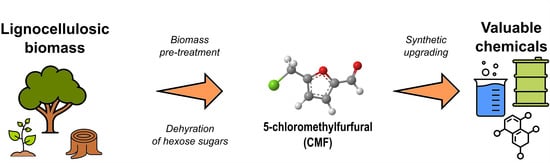

Production and Synthetic Possibilities of 5-Chloromethylfurfural as Alternative Biobased Furan

Abstract

:1. Introduction

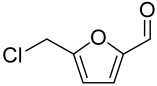

| Name | 5-chloromethylfurfural (CMF) | 5-hydroxymethylfurfural (HMF) |

|---|---|---|

| Chemical structure |  |  |

| CAS number | 1623-88-7 | 67-47-0 |

| Canonical SMILES code | C1=C(OC(=C1)C=O)CCl | C1=C(OC(=C1)C=O)CO |

| Molecular formula | C6H5ClO2 | C6H6O3 |

| Molecular weight (g/mol) | 144.55 | 126.11 |

| Boiling point (°C) | 137–138 (P = 5 Torr) [22] | 350–354 (P = 760 Torr) [23] |

| Melting point (°C) | 37.8–38.6 [24] | 28–33 [23] |

| Relative density (g/mL) at T = 33 °C | 1.24 [20] | 1.24 [23] |

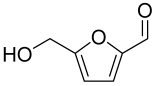

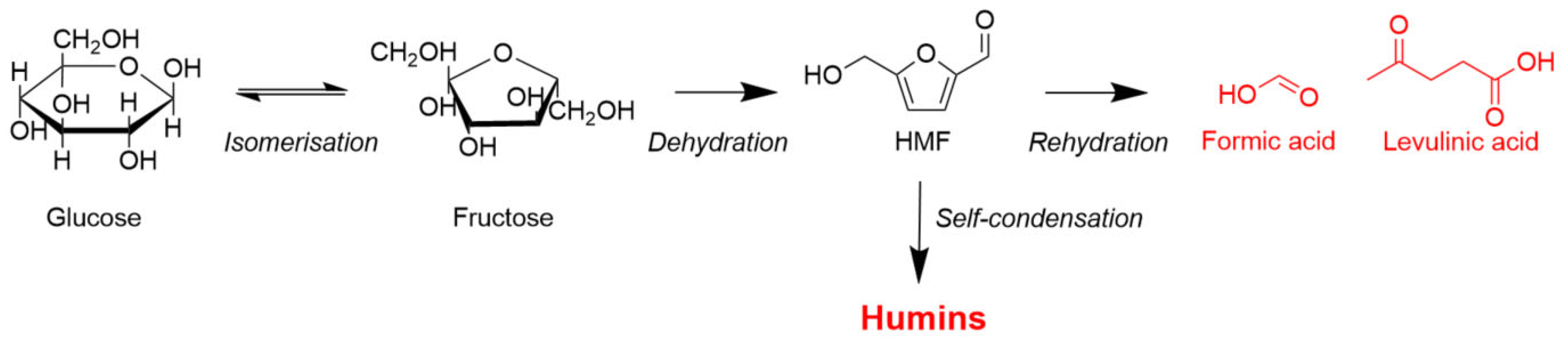

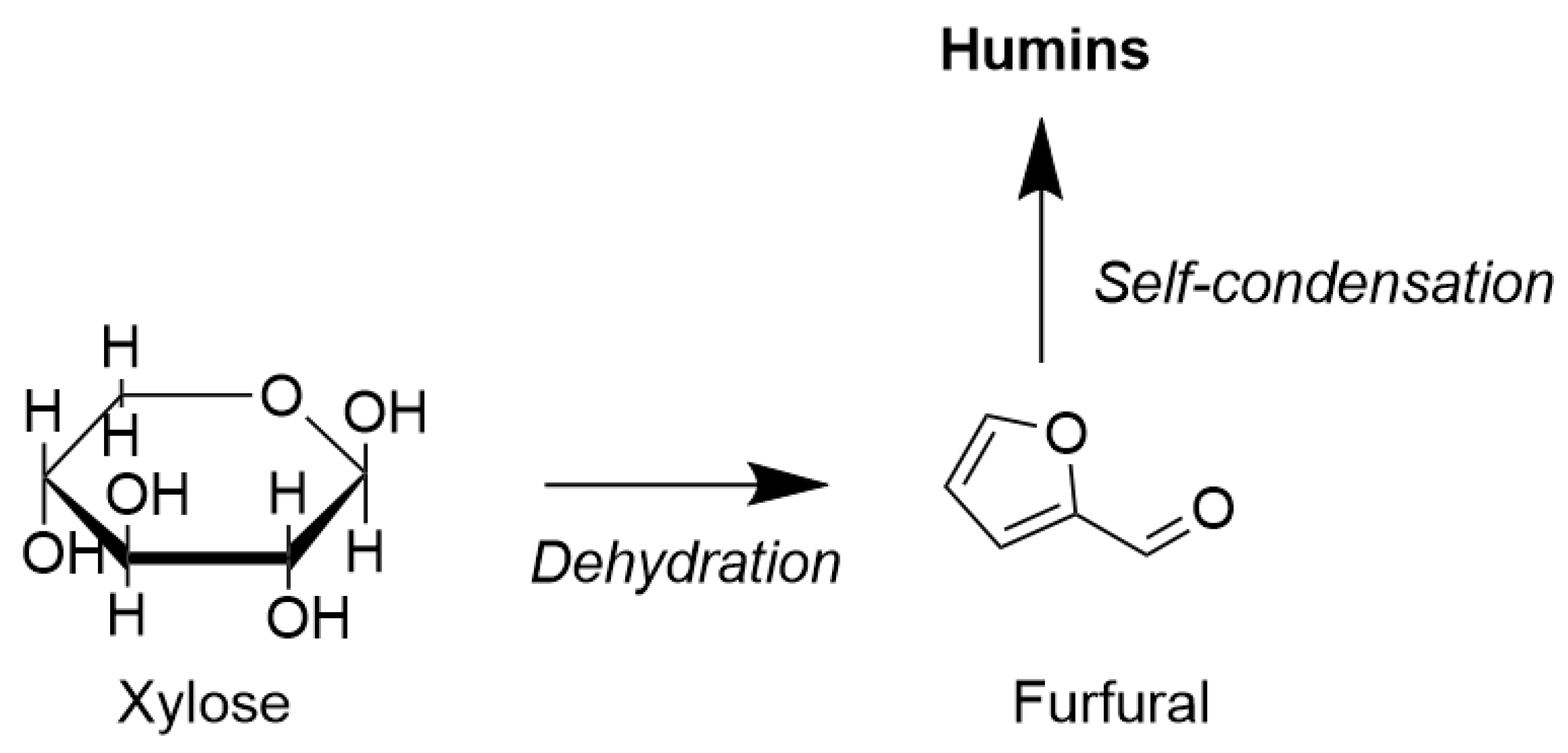

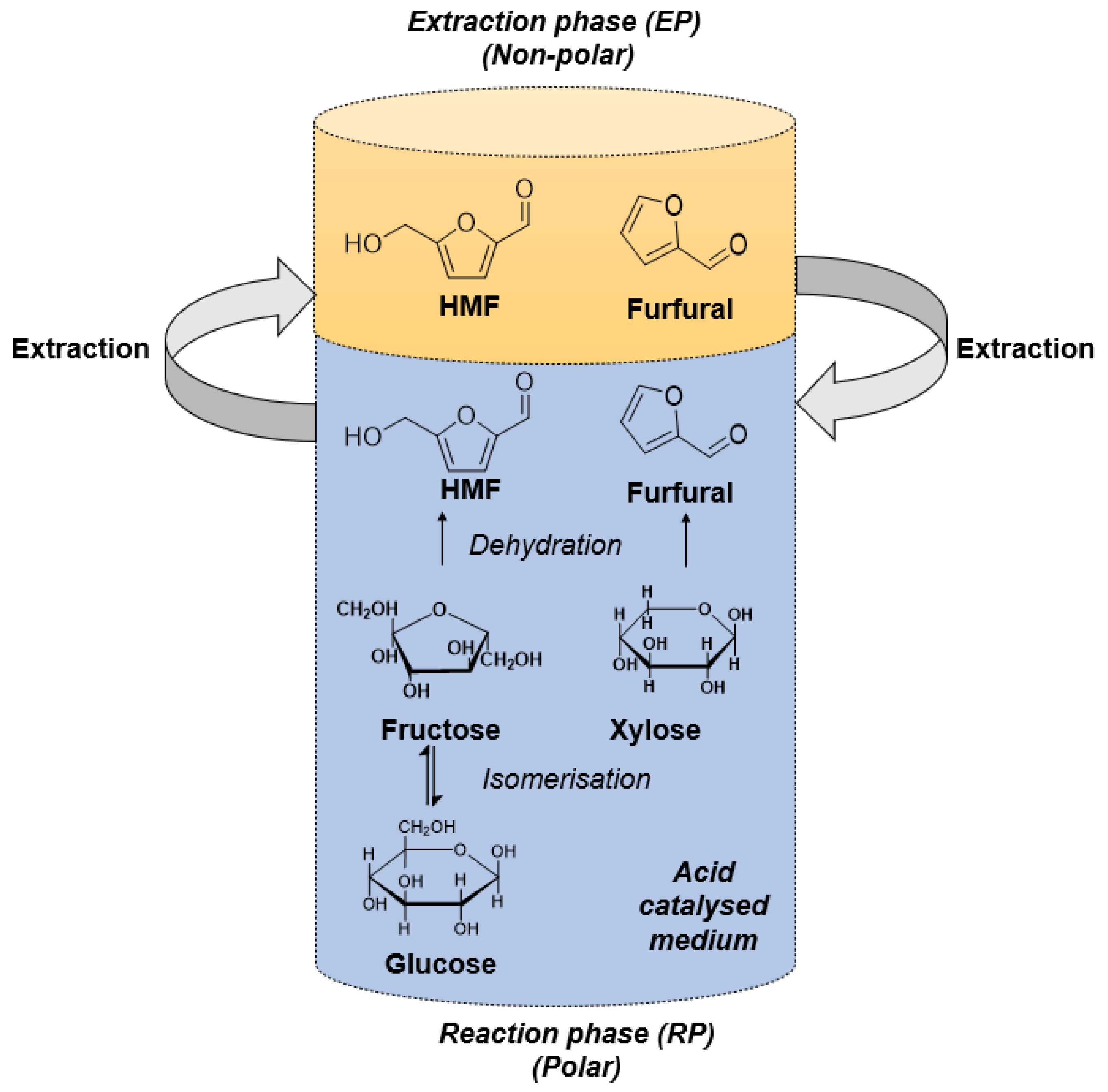

2. Production of HMF and Furfural

| HMF | ||||||

|---|---|---|---|---|---|---|

| Feedstock | Catalyst | Temperature (°C) | Time (min) | Feedstock Conversion (%) | Yield (%) | Ref. |

| Fructose 52 mM | HCl 1 M | 160 | 30 | 78 | 32 | [29] |

| Sucrose 0.5 M | H2SO4 0.5 M | 130 | 240 | 90 | 22 | [30] |

| Furfural | ||||||

| Xylose 52 mM | H2SO4 0.1 M | 200 | 4 | 98 | 65 | [31] |

| Corn cob 70.6 g·L−1 | PTSA 0.28 M | 165 | 48 | 96 | 75 | [32] |

| HMF | |||||||

|---|---|---|---|---|---|---|---|

| Feedstock | Polar/Non-Polar | Catalyst | Temperature (°C) | Time (min) | Feedstock Conversion (%) | Yield (%) | Ref. |

| Fructose 50 mM | H2O/GVL 1/9 | HCl 10 mM | 100 | 10 | 90 | 78 | [35] |

| Cellulose 50 mM | H2O (with NaCl)/1-butanol 1/1 | FeCl3-CuCl2 0.02 M | 190 | 45 | 91.3 | 49 | [38] |

| Fructose 0.5 M | H2O/MIBK 1/4 | H2SO4 0.05 M | 155 | 16 | 96 | 81 | [36] |

| Glucose 25 mM | H2O (with NaCl)/THF 1/3 | AlCl3 25 mM | 140 | 90 | 90 | 40 | [37] |

| Furfural | |||||||

| Corn cob 26.7 g·L−1 | Water/GVL 1/4 | H2SO4 10 mM | 190 | 20 | - | 99.5 | [39] |

| Arabinose 2 mM | H2O/2-butanone 1/4 | [BMIM]Cl-AlCl3 1:1 (IL ratio) | 140 | 30 | 100 | 60 | [40] |

| Xylose 0.25 mmol | [ChCl:OA]/MIBK 1/1 | AlCl3·6H2O 0.125 mmol | 100 | 40 | 44.8 | 84.8 | [41] |

| Xylose 80 mM | H2O/MIBK 1/1 | HCl 0.1 M | 170 | 30 | 93 | 85 | [42] |

| Xylan 14 mM | H2O (with NaCl)/GVL 1/4 | Al2(SO4)3 10 mM | 160 | 30 | 99 | 87.8 | [43] |

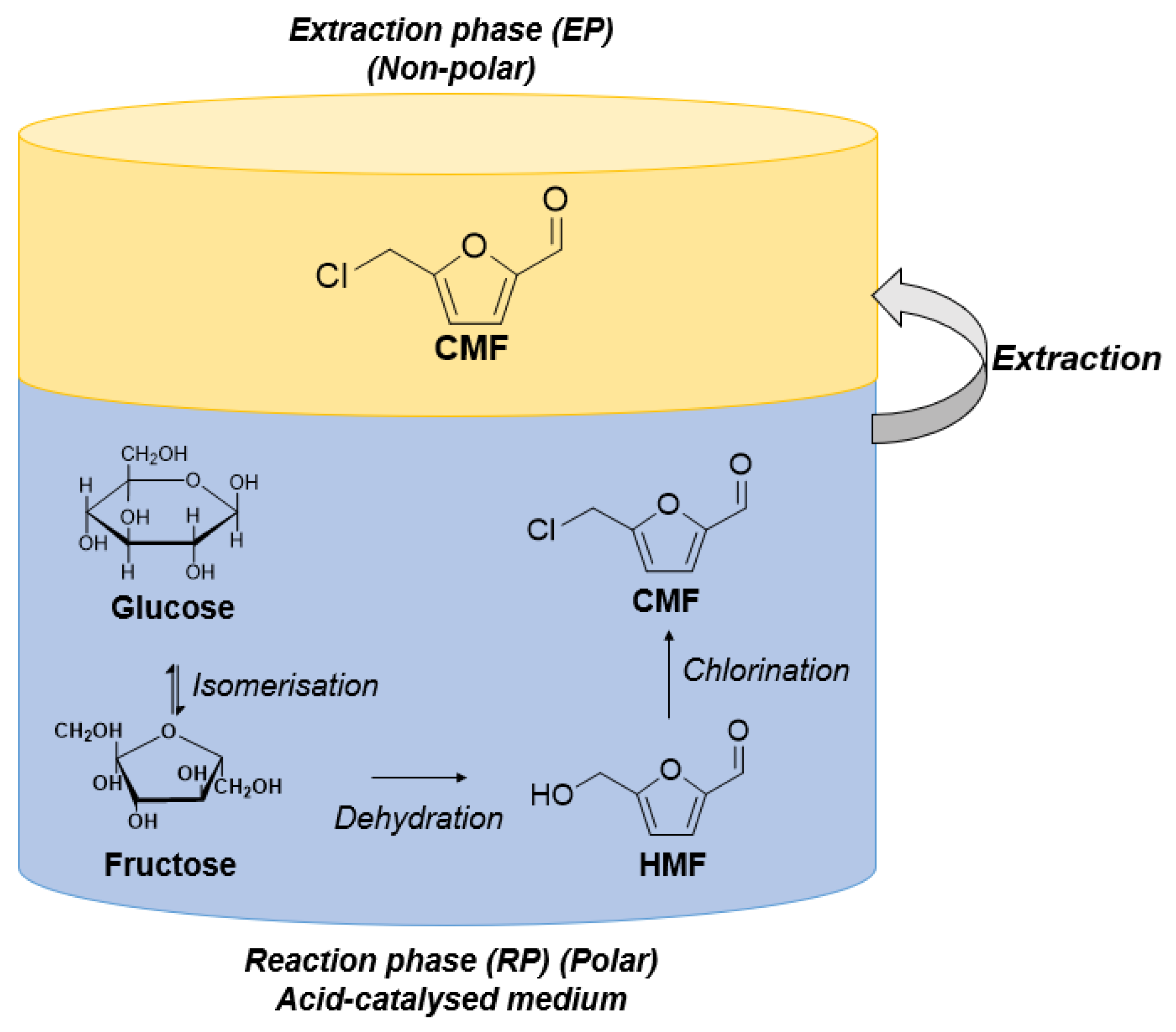

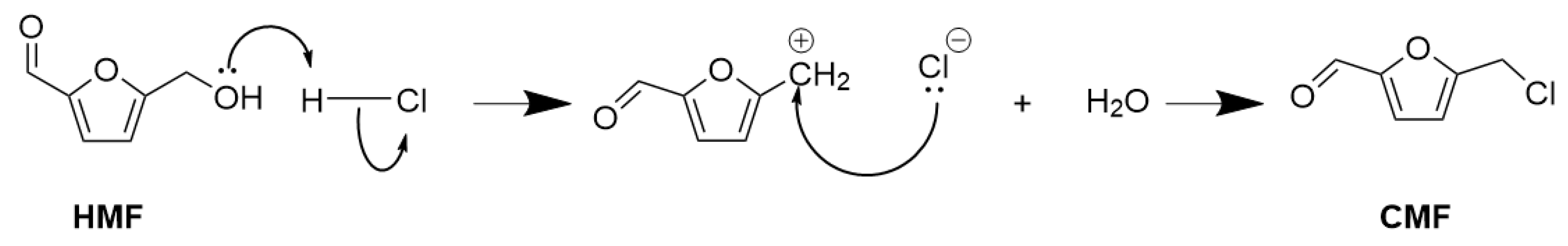

3. Production of CMF

3.1. CMF Production from Sugar Monomers and Dimers

| Feedstock | Polar Phase/Non-Polar Phase | Catalyst | Temperature (°C) | Time (h) | CMF Yield (%) | Ref. |

|---|---|---|---|---|---|---|

| Sucrose 0.12 M | H2O/DCM 1/1 | HCl 32 wt.% | 100 | 0.04 | 51 | [46] |

| Fructose 0.12 M | H2O/DCM 1/1 | HCl 32 wt.% | 100 | 0.04 | 80 | [46] |

| Glucose 0.12 M | H2O/DCM 1/1 | HCl 32 wt.% | 100 | 0.04 | 15 | [46] |

| Fructose 0.132 M | H2O (with LiCl)/Toluene 10.5 g·L−1 | HCl 32 wt.% | 65 | 3 | 72 | [47] |

| Fructose 0.17 M | H2O/DCE 1/2 | HCl (Conc.) | 80 | 0.25 | 71 | [53] |

| Fructose 0.005 M | H2O/CHCl3 1/3 | HCl (25 wt.% | 45 | 10 | 80 | [45] |

| Fructose 33.3 g·L−1 | H2O/DCE 1/2 | HCl 37 wt.% | 70 | 0.16 | 85 | [54] |

| Fructose 0.005 M | [ChCl:fructose (1:5)]/MIBK 1/10 | AlCl3·6H2O 0.005 M | 120 | 5 | 50.3 | [52] |

| Sucrose 0.005 M | [ChCl:fructose (1:5)]/MIBK 1/10 | AlCl3·6H2O 0.005 M | 120 | 5 | 17.8 | [52] |

| Glucose 1.5 M | H2O/4CA | HCl 6 M | 110 | 1 | 29 | [49] |

| High-fructose corn syrup 37 wt.% | H2O/DCM 2/3 | HCl 37 wt.% | 100 | 0.32 | 85 | [51] |

| Glucose 2.1 wt.% | H2O/DCE 1/2 | BTBAC 0.2 wt.% | 90 | 3 | 64 | [55] |

| Glucose and xylose 5 wt.% | H2O/DCE 1/2 | BTBAC 0.05 wt% | 100 | 3 | 17 | [56] |

| Fructose 1 wt.% | H2O/Toluene 1/2 | HCl 37 wt.% | 80 | 4 | 81.9 | [48] |

| Sucrose 1 wt.% | H2O/Toluene 1/2 | HCl 37 wt.% | 100 | 4 | 70.2 | [48] |

| Fructose 0.002 M | [ChCl:OA (5:6)]/DCE 1/2 | AlCl3·6H2O hydrolyses to HCl 0.015 M | 120 | 0.5 | 86 | [59] |

| Sucrose 0.002 M | [ChCl:OA (5:6)]/DCE 1/2 | AlCl3·6H2O hydrolyses to HCl 0.015 M | 120 | 0.5 | 80 | [59] |

| Glucose 0.05 M | H2O/DCE 1/2 | HCl 37.2 mmol | 80 | 2 | 38 | [57] |

| Fructose 10 g·L−1 | H2O/anisole | HCl 26% | 90 | 0.07 | 79 | [58] |

3.2. CMF Production from Real Biomass Sources

| Feedstock | Polar Phase:/Non-Polar Phase | Catalyst | Temperature (°C) | Time (h) | CMF Yield (%) | Ref. |

|---|---|---|---|---|---|---|

| Microcrystalline cellulose 1.4 wt.% a | H2O (with LiCl)/DCE 1.5/5 | HCl (Conc.) | 65 | 30 | 71 | [18] |

| Microcrystalline cellulose 1 wt.% a | H2O//DCE 1/2 | HCl (Conc.) | 100 | 2 | 84 | [60] |

| Eucalyptus kraft pulp 0.02 wt.% a | H2O/CHCl3 4/5 | H3PO4 85 wt.% | 45 | 20 | 21.3 | [61] |

| Norway spruce softwood 0.02 wt.% a | H2O/CHCl3 4/5 | H3PO4 85 wt.% | 45 | 20 | 33.7 | [61] |

| Eucalyptus hardwood 0.02 wt.% a | H2O/CHCl3 4/5 | H3PO4 85 wt.% | 45 | 20 | 47.4 | [61] |

| Cellulose 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 70 | [50] |

| Agarose 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 54 | [50] |

| Rice straw 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 57 | [50] |

| Barley straw 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 68 | [50] |

| Wheat straw 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 61 | [50] |

| Triticale 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 59 | [50] |

| Rape stem 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 53 | [50] |

| Grass (Miscanthus sinensis var. purpurascens) 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 58 | [50] |

| Reed (Phragmites communis, Trin.) 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 59 | [50] |

| Paper 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 51 | [50] |

| Fibreboard 16.7 g·L−1 | H2O/TCE 1/1 | HCl 37 wt.% | 90 | 1 | 42 | [50] |

| Inulin 0.005 M | [ChCl:fructose (1:5)]/MIBK 1/10 | AlCl3·6H2O 0.005 M | 120 | 5 | 22.6 | [52] |

| Sugarcane bagasse 1 wt.% | H2O/DCE 1/2 | HCl 37 wt.% | 90 | 3 | 81.9 | [64] |

| Corn stover 10 wt.% | H2O/DCE 1/2 | HCl 37 wt.% | 100 | 2 | 63 | [63] |

| Palmarosa 20 wt.% a | H2O (with NaCl)/CHCl3 1/3 | HCl 37 wt.% | 100 | 1 | 76.5 | [62] |

| Lemon grass 20 wt.% a | H2O (with NaCl)/CHCl3 1/3 | HCl 37 wt.% | 100 | 1 | 72.4 | [62] |

| Citronella grass 20 wt.% a | H2O (with NaCl)//CHCl3 1/3 | HCl 37 wt.% | 100 | 1 | 65.8 | [62] |

| Cellulose 0.002 M | [ChCl:OA (5:6)]/DCE 1/2 | AlCl3·6H2O hydrolyses to HCl 0.015 M | 120 | 0.5 | 30 | [59] |

| Bamboo 0.002 M | [ChCl:OA (5:6)]/DCE 1/2 | AlCl3·6H2O hydrolyses to HCl 0.015 M | 120 | 0.5 | 29 | [59] |

| Bamboo pulp 0.002 M | [ChCl:OA (5:6)]/DCE 1/2 | AlCl3·6H2O hydrolyses to HCl 0.015 M | 120 | 0.5 | 35 | [59] |

| Microcrystalline cellulose 1.7 wt.% | H2O/DCE 2/3 | ZnCl2 3.4 wt.% | 80 | 2 | 72 | [65] |

| Rice Bran 4 wt.% | H2O/CHCl3 1/4 | HCl 32% | 100 | 2 | 22.7 | [19] |

| Rice hull 4 wt.% | H2O/CHCl3 1/4 | HCl 32% | 100 | 2 | 29.6 | [19] |

| Broken white rice 4 wt.% | H2O/CHCl3 1/4 | HCl 32% | 100 | 2 | 52.2 | [19] |

| Immature brown rice 4 wt.% | H2O/CHCl3 1/4 | HCl 32% | 100 | 2 | 48 | [19] |

| Soluble starch 20 g·L−1 | H2O/cyclohexane 1/1.5 | Smopex-101 and TiO2:ChCl 0.1 g | 80 | 1 | 58.75 | [67] |

| Glucose hydrolysate derived from Aspen wood chips (3.03 wt.% glucose, 0.07 wt.% mannose, 0.090 wt.% xylose) | H2O/chlorobenzene 1/2 | HCl | 90 | 2 | 96.70 | [66] |

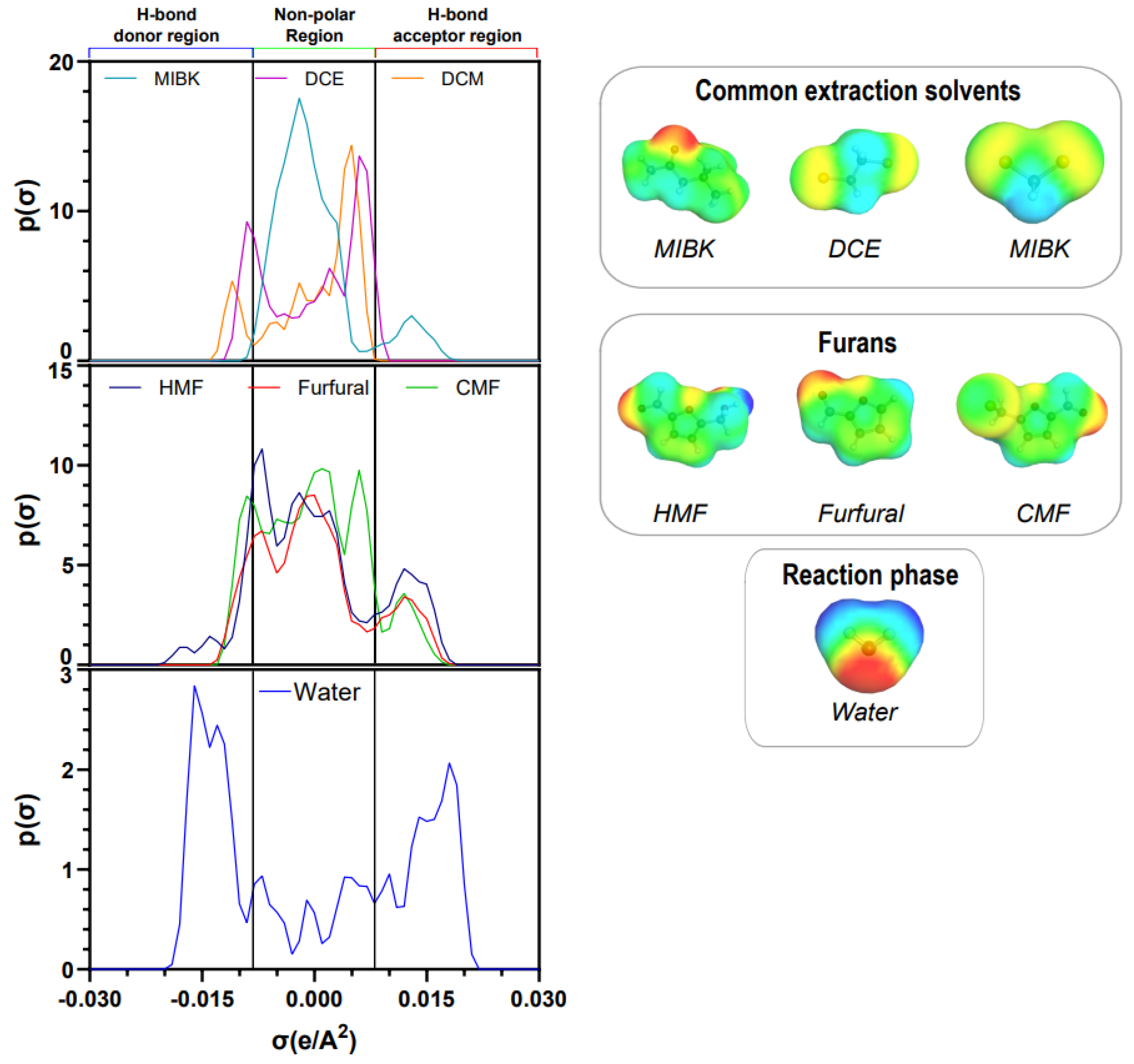

3.3. Considerations and Tools for Solvent Selection in the Biphasic Production of CMF and Other Furans

4. Overview of the Synthetic Possibilities of CMF

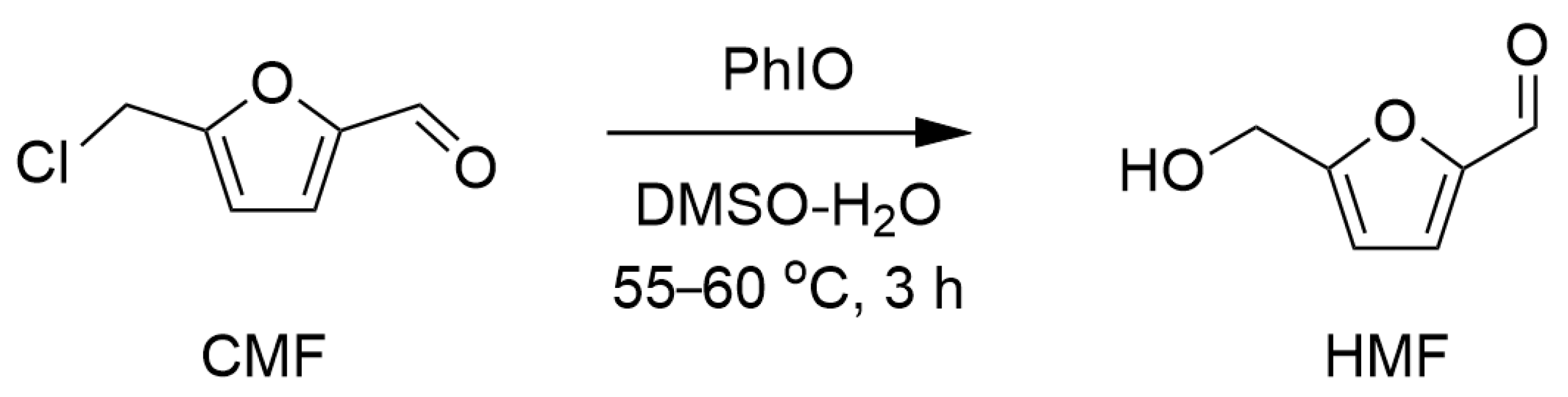

4.1. Rehydration and Hydrolysis

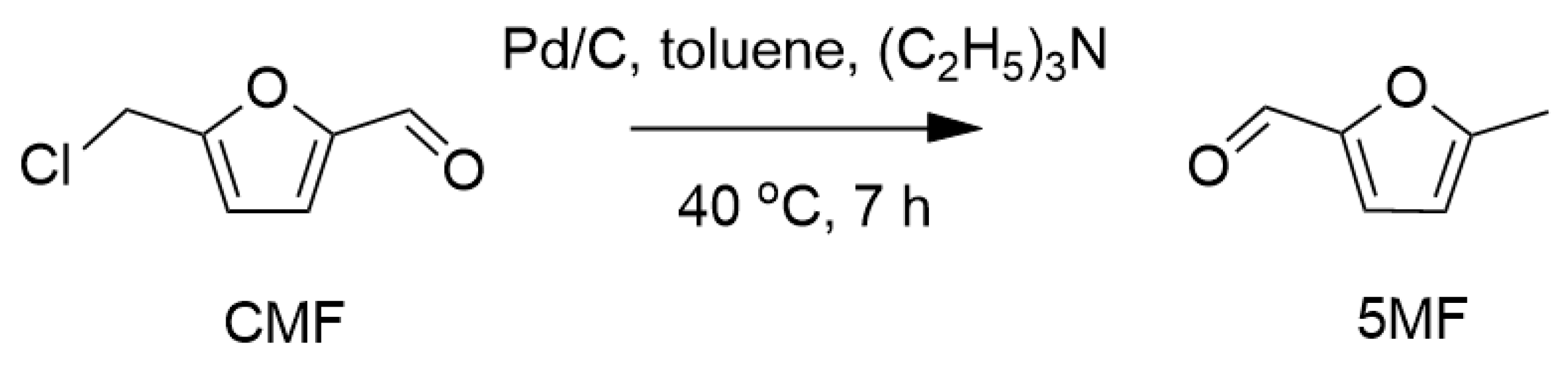

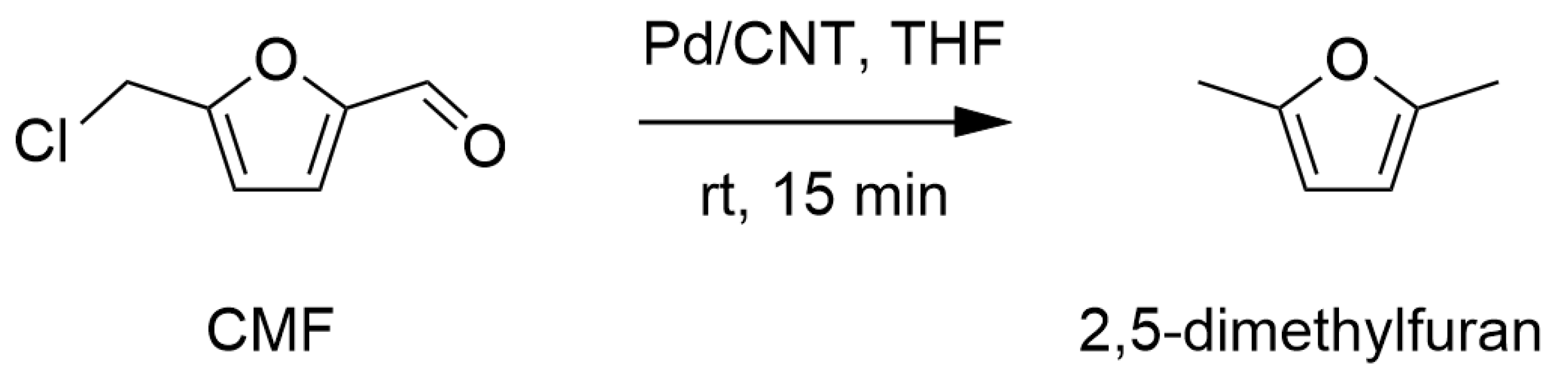

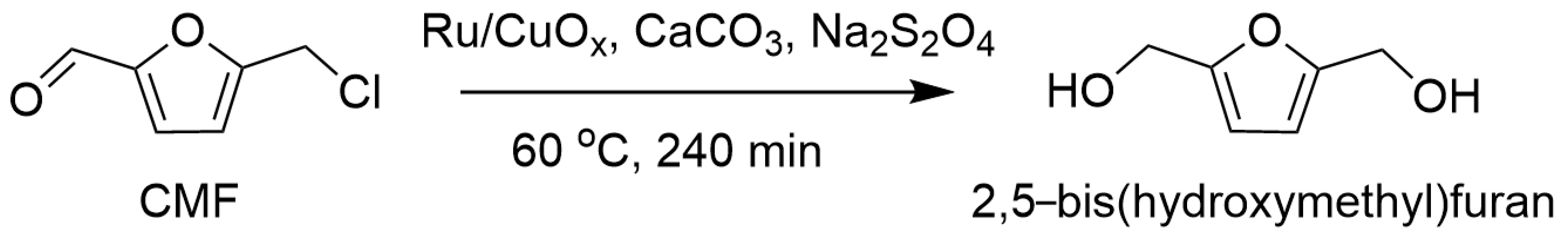

4.2. Hydrogenation and Reduction

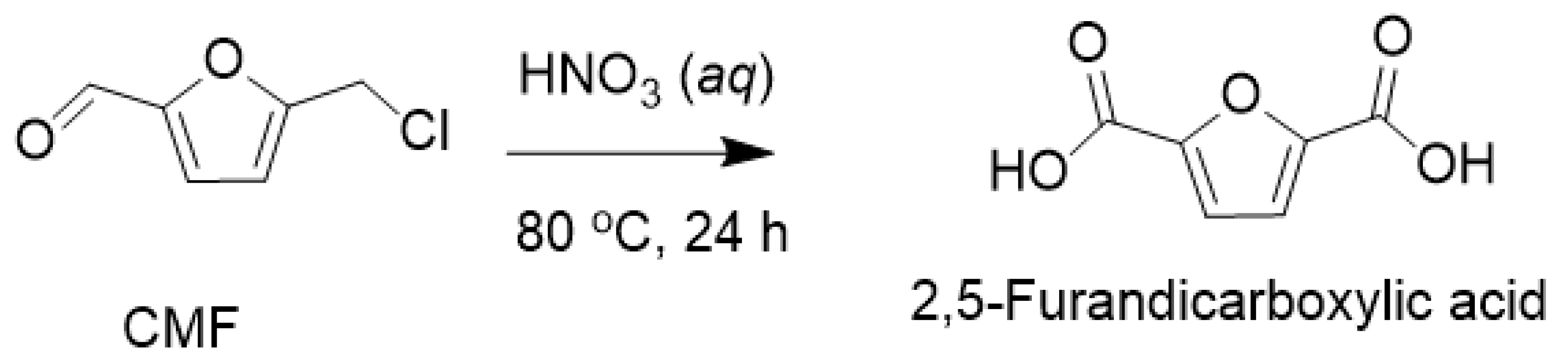

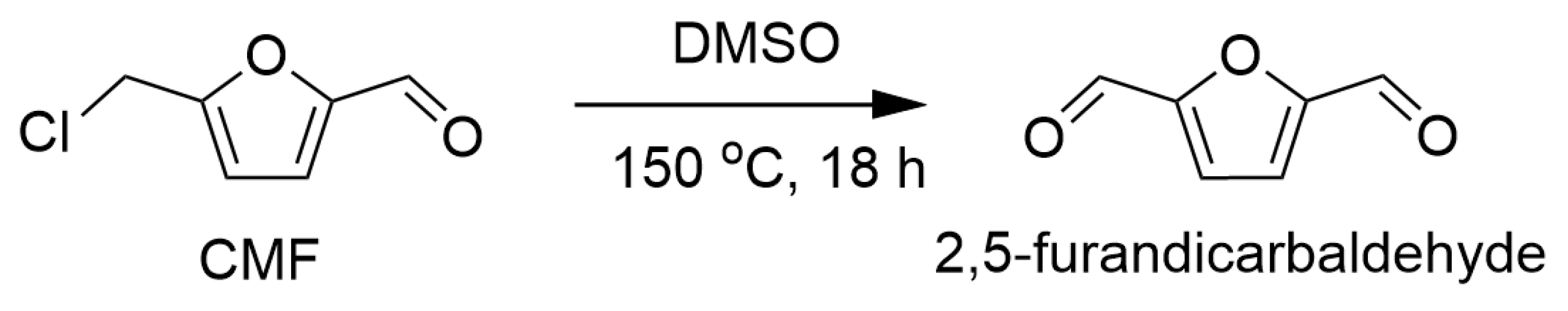

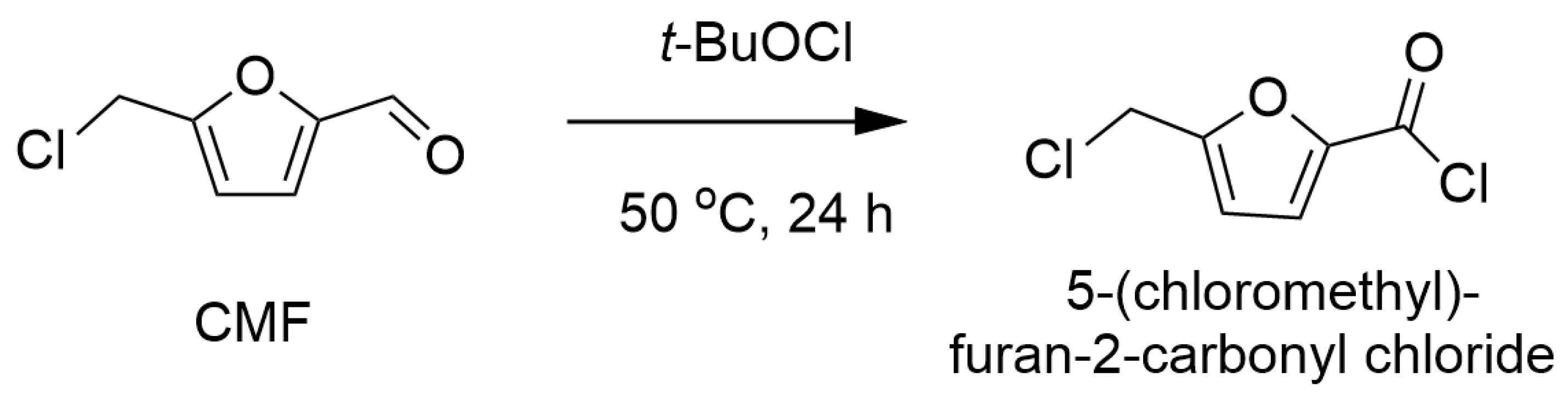

4.3. Oxidation

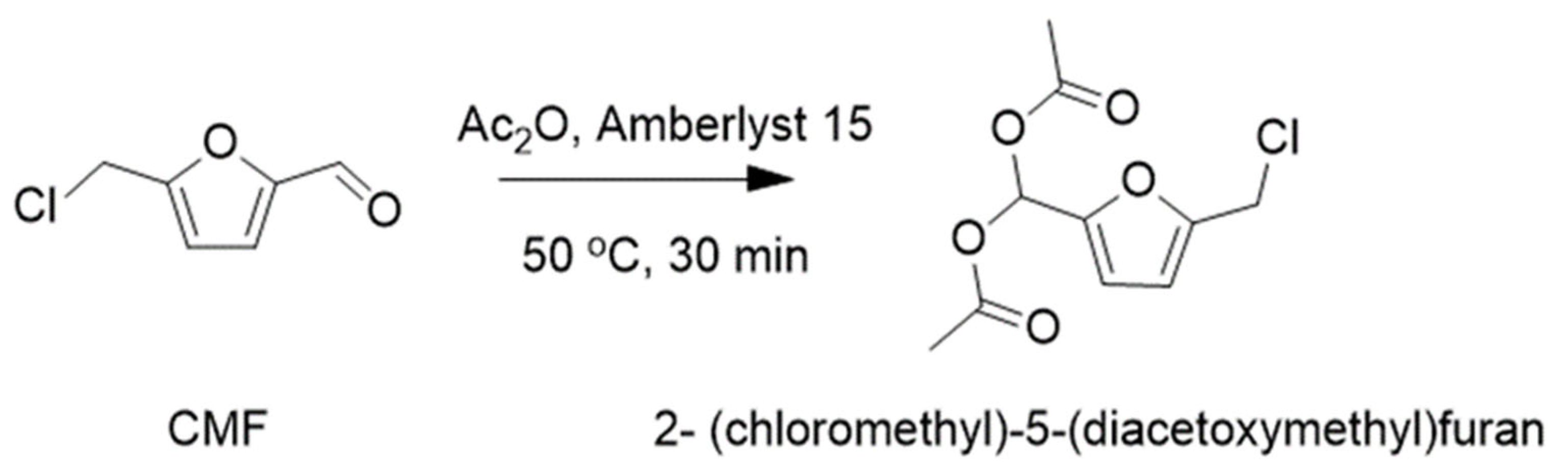

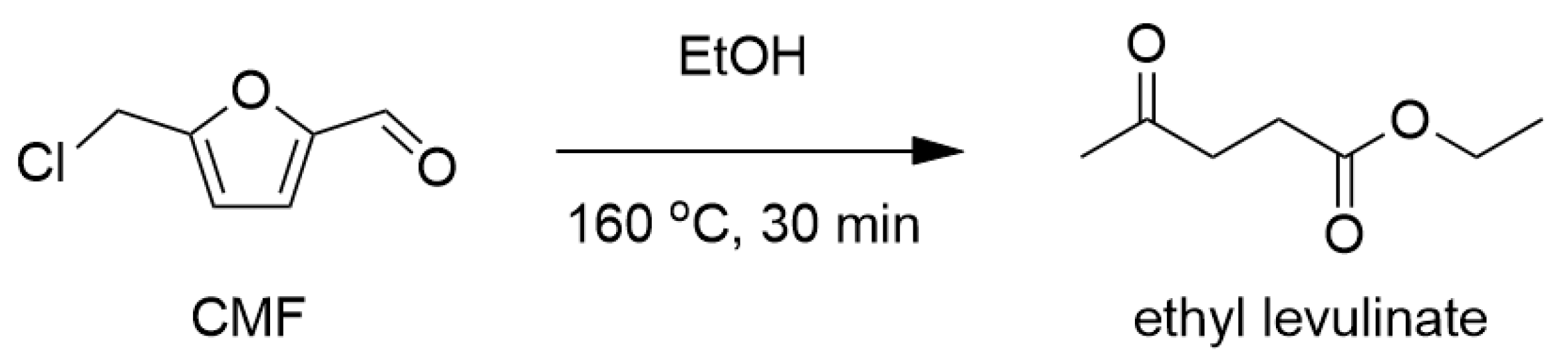

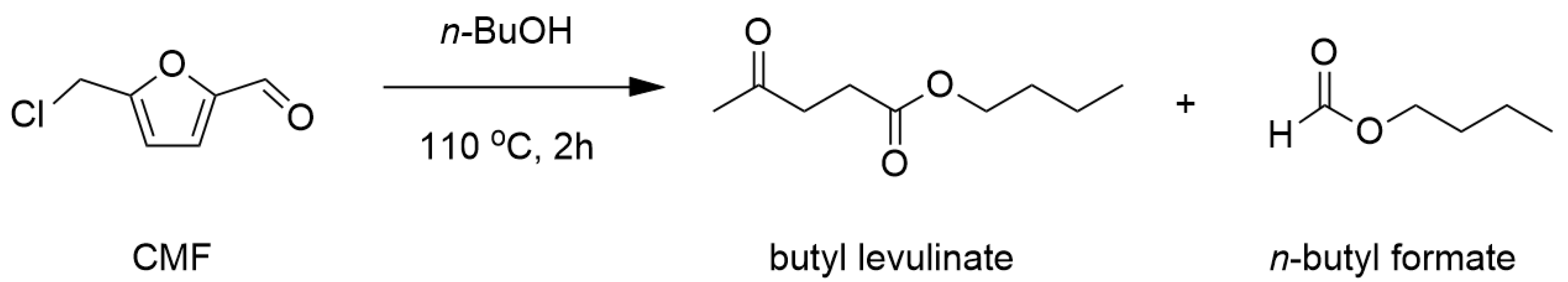

4.4. Esterification

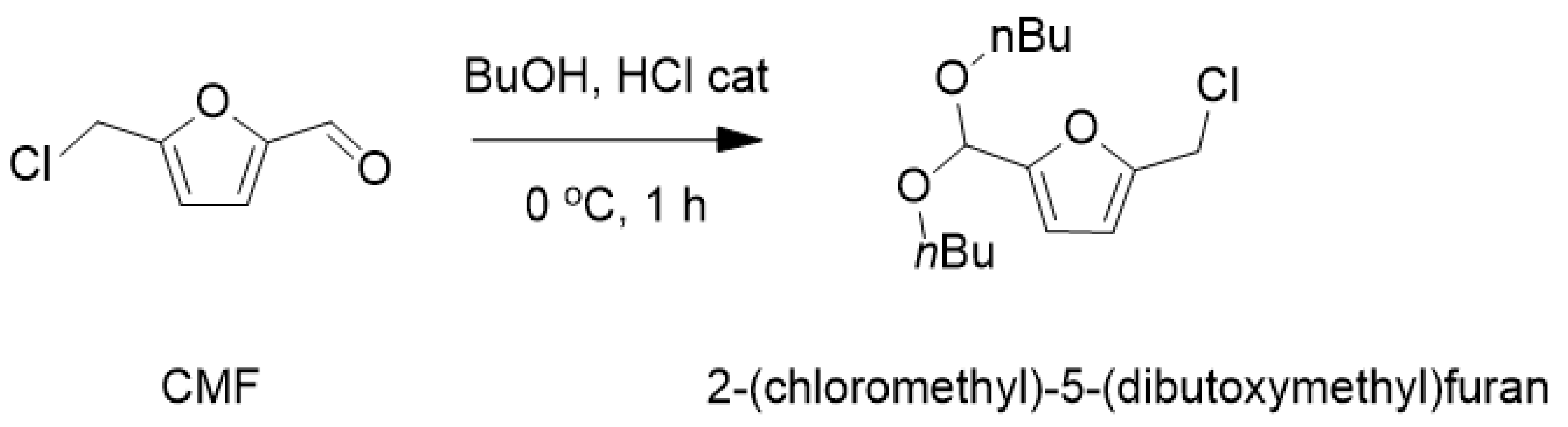

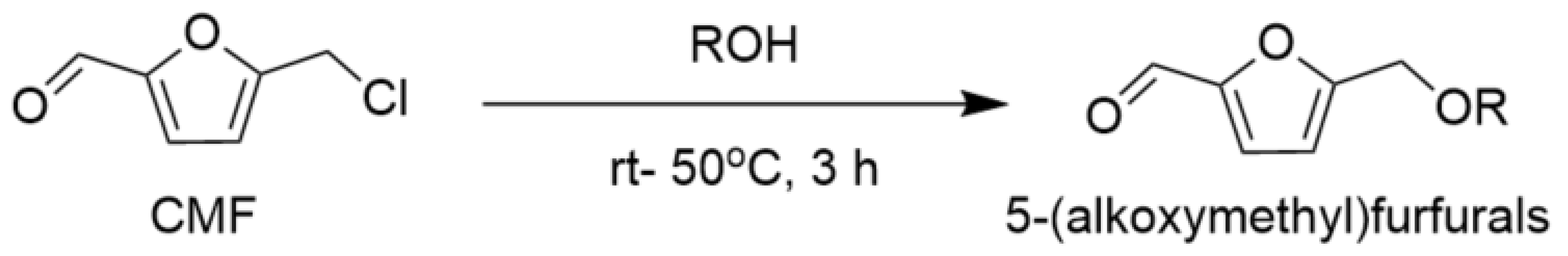

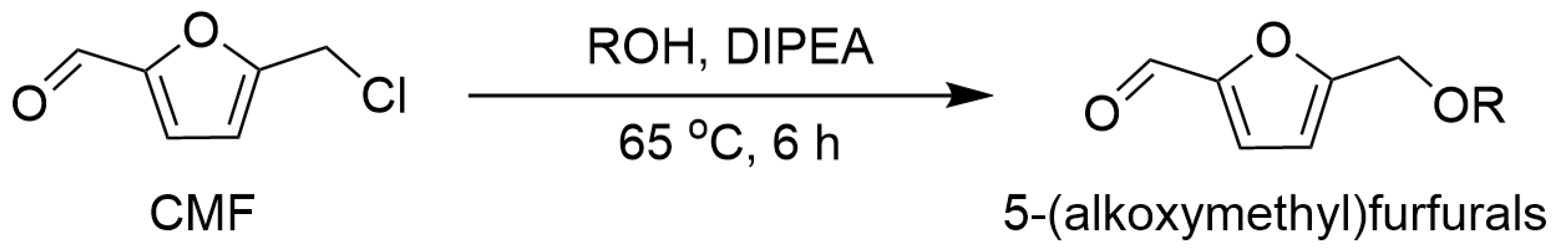

4.5. Etherification

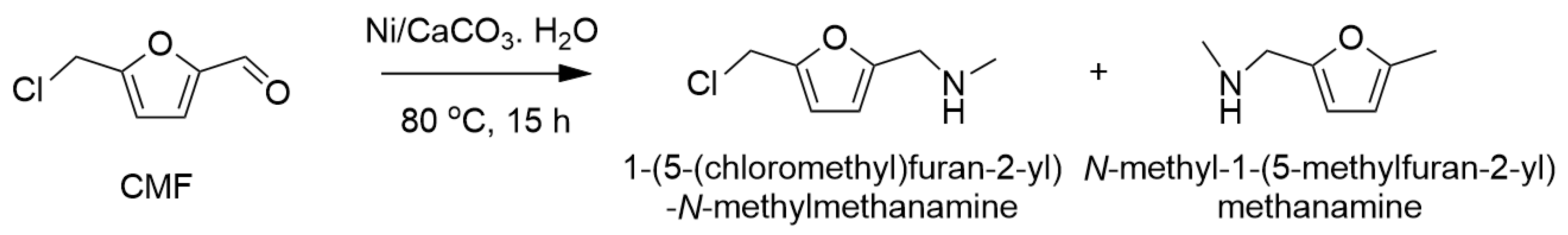

4.6. Amination

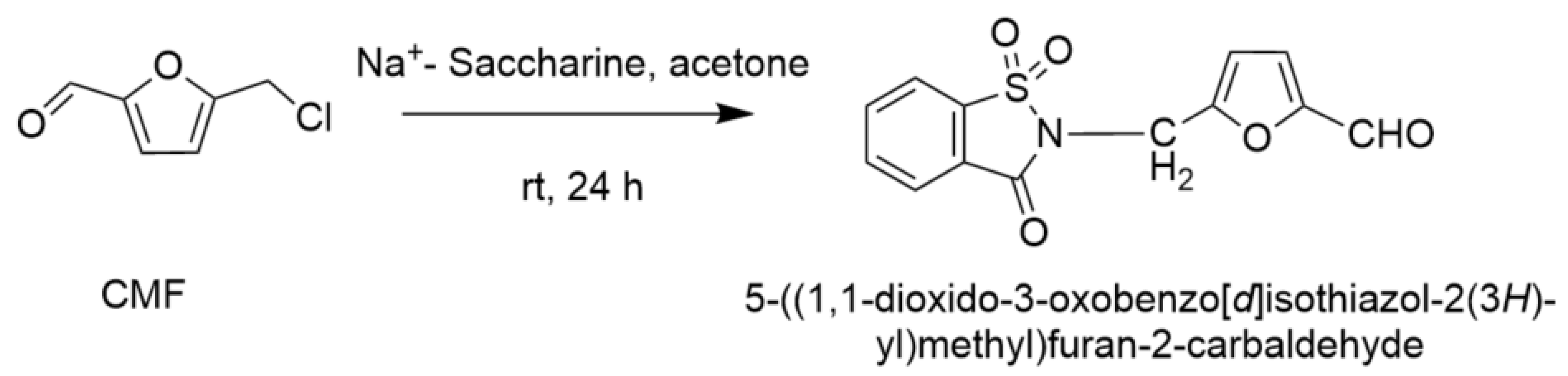

4.7. Other

5. Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| 4CA | Tetrachloroethane |

| 5MF | 5-methylfurfural |

| ACN | Acetonitrile |

| CMF | 5-chloromethylfurfural |

| CNT | Carbon nanotube |

| COSMO-RS | COnductor-like Screening MOdel for Real Solvents |

| DCE | 1,2-dichloroethane |

| DCM | Dichloromethane |

| DES | Deep eutectic solvents |

| DIPEA | N,N-diisopropylethylamine |

| DMF | 2,5-dimethylfuran |

| DMSO | Dimethyl sulfoxide |

| EHS | Environmental, health and safety |

| Et3N | Triethylamine |

| FA | Formic acid |

| FDCA | 2,5-furandicarboxylic acid |

| GVL | γ-valerolactone |

| HBA | Hydrogen bond acceptor |

| HBD | Hydrogen bond donor |

| HMF | 5-hydroxymethylfurfural |

| HSP | Hansen solubility parameters |

| IL | Ionic liquid |

| LA | Levulinic acid |

| MIBK | Methyl isobutyl ketone |

| PCE | Perchloroethylene |

| PET | Polyethylene terephthalate |

| TCE | 1,1,2-trichloroethane |

References

- British Energy Security and Net Zero, Energy and Industrial Strategy. Net Zero Strategy: Build Back Greener; HM Government: London, UK, 2021; p. 368. [Google Scholar]

- Presidency, C. Long-Term Low Greenhouse Gas Emission Development Strategy of the European Union and Its Member States; Council of the European Union: Brussels, Belgium, 2020. [Google Scholar]

- Directorate-General for Research and Innovation (European Commission). A Sustainable Bioeconomy for Europe: Strengthening the Connection between Economy, Society and the Environment: Updated Bioeconomy Strategy; Publications Office: Luxembourg, 2018. [Google Scholar]

- McKendry, P. Energy production from biomass (part 1): Overview of biomass. Bioresour. Technol. 2002, 83, 37–46. [Google Scholar] [CrossRef] [PubMed]

- Bozell, J.J.; Petersen, G.R. Technology development for the production of biobased products from biorefinery carbohydrates—The US Department of Energy’s “Top 10” revisited. Green Chem. 2010, 12, 539–554. [Google Scholar] [CrossRef]

- Werpy, T.; Petersen, G. Top Value Added Chemicals from Biomass: Volume I—Results of Screening for Potential Candidates from Sugars and Synthesis Gas; DOE/GO-102004-1992. TRN: US200427%%671 United States 10.2172/15008859 TRN: US200427%%671 NREL English; National Renewable Energy Lab.: Golden, CO, USA, 2004; 76p. [Google Scholar]

- van Putten, R.-J.; van der Waal, J.C.; de Jong, E.; Rasrendra, C.B.; Heeres, H.J.; de Vries, J.G. Hydroxymethylfurfural, A Versatile Platform Chemical Made from Renewable Resources. Chem. Rev. 2013, 113, 1499–1597. [Google Scholar] [CrossRef] [PubMed]

- Soukup-Carne, D.; Fan, X.; Esteban, J. An overview and analysis of the thermodynamic and kinetic models used in the production of 5-hydroxymethylfurfural and furfural. Chem. Eng. J. 2022, 442, 136313. [Google Scholar] [CrossRef]

- Hou, Q.; Qi, X.; Zhen, M.; Qian, H.; Nie, Y.; Bai, C.; Zhang, S.; Bai, X.; Ju, M. Biorefinery roadmap based on catalytic production and upgrading 5-hydroxymethylfurfural. Green Chem. 2021, 23, 119–231. [Google Scholar] [CrossRef]

- Naga Sai, M.S.; De, D.; Satyavathi, B. Sustainable production and purification of furfural from waste agricultural residue: An insight into integrated biorefinery. J. Clean. Prod. 2021, 327, 129467. [Google Scholar] [CrossRef]

- Mariscal, R.; Maireles-Torres, P.; Ojeda, M.; Sádaba, I.; López Granados, M. Furfural: A renewable and versatile platform molecule for the synthesis of chemicals and fuels. Energy Environ. Sci. 2016, 9, 1144–1189. [Google Scholar] [CrossRef]

- Esteban, J.; Yustos, P.; Ladero, M. Catalytic Processes from Biomass-Derived Hexoses and Pentoses: A Recent Literature Overview. Catalysts 2018, 8, 637. [Google Scholar] [CrossRef]

- Schrimpf, M.; Esteban, J.; Rösler, T.; Vorholt, A.J.; Leitner, W. Intensified reactors for gas-liquid-liquid multiphase catalysis: From chemistry to engineering. Chem. Eng. J. 2019, 372, 917–939. [Google Scholar] [CrossRef]

- Groot, W.J.; van der Lans, R.G.J.M.; Luyben, K.C.A.M. Technologies for butanol recovery integrated with fermentations. Process Biochem. 1992, 27, 61–75. [Google Scholar] [CrossRef]

- Anchan, H.N.; Dutta, S. Recent advances in the production and value addition of selected hydrophobic analogs of biomass-derived 5-(hydroxymethyl)furfural. Biomass Convers. Biorefin. 2021, 13, 2571–2593. [Google Scholar] [CrossRef]

- Mascal, M. 5-(Chloromethyl)furfural (CMF): A Platform for Transforming Cellulose into Commercial Products. ACS Sustain. Chem. Eng. 2019, 7, 5588–5601. [Google Scholar] [CrossRef]

- Fenton, H.J.H.; Gostling, M. LXXXV.—Derivatives of methylfurfural. J. Chem. Soc. Trans. 1901, 79, 807–816. [Google Scholar] [CrossRef]

- Mascal, M.; Nikitin, E.B. Direct, High-Yield Conversion of Cellulose into Biofuel. Angew. Chem. Int. Ed. 2008, 47, 7924–7926. [Google Scholar] [CrossRef] [PubMed]

- Lakmini, L.M.N.; Deshan, A.D.K.; Pham, H.D.; Doherty, W.; Rackemann, D.; Dubal, D.P.; Moghaddam, L. High carbon utilization: 5-(Chloromethyl)furfural (CMF) production from rice by-products and transformation of CMF residues into Li-ion energy storage systems. J. Clean. Prod. 2022, 375, 134082. [Google Scholar] [CrossRef]

- Origin Materials. 5-Chloromethylfurfural. Available online: https://www.originmaterials.com/products/5-chloromethylfurfural-cmf (accessed on 5 May 2023).

- Alex, B.; Wood, M.M.; Smith, R.; Bissel, J.; Hirsch-Weil, D.; Araiza, R.; Henton, D.; Plonka, J. Methods for Producing 5-(halomethylfurfural). U.S. Patent US9388151B2, 2 February 2023. [Google Scholar]

- Kawai, S.I.; Tanaka, S.; Terai, K.; Tezuka, M.; Nishiwaki, T. Synthesis of 1,4,7-Cyclononatrione. Bull. Chem. Soc. Jpn. 1960, 33, 669–674. [Google Scholar] [CrossRef]

- ChemSpider. 5-(Hydroxymethyl)-2-Furaldehyde. Available online: http://www.chemspider.com/Chemical-Structure.207215.html (accessed on 29 September 2021).

- Bredihhin, A.; Mäeorg, U.; Vares, L. Evaluation of carbohydrates and lignocellulosic biomass from different wood species as raw material for the synthesis of 5-bromomethyfurfural. Carbohydr. Res. 2013, 375, 63–67. [Google Scholar] [CrossRef]

- Jessop, P.G. Searching for green solvents. Green Chem. 2011, 13, 1391–1398. [Google Scholar] [CrossRef]

- González-Miquel, M.; Esteban, J. 2.53—Novel Solvents for Biotechnology Applications. In Comprehensive Biotechnology, 3rd ed.; Moo-Young, M., Ed.; Pergamon: Oxford, UK, 2019; pp. 790–806. [Google Scholar]

- Sheldon, R.A. Green and sustainable manufacture of chemicals from biomass: State of the art. Green Chem. 2014, 16, 950–963. [Google Scholar]

- Sheldon, R.A. Metrics of Green Chemistry and Sustainability: Past, Present, and Future. ACS Sustain. Chem. Eng. 2018, 6, 32–48. [Google Scholar] [CrossRef]

- Swift, T.D.; Bagia, C.; Choudhary, V.; Peklaris, G.; Nikolakis, V.; Vlachos, D.G. Kinetics of Homogeneous Brønsted Acid Catalyzed Fructose Dehydration and 5-Hydroxymethyl Furfural Rehydration: A Combined Experimental and Computational Study. ACS Catal. 2014, 4, 259–267. [Google Scholar] [CrossRef]

- Tan-Soetedjo, J.N.M.; van de Bovenkamp, H.H.; Abdilla, R.M.; Rasrendra, C.B.; van Ginkel, J.; Heeres, H.J. Experimental and Kinetic Modeling Studies on the Conversion of Sucrose to Levulinic Acid and 5-Hydroxymethylfurfural Using Sulfuric Acid in Water. Ind. Eng. Chem. Res. 2017, 56, 13228–13239. [Google Scholar] [CrossRef] [PubMed]

- Ershova, O.; Kanervo, J.; Hellsten, S.; Sixta, H. The role of xylulose as an intermediate in xylose conversion to furfural: Insights via experiments and kinetic modelling. Rsc Adv. 2015, 5, 66727–66737. [Google Scholar] [CrossRef]

- Ji, H.; Chen, L.; Zhu, J.Y.; Gleisner, R.; Zhang, X. Reaction Kinetics Based Optimization of Furfural Production from Corncob Using a Fully Recyclable Solid Acid. Ind. Eng. Chem. Res. 2016, 55, 11253–11259. [Google Scholar] [CrossRef]

- Stankiewicz, A.I.; Moulijn, J.A. Process intensification: Transforming chemical engineering. Chem. Eng. Prog. 2000, 96, 22–34. [Google Scholar]

- Esteban, J.; Vorholt, A.J.; Leitner, W. An overview of the biphasic dehydration of sugars to 5-hydroxymethylfurfural and furfural: A rational selection of solvents using COSMO-RS and selection guides. Green Chem. 2020, 22, 2097–2128. [Google Scholar] [CrossRef]

- Mellmer, M.A.; Sanpitakseree, C.; Demir, B.; Ma, K.; Elliott, W.A.; Bai, P.; Johnson, R.L.; Walker, T.W.; Shanks, B.H.; Rioux, R.M.; et al. Effects of chloride ions in acid-catalyzed biomass dehydration reactions in polar aprotic solvents. Nat. Commun. 2019, 10, 1132. [Google Scholar] [CrossRef] [PubMed]

- Guo, W.; Zhang, Z.; Hacking, J.; Heeres, H.J.; Yue, J. Selective fructose dehydration to 5-hydroxymethylfurfural from a fructose-glucose mixture over a sulfuric acid catalyst in a biphasic system: Experimental study and kinetic modelling. Chem. Eng. J. 2021, 409, 128182. [Google Scholar] [CrossRef]

- Tang, J.; Zhu, L.; Fu, X.; Dai, J.; Guo, X.; Hu, C. Insights into the Kinetics and Reaction Network of Aluminum Chloride-Catalyzed Conversion of Glucose in NaCl–H2O/THF Biphasic System. ACS Catal. 2017, 7, 256–266. [Google Scholar] [CrossRef]

- Zhang, L.L.; Tian, Y.B.; Wang, Y.Y.; Dai, L.Y. Enhanced conversion of alpha-cellulose to 5-HMF in aqueous biphasic system catalyzed by FeCl3-CuCl2. Chin. Chem. Lett. 2021, 32, 2233–2238. [Google Scholar] [CrossRef]

- Li, X.; Liu, Q.; Luo, C.; Gu, X.; Lu, L.; Lu, X. Kinetics of Furfural Production from Corn Cob in gamma-Valerolactone Using Dilute Sulfuric Acid as Catalyst. ACS Sustain. Chem. Eng. 2017, 5, 8587–8593. [Google Scholar] [CrossRef]

- Zhao, Y.; Xu, H.; Lu, K.; Qu, Y.; Zhu, L.; Wang, S. Experimental and Kinetic Study of Arabinose Conversion to Furfural in Renewable Butanone-Water Solvent Mixture Catalyzed by Lewis Acidic Ionic Liquid Catalyst. Ind. Eng. Chem. Res. 2019, 58, 17088–17097. [Google Scholar] [CrossRef]

- Zhang, L.-X.; Yu, H.; Yu, H.-B.; Chen, Z.; Yang, L. Conversion of xylose and xylan into furfural in biorenewable choline chloride–oxalic acid deep eutectic solvent with the addition of metal chloride. Chin. Chem. Lett. 2014, 25, 1132–1136. [Google Scholar] [CrossRef]

- Weingarten, R.; Cho, J.; Conner, J.W.C.; Huber, G.W. Kinetics of furfural production by dehydration of xylose in a biphasic reactor with microwave heating. Green Chem. 2010, 12, 1423–1429. [Google Scholar] [CrossRef]

- Yang, T.; Zhou, Y.H.; Zhu, S.Z.; Pan, H.; Huang, Y.B. Insight into Aluminum Sulfate-Catalyzed Xylan Conversion into Furfural in a -Valerolactone/Water Biphasic Solvent under Microwave Conditions. Chemsuschem 2017, 10, 4066–4079. [Google Scholar] [CrossRef] [PubMed]

- Mascal, M. 5-(Chloromethyl)furfural is the New HMF: Functionally Equivalent But More Practical in Terms of its Production From Biomass. ChemSusChem 2015, 8, 3391–3395. [Google Scholar] [CrossRef] [PubMed]

- Wu, F.S.; Yang, R.D.; Yang, F. Metal Chlorides as Effective Catalysts for the One-Pot Conversion of Lignocellulose into 5-Chloromethylfurfural (5-CMF). Bioresources 2015, 10, 3293–3301. [Google Scholar] [CrossRef]

- Brasholz, M.; von Känel, K.; Hornung, C.H.; Saubern, S.; Tsanaktsidis, J. Highly efficient dehydration of carbohydrates to 5-(chloromethyl)furfural (CMF), 5-(hydroxymethyl)furfural (HMF) and levulinic acid by biphasic continuous flow processing. Green Chem. 2011, 13, 1114–1117. [Google Scholar] [CrossRef]

- Jadhav, H.; Pedersen, C.M.; Sølling, T.; Bols, M. 3-Deoxy-glucosone is an Intermediate in the Formation of Furfurals from D-Glucose. ChemSusChem 2011, 4, 1049–1051. [Google Scholar] [CrossRef]

- Smith, B.A.; Champagne, P.; Jessop, P.G. A Semi-Batch Flow System for the Production of 5-Chloromethylfurfural. Chem. Methods 2021, 1, 438–443. [Google Scholar] [CrossRef]

- Lane, D.R.; Mascal, M.; Stroeve, P. Experimental studies towards optimization of the production of 5-(chloromethyl)furfural (CMF) from glucose in a two-phase reactor. Renew. Energy 2016, 85, 994–1001. [Google Scholar] [CrossRef]

- Kang, E.-S.; Hong, Y.-W.; Chae, D.W.; Kim, B.; Kim, B.; Kim, Y.J.; Cho, J.K.; Kim, Y.G. From Lignocellulosic Biomass to Furans via 5-Acetoxymethylfurfural as an Alternative to 5-Hydroxymethylfurfural. ChemSusChem 2015, 8, 1179–1188. [Google Scholar] [CrossRef]

- Kohl, T.M.; Bizet, B.; Kevan, P.; Sellwood, C.; Tsanaktsidis, J.; Hornung, C.H. Efficient synthesis of 5-(chloromethyl)furfural (CMF) from high fructose corn syrup (HFCS) using continuous flow processing. React. Chem. Eng. 2017, 2, 541–549. [Google Scholar] [CrossRef]

- Zuo, M.; Li, Z.; Jiang, Y.; Tang, X.; Zeng, X.; Sun, Y.; Lin, L. Green catalytic conversion of bio-based sugars to 5-chloromethyl furfural in deep eutectic solvent, catalyzed by metal chlorides. RSC Adv. 2016, 6, 27004–27007. [Google Scholar] [CrossRef]

- Breeden, S.W.; Clark, J.H.; Farmer, T.J.; Macquarrie, D.J.; Meimoun, J.S.; Nonne, Y.; Reid, J.E.S.J. Microwave heating for rapid conversion of sugars and polysaccharides to 5-chloromethyl furfural. Green Chem. 2013, 15, 72–75. [Google Scholar] [CrossRef]

- Budarin, V.L.; Shuttleworth, P.S.; De Bruyn, M.; Farmer, T.J.; Gronnow, M.J.; Pfaltzgraff, L.; Macquarrie, D.J.; Clark, J.H. The potential of microwave technology for the recovery, synthesis and manufacturing of chemicals from bio-wastes. Catal. Today 2015, 239, 80–89. [Google Scholar] [CrossRef]

- Onkarappa, S.B.; Dutta, S. Phase Transfer Catalyst Assisted One-Pot Synthesis of 5-(Chloromethyl)furfural from Biomass-Derived Carbohydrates in a Biphasic Batch Reactor. ChemistrySelect 2019, 4, 7502–7506. [Google Scholar] [CrossRef]

- Bhat, N.S.; Vinod, N.; Onkarappa, S.B.; Dutta, S. Hydrochloric acid-catalyzed coproduction of furfural and 5-(chloromethyl)furfural assisted by a phase transfer catalyst. Carbohydr. Res. 2020, 496, 108105. [Google Scholar] [CrossRef]

- Antonyraj, C.A.; Chennattussery, A.J.; Haridas, A. 5-(Chloromethyl)furfural production from glucose: A pioneer kinetic model development exploring the mechanism. Int. J. Chem. Kinet. 2021, 53, 825–833. [Google Scholar] [CrossRef]

- Rojahn, P.; Nigam, K.D.P.; Schael, F. Experimental study and kinetic modeling of continuous flow conversion of fructose to 5-(chloromethyl)furfural using micro- and millistructured coiled flow inverter. Chem. Eng. J. 2022, 450, 138243. [Google Scholar] [CrossRef]

- Chen, B.L.; Li, Z.; Feng, Y.C.; Hao, W.W.; Sun, Y.; Tang, X.; Zeng, X.H.; Lin, L. Green Process for 5-(Chloromethyl)furfural Production from Biomass in Three-Constituent Deep Eutectic Solvent. Chemsuschem 2021, 14, 847–851. [Google Scholar] [CrossRef] [PubMed]

- Mascal, M.; Nikitin, E.B. Dramatic Advancements in the Saccharide to 5-(Chloromethyl)furfural Conversion Reaction. ChemSusChem 2009, 2, 859–861. [Google Scholar] [CrossRef] [PubMed]

- Gao, W.; Li, Y.; Xiang, Z.; Chen, K.; Yang, R.; Argyropoulos, D.S. Efficient One-Pot Synthesis of 5-Chloromethylfurfural (CMF) from Carbohydrates in Mild Biphasic Systems. Molecules 2013, 18, 7675–7685. [Google Scholar] [CrossRef] [PubMed]

- Singh, M.; Pandey, N.; Mishra, B.B. A divergent approach for the synthesis of (hydroxymethyl)furfural (HMF) from spent aromatic biomass-derived (chloromethyl)furfural (CMF) as a renewable feedstock. RSC Adv. 2020, 10, 45081–45089. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Eren, N.M.; Kreke, T.; Mosier, N.S.; Engelberth, A.S.; Kilaz, G. Concentrated HCl Catalyzed 5-(Chloromethyl)furfural Production from Corn Stover of Varying Particle Sizes. BioEnergy Res. 2017, 10, 1018–1024. [Google Scholar] [CrossRef]

- Howard, J.; Rackemann, D.W.; Zhang, Z.; Moghaddam, L.; Bartley, J.P.; Doherty, W.O.S. Effect of pretreatment on the formation of 5-chloromethyl furfural derived from sugarcane bagasse. RSC Adv. 2016, 6, 5240–5248. [Google Scholar] [CrossRef]

- Bhat, N.S.; Hegde, S.L.; Dutta, S.; Sudarsanam, P. Efficient Synthesis of 5-(Hydroxymethyl)furfural Esters from Polymeric Carbohydrates Using 5-(Chloromethyl)furfural as a Reactive Intermediate. ACS Sustain. Chem. Eng. 2022, 10, 5803–5809. [Google Scholar] [CrossRef]

- Bueno Moron, J.; van Klink, G.; Gruter, G.-J.M. Production and Downstream Integration of 5-(Chloromethyl)furfural from Lignocellulose. ACS Sustain. Chem. Eng. 2023, 11, 17492–17509. [Google Scholar] [CrossRef]

- Barman, S.; Chakraborty, R. Energy-efficient and eco-friendly continuous production of 5-CMF in a UV-ultrasound irradiated catalytic packed bed reactor: Heterogeneous kinetics, reactor simulation and LCA analysis. React. Chem. Eng. 2023, 9, 160–171. [Google Scholar] [CrossRef]

- Prat, D.; Wells, A.; Hayler, J.; Sneddon, H.; McElroy, C.R.; Abou-Shehada, S.; Dunn, P.J. CHEM21 selection guide of classical- and less classical-solvents. Green Chem. 2016, 18, 288–296. [Google Scholar] [CrossRef]

- Hansen, C. The three dimensional solubility parameter: II Dyes, emulsifiers, mutual solubility and compatibility and pigments. JPT 1967, 39, 511. [Google Scholar]

- Hansen, C.M. Hansen Solubility Parameters: A User’s Handbook; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Klamt, A. Conductor-like Screening Model for Real Solvents: A New Approach to the Quantitative Calculation of Solvation Phenomena. J. Phys. Chem. 1995, 99, 2224–2235. [Google Scholar] [CrossRef]

- Mascal, M.; Nikitin, E.B. Co-processing of Carbohydrates and Lipids in Oil Crops To Produce a Hybrid Biodiesel. Energy Fuels 2010, 24, 2170–2171. [Google Scholar] [CrossRef]

- Mascal, M.; Dutta, S. Synthesis of the natural herbicide δ-aminolevulinic acid from cellulose-derived 5-(chloromethyl)furfural. Green Chem. 2011, 13, 40–41. [Google Scholar] [CrossRef]

- Mascal, M.; Dutta, S. Synthesis of ranitidine (Zantac) from cellulose-derived 5-(chloromethyl)furfural. Green Chem. 2011, 13, 3101–3102. [Google Scholar] [CrossRef]

- Mascal, M.; Nikitin, E.B. High-yield conversion of plant biomass into the key value-added feedstocks 5-(hydroxymethyl)furfural, levulinic acid, and levulinic esters via 5-(chloromethyl)furfural. Green Chem. 2010, 12, 370–373. [Google Scholar] [CrossRef]

- Park, D.; Lee, S.; Kim, J.; Yeong Ryu, G.; Suh, Y.-W. 5-(Chloromethyl)Furfural as a Potential Source for Continuous Hydrogenation of 5-(Hydroxymethyl)Furfural to 2,5-Bis(Hydroxymethyl)Furan. ChemPlusChem 2022, 87, e202200166. [Google Scholar] [CrossRef] [PubMed]

- Zhong, S.; Daniel, R.; Xu, H.; Zhang, J.; Turner, D.; Wyszynski, M.L.; Richards, P. Combustion and Emissions of 2,5-Dimethylfuran in a Direct-Injection Spark-Ignition Engine. Energy Fuels 2010, 24, 2891–2899. [Google Scholar] [CrossRef]

- Li, S.; Dong, M.; Yang, J.; Cheng, X.; Shen, X.; Liu, S.; Wang, Z.-Q.; Gong, X.-Q.; Liu, H.; Han, B. Selective hydrogenation of 5-(hydroxymethyl)furfural to 5-methylfurfural over single atomic metals anchored on Nb2O5. Nat. Commun. 2021, 12, 584. [Google Scholar] [CrossRef]

- Hamada, K.; Yoshihara, H.; Suzukamo, G. Novel Synthetic Route to 2,5-Disubstituted Furan Derivatives through Surface Active Agent-Catalysed Dehydration of D(-)-Fructose. J. Oleo Sci. 2001, 50, 533–536. [Google Scholar] [CrossRef]

- Dutta, S.; Mascal, M. Novel Pathways to 2,5-Dimethylfuran via Biomass-Derived 5-(Chloromethyl)furfural. ChemSusChem 2014, 7, 3028–3030. [Google Scholar] [CrossRef] [PubMed]

- Torben Lund, H.L. Electrochemical reduction of furan derivatives derived from biomass. Acta Chem. Scand. 1985, 39, 429–435. [Google Scholar] [CrossRef]

- Chen, B.; Feng, Y.; Huang, R.; Yang, S.; Li, Z.; Sperry, J.; Yang, S.; Tang, X.; Sun, Y.; Lin, L.; et al. Efficient synthesis of the liquid fuel 2,5-dimethylfuran from biomass derived 5-(chloromethyl)furfural at room temperature. Appl. Catal. B Environ. 2022, 318, 121842. [Google Scholar] [CrossRef]

- Li, H.; Wang, C.; Xu, Y.; Yu, Z.; Saravanamurugan, S.; Wu, Z.; Yang, S.; Luque, R. Heterogeneous (de)chlorination-enabled control of reactivity in the liquid-phase synthesis of furanic biofuel from cellulosic feedstock. Green Chem. 2020, 22, 637–645. [Google Scholar] [CrossRef]

- Chen, B.; Feng, Y.; Ma, S.; Xie, W.; Yan, G.; Li, Z.; Sperry, J.; Yang, S.; Tang, X.; Sun, Y.; et al. One-pot synthesis of 2,5-bis(hydroxymethyl)furan from biomass derived 5-(chloromethyl)furfural in high yield. J. Energy Chem. 2023, 76, 421–428. [Google Scholar] [CrossRef]

- Takei, T.; Akita, T.; Nakamura, I.; Fujitani, T.; Okumura, M.; Okazaki, K.; Huang, J.; Ishida, T.; Haruta, M. Chapter One—Heterogeneous Catalysis by Gold. In Advances in Catalysis; Gates, B.C., Jentoft, F.C., Eds.; Academic Press: Cambridge, MA, USA, 2012; Volume 55, pp. 1–126. [Google Scholar]

- Cooper, W.F.; Nuttall, W.H. CXII.—Furan-2: 5-dialdehyde. J. Chem. Soc. Trans. 1912, 101, 1074–1081. [Google Scholar] [CrossRef]

- Dutta, S.; Wu, L.; Mascal, M. Production of 5-(chloromethyl)furan-2-carbonyl chloride and furan-2,5-dicarbonyl chloride from biomass-derived 5-(chloromethyl)furfural (CMF). Green Chem. 2015, 17, 3737–3739. [Google Scholar] [CrossRef]

- Onkarappa, S.B.; Dutta, S. High-Yielding Synthesis of 5-(alkoxymethyl)furfurals from Biomass-Derived 5-(halomethyl)furfural (X = Cl, Br). ChemistrySelect 2019, 4, 5540–5543. [Google Scholar] [CrossRef]

- Jia, W.; Liu, H.; Feng, Y.; Zhang, J.; Zhao, X.; Sun, Y.; Wei, Z.; Yang, S.; Tang, X.; Zeng, X.; et al. Efficient supercritical carbon dioxide promoted reductive amination of furfural using water as hydrogen donor over Ni/CaCO3. J. Clean. Prod. 2022, 345, 131029. [Google Scholar] [CrossRef]

- Karlinskii, B.Y.; Romashov, L.V.; Galkin, K.I.; Kislitsyn, P.G.; Ananikov, V.P. Synthesis of 2-azidomethyl-5-ethynylfuran: A new bio-derived self-clickable building block. Synthesis 2019, 51, 1235–1242. [Google Scholar] [CrossRef]

- Szmant, H.H.; Chundury, D.D. The preparation of 5-chloromethylfurfuraldehyde from high fructose corn syrup and other carbohydrates. J. Chem. Technol. Biotechnol. 1981, 31, 205–212. [Google Scholar]

- Sakhautdinova, G.F.; Malikova, R.N.; Bortsova, Y.L.; Mochalov, K.S.; Muratov, E.M.; Galimova, E.F.; Sakhautdinov, I.M.; Mustafin, A.G. Synthesis of 5-(hydroxy-, chloro-, bromomethyl)furan-2-enones Based on Fructose and their Antioxidant Activity. Chem. Nat. Compd. 2021, 57, 869–874. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soukup-Carne, D.; Bragagnolo, F.S.; Soleo Funari, C.; Esteban, J. Production and Synthetic Possibilities of 5-Chloromethylfurfural as Alternative Biobased Furan. Catalysts 2024, 14, 117. https://doi.org/10.3390/catal14020117

Soukup-Carne D, Bragagnolo FS, Soleo Funari C, Esteban J. Production and Synthetic Possibilities of 5-Chloromethylfurfural as Alternative Biobased Furan. Catalysts. 2024; 14(2):117. https://doi.org/10.3390/catal14020117

Chicago/Turabian StyleSoukup-Carne, Dominik, Felipe Sanchez Bragagnolo, Cristiano Soleo Funari, and Jesús Esteban. 2024. "Production and Synthetic Possibilities of 5-Chloromethylfurfural as Alternative Biobased Furan" Catalysts 14, no. 2: 117. https://doi.org/10.3390/catal14020117

APA StyleSoukup-Carne, D., Bragagnolo, F. S., Soleo Funari, C., & Esteban, J. (2024). Production and Synthetic Possibilities of 5-Chloromethylfurfural as Alternative Biobased Furan. Catalysts, 14(2), 117. https://doi.org/10.3390/catal14020117