Anticancer Asparaginases: Perspectives in Using Filamentous Fungi as Cell Factories

Abstract

:1. Introduction

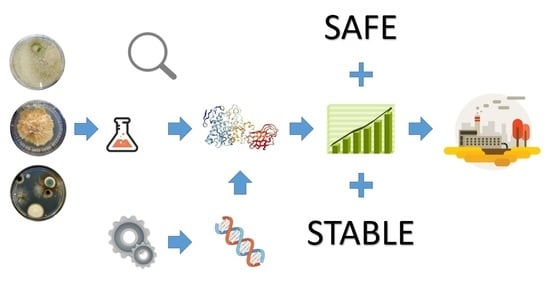

2. Filamentous Fungi as L-Asparaginase Production Sources

3. Fungal Cell Factory Construction for Enzyme Production

4. Perspectives in the Humanization of N-Glycosylation Pathways for L-Asparaginase Production

5. Protein Engineering of L-Asparaginases

5.1. L-Glutaminase Activity

5.2. Reducing Immunogenic Reaction

5.3. Enzyme Stability

5.4. Perspectives for Engineering Fungal Asparaginases

6. Conclusions and Perspectives

Author Contributions

Funding

Conflicts of Interest

References

- Cardoso, S.L.; de Freitas, M.M.; de Souza, P.M.; Homem-de-Mello, M.; Silveira, D.; Fonseca-Bazzo, Y.M.; Filho, E.X.; Junior, A.P.; Magalhães, P.O. Optimization of aqueous two-phase micellar system for partial purification of L-asparaginase from Penicillium sp. grown in wheat bran as agro-industrial residue. Braz. J. Microbiol. 2020, 51, 979–988. [Google Scholar] [CrossRef] [PubMed]

- Costa-Silva, T.A.; Camacho-Córdova, D.I.; Agamez-Montalvo, G.S.; Parizotto, L.A.; Sánchez-Moguel, I.; Pessoa-Jr, A. Optimization of culture conditions and bench-scale production of anticancer enzyme L-asparaginase by submerged fermentation from Aspergillus terreus CCT 7693. Prep. Biochem. Biotechnol. 2018, 49, 95–104. [Google Scholar] [CrossRef] [PubMed]

- Asitok, A.; Ekpenyong, M. Production of the Anti-Leukemic Therapeutic Enzyme, L-Asparaginase, by A Brackish Sediment Strain of Aspergillus candidus. Br. J. Med. Health Res. 2019, 6, 47–68. [Google Scholar] [CrossRef]

- da Cunha, M.C.; Silva, L.C.; Sato, H.H.; de Castro, R.J.S. Using response surface methodology to improve the L-asparaginase production by Aspergillus niger under solid-state fermentation. Biocatal. Agric. Biotechnol. 2018, 16, 31–36. [Google Scholar] [CrossRef]

- Batool, T.; Makky, E.A.; Jalal, M.; Yusoff, M.M. A Comprehensive Review on l-Asparaginase and Its Applications. Appl. Biochem. Biotechnol. 2016, 178, 900–923. [Google Scholar] [CrossRef] [Green Version]

- Benson, D.A.; Cavanaugh, M.; Clark, K.; Karsch-Mizrachi, I.; Lipman, D.J.; Ostell, J.; Sayers, E.W. GenBank. Nucleic Acids Res. 2013, 41, D36–D42. [Google Scholar] [CrossRef] [Green Version]

- Haskel, C.M.; Canellos, G.P.; Leventhal, B.G.; Carbone, P.P.; Serpick, A.A.; Hansen, H.H. L-Asparaginase Toxicity. Cancer Res. 1969, 29, 974–975. [Google Scholar]

- Mahajan, R.V.; Saran, S.; Kameswaran, K.; Kumar, V.; Saxena, R.K. Efficient production of l-asparaginase from Bacillus licheniformis with low-glutaminase activity: Optimization, scale up and acrylamide degradation studies. Bioresour. Technol. 2012, 125, 11–16. [Google Scholar] [CrossRef]

- El-Nagga, N.E.-A.; El-Ewasy, S.M.; El-Shweihy, N.M. Microbial L-asparaginase as a Potential Therapeutic Agent for the Treatment of Acute Lymphoblastic Leukemia: The Pros and Cons. Int. J. Pharmacol. 2014, 10, 182–199. [Google Scholar] [CrossRef] [Green Version]

- Hamed, M.; Osman, A.; Ates, M. Statistical optimization of L-asparaginase production by Cladosporium tenuissimum. Egypt. Pharm. J. 2021, 20, 51–58. [Google Scholar] [CrossRef]

- Zuo, S.; Zhang, T.; Jiang, B.; Mu, W. Recent research progress on microbial l-asparaginases. Appl. Microbiol. Biotechnol. 2015, 99, 1069–1079. [Google Scholar] [CrossRef] [PubMed]

- Mashburn, L.T.; Wriston, J.C. Tumor inhibitory effect of l-asparaginase from Escherichia coli. Arch. Biochem. Biophys. 1964, 105, 450–453. [Google Scholar] [CrossRef] [PubMed]

- Costa-Silva, T.A.; Flores-Santos, J.C.; Freire, R.K.B.; Vitolo, M.; Pessoa-Jr, A. Microbial cell disruption methods for efficient release of enzyme L-asparaginase. Prep. Biochem. Biotechnol. 2018, 48, 707–717. [Google Scholar] [CrossRef]

- Costa-Silva, T.A.; Costa, I.M.; Biasoto, H.P.; Lima, G.M.; Silva, C.; Pessoa, A.; Monteiro, G. Critical overview of the main features and techniques used for the evaluation of the clinical applicability of L-asparaginase as a biopharmaceutical to treat blood cancer. Blood Rev. 2020, 43, 100651. [Google Scholar] [CrossRef]

- Brumano, L.P.; da Silva, F.V.S.; Costa-Silva, T.A.; Apolinário, A.C.; Santos, J.H.P.M.; Kleingesinds, E.K.; Monteiro, G.; de Oliveira Rangel-Yagui, C.; Benyahia, B.; Junior, A.P. Development of L-asparaginase biobetters: Current research status and review of the desirable quality profiles. Front. Bioeng. Biotechnol. 2019, 6, 212. [Google Scholar] [CrossRef] [Green Version]

- Taís Maziero, M.; Dos, L.; Bersot, S. Review Micotoxinas Em Alimentos Produzidos No Brasil. Rev. Bras. Prod. Agroind. 2010, 12, 89–99. [Google Scholar]

- Caddick, M.X.; Peters, D.; Platt, A. Nitrogen Regulation in Mycelial Fungi. In Biochemistry and Molecular Biology; Springer: Berlin/Heidelberg, Germany, 1994; pp. 169–177. [Google Scholar] [CrossRef]

- Lapmak, K.; Lumyong, S.; Thongkuntha, S.; Wongputtisin, P.; Sardsud, U. L-Asparaginase Production by Bipolaris sp. BR438 Isolated from Brown Rice in Thailand. Chiang Mai J. Sci. 2010, 37, 160–164. [Google Scholar]

- El-Gendy, M.M.A.A.; Awad, M.F.; El-Shenawy, F.S.; El-Bondkly, A.M.A. Production, purification, characterization, antioxidant and antiproliferative activities of extracellular L-asparaginase produced by Fusarium equiseti AHMF4. Saudi J. Biol. Sci. 2021, 28, 2540–2548. [Google Scholar] [CrossRef]

- Schalén, M.; Anyaogu, D.C.; Hoof, J.B.; Workman, M. Effect of secretory pathway gene overexpression on secretion of a fluorescenreporter protein in aspergillus nidulans. Fungal Biol. Biotechnol. 2016, 3, 1–14. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thakur, M.; Lincoln, L.; Niyonzima, F.N.; More, S.S. Isolation, Purification and Characterization of Fungal Extracellular L-Asparaginase from Mucor hiemalis. J. Biocatal. Biotransform. 2014, 2, 12–14. [Google Scholar] [CrossRef]

- Bedaiwy, M.Y.; Awadalla, O.A.; Abou-Zeid, A.M.; Hamada, H.T. Optimal conditions for production of L-Asparaginase from Aspergillus tamarii. Egypt. J. Exp. Biol. 2016, 12, 229–237. [Google Scholar]

- da Cunha, M.C.; dos S. Aguilar, J.G.; Orrillo Lindo, S.M.D.R.; de Castro, R.J.S.; Sato, H.H. L-asparaginase from Aspergillus oryzae spp.: Effects of production process and biochemical parameters. Prep. Biochem. Biotechnol. 2022, 52, 253–263. [Google Scholar] [CrossRef] [PubMed]

- Battiston Loureiro, C.; Silva Borges, K.; Faria Andrade, A.; Gonzaga Tone, L.; Said, S. Purification and Biochemical Characterization of Native and Pegylated Form of L-Asparaginase from Aspergillus terreus and Evaluation of Its Antiproliferative Activity. Adv. Microbiol. 2012, 2, 138–145. [Google Scholar] [CrossRef]

- de M. Sarquis, M.I.; Oliveira, E.M.M.; Santos, A.S.; da Costa, G.L. Production of L-asparaginase by filamentous fungi. Mem. Inst. Oswaldo Cruz 2004, 99, 489–492. [Google Scholar] [CrossRef] [Green Version]

- da Rocha, W.R.V.; Costa-Silva, T.A.; Agamez-Montalvo, G.S.; Feitosa, V.A.; Machado, S.E.F.; de Souza Lima, G.M.; Pessoa, A.; Alves, H.S. Screening and optimizing fermentation production of l-asparaginase by Aspergillus terreus strain S-18 isolated from the Brazilian Caatinga Biome. J. Appl. Microbiol. 2019, 126, 1426–1437. [Google Scholar] [CrossRef] [PubMed]

- Ali, D.; Ouf, S.; Eweis, M.; Solieman, D. Optimization of L-Asparaginase production from some filamentous fungi with potential pharmaceutical properties. Egypt. J. Bot. 2018, 58, 355–369. [Google Scholar] [CrossRef]

- Shafei, M.S.; El-Refai, H.A.; Mostafa, H.; El-Refai, A.M.H.; El-Beih, F.M.; Easa, S.M.; Gomaa, S.K. Purification, characterization and kinetic properties of penicillium cyclopium L-asparaginase: Impact of lasparaginase on acrylamide content in potato products and its cytotoxic activity. Curr. Trends Biotechnol. Pharm. 2015, 9, 132–140. [Google Scholar]

- Meghavarnam, A.K.; Janakiraman, S. Solid state fermentation: An effective fermentation strategy for the production of L-asparaginase by Fusarium culmorum (ASP-87). Biocatal. Agric. Biotechnol. 2017, 11, 124–130. [Google Scholar] [CrossRef]

- Shrivastava, A.; Khan, A.A.; Shrivastav, A.; Jain, S.K.; Singhal, P.K. Kinetic studies of L-asparaginase from Penicillium digitatum. Prep. Biochem. Biotechnol. 2012, 42, 574–581. [Google Scholar] [CrossRef] [PubMed]

- Silva, L.F.; Freire, K.T.L.S.; Araújo-Magalhães, G.R.; Agamez-Montalvo, G.S.; Sousa, M.A.; Costa-Silva, T.A.; Paiva, L.M.; Pessoa-Junior, A.; Bezerra, J.D.P.; Souza-Motta, C.M. Penicillium and Talaromyces endophytes from Tillandsia catimbauensis, a bromeliad endemic in the Brazilian tropical dry forest, and their potential for l-asparaginase production. World J. Microbiol. Biotechnol. 2018, 34, 162–174. [Google Scholar] [CrossRef]

- Wang, Q.; Zhong, C.; Xiao, H. Genetic Engineering of Filamentous Fungi for Efficient Protein Expression and Secretion. Front. Bioeng. Biotechnol. 2020, 8, 293. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ward, O.P. Production of recombinant proteins by filamentous fungi. Biotechnol. Adv. 2012, 30, 1119–1139. [Google Scholar] [CrossRef]

- Fonseca, L.M.; Parreiras, L.S.; Murakami, M.T. Rational engineering of the Trichoderma reesei RUT-C30 strain into an industrially relevant platform for cellulase production. Biotechnol. Biofuels 2020, 13, 1–15. [Google Scholar] [CrossRef] [PubMed]

- Conesa, A.; Punt, P.J.; Van Luijk, N.; Van den Hondel, C.A.M.J.J. The secretion pathway in filamentous fungi: A biotechnological view. Fungal Genet. Biol. 2001, 33, 155–171. [Google Scholar] [CrossRef]

- Carvalho, N.D.S.P.; Arentshorst, M.; Jin Kwon, M.; Meyer, V.; Ram, A.F.J. Expanding the ku70 toolbox for filamentous fungi: Establishment of complementation vectors and recipient strains for advanced gene analyses. Appl. Microbiol. Biotechnol. 2010, 87, 1463–1473. [Google Scholar] [CrossRef] [Green Version]

- Pohl, C.; Kiel, J.A.K.W.; Driessen, A.J.M.; Bovenberg, R.A.L.; Nygård, Y. CRISPR/Cas9 Based Genome Editing of Penicillium chrysogenum. ACS Synth. Biol. 2016, 5, 754–764. [Google Scholar] [CrossRef]

- Schuster, M.; Kahmann, R. CRISPR-Cas9 genome editing approaches in filamentous fungi and oomycetes. Fungal Genet. Biol. 2019, 130, 43–53. [Google Scholar] [CrossRef]

- Pi, C.; Zhang, Z.; Xiang, B.; Tian, H.; Liao, Q.; Chen, Y.; Xia, L.; Hu, Y.; Hu, S. Constructing a novel expression system by specific activation of amylase expression pathway in Penicillium. Microb. Cell Fact. 2020, 19, 155. [Google Scholar] [CrossRef] [PubMed]

- Nevalainen, H.; Peterson, R. Making recombinant proteins in filamentous fungi- Are we expecting too much? Front. Microbiol. 2014, 5, 75. [Google Scholar] [CrossRef]

- Sims, A.H.; Gent, M.E.; Lanthaler, K.; Dunn-Coleman, N.S.; Oliver, S.G.; Robson, G.D. Transcriptome analysis of recombinant protein secretion by Aspergillus nidulans and the unfolded-protein response in vivo. Appl. Environ. Microbiol. 2005, 71, 2737–2747. [Google Scholar] [CrossRef] [Green Version]

- Krishnan, K.; Askew, D.S. The fungal UPR: A regulatory hub for virulence traits in the mold pathogen Aspergillus fumigatus. Virulence 2014, 5, 334–340. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Wang, S.; Zhang, X.; Ji, W.; Song, F.; Zhao, Y.; Li, J. The amyR-deletion strain of Aspergillus niger CICC2462 is a suitable host strain to express secreted protein with a low background. Microb. Cell Fact. 2016, 15, 68. [Google Scholar] [CrossRef] [Green Version]

- Kamaruddin, N.; Storms, R.; Mahadi, N.M.; Illias, R.M.; Bakar, F.D.A.; Murad, A.M.A. Reduction of Extracellular Proteases Increased Activity and Stability of Heterologous Protein in Aspergillus niger. Arab. J. Sci. Eng. 2018, 43, 3327–3338. [Google Scholar] [CrossRef]

- Fiedler, M.R.M.; Barthel, L.; Kubisch, C.; Nai, C.; Meyer, V. Construction of an improved Aspergillus niger platform for enhanced glucoamylase secretion. Microb. Cell Fact. 2018, 17, 95. [Google Scholar] [CrossRef] [PubMed]

- Zubieta, M.P.; Gerhardt, J.A.; Rubio, M.V.; Terrasan, C.R.F.; Persinoti, G.F.; Antoniel, E.P.; Contesini, F.J.; Prade, R.A.; Damasio, A. Improvement of homologous GH10 xylanase production by deletion of genes with predicted function in the Aspergillus nidulans secretion pathway. Microb. Biotechnol. 2020, 13, 1245–1253. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Q.; Qiu, H. The Mechanistic Impact of N-Glycosylation on Stability, Pharmacokinetics, and Immunogenicity of Therapeutic Proteins. J. Pharm. Sci. 2019, 108, 1366–1377. [Google Scholar] [CrossRef]

- Deshpande, N.; Wilkins, M.R.; Packer, N.; Nevalainen, H. Protein glycosylation pathways in filamentous fungi. Glycobiology 2008, 18, 626–637. [Google Scholar] [CrossRef]

- Anyaogu, D.C.; Hansen, A.H.; Hoof, J.B.; Majewska, N.I.; Contesini, F.J.; Paul, J.T.; Nielsen, K.F.; Hobley, T.J.; Yang, S.; Zhang, H.; et al. Glycoengineering of Aspergillus nidulans to produce precursors for humanized N-glycan structures. Metab. Eng. 2021, 67, 153–163. [Google Scholar] [CrossRef]

- Srichaisupakit, A.; Ohashi, T.; Misaki, R.; Fujiyama, K. Production of initial-stage eukaryotic N-glycan and its protein glycosylation in Escherichia coli. J. Biosci. Bioeng. 2015, 119, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Nakanishi-Shindo, Y.; Nakayama, K.I.; Tanaka, A.; Toda, Y.; Jigami, Y. Structure of the N-linked oligosaccharides that show the complete loss of alpha-1,6-polymannose outer chain from och1, och1 mnn1, and och1 mnn1 alg3 mutants of Saccharomyces cerevisiae. J. Biol. Chem. 1993, 268, 26338–26345. [Google Scholar] [CrossRef] [PubMed]

- Hamilton, S.R.; Bobrowicz, P.; Bobrowicz, B.; Davidson, R.C.; Li, H.; Mitchell, T.; Nett, J.H.; Rausch, S.; Stadheim, T.A.; Wischnewski, H.; et al. Production of complex human glycoproteins in yeast. Science 2003, 301, 1244–1246. [Google Scholar] [CrossRef]

- Ha, S.; Wang, Y.; Rustandi, R.R. Biochemical and biophysical characterization of humanized IgG1 produced in Pichia pastoris. MAbs 2011, 3, 453–460. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lima, G.M.; Effer, B.; Biasoto, H.P.; Feijoli, V.; Pessoa, A.; Palmisano, G.; Monteiro, G. Glycosylation of L-asparaginase from E. coli through yeast expression and site-directed mutagenesis. Biochem. Eng. J. 2020, 156, 107516. [Google Scholar] [CrossRef]

- Effer, B.; Kleingesinds, E.K.; Lima, G.M.; Costa, I.M.; Sánchez-Moguel, I.; Pessoa, A.; Santiago, V.F.; Palmisano, G.; Farías, J.G.; Monteiro, G. Glycosylation of Erwinase results in active protein less recognized by antibodies. Biochem. Eng. J. 2020, 163, 107750. [Google Scholar] [CrossRef]

- Kainz, E.; Gallmetzer, A.; Hatzl, C.; Nett, J.H.; Li, H.; Schinko, T.; Pachlinger, R.; Berger, H.; Reyes-Dominguez, Y.; Bernreiter, A.; et al. N-glycan modification in Aspergillus species. Appl. Environ. Microbiol. 2008, 74, 1076–1086. [Google Scholar] [CrossRef] [Green Version]

- Duval, M.; Suciu, S.; Ferster, A.; Rialland, X.; Nelken, B.; Lutz, P.; Benoit, Y.; Robert, A.; Manel, A.M.; Vilmer, E.; et al. Comparison of Escherichia coli–asparaginase withErwinia-asparaginase in the treatment of childhood lymphoid malignancies: Results of a randomized European Organisation for Research and Treatment of Cancer—Children’s Leukemia Group phase 3 trial. Blood 2002, 99, 2734–2739. [Google Scholar] [CrossRef] [Green Version]

- OLLENSCHLÄGER, G.; ROTH, E.; LINKESCH, W.; JANSEN, S.; SIMMEL, A.; MÖDDER, B. Asparaginase-induced derangements of glutamine metabolism: The pathogenetic basis for some drug-related side-effects. Eur. J. Clin. Investig. 1988, 18, 512–516. [Google Scholar] [CrossRef]

- Derst, C.; Henseling, J.; Röhm, K.-H. Engineering the substrate specificity of Escherichia coli asparaginase. II. Selective reduction of glutaminase activity by amino acid replacements at position 248. Protein Sci. 2000, 9, 2009–2017. [Google Scholar] [CrossRef]

- Aghaeepoor, M.; Akbarzadeh, A.; Mirzaie, S.; Hadian, A.; Jamshidi Aval, S.; Dehnavi, E. Selective reduction in glutaminase activity of l-Asparaginase by asparagine 248 to serine mutation: A combined computational and experimental effort in blood cancer treatment. Int. J. Biol. Macromol. 2018, 120, 2448–2457. [Google Scholar] [CrossRef]

- Chan, W.K.; Lorenzi, P.L.; Anishkin, A.; Purwaha, P.; Rogers, D.M.; Sukharev, S.; Rempe, S.B.; Weinstein, J.N. The glutaminase activity of l-asparaginase is not required for anticancer activity against ASNS-negative cells. Blood 2014, 123, 3596–3606. [Google Scholar] [CrossRef] [Green Version]

- Offman, M.N.; Krol, M.; Patel, N.; Krishnan, S.; Liu, J.Z.; Saha, V.; Bates, P.A. Rational engineering of L-asparaginase reveals importance of dual activity for cancer cell toxicity. Blood 2011, 117, 1614–1621. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mehta, R.K.; Verma, S.; Pati, R.; Sengupta, M.; Khatua, B.; Jena, R.K.; Sethy, S.; Kar, S.K.; Mandal, C.; Roehm, K.H.; et al. Mutations in Subunit Interface and B-cell Epitopes Improve Antileukemic Activities of Escherichia coli Asparaginase-II: Evaluation of immunogenicity in MICE*. J. Biol. Chem. 2014, 289, 3555. [Google Scholar] [CrossRef] [Green Version]

- Verma, S.; Mehta, R.K.; Maiti, P.; Röhm, K.H.; Sonawane, A. Improvement of stability and enzymatic activity by site-directed mutagenesis of E. coli asparaginase II. Biochim. Biophys. Acta-Proteins Proteom. 2014, 1844, 1219–1230. [Google Scholar] [CrossRef] [PubMed]

- Munhoz Costa, I.; Custódio Moura, D.; Meira Lima, G.; Pessoa, A.; Oresco dos Santos, C.; de Oliveira, M.A.; Monteiro, G. Engineered asparaginase from Erwinia chrysanthemi enhances asparagine hydrolase activity and diminishes enzyme immunoreactivity—A new promise to treat acute lymphoblastic leukemia. J. Chem. Technol. Biotechnol. 2022, 97, 228–239. [Google Scholar] [CrossRef]

- Meneguetti, G.P.; Madalena, P.; Mariana, K.; Obreque, T.; Marcello, C.; Barbosa, V.; Monteiro, G.; Helena, S.; Farsky, P.; De Oliveira, A.M.; et al. Novel site-specific PEGylated L-asparaginase. PLoS ONE 2019, 14, e0211951. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Werner, A.; Röhm, K.H.; Müller, H.J. Mapping of B-cell epitopes in E. coli asparaginase II, an enzyme used in leukemia treatment. Biol. Chem. 2005, 386, 535–540. [Google Scholar] [CrossRef] [PubMed]

- Moola, Z.B.; Scawen, M.D.; Atkinson, T.; Nicholls, D.J. Erwinia chrysanthemil-asparaginase: Epitope mapping and production of antigenically modified enzymes. Biochem. J. 1994, 302, 921–927. [Google Scholar] [CrossRef] [Green Version]

- Jianhua, C.; Yujun, W.; Ruibo, J.; Min, W.; Wutong, W. Probing the Antigenicity of E. coli L-Asparaginase by Mutational Analysis. Mol. Biotechnol. 2006, 33, 57–65. [Google Scholar]

- Cantor, J.R.; Yoo, T.H.; Dixit, A.; Iverson, B.L.; Forsthuber, T.G.; Georgiou, G. Therapeutic enzyme deimmunization by combinatorial T-cell epitope removal using neutral drift. Proc. Natl. Acad. Sci. USA 2011, 108, 1272–1277. [Google Scholar] [CrossRef] [Green Version]

- Rodrigues, M.A.D.; Pimenta, M.V.; Costa, I.M.; Zenatti, P.P.; Migita, N.A.; Yunes, J.A.; Rangel-Yagui, C.O.; de Sá, M.M.; Pessoa, A.; Costa-Silva, T.A.; et al. Influence of lysosomal protease sensitivity in the immunogenicity of the antitumor biopharmaceutical asparaginase. Biochem. Pharmacol. 2020, 182, 114230. [Google Scholar] [CrossRef]

- Boos, J.; Werber, G.; Ahlke, E.; Schulze-Westhoff, P.; Nowak-Göttl, U.; Würthwein, G.; Verspohl, E.J.; Ritter, J.; Jürgens, H. Monitoring of asparaginase activity and asparagine levels in children on different asparaginase preparations. Eur. J. Cancer 1996, 32A, 1544–1550. [Google Scholar] [CrossRef] [PubMed]

- Li, L.Z.; Xie, T.H.; Li, H.J.; Qing, C.; Zhang, G.M.; Sun, M.S. Enhancing the thermostability of Escherichia coli l-asparaginase II by substitution with pro in predicted hydrogen-bonded turn structures. Enzyme Microb. Technol. 2007, 41, 523–527. [Google Scholar] [CrossRef]

- Patel, N.; Krishnan, S.; Offman, M.N.; Krol, M.; Moss, C.X.; Leighton, C.; Van Delft, F.W.; Holland, M.; Liu, J.Z.; Alexander, S.; et al. A dyad of lymphoblastic lysosomal cysteine proteases degrades the antileukemic drug L-asparaginase. J. Clin. Investig. 2009, 119, 1964–1973. [Google Scholar] [CrossRef]

- Maggi, M.; Mittelman, S.D.; Parmentier, J.H.; Colombo, G.; Meli, M.; Whitmire, J.M.; Merrell, D.S.; Whitelegge, J.; Scotti, C. A protease-resistant Escherichia coli asparaginase with outstanding stability and enhanced anti-leukaemic activity in vitro. Sci. Rep. 71 2017, 7, 14479. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Vidya, J.; Ushasree, M.V.; Pandey, A. Effect of surface charge alteration on stability of l-asparaginase II from Escherichia sp. Enzyme Microb. Technol. 2014, 56, 15–19. [Google Scholar] [CrossRef]

- Kotzia, G.A.; Labrou, N.E. Engineering thermal stability of l-asparaginase by in vitro directed evolution. FEBS J. 2009, 276, 1750–1761. [Google Scholar] [CrossRef] [PubMed]

- Schalk, A.M.; Nguyen, H.A.; Rigouin, C.; Lavie, A. Identification and structural analysis of an L-asparaginase enzyme from guinea pig with putative tumor cell killing properties. J. Biol. Chem. 2014, 289, 33175–33186. [Google Scholar] [CrossRef] [Green Version]

- Rigouin, C.; Nguyen, H.A.; Schalk, A.M.; Lavie, A. Discovery of human-like L-asparaginases with potential clinical use by directed evolution. Sci. Rep. 2017, 7, 10224. [Google Scholar] [CrossRef] [PubMed]

| Fungal Source | Carbon Source | Nitrogen Source | Production Time (h) | Optimal Temperature (°C) | Optimal pH | Km (mM) | Vmax (U/mL) | Enzyme Activity | In Vitro Trial | Authors |

|---|---|---|---|---|---|---|---|---|---|---|

| Aspergillus niger LBA 02 | Passion fruit peel flour | Passion fruit peel flour | 24 | 25 | 8 | - | - | 3023.98 U/g | No | [4] |

| Bipolaris sp. BR438 | Glucose | Sodium nitrate | 72 | 27–30 | 8.5 | - | - | 6.2 U/mL | No | [18] |

| Aspergillus candidus IR-A4 | Asparagine | Asparagine | 120 | 35–45 | 8.5± 0.5 | - | - | 17.26 U/mg | Cytotoxic assay using HL-60 cell lines | [3] |

| Aspergillus tamarii | Sucrose | Asparagine | 168 | 30 | 7 | - | - | 11.01 U/mL | No | [22] |

| Aspergillus oryzae sp IOC 3999 | Lactose | Asparagine/Hydrolyzed casein | 4 | 30 | 5 | 3.28 | 45.04 | 742.22 U/mg | No | [23] |

| Aspergillus terreus CCT7693 | Glucose | Proline | 7 | 37.2 | 8.56 | 2.42 | - | 13.81 U/mL | Cytotoxic assay using HL-60 cell lines | [24] |

| Penicillium sp. | Wheat Bran and sucrose | Wheat bran and Asparagine | 72 | 35 | 5 | - | - | 2.33 U/mL | No | [24] |

| Fusarium equiseti AHMF4 | Glucose | Sodium nitrate | 16 | 30 | 7 | - | - | 488.1 U/mg | Cytotoxic assay using Hela, Hep-2, HepG-2 and HCT-116 cell lines | [19] |

| Cladosporium tenuissimum | Glucose | Asparagine | 72 | 37 | 6.2 | - | - | 2.6471 U/mL | No | [10] |

| Mucor hiemalis | Maltose | Peptone | 72 | 37 | 7 | 4.3 | 625 | 825.4 U/mL | No | [21] |

| Aspergillus tamarii | Glucose | Proline | 72 | 30 | - | - | - | 38 U/L | No | [25] |

| Aspergillus terreus S-18 | Glucose | Proline | 120 | 30 | 8.5 | - | - | 3.3 U/g | No | [26] |

| Aspergillus sydowii | Glucose | Asparagine | 120 | 4 | - | - | - | 146 U/mL | Cytotoxic assay using murine RAW264.7 leukemia cells line | [27] |

| Fusarium oxysporum | Glucose | Asparagine | 120 | 40 | - | - | - | 143 U/mL | Cytotoxic assay using murine RAW264.7 leukemia cells line | [27] |

| Penicillium cyclopium | Glucose | Proline | 72 | 30 | - | 0.3 | 625 | 39480 U/mg | Cytotoxic assay using Hep-G2, MCF-7 and PC3 cell lines | [28] |

| Fusarium culmorum | Glucose | Soybean meal | 144 | 30 | - | - | 18.91 U/gds | No | [29] | |

| Penicillium digitatum | Glucose | Asparagine | 96 | 30 | - | - | 833.15 U/mg | No | [30] | |

| Talaromyces cf. cecidicola | Glucose | Asparagine | 96 | 30 | - | - | 2.30 U/g | - | [31] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Garcia, P.H.D.; Costa-Silva, T.A.; Gómez, M.M.; Contesini, F.J.; Canella, P.R.B.C.; Carvalho, P.d.O. Anticancer Asparaginases: Perspectives in Using Filamentous Fungi as Cell Factories. Catalysts 2023, 13, 200. https://doi.org/10.3390/catal13010200

Garcia PHD, Costa-Silva TA, Gómez MM, Contesini FJ, Canella PRBC, Carvalho PdO. Anticancer Asparaginases: Perspectives in Using Filamentous Fungi as Cell Factories. Catalysts. 2023; 13(1):200. https://doi.org/10.3390/catal13010200

Chicago/Turabian StyleGarcia, Pedro Henrique Dias, Tales Alexandre Costa-Silva, Martí Morera Gómez, Fabiano Jares Contesini, Paula Renata Bueno Campos Canella, and Patrícia de Oliveira Carvalho. 2023. "Anticancer Asparaginases: Perspectives in Using Filamentous Fungi as Cell Factories" Catalysts 13, no. 1: 200. https://doi.org/10.3390/catal13010200

APA StyleGarcia, P. H. D., Costa-Silva, T. A., Gómez, M. M., Contesini, F. J., Canella, P. R. B. C., & Carvalho, P. d. O. (2023). Anticancer Asparaginases: Perspectives in Using Filamentous Fungi as Cell Factories. Catalysts, 13(1), 200. https://doi.org/10.3390/catal13010200