Abstract

Pollution caused by antibiotics has brought significant challenges to the ecological environment. To improve the efficiency of the removal of tetracycline (TC) from aqueous solutions, a composite material consisting of TiO2 and phosphoric acid-treated peanut shell biochar (p-BC) has been successfully synthesized in the present study by the sol-gel method. In addition, the composite material was characterized using various techniques, including scanning electron microscopy (SEM), Fourier-transform infrared spectroscopy (FTIR), X-ray diffraction (XRD) spectroscopy, X-ray photoelectron spectroscopy (XPS), photoluminescence (PL) spectroscopy, and ultraviolet–visible diffuse reflectance spectroscopy (UV-vis DRS). The XPS and FTIR analyses revealed the formation of a new Ti–O–C bond, while the XRD analysis confirmed the presence of TiO2 (with an anatase phase) in the composite material. Also, the PL analyses showed a notable decrease in the recombination efficiency of electrons and holes, which was due to the formation of a composite. This was further supported by the UV-vis DRS analyses, which revealed a decrease in bandgap (to 2.73 eV) of the composite material and led to enhanced light utilization and improved photocatalytic activity. Furthermore, the effects of pH, composite dosage, and initial concentration on the removal of TC were thoroughly examined, which resulted in a maximum removal efficiency of 95.3% under optimal conditions. Additionally, five consecutive cycle tests demonstrated an exceptional reusability and stability of the composite material. As a result of the experiments, the active species verified that ·O2− played a key role in the photodegradation of TC. Four possible degradation pathways of TC were then proposed. As a general conclusion, the TiO2/p–BC composite can be used as an efficient photocatalyst in the removal of TC from aqueous solutions.

1. Introduction

Antibiotics have been widely used to treat various bacterial diseases in humans and livestock all over the world [1]. However, only a small portion of the antibiotics can be absorbed and utilized in the body, and a high portion of antibiotics is discharged into the in vitro environment in the form of original drugs or primary metabolites [2]. Furthermore, residual antibiotics can cause antibiotic resistance bacteria (ARB) and antibiotic resistance genes (ARGs) [3], which threaten human health and ecosystem security. As one of the major broad-spectrum antibiotics, tetracycline (TC) is widely used for the treatment of human and animal infection diseases [4], especially in the livestock industry. In recent years, the abuse and wanton discharge of TC has led to its detection in surface water [5], groundwater [6], and sediment [7]. The physicochemical properties and structure of TC have difficulties regarding their degradation in the environment [8]. The environmental accumulation of TC has aroused widespread concern [9]. It is necessary to remove TC from contaminated water to minimize the environmental and ecological risks.

Up to now, researchers have developed a variety of technologies for the removal of TC from contaminated water. They include microbial degradation [10], chemical oxidation [11], physical adsorption [12], and membrane separation [13]. Among these, adsorption was a preferred method for the removal of various pollutants, which was due to its low cost and easy operation. Biochar is the material created by pyrolysis of available waste biomass under the condition of limiting oxygen, which usually has a high specific surface area and rich functional groups. Biochar or modified biochar, as an adsorbent by which it has been possible to remove TC from contaminated water, has received extensive attention. Chen et al. [14] reported on the adsorption capacity of TC, which increased from 150.2 mg g−1 to 166.3 mg g−1 when using the phosphoric acid-modified biochar. However, the main disadvantage of the adsorption technology was that TC was only transferred from one phase to the other, and it was not destroyed or disappeared [15].

As an environmentally friendly technology, photocatalysis has been used for the degradation of a variety of organic pollutants [16]. TiO2 is a photocatalyst that is most widely studied for water purification [17,18], which has here been used due to its low cost, high stability, minimum photo-corrosion, high photo-activity, and low toxicity. Zhang et al. [19] found that TiO2 can be removed by approximately 55% of TC in an aqueous solution. However, TiO2 also has some disadvantages, such as small surface area, low light utilization, quick recombination of electron–hole pairs, easy agglomeration, low reactivity for low concentrations of contaminants, and difficulties in recovering in aqueous solutions. All these disadvantages limit the use of TiO2 for contaminated water treatments. Researchers have used various methods to modify TiO2 for the improvement of its photocatalytic removal of pollutants and its wide applicability. Xu et al. [20] reported on P-doped TiO2, which had a smaller band gap value and could use more light energy than pure TiO2 for a red shift of the absorption spectrum. Some studies have also loaded TiO2 onto various materials, such as carbon nanotubes [21] and graphene [22]. Although the photocatalytic effect has been improved, the cost was high, and there was a lack of practical applications. Due to its high adsorption capacity and economic performance, biochar has received large attention as an excellent support material for TiO2. Lu et al. [23] prepared a TiO2–biochar composite catalyst and used it for the photocatalytic degradation of methyl orange. The modification by phosphoric acid may increase the specific surface area of biochar [24], which is beneficial for the adsorption of pollutants and the loading of TiO2. Also, the combination of biochar and TiO2 can reduce the band gap value and enhance the use of visible light [25], which is due to the formation of new states above the VB of the composite [26]. In fact, the adsorption of pollutants from the liquid phase to the solid surface of biochar is more conducive to photocatalytic degradation [27].

In the present study, phosphoric acid-treated peanut shell biochar (p-BC) has been used as a support material in the preparation of the TiO2/p-BC composite, which has been characterized by SEM, FTIR, XRD, XPS, PL, and UV–vis DRS. The adsorption and photocatalytic performance have been evaluated by the removal efficiency of TC. The reusability of the composite was also studied by a recyclability experiment, and the photocatalytic degradation mechanism and the degradation pathways of TC were finally proposed.

2. Results and Discussion

2.1. Characterization

2.1.1. SEM

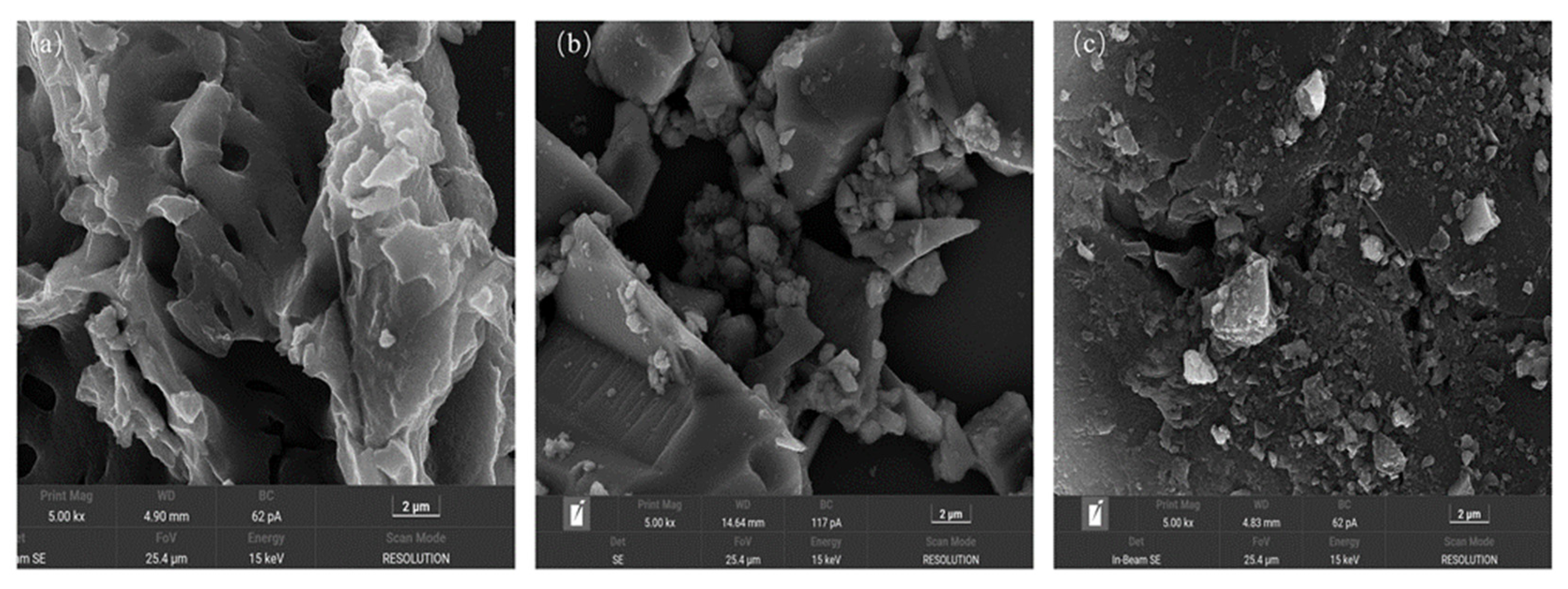

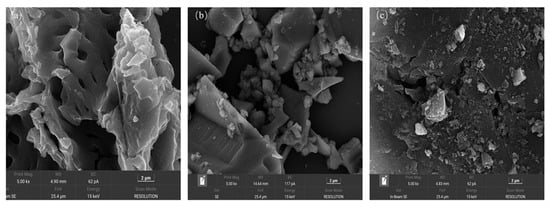

The surface morphologies of p-BC, TiO2, and TiO2/p-BC were examined by SEM analyses. The results showed a smooth and porous structure of p-BC (Figure 1a). As can be seen in Figure 1b, the TiO2 particles showed irregular agglomerated morphologies with random shapes. As compared with the p-BC, the surface morphology of TiO2/p-BC (Figure 1c) was much rougher, with an accumulation of many TiO2 particles. Thus, the pore structure of TiO2/p-BC was severely blocked.

Figure 1.

SEM images of (a) p-BC, (b) TiO2, and (c) TiO2/p-BC.

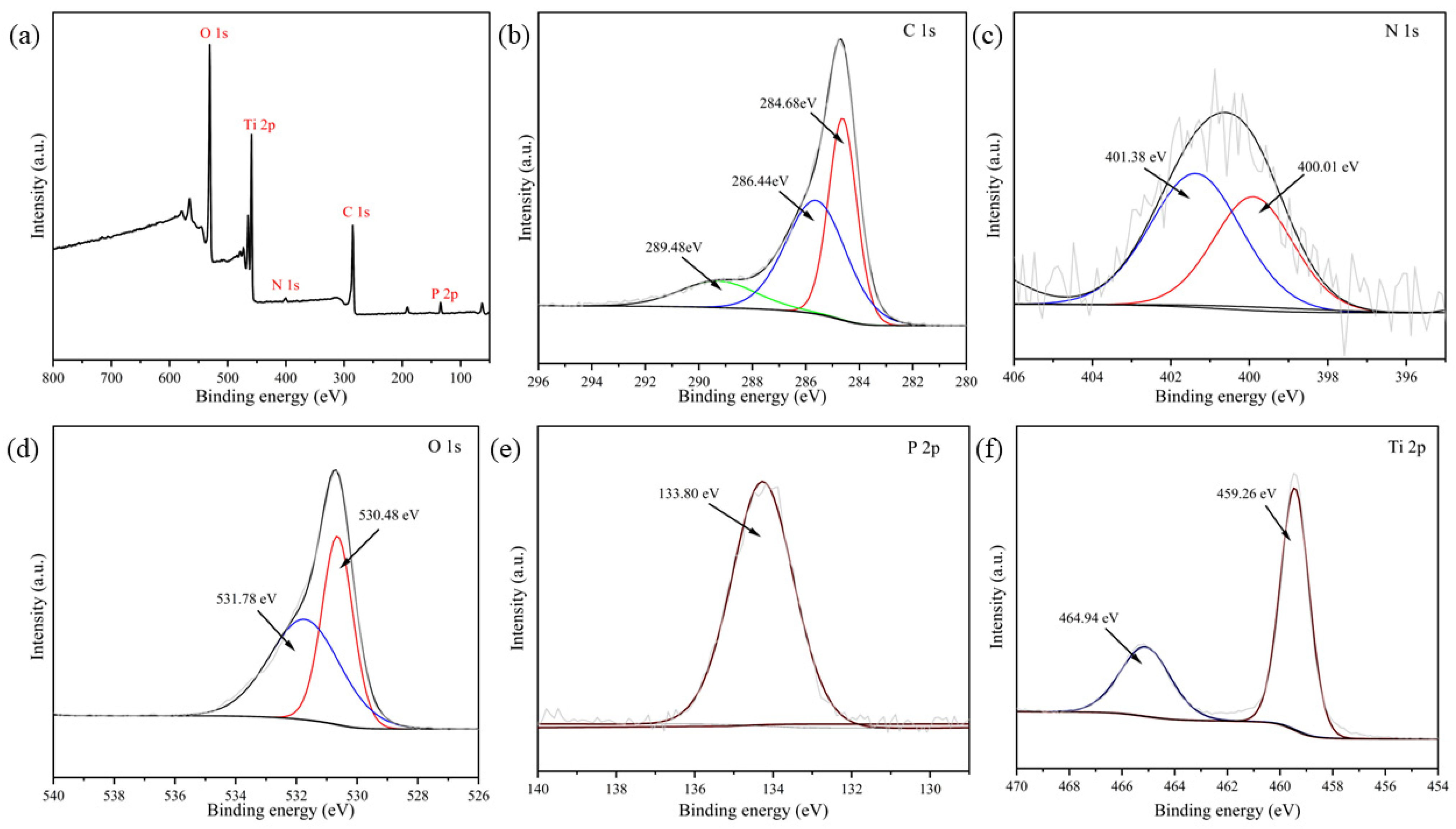

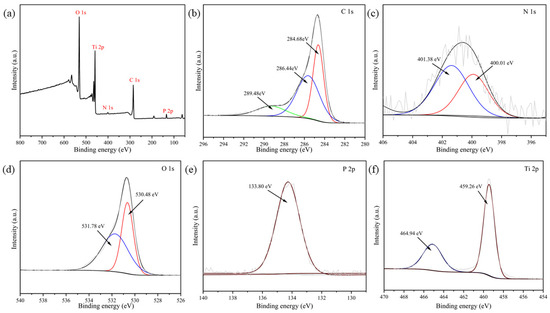

2.1.2. XPS Analyses

The survey spectrum of TiO2/p-BC is presented in Figure 2a. According to the five peaks that are related to C1s, N1s, O1s, P2p, and Ti2p core levels, this spectrum clearly shows that the composite material mainly contains C, N, O, P, and Ti elements, respectively. As can be seen in Figure 2b, the C1s spectrum was deconvoluted into three peaks at 284.68 eV, 286.08 eV, and 289.48 eV, which corresponded to C–C, C–O, and C=O bonds, respectively. The high-resolution N1s spectrum in Figure 2c shows two peaks at 400.01 eV and 401.38 eV, which correspond to C=N–C and C–NHx bonds, respectively. Furthermore, the O1s spectrum was divided into two peaks at 530.68 eV and 531.98 eV, which corresponded to the O–Ti and O–H bonds (Figure 2d). Also, Figure 2e shows the high-resolution P2p spectrum with peaks at 134.20 and 135.15 eV, representing C–O–P and O=P–O, respectively. This spectrum indicated that the preparation of biochar by phosphoric acid-modified peanut shell was successful and that the phosphorus element was present in the prepared composite material. The fitting of the Ti2p spectrum is shown in Figure 2f, with characteristic peaks of Ti 2p2/3 and Ti 2p1/2 at 459.26 eV and 464.94 eV, respectively. This result indicated that the titanium element in the composite mainly existed in the form of Ti4+ [28]. Also, the binding energies of Ti 2p1/2 and Ti 2p3/2 were higher than the corresponding ones in pure TiO2 (458.5 eV and 464.3 eV, respectively), which was due to the fact that the C atoms in the composite affected the electron cloud density around the Ti and O atoms, thereby forming Ti–O–C bonds [19].

Figure 2.

XPS spectra of TiO2/p-BC: (a) survey, (b) C 1s, (c) N 1s, (d) O 1s, (e) P 2p, and (f) Ti 2p.

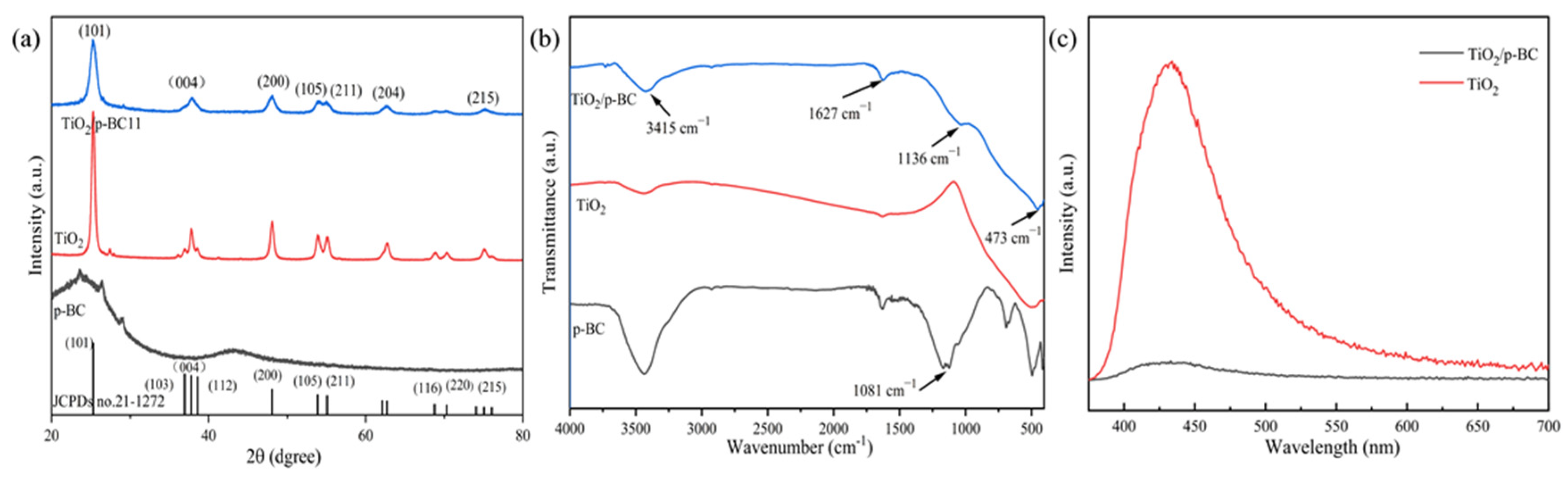

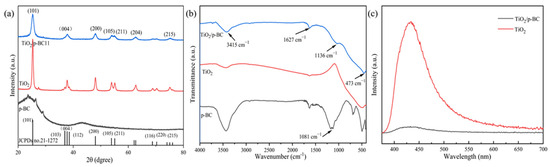

2.1.3. XRD Analyses

The XRD patterns of p-BC, TiO2, and TiO2/p-BC are displayed in Figure 3a. For p-BC, the broad peak at about 25 degrees is the characteristic diffraction peak of p-BC. For TiO2, the peaks at about 25.26, 28.61, 37.79, 48.04, 54.02, 55.01, 62.65, 68.73, 70.51, and 75.15 degrees corresponded to the 101, 110, 004, 200, 105, 211, 204, 116, 220, and 215 crystalline planes, respectively, of anatase TiO2 (JCPDS No. 21-1272) [29]. Furthermore, the XRD pattern of TiO2/p-BC lacked the characteristic diffraction peak of p-BC, which might be due to the overlap of characteristic peaks of TiO2 at similar positions. Also, the characteristic diffraction peaks of anatase TiO2 were present in the TiO2/p-BC pattern, which indicated that the anatase phase of TiO2 was successfully synthesized to p-BC, and the crystalline form of TiO2 was not affected in this process. These results are consistent with previous reports [29,30].

Figure 3.

(a) XRD and (b) FTIR patterns of p-BC, TiO2, and TiO2/pBC. (c) PL emission spectra of TiO2 and TiO2/pBC.

2.1.4. FTIR Analyses

The FTIR results of p-BC, TiO2, and TiO2/p-BC are shown in Figure 3b. The characteristic peaks at about 3415 cm−1 were assigned to –OH stretching vibrations and the peaks at about 1627 cm−1 corresponded to stretching vibrations of C=O and C=C [31]. Furthermore, the characteristic Ti–O peak of TiO2 (at about 473 cm−1) was observed in the spectrum of TiO2/p-BC [32]. Also, the peak at 1066 cm−1 was assigned to Ti–O–C stretching vibration, which suggested that new chemical bonds were formed between TiO2 and p-BC [33]. These results indicated that TiO2/p-BC was successfully prepared, and it was consistent with the SEM and XRD results.

2.1.5. PL Analyses

PL spectra have been used to evaluate the electron and hole recombination efficiency of different photocatalytic materials [34]. In general, the low and high PL intensities of the PL spectra indicated low and high recombination rates, respectively, of TiO2 and TiO2/p-BC (Figure 3c). However, the PL intensity of TiO2/p-BC was much lower than that of TiO2, which indicated that TiO2/p-BC had low recombination efficiency of electrons and holes. In addition, this indicated a high photocatalytic activity of TiO2/p-BC. As an explanation of these results, the conducting p-BC can assist in the transfer of photogenerated electrons, thereby preventing the recombination of electrons and holes [35].

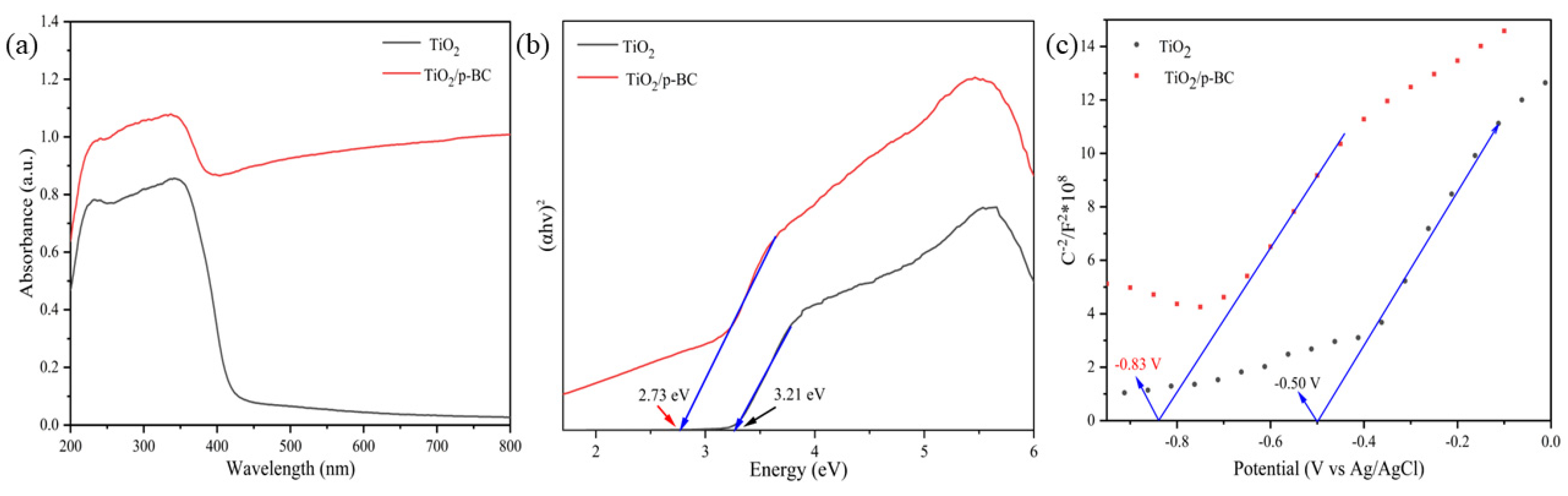

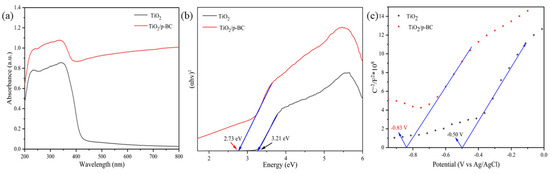

2.1.6. UV-Vis DRS Analyses

The UV-vis DRS spectra of TiO2 and TiO2/p-BC are presented in Figure 4a. For TiO2, the strong adsorption was obtained for a wavelength less than 400 nm, which indicates that they had no obvious absorption in the visible light. However, TiO2/p-BC showed obvious absorption above the wavelength of 400 nm. This indicated that TiO2/p-BC had improved light utilization and higher photocatalytic activity as compared with TiO2. Furthermore, the bandgaps (Eg) of TiO2 and TiO2/p-BC were 3.21 eV and 2.73 eV, respectively (Figure 4b), which were calculated by using the Kubelka-Munk equation [36]. This result indicated that the addition of p-BC contributed to the reduction of the Eg of the composite. According to the Mott–Schottky equation [37], the flat band potential (EFB) of TiO2 and TiO2/p-BC were determined as −0.50 eV and −0.83 eV, respectively (Figure 4c). Generally, the lower conduction band potential (ECB) of n-type semiconductors was approximately equal to EFB [38]. Based on the above analyses, the upper valence band potentials (EVB) of TiO2 (2.71 eV) and TiO2/p-BC (1.90 eV) could be estimated.

Figure 4.

(a) UV–vis DRS spectra of TiO2 and TiO2/p-BC, (b) calculated corresponding bandgaps, and (c) corresponding Mott–Schottky curves.

2.2. Effect of Solution pH

2.2.1. Comparison of Removal Efficiency

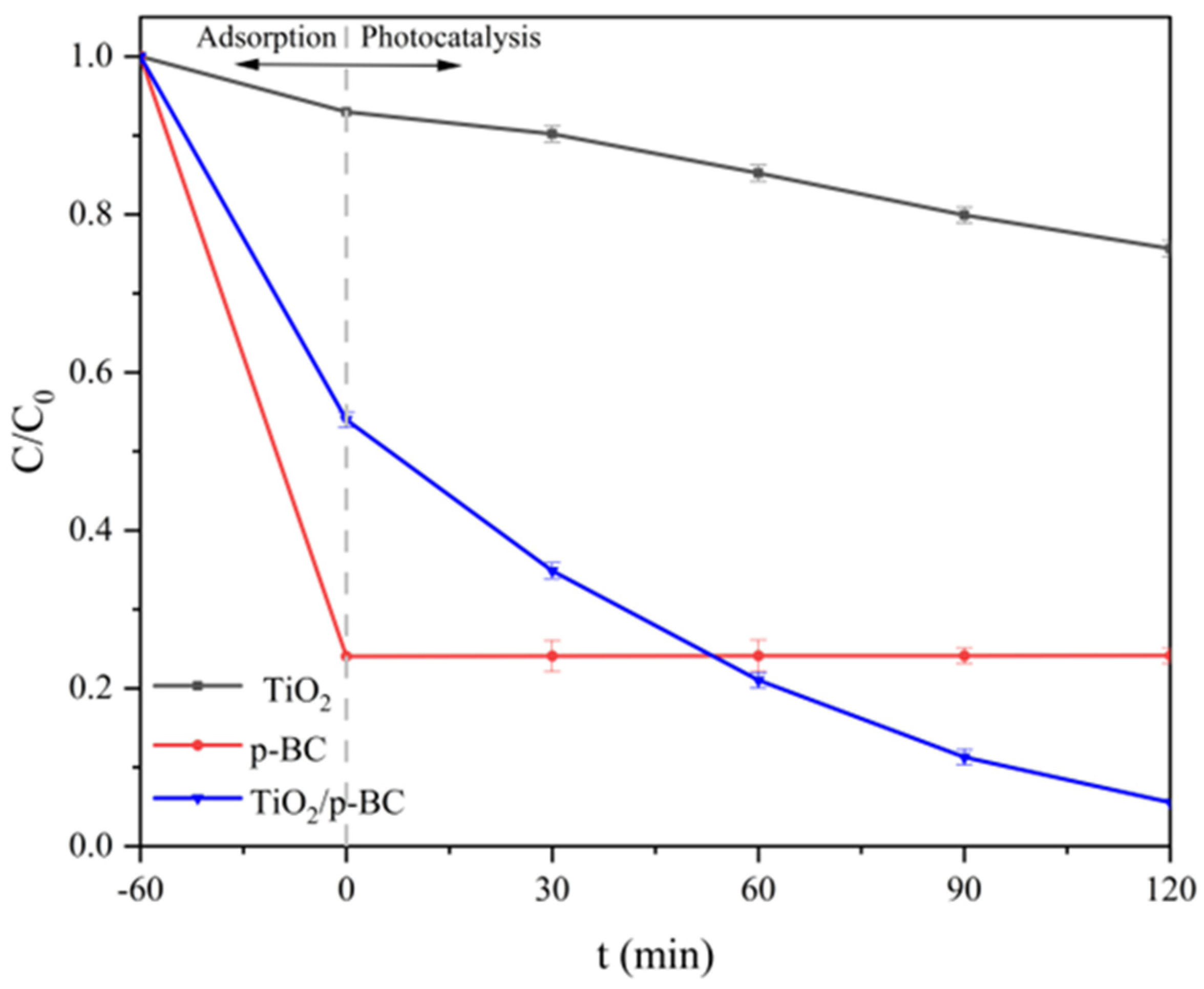

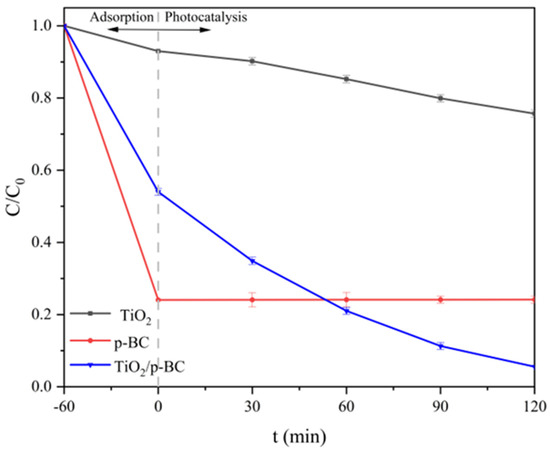

Figure 5 shows the removal efficiency for three different samples on TC. The data show that p-BC can achieve a high removal efficiency of about 75.8% on TC. However, adsorption played a major role in this process, and light hardly contributed to the removal of TC. The adsorption only transfers TC from solution to p-BC, which may cause secondary pollution to the environment. The removal efficiency of TC by TiO2 alone was 24.4 %. The adsorption of TiO2 was weak, and photocatalytic was mainly responsible for the removal of TC. TiO2/p-BC composite has excellent adsorption and photocatalytic effects on TC at the same time, and the removal efficiency was 94.5%. Compared with p-BC and TiO2 alone, the removal efficiency of TC was increased by 18.7% and 70.1%, respectively. The recovered TiO2/p-BC was sonicated in 30 ml deionized water for 30 min, and no TC was detected in the solution by the ultraviolet spectrophotometer, indicating that the adsorbed TC has been photocatalytically degraded. The synergistic effect of adsorption and photocatalysis was beneficial in improving the removal efficiency of TC by the TiO2/p-BC composite.

Figure 5.

TC removal performance of different samples.

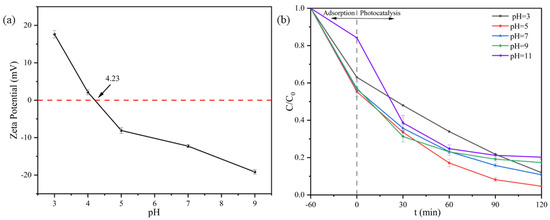

2.2.2. Effect of Solution pH

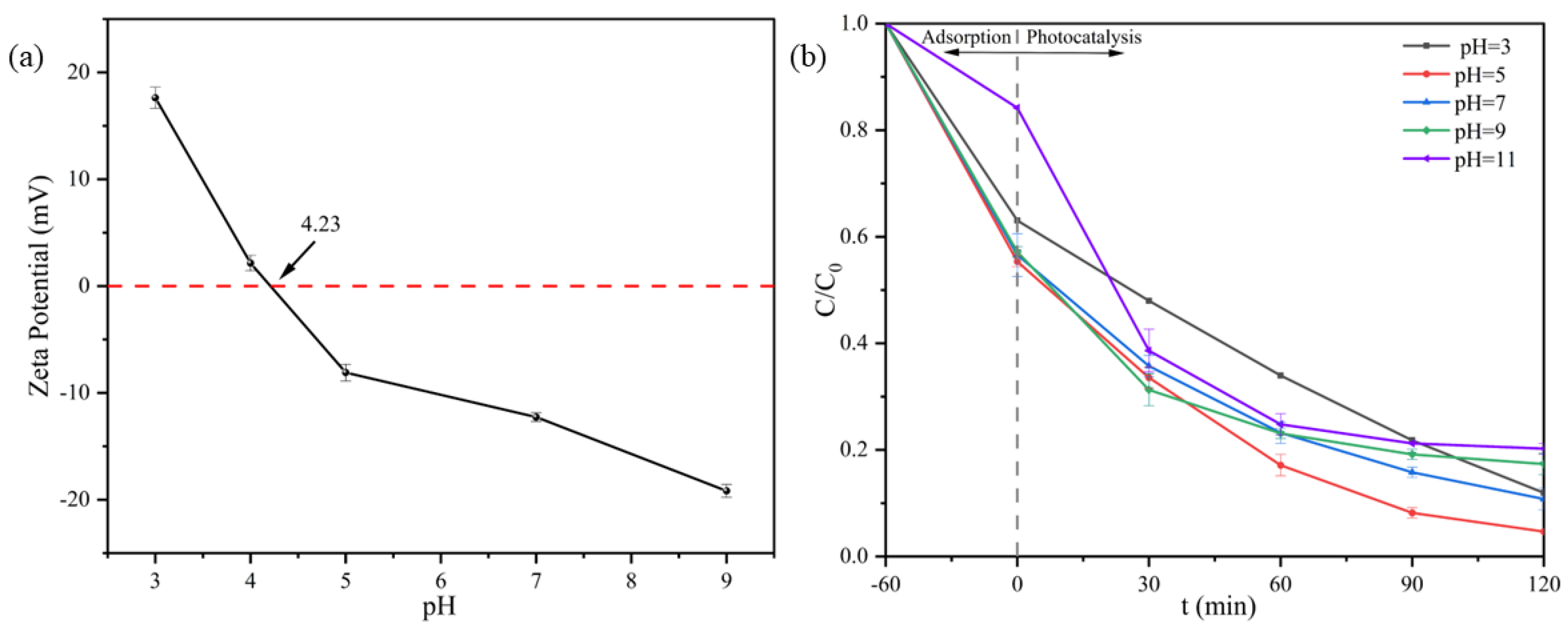

The initial pH value of the solution was a key parameter in the process of photocatalysis, which influenced the adsorption and photodegradation removal of pollutants. The zeta charge (pHPZC) of TiO2/p-BC was determined, as can be seen in Figure 6a. Also, at pH 4.23, the surface charge of TiO2/p-BC was neutral. However, the surface charge was positive at pH values less than 4.23 and negative for pH values larger than 4.23. Also, the TC molecules had three different forms at different pH values: TC+ (pH < 3.3), TC0 (3.3 < pH < 7.7), and TC− and TC2− (pH > 7.7) [39]. The effects of pH on the removal of the TC are shown in Figure 6b. For the initial pH value of the solution, there were repulsive forces between the positive charges on the surface, which resulted in a low removal efficiency. Furthermore, the interactions between the charges on the surface were weak.

Figure 6.

(a) Point of zeta charge of TiO2/p-BC. (b) Removal efficiency of TC by TiO2/p-BC at different pH values.

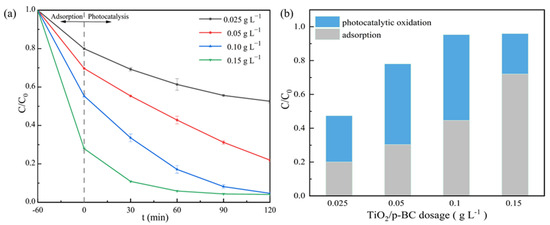

2.2.3. Effect of the TiO2/p-BC Dosage

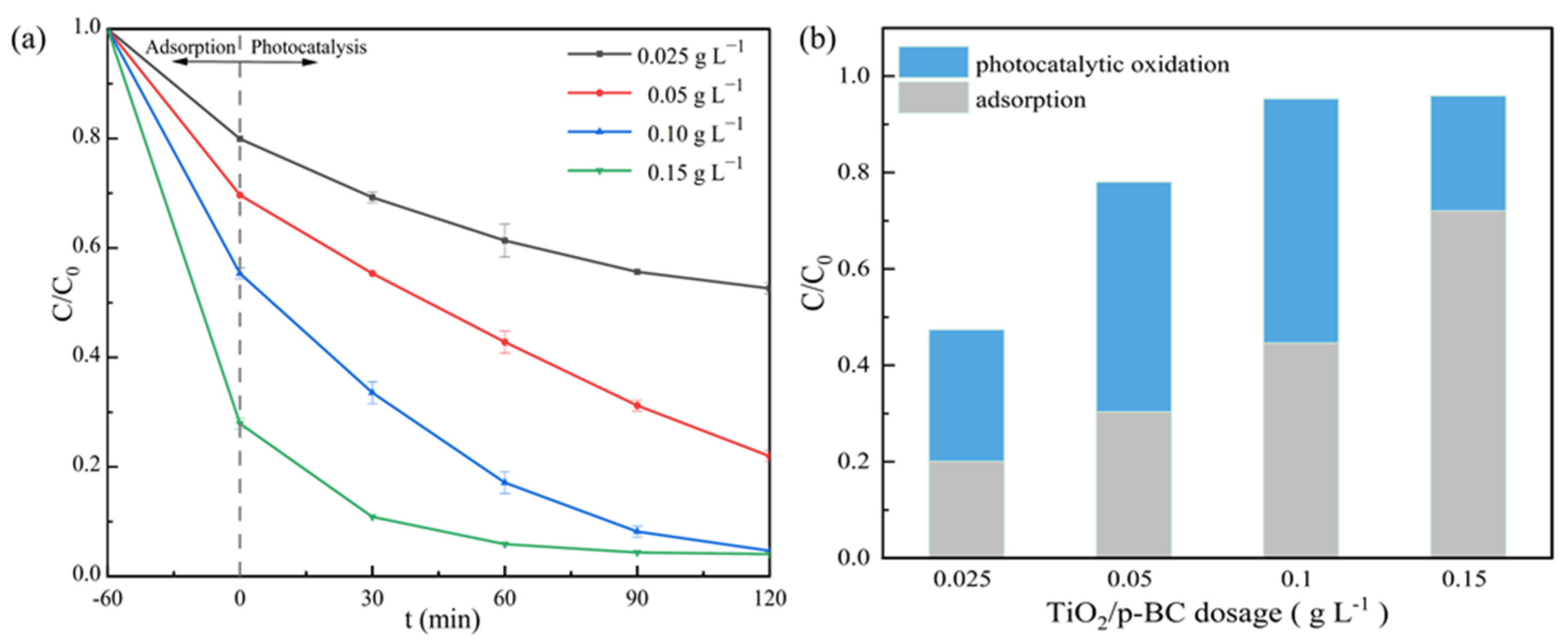

The effects of TiO2/p-BC on the removal of TC are shown in Figure 7a. As can be seen in Figure 7a, with an increase in composite dosage from 0.025 g L−1 to 0.1 g L−1, the removal efficiency increased from 47.4% to 96%. It thereafter increased with a further increase in the composite dosage (at a minor level). The removal of TC by the composite mainly included two processes: the adsorption of p-BC (dark stage) and the photocatalytic degradation of TiO2 (light stage). Figure 7b shows the contribution of adsorption and photocatalytic degradation to the TC removal for different composite dosages. The results showed that the removal of TC by the removal of adsorption increased with an increase in composite dosage. With the dosage increase from 0.025 g L−1 to 0.1 g L−1, the removal of TC by photocatalytic degradation increased from 27.3% to 50.7%. For a further increase in the composite dosage, the removal of photocatalytic degradation diminished further. The reason for this observation was that the high composite concentration blocked the penetration of light, thereby reducing the utilization of light [40]. Therefore, the composite dosage was selected as 0.1 g L−1. At this dosage, the composite showed a high adsorption capacity and photocatalytic removal of TC and also ensured a high total removal efficiency.

Figure 7.

(a) Removal efficiency of TC at different dosages of TiO2/p-BC. (b) Proportion of photocatalytic oxidation and adsorption at different dosages.

2.2.4. Effect of Initial TC Concentration

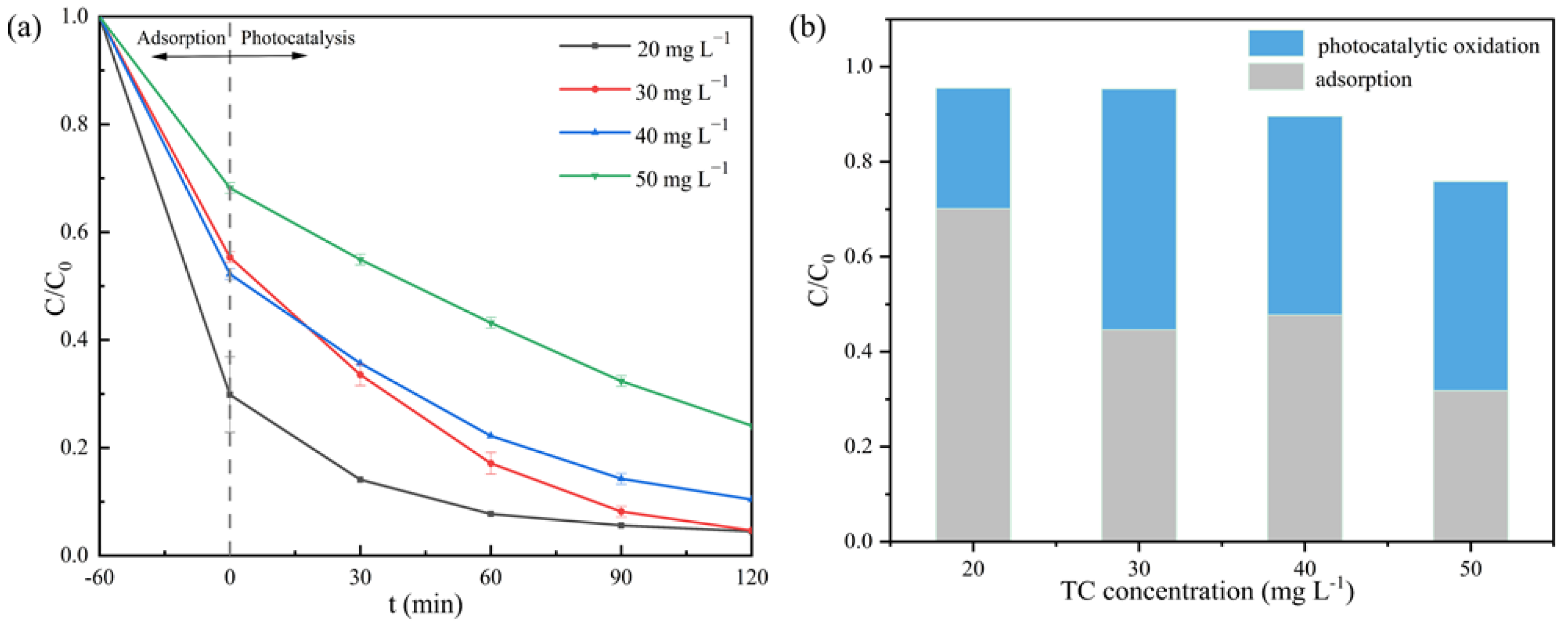

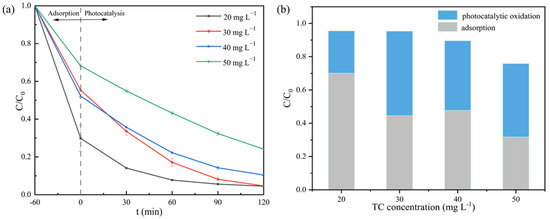

The effects of the initial concentration on the removal of TC are shown in Figure 8a. With the increase in initial TC concentration from 20 mg L−1 to 50 mg −1, the removal efficiency decreased from 95.5% to 75.8%. Also, Figure 8b shows the contribution of adsorption and photocatalytic degradation to the TC removal under different initial concentrations. The results showed that adsorption played a key role in the removal of TC at the initial concentration of 20 mg L−1, while the photocatalytic degradation contributed with a lesser degree to the removal. When the initial concentration was 30 mg L−1, the composite had considerable adsorption and photocatalytic removal effect on TC, and the total removal efficiency was larger than 95%. Thereafter, with an increase in the initial concentration, the total removal efficiency of TC was less than 90%. One of the reasons was that the adsorption site of the composite was unchanged, and the increase in TC concentration led to a decrease in adsorption removal efficiency. In addition, the increase in TC concentration reduced the penetration of light and prevented light from reaching the surface of the composite, thereby reducing the utilization of light [41].

Figure 8.

(a) Removal efficiency of TC at different initial concentrations of TiO2/p-BC. (b) Proportion of photocatalytic oxidation and adsorption at different initial concentrations.

2.3. Reusability Test of TiO2/p-BC

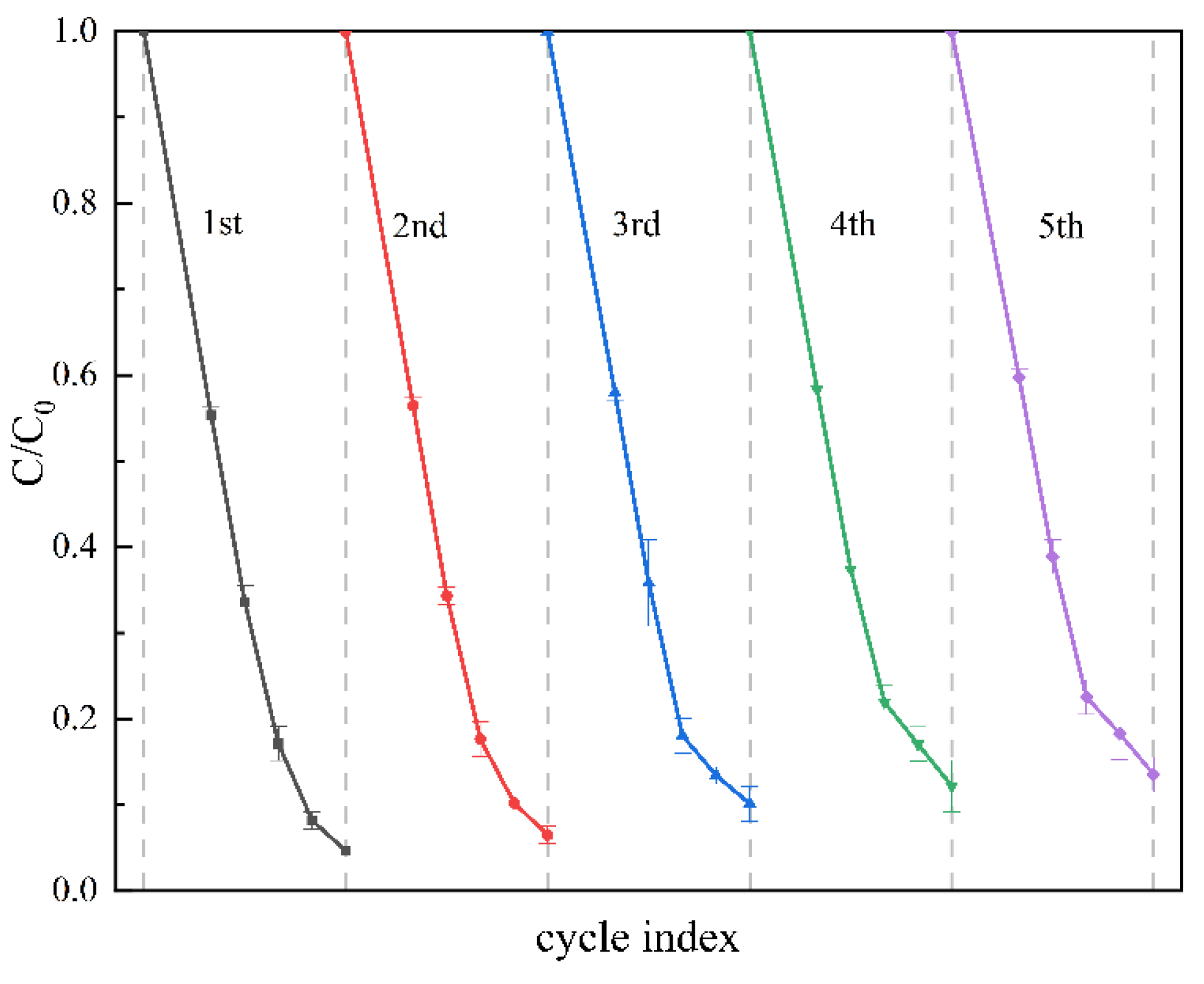

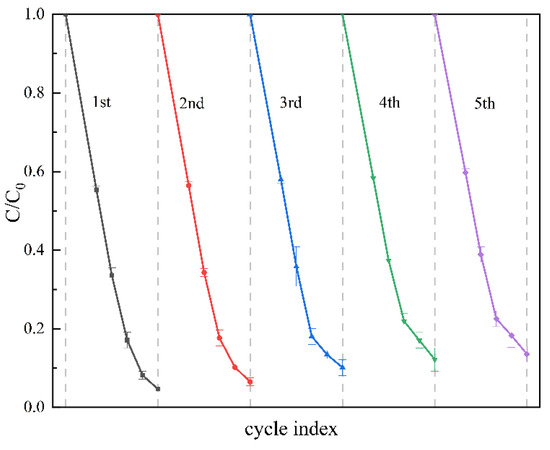

The reusability of the photocatalyst is related to the economic feasibility of the photocatalytic process, and it can also indicate the stability of the photocatalyst. In the present study, the reusability of TiO2/p-BC has been evaluated by five successive photocatalysis experiments for the removal of TC. As can be seen in Figure 9, the removal efficiencies were 95.3%, 93.5%, 89.9%, 87.8%, and 86.5% after five cycles. Although the removal efficiency decreased slightly after each cycle, the removal efficiency of TC by TiO2/p-BC remained above 86% after five cycles, indicating that it had excellent reusability and stability. The decrease in removal efficiency could be attributed to the accumulation of intermediates on the TiO2/p-BC surface [30,42] and the detachment of a small amount of TiO2 [43].

Figure 9.

Cycles for the photodegradation of TC in the presence of TiO2/p-BC.

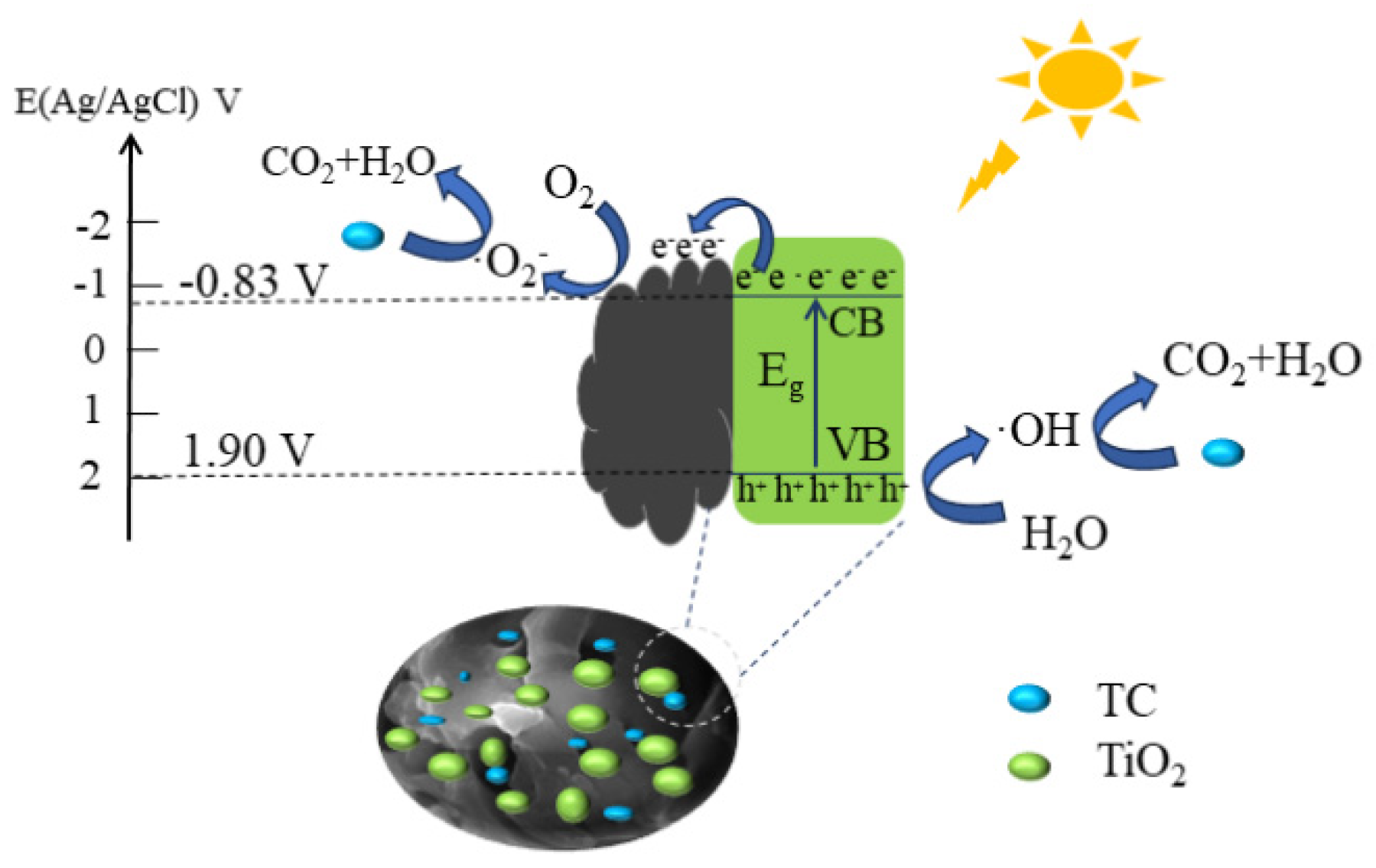

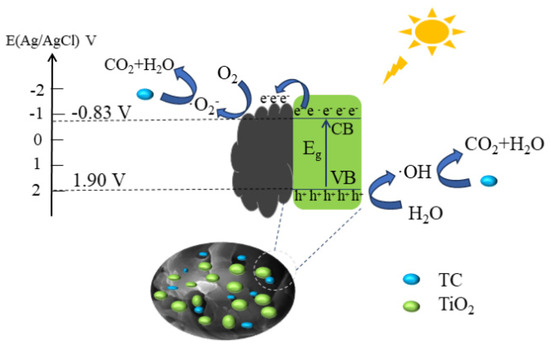

2.4. Photocatalytic Removal Mechanism

Based on the above analysis results, a possible photocatalytic degradation mechanism of TC by TiO2/p-BC has been proposed (Figure 10). It was found that p-BC, with an abundant porous structure and rich in functional groups, was an excellent carrier of TiO2 and an adsorbent for the adsorption of TC. It, thereby, provided more contact opportunities for TiO2 and TC. In addition, studies have confirmed that the combination with biochar was beneficial for the reduction of the bandgap energy of the photocatalyst. Compared with TiO2 (3.21 eV), the bandgap of TiO2/p-BC was 2.73 eV. In addition, the potentials of the conduction band (CB) and valence band (VB) were −0.83 eV and 1.90 eV, respectively. For sunlight excitation, the TiO2/p-BC could generate electrons (e−) from the valence band to the conduction band, with resulting holes (h+) in the valence band. Acting as both an electron donor and acceptor, p-BC inhibited the recombination of electron-hole pairs through electron transport. The e− could react with O2 to generate ·O2−, and the h+ could react with H2O to generate ·OH [4]. Therefore, ·O2−, ·OH, and h+ were all involved in the photocatalytic degradation of TC and eventually converted to CO2 and H2O.

Figure 10.

Schematic illustration of the TiO2/p-BC photocatalytic enhancement mechanism in the TC degradation.

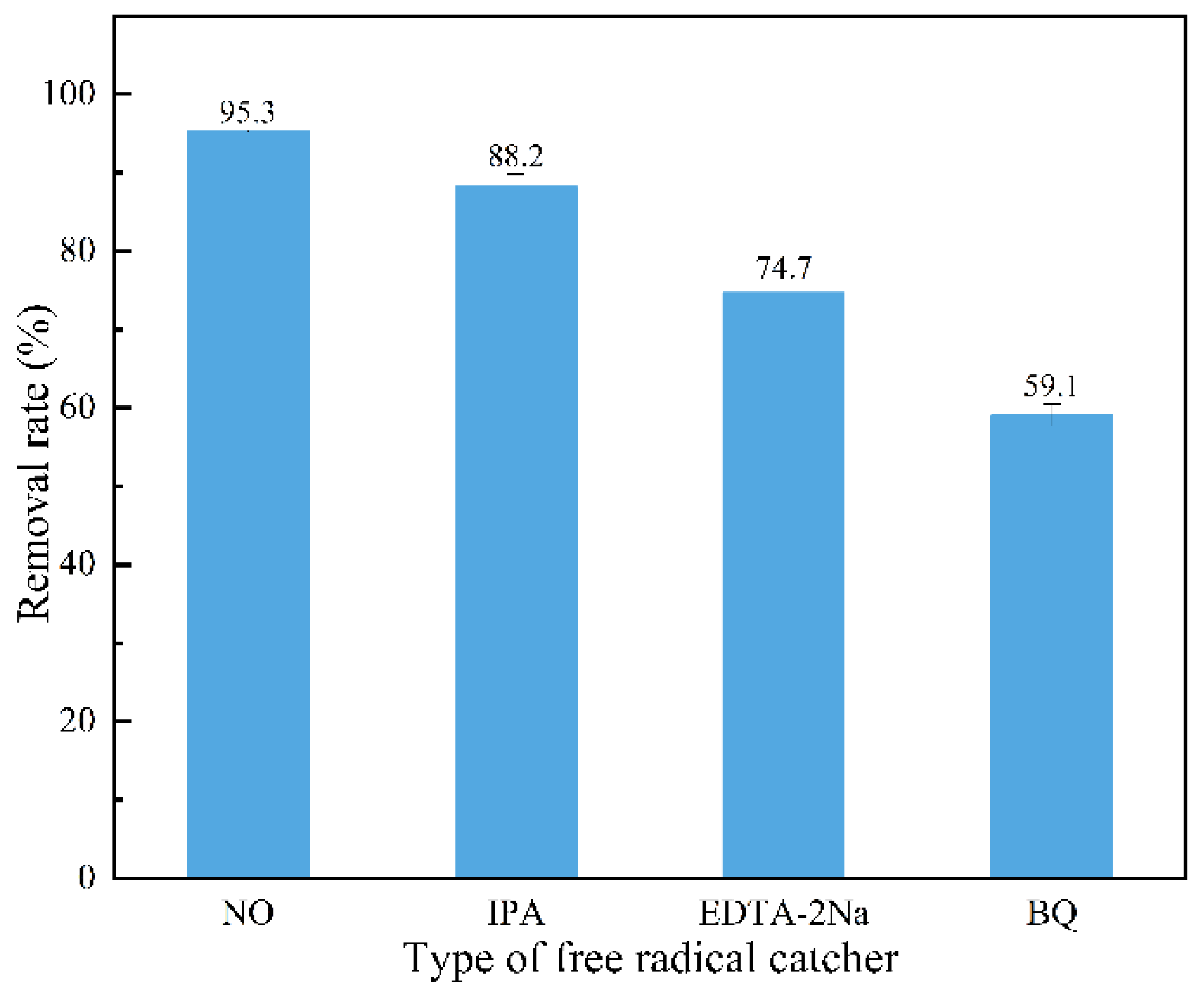

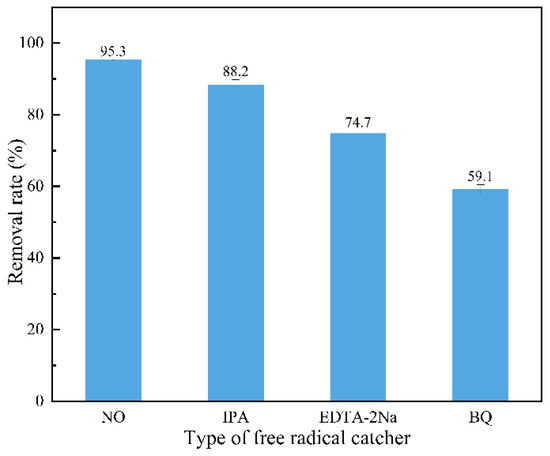

To explore the photocatalytic degradation mechanism of TC by TiO2/p-BC, an active species capturing experiment was designed. BQ, IPA, and EDTA-2Na were then added to the reaction system as quenchers for ·O2−, ·OH, and h+, respectively. The results (Figure 11) showed that the removal efficiency of TC decreased from 95.3% to 59.1%, 88.2%, and 74.7% in the presence of BQ, IPA, and EDTA-2Na, respectively. This indicated that ·O2− made an important contribution to the photocatalytic degradation of TC, which was not the case for ·OH and h+.

Figure 11.

Quenching experiments of active species during the photocatalytic degradation of TC by TiO2/p-BC (scavenger dosage: 0.1 mmol L−1).

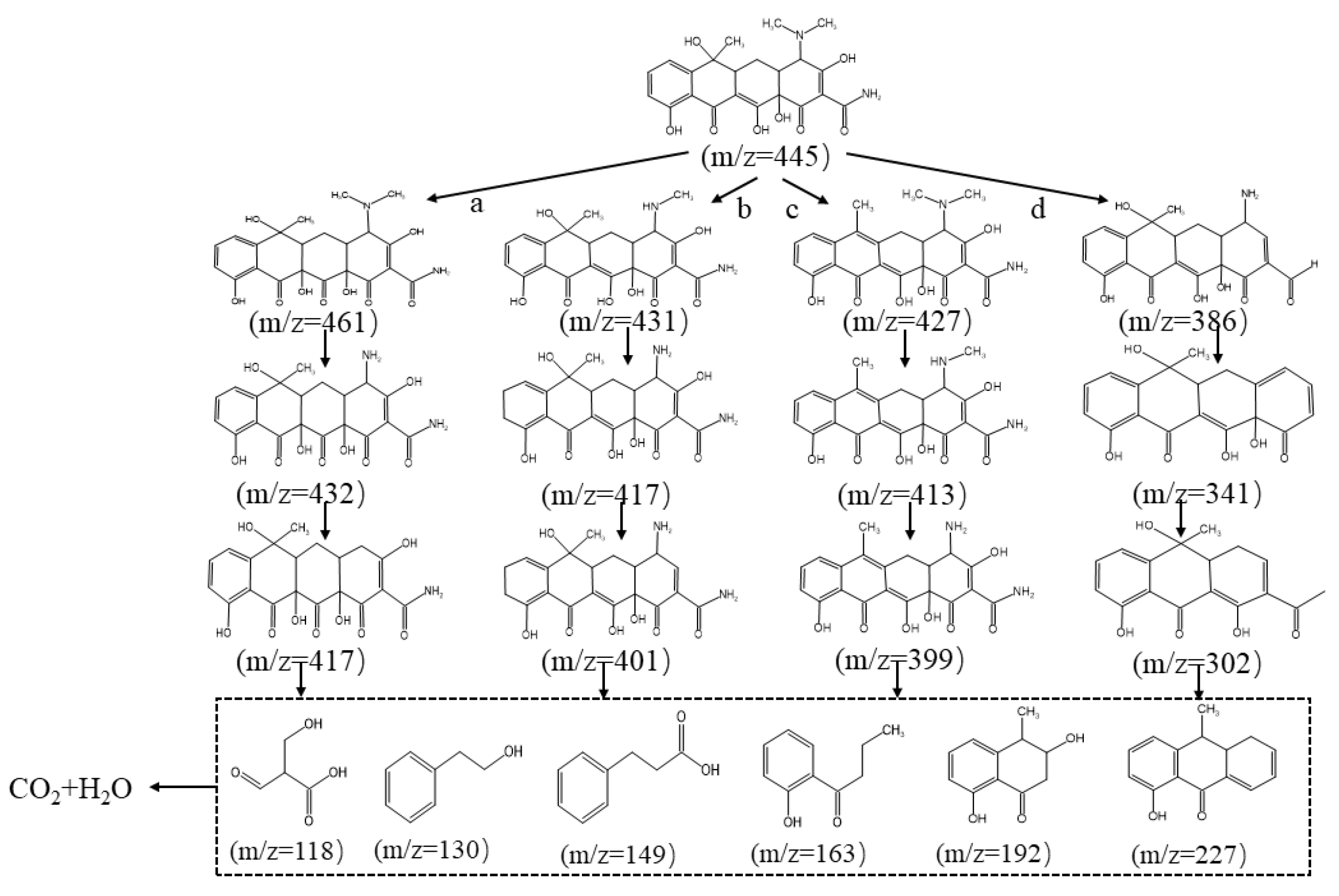

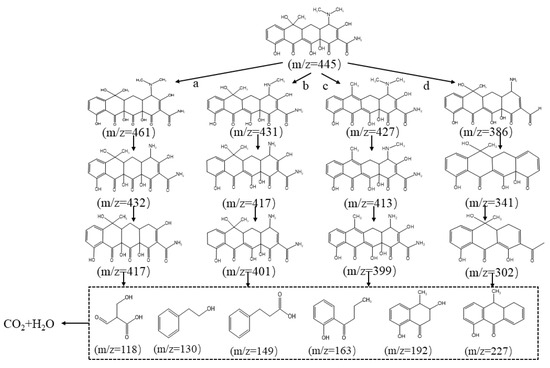

The intermediate products of TC photodegradation were analyzed by LCMS. The samples were detected after 15 min of illumination. The characteristic peak at m/z = 445 corresponded to the TC molecule. Also, the O2−, ·OH and h+ that were generated in the reaction attacked the TC molecules, resulting in a C–C, C=C, C–N, and C–O cleavage in generating various intermediates. The became eventually degraded into CO2, H2O, and other small molecules. Based on the m/z value in the LCMS results (Figure S1 Supporting Information), four possible pathways for the photocatalytic degradation of TC have then been proposed (Figure 12).

Figure 12.

Possible degradation pathways of TC.

3. Materials and Methods

3.1. Materials

The peanut shell was obtained from a local market in Jinan, Shandong, China. Also, tetrabutyl titanate (99%), TC (99%), benzoquinone (BQ; 97%), ethylenediaminetetraacetic acid disodium salt (EDTA-2Na; 99%), and isopropyl alcohol (IPA; 99%) were purchased from Shanghai Macklin Biochemical Co. Ltd., Shanghai, China. In addition, anhydrous ethanol, glacial acetic acid, phosphoric acid, NaOH, and hydrochloric acid were purchased from Tianjin Fuyu Fine Chemical Co. Ltd., Tianjin, China. Furthermore, nitric acid was purchased from Shanghai Sinopharm Chemical Reagent Co. Ltd., Shanghai, China. All chemical reagents were analytically pure and without the need for further purification. Also, deionized water was used throughout all experiments.

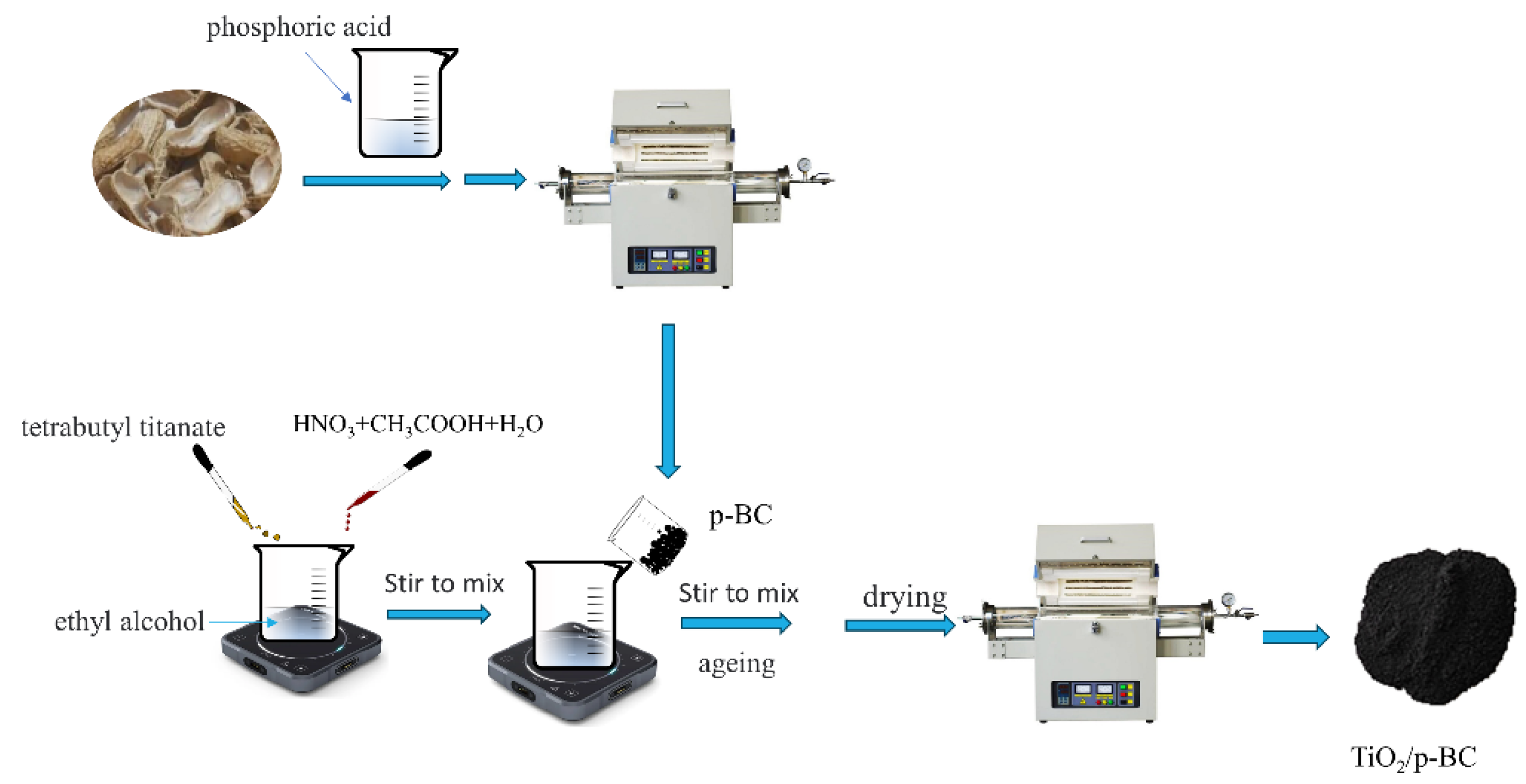

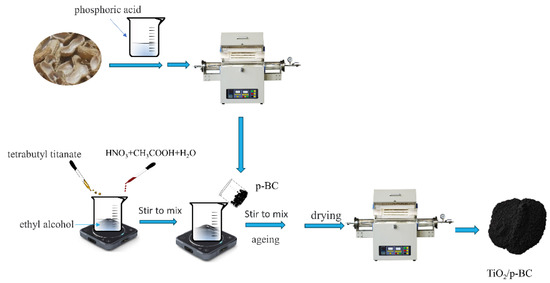

3.2. Preparation of Modified Biochar (p-BC) and Composite Photocatalyst (TiO2/p-BC)

The peanut shell was first cleaned with deionized water and then dried in an oven at 75 °C. Thereafter, it was crushed through a 100-mesh sieve. The method used for the following activation by the phosphoric acid was based on the previous work by Zhao et al. [44]. Briefly, 10 g of the peanut shell was impregnated with 30 mL of 50% H3PO4 for 24 h at room temperature. After filtration, the impregnated sample was dried in an oven at 110 °C for 5 h. Thereafter, the sample was placed in a crucible and pyrolyzed in a furnace at 500 °C for 2 h, with a slow rate of 5 °C min−1 in an N2 atmosphere. As the next step, the sample was washed with deionized water until the filtrate had a neutral pH value. In the following step, the sample was dried in an oven at 110 °C and ground through a 100-mesh sieve to obtain a phosphoric acid-modified biochar (p-BC).

The TiO2/p-BC composite was prepared through a modified sol–gel method [32]. The specific steps are as follows: (1) 6 mL of tetrabutyl titanate was added dropwise to 16 mL of anhydrous ethanol. Thereafter, the solution was stirred for 20 min to obtain a homogeneous solution, which was labeled as A. (2) Ten mL of anhydrous ethanol, 1.3 mL of deionized water, 0.7 mL of glacial acetic acid, and 0.7 mL of nitric acid (40 wt.%) were mixed into a homogeneous solution, and was labeled as B. (3) B was added dropwise to the A solution to obtain a mixed solution. Two grams of p-BC were added to this solution and stirred for 4 h before a static aging for 48 h. After 48 h, the gel was dried in an oven at 80 °C for 24 h and ground through a 100 mesh sieve. Finally, the solid was pyrolyzed in a furnace at 500 °C for 2 h, with a slow rate of 5 °C min−1 in an N2 atmosphere. Thereby, the TiO2/p-BC composite was obtained. The preparation process of the TiO2/p-BC composite is displayed in Figure 13. Pure TiO2 was prepared by the same method as above, except for the omission of p-BC.

Figure 13.

Schematic for the preparation of TiO2/p-BC.

3.3. Characterizations

The surface morphologies and structures of the samples were characterized by scanning electron microscopy (SEM) (MIRA LMS, TESCAN, Brno, Czech Republic) with the working test parameters at 0.2–30 kV acceleration voltage. In addition, the surface chemical compositions and element-binding states of TiO2/p-BC were analyzed by X-ray photoelectron spectroscopy (XPS) (K-Alpha, Thermo Scientific, Norristown, PA, USA) with Al Kα X-ray excitation source. Also, the crystalline phase of TiO2/p-BC was examined by X-ray diffraction spectroscopy (XRD) (MiniFlex600, Rigaku, Tokyo, Japan) with Cu Kα radiation. Fourier-transform infrared spectroscopy (FTIR) (Nicolet iS20, Thermo Scientific, Norristown, PA, USA) was used to analyze the surface functional groups of the samples using KBr pellets in the range of 400–4000 cm−1. Furthermore, the migration efficiency of the photoinduced electrons and holes was evaluated by photoluminescence spectroscopy (PL) at the excitation wavelength of 355 nm. (FLS1000, Edinburgh, UK). Ultraviolet–visible diffuse reflectance spectroscopy (UV-vis-DRS) (UV-3600, Shimadzu, Kyoto, Japan) was used to evaluate the optical absorption performance of TiO2/p-BC. The zeta potential of the TiO2/p-BC was analyzed by nanoparticle size and zeta potential analyzer (DLS) (Zetasizer Nano ZS90, Malvern, UK). Finally, the TC concentration in the solutions was determined by an ultraviolet spectrophotometer at 356 nm, and a liquid chromatograph mass spectrometer (LCMS) (Ultimate 3000 UHPLC-Q, Thermo Scientific, Norristown, PA, USA) was used for the analyses of the intermediate products in the photodegradation process.

3.4. Photocatalytic Experiments

The photocatalytic experiments were conducted in a photochemical reactor (CME-PC4, microenerg, Beijing, China) with a 500 W xenon lamp as the sunlight source. For these experiments, 0.03 g of a photocatalyst and 30 mL of a 30 mg L−1 TC solution were evenly mixed in a quartz tube. Thereafter, this tube was placed in a dark environment for 1 h to ensure an adsorption/desorption equilibrium. As the next step, the photocatalytic reaction was conducted for a duration of 1 h. Three milliliters of the reaction solution was, thereafter, filtered through a 0.45 μm membrane, and the concentration of the residual TC in the solution was measured by a UV spectrophotometer. Magnetic stirrers were then used to ensure a uniform mixing of the solution during adsorption and photocatalytic degradation under dark conditions. Finally, the effective factors, with their ranges, for the removal of TC were especially investigated, including pH value (3–11), TC initial concentration (20 mg L−1–50 mg L−1), and photocatalyst dosage (0.025 g L−1–0.15 g L−1). The reusability of the photocatalyst was also evaluated by performing five repetitive cycles. After the photocatalytic experiment, the photocatalyst was recovered by filtration and washed several times. Thereafter, it was dried at 75 °C for the next coming use. The condition for each photocatalytic operation was identical to the one used for a fresh photocatalyst.

4. Conclusions

In the present study, the TiO2/p-BC composite photocatalytic material has been prepared for the removal of TC. The characterization showed that the TiO2 (with an anatase phase) was successfully synthesized to p-BC, and the crystalline form of TiO2 was not affected in this process. Compared with TiO2, the TiO2/p-BC had a lower bandgap (2.73 eV) and recombination rates of electrons and holes. Thus, the TiO2/p-BC demonstrated a higher light utilization and photocatalytic activity. Under the optimum conditions of an initial pH value of 5 in the solution, a composite dosage of 0.1 g L−1, and an initial TC concentration of 30 mg −1, the removal efficiency of TC by TiO2/p-BC reached 95.3%. The removal efficiency remained above 86% after five consecutive cycles, which indicated that TiO2/p-BC had excellent reusability and stability. Furthermore, the active species capturing experiment verified that ·O2− made an important contribution to the photocatalytic degradation of TC, which was not the case with ·OH and h+. At a low cost, the environmentally friendly, recyclable, and reusable photocatalytic material TiO2/p-BC can be used for the efficient removal of TC and other organic pollutants.

Supplementary Materials

The following supporting information can be downloaded at https://www.mdpi.com/article/10.3390/catal14060357/s1. Figure S1: m/z of degrading TC over TiO2/p-BC composite photocatalyst in different pathways (a–d) and m/z of the degraded small molecular fragments.

Author Contributions

Conceptualization, L.Z.; methodology, L.Z.; software, J.L., L.Z., H.W. and J.D.; validation.; Y.G.; formal analysis, M.S.; investigation, L.Z. and Z.Y.; resources, M.S.; data curation, L.J.; writing—original draft preparation, L.Z.; writing—review and editing, L.Z., Y.G. and X.Y.; funding acquisition, Y.G. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Shandong Provincial Key Research and Development Program, China (Major Scientific and Technological Innovation Project No. 2021CXGC011201; Rural Revitalization Project to Boost Science, Technology and Innovation, No. 2023TZXD003) and Shandong Provincial Natural Science Foundation, China (No. ZR2021MD126).

Data Availability Statement

The datasets used and analyzed in this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

Author Jianhua Du was employed by the WSP Australia Pty Limited. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Ben, Y.; Fu, C.; Hu, M.; Liu, L.; Wong, M.H.; Zheng, C. Human health risk assessment of antibiotic resistance associated with antibiotic residues in the environment: A review. Environ. Res. 2019, 169, 483–493. [Google Scholar] [CrossRef] [PubMed]

- Zhou, H.; Cui, J.; Pang, L.; Wangjin, Y.; Li, M.; Zhao, Z.; Huang, L. Removal of antibiotics and antibiotic resistance genes from urban rivers using a photocatalytic-and-bionic artificial ecosystem. J. Clean. Prod. 2022, 348, 131311. [Google Scholar] [CrossRef]

- Zheng, D.; Yin, G.; Liu, M.; Chen, C.; Jiang, Y.; Hou, L.; Zheng, Y. A systematic review of antibiotics and antibiotic resistance genes in estuarine and coastal environments. Sci. Total Environ. 2021, 777, 146009. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Hu, H.; Lin, Y.; Zhang, J.; Hu, Y. Visible light photocatalytic degradation of tetracycline over TiO2. Chem. Eng. J. 2020, 382, 122842. [Google Scholar] [CrossRef]

- Yan, C.; Yang, Y.; Zhou, J.; Liu, M.; Nie, M.; Shi, H.; Gu, L. Antibiotics in the surface water of the Yangtze Estuary: Occurrence. distribution and risk assessment. Environ. Pollut. 2013, 175, 22–29. [Google Scholar] [CrossRef] [PubMed]

- Yao, L.; Wang, Y.; Tong, L.; Deng, Y.; Li, Y.; Gan, Y.; Guo, W.; Dong, C.; Duan, Y.; Zhao, K. Occurrence and risk assessment of antibiotics in surface water and groundwater from different depths of aquifers: A case study at Jianghan Plain. central China. Ecotoxicol. Environ. Saf. 2017, 135, 236–242. [Google Scholar] [CrossRef] [PubMed]

- Li, S.; Shi, W.; Liu, W.; Li, H.; Zhang, W.; Hu, J.; Ke, Y.; Sun, W.; Ni, J. A duodecennial national synthesis of antibiotics in China’s major rivers and seas (2005–2016). Sci. Total Environ. 2018, 615, 906–917. [Google Scholar] [CrossRef] [PubMed]

- Xiao, C.; Yuan, J.; Li, L.; Zhong, N.; Zhong, D.; Xie, Q.; Chang, H.; Xu, Y.; He, X.; Li, M. Photocatalytic synergistic biofilms enhance tetracycline degradation and conversion. Environ. Sci. Ecotechnol. 2023, 14, 100234. [Google Scholar] [CrossRef]

- He, Y.; Huang, Z.; Ma, Z.; Yao, B.; Liu, H.; Hu, L.; Zhao, Q.; Yang, Q.; Liu, D.; Du, D. Highly efficient photocatalytic performance and mechanism of α-ZnTcPc/g-C3N4 composites for methylene blue and tetracycline degradation under visible light irradiation. Appl. Surf. Sci. 2019, 498, 143834. [Google Scholar] [CrossRef]

- Chen, X.; Ke, Y.; Zhu, Y.; Xu, M.; Chen, C.; Xie, S. Enrichment of tetracycline-degrading bacterial consortia: Microbial community succession and degradation characteristics and mechanism. J. Hazard. Mater. 2023, 448, 130984. [Google Scholar] [CrossRef]

- Weng, M.; Cai, M.; Xie, Z.; Dong, C.; Zhang, Y.; Song, Z.; Shi, Y.; Jin, M.; Wang, Q.; Wei, Z. Hydrodynamic cavitation-enhanced heterogeneous activation of persulfate for tetracycline degradation: Synergistic effects. degradation mechanism and pathways. Chem. Eng. J. 2022, 431, 134238. [Google Scholar] [CrossRef]

- Rouhani, M.; Ashrafi, S.D.; Taghavi, K.; Joubani, M.N.; Jaafari, J. Evaluation of tetracycline removal by adsorption method using magnetic iron oxide nanoparticles (Fe3O4) and clinoptilolite from aqueous solutions. J. Mol. Liq. 2022, 356, 119040. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Zhuang, G.-L.; Tasi, P.-F.; Tseng, H.-H. Removal of protein. histological dye and tetracycline from simulated bioindustrial wastewater with a dual pore size PPSU membrane. J. Hazard. Mater. 2022, 431, 128525. [Google Scholar] [CrossRef] [PubMed]

- Chen, T.; Luo, L.; Deng, S.; Shi, G.; Zhang, S.; Zhang, Y.; Deng, O.; Wang, L.; Zhang, J.; Wei, L. Sorption of tetracycline on H3PO4 modified biochar derived from rice straw and swine manure. Bioresour. Technol. 2018, 267, 431–437. [Google Scholar] [CrossRef]

- Daghrir, R.; Drogui, P. Tetracycline antibiotics in the environment: A review. Environ. Chem. Lett. 2013, 11, 209–227. [Google Scholar] [CrossRef]

- Li, L.; Yuan, X.; Zhou, Z.; Tang, R.; Deng, Y.; Huang, Y.; Xiong, S.; Su, L.; Zhao, J.; Gong, D. Research progress of photocatalytic activated persulfate removal of environmental organic pollutants by metal and nonmetal based photocatalysts. J. Clean. Prod. 2022, 372, 133420. [Google Scholar] [CrossRef]

- Sendão, R.M.; da Silva JC, E.; da Silva, L.P. Photocatalytic removal of pharmaceutical water pollutants by TiO2-Carbon dots nanocomposites: A review. Chemosphere 2022, 301, 134731. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, B.; Chen, H.; Yuan, R. Heterogeneous photocatalytic oxidation for the removal of organophosphorus pollutants from aqueous solutions: A review. Sci. Total Environ. 2023, 856, 159048. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, H.; Liu, S.; Zhang, B.; Zhu, H.; Chen, H.; Wen, B.; Chen, L. Preparation of TiO2-graphitized carbon composite photocatalyst and their degradation properties for tetracycline antibiotics. J. Mol. Struct. 2022, 1270, 133897. [Google Scholar] [CrossRef]

- Xu, L.; Tang, C.-Q.; Qian, J.; Huang, Z.-B. Theoretical and experimental study on the electronic structure and optical absorption properties of P-doped TiO2. Appl. Surf. Sci. 2010, 256, 2668–2671. [Google Scholar] [CrossRef]

- Ahmadi, M.; Motlagh, H.R.; Jaafarzadeh, N.; Mostoufi, A.; Saeedi, R.; Barzegar, G.; Jorfi, S. Enhanced photocatalytic degradation of tetracycline and real pharmaceutical wastewater using MWCNT/TiO2 nano-composite. J. Environ. Manag. 2017, 186, 55–63. [Google Scholar] [CrossRef] [PubMed]

- Trapalis, A.; Todorova, N.; Giannakopoulou, T.; Boukos, N.; Speliotis, T.; Dimotikali, D.; Yu, J. TiO2/graphene composite photocatalysts for NOx removal: A comparison of surfactant-stabilized graphene and reduced graphene oxide. Appl. Catal. B Environ. 2016, 180, 637–647. [Google Scholar] [CrossRef]

- Lu, L.; Shan, R.; Shi, Y.; Wang, S.; Yuan, H. A novel TiO2/biochar composite catalysts for photocatalytic degradation of methyl orange. Chemosphere 2019, 222, 391–398. [Google Scholar] [CrossRef] [PubMed]

- PePeng, H.; Gao, P.; Chu, G.; Pan, B.; Peng, J.; Xing, B. Enhanced adsorption of Cu (II) and Cd (II) by phosphoric acid-modified biochars. Environ. Pollut. 2017, 229, 846–853. [Google Scholar] [CrossRef]

- Fazal, T.; Razzaq, A.; Javed, F.; Hafeez, A.; Rashid, N.; Amjad, U.S.; Rehman, M.S.U.; Faisal, A.; Rehman, F. Integrating adsorption and photocatalysis: A cost effective strategy for textile wastewater treatment using hybrid biochar-TiO2 composite. J. Hazard. Mater. 2020, 390, 121623. [Google Scholar] [CrossRef] [PubMed]

- Khan, H.; Shah, M.U.H. Modification strategies of TiO2 based photocatalysts for enhanced visible light activity and energy storage ability: A review. J. Environ. Chem. Eng. 2023, 11, 111532. [Google Scholar] [CrossRef]

- Kim, J.R.; Kan, E. Heterogeneous photocatalytic degradation of sulfamethoxazole in water using a biochar-supported TiO2 photocatalyst. J. Environ. Manag. 2016, 180, 94–101. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.X.; Zhu, Q.; Dong, W.P.; Fan, Y.Q.; Wang, W.L. Preparation and characterization of phosphoric scid-modified biochar nanomaterials with highly efficient adsorption and photodegradation ability. Langmuir 2021, 37, 9253–9263. [Google Scholar] [CrossRef] [PubMed]

- Yongheng, D.; Huayu, Y.; Jiang, L.; Qi, S.; Qianwen, Y.; Yuntao, Z. Direct Z-scheme P-TiO2/g-C3N4 heterojunction for the photocatalytic degradation of sulfa antibiotics. RSC Adv. 2023, 13, 5957–5969. [Google Scholar] [CrossRef]

- Wang, G.; Li, Y.; Dai, J.; Deng, N. Highly efficient photocatalytic oxidation of antibiotic ciprofloxacin using TiO2@g-C3N4@biochar composite. Environ. Sci. Pollut. Res. 2022, 29, 48522–48538. [Google Scholar] [CrossRef]

- Zheng, L.; Gao, Y.; Du, J.; Zhang, W.; Huang, Y.; Wang, L.; Zhao, Q.; Pan, X. A novel, recyclable magnetic biochar modified by chitosan–EDTA for the effective removal of Pb (II) from aqueous solution. RSC Adv. 2020, 10, 40196–40205. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Z.; Li, R.; Guo, J.; Li, Y.; Zhu, J.; Xie, X. TiO2 supported on reed straw biochar as an adsorptive and photocatalytic composite for the efficient degradation of sulfamethoxazole in aqueous matrices. Chemosphere 2017, 185, 351–360. [Google Scholar] [CrossRef] [PubMed]

- Xie, Y.; Liu, A.; Bandala, E.R.; Goonetilleke, A. TiO2-biochar composites as alternative photocatalyst for stormwater disinfection. J. Water Process Eng. 2022, 48, 102913. [Google Scholar] [CrossRef]

- Khan, H.; Berk, D. Selenium modified oxalate chelated titania: Characterization. mechanistic and photocatalytic studies. Appl. Catal. A Gen. 2015, 505, 285–301. [Google Scholar] [CrossRef]

- Mian, M.M.; Liu, G. Recent progress in biochar-supported photocatalysts: Synthesis. role of biochar, and applications. RSC Adv. 2018, 8, 14237–14248. [Google Scholar] [CrossRef] [PubMed]

- Zhu, J.; Wang, J.; He, J.; Hu, L. Fabrication of CdS/ZnCr-LDH heterojunctions with enhanced of tetracycline hydrochloride photocatalytic degradation under visible light. Opt. Mater. 2023, 136, 113456. [Google Scholar] [CrossRef]

- Zhang, Y.; Qi, F.; Li, Y.; Zhou, X.; Sun, H.; Zhang, W.; Liu, D.; Song, X.-M. Graphene oxide quantum dot-sensitized porous titanium dioxide microsphere: Visible-light-driven photocatalyst based on energy band engineering. J. Colloid Interface Sci. 2017, 498, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Geng, X.; Wang, L.; Zhang, L.; Wang, H.; Peng, Y.; Bian, Z. H2O2 production and in situ sterilization over a ZnO/g-C3N4 heterojunction photocatalyst. Chem. Eng. J. 2021, 420, 129722. [Google Scholar] [CrossRef]

- Sun, S.; Yang, Z.; Cao, J.; Wang, Y.; Xiong, W. Copper-doped ZIF-8 with high adsorption performance for removal of tetracycline from aqueous solution. J. Solid State Chem. 2020, 285, 121219. [Google Scholar] [CrossRef]

- Jiang, Y.; Liu, A. Cornstalk biochar-TiO2 composites as alternative photocatalyst for degrading methyl orange. Environ. Sci. Pollut. Res. 2023, 30, 31923–31934. [Google Scholar] [CrossRef]

- Zhang, L.; Song, X.; Liu, X.; Yang, L.; Pan, F.; Lv, J. Studies on the removal of tetracycline by multi-walled carbon nanotubes. Chem. Eng. J. 2011, 178, 26–33. [Google Scholar] [CrossRef]

- Asgharzadeh, F.; Kalantary, R.R.; Gholami, M.; Jafari, A.J.; Kermani, M.; Asgharnia, H. TiO2-decorated magnetic biochar mediated heterogeneous photocatalytic degradation of tetracycline and evaluation of antibacterial activity. Biomass Convers. Biorefinery 2023, 13, 8949–8959. [Google Scholar] [CrossRef]

- Afzal, M.Z.; Zu, P.; Zhang, C.-M.; Guan, J.; Song, C.; Sun, X.-F.; Wang, S.-G. Sonocatalytic degradation of ciprofloxacin using hydrogel beads of TiO2 incorporated biochar and chitosan. J. Hazard. Mater. 2022, 434, 128879. [Google Scholar] [CrossRef]

- Zhao, N.; Zhao, C.; Lv, Y.; Zhang, W.; Du, Y.; Hao, Z.; Zhang, J. Adsorption and coadsorption mechanisms of Cr(VI) and organic contaminants on H3PO4 treated biochar. Chemosphere 2017, 186, 422–429. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).