Environmentally Friendly Biological Activated Carbon Derived from Sugarcane Waste as a Promising Carbon Source for Efficient and Robust Rechargeable Zinc–Air Battery

Abstract

1. Introduction

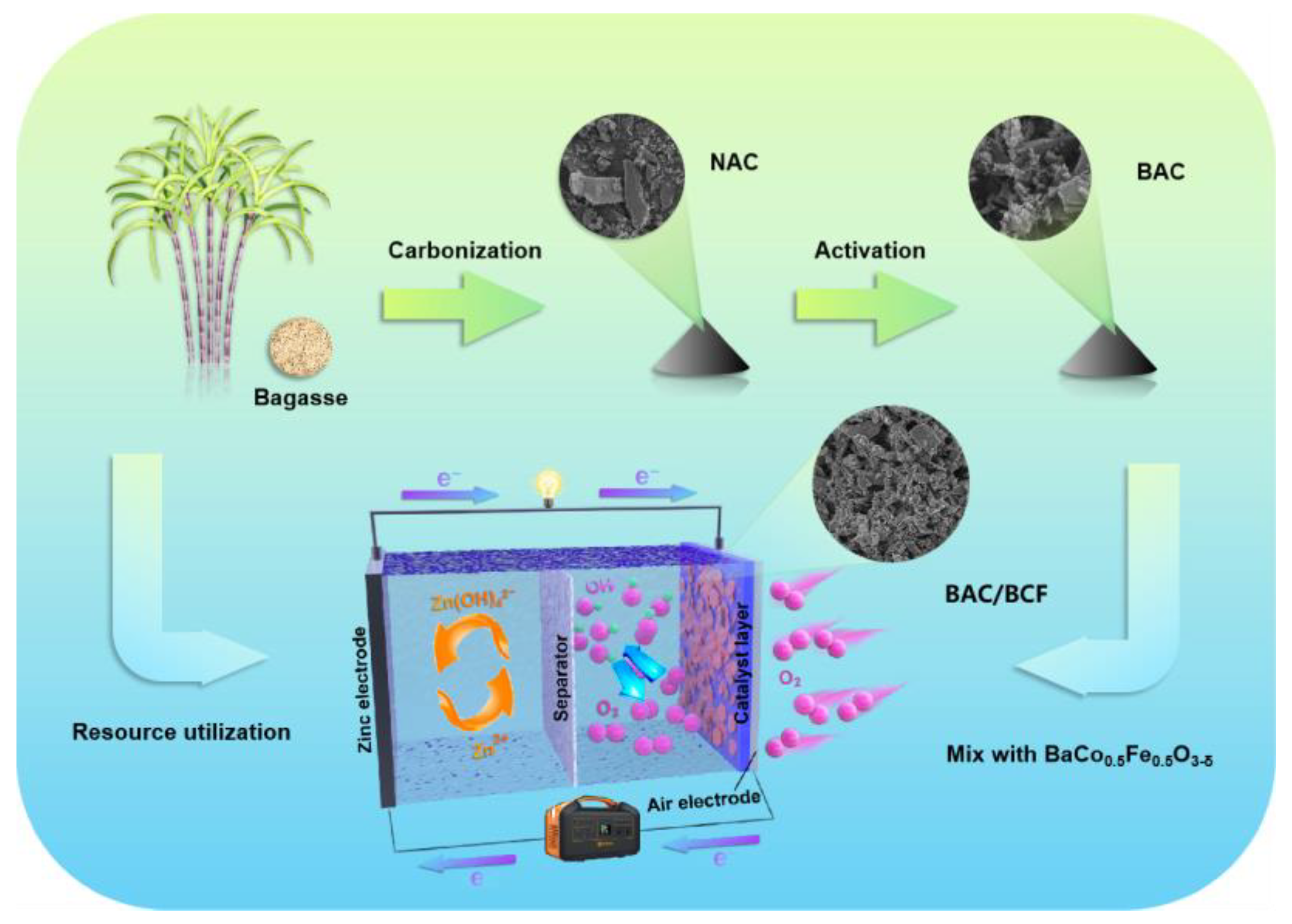

2. Results and Discussion

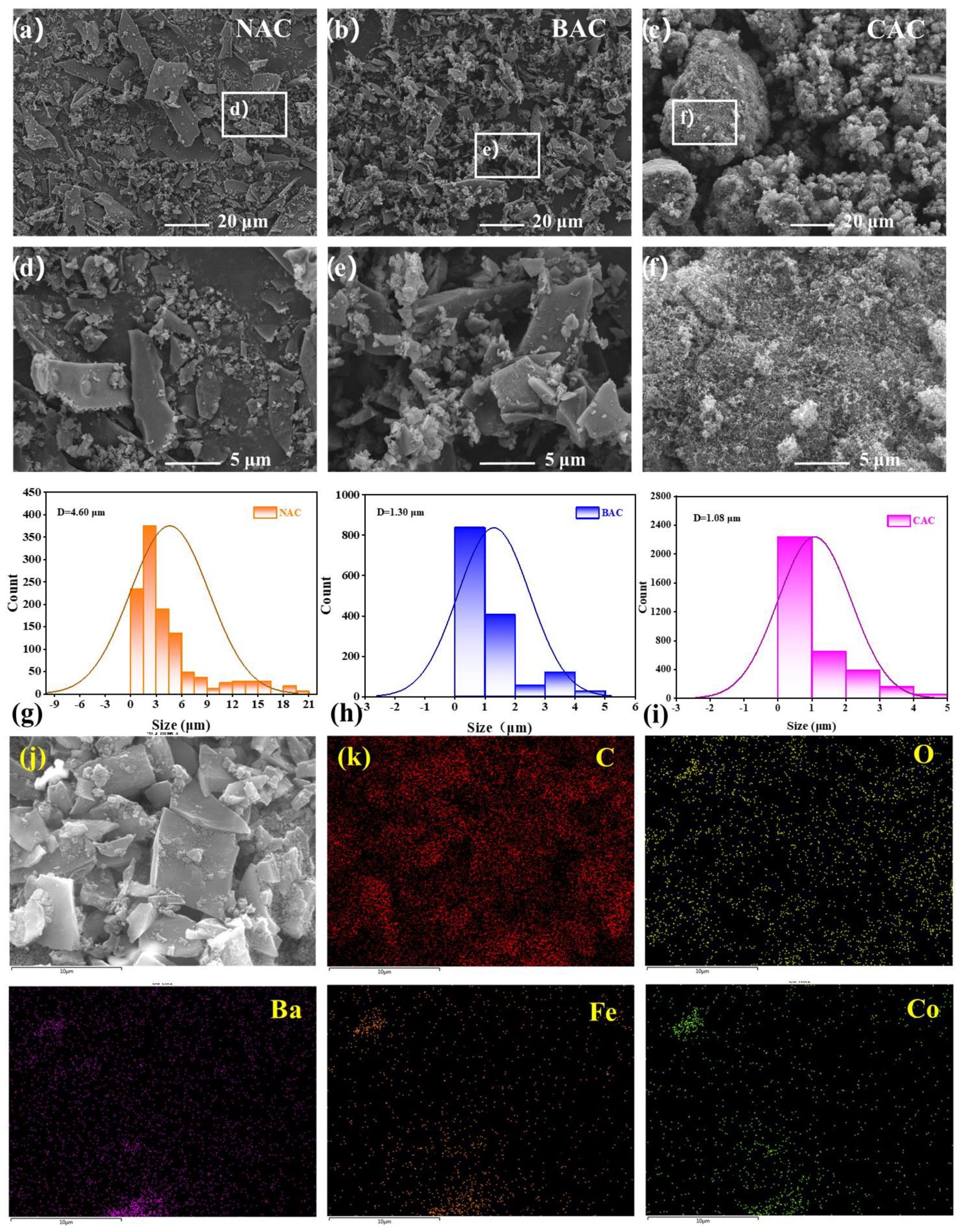

2.1. Physicochemical Properties

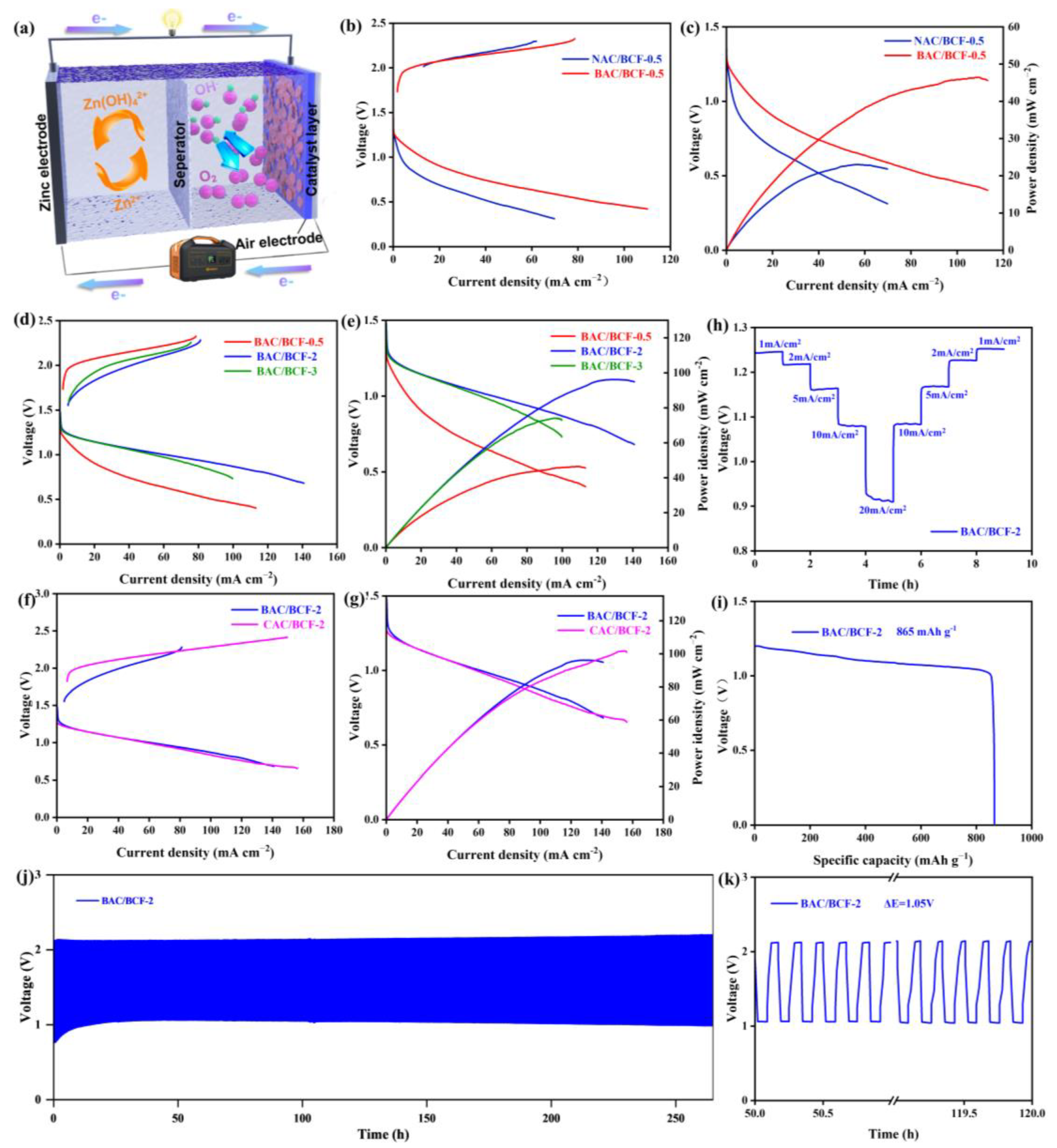

2.2. Electrochemical Performance

3. Materials and Methods

3.1. Materials Synthesis

3.2. Characterizations

3.3. Electrochemical Measurements

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, L.S.; Zhou, Y.F.; Meng, B.; Li, H.J.; Zhan, J.; Xiong, H.Y.; Zhao, H.Y.; Cong, W.F.; Wang, X.Z.; Zhang, W.S.; et al. Reconciling productivity, profitability and sustainability of small-holder sugarcane farms: A combined life cycle and data envelopment analysis. Agric. Syst. 2022, 199, 103392. [Google Scholar] [CrossRef]

- Ajala, E.O.; Ighalo, J.O.; Ajala, M.A.; Adeniyi, A.G.; Ayanshola, A.M. Sugarcane bagasse: A biomass sufficiently applied for improving global energy, environment and economic sustainability. Bioresour. Bioprocess. 2021, 8, 87. [Google Scholar] [CrossRef] [PubMed]

- Hamawand, I.; da Silva, W.; Seneweera, S.; Bundschuh, J. Value Proposition of Different Methods for Utilisation of Sugarcane Wastes. Energies 2021, 14, 5483. [Google Scholar] [CrossRef]

- Novais, R.M.; Ascensão, G.; Tobaldi, D.M.; Seabra, M.P.; Labrincha, J.A. Biomass fly ash geopolymer monoliths for effective methylene blue removal from wastewaters. J. Clean. Prod. 2018, 171, 783–794. [Google Scholar] [CrossRef]

- Sousa, L.N.; Figueiredo, P.F.; França, S.; de Moura Solar Silva, M.V.; Borges, P.H.R.; Bezerra, A.C.d.S. Effect of Non-Calcined Sugarcane Bagasse Ash as an Alternative Precursor on the Properties of Alkali-Activated Pastes. Molecules 2022, 27, 1185. [Google Scholar] [CrossRef]

- Farias, D.; Maugeri-Filho, F. Sequential fed batch extractive fermentation for enhanced bioethanol production using recycled Spathaspora passalidarum and mixed sugar composition. Fuel 2021, 288, 119673. [Google Scholar] [CrossRef]

- Biswas, S.; Mohapatra, S.S.; Kumari, U.; Meikap, B.C.; Sen, T.K. Batch and continuous closed circuit semi-fluidized bed operation: Removal of MB dye using sugarcane bagasse biochar and alginate composite adsorbents. J. Environ. Chem. Eng. 2020, 8, 103637. [Google Scholar] [CrossRef]

- Yin, W.W.; Fu, Z.W. The Potential of Na-Air Batteries. ChemCatChem 2017, 9, 1545–1553. [Google Scholar] [CrossRef]

- Khan, M.M.; Khan, A.; Bhatti, H.N.; Zahid, M.; Alissa, S.A.; El-Badry, Y.A.; Hussein, E.E.; Iqbal, M. Composite of polypyrrole with sugarcane bagasse cellulosic biomass and adsorption efficiency for 2,4-dichlorophenoxyacetic acid in column mode. J. Mater. Res. Technol. 2021, 15, 2016–2025. [Google Scholar] [CrossRef]

- Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Aslam, F.; Joyklad, P.; Zajdel, P. Sustainable approach of using sugarcane bagasse ash in cement-based composites: A systematic review. Case Stud. Constr. Mater. 2021, 15, e00698. [Google Scholar] [CrossRef]

- Madhoushi, M.; Malakani, A.; Ebrahimi, G.; Rashidi, A. Influence of spherical-shaped carbon nanoparticles on the mechanical properties of a foamed sugarcane bagasse/polypropylene composite. Ind. Crops Prod. 2021, 172, 114041. [Google Scholar] [CrossRef]

- Kumari, N.; Sarangi, S.K. Bagasse reinforced epoxy-based green composite for orthotic callipers: A tribological study. Mater. Today Proc. 2022, 56, 1156–1159. [Google Scholar] [CrossRef]

- Andrade, J.P.d.S.C.; Cecchin, D.; Vieira, C.M.F.; Delaqua, G.C.G.; Silva, F.C.d.; Hamacher, L.d.S.; da Silva, T.R.; Amran, M.; Paes, J.L.; Moll Hüther, C. Agro-Industrial Waste of Malt Bagasse: Perspectives on the Development of Eco-Friendly Ceramic Material. Sustainability 2023, 15, 9120. [Google Scholar] [CrossRef]

- Ferreira, D.C.M.; Molina, G.; Pelissari, F.M. Biodegradable trays based on cassava starch blended with agroindustrial residues. Compos. Part B Eng. 2020, 183, 107682. [Google Scholar] [CrossRef]

- Rattanachueskul, N.; Dokkathin, O.; Dechtrirat, D.; Panpranot, J.; Watcharin, W.; Kaowphong, S.; Chuenchom, L. Sugarcane Bagasse Ash as a Catalyst Support for Facile and Highly Scalable Preparation of Magnetic Fenton Catalysts for Ultra-Highly Efficient Removal of Tetracycline. Catalysts 2022, 12, 446. [Google Scholar] [CrossRef]

- Sazali, N.; Wan Salleh, W.N.; Jamaludin, A.S.; Mhd Razali, M.N. New Perspectives on Fuel Cell Technology: A Brief Review. Membranes 2020, 10, 99. [Google Scholar] [CrossRef]

- Borelli, D.; Devia, F.; Schenone, C.; Silenzi, F.; Sollai, F.; Tagliafico, L.A. Assessing environmental benefits of the transition from standard fossil fuels to liquefied natural gas: The Sardinia Region case study. Energy Sustain. Dev. 2023, 73, 205–217. [Google Scholar] [CrossRef]

- Rashedi, A.; Khanam, T.; Jonkman, M. On Reduced Consumption of Fossil Fuels in 2020 and Its Consequences in Global Environment and Exergy Demand. Energies 2020, 13, 6048. [Google Scholar] [CrossRef]

- Shelare, S.D.; Belkhode, P.N.; Nikam, K.C.; Jathar, L.D.; Shahapurkar, K.; Soudagar, M.E.M.; Veza, I.; Khan, T.M.Y.; Kalam, M.A.; Nizami, A.-S.; et al. Biofuels for a sustainable future: Examining the role of nano-additives, economics, policy, internet of things, artificial intelligence and machine learning technology in biodiesel production. Energy 2023, 282, 128874. [Google Scholar] [CrossRef]

- Wang, M.; Su, K.; Zhang, M.; Du, X.; Li, Z. Advanced trifunctional electrocatalysis with Cu-, N-, S-doped defect-rich porous carbon for zinc-air batteries. ACS Sustain. Chem. Eng. 2021, 9, 13324–13336. [Google Scholar] [CrossRef]

- Lin, H.; Xie, J.; Zhang, Z.; Wang, S.; Chen, D. Perovskite nanoparticles@N-doped carbon nanofibers as robust and efficient oxygen electrocatalysts for Zn-air batteries. J. Colloid Interface Sci. 2021, 581 Pt. A, 374–384. [Google Scholar] [CrossRef]

- Ma, R.; Gao, F.; Breaz, E.; Huangfu, Y.; Briois, P. Multidimensional Reversible Solid Oxide Fuel Cell Modeling for Embedded Applications. IEEE Trans. Energy Convers. 2018, 33, 692–701. [Google Scholar] [CrossRef]

- Milikić, J.; Nastasić, A.; Martins, M.; Sequeira, C.A.C.; Šljukić, B. Air Cathodes and Bifunctional Oxygen Electrocatalysts for Aqueous Metal–Air Batteries. Batteries 2023, 9, 394. [Google Scholar] [CrossRef]

- Wang, H.F.; Xu, Q. Materials Design for Rechargeable Metal-Air Batteries. Matter 2019, 1, 565–595. [Google Scholar] [CrossRef]

- Gao, X.Y.; Liu, H.; Wang, Y.; Guo, J.H.; Sun, X.W.; Sun, W.Y.; Zhao, H.T.; Bai, J.; Li, C.P. Tailoring the d-band electronic structure of deficient LaMn0.3Co0.7O3-δ perovskite nanofibers for boosting oxygen electrocatalysis in Zn-Air batteries. J. Colloid Interface Sci. 2023, 650, 951–960. [Google Scholar] [CrossRef]

- Ran, J.Q.; Wu, J.F.; Hu, Y.F.; Shakouri, M.; Xia, B.; Gao, D.Q. Atomic-level coupled spinel@perovskite dual-phase oxides toward enhanced performance in Zn–air batteries. J. Mater. Chem. A 2022, 10, 1506–1513. [Google Scholar] [CrossRef]

- Bu, Y.F.; Gwon, O.; Nam, G.; Jang, H.; Kim, S.; Zhong, Q.; Cho, J.; Kim, G. A Highly Efficient and Robust Cation Ordered Perovskite Oxide as a Bifunctional Catalyst for Rechargeable Zinc-Air Batteries. ACS Nano 2017, 11, 11594–11601. [Google Scholar] [CrossRef]

- Ajay, K.M.S.; Dinesh, M.N.; Yashaswini, M.; Gopalakrishna, B.; Kathyayini, N.; Sundarayya, Y.; Vijeth, H. Natural Biomass Derived Microporous Activated Carbon Electrodes for Highly Efficient Supercapacitor Applications. ChemistrySelect 2022, 7, e202201301. [Google Scholar] [CrossRef]

- Liu, R.M.; Liu, H.N.; Yang, Q.Y.; Ma, Y.J.; Dong, D.Q.; Wang, J. Longan-Derived Biomass Carbon-Induced Cubic-Type Ferric Oxide Nanoparticles for Efficient Lithium-Ion Battery Anodes. Energy Fuels 2023, 37, 16979–16987. [Google Scholar] [CrossRef]

- Yang, S.; Qu, K.Q.; Huang, Z.H. Optimizing Hierarchical Porous Carbon from Biomass Waste for High-Performance Supercapacitors. ES Food Agrofor. 2022, 10, 39–50. [Google Scholar] [CrossRef]

- Xu, X.J.; Huang, Y.; Wei, W.R.; Fan, Y.; Jiang, Z.D.; Li, R.H.; Yuan, X.X. Long-Cycling and High-Rate Potassium Storage Enabled by Sulfur-Doped Carbon Derived from Disposable Chopsticks. Energy Fuels 2023, 37, 14375–14382. [Google Scholar] [CrossRef]

- Wu, J.Q.; Ma, Z.H.; Wang, G.N.; Chen, T.T. Biomass Porous Carbon Derived from Celery Leaves with High Capacitance for Supercapacitor. ChemistrySelect 2023, 8, e202204616. [Google Scholar] [CrossRef]

- Yu, J.; Jia, X.F.; Peng, J.X.; Meng, B.; Wei, Y.B.; Hou, X.Y.; Zhao, J.K.; Yang, N.X.; Xie, K.Y.; Chu, D.W.; et al. Synergistic Effect of Nitrogen–Sulfur Codoping on Honeycomb-like Carbon-Based High-Energy-Density Zinc-Ion Hybrid Supercapacitors. ACS Appl. Energy Mater. 2023, 6, 2728–2738. [Google Scholar] [CrossRef]

- Zheng, S.M.; Yuan, Z.H.; Dionysiou, D.D.; Zhong, L.B.; Zhao, F.; Yang, J.C.E.; Zheng, Y.M. Silkworm cocoon waste-derived nitrogen-doped hierarchical porous carbon as robust electrode materials for efficient capacitive desalination. Chem. Eng. J. 2023, 458, 141471. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, Z.Y.; Luo, Q.T.; Li, H.J.; Li, J.; Yang, W.Q. Capillary Evaporation on High-Dense Conductive Ramie Carbon for Assisting Highly Volumetric-Performance Supercapacitors. Small 2023, 19, 2303349. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Z.X.; Zhang, X.; Chen, H.S.; Hu, X.; Yang, P. Formation of g-C3N4 Nanotubes towards Superior Photocatalysis Performance. ChemCatChem 2019, 11, 4558–4567. [Google Scholar] [CrossRef]

- Shi, K.J.; Li, Y.; Zhang, Y.Y.; Li, X.F.; Zhu, Z.J.; Xu, H.Y.; Zheng, L.C.; Gao, J. N-doped 3D hierarchical carbon from water hyacinth for high-performance Zn-air batteries. Diam. Relat. Mater. 2023, 135, 109841. [Google Scholar] [CrossRef]

- Jaiswal, K.; Groutchik, K.; Bawari, D.; Dobrovetsky, R. An “On-Demand”, Selective Dehydrogenative Borylation or Hydroboration of Terminal Alkynes Using Zn2±based Catalyst. ChemCatChem 2022, 14, e202200004. [Google Scholar] [CrossRef]

- Dubey, P.; Shrivastav, V.; Jain, M.; Pant, K.K.; Maheshwari, P.H.; Sundriyal, S. Facile Synthesis of Pineapple Waste-Derived Carbon and Polyaniline Composite for High-Energy-Density Asymmetric Supercapacitors. Energy Fuels 2023, 37, 8659–8671. [Google Scholar] [CrossRef]

- Yu, J.; Ran, R.; Zhong, Y.; Zhou, W.; Ni, M.; Shao, Z. Advances in porous perovskites: Synthesis and electrocatalytic performance in fuel and metal–air batteries. Energy Environ. Mater. 2020, 3, 121–145. [Google Scholar] [CrossRef]

- Xu, X.; Pan, Y.; Ge, L.; Chen, Y.; Mao, X.; Guan, D.; Li, M.; Zhong, Y.; Hu, Z.; Peterson, V.K.; et al. High-performance perovskite composite electrocatalysts enabled by controllable interface engineering. Small 2021, 17, 2101573. [Google Scholar] [CrossRef] [PubMed]

- Xu, A.Q.; Zhou, J.; Liu, T.; Wang, J.; Wang, Y.; Zhang, D.; Huang, D.X.; Liu, Y.L.; Hu, X.L. Compositional engineering of perovskite oxide BaCo0.5Fe0.5O3-δ as an efficient bifunctional oxygen electrocatalyst for rechargeable zinc-air battery. Catal. Sci. Technol. 2024, 14, 589–605. [Google Scholar] [CrossRef]

- Abbas, A.; Rubab, S.; Rehman, A.; Irfan, S.; Sharif, H.M.A.; Liang, Q.; Tabish, T.A. One-step green synthesis of biomass-derived graphene quantum dots as a highly selective optical sensing probe. Mater. Today Chem. 2023, 30, 101555. [Google Scholar] [CrossRef]

- Chen, Z.H.; Zou, Y.H.; Chen, H.J.; Zhang, K.W.; Hui, B. Bamboo-Modulated Helical Carbon Nanotubes for Rechargeable Zn-Air Battery. Small 2023, 20, 2307776. [Google Scholar] [CrossRef]

- Li, C.; Wang, Y.R.; Jin, C.; Lu, J.; Sun, J.W.; Yang, R.Z. Preparation of Perovskite Oxides/(CoFe)P2 Heterointerfaces to Improve Oxygen Evolution Activity of La0.8Sr0.2Co0.2Fe0.8O4+δ Layered Perovskite Oxide. Int. J. Hydrogen Energy 2020, 45, 22959–22964. [Google Scholar] [CrossRef]

- Su, C.; Wang, W.; Chen, Y.B.; Yang, G.M.; Xu, X.M.; Tadé, M.O.; Shao, Z.P. SrCo0.9Ti0.1O3-δ As a New Electrocatalyst for the Oxygen Evolution Reaction in Alkaline Electrolyte with Stable Performance. ACS Appl. Mater. Interfaces 2015, 7, 17663–17670. [Google Scholar] [CrossRef]

- Hua, B.; Li, M.; Sun, Y.F.; Zhang, Y.Q.; Yan, N.; Chen, J.; Thundat, T.; Li, J.; Luo, J.L. A Coupling for Success: Controlled Growth of Co/CoOx Nanoshoots on Perovskite Mesoporous Nanofibres as High-Performance Trifunctional Electrocatalysts in Alkaline Condition. Nano Energy 2017, 32, 247–254. [Google Scholar] [CrossRef]

- Huang, Y.L.; Liu, Y.Z.; Deng, Y.Z.; Zhang, J.; He, B.; Sun, J.; Yang, Z.; Zhou, W.; Zhao, L. Enhancing the Bifunctional Activity of CoSe2 Nanocubes by Surface Decoration of CeO2 for Advanced Zinc-Air Batteries. J. Colloid Interface Sci. 2022, 625, 839–849. [Google Scholar] [CrossRef]

- Li, P.Z.; Wei, B.; Lü, Z.; Wu, Y.Y.; Zhang, Y.H.; Huang, X.Q. La1.7Sr0.3CO0.5Ni0.5O4+δ Layered Perovskite as an Efficient Bifunctional Electrocatalyst for Rechargeable Zinc-Air Batteries. Appl. Surf. Sci. 2019, 464, 494–501. [Google Scholar] [CrossRef]

- Gui, L.Q.; Wang, Z.B.; Zhang, K.; He, B.B.; Liu, Y.Z.; Zhou, W.; Xu, J.M.; Wang, Q.; Zhao, L. Oxygen Vacancies-Rich Ce0.9Gd0.1O2-δ Decorated Pr0.5Ba0.5CoO3-δ Bifunctional Catalyst for Efficient and Long-Lasting Rechargeable Zn-Air Batteries. Appl. Catal. B Environ. 2020, 266, 118656. [Google Scholar] [CrossRef]

- Zhou, J.; Liu, T.; Zhang, J.; Zhao, L.; He, W.; Wang, Y. Rational Design of Ultrafine Cobalt-Free Electrospun Nanofibers as Efficient and Durable Bifunctional Oxygen Electrocatalysts for Rechargeable Zinc-Air Battery. Sep. Purif. Technol. 2023, 304, 122316. [Google Scholar] [CrossRef]

- Zhou, J.; Wang, Y.; Zhang, D.; Zhong, D.; Liu, T.; Ding, M.Y. Electrospun 3D Structured Double Perovskite Oxide PrBa0.8Ca0.2Co2O5+δ Bifunctional Electrocatalyst for Zinc-Air Battery. J. Am. Ceram. Soc. 2024, 107, 3265–3276. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Y.Y.; Yuan, M.K.; Hao, H.R.; Lv, Z.; Xu, L.L.; Wei, B. Operando Spectroscopies Unveil Interfacial FeOOH Induced Highly Reactive β-Ni(Fe)OOH for Efficient Oxygen Evolution. Appl. Catal. B Environ. 2022, 318, 121825. [Google Scholar] [CrossRef]

- Huang, D.X.; Liu, T.; Xu, A.Q.; Zhou, J.; Wang, Y.; Hu, X.L. A Novel Layered Cobalt Oxide Ba2Co9O14 as an Efficient and Durable Bifunctional Oxygen Electrocatalyst for Rechargeable Zinc-Air Batteries. Electrochim. Acta 2024, 494, 144450. [Google Scholar] [CrossRef]

- Tan, P.; Chen, B.; Xu, H.R.; Cai, W.Z.; He, W.; Ni, M. In-situ Growth of Co3O4 Nanowire-Assembled Clusters on Nickel Foam for Aqueous Rechargeable Zn-Co3O4 and Zn-Air Batteries. Appl. Catal. B Environ. 2019, 241, 104–112. [Google Scholar] [CrossRef]

- Wang, Y.B.; Ge, X.L.; Lu, Q.; Bai, W.J.; Ye, C.C.; Shao, Z.P.; Bu, Y.F. Accelerated Deprotonation with a Hydroxy-Silicon Alkali Solid for Rechargeable Zinc-Air Batteries. Nat. Commun. 2023, 14, 6968. [Google Scholar] [CrossRef]

- Zhao, S.Y.; Liu, T.; Dai, Y.W.; Wang, J.; Wang, Y.; Guo, Z.J.; Yu, J.; Bello, I.T.; Ni, M. Pt/C as a Bifunctional ORR/Iodide Oxidation Reaction (IOR) Catalyst for Zn-Air Batteries with Unprecedentedly High Energy Efficiency of 76.5%. Appl. Catal. B Environ. 2023, 320, 121992. [Google Scholar] [CrossRef]

- Wang, L.; Li, H.; Liu, J.; Lang, X.; Wang, W. Labile oxygen participant adsorbate evolving mechanism to enhance oxygen reduction in SmMn 2 O 5 with double-coordinated crystal fields. J. Mater. Chem. A 2023, 9, 380–389. [Google Scholar] [CrossRef]

- Yoo, J.S.; Rong, X.; Liu, Y.; Kolpak, A.M. Role of lattice oxygen participation in understanding trends in the oxygen evolution reaction on perovskites. ACS Catal. 2018, 8, 4628–4636. [Google Scholar] [CrossRef]

- Zagalskaya, A.; Alexandrov, V. Role of defects in the interplay between adsorbate evolving and lattice oxygen mechanisms of the oxygen evolution reaction in RuO2 and IrO2. ACS Catal. 2020, 10, 3650–3657. [Google Scholar] [CrossRef]

- Wang, Y.H.; Li, L.; Shi, J.; Xie, M.Y.; Nie, J.; Huang, G.F.; Li, B.; Hu, W.; Pan, A.; Huang, W.Q. Oxygen defect engineering promotes synergy between adsorbate evolution and single lattice oxygen mechanisms of OER in transition metal-based (oxy) hydroxide. Adv. Sci. 2023, 10, 2303321. [Google Scholar] [CrossRef] [PubMed]

- Rossmeisl, J.; Qu, Z.W.; Zhu, H.; Kroes, G.J.; Nørskov, J.K. Electrolysis of water on oxide surfaces. J. Electroanal. Chem. 2007, 607, 83–89. [Google Scholar] [CrossRef]

- Soltani, M.; Amin, H.M.; Cebe, A.; Ayata, S.; Baltruschat, H. Metal-supported perovskite as an efficient bifunctional electrocatalyst for oxygen reduction and evolution: Substrate effect. J. Electrochem. Soc. 2021, 168, 034504. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, L.; Wang, C.; Xu, A.; Zha, F.; Liu, T.; Hu, X.; Wang, Y. Environmentally Friendly Biological Activated Carbon Derived from Sugarcane Waste as a Promising Carbon Source for Efficient and Robust Rechargeable Zinc–Air Battery. Catalysts 2024, 14, 740. https://doi.org/10.3390/catal14100740

Deng L, Wang C, Xu A, Zha F, Liu T, Hu X, Wang Y. Environmentally Friendly Biological Activated Carbon Derived from Sugarcane Waste as a Promising Carbon Source for Efficient and Robust Rechargeable Zinc–Air Battery. Catalysts. 2024; 14(10):740. https://doi.org/10.3390/catal14100740

Chicago/Turabian StyleDeng, Lianghao, Chenyang Wang, Anqi Xu, Fanglin Zha, Tong Liu, Xuelei Hu, and Yao Wang. 2024. "Environmentally Friendly Biological Activated Carbon Derived from Sugarcane Waste as a Promising Carbon Source for Efficient and Robust Rechargeable Zinc–Air Battery" Catalysts 14, no. 10: 740. https://doi.org/10.3390/catal14100740

APA StyleDeng, L., Wang, C., Xu, A., Zha, F., Liu, T., Hu, X., & Wang, Y. (2024). Environmentally Friendly Biological Activated Carbon Derived from Sugarcane Waste as a Promising Carbon Source for Efficient and Robust Rechargeable Zinc–Air Battery. Catalysts, 14(10), 740. https://doi.org/10.3390/catal14100740