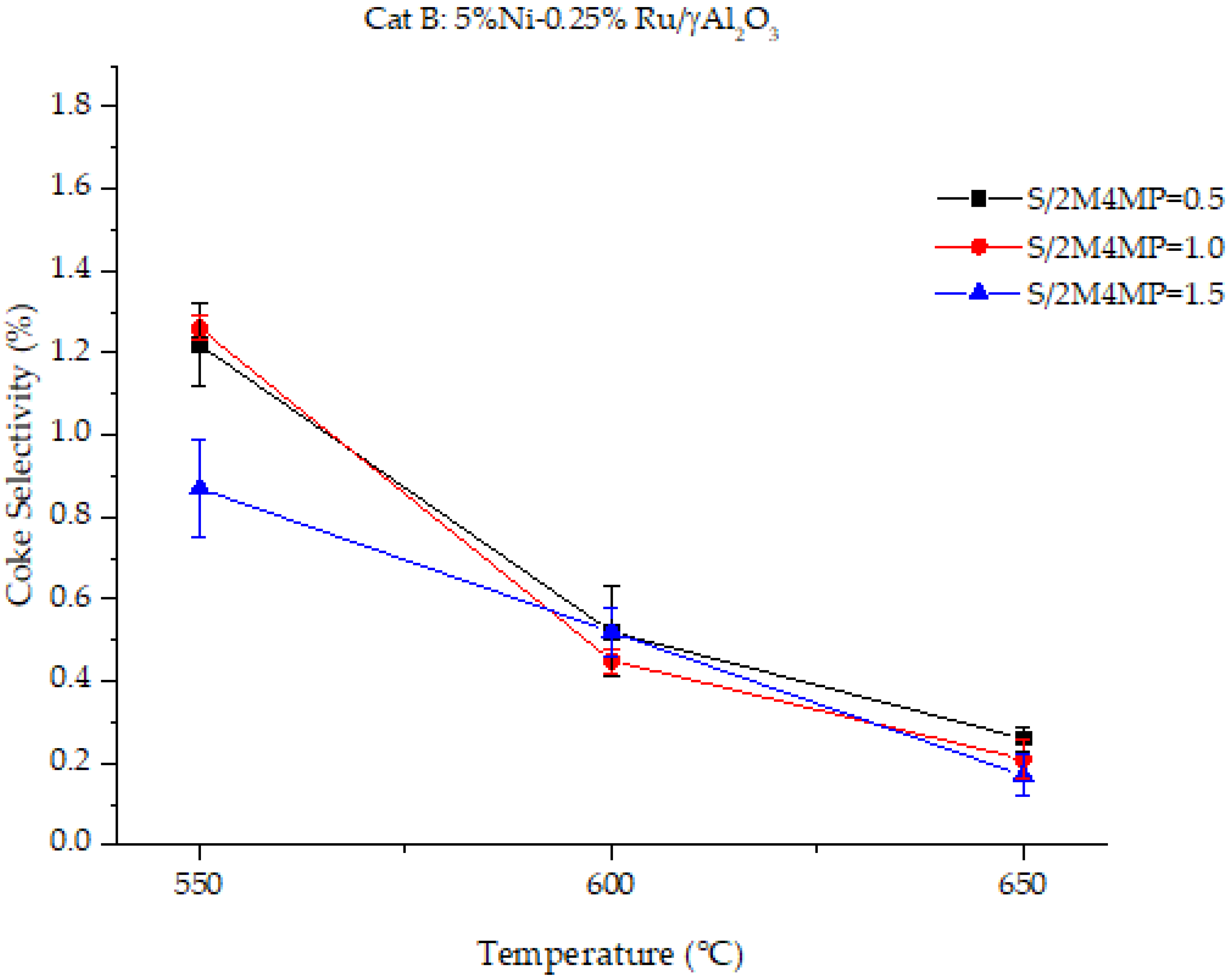

- The Ru on Ni/γAl2O3 catalyst reduces coke selectivity (60%), with this being more significant at the higher temperatures studied. This indicates that Ni with added Ru likely promotes char gasification and the Boudouard reaction. This was consistent with the acid site reduction observed with Ru addition;

- (e)

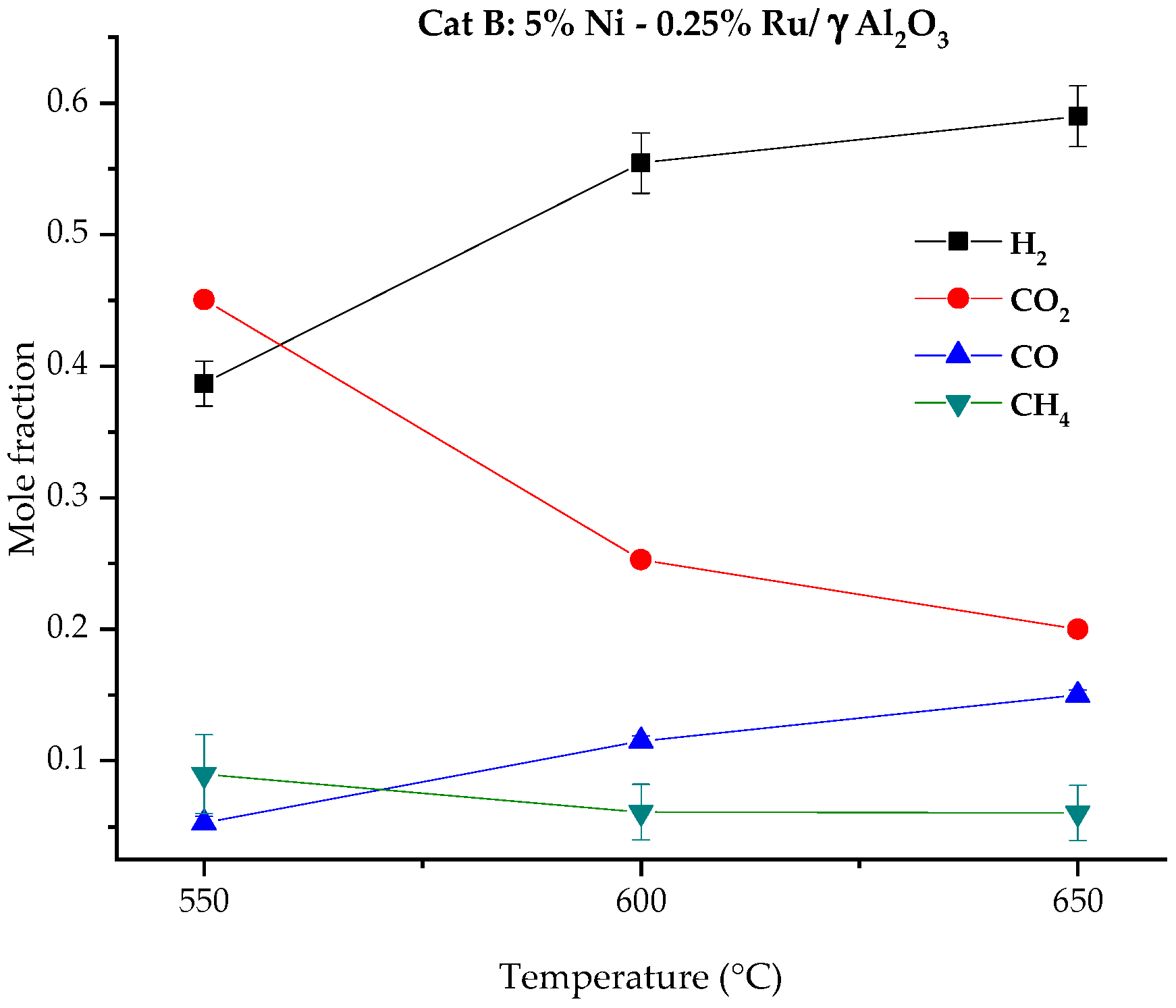

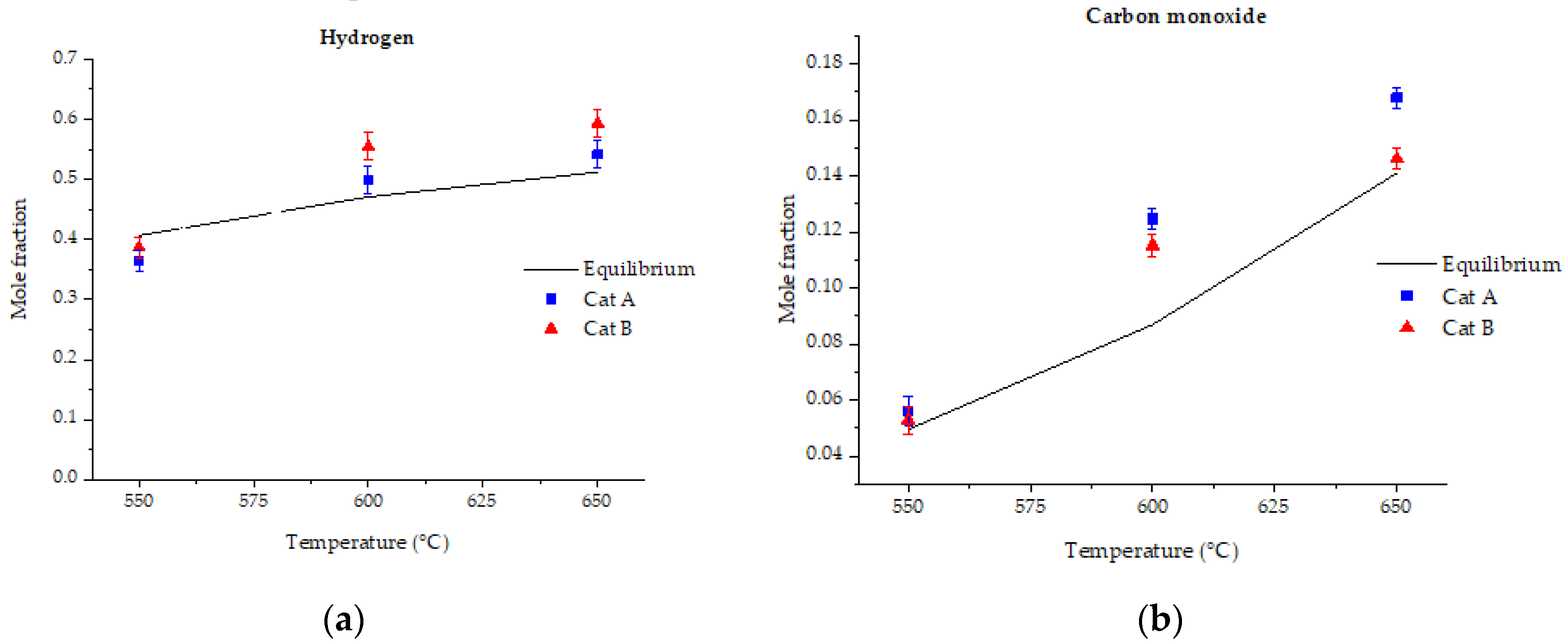

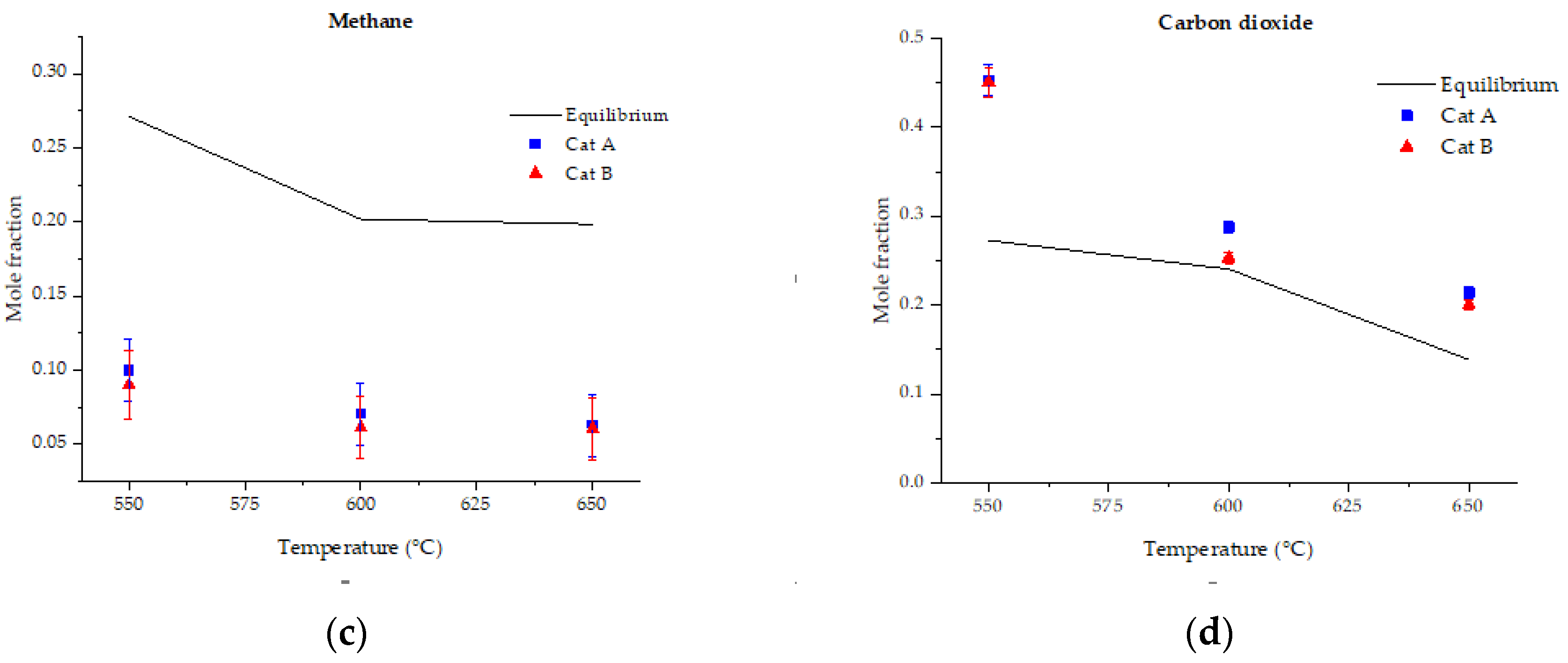

- The H2, CO2 and CO yields remain for all catalysts studied, at supra-equilibrium levels with methane remaining, however, significantly below chemical equilibrium. This finding is assigned to the significant role of methane reforming;

- (f)

- A Ru addition above 0.25 wt. % Ru does not improve further hydrogen mole fractions but decrease in CO2;

- (g)

- Increased loading of Cat A (5% Ni/γAl2O3) and Cat B (5% Ni-0.25% Ru/γAl2O3) in the CREC Riser Simulator leads to unchanged gas phase product fractions, only slightly increasing the coke deposited;

- (h)

- For both Cat A (5% Ni/γAl2O3) and Cat B (5% Ni-0.25% Ru/γAl2O3), the temperature effect on product mole fractions is similar with the water–gas shift reaction and methane reforming, leading to a CO2 reduction and a CO increase.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

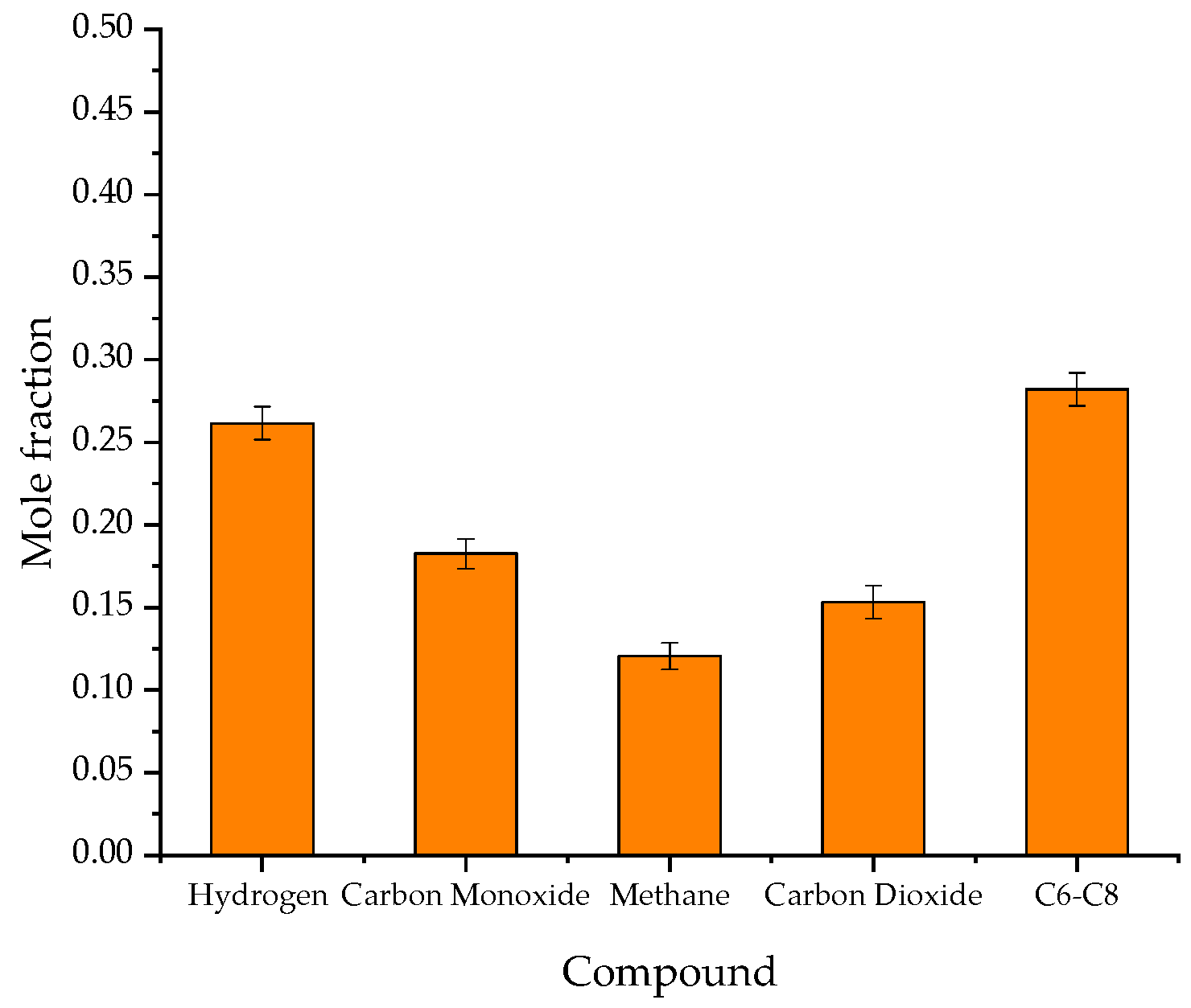

Appendix A. 2M4MP Thermal Gasification

Appendix B. Product Mole Fractions at Different Temperatures for Cat A and Cat B

References

- Mao, G.; Huang, N.; Chen, L.; Wang, H. Research on biomass energy and environment from the past to the future: A bibliometric analysis. Sci. Total Environ. 2018, 635, 1081–1090. [Google Scholar] [CrossRef] [PubMed]

- Nunes, L.J.R.; Causer, T.P.; Ciolkosz, D. Biomass for energy: A review on supply chain management models. Renew. Sustain. Energy Rev. 2020, 120, 109658. [Google Scholar] [CrossRef]

- Ren, J.; Cao, J.-P.; Zhao, X.-Y.; Yang, F.-L.; Wei, X.-Y. Recent advances in syngas production from biomass catalytic gasification: A critical review on reactors, catalysts, catalytic mechanisms and mathematical models. Renew. Sustain. Energy Rev. 2019, 116, 109426. [Google Scholar] [CrossRef]

- Li, D.; Tamura, M.; Nakagawa, Y.; Tomishige, K. Metal catalysts for steam reforming of tar derived from the gasification of lignocellulosic biomass. Bioresour. Technol. 2015, 178, 53–64. [Google Scholar] [CrossRef]

- Guan, G.; Kaewpanha, M.; Hao, X.; Abudula, A. Catalytic steam reforming of biomass tar: Prospects and challenges. Renew. Sustain. Energy Rev. 2016, 58, 450–461. [Google Scholar] [CrossRef]

- Guan, G.; Chen, G.; Kasai, Y.; Lim, E.W.C.; Hao, X.; Kaewpanha, M.; Abuliti, A.; Fushimi, C.; Tsutsumi, A. Catalytic steam reforming of biomass tar over iron- or nickel-based catalyst supported on calcined scallop shell. Appl. Catal. B Environ. 2012, 115, 159–168. [Google Scholar] [CrossRef]

- De Lasa, H.; Salaices, E.; Mazumder, J.; Lucky, R. Catalytic Steam Gasification of Biomass: Catalysts, Thermodynamics and Kinetics. Chem. Rev. 2011, 111, 5404–5433. [Google Scholar] [CrossRef]

- Mazumder, J.; de Lasa, H.I. Catalytic steam gasification of biomass surrogates: Thermodynamics and effect of operating conditions. Chem. Eng. J. 2016, 293, 232–242. [Google Scholar] [CrossRef]

- Vera, D.; Jurado, F.; Carpio, J.; Kamel, S. Biomass gasification coupled to an EFGT-ORC combined system to maximize the electrical energy generation: A case applied to the olive oil industry. Energy 2018, 144, 41–53. [Google Scholar] [CrossRef]

- Claude, V.; Courson, C.; Köhler, M.; Lambert, S.D. Overview and Essentials of Biomass Gasification Technologies and Their Catalytic Cleaning Methods. Energy Fuels 2016, 30, 8791–8814. [Google Scholar] [CrossRef]

- Abu El-Rub, Z.; Bramer, E.A.; Brem, G. Review of Catalysts for Tar Elimination in Biomass Gasification Processes. Ind. Eng. Chem. Res. 2004, 43, 6911–6919. [Google Scholar] [CrossRef]

- Ashok, J.; Kathiraser, Y.; Ang, M.L.; Kawi, S. Bi-functional hydrotalcite-derived NiO–CaO–Al2O3 catalysts for steam reforming of biomass and/or tar model compound at low steam-to-carbon conditions. Appl. Catal. B Environ. 2015, 172, 116–128. [Google Scholar] [CrossRef]

- Mazumder, J.; de Lasa, H.I. Ni catalysts for steam gasification of biomass: Effect of La2O3 loading. Catal. Today 2014, 237, 100–110. [Google Scholar] [CrossRef]

- Xiao, X.; Liu, J.; Gao, A.; Zhouyu, M.; Liu, B.; Gao, M.; Zhang, X.; Lu, Q.; Dong, C. The performance of nickel-loaded lignite residue for steam reforming of toluene as the model compound of biomass gasification tar. J. Energy Inst. 2018, 91, 867–876. [Google Scholar] [CrossRef]

- Liu, H.; Wang, B.; Fan, M.; Henson, N.; Zhang, Y.; Towler, B.F.; Gordon Harris, H. Study on carbon deposition associated with catalytic CH4 reforming by using density functional theory. Fuel 2013, 113, 712–718. [Google Scholar] [CrossRef]

- Lee, S.; Bae, M.; Bae, J.; Katikaneni, S.P. Ni–Me/Ce0.9Gd0.1O2−x (Me: Rh, Pt and Ru) catalysts for diesel pre-reforming. Int. J. Hydrog. Energy 2015, 40, 3207–3216. [Google Scholar] [CrossRef]

- Crisafulli, C.; Scirè, S.; Maggiore, R.; Minicò, S.; Galvagno, S. CO2 reforming of methane over Ni–Ru and Ni–Pd bimetallic catalysts. Catal. Lett. 1999, 59, 21–26. [Google Scholar] [CrossRef]

- Iida, H.; Fujiyama, A.; Igarashi, A.; Okumura, K. Steam reforming of toluene over Ru/SrCO3-Al2O3 catalysts. Fuel Process. Technol. 2017, 168, 50–57. [Google Scholar] [CrossRef]

- Katheria, S.; Deo, G.; Kunzru, D. Rh-Ni/MgAl2O4 catalyst for steam reforming of methane: Effect of Rh doping, calcination temperature and its application on metal monoliths. Appl. Catal. A Gen. 2019, 570, 308–318. [Google Scholar] [CrossRef]

- Tomishige, K.; Asadullah, M.; Kunimori, K. Syngas production by biomass gasification using Rh/CeO2/SiO2 catalysts and fluidized bed reactor. Catal. Today 2004, 89, 389–403. [Google Scholar] [CrossRef]

- Zhang, R.; Liu, H.; Li, Q.; Wang, B.; Ling, L.; Li, D. Insight into the role of the promoters Pt, Ru and B in inhibiting the deactivation of Co catalysts in Fischer-Tropsch synthesis. Appl. Surf. Sci. 2018, 453, 309–319. [Google Scholar] [CrossRef]

- Li, S.; Gong, D.; Tang, H.; Ma, Z.; Liu, Z.-T.; Liu, Y. Preparation of bimetallic Ni@Ru nanoparticles supported on SiO2 and their catalytic performance for CO methanation. Chem. Eng. J. 2018, 334, 2167–2178. [Google Scholar] [CrossRef]

- González, C.D.G.; Sanchez, E.A.; Cruz, R.I.; Calzada, H.A.R.; Serrano, R.B. Catalytic Steam Gasification of Glucose for Hydrogen Production Using Stable Based Ni on a γ–Alumina Fluidizable Catalyst. Int. J. Chem. React. Eng. 2019, 17. [Google Scholar] [CrossRef]

- Mazumder, J.; de Lasa, H.I. Fluidizable La2O3 promoted Ni/γ-Al2O3 catalyst for steam gasification of biomass: Effect of catalyst preparation conditions. Appl. Catal. B Environ. 2015, 168, 250–265. [Google Scholar] [CrossRef]

- Sharma, S.; Hines, L. Oxidation of Ruthenium. IEEE Trans. Compon. Hybrids Manuf. Technol. 1983, 6, 89–92. [Google Scholar] [CrossRef]

- Mazumder, J.; de Lasa, H.I. Steam gasification of a cellulosic biomass surrogate using a Ni/La2O3-γAl2O3 catalyst in a CREC fluidized riser simulator. Kinetics and model validation. Fuel 2018, 216, 101–109. [Google Scholar] [CrossRef]

| Catalysts | SBET (m2/g) | Pore Size (A) |

|---|---|---|

| γAl2O3 | 191 | 110.2 ± 16 |

| Cat A: 5%Ni/γAl2O3 | 182.3 | 108.4 ± 15 |

| Cat B: 5%Ni-0.25%Ru/γAl2O3 | 190.7 | 105.6 ± 10 |

| Cat C: 5%Ni-0.5%Ru/γAl2O3 | 194.8 | 100 ± 14 |

| Cat D: 5%Ni-1.0%Ru/γAl2O3 | 194.9 | 104.6 ± 12 |

| Catalysts | H2 Consumption (cm3/g STP) | Reducible Ni (wt. %) | H2 Consumption (cm3/g STP) | Reducible Ru (wt. %) |

|---|---|---|---|---|

| Cat A: 5%Ni/γAl2O3 | 7.73 | 2.02 | ||

| Cat B: 5%Ni-0.25%Ru/γAl2O3 | 10.12 | 2.71 | 2.2 | 0.33 |

| Cat C: 5%Ni-0.5%Ru/γAl2O3 | 12.07 | 3.16 | 3.21 | 0.48 |

| Cat D: 5%Ni-1.0%Ru/γAl2O3 | 14.86 | 3.89 | 4.13 | 0.77 |

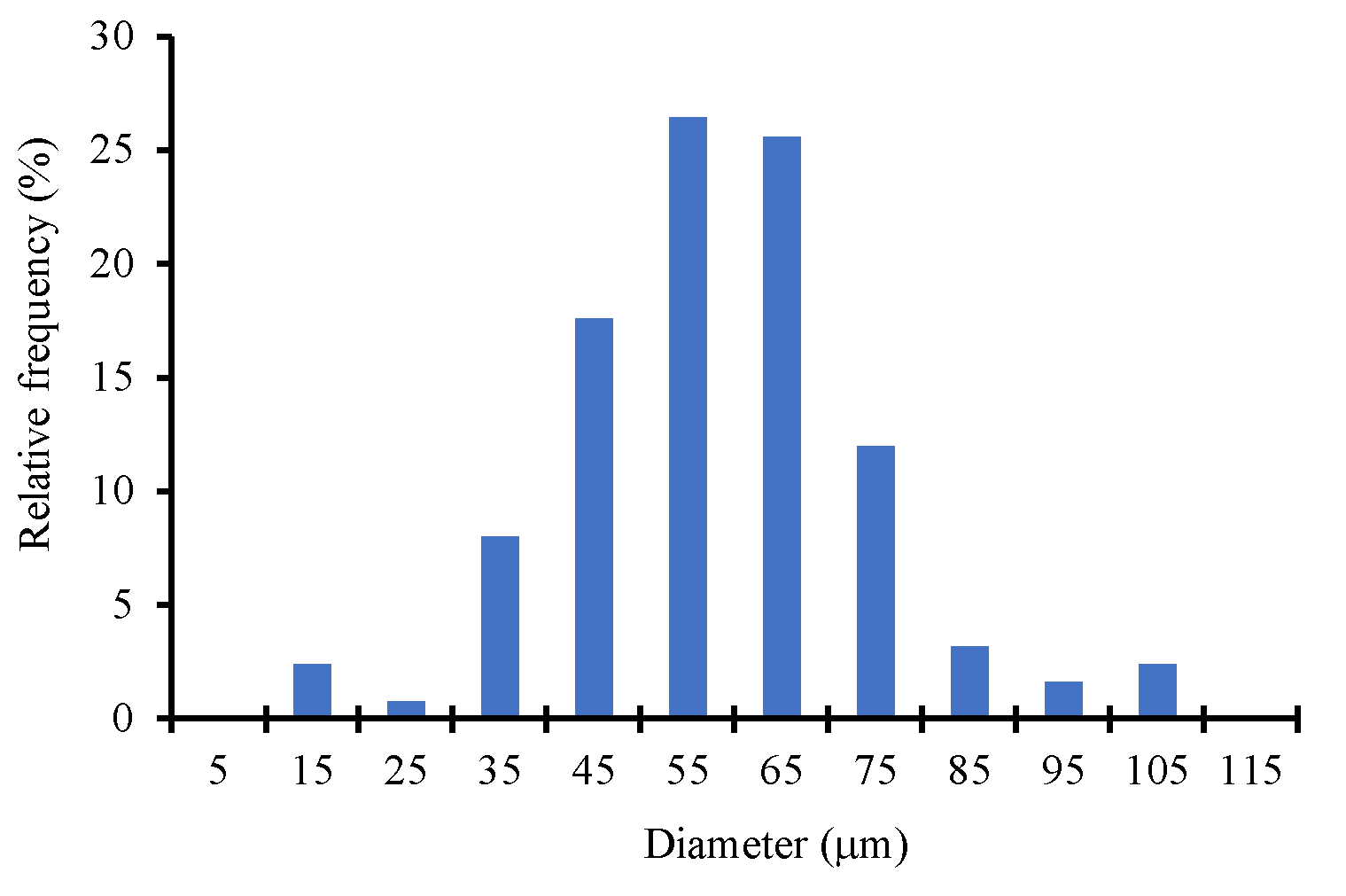

| Catalyst | Particle Size (μm) | wt. % of Ni |

|---|---|---|

| Cat A: 5%Ni/γAl2O3 | 58.6 | 5.7 |

| Cat B: 5%Ni-0.25%Ru/γAl2O3 | 54.6 | 4.2 |

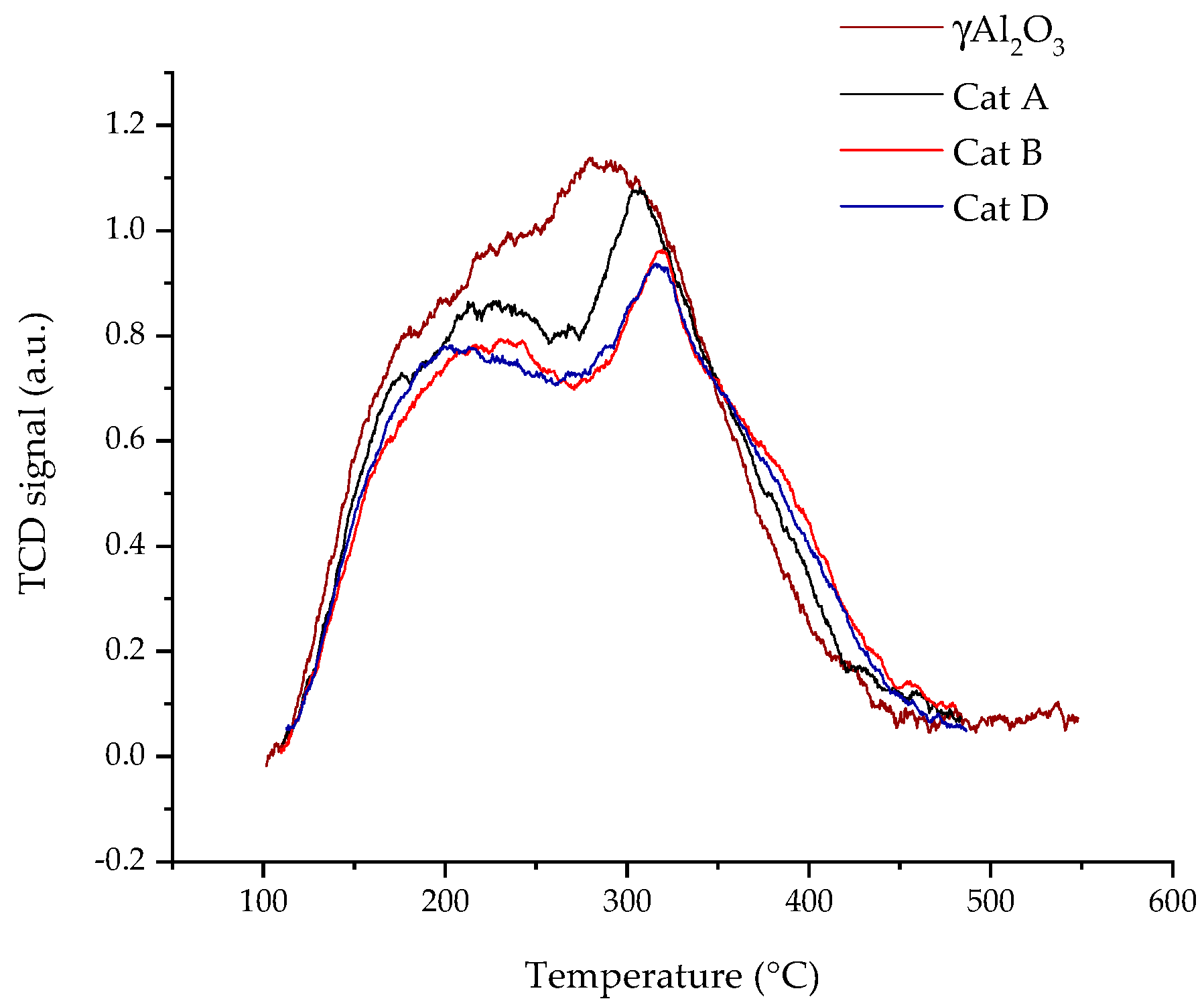

| Catalyst | Acid Sites (µmole/g) | ||

|---|---|---|---|

| Weak (25–200 °C) | Medium (200–400 °C) | Total | |

| γ-Al2O3 | 42.3 | 192.4 | 234.7 |

| Cat A: 5%Ni/γAl2O3 | 64 | 149.3 | 213.3 |

| Cat B: 5%Ni-0.25%Ru/γAl2O3 | 54.6 | 138.7 | 193.3 |

| Cat D: 5%Ni-1.0%Ru/γAl2O3 | 54.3 | 136 | 190.3 |

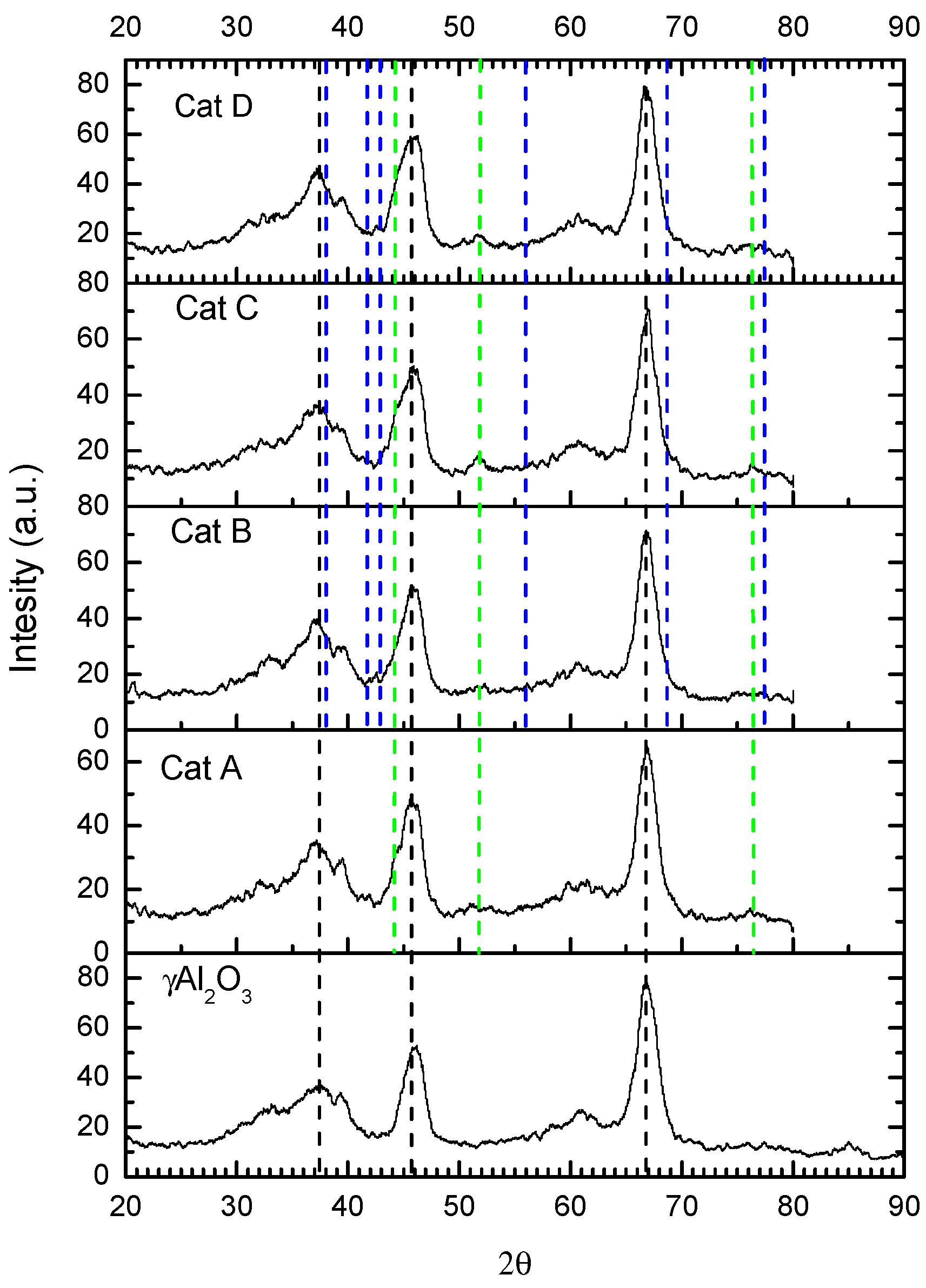

| Catalysts | Metal Dispersion (%) | Ni–Crystallite Size (nm) |

|---|---|---|

| Cat A: 5%Ni/γAl2O3 | 3.9 ± 0.1 | 21.7 ± 0.54 |

| Cat B: 5%Ni-0.25%Ru/γAl2O3 | 8.7 ± 0.1 | 9.7 ± 0.7 |

| Cat C: 5%Ni-0.5%Ru/γAl2O3 | 5.9 ± 1.2 | 14.38 ± 2.9 |

| Cat D: 5%Ni-1.0%Ru/γAl2O3 | 5.1 ± 0.1 | 16.5 ± 0.33 |

| Experiment | 2M4MP Conversion (%) |

|---|---|

| Thermal runs | 50 ± 5.5 |

| Catalysts A,B,C,D | 80 ± 3.5 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Calzada Hernandez, A.R.; Gibran González Castañeda, D.; Sánchez Enriquez, A.; de Lasa, H.; Serrano Rosales, B. Ru-Promoted Ni/Al2O3 Fluidized Catalyst for Biomass Gasification. Catalysts 2020, 10, 316. https://doi.org/10.3390/catal10030316

Calzada Hernandez AR, Gibran González Castañeda D, Sánchez Enriquez A, de Lasa H, Serrano Rosales B. Ru-Promoted Ni/Al2O3 Fluidized Catalyst for Biomass Gasification. Catalysts. 2020; 10(3):316. https://doi.org/10.3390/catal10030316

Chicago/Turabian StyleCalzada Hernandez, Alan Rubén, Daniel Gibran González Castañeda, Adriana Sánchez Enriquez, Hugo de Lasa, and Benito Serrano Rosales. 2020. "Ru-Promoted Ni/Al2O3 Fluidized Catalyst for Biomass Gasification" Catalysts 10, no. 3: 316. https://doi.org/10.3390/catal10030316

APA StyleCalzada Hernandez, A. R., Gibran González Castañeda, D., Sánchez Enriquez, A., de Lasa, H., & Serrano Rosales, B. (2020). Ru-Promoted Ni/Al2O3 Fluidized Catalyst for Biomass Gasification. Catalysts, 10(3), 316. https://doi.org/10.3390/catal10030316