Repurposing Mining and Metallurgical Waste as Electroactive Materials for Advanced Energy Applications: Advances and Perspectives

Abstract

:1. Introduction

2. Mining and Metallurgical Waste-Based Electroactive Materials for Advanced Energy Applications

2.1. Batteries

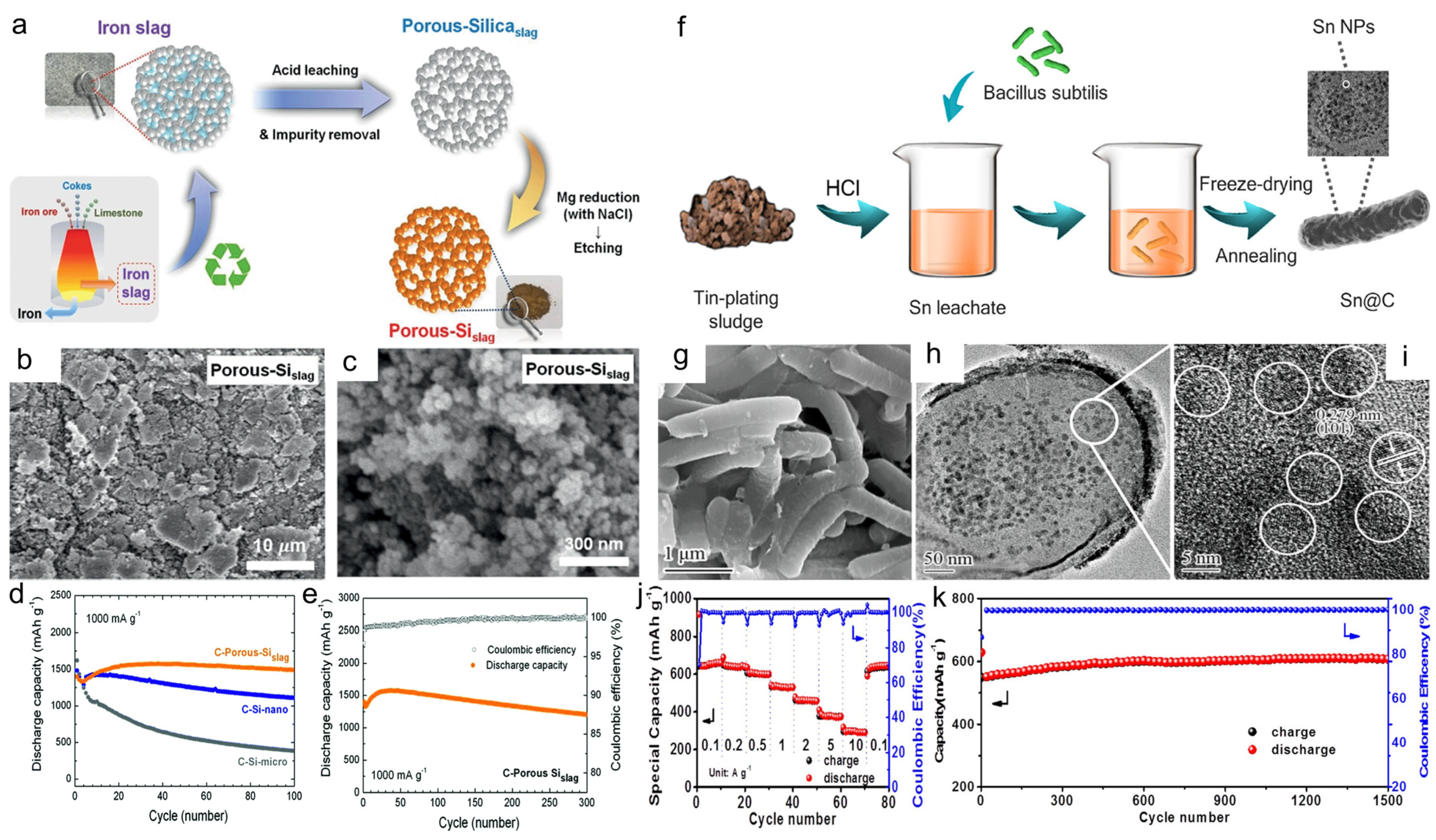

2.1.1. Anode Materials

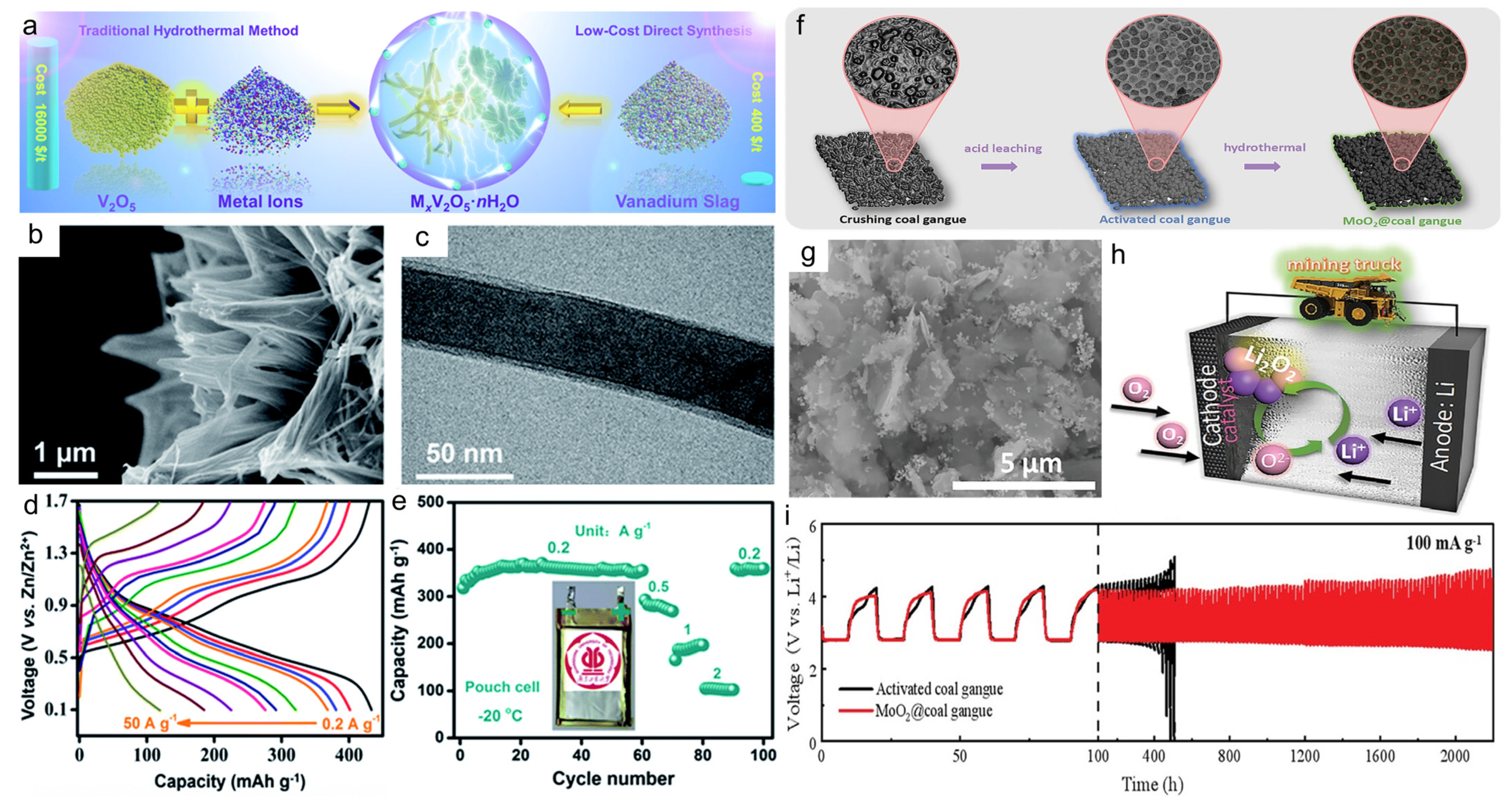

2.1.2. Cathode Materials

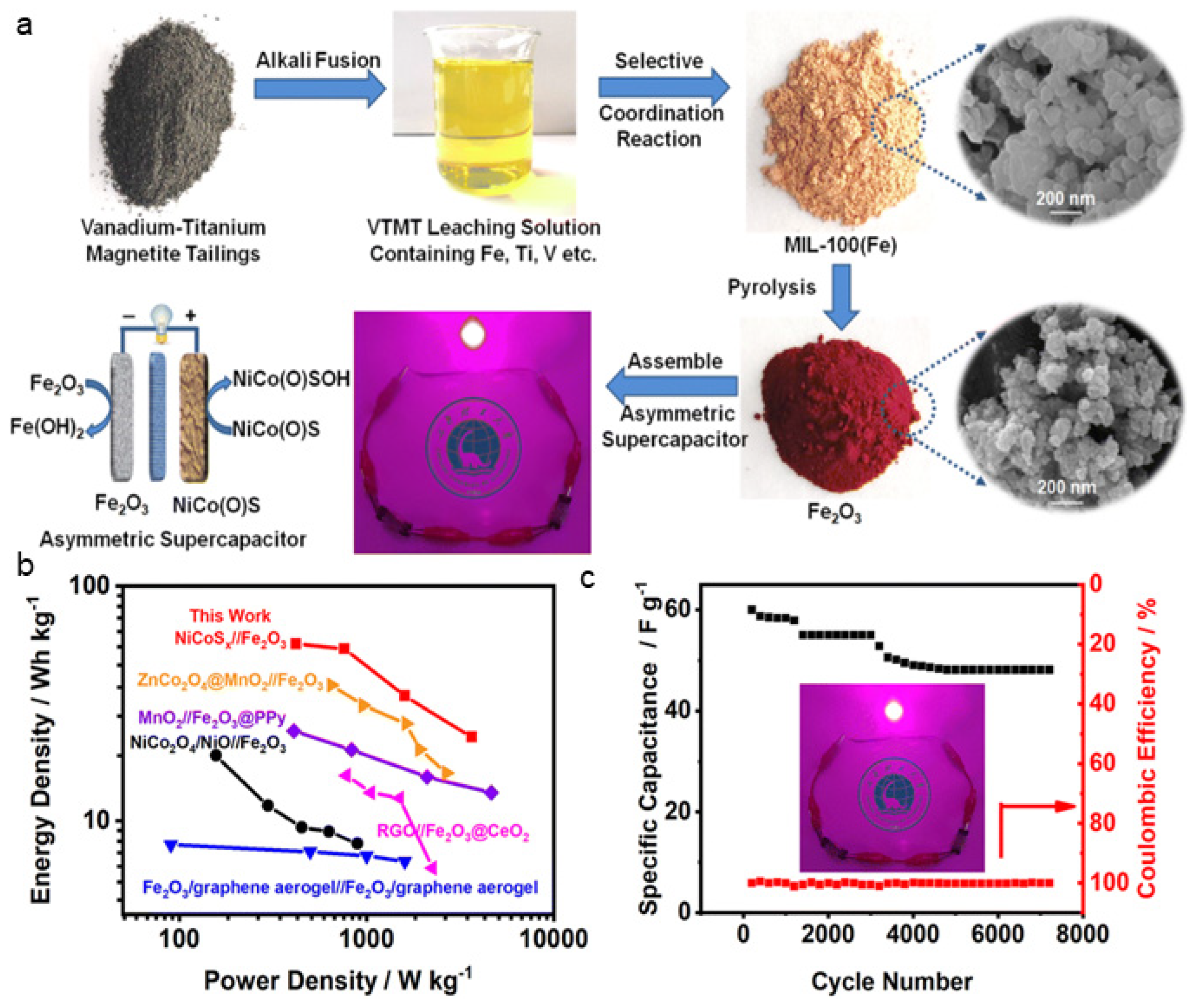

2.2. Supercapacitors

2.2.1. Metal (Hydr)oxide Materials

2.2.2. Composite Materials

2.3. Fuel Cells

2.4. Small-Molecule Conversion

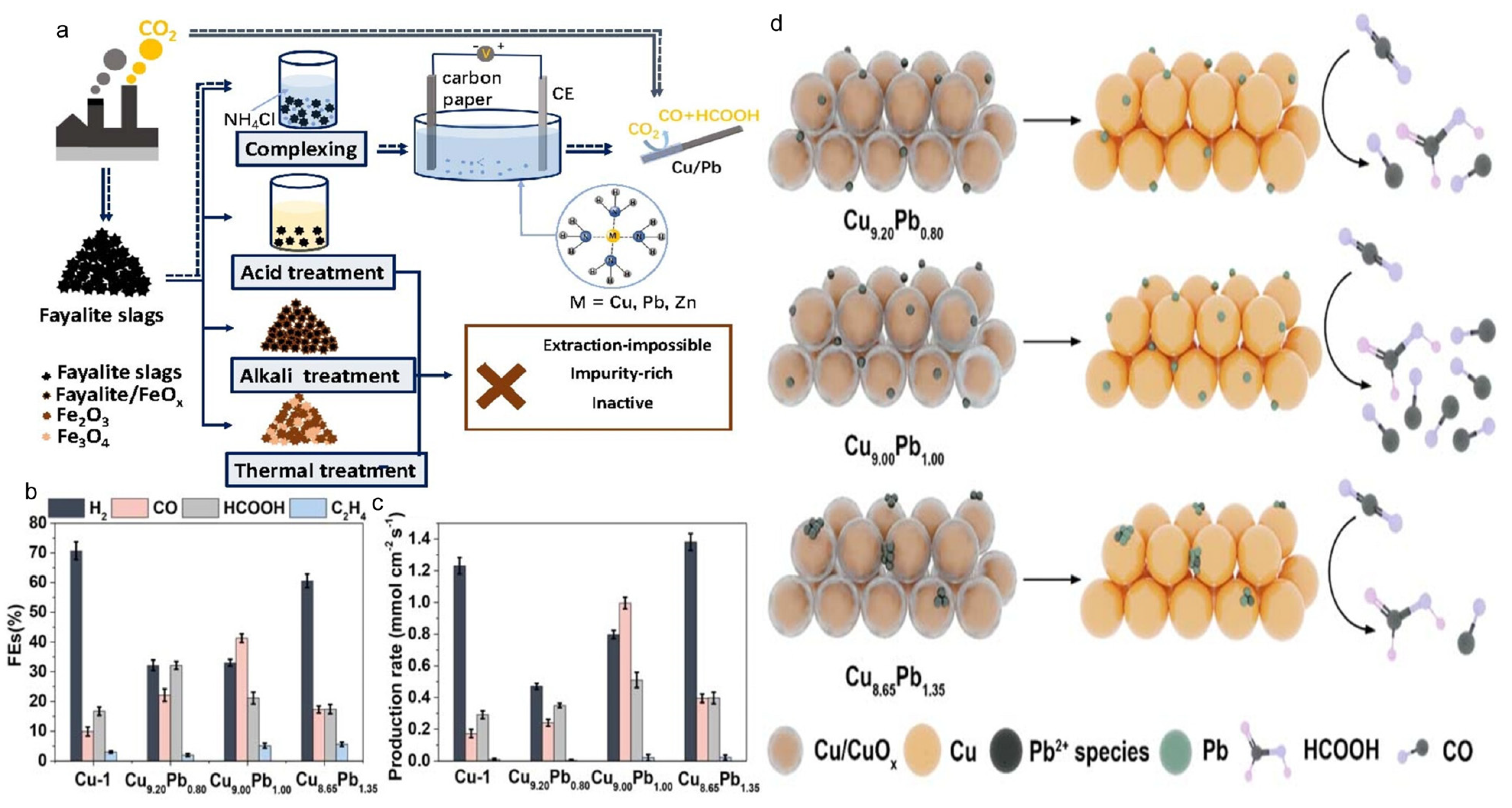

2.4.1. Materials for CO2 Reduction

2.4.2. Materials for N2/Nitrate Reduction

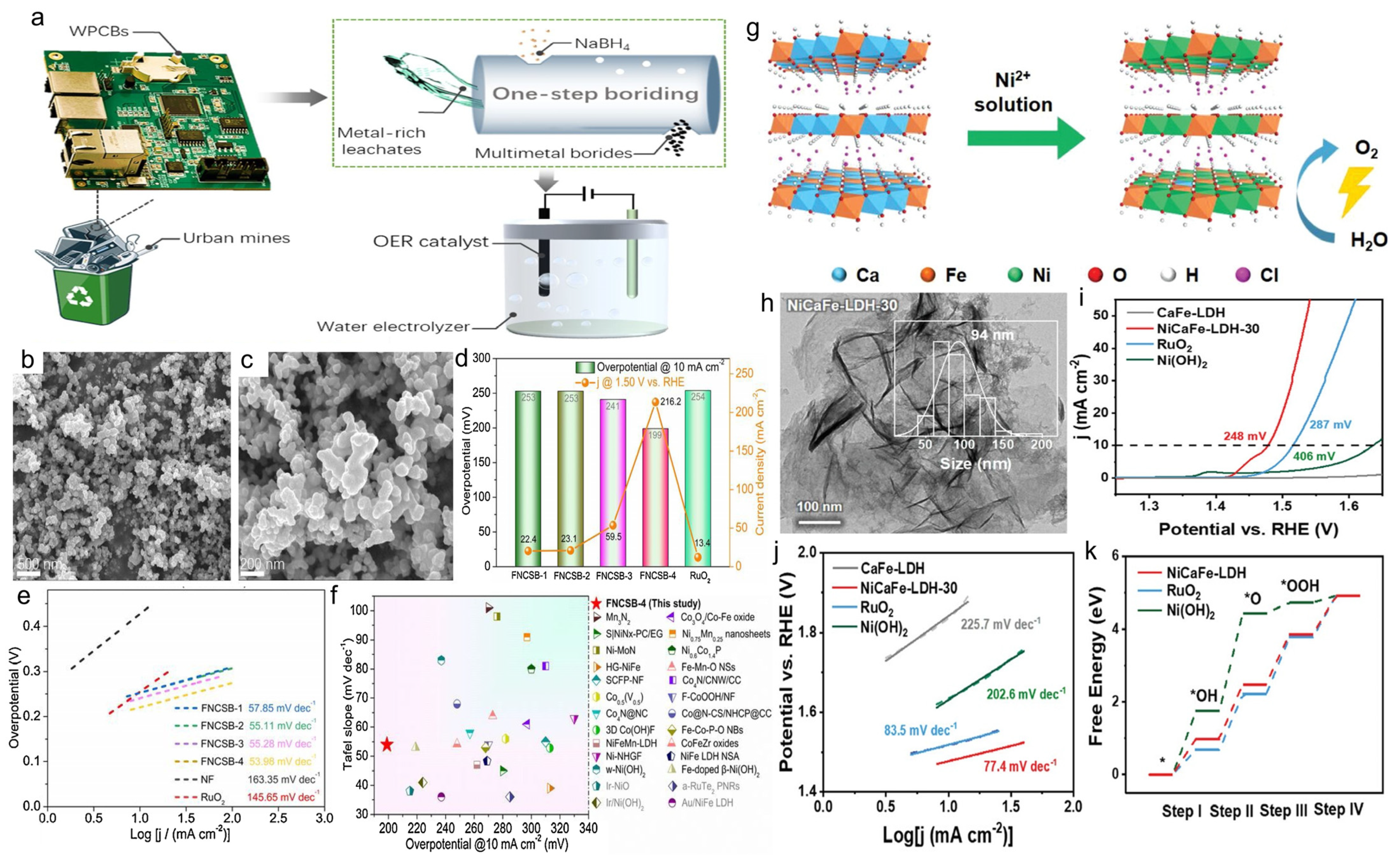

2.4.3. Materials for Water Oxidation

3. Conclusions and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xavier, L.H.; Ottoni, M.; Abreu, L.P.P. A comprehensive review of urban mining and the value recovery from e-waste materials. Resour. Conserv. Recycl. 2023, 190, 106840. [Google Scholar] [CrossRef]

- Šajn, R.; Ristović, I.; Čeplak, B. Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region. Minerals 2022, 12, 547. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, Z.; Zheng, R.; Gao, H.; Ni, B.-J. Migration behavior of impurities during the purification of waste graphite powders. J. Environ. Manag. 2022, 315, 115150. [Google Scholar] [CrossRef] [PubMed]

- Makhathini, T.P.; Bwapwa, J.K.; Mtsweni, S. Various Options for Mining and Metallurgical Waste in the Circular Economy: A Review. Sustainability 2023, 15, 2518. [Google Scholar] [CrossRef]

- Araujo, F.S.M.; Taborda-Llano, I.; Nunes, E.B.; Santos, R.M. Recycling and Reuse of Mine Tailings: A Review of Advancements and Their Implications. Geosciences 2022, 12, 319. [Google Scholar] [CrossRef]

- Kaniki, A.T.; Tumba, K. Management of mineral processing tailings and metallurgical slags of the Congolese copperbelt: Environmental stakes and perspectives. J. Clean. Prod. 2019, 210, 1406–1413. [Google Scholar] [CrossRef]

- Chen, Z.; Yun, S.; Wu, L.; Zhang, J.; Shi, X.; Wei, W.; Liu, Y.; Zheng, R.; Han, N.; Ni, B.-J. Waste-Derived Catalysts for Water Electrolysis: Circular Economy-Driven Sustainable Green Hydrogen Energy. Nano-Micro Lett. 2023, 15, 4. [Google Scholar] [CrossRef]

- Yang, T.; Niu, Y.; Liu, Q.; Xu, M. Cathode host engineering for non-lithium (Na, K and Mg) sulfur/selenium batteries: A state-of-the-art review. Nano Mater. Sci. 2023, 5, 119–140. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, R.; Graś, M.; Wei, W.; Lota, G.; Chen, H.; Ni, B.-J. Tuning electronic property and surface reconstruction of amorphous iron borides via W-P co-doping for highly efficient oxygen evolution. Appl. Catal. B Environ. 2021, 288, 120037. [Google Scholar] [CrossRef]

- Zhang, Y.; Fu, C.; Weng, S.; Lv, H.; Li, P.; Deng, S.; Hao, W. Construction of an “environment-friendly” CuBx@PU self-supporting electrode toward efficient seawater electrolysis. Green Chem. 2022, 24, 5918–5929. [Google Scholar] [CrossRef]

- Pei, Y.R.; Zhao, M.; Zhu, Y.P.; Yang, C.C.; Jiang, Q. VN nanoparticle-assembled hollow microspheres/N-doped carbon nanofibers: An anode material for superior potassium storage. Nano Mater. Sci. 2022, 4, 104–112. [Google Scholar] [CrossRef]

- Hou, Z.; Meng, H.; Shao, X.; Wang, X.; Tahir, M.U.; Ahmad, S.; Yang, C.; Su, X.; Zhang, L. Synthesis of amorphous hollow Ni(HCO3)2 nanostructures with excellent supercapacitor performance from nickel-containing electroplating sludge. J. Environ. Chem. Eng. 2022, 10, 106906. [Google Scholar] [CrossRef]

- Zhang, K.; Cen, Z.; Yang, F.; Xu, K. Rational construction of NiCo2O4@Fe2O3 core-shell nanowire arrays for high-performance supercapacitors. Prog. Nat. Sci. Mater. Int. 2021, 31, 19–24. [Google Scholar] [CrossRef]

- Yao, J.; Li, H.; Li, Y.; Yang, J.; Liu, B. Based on the utilization of jarosite residue: The lithium storage performance of α-Fe2O3 materials synthesized from different iron solution systems. J. Electroanal. Chem. 2022, 907, 116085. [Google Scholar] [CrossRef]

- Oh, K.-S.; Lee, J.E.; Lee, Y.-H.; Jeong, Y.-S.; Kristanto, I.; Min, H.-S.; Kim, S.-M.; Hong, Y.J.; Kwak, S.K.; Lee, S.-Y. Elucidating Ion Transport Phenomena in Sulfide/Polymer Composite Electrolytes for Practical Solid-State Batteries. Nano-Micro Lett. 2023, 15, 179. [Google Scholar] [CrossRef]

- Chen, Z.; Duan, X.; Wei, W.; Wang, S.; Ni, B.-J. Recent advances in transition metal-based electrocatalysts for alkaline hydrogen evolution. J. Mater. Chem. A 2019, 7, 14971–15005. [Google Scholar] [CrossRef]

- Yu, K.; Yang, H.; Zhang, H.; Huang, H.; Wang, Z.; Kang, Z.; Liu, Y.; Menezes, P.W.; Chen, Z. Immobilization of Oxyanions on the Reconstructed Heterostructure Evolved from a Bimetallic Oxysulfide for the Promotion of Oxygen Evolution Reaction. Nano-Micro Lett. 2023, 15, 186. [Google Scholar] [CrossRef]

- Yao, J.; Yang, Y.; Li, Y.; Jiang, J.; Xiao, S.; Yang, J. Interconnected α-Fe2O3 nanoparticles prepared from leaching liquor of tin ore tailings as anode materials for lithium-ion batteries. J. Alloys Compd. 2021, 855, 157288. [Google Scholar] [CrossRef]

- Chen, J.; Qian, L.; Fu, Z.; Li, G.; Zeng, Y. Recycling of iron from vanadium titanium magnetite tailings and its application in an asymmetric supercapacitor. New J. Chem. 2023, 47, 9383–9391. [Google Scholar] [CrossRef]

- Jadhav, D.A.; Ghadge, A.N.; Ghangrekar, M.M. Enhancing the power generation in microbial fuel cells with effective utilization of goethite recovered from mining mud as anodic catalyst. Bioresour. Technol. 2015, 191, 110–116. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, R.; Zou, W.; Wei, W.; Li, J.; Wei, W.; Ni, B.-J.; Chen, H. Integrating high-efficiency oxygen evolution catalysts featuring accelerated surface reconstruction from waste printed circuit boards via a boriding recycling strategy. Appl. Catal. B Environ. 2021, 298, 120583. [Google Scholar] [CrossRef]

- Zhong, X.; Zhong, Z.; Liang, S.; Zeng, G.; Cheng, S.; Deng, H.; Lin, Z. Towards a broad-operation window for stable CO2 electroreduction to HCOOH by a design involving upcycling electroplating sludge-derived Sn@N/P-doped carbon. Environ. Sci. Nano 2022, 9, 511–522. [Google Scholar] [CrossRef]

- Liu, H.; Hu, G.; Luo, Y.; Zhang, K.; Chen, S.; Qin, A. Red mud-based lithium-ion battery anode material with high electrochemical performance prepared by acid and SDS-assisted hydrothermal method. J. Mater. Sci. Mater. Electron. 2022, 33, 6201–6213. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, M.; Chen, Z.; Wang, Y.; Li, S.; Duan, P.; Zhong, Y.; Wu, Z.; Guo, X.; Yan, Z.; et al. Constructing cycle-stable Si/TiSi2 composites as anode materials for lithium ion batteries through direct utilization of low-purity Si and Ti-bearing blast furnace slag. J. Alloys Compd. 2021, 876, 160125. [Google Scholar] [CrossRef]

- Weng, C.; Sun, X.; Han, B.; Ye, X.; Zhong, Z.; Li, W.; Liu, W.; Deng, H.; Lin, Z. Targeted conversion of Ni in electroplating sludge to nickel ferrite nanomaterial with stable lithium storage performance. J. Hazard. Mater. 2020, 393, 122296. [Google Scholar] [CrossRef]

- Chun, J.; An, S.; Lee, J. Highly mesoporous silicon derived from waste iron slag for high performance lithium ion battery anodes. J. Mater. Chem. A 2015, 3, 21899–21906. [Google Scholar] [CrossRef]

- Sun, Z.; Hu, Y.; Zeng, K.; Li, M.; Zhao, S.; Zhang, J. Turn “Waste” Into Wealth: MoO2@coal Gangue Electrocatalyst with Amorphous/Crystalline Heterostructure for Efficient Li–O2 Batteries. Small 2023, 19, 2208145. [Google Scholar] [CrossRef]

- Wu, Z.J.; Yue, H.F.; Li, L.S.; Jiang, B.F.; Wu, X.R.; Wang, P. Synthesis and electrochemical properties of multi-doped LiFePO4/C prepared from the steel slag. J. Power Sources 2010, 195, 2888–2893. [Google Scholar] [CrossRef]

- Chen, D.; Chen, H.; Du, C.-F.; Liu, L.; Geng, H.; Yu, H.; Rui, X. From vanadium slag to multi-cation-intercalated V2O5·nH2O: Low-cost direct synthesis and high-performance aqueous battery application. J. Mater. Chem. A 2022, 10, 5479–5487. [Google Scholar] [CrossRef]

- Lv, T.; Li, J.; Shi, Y.; Yu, H.; Chen, J. Activating biomass carbon with metallurgical slag by pyrolysis in molten salt for high-performance supercapacitors. RSC Adv. 2023, 13, 23021–23029. [Google Scholar] [CrossRef]

- Shaikh, A.; Singh, B.K.; Purnendu, K.; Kumari, P.; Sankar, P.R.; Mundra, G.; Bohm, S. Utilization of the nickel hydroxide derived from a spent electroless nickel plating bath for energy storage applications. RSC Sustain. 2023, 1, 294–302. [Google Scholar] [CrossRef]

- Xie, Y.; Sun, Z.; Han, T.; Xie, Z.; Zhang, J.; Sun, H.; Xiao, J.; Wang, Y.; Yu, F.; Yang, N. Highly efficient utilization of industrial barium slag for carbon gasification in direct carbon solid oxide fuel cells. Int. J. Hydrogen Energy 2021, 46, 37029–37038. [Google Scholar] [CrossRef]

- Yang, S.; An, H.; Anastasiadou, D.; Xu, W.; Wu, L.; Wang, H.; de Ruiter, J.; Arnouts, S.; Figueiredo, M.C.; Bals, S.; et al. Waste-Derived Copper-Lead Electrocatalysts for CO2 Reduction. ChemCatChem 2022, 14, e202200754. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Cui, Y.; Zhang, J.; Xu, Y.; Liu, Q.; Qian, G. Synthesis of electrocatalyst from electroplating sludge for efficient N2 reduction under ambient conditions. Chem. Eng. J. 2022, 429, 132357. [Google Scholar] [CrossRef]

- Xu, Y.-T.; Ren, K.-C.; Tao, Z.-M.; Sam, D.K.; Feng, E.; Wang, X.; Zhang, G.; Wu, J.; Cao, Y. A new catalyst based on disposed red mud for the efficient electrochemical reduction of nitrate-to-ammonia. Green Chem. 2023, 25, 589–595. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Ni, B.-J.; Chen, H. Plastic wastes derived carbon materials for green energy and sustainable environmental applications. Environ. Funct. Mater. 2022, 1, 34–48. [Google Scholar] [CrossRef]

- Lv, X.; Tang, F.; Yao, Y.; Xu, C.; Chen, D.; Liu, L.; Feng, Y.; Rui, X.; Yu, Y. Sodium–gallium alloy layer for fast and reversible sodium deposition. SusMat 2022, 2, 699–707. [Google Scholar] [CrossRef]

- Li, Y.; Ma, D.; Wang, Y.; Yang, H.; Lou, Z.; Qin, R.; Zhao, Q.; Pan, F.; Liu, H. A novel bimetallic RuFe nanocluster to enable highly efficient oxygen reduction in zinc-air batteries. Prog. Nat. Sci. Mater. Int. 2022, 32, 769–775. [Google Scholar] [CrossRef]

- Yan, N.-F.; Cui, H.-M.; Shi, J.-S.; You, S.-Y.; Liu, S. Recent progress of W18O49 nanowires for energy conversion and storage. Tungsten 2023. [Google Scholar] [CrossRef]

- Fu, Y.; Jin, Y.; Ma, J.; Liu, J.; Wang, Z.; Wang, B.; Gong, X. Lithium-ion transfer strengthened by graphite tailings and coking coal for high-rate performance anode. Chem. Eng. J. 2022, 442, 136184. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, C.; Yu, S.; Ge, D.; Zhou, H. Status and challenges facing representative anode materials for rechargeable lithium batteries. J. Energy Chem. 2022, 66, 260–294. [Google Scholar] [CrossRef]

- Li, X.; Chen, Y.; Huang, H.; Mai, Y.-W.; Zhou, L. Electrospun carbon-based nanostructured electrodes for advanced energy storage–a review. Energy Storage Mater. 2016, 5, 58–92. [Google Scholar] [CrossRef]

- Hou, L.; Xing, B.; Zeng, H.; Kang, W.; Guo, H.; Cheng, S.; Huang, G.; Cao, Y.; Chen, Z.; Zhang, C. Aluminothermic reduction synthesis of Si/C composite nanosheets from waste vermiculite as high-performance anode materials for lithium-ion batteries. J. Alloys Compd. 2022, 922, 166134. [Google Scholar] [CrossRef]

- Zhang, S.; Zhang, N.; Zhao, W.; Lan, D.; Hao, G.; Yi, X.; Yang, Z.; Hu, J.; He, W.; Liu, Y.; et al. Green preparation of hierarchical porous C/SiOx composites from coal gangue as anodes for Li-ion batteries. Solid State Ion. 2021, 371, 115772. [Google Scholar] [CrossRef]

- Idota, Y.; Kubota, T.; Matsufuji, A.; Maekawa, Y.; Miyasaka, T. Tin-based amorphous oxide: A high-capacity lithium-ion-storage material. Science 1997, 276, 1395–1397. [Google Scholar] [CrossRef]

- Ye, X.; Lin, Z.; Liang, S.; Huang, X.; Qiu, X.; Qiu, Y.; Liu, X.; Xie, D.; Deng, H.; Xiong, X.; et al. Upcycling of Electroplating Sludge into Ultrafine Sn@C Nanorods with Highly Stable Lithium Storage Performance. Nano Lett. 2019, 19, 1860–1866. [Google Scholar] [CrossRef] [PubMed]

- Zheng, M.; Tang, H.; Li, L.; Hu, Q.; Zhang, L.; Xue, H.; Pang, H. Hierarchically nanostructured transition metal oxides for lithium-ion batteries. Adv. Sci. 2018, 5, 1700592. [Google Scholar] [CrossRef] [PubMed]

- Chen, Z.; Wei, W.; Chen, H.; Ni, B.-J. Eco-designed electrocatalysts for water splitting: A path toward carbon neutrality. Int. J. Hydrogen Energy 2023, 48, 6288–6307. [Google Scholar] [CrossRef]

- Suryawanshi, A.; Aravindan, V.; Madhavi, S.; Ogale, S. Red Mud and Li-Ion Batteries: A Magnetic Connection. ChemSusChem 2016, 9, 2193–2200. [Google Scholar] [CrossRef]

- Zhang, Y.; Ma, C.; He, W.; Zhang, C.; Zhou, L.; Wang, G.; Wei, W. MXene and MXene-based materials for lithium-sulfur batteries. Prog. Nat. Sci. Mater. Int. 2021, 31, 501–513. [Google Scholar] [CrossRef]

- Zou, W.; Li, J.; Wang, R.; Ma, J.; Chen, Z.; Duan, L.; Mi, H.; Chen, H. Hydroxylamine mediated Fenton-like interfacial reaction dynamics on sea urchin-like catalyst derived from spent LiFePO4 battery. J. Hazard. Mater. 2022, 431, 128590. [Google Scholar] [CrossRef]

- Guo, J.; Feng, Y.; Mo, X.; Liao, G. Preparation of LiFePO4 using iron(II) sulfate as product from titanium dioxide slag purification process and its electrochemical properties. Int. J. Electrochem. Sci. 2021, 16, 211141. [Google Scholar] [CrossRef]

- Kang, H.; Wang, G.; Guo, H.; Chen, M.; Luo, C.; Yan, K. Facile Synthesis and Electrochemical Performance of LiFePO4/C Composites Using Fe–P Waste Slag. Ind. Eng. Chem. Res. 2012, 51, 7923–7931. [Google Scholar] [CrossRef]

- Lan, D.; Zhang, G.; Mo, M.; Fang, Z.; Shi, S.; Hu, K.; Huang, Y.; Zang, R.; Li, W.; Zhan, H.; et al. Short-process simultaneously recycling cobalt and manganese from environment-hazardous di-methyl-dithiocarbamate chelate slag as lithium-ion battery cathode material. Sustain. Energy Technol. Assess. 2023, 57, 103231. [Google Scholar] [CrossRef]

- Meng, X.; Cao, H.; Hao, J.; Ning, P.; Xu, G.; Sun, Z. Sustainable Preparation of LiNi1/3Co1/3Mn1/3O2–V2O5 Cathode Materials by Recycling Waste Materials of Spent Lithium-Ion Battery and Vanadium-Bearing Slag. ACS Sustain. Chem. Eng. 2018, 6, 5797–5805. [Google Scholar] [CrossRef]

- Wu, L.; Li, X.-H.; Wang, Z.-X.; Li, L.-J.; Zheng, J.-C.; Guo, H.-J.; Hu, Q.-Y.; Fang, J. Synthesis and electrochemical properties of metals-doped LiFePO4 prepared from the FeSO4·7H2O waste slag. J. Power Sources 2009, 189, 681–684. [Google Scholar] [CrossRef]

- Wu, L.; Wang, Z.; Li, X.; Guo, H.; Li, L.; Wang, X.; Zheng, J. Cation-substituted LiFePO4 prepared from the FeSO4·7H2O waste slag as a potential Li battery cathode material. J. Alloys Compd. 2010, 497, 278–284. [Google Scholar] [CrossRef]

- Li, P.; Luo, S.-H.; Wang, J.; Wang, Y.; Wang, Q.; Zhang, Y.; Liu, X.; Gao, D.; Lv, F.; Mu, W.; et al. Extraction and separation of Fe and Ti from extracted vanadium residue by enhanced ammonium sulfate leaching and synthesis of LiFePO4/C for lithium-ion batteries. Sep. Purif. Technol. 2022, 282, 120065. [Google Scholar] [CrossRef]

- Yang, L.; Feng, Y.; Wang, C.; Fang, D.; Yi, G.; Gao, Z.; Shao, P.; Liu, C.; Luo, X.; Luo, S. Closed-loop regeneration of battery-grade FePO4 from lithium extraction slag of spent Li-ion batteries via phosphoric acid mixture selective leaching. Chem. Eng. J. 2022, 431, 133232. [Google Scholar] [CrossRef]

- Lv, T.; Peng, Y.; Zhang, G.; Jiang, S.; Yang, Z.; Yang, S.; Pang, H. How About Vanadium-Based Compounds as Cathode Materials for Aqueous Zinc Ion Batteries? Adv. Sci. 2023, 10, 2206907. [Google Scholar] [CrossRef]

- Xu, G.; Liu, X.; Huang, S.; Li, L.; Wei, X.; Cao, J.; Yang, L.; Chu, P.K. Freestanding; Hierarchical, and Porous Bilayered NaxV2O5 nH2O/rGO/CNT Composites as High-Performance Cathode Materials for Nonaqueous K-Ion Batteries and Aqueous Zinc-Ion Batteries. ACS Appl. Mater. Interfaces 2019, 12, 706–716. [Google Scholar] [CrossRef]

- Hua, W.; Li, H.; Pei, C.; Xia, J.; Sun, Y.; Zhang, C.; Lv, W.; Tao, Y.; Jiao, Y.; Zhang, B. Selective catalysis remedies polysulfide shuttling in lithium-sulfur batteries. Adv. Mater. 2021, 33, 2101006. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Ke, Y.; Tang, J.; Lei, X.; Deng, H.; Lin, Z. Upcycling of electroplating sludge into Fe3C-decorated N,P dual-doped porous carbon via microalgae as efficient sulfur host for lithium–sulfur batteries. Surf. Interfaces 2022, 30, 101869. [Google Scholar] [CrossRef]

- Kwak, W.-J.; Rosy; Sharon, D.; Xia, C.; Kim, H.; Johnson, L.R.; Bruce, P.G.; Nazar, L.F.; Sun, Y.-K.; Frimer, A.A.; et al. Lithium–Oxygen Batteries and Related Systems: Potential, Status, and Future. Chem. Rev. 2020, 120, 6626–6683. [Google Scholar] [CrossRef]

- Sun, Z.; Zhou, N.; Li, M.; Xu, J.; Feng, W.; Liu, S. Functional Control Engineering of Coal Gangue Electrocatalyst with Amorphous SiCX/SiOX Active Layer Loading Enables Efficient Li-O2 Batteries. Appl. Sci. 2023, 13, 5551. [Google Scholar] [CrossRef]

- Zhao, J.; Burke, A.F. Review on supercapacitors: Technologies and performance evaluation. J. Energy Chem. 2021, 59, 276–291. [Google Scholar] [CrossRef]

- Liu, W.-J.; Yuan, M.; Lian, J.-B.; Li, G.-C.; Li, Q.-P.; Qiao, F.; Zhao, Y. Embedding partial sulfurization of iron–cobalt oxide nanoparticles into carbon nanofibers as an efficient electrode for the advanced asymmetric supercapacitor. Tungsten 2023, 5, 118–129. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Ni, B.-J. Cost-effective catalysts for renewable hydrogen production via electrochemical water splitting: Recent advances. Curr. Opin. Green Sustain. Chem. 2021, 27, 100398. [Google Scholar] [CrossRef]

- Bhattacharya, G.; Fishlock, S.J.; Roy, J.S.; Pritam, A.; Banerjee, D.; Deshmukh, S.; Ghosh, S.; McLaughlin, J.A.; Roy, S.S. Effective Utilization of Waste Red Mud for High Performance Supercapacitor Electrodes. Glob. Chall. 2019, 3, 1800066. [Google Scholar] [CrossRef]

- Yadav, P.; Raju, M.K.; Samudrala, R.K.; Gangadhar, M.; Pani, J.; Borkar, H.; Azeem, P.A. Cost-effective akermanite derived from industrial waste for working electrodes in supercapacitor applications. New J. Chem. 2023, 47, 3255–3265. [Google Scholar] [CrossRef]

- Liu, T.; Zhou, H.; Zhong, G.; Yan, X.; Su, X.; Lin, Z. Synthesis of NiFeAl LDHs from electroplating sludge and Their excellent supercapacitor performance. J. Hazard. Mater. 2021, 404, 124113. [Google Scholar] [CrossRef] [PubMed]

- Zhan, P.; Xu, J.; Wang, J.; Zuo, J.; He, Z. Structural supercapacitor electrolytes based on cementitious composites containing recycled steel slag and waste glass powders. Cem. Concr. Compos. 2023, 137, 104924. [Google Scholar] [CrossRef]

- Zeng, C.; Duan, C.; Guo, Z.; Liu, Z.; Dou, S.; Yuan, Q.; Liu, P.; Zhang, J.; Luo, J.; Liu, W.; et al. Ultrafastly activated needle coke as electrode material for supercapacitors. Prog. Nat. Sci. Mater. Int. 2022, 32, 786–792. [Google Scholar] [CrossRef]

- Muthukannan, V.; Praveen, K.; Natesan, B. Fabrication and characterization of magnetite/reduced graphene oxide composite incurred from iron ore tailings for high performance application. Mater. Chem. Phys. 2015, 162, 400–407. [Google Scholar] [CrossRef]

- Livinus, O.C.; Sochima, E.V.; Joy, E.N.; Aigbodion, V.S. Insights in the synthesis and electrochemical performance of tin tailings/grapheme derived from rice husk/polyester composite electrode materials for supercapacitors. Int. J. Adv. Manuf. Technol. 2023, 128, 1879–1888. [Google Scholar] [CrossRef]

- Bhattacharya, G.; Fishlock, S.J.; Pritam, A.; Roy, S.S.; McLaughlin, J.A. Recycled Red Mud–Decorated Porous 3D Graphene for High-Energy Flexible Micro-Supercapacitor. Adv. Sustain. Syst. 2020, 4, 1900133. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Chen, H.; Ni, B. Recent advances in waste-derived functional materials for wastewater remediation. Eco-Environ. Health 2022, 1, 86–104. [Google Scholar] [CrossRef]

- Li, Y.; Han, X.; Yi, T.; He, Y.; Li, X. Review and prospect of NiCo2O4-based composite materials for supercapacitor electrodes. J. Energy Chem. 2019, 31, 54–78. [Google Scholar] [CrossRef]

- Hou, Z.; Liu, T.; Tahir, M.U.; Ahmad, S.; Shao, X.; Yang, C.; He, B.; Su, X. Facile conversion of nickel-containing electroplating sludge into nickel-based multilevel nano-material for high-performance pseudocapacitors. Appl. Surf. Sci. 2021, 538, 147978. [Google Scholar] [CrossRef]

- Wan, Z.; Tao, Y.; Shao, J.; Zhang, Y.; You, H. Ammonia as an effective hydrogen carrier and a clean fuel for solid oxide fuel cells. Energy Convers. Manag. 2021, 228, 113729. [Google Scholar] [CrossRef]

- Graś, M.; Kolanowski, Ł.; Chen, Z.; Lota, K.; Jurak, K.; Ryl, J.; Ni, B.-J.; Lota, G. Partial inhibition of borohydride hydrolysis using porous activated carbon as an effective method to improve the electrocatalytic activity of the DBFC anode. Sustain. Energy Fuels 2021, 5, 4401–4413. [Google Scholar] [CrossRef]

- Glibin, V.P.; Dodelet, J.-P.; Zhang, G. Energetics and thermodynamic stability of potential Fe(II)-hexa-aza-active sites for O2 reduction in PEM fuel cells. SusMat 2022, 2, 731–748. [Google Scholar] [CrossRef]

- Han, T.; Wu, Y.; Xie, Z.; Li, L.; Wang, Y.; Xie, Y.; Zhang, J.; Xiao, J.; Yu, F.; Yang, N. A novel Boudouard reaction catalyst derived from strontium slag for enhanced performance of direct carbon solid oxide fuel cells. J. Alloys Compd. 2022, 895, 162643. [Google Scholar] [CrossRef]

- Murmu, R.; Roy, D.; Patra, S.C.; Sutar, H.; Choudhary, B. Preparation and Characterization of Red Mud Modified Chitosan-PVA Composite Membrane for Direct Methanol Fuel Cell. J. Electrochem. Energy Convers. Storage 2023, 20, 031008. [Google Scholar] [CrossRef]

- Kim, K.; Nakashita, S.; Hibino, T. Enhanced power performance of an in situ sediment microbial fuel cell with steel-slag as the redox catalyst: I. electricity generation. Sustain. Energy Fuels 2020, 4, 1363–1371. [Google Scholar] [CrossRef]

- Jiang, C.; Ma, J.; Corre, G.; Jain, S.L.; Irvine, J.T. Challenges in developing direct carbon fuel cells. Chem. Soc. Rev. 2017, 46, 2889–2912. [Google Scholar] [CrossRef] [PubMed]

- Jiao, Y.; Wang, C.; Zhang, L.; An, W.; Zhou, N.; Yang, G.; Wang, W.; Zhou, W.; Li, S.-D. A steel slag–derived Boudouard reaction catalyst for improved performance of direct carbon solid oxide fuel cells. Int. J. Energy Res. 2019, 43, 6970–6982. [Google Scholar] [CrossRef]

- Yaqoob, A.A.; Ibrahim, M.N.M.; Yaakop, A.S.; Umar, K.; Ahmad, A. Modified graphene oxide anode: A bioinspired waste material for bioremediation of Pb2+ with energy generation through microbial fuel cells. Chem. Eng. J. 2021, 417, 128052. [Google Scholar] [CrossRef]

- Chen, Z.; Han, N.; Zheng, R.; Ren, Z.; Wei, W.; Ni, B.J. Design of earth-abundant amorphous transition metal-based catalysts for electrooxidation of small molecules: Advances and perspectives. SusMat 2023, 3, 290–319. [Google Scholar] [CrossRef]

- Du, C.; Qiu, C.; Fang, Z.; Li, P.; Gao, Y.; Wang, J.; Chen, W. Interface hydrophobic tunnel engineering: A general strategy to boost electrochemical conversion of N2 to NH3. Nano Energy 2022, 92, 106784. [Google Scholar] [CrossRef]

- Rossi, K.; Buonsanti, R. Shaping copper nanocatalysts to steer selectivity in the electrochemical CO2 reduction reaction. Acc. Chem. Res. 2022, 55, 629–637. [Google Scholar] [CrossRef]

- Han, N.; Feng, S.; Guo, W.; Mora, O.M.; Zhao, X.; Zhang, W.; Xie, S.; Zhou, Z.; Liu, Z.; Liu, Q. Rational design of Ruddlesden–Popper perovskite electrocatalyst for oxygen reduction to hydrogen peroxide. SusMat 2022, 2, 456–465. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, R.; Zou, H.; Wang, R.; Huang, C.; Dai, W.; Wei, W.; Duan, L.; Ni, B.-J.; Chen, H. Amorphous Iron-doped Nickel Boride with Facilitated Structural Reconstruction and Dual Active Sites for Efficient Urea Electrooxidation. Chem. Eng. J. 2023, 465, 142684. [Google Scholar] [CrossRef]

- Zheng, D.; Li, J.; Ci, S.; Cai, P.; Ding, Y.; Zhang, M.; Wen, Z. Three-birds-with-one-stone electrolysis for energy-efficiency production of gluconate and hydrogen. Appl. Catal. B Environ. 2020, 277, 119178. [Google Scholar] [CrossRef]

- Luo, Y.; Zhang, Z.; Yang, F.; Li, J.; Liu, Z.; Ren, W.; Zhang, S.; Liu, B. Stabilized hydroxide-mediated nickel-based electrocatalysts for high-current-density hydrogen evolution in alkaline media. Energy Environ. Sci. 2021, 14, 4610–4619. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, Y.; Zhao, B.; Chang, Y.; Li, Z. Electrochemical reduction of carbon dioxide in an MFC–MEC system with a layer-by-layer self-assembly carbon nanotube/cobalt phthalocyanine modified electrode. Environ. Sci. Technol. 2012, 46, 5198–5204. [Google Scholar] [CrossRef]

- Yuan, H.; Deng, L.; Cai, X.; Zheng, T.; Zhou, S.; Chen, Y.; Yuan, Y. Recycling electroplating sludge to produce sustainable electrocatalysts for the efficient conversion of carbon dioxide in a microbial electrolysis cell. Electrochim. Acta 2016, 222, 177–184. [Google Scholar] [CrossRef]

- Li, C.; Ding, S.; Zhang, J.; Wu, J.; Yue, Y.; Qian, G. Ball milling transformed electroplating sludges with different components to spinels for stable electrocatalytic ammonia production under ambient conditions. Chemosphere 2022, 296, 134060. [Google Scholar] [CrossRef]

- Chen, G.-F.; Yuan, Y.; Jiang, H.; Ren, S.-Y.; Ding, L.-X.; Ma, L.; Wu, T.; Lu, J.; Wang, H. Electrochemical reduction of nitrate to ammonia via direct eight-electron transfer using a copper–molecular solid catalyst. Nat. Energy 2020, 5, 605–613. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Shen, Y.; Ni, B.-J. Defective nickel sulfide hierarchical structures for efficient electrochemical conversion of plastic waste to value-added chemicals and hydrogen fuel. Green Chem. 2023, 25, 5979–5988. [Google Scholar] [CrossRef]

- Dai, W.; Wang, R.; Chen, Z.; Deng, S.; Huang, C.; Luo, W.; Chen, H. Highly-efficient photocatalytic hydrogen evolution triggered by spatial confinement effects over co-crystal templated boron-doped carbon nitride hollow nanotubes. J. Mater. Chem. A 2023, 11, 7584–7595. [Google Scholar] [CrossRef]

- Li, X.-X.; Liu, X.-C.; Liu, C.; Zeng, J.-M.; Qi, X.-P. Co3O4/stainless steel catalyst with synergistic effect of oxygen vacancies and phosphorus doping for overall water splitting. Tungsten 2023, 5, 100–108. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, H.; Xu, S.; Liu, Q.; Li, T.; Luo, Y.; Gao, S.; Shi, X.; Asiri, A.M.; Sun, X. Recent Advances in 1D Electrospun Nanocatalysts for Electrochemical Water Splitting. Small Struct. 2021, 2, 2000048. [Google Scholar] [CrossRef]

- Han, N.; Zhang, W.; Guo, W.; Pan, H.; Jiang, B.; Xing, L.; Tian, H.; Wang, G.; Zhang, X.; Fransaer, J. Designing Oxide Catalysts for Oxygen Electrocatalysis: Insights from Mechanism to Application. Nano-Micro Lett. 2023, 15, 185. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Tao, S.; Lin, H.; Wang, G.; Zhao, K.; Cai, R.; Tao, K.; Zhang, C.; Sun, M.; Hu, J.; et al. Atomically targeting NiFe LDH to create multivacancies for OER catalysis with a small organic anchor. Nano Energy 2021, 81, 105606. [Google Scholar] [CrossRef]

- Han, N.; Feng, S.; Liang, Y.; Wang, J.; Zhang, W.; Guo, X.; Ma, Q.; Liu, Q.; Guo, W.; Zhou, Z.; et al. Achieving Efficient Electrocatalytic Oxygen Evolution in Acidic Media on Yttrium Ruthenate Pyrochlore through Cobalt Incorporation. Adv. Funct. Mater. 2023, 33, 2208399. [Google Scholar] [CrossRef]

- Chen, Z.; Zheng, R.; Wei, W.; Wei, W.; Zou, W.; Li, J.; Ni, B.-J.; Chen, H. Recycling spent water treatment adsorbents for efficient electrocatalytic water oxidation reaction. Resour. Conserv. Recycl. 2022, 178, 106037. [Google Scholar] [CrossRef]

- Zhang, L.; Li, L.; Liang, J.; Fan, X.; He, X.; Chen, J.; Li, J.; Li, Z.; Cai, Z.; Sun, S. Highly efficient and stable oxygen evolution from seawater enabled by a hierarchical NiMoSx microcolumn@NiFe-layered double hydroxide nanosheet array. Inorg. Chem. Front. 2023, 10, 2766–2775. [Google Scholar] [CrossRef]

- Kim, M.; Kim, J.; Qin, L.; Mathew, S.; Han, Y.; Li, O.L. Gas-Liquid Interfacial Plasma engineering under dilute nitric acid to improve hydrophilicity and OER performance of nickel foam. Prog. Nat. Sci. Mater. Int. 2022, 32, 608–616. [Google Scholar] [CrossRef]

- Chen, Z.; Zou, W.; Zheng, R.; Wei, W.; Wei, W.; Ni, B.-J.; Chen, H. Synergistic recycling and conversion of spent Li-ion battery leachate into highly efficient oxygen evolution catalysts. Green Chem. 2021, 23, 6538–6547. [Google Scholar] [CrossRef]

- Chen, Z.; Wei, W.; Zou, W.; Li, J.; Zheng, R.; Wei, W.; Ni, B.-J.; Chen, H. Integrating electrodeposition with electrolysis for closing loop resource utilization of battery industrial wastewater. Green Chem. 2022, 44, 3208–3217. [Google Scholar] [CrossRef]

- Chi, H.; Wang, J.; Wang, H.; Li, S.; Yang, M.; Bai, S.; Li, C.; Sun, X.; Zhao, Y.; Song, Y.-F. Super-Stable Mineralization of Ni2+ Ions from Wastewater using CaFe Layered Double Hydroxide. Adv. Funct. Mater. 2022, 32, 2106645. [Google Scholar] [CrossRef]

| Material | Waste | Synthesis Method | Application | Performance |

|---|---|---|---|---|

| Si/TiSi2 [24] | Ti-bearing blast furnace slag | Induction melting–mechanical ball milling | LIBs 1 | Reversible capacity: 530 mAh g−1 (after 200 cycles at 0.8 A·g−1) |

| NiFe2O4 [25] | Electroplating sludge | Hydrothermal process–acid washing | LIBs | Reversible capacity: 316.94 mAh·g−1 (at 0.5 A·g−1) |

| Mesoporous silicon [26] | Iron slag | Acid leaching–magnesiothermic reaction | LIBs | Reversible capacity: 1566 mAh g−1 (after 30 cycles at 1 A·g−1) |

| MoO2@coal gangue [27] | Coal gangue | Acid leaching–hydrothermal process | LOBs 2 | Initial discharge capacity: 9748 mAh·g−1 |

| Multi-doped LiFePO4/C [28] | Steel slag | Roasting–carbothermic reduction | LIBs | Capacity: 117 mAh·g−1 (at 0.15 A·g−1) |

| Cation-intercalated V2O5·nH2O [29] | Vanadium slag | Roasting–leaching–hydrothermal process | AZIBs 3 | Capability: 317 mAh g−1 (after 4000 cycles at 20 A·g−1) |

| Fe2O3 [19] | Vanadium titanomagnetite tailings | Alkali fusion–hydrothermal process–pyrolysis | Supercapacitors | Capacitance: 151.5 F·g−1 at 1 A·g−1 (NiCo(O)S//Fe2O3 ASC 4) |

| Metal-doped carbon [30] | Metallurgical slag | Pyrolysis | Supercapacitors | Capacitance: 135 F·g−1 at 0.5 A·g−1 |

| β-Ni(OH)2 [31] | Electroless nickel plating bath | Precipitation | Supercapacitors | Energy density: 11.5 W·h·kg−1, power density: 207.5 W·kg−1 |

| Amorphous Ni(HCO3)2 [12] | Nickel-containing electroplating sludge | Hydrothermal method | Supercapacitors | Capacitance: 599.8 C·g−1 at 1 A·g−1 |

| Barium slag-derived catalyst [32] | Barium slag | Precipitation–heating | DC-SOFCs 5 | Power: 249 mW·cm−2 |

| Goethite [20] | Mining mud | Precipitation | MFCs 6 | Power: 17.1 W·m−3 at 20 Ω |

| Sn@N/P-doped carbon [22] | Electroplating sludge | Annealing | CO2RR 7 | FE 8 for HCOOH: 87.93% at −1.05 V vs. RHE 9 |

| CuPb electrocatalyst [33] | Fayalite slag | Chemical extraction–electrodeposition | CO2RR | FE for CO: 41.1% at −1.05 V vs. RHE |

| Metal-doped CuCr2O4 [34] | Electroplating sludge | Calcination | N2RR 10 | Ammonia yield: 15.9 μg·h−1 mg−1cat |

| Red mud [35] | Red mud | Ball milling | NO3RR 11 | Ammonia yield: 0.16 mmol cm−2 h−1 at −0.73 V vs. RHE |

| FeNiCuSnB [21] | Hydrometallurgical wastewater | Boriding | OER 12 | η10 13: 199 mV, Tafel slope: 53.98 mV·dec−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, F.; Chen, Q.; Liu, Z.; Cheng, D.; Han, N.; Chen, Z. Repurposing Mining and Metallurgical Waste as Electroactive Materials for Advanced Energy Applications: Advances and Perspectives. Catalysts 2023, 13, 1241. https://doi.org/10.3390/catal13091241

Guo F, Chen Q, Liu Z, Cheng D, Han N, Chen Z. Repurposing Mining and Metallurgical Waste as Electroactive Materials for Advanced Energy Applications: Advances and Perspectives. Catalysts. 2023; 13(9):1241. https://doi.org/10.3390/catal13091241

Chicago/Turabian StyleGuo, Fenghui, Qian Chen, Zhihao Liu, Dongle Cheng, Ning Han, and Zhijie Chen. 2023. "Repurposing Mining and Metallurgical Waste as Electroactive Materials for Advanced Energy Applications: Advances and Perspectives" Catalysts 13, no. 9: 1241. https://doi.org/10.3390/catal13091241