Metal-Doped HZSM-5 Zeolite Catalysts for Catalytic Cracking of Raw Bio-Oil: Exploring Activity toward Value-Added Products

Abstract

:1. Introduction

2. Results and Discussion

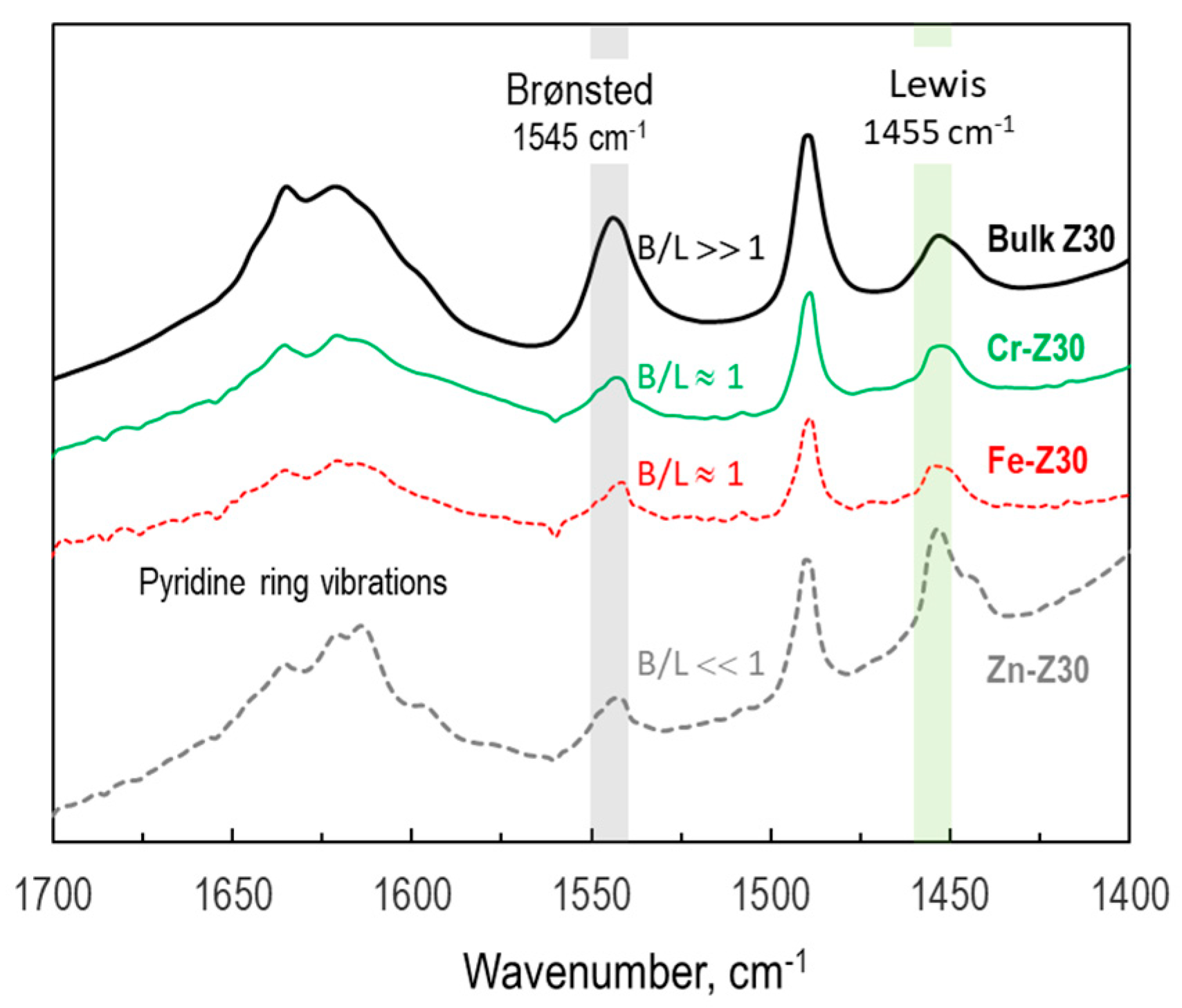

2.1. Physicochemical Properties of Catalysts

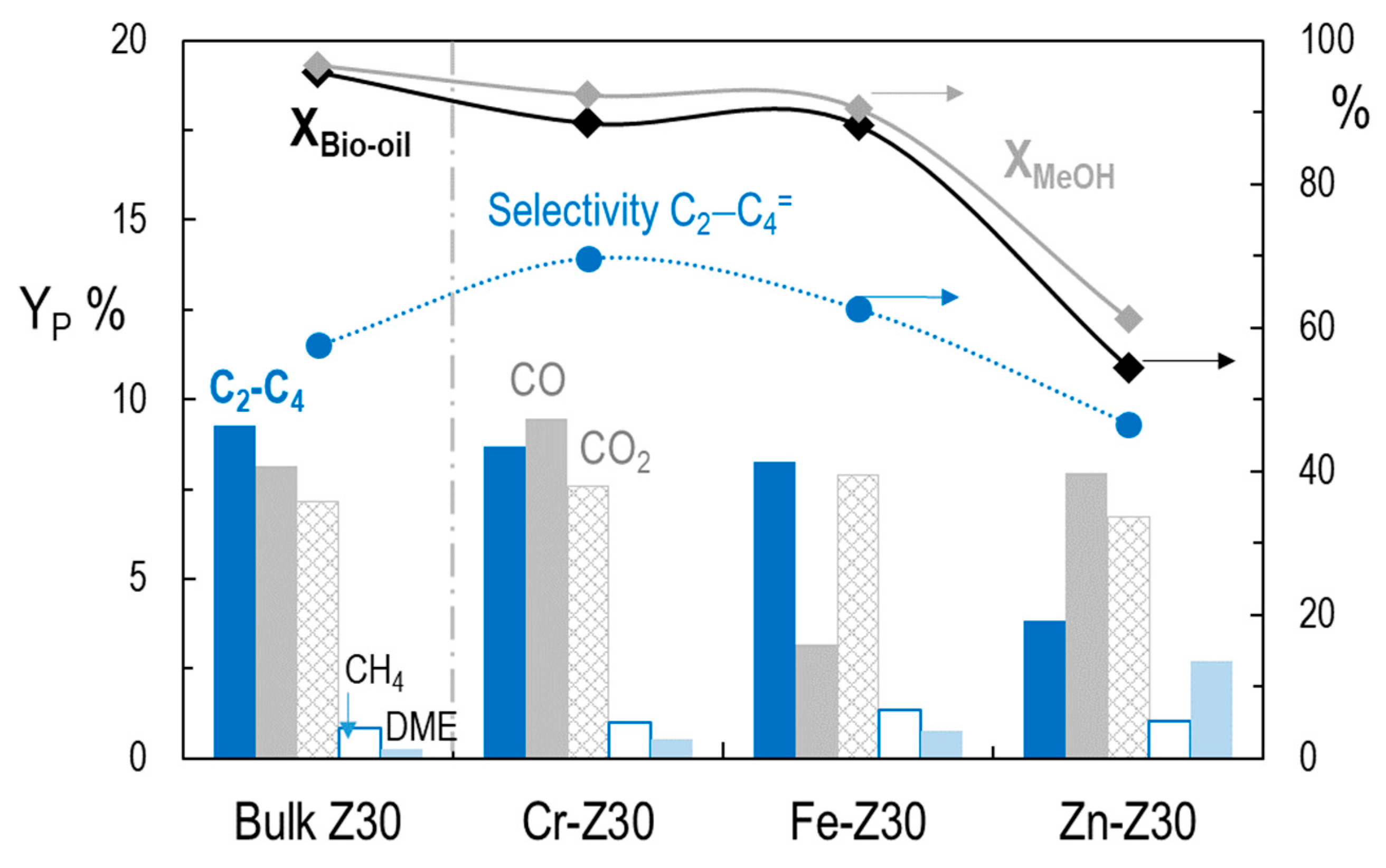

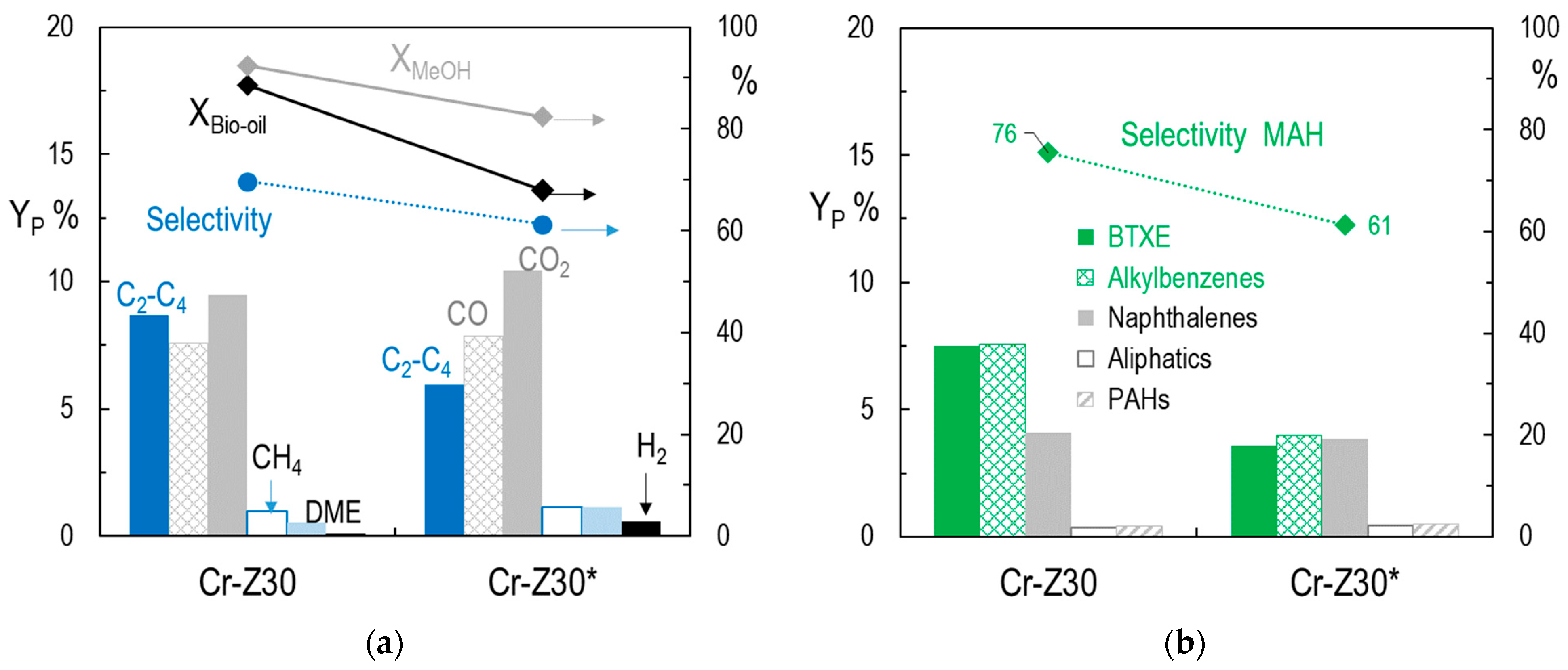

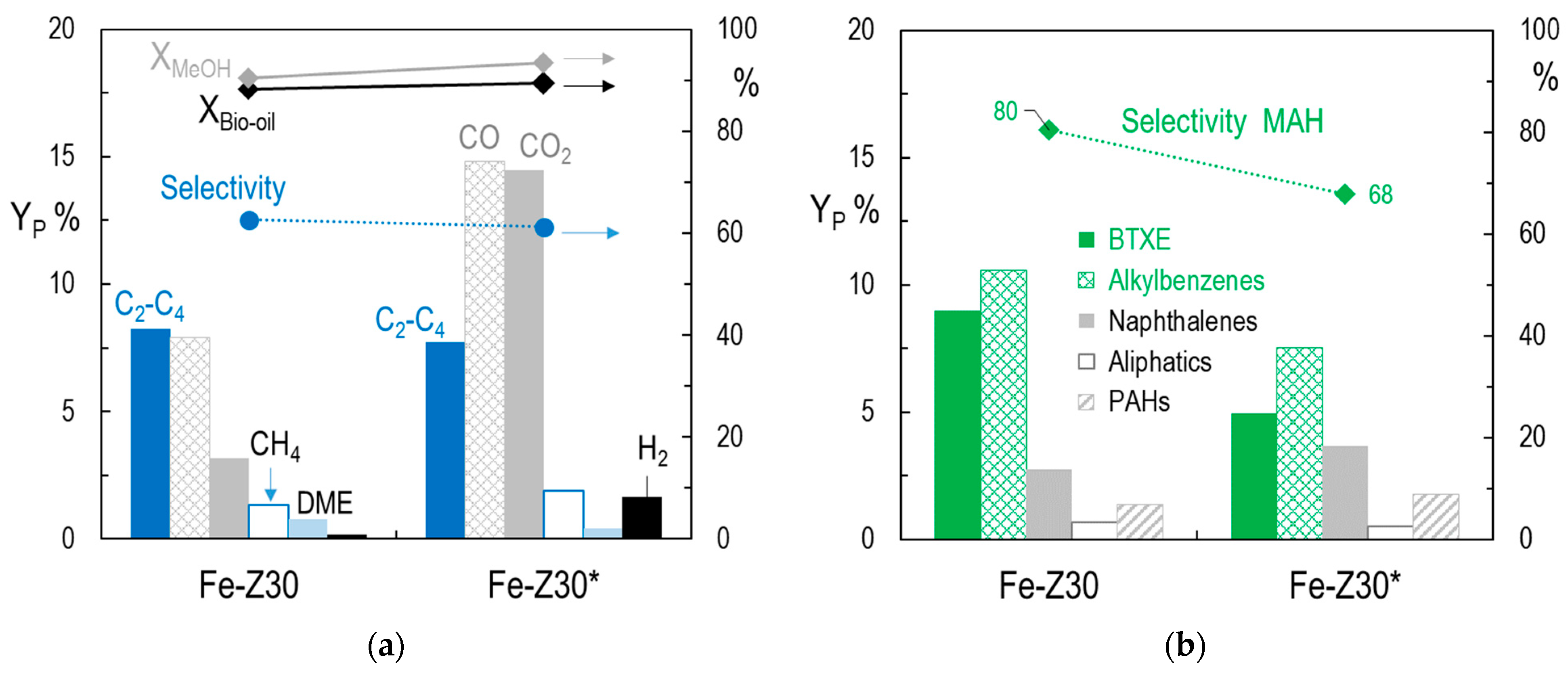

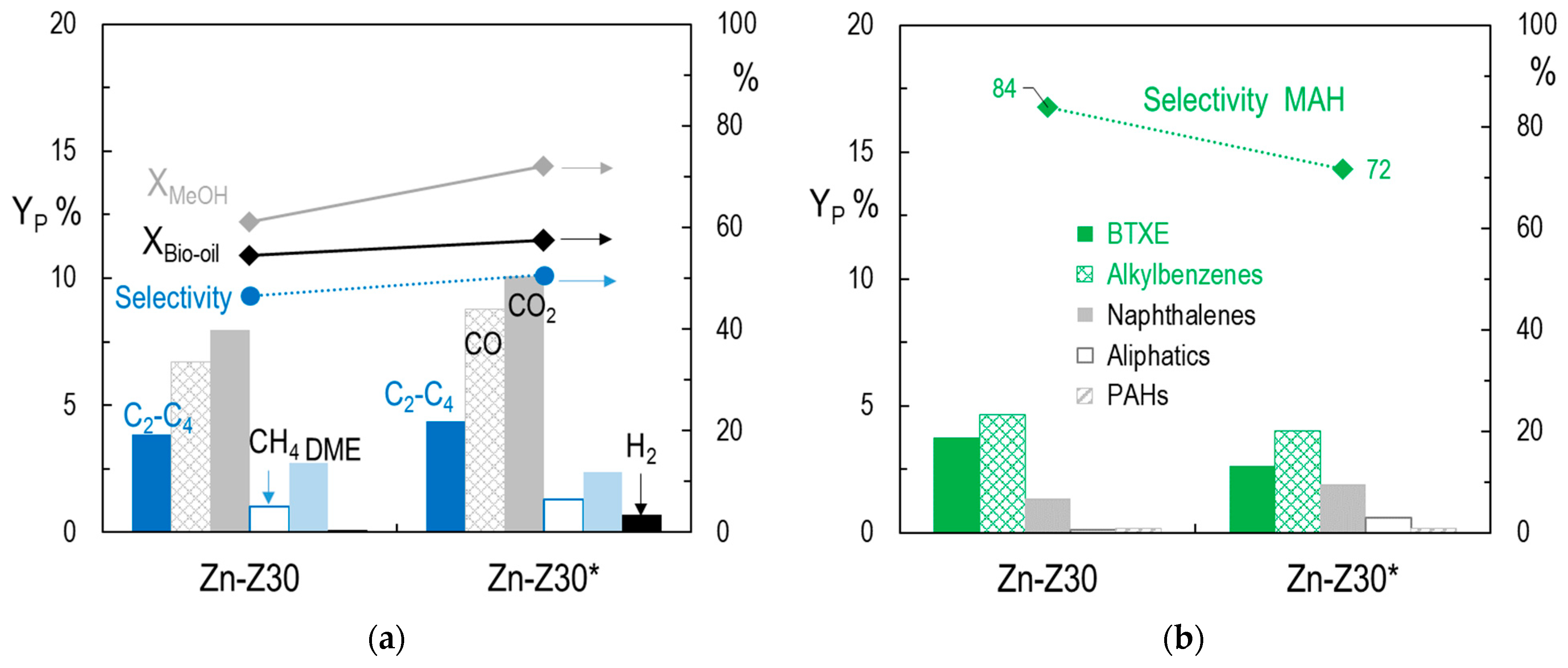

2.2. Evaluation of Activity for Catalytic Cracking of Bio-Oil

3. Materials and Methods

3.1. Synthesis of Catalysts

3.2. Characterization of Catalysts

3.3. Catalytic Cracking Experiments

3.4. Analysis of Reaction Products

- (1)

- H2, N2, CH4, CO (MS5A column);

- (2)

- C4–C12 bio-oil oxygenates, C5+ hydrocarbons (CPSil 5CB column);

- (3)

- CO2, C2–C4 hydrocarbons, H2O, MeOH, dimethyl ether, C2–C4 oxygenates (PPQ);

- (4)

- C6–C12 aromatics, C6–C12 oxygenates (Stabilwax).

3.5. Parameters for Quantifying the Catalytic Behavior

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Hansen, S.; Mirkouei, A.; Diaz, L.A. A Comprehensive State-of-Technology Review for Upgrading Bio-Oil to Renewable or Blended Hydrocarbon Fuels. Renew. Sustain. Energy Rev. 2020, 118, 109548. [Google Scholar] [CrossRef]

- Valle, B.; Remiro, A.; García-Gómez, N.; Gayubo, A.G.; Bilbao, J. Recent Research Progress on Bio-Oil Conversion into Bio-Fuels and Raw Chemicals: A Review. J. Chem. Technol. Biotechnol. 2019, 94, 670–689. [Google Scholar] [CrossRef]

- Liang, J.; Shan, G.; Sun, Y. Catalytic Fast Pyrolysis of Lignocellulosic Biomass: Critical Role of Zeolite Catalysts. Renew. Sustain. Energy Rev. 2021, 139, 110707. [Google Scholar] [CrossRef]

- Puértolas, B.; Veses, A.; Callén, M.S.; Mitchell, S.; García, T.; Pérez-Ramírez, J. Porosity–Acidity Interplay in Hierarchical ZSM-5 Zeolites for Pyrolysis Oil Valorization to Aromatics. ChemSusChem 2015, 8, 3283–3293. [Google Scholar] [CrossRef] [PubMed]

- Cai, Q.; Yu, T.; Meng, X.; Zhang, S. Selective Generation of Aromatic Hydrocarbons from Hydrotreating-Cracking of Bio-Oil Light Fraction with MOx Modified HZSM-5 (M = Ga, Mo and Zn). Fuel Process. Technol. 2020, 204, 106424. [Google Scholar] [CrossRef]

- Zheng, Y.; Wang, F.; Yang, X.; Huang, Y.; Liu, C.; Zheng, Z.; Gu, J. Study on Aromatics Production via the Catalytic Pyrolysis Vapor Upgrading of Biomass Using Metal-Loaded Modified H-ZSM-5. J. Anal. Appl. Pyrolysis 2017, 126, 169–179. [Google Scholar] [CrossRef]

- Chaihad, N.; Karnjanakom, S.; Abudula, A.; Guan, G. Zeolite-Based Cracking Catalysts for Bio-Oil Upgrading: A Critical Review. Resour. Chem. Mater. 2022, 1, 167–183. [Google Scholar] [CrossRef]

- Kosinov, N.; Liu, C.; Hensen, E.J.M.; Pidko, E.A. Engineering of Transition Metal Catalysts Confined in Zeolites. Chem. Mater. 2018, 30, 3177–3198. [Google Scholar] [CrossRef]

- Valle, B.; Gayubo, A.G.; Aguayo, A.T.; Olazar, M.; Bilbao, J. Selective Production of Aromatics by Crude Bio-Oil Valorization with a Nickel-Modified HZSM-5 Zeolite Catalyst. Energy Fuels 2010, 24, 2060–2070. [Google Scholar] [CrossRef]

- Iliopoulou, E.F.; Stefanidis, S.D.; Kalogiannis, K.G.; Delimitis, A.; Lappas, A.A.; Triantafyllidis, K.S. Catalytic Upgrading of Biomass Pyrolysis Vapors Using Transition Metal-Modified ZSM-5 Zeolite. Appl. Catal. B Environ. 2012, 127, 281–290. [Google Scholar] [CrossRef]

- Argyle, D.M.; Bartholomew, H.C. Heterogeneous Catalyst Deactivation and Regeneration: A Review. Catalysts 2015, 5, 145–269. [Google Scholar] [CrossRef] [Green Version]

- Razzaq, M.; Zeeshan, M.; Qaisar, S.; Iftikhar, H.; Muneer, B. Investigating Use of Metal-Modified HZSM-5 Catalyst to Upgrade Liquid Yield in Co-Pyrolysis of Wheat Straw and Polystyrene. Fuel 2019, 257, 116119. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, X.; Chen, L.; Zhao, B.; Yang, S.; Xie, X. Effects of Fe Contents on Fast Pyrolysis of Biomass with Fe/CaO Catalysts. J. Anal. Appl. Pyrolysis 2016, 119, 133–138. [Google Scholar] [CrossRef]

- Mohiuddin, E.; Mdleleni, M.M.; Key, D. Catalytic Cracking of Naphtha: The Effect of Fe and Cr Impregnated ZSM-5 on Olefin Selectivity. Appl. Petrochem. Res. 2018, 8, 119–129. [Google Scholar] [CrossRef] [Green Version]

- Che, Q.; Yang, M.; Wang, X.; Yang, Q.; Rose Williams, L.; Yang, H.; Zou, J.; Zeng, K.; Zhu, Y.; Chen, Y.; et al. Influence of Physicochemical Properties of Metal Modified ZSM-5 Catalyst on Benzene, Toluene and Xylene Production from Biomass Catalytic Pyrolysis. Bioresour. Technol. 2019, 278, 248–254. [Google Scholar] [CrossRef]

- Wang, D.; Jin, L.; Li, Y.; Wei, B.; Yao, D.; Hu, H. Effect of Reducibility of Transition Metal Oxides on In-Situ Oxidative Catalytic Cracking of Tar. Energy Convers. Manag. 2019, 197, 111871. [Google Scholar] [CrossRef]

- Emeis, C.A. Determination of Integrated Molar Extinction Coefficients for Infrared Absorption Bands of Pyridine Adsorbed on Solid Acid Catalysts. J. Catal. 1993, 141, 347–354. [Google Scholar] [CrossRef]

- Chen, H.-Y.; Sachtler, W.M.H. Activity and Durability of Fe/ZSM-5 Catalysts for Lean Burn NOx Reduction in the Presence of Water Vapor. Catal. Today 1998, 42, 73–83. [Google Scholar] [CrossRef]

- Denardin, F.; Perez-Lopez, O.W. Tuning the Acidity and Reducibility of Fe/ZSM-5 Catalysts for Methane Dehydroaromatization. Fuel 2019, 236, 1293–1300. [Google Scholar] [CrossRef]

- Jiménez-López, A.; Rodríguez-Castellón, E.; Maireles-Torres, P.; Díaz, L.; Mérida-Robles, J. Chromium Oxide Supported on Zirconium- and Lanthanum-Doped Mesoporous Silica for Oxidative Dehydrogenation of Propane. Appl. Catal. A Gen. 2001, 218, 295–306. [Google Scholar] [CrossRef]

- Karami, H.; Soltanali, S.; Najafi, A.M.; Ghazimoradi, M.; Yaghoobpour, E.; Abbasi, A. Amorphous Silica-Alumina as Robust Support for Catalytic Dehydrogenation of Propane: Effect of Si/Al Ratio on Nature and Dispersion of Cr Active Sites. Appl. Catal. A Gen. 2023, 658, 119167. [Google Scholar] [CrossRef]

- Wan, B.-Z.; Chu, H.M. Reaction Kinetics of Propane Dehydrogenation over Partially Reduced Zinc Oxide Supported on Silicalite. J. Chem. Soc. Faraday Trans. 1992, 88, 2943–2947. [Google Scholar] [CrossRef]

- Lai, S.; She, Y.; Zhan, W.; Guo, Y.; Guo, Y.; Wang, L.; Lu, G. Performance of Fe-ZSM-5 for Selective Catalytic Reduction of NOx with NH3: Effect of the Atmosphere during the Preparation of Catalysts. J. Mol. Catal. A Chem. 2016, 424, 232–240. [Google Scholar] [CrossRef]

- de Oliveira, T.K.R.; Rosset, M.; Perez-Lopez, O.W. Ethanol Dehydration to Diethyl Ether over Cu-Fe/ZSM-5 Catalysts. Catal. Commun. 2018, 104, 32–36. [Google Scholar] [CrossRef]

- Pérez-Uriarte, P.; Gamero, M.; Ateka, A.; Díaz, M.; Aguayo, A.T.; Bilbao, J. Effect of the Acidity of HZSM-5 Zeolite and the Binder in the DME Transformation to Olefins. Ind. Eng. Chem. Res. 2016, 55, 1513–1521. [Google Scholar] [CrossRef]

- Bertero, M.; García, J.R.; Falco, M.; Sedran, U. Hydrocarbons from Bio-Oils: Performance of the Matrix in FCC Catalysts in the Immediate Catalytic Upgrading of Different Raw Bio-Oils. Waste Biomass Valorization 2017, 8, 933–948. [Google Scholar] [CrossRef]

- Crespo, I.; Hertzog, J.; Carré, V.; Aubriet, F.; Valle, B. Alumina-Embedded HZSM-5 with Enhanced Behavior for the Catalytic Cracking of Biomass Pyrolysis Bio-Oil: Insights into the Role of Mesoporous Matrix in the Deactivation by Coke. J. Anal. Appl. Pyrolysis 2023, 172, 106009. [Google Scholar] [CrossRef]

- Arumugam, M.; Goh, C.K.; Zainal, Z.; Triwahyono, S.; Lee, A.F.; Wilson, K.; Taufiq-Yap, Y.H. Hierarchical HZSM-5 for Catalytic Cracking of Oleic Acid to Biofuels. Nanomaterials 2021, 11, 747. [Google Scholar] [CrossRef]

- Gao, J.; Zhou, H.; Zhang, F.; Ji, K.; Liu, P.; Liu, Z.; Zhang, K. Effect of Preparation Method on the Catalytic Performance of HZSM-5 Zeolite Catalysts in the MTH Reaction. Materials 2022, 15, 2206. [Google Scholar] [CrossRef]

- Gayubo, A.G.; Valle, B.; Aguayo, A.T.; Olazar, M.; Bilbao, J. Attenuation of Catalyst Deactivation by Cofeeding Methanol for Enhancing the Valorisation of Crude Bio-Oil. Energy Fuels 2009, 23, 4129–4136. [Google Scholar] [CrossRef]

- Du, L.; Luo, Z.; Wang, K.; Miao, F.; Qian, Q. Catalytic Co-Conversion of Poplar Pyrolysis Vapor and Methanol for Aromatics Production via Ex-Situ Configuration. J. Anal. Appl. Pyrolysis 2022, 165, 105571. [Google Scholar] [CrossRef]

| Bulk HZ-30 | Cr-Z30 | Fe-Z30 | Zn-Z30 | |

|---|---|---|---|---|

| SBET (m2 g−1) | 267 | 271 | 254 | 251 |

| VMicropore (cm3 g−1) | 0.06 | 0.06 | 0.05 | 0.04 |

| VMesopore (cm3 g−1) | 0.31 | 0.29 | 0.29 | 0.30 |

| Acidity (μmolNH3 g−1) | 227 | 170 | 175 | 128 |

| Bulk HZ-30 | Cr-Z30 | Fe-Z30 | Zn-Z30 | |

|---|---|---|---|---|

| CC (wt%) | 12.8 | 12.1 | 10.8 | 10.1 |

| SBET (m2 g−1) | 93 | 87 | 105 | 107 |

| Surface loss (%) | 65 | 68 | 59 | 57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiosso, M.E.; Crespo, I.; Merlo, A.B.; Valle, B. Metal-Doped HZSM-5 Zeolite Catalysts for Catalytic Cracking of Raw Bio-Oil: Exploring Activity toward Value-Added Products. Catalysts 2023, 13, 1198. https://doi.org/10.3390/catal13081198

Chiosso ME, Crespo I, Merlo AB, Valle B. Metal-Doped HZSM-5 Zeolite Catalysts for Catalytic Cracking of Raw Bio-Oil: Exploring Activity toward Value-Added Products. Catalysts. 2023; 13(8):1198. https://doi.org/10.3390/catal13081198

Chicago/Turabian StyleChiosso, María Eugenia, Iratxe Crespo, Andrea Beatriz Merlo, and Beatriz Valle. 2023. "Metal-Doped HZSM-5 Zeolite Catalysts for Catalytic Cracking of Raw Bio-Oil: Exploring Activity toward Value-Added Products" Catalysts 13, no. 8: 1198. https://doi.org/10.3390/catal13081198