1. Introduction

Biosurfactants show diverse applications in the fields of biomedical, food, cosmetic, agriculture and bioremediation [

1], among others, mainly due to their low toxicity, high biodegradability, and multifunctionality. For example, in food, they are used as emulsifiers and preservatives [

2]; in cosmetics, they are used due to their lower moisturizing properties and skin compatibility [

3]; and in agriculture, they are used to dilute and disperse other compounds like fertilizers [

2]. Moreover, among biosurfactants, cationic surfactants are a group that have the capability to disrupt bacterial membranes by combining hydrophobic and electrostatic adsorption [

4]. Additionally, due to its detergent-like features, they also compromise the adhesion of pathogenic organisms to the surfaces, proving effective in preventing colonization and infection when used as, for example, a coating in medical insertional materials [

3].

Gemini biosurfactants are dimers of the simpler one chained structures with one polar group (

Figure 1). This class of amphipathic compounds shows a higher surface activity when compared to single chain structures or conventional surfactants [

5], high solubilizing, wetting, foaming capacities, antimicrobial and lime soap dispersion [

5]. The supramolecular organization of gemini structures depends on the spacer length, valency, head group size, and tail length. Studies [

6] have shown that the spacer length for a good gene vehicle is six methylene groups: two nitrogen atoms prone to be protonated, two unsaturated alkyl tails, and a hydrophilic sugar head.

Lipoaminoacid (LAA) surfactants are gemini biosurfactants formed by a polar head, the amino acid, and a chain of hydrocarbon alkyl as the hydrophobic moiety [

5,

7]. They can be synthesized from acidic, basic, or neutral amino acids such as glutamate, glycine, alanine, arginine, aspartate, leucine, serine, proline, or even from protein hydrolysates [

8]. The amino acid head defines properties like adsorption, aggregation, and biological activity [

5]. In the medical sector, many lipoamino acid/peptides are known to have antibiotic, antiviral [

9], or even antitumor activity, and to have the ability to modulate the immune system or inhibit some enzymes and toxins [

3]. Additionally, the combination of LAA activity with nucleic acids and the ability to form complex aggregates are promising candidates in the field of gene therapies as a new vehicle for delivery inside the cell [

4]. Spontaneous formation of complexes between cationic lipids and DNA are called lipoplexes and have special interaction features with the plasma membrane due to electrostatic interactions, facilitating adsorption [

10,

11]. The arrangement of lipoplexes is identified by combining small-angle x-ray scattering and electron microscopy [

11,

12]. Studies have revealed that gemini structure surfactants show a greater efficiency compacting DNA [

2,

6] than other biosurfactants.

The critical micellar concentration (CMC) is a parameter related to hydrophobicity [

5] that represents the concentration above which monomeric surfactant molecules assemble into aggregates, called micelles [

13]. The CMC levels for gemini structures are up to two orders of magnitude lower than the respective linear surfactant [

5], which therefore increases their efficiency in reducing the surface tension of water [

9].

Biosurfactants can be produced through a biosynthetic process, using more competitive substrates that are eco-friendly, biodegradable [

14], and show low toxicity, among others properties [

9]. In fact, a biocatalytic process offers several advantages such as mild reaction conditions, selectivity, direct performance of a reaction on a substrate, reduced or inexistent toxic sub-products, which consequently has better results in product separation and purification [

7]. Lipases are biocatalysts that do not need cofactors, are not too costly, thus they contribute to make the overall process less expensive than conventional chemistry and all the costs associated with time to industry.

In the context of this work, a gemini LAA was developed by the enzymatic route with lipases using a cystine based approach.

Lipases are naturally involved in lipid and protein metabolism and are currently one of the most widely used enzymes in biotechnology [

15,

16,

17]. Lipases (EC 3.1.1.3, triacylglycerol lipase) are water-soluble hydrolases, which can be found in animals, plants, and microorganisms [

18]. In the catalytic domain of these enzymes can be found the active site and lipid binding determinants. At the core of this catalytic domain, there is an α/β-hydrolase fold, which basically translates into a motif of β-sheets connected by α-helices, chemically similar but structurally different to what is found in serine proteases [

18] and supporting a catalytic triad of Ser-His-Glu/Asp [

19]. The serine is inserted in a motif of stand-turn-helix in stand β5 with unusual Φ and Ψ torsion angles. This forms a sharp turn, highly conserved due to its functional relevance, called the nucleophile elbow [

20].

Typical substrates are mainly water-insoluble apolar substrates like fats and oils, which have long hydrocarbon-like groups that are mostly flexible, and a wide variety of these molecules are accommodated in the active site of the enzyme. Specificity usually differs in preference of acyl and alkyl group size, but some, like

Rizhomucor miehei lipase (RML), have a strong stereospecificity while others, like porcine pancreatic lipase (PPL), do not [

19]. This specificity is categorized by the position of ester bonds (hydrolyzed or formed) in the substrate molecules (regioselectivity), the class of substrate accepted (chemo-selectivity), and the stereoselectivity [

20].

Organic solvents have been an option to solubilize apolar substrates, which follow some prerequisites, like (i) not being a substrate for lipase, (ii) not interfering in the reaction by inactivating the enzyme [

21], and (iii) allow easy separation from the final product. Some studies suggest that solvents with a log P lower than 3 are preferable to the bioreaction by lipases [

21]. As eutectic mixtures can be a “green” alternative to organic solvents, they can be tested in this biocatalytic system where they combine a solid organic salt, like sodium chloride, and a complexing agent, like urea or glycol [

22]. Eutectic liquids tend to cost about the same as organic solvents and because purification processes for salt removal can be discarded, the process can become even cheaper [

23]. These solvents have been shown to be appropriate for enzymatic reactions with lipases, maintaining enzyme stability and increasing activity [

22]. A high stability of the enzyme in the solvent used could allow a rise in temperature, thus, increasing the catalysis rate [

23].

The main disadvantages in the use of biocatalytic systems are the cost of some enzymes and their mixing with the final products, slow reaction rates, and the absence of optimized reactors for biphasic media catalysis [

24]. Nonetheless, the immobilization of lipases can overcome some of the drawbacks. The choice of the solid matrix is crucial to provide a good operational and thermo stability [

21]. Another requisite for immobilization is that the method should be cost-effective, reproducible, and should pay attention to the grade of the materials and equipment used [

25].

The main forms of commercial immobilized lipases are by adsorption onto polymer based matrices, nonetheless Novozymes has also developed a new and less expensive method by combining adsorption and encapsulation in silica granules. Additionally, when the immobilized particles are also magnetic, the enzyme becomes easy to recover and the overall process becomes even more productive.

Another critical point concerning the reaction, specifically involving lipase, is the conformational changes. Lipase has two different conformations, closed (inactive) and open (active), so it is very important to ensure that the enzyme is immobilized in its active form to guarantee good reactions rates [

26,

27]. The strategies to immobilize the enzyme in an active conformation are the use of hydrophobic materials or the use of detergents during the method [

28]. The use of hydrophobic matrices increases the lipase activity in most of the immobilization protocols.

The main goal of this work was the development of a new cystine derived gemini lipoaminoacid biosurfactant using an eco-friendly production system based on immobilized lipases, toward future specific applications in gene and drug delivery. To attain the main goal, specific intermediate milestones were designed, namely (i) docking studies; (ii) screening the best lipase for the biosynthesis; (iii) development of an efficient method of lipase immobilization for the biocatalytic process; (iv) effect of reaction conditions (e.g., temperature, reaction time-course and operational stability) in lipoaminoacid surfactant production; and (v) design and optimization of the bioreaction media.

3. Experimental

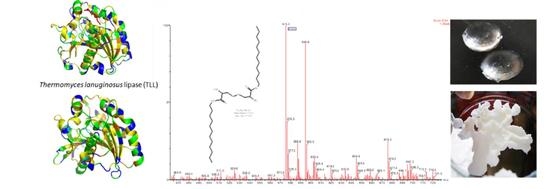

3.1. Enzymes

Three lipases were used: porcine pancreatic lipase, Type II, Crude (PPL) (Sigma-Aldrich L3126, E.C. 3.1.1.3), Lipozyme® TL IM (TLL) (from Thermomyces lanuginosus) (Novozymes), and Lipozyme® RM (RML) (from Rizhomucor miehei) (E.C. 3.1.1.1, Sigma-Aldrich, Saint Louis, MO, USA). TLL are RML are commercially immobilized forms in a macroporous ion-exchange resin, and in silica, respectively.

3.2. Substrates

L-cystine (Cys2) (Sigma-Aldrich, Saint Louis, MO, USA) (

Figure 7) and dodecylamine (Dda) (Sigma-Aldrich) (

Figure 8) were used as substrates to create the polar heads and the hydrophilic tails of the gemini surfactants, respectively.

3.3. Other Chemicals

Tris buffer (Tris-(hydroxymethiyl)aminomethane) was purchased from Merck and sodium chloride (NaCl) from Panreac. Dimethylsulfoxide (DMSO) was acquired from Carlo Erba and 2-propanol, n-hexane, and ethanol were from Merck. The eutectic mixture Dowtherm® A was purchased from Sigma-Aldrich as well as methanol, the ninhydrin reagent according to Stahl (17975), and Dragendorff reagent. Tetramethyl orthosilicate (TMOS) was bought from Fluka Analytical and the Protein Assay Dye Reagent concentrate from Bio-Rad.

Three types of buffer solutions were used: (i) Tris buffer 10 mM at pH 6, pH 8, and pH 9; (ii) Tris 10 mM combined buffer with NaCl 150 mM at pH 8 and pH 9; and (iii) acetate buffer 20 mM, pH 6.

All pH measurements were carried out using a Metrohm 744 pH meter.

3.4. Docking Studies

Cystine and dodecylamine structures were fitted to the TLL and RML active sites to evaluate their potential as substrates.

All lipases show a common hydrolase fold and a catalytic triad composed of a nucleophilic serine, which is activated via hydrogen bonds as part of a charge relay system, along with the histidine and the aspartate or glutamate residues. In this study, the structures of two lipases, TLL and RML, were used.

There are seventeen crystallographic structures available for Thermomyces lanuginosus lipase (TLL) with resolutions between 1.84 and 3 Å. The enzyme structure from the available TLL crystal structure in complex with the lauric acid (PDB code: 4KJX) at 2.7 Å resolution was retrieved from the Protein Data Bank (PDB) databank, although other available crystallographic data showed a better resolution, 4KJX was chosen because in the PDB, the enzyme is complexed with lauric acid, a low molecular-weight molecule very similar with the one in this study. The complex had two chains (A, and B). For this study, we decided to work with only the A chain.

There are four crystallographic structures available for Rhizomucor miehei triacylglyceride lipase (RML) with resolutions between 1.9 and 3 Å. In this work, we used the three dimensional 3TGL structure (3TGL uncomplexed at 1.9 Å resolution). The 3TGL structure is a single polypeptide chain with 269 residues.

The enzyme structures retrieved from the PDB databank were prepared using the protein preparation tools implemented in MOE 2018.10 software.

All crystallographic waters and other non-residue molecules were removed from the coordinate sets, hydrogen atoms were added to this reduced crystal structure, and the protein was protonated to pH 7. The enzyme was then submitted to restrained molecular mechanics refinement using the AMBER99 force field implemented in MOE software. To assess the suitability of these crystal structure-based models, a preliminary validation of the enzyme structures were carried out involving non-covalent re-docking lauric acid to the prepared TLL and RML structures with GOLD software version 5.1.0, with no restrictions on the flexibility of the linking options. For all the docking calculations, standard default settings mode was used: the number of islands was 5, population size of 100, number of operations was 100,000, a niche size of 2, and a selection pressure of 1.1. Gold Score scoring function was used to rank the ligand conformations.

3.5. Solubility Assays

The solubility of the substrates L-cystine and dodecylamine in several solvents was tested by weighing a certain mass of the compound, and progressively adding the solvent to be tested until the solution was clear. At each addition of solvent, OD 600 (optic density at 600 nm) was evaluated in order to determine the solubility curves.

The aqueous systems tested were buffer solutions of Tris 10 mM or a combination of Tris 10 mM and NaCl 150 mM, both at pH 8 and 9. The organic solvents tested were dimethylsulfoxide (DMSO), methanol, 2-propanol, n-hexane, ethanol, and the eutectic mixture Dowtherm® A.

Due to the low solubility of the substrates in water, a biphasic system of Tris (10 mM) pH 9 and n-hexane was also tested.

In these assays, the substrates were dissolved in aqueous and organic solvents to maximum concentrations. Volumes of the two solutions, respectively, cystine and dodecylamine, were combined as the stoichiometry of 1:2 (Cys:Dda). The substrates’ final concentrations (mg mL−1) were: for Cys 3.6, 2.5, 1.8, 1.3, 0.9, 0.5 and for Dda 4.6, 3.5, 2.3, 1.6, 1.2, 0.7. Tris buffer solution pH 9, was used in a final volume of 1.5 mL. The test tubes were incubated at different temperatures, respectively, 20 °C, 40 °C, 50 °C, and 60 °C.

3.6. Immobilization of PPL on Sol-Gel Lenses and Characterization

Sol-gel is a porous material and an optically transparent matrix that enables tailoring of specific necessities in simple methodologies [

42]. It has been typically used to encapsulate biomolecules [

42,

43]. In this type of entrapment, the siloxane polymer chains grow around the enzyme within an inorganic oxide network and the biocatalyst remains accessible to external species due to the pores [

42].

In this work, to create the matrix, a sol phase was first produced by adding the alkoxide precursor, tetramethyl-orthosilicate (TMOS) or tetraethyl-orthosilicate (TEOS) with water, a co-solvent and an acid or base catalyst at room temperature [

42,

43]. Other authors [

43] suggest that for lipase immobilization, TMOS allows better activity results. The metal alkoxide (≡Si–OR) then reacts with the water, initiating the sol-gel reaction [

42]. The whole process can be described as the hydrolysis of a silane precursor, followed by cross-linking condensation that causes the development of a SiO

2 matrix [

43]. The sol-gel events are described in

Table 1.

The gelation time of the sol is known [

42] to increase with the quantity of organosilane and buffer pH, but decrease with buffer concentration.

In the process of aging, or simply the drying of the material, the network cross-links and the solvent is slowly excluded from the matrix. During this stage, the support suffers internal alterations like the change of polarity, and viscosity and pore size decrease [

42]. If the shrinkage occurs too drastically, the pores collapse and the material fractures, or they became so small that can make the enzyme inaccessible [

42,

43]. To suppress this problem, additives like trehalose and glycerol can be used to better control the drying process [

43].

The methods described and optimized for other enzymes were followed, in order to apply the sol-gel immobilization process to PPL [

34].

Briefly, in an Eppendorf was added 96 mg of glycerol (98%), 70 µL of distilled water, 15 µL of HCl (80 mM), and 300 µL of TMOS. The mixture was sonicated for 20 min, at a temperature from 0 to 4 °C. In

Table 2, the concise protocols (method A and B) are described. Following the formation of the hydrogel, the shape of the lenses was created using a 96 rounded well microplate for the sol-gel.

In method A (

Table 2), the hydrogel was formed directly in the microplate well by independently pipetting 25 µL of sol solution in each one and quickly adding 25 µL of the enzyme solution. Gentle tapping on the microplate was used to unify the mixture.

At this stage, the PPL was added in solutions of three different buffers: Tris (10 mM), at both pH 6 and pH 9, and acetate (20 mM), at pH 6.

In method B (

Table 2), the sol was prepared, then 500 µL of PPL solution (in Tris and acetate buffers, pH 6) was added directly in the microtube. Finally, 50 µL of the mixture was pipetted to each microplate well. The lenses were left to dry in the uncovered microplate for a period of no less than 20 h at a controlled temperature of 24 °C.

The quality of the lenses was determined by measuring the diameter, thickness, and weight of the lenses produced by each method.

3.7. Sol-Gel Lenses Stability in Biphasic and Co-Solvent Systems

PPL lenses (B1 and B2) produced according to method B (c.f. 3.6) were incubated in a biphasic system of Tris buffer pH 9 and n-hexane, and a co-solvent system of DMSO and methanol, in order to determine the resistance of the sol-gel immobilization to the solvents used in these combinations.

Incubations were carried at 20 °C and 60 °C for 24 h. After that period, the diameter, weight, and thickness of the lenses were measured and compared to the values obtained before any incubation.

3.8. Biocatalyst Lipozyme® RM Thermostability in Aqueous Media

The thermostability of Lipozyme® RM in different concentrations, 0.5 mg mL−1, 2 mg mL−1, and 4 mg mL−1, was assessed in aqueous media of Tris buffer 10 mM, pH 8, and pH 9.

Three sets of experiments were simultaneously analyzed, the first two monitoring only the evolution of the substrates and the enzyme separately, and the third evaluating the progression the of reaction in aqueous media (Cys 0.23 mg mL−1 and Dda 0.26 mg mL−1).

The enzyme was tested for three batches of 24 h each at 40 °C, 50 °C, and 60 °C, in a water bath (Julabo SW20) with agitation at 180 rpm.

Samples were collected periodically at 0, 15, 30, 60, 90, 120, 180, 240, 300 min, and 24 h and immediately analyzed through spectrometry at 260 nm. Protein quantification in each sample was carried out using the Bradford method.

After each batch, all media were discharged, the RML particles were rinsed with distilled water, and a new set of assays started. The substrate control was also changed with new solutions at each new reutilization of the enzyme.

3.9. Media Design Assays

Liquid reactions were tested using (i) aqueous media of Tris buffer pH 9, (ii) co-solvent systems (Tris:2-propanol; DMSO:MeOH; Tris:DMSO:MeOH, and (iii) biphasic system (Tris:n-hexane).

The reactions were conducted at 40 °C in a water bath (Julabo SW20, Seelbach, Germany) with agitation at 180 rpm.

3.9.1. Tris Buffer 10 mM, pH 9

After preliminary studies, the effects of pH and temperature were carried out. The thermostability of RML was evaluated in aqueous media, using stock solutions of Cys 0.45 mg mL−1 and Dda 0.5 mg mL−1 in Tris buffer, in volumes of 2.3 and 2.4, respectively, to a final volume of 4.7 mL.

3.9.2. Co-Solvent Systems

The co-solvent systems tested were DMSO:MeOH (1:1), Tris buffer pH 9:DMSO:MeOH (12:1:1), and Tris buffer pH 9:2-propanol (2:1). Stock solutions were prepared for cystine, dissolved in DMSO at either 0.4 mg mL−1 or 52 mg mL−1, and dodecylamine, in methanol at 0.5 mg mL−1 or 62 mg mL−1.

For the reactions in the Tris buffer:2-propanol system, one single scheme was tested. In this case, cystine was dissolved at 0.225 mg mL−1 in Tris buffer pH 9 and dodecylamine at 0.5 mg mL−1 in 2-propanol.

3.9.3. Biphasic Systems

In the biphasic system tested, Tris buffer pH 9:n-hexane (2:1), cystine was dissolved in Tris buffer pH 9 at 0.225 mg mL−1, and dodecylamine was dissolved in n-hexane at 0.5 mg mL−1. Volumes of each solution were added in different concentrations.

3.9.4. Solvent-Free Systems

These solvent-free reactions were carried at 40 °C. At this temperature, one of the substrates, dodecylamine, is liquid, with a melting point of 27–29 °C. One g of dodecylamine was weighed into each reaction tube and all were stabilized at 40 °C to complete melting of the dodecylamine. Then, 300 mg of cystine were added to each tube, along with 500 µL of the eutectic mixture Dowtherm®A. RML and TLL were used in a quantity of 33 mg in the respective reactions. PPL was immobilized using an in house process, afterward, 126 mg of PPL lenses were used.

The tubes were maintained at 40 °C for a period no shorter than 5 h, and up to 24 h. Gently tapping on the tubes was applied periodically to unify the mixture.

3.10. Analytic Methods

Thin layer chromatography (TLC) assays conducted on TLC aluminum sheets 20 × 20 cm silica gel 60 F254 (Merck-1.05554.0001) cropped to 2.5 × 10 cm stripes were carried out to follow the bioreaction, substrate consumption, and product formation. The polarity of the eluents chloroform (7): methanol (3) was optimized. The plates were stained either with ninhydrin or Dragendorff reagents. The sample volume applied to the plates was 10 µL.

The measurements of the absorbance at 260 nm were used to monitoring of the evolution of the assays, as this is a general wavelength for peptide species or proteins.

Calibration curves were determined for the substrates individually and in a 1:2 (Cys:Dda) proportion in Tris buffer pH 8 and Tris buffer pH 9.

For product evaluation, controls of the substrates were carried out in each reaction and subtracted from the global absorbance.

Protein quantification was carried out according to the Bradford method [

44] adapted to a micromethod [

43] for faster multiple sample processing. In this adapted method, 50 µL of dye was added to 100 µL of the sample to be tested in a microplate (Thermo Scientific NuncTM 96 well microplates). The reaction was developed for 2 min and absorbance was read at 595 nm in a microplate reader (Fluostar Omega, BMG LABTACH, Ortenberg, Germany).

Calibration curves of the Bradford reaction with several concentrations of each substrate and of both substrates at 1:2 proportions were carried out.

Interactions between cationic surfactants and eosin have long been reported to cause alterations in the absorption and fluorescence spectra of the dye [

45]. In fact, micellization properties of the surfactants and these dyes can be applied to water treatments through micellar-enhanced ultrafiltration [

38].

The interaction of the xanthene dyes has been studied by other authors [

46,

47], who have demonstrated that eosin and cationic surfactants interact mainly through electrostatic interactions.

Additionally, Chakraborty and co-workers [

45] analyzed the spectra response of eosin when exposed to several surfactants, observing a decrease in the absorption maximum of eosin in aqueous solutions, which is usually around 517 nm, and a shift of the absorption maximum to higher wavelengths. When the double tailed cationic surfactant DDA (didodecyldimethylammonium bromide) was added to eosin, the absorption maximum shifted to 536 nm. For the determination of the eosin maximum absorption wavelength, 300 µL of the eosin solution was added to 500 µL of distilled water. The solution of eosin showed a maximum of absorption around 517 nm, and in the presence of the gemini, the absorption peak moved to 538, which is very similar to the one recorded for DDA [

45].

Aqueous solutions of eosin 0.001%, and the gemini lipoaminoacid at several concentrations were prepared.

The colorimetric reaction was produced by adding 500 µL of each to 300 µL of eosin solution. Spectrometry measurements were made using a HITACHI U-2000 Double-Beam Spectrophotometer. A calibration curve was constructed with the solutions of reference gemini, demonstrating a significant correlation between color intensity and product concentration at 538 nm.

3.10.1. Equipment

The HPLC-MS/MS sample analysis was conducted in a quadropole, enabling mass selection with the separation of ions of a certain

m/

z or a scanning mode, with ramped voltages where only a certain

m/

z crosses the chamber [

48].

The first step of tandem mass spectrometry is to choose a

m/

z from the first spectrometer scanning. Then, this ion is sent to collide and fragment into products that are analyzed by a second spectrometer, producing a “fragmentation scan” or “daughter scan”. In this way, the selected

m/

z from a source spectrum allows a unique fragmentation pattern to be defined. Inverting the method produces a “percursor scan” or “parent scan”, where the second spectrometer is set for an ion while the first one scans for masses, detecting the percursor ion [

48].

MRM assays are ideal for a very sensitive and specific quantification because it is based on two ion selections, one from each scanning mode, full and daughter scans.

The HPLC analyses were performed on a Waters Alliance 2695 (Waters®, Dublin, Ireland) equipped with a quaternary pump, solvent degasser, auto sampler, and column oven, coupled to a Waters 996 PDA photodiode array detector (Waters®, Ireland).

The tandem mass spectrometer (MS/MS) used was a MicroMass Quattromicro® API (Waters®, Ireland), triple quadrupole type. Compound ionization was performed by an electrospray source in positive mode (ESI+).

Two methods of sample preparation were used: (i) liquid state reactions were evaporated and resuspended in DMSO. For analysis of co-solvent liquid state reactions, the full volume of 14 mL reactions was evaporated in a rotary evaporator, and 2 mL of DMSO was added to the same recipient for total resuspension of the remaining compounds. The same process was used for biphasic liquid state reaction with the exception of the phases having been separated, resulting in the evaporation of smaller total volumes. This analysis was applied only for the reactions carried on with a 27 mg mL−1 enzyme concentration; (ii) solid state reaction samples were prepared by collecting 2 mg of the reaction and adding 2 mL of DMSO for a final concentration of 1 mg mL−1.

The separation was performed on a normal-phase column (Luna HILIC 1000 × 3.00 mm) at 35 °C using an injection volume of 10 μL. The mobile phase consisted of Milli-Q water containing 0.5% formic acid (A) and acetonitrile (B) at a flow rate of 0.30 mL min−1. The eluting conditions applied were as follows: initial time (0 min) A 5.0%, B 95%; (5 min) A 100.0%, B 0%; (7 min) A 100.0%, B 0%; (10 min) A 5.0%, B 95%; (15 min) A 5.0%, B 95%.

A photodiode array detector was use to scan wavelength absorption from 210 to 600 nm.

MS/MS experiments were performed on Micromass® Quattro Micro triple quadrupole (Waters®, Ireland) with an electrospray in positive ion mode (ESI+) with an ion source at 120 °C, desolvatation temperature of 350 °C, capillary voltage of 3.50 kV, and source voltage of 60 V. The compounds were ionized and spectra of the column eluate were recorded in the full scan mode m/z 60–2000, and SIR m/z 575, 241, 186. Analytical conditions were optimized to maximize the precursor ion signal ([M − H]+). For the MS/MS experiments, different collision energies (eV) were applied to determined characteristic fragments to be used in MRM mode. High purity nitrogen (N2) was used both as a drying gas and as a nebulizing gas. Ultrahigh-purity argon (Ar) was used as the collision gas.

The sample were initially analyzed in full scan mode

m/

z 60–2000 with ESI+, and SIR

m/

z 575, 241, 186. Two different collision energies (20 eV and 30 eV) were used to promote fragmentation and determine characteristic fragmentation patterns of the compounds (

Table 3).

Full scans and daughter scans (20 eV and 30 eV) were carried out for the substrates (

Figure 7 and

Figure 8) and for the new gemini lipoaminoacid (

Figure 9). For these compounds,

m/

z 241 and 186 ions were selected from the first scans of cystine and dodecylamine, respectively, and both collision energies were also tested with the fragmentation spectrums presented in

Figure 7 and

Figure 8. For the product, a

m/

z 575 ion was selected from the first scan (

Figure 9) and sent to fragmentation (

Figure 9). The fragmentation scan at 30 eV was clearer, pointing to the

m/

z 287 ion as the most frequent, followed by

m/

z 240, 345, and 270.

Based on the fragmentation patterns obtained previously, two transitions (parent mass > fragment mass) were determined for each compound and MRM assays run in standard solutions to provide data relating to the retention times and enable the exact quantification of the product in the experimental samples.

To the gemini lipoaminoacid, transitions of 575 > 287 and 575 > 286 were established and in these conditions, the retention time was 2.15 min (

Table 3 and

Figure 9). Two transitions for the MRM assays were used: MRM1 was the most intense and was used for quantification, while MRM2 served as confirmation. The two transitions contribute with specificity to the MRM since it is not unusual for two different compounds with the same

m/

z to have one fragment in common, but two fragments in common is rarer. Additionally, the retention point should be the same as well as the MRM1/MRM2 ratio for any concentration.

Figure 10 presents the structure of the gemini derived cystine lipoaminoacid.

3.10.2. Software

Data processing and graphic construction were conducted in either Microsoft Office™ Excel

® 2010 or using GraphPad Prism version 5.03 for Windows

®, GraphPad Software (San Diego, CA, USA,

www.graphpad.com).

For acquisition and processing of HPLC-MS/MS data, MassLynx® version 4.1 was used.