Abstract

The efficient utilization of heavy oil is of great significance to alleviating the global energy crisis. How to efficiently convert heavy oil into high-value-added light fuel oil has become a hot issue in the field of petrochemicals. As the residual part of crude oil processing, heavy oil has a complex composition and contains polycyclic aromatic hydrocarbons, long-chain alkanes, and heteroatom compounds, which makes it difficult to process directly. Zeolite, as an important type of solid acid catalyst, has a unique pore structure, adjustable acidity, and good thermal stability. It can promote the efficient cracking and conversion of heavy oil molecules, reduce coke formation, and improve the yield and quality of light oil products. This paper systematically reviews the development status of heavy oil cracking technology, focusing on the structural characteristics, acidity regulation of zeolite catalysts, and their applications in heavy oil cracking and hydrocracking. The mechanism of the cracking reaction of polycyclic aromatic hydrocarbons and long-chain alkanes is analyzed in detail, and the catalytic characteristics and modification methods of zeolite in the reaction process are explained. In addition, this paper summarizes the main challenges faced by zeolite catalysts in practical applications, including uneven acidity distribution, limited pore diffusion, and easy catalyst deactivation, and proposes targeted development strategies. Finally, this paper looks forward to the future development direction of zeolite catalysts in the field of heavy oil cracking and upgrading reactions, emphasizes the importance of structural optimization and multi-scale characterization, and provides theoretical support and practical reference for the design and industrial application of efficient zeolite catalysts.

1. Introduction

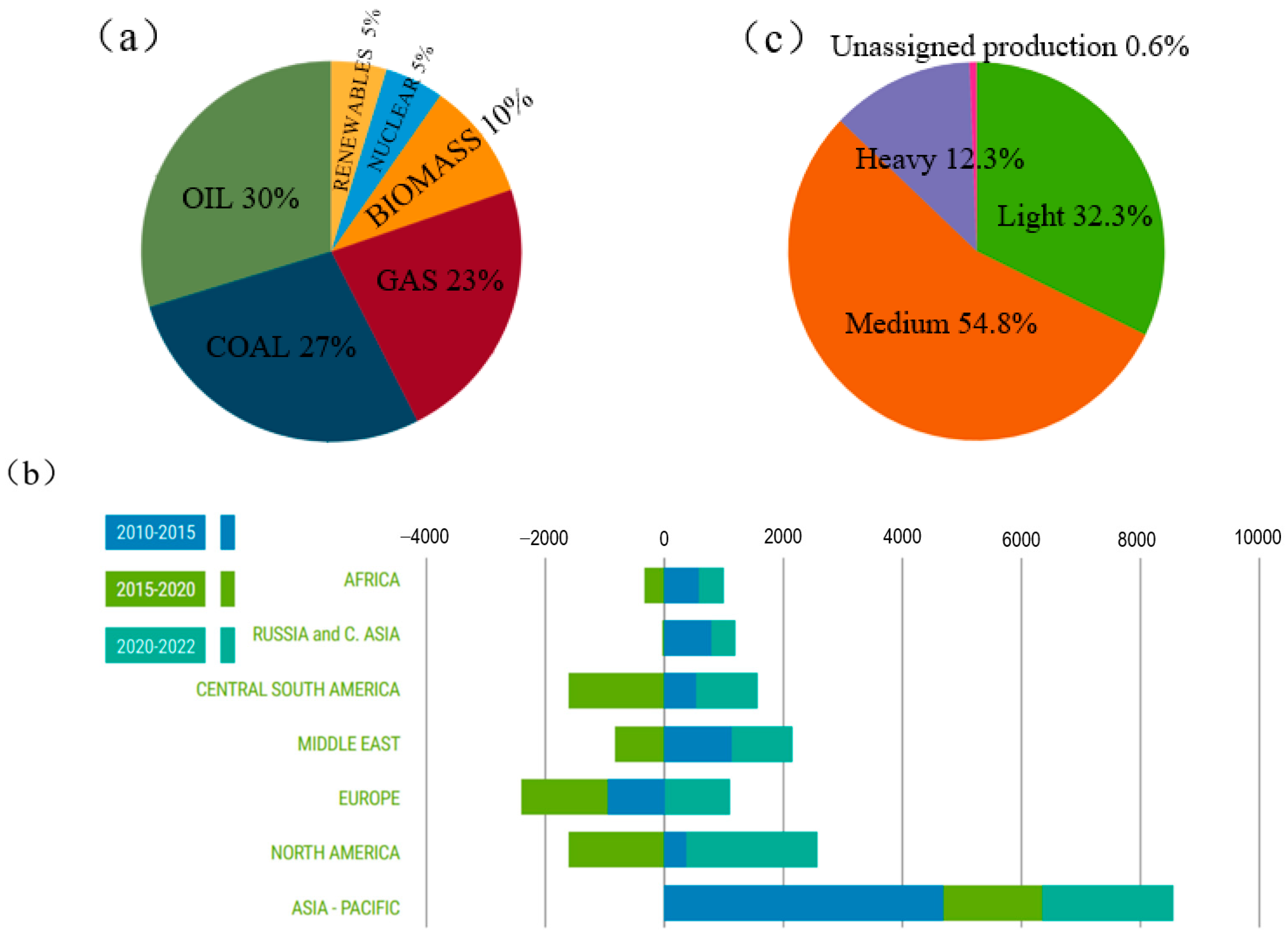

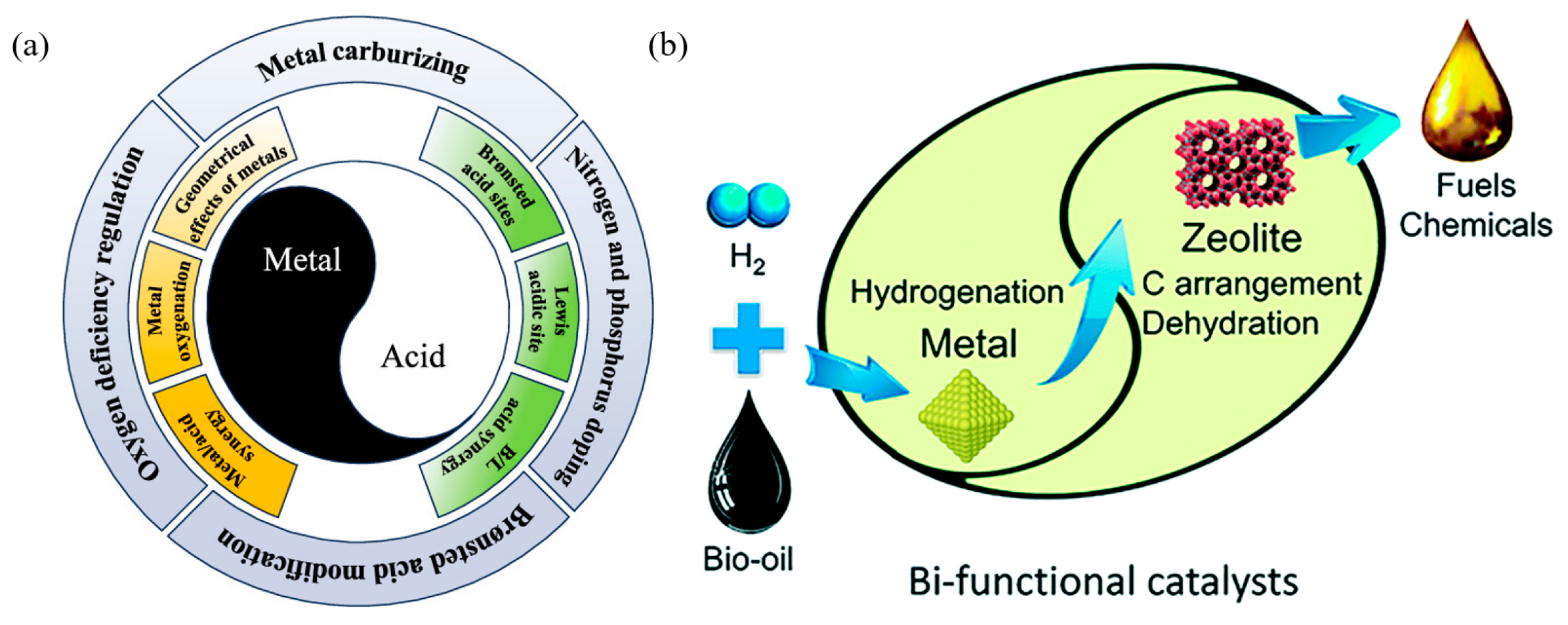

With the development of the global economy and population growth, human demand for energy continues to increase. According to a research report by the International Energy Agency (IEA) [1], the current global energy structure is still dominated by oil, accounting for 30% (Figure 1a). In addition, global oil consumption has been growing in recent years, especially in the Asia-Pacific region. This rapid increase in demand for oil may cause a shortage of oil resources (Figure 1b). At present, the global heavy oil production accounts for a large proportion (Figure 1c). Due to the rapid growth in global demand for oil energy, light crude oil is relatively easy to process, so the proportion of light crude oil in the world’s oil reserves is rapidly declining. If the abundant heavy oil components are utilized, the energy shortage problem will be greatly alleviated. It can be seen that with the increasing reduction in global light crude oil resources and the continuous growth of energy demand, unconventional oil resources such as heavy oil, extra-heavy oil and oil sands are gradually becoming an important part of the future energy supply. Therefore, how to make full use of heavy oil is very important.

Figure 1.

Global energy production and consumption [1]: (a) global energy structure in 2022; (b) world oil consumption growth from 2010 to 2022 (million barrels per day); (c) global crude oil production in 2022.

Heavy oil is abundant on Earth, accounting for more than 50% of global oil resources [2,3], and has huge development potential. However, it is not easy to utilize this petroleum fraction with high viscosity, high boiling point, and high impurities. Its complex chemical composition and processing characteristics pose great challenges to its efficient utilization. Heavy oil has a complex composition, containing a large amount of polycyclic aromatic hydrocarbons, long-chain alkanes, colloids, and asphaltene, as well as metal impurities such as sulfur, nitrogen, nickel, and vanadium [4,5]. These substances will cause a series of problems during the processing, resulting in low conversion efficiency of heavy oil, further increasing processing costs and technical difficulties.

The viscosity of heavy oil is several times that of conventional crude oil, and its poor fluidity makes it difficult to transport. It must be heated or diluted to achieve effective transportation and processing, which increases energy consumption and economic costs. In addition, heavy oil contains a high proportion of impurities such as sulfur and nitrogen. These impurities not only reduce product quality during processing, but also easily react with catalysts, causing catalyst poisoning, seriously affecting catalytic efficiency, and causing equipment corrosion problems [6]. At the same time, polycyclic aromatic hydrocarbons and asphaltene in heavy oil are easily decomposed to form coke under high-temperature cracking conditions. A large amount of coke is deposited on the reactor surface and in the catalyst pores, which not only hinders the diffusion of reactants, but also causes reactor coking, reduced thermal efficiency, and ultimately leads to rapid catalyst deactivation [7,8]. These problems greatly limit the efficient conversion and industrial application of heavy oil. Therefore, the development of efficient and economical heavy oil upgrading technology, especially through catalytic cracking and hydrocracking and other efficient technologies, to achieve efficient utilization of heavy oil resources, has become a core issue that needs to be urgently solved in the current energy field.

Heavy oil cracking technology is an important way to convert heavy oil with high molecular weight and complex components into light oil products (such as gasoline and diesel) and high value-added chemicals, with significant economic and environmental benefits. Compared with traditional thermal cracking technology, catalytic cracking and hydrocracking technology have become the mainstream methods of heavy oil processing at present [9]. The introduction of solid acid catalysts through catalytic cracking technology can promote the cracking and recombination of large molecular hydrocarbons in heavy oil at relatively low temperatures, effectively reduce energy consumption, improve the economy of the cracking process, and significantly improve the selectivity of the target product. Catalytic cracking technology is particularly suitable for the efficient degradation of large molecular hydrocarbons in heavy oil and has important industrial application value. Secondly, hydrocracking technology relies on the synergistic effect of hydrogen and catalysts to achieve efficient breaking of C-C bonds and convert polycyclic aromatic hydrocarbons into saturated hydrocarbons through the hydrogenation ring-opening reaction, effectively reducing the content of impurities such as sulfur and nitrogen, and producing higher quality and cleaner light oil products [10,11]. In addition, the by-products such as low-carbon olefins and aromatics produced in the cracking process are important basic chemical raw materials with broad market demand, providing a new economic growth point for the petrochemical industry chain [12]. From the perspective of energy security, heavy oil cracking technology can significantly increase the utilization rate of unconventional oil resources and alleviate the supply pressure caused by the depletion of light crude oil resources worldwide. At the same time, the use of hydrocracking technology can effectively reduce the emission of pollutants such as sulfur oxides and nitrogen oxides, which meets the strict requirements of the world for clean energy and environmental protection [13]. Therefore, heavy oil cracking technology is not only an important way to solve the problem of energy supply, but also a key technology to promote green and sustainable development.

Zeolite catalysts are the core of heavy oil catalytic cracking technology. With their unique microporous structure, adjustable acidity, and good thermal stability, they play an irreplaceable role in the field of heavy oil processing [14]. Zeolites have regular micropores and supercage structures. These pore structures provide ideal reaction space for large molecular hydrocarbons in heavy oil, promoting the diffusion and efficient cracking of large molecular hydrocarbons. For example, the supercage structure of Y-type zeolite can accommodate heavy oil molecules with larger diameters, significantly improving the cracking efficiency of large molecular hydrocarbons. In addition, ZSM-5 zeolite has good shape-selective catalytic performance due to its unique ten-membered ring pore structure, which can promote the efficient generation of light hydrocarbons and aromatics [15]. In addition, the acidity of zeolite can be precisely controlled by adjusting the silicon–aluminum ratio, metal ion exchange, dealumination treatment, and other methods to optimize the acidity distribution and acid strength of the catalyst. Appropriate acidity helps to improve the selectivity of the cracking reaction and reduce the occurrence of side reactions, such as coke formation. At the same time, the acidity control of zeolite can achieve personalized optimization of catalyst performance for different types of heavy oil components [16,17]. Zeolite catalysts have good thermal stability and can maintain structural stability under high-temperature cracking conditions. They are not prone to lattice collapse and are suitable for long-term industrial operation. By introducing rare earth metals (such as La and Ce), the resistance of zeolite catalysts to metal poisoning is further enhanced, effectively resisting the poisoning effect of metal impurities such as nickel and vanadium in heavy oil, thereby extending the service life of the catalyst and reducing production costs [18].

Based on the importance of heavy oil resource utilization and the advantages of zeolite catalysts in heavy oil cracking, this paper reviews the application of zeolite catalysts in heavy oil cracking and upgrading reactions, aiming to summarize the current research status, analyze the existing challenges, and look forward to future research directions. The research framework of this paper is as follows: first, the current status and challenges of heavy oil resource utilization are introduced, and the importance of heavy oil cracking technology and the application advantages of zeolite catalysts are explained; secondly, the development status of heavy oil cracking technology is reviewed, and the characteristics and limitations of thermal cracking, catalytic cracking, and hydrocracking technologies are analyzed; thirdly, the structural characteristics and catalytic properties of Y-type zeolite, ZSM-5 zeolite, Beta zeolite, Ferrierite zeolite, and Mordenite zeolite are discussed in detail, as well as their applications in heavy oil cracking and hydrocracking; fourthly, the reaction mechanism of polycyclic aromatic hydrocarbons and long-chain alkanes cracking is analyzed, and the catalytic characteristics and reaction paths of zeolites are discussed; fifthly, the main challenges faced by zeolite catalysts in practical applications are summarized, and improvement strategies are proposed; finally, the whole paper is summarized, and the future development direction of zeolite catalysts in the field of heavy oil cracking is prospected. Through a systematic review and analysis, this paper aims to provide theoretical support and practical reference for the design and application of zeolite catalysts in heavy oil cracking.

2. Research Progress of Heavy Oil Cracking Reaction

2.1. Composition and Properties of Heavy Oil

The American Petroleum Institute gravity index (API gravity) is an important indicator for measuring crude oil types. Heavy oil is defined as crude oil with an API gravity between 10.0 and 22.3, and crude oil with an API gravity below 10.0 is defined as extra-heavy crude oil [4]. Generally speaking, the higher the API gravity value, the higher the value of the crude oil. The classification of crude oil is based on its flow characteristics, which can reflect the technical characteristics of crude oil for subsequent production, transportation, and refining.

Heavy oil is a high molecular weight component remaining in the oil processing process. Its composition and properties are complex, mainly including long-chain alkanes, polycyclic aromatic hydrocarbons, gums, and asphaltene [16,19]. The physical and chemical properties of these components directly affect the processing and upgrading efficiency of heavy oil. Long-chain alkanes are relatively simple components in heavy oil, but due to their large molecular weight and strong thermal stability, direct cracking is difficult. Polycyclic aromatic hydrocarbons are structures composed of multiple benzene rings fused together, with a highly stable conjugated system, and are not prone to cracking reactions. In addition, gums and asphaltene contain a large amount of metal impurities (such as nickel and vanadium) and heteroatoms (such as sulfur and nitrogen), which can easily lead to catalyst deactivation during the cracking process and affect the reaction efficiency [18,20].

Heavy oil usually contains more asphaltenes and resins than conventional oil [21], which directly affects the recovery, transportation, and refining processes. Table 1 shows the common composition differences between conventional oil, heavy oil, and residue [4,21]. The asphaltene content shown represents typical ranges from various crude oil sources; in some cases, heavy oils—especially from unconventional deposits—may contain more asphaltenes than residue fractions derived from lighter crudes. Asphaltene is one of the components of heavy oil and is also the most complex heavy organic compound. The hydrocarbons of asphaltene contain different components, such as polycyclic aromatic hydrocarbons, heteroaromatic compounds, bifunctional or multifunctional molecules (such as ketones, amides, phenols, carboxylic acids), and metal (such as Ni and V) complex compounds [22]. Asphaltene tends to clump and precipitate, causing equipment fouling [23]. The number of carbon atoms in the molecular chain of heavy crude oil often exceeds 15, and it has long-chain hydrocarbons, while short-chain hydrocarbons are considered light crude oil. In heavy petroleum, polycyclic aromatic hydrocarbons and long-chain alkanes account for a large proportion [24,25]. Polycyclic aromatic hydrocarbons refer to polycyclic aromatic hydrocarbons in which two carbon atoms are shared by two benzene rings.

Table 1.

Composition of conventional petroleum, heavy oil, and residual oil [4,21].

In addition, heavy oils from different sources have significant differences in composition. For example, the asphaltene content of Canadian oil sands heavy oil is as high as 30–50%, with a large amount of metal impurities, while the aromatic hydrocarbon content of Middle Eastern crude oil residues is relatively high, and the content of resins and asphaltene is low [6,16]. Therefore, a deep understanding of the composition and properties of heavy oil is an important basis for selecting appropriate processing technology and catalysts.

2.2. The Main Upgrading Methods of Heavy Oil

Heavy oil upgrading refers to the process of converting heavy oil into light oil products and high value-added chemicals by physical or chemical methods. At present, the main ways to upgrade heavy oil include thermal cracking technology, catalytic cracking technology, and hydrocracking technology. These technologies have their own characteristics and different applicability and limitations in practical applications. The main ways to upgrade heavy oil are summarized in Table 2. Thermal cracking technology generates small molecular hydrocarbons by high-temperature cracking of heavy oil molecules. However, thermal cracking technology easily leads to large amounts of coke production and difficult-to-control product distribution. Catalytic cracking technology performs cracking reactions under the action of catalysts, with mild reaction conditions, less coke production, and higher selectivity for target products. Hydrocracking technology not only achieves heavy oil cracking through the synergistic effect of hydrogen and catalysts, but also can improve the hydrogen-to-carbon ratio of the product and reduce the content of impurities such as sulfur and nitrogen. In comparison, catalytic cracking technology and hydrocracking technology have good industrial application prospects and are the focus of current research.

Table 2.

Main upgrading methods of heavy oil.

2.2.1. Thermal Cracking Technology

Thermal cracking technology is the earliest process used in heavy oil upgrading and has been used by refineries since the first half of the 20th century. The thermal cracking process has attracted much attention because it does not require expensive catalysts. It cracks in a container to produce small molecular products by pressurizing and heating, which often have lower boiling points [26,27].

Thermal cracking technology generates lighter hydrocarbon products by breaking C-C bonds in heavy oil under high-temperature conditions. The reaction temperature is generally between 500 and 700 °C, and the molecular chain is mainly broken by the action of heat [18,21]. This technology is simple and has low equipment investment, but it has many limitations. First, the reaction selectivity is poor during thermal cracking, the product distribution is wide, and the yield of light oil products is low; second, polycyclic aromatic hydrocarbons and asphaltene in heavy oil are prone to generate a large amount of coke at high temperatures, resulting in coking of the reactor and affecting normal production operations [28].

Although the thermal cracking process has high operational flexibility, its high energy consumption and low selectivity limit the promotion of industrial applications. Therefore, catalytic cracking technology combined with catalysts has gradually become the mainstream method for heavy oil upgrading.

2.2.2. Catalytic Cracking Technology

Catalytic cracking technology (FCC) is one of the most widely used heavy oil upgrading technologies. By introducing solid acid catalysts, efficient cracking and conversion of heavy oil can be achieved at relatively low temperatures. Commonly used catalysts include Y-type zeolite and ZSM-5 zeolite. They promote the breakage and recombination of C-C bonds of macromolecular hydrocarbons in heavy oil to produce light oil products by providing evenly distributed acid sites and suitable pore structures [29,30]. Y-type zeolite is the core component of FCC catalysts. It has a large supercage structure and high acidity, which is suitable for the cracking reaction of macromolecular hydrocarbons in heavy oil. ZSM-5 zeolite has a unique ten-membered ring pore structure that can improve the selectivity of light olefins and aromatics. It is often used in combination with Y-type zeolite to improve the product distribution in the catalytic cracking process [31,32]. In addition, the acid distribution and stability of zeolite catalysts can be effectively optimized through metal modification, dealumination treatment, and other means, further improving the yield and quality of light oil products.

Compared with thermal cracking technology, catalytic cracking technology can avoid coking caused by excessive temperature, and the quality and stability of the products are higher. The raw materials of catalytic cracking technology can be straight run or vacuum gas oil, or heavy raw materials, such as heavy oil or extra-heavy oil, atmospheric or vacuum residue oil, etc., or a mixture of the above substances. When the raw material is the above mixture, it is necessary to ensure that too much coke will not be produced on the catalyst under the reaction conditions. Before catalytic cracking technology is carried out, deasphalting, demetallization, and hydrotreatment or hydrocracking processes are often required to avoid excessive coking or catalyst deactivation [33,34,35]. It is worth noting that hydrotreatment of catalytic cracking technology raw materials can reduce the emission of harmful sulfur oxides and can effectively improve the quality and yield of naphtha in the product. Therefore, hydrotreatment before catalytic cracking technology can obtain considerable benefits.

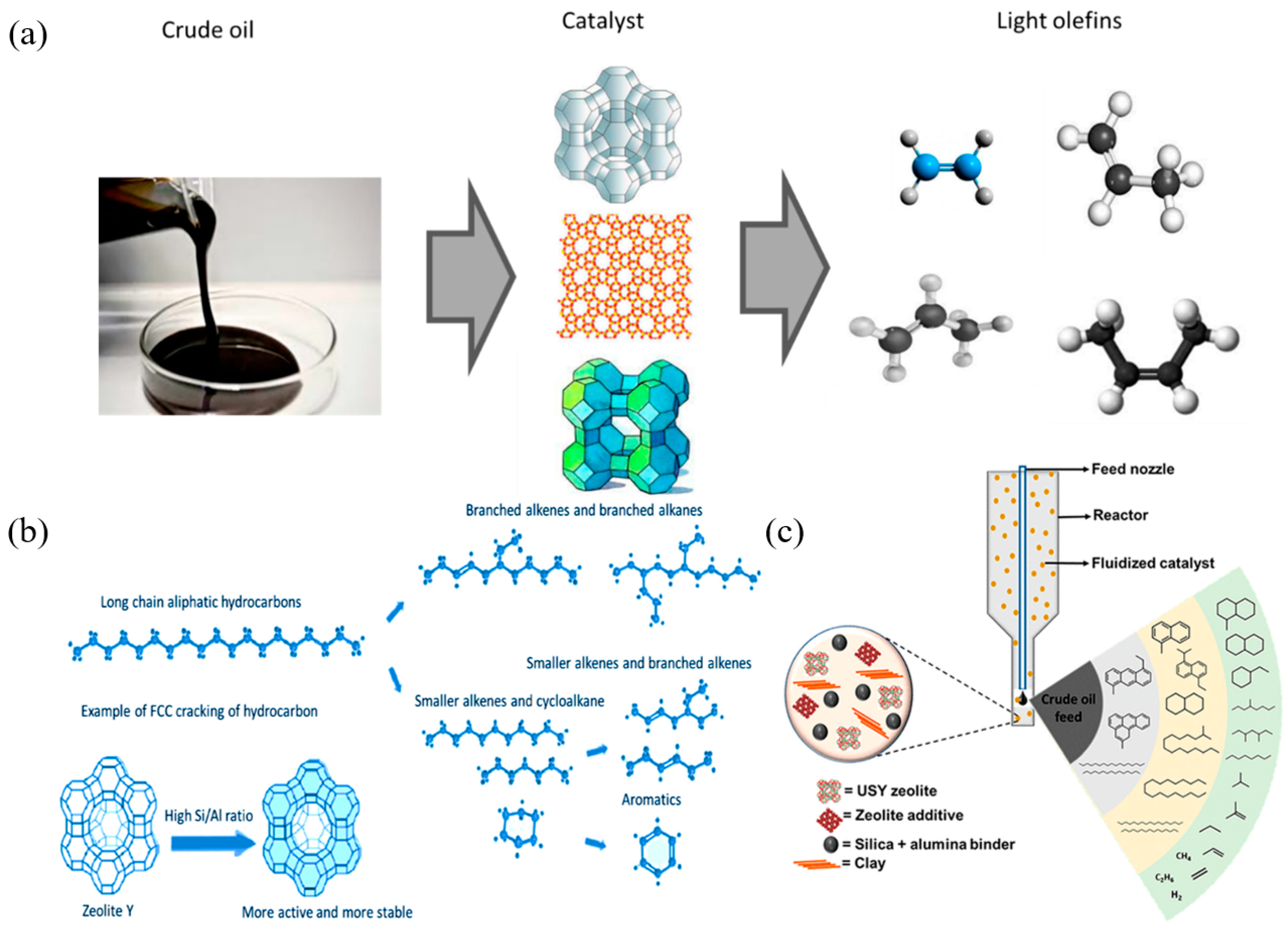

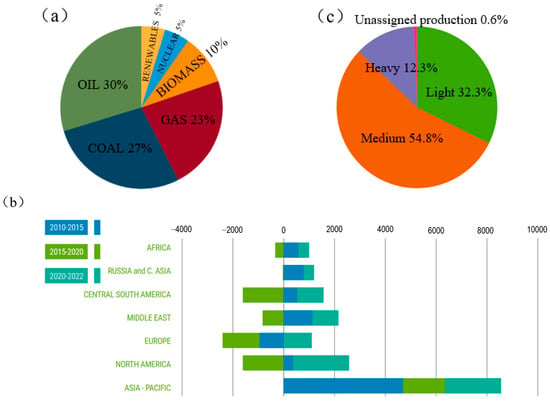

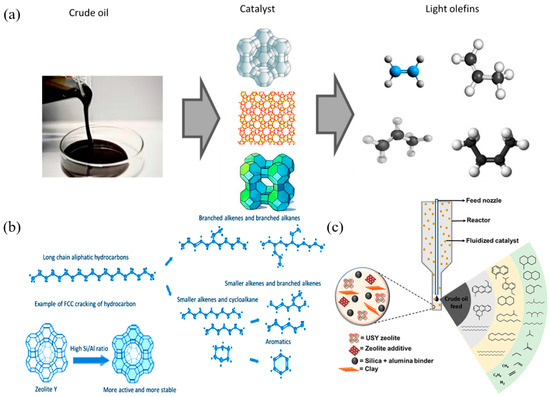

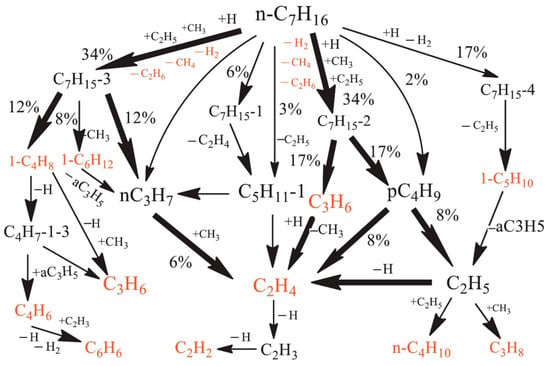

Compared with non-catalytic processes such as steam cracking and thermal cracking, catalytic cracking (FCC) technology has significant advantages in product selectivity control. Through the FCC process, crude oil can be efficiently converted into light olefins, which is widely regarded as one of the most cost-effective and reliable methods for producing petrochemical feedstocks such as ethylene, propylene, and butenes. Figure 2a shows the process of directly converting crude oil into light olefins such as ethylene, propylene, 1-butene, and 2-butene through catalytic cracking [30]. In the FCC reactor, crude oil will rapidly undergo catalytic cracking after contacting with the high-temperature zeolite-based catalyst to produce a variety of different products. Figure 2b shows a typical hydrocarbon catalytic cracking and light olefin production pathway. In this process, long-chain hydrocarbons are cracked to produce straight-chain and branched alkanes and olefins. The Y-type zeolite catalyst in Figure 2b is characterized by a higher Si/Al ratio, which indicates that it has more and more stable active sites, which can significantly improve the efficiency of hydrocarbon cracking [36]. USY zeolite is the most commonly used active catalyst component in the FCC process, followed by ZSM-5 zeolite, which is also widely used in FCC catalytic cracking. USY zeolite plays a key role in cracking VGO (vacuum gas oil) and HGO (heavy gas oil) into gasoline-range hydrocarbons, while ZSM-5 zeolite relies on its unique pore size to efficiently convert naphtha fractions into light olefins through shape selectivity. The schematic diagram of Figure 2c shows the composition structure of a typical FCC catalyst and the cracking reaction process triggered by its interaction with crude oil [37].

Figure 2.

(a) Illustration of the catalytic cracking of crude oil into petrochemical feedstock [30]; (b) typical catalytic cracking of hydrocarbons once in contact with the hot catalyst in the FCC reactor [36]; (c) schematic diagram of the FCC catalyst’s composition and cracking activities [37]. Reproduced with permission from Abdulkadir Tanimu et al., Energy & Fuels; published by American Chemical Society, 2022 [37].

2.2.3. Hydrocracking Technology

Hydrocracking technology is a process that uses the synergistic effect of hydrogen and catalysts to achieve the hydrogenation ring opening and C-C bond breaking of polycyclic aromatic hydrocarbons in heavy oil, thereby producing light oil products. The reaction temperature of this technology is generally between 300 and 450 °C, and commonly used catalysts include metal/zeolite composite catalysts, such as NiMo/Y zeolite, Pt/ZSM-5 zeolite, etc. [10,38,39,40]. Compared with thermal cracking, hydrocracking requires the combined action of hydrogen and a suitable catalyst and can be carried out at a lower temperature, so the energy consumption required for the reaction is lower [41].

The main advantages of hydrocracking technology are as follows: on the one hand, the introduction of hydrogen can effectively reduce the content of impurities such as sulfur and nitrogen, and improve the quality of oil products; on the other hand, polycyclic aromatic hydrocarbons are converted into saturated hydrocarbons through a hydrogenation ring-opening reaction, reducing the formation of coke [11,42]. However, the hydrocracking process has problems such as high hydrogen consumption and large equipment investment. How to reduce the hydrogen consumption in the reaction process and improve the activity and stability of the catalyst is the focus of current research on hydrocracking technology.

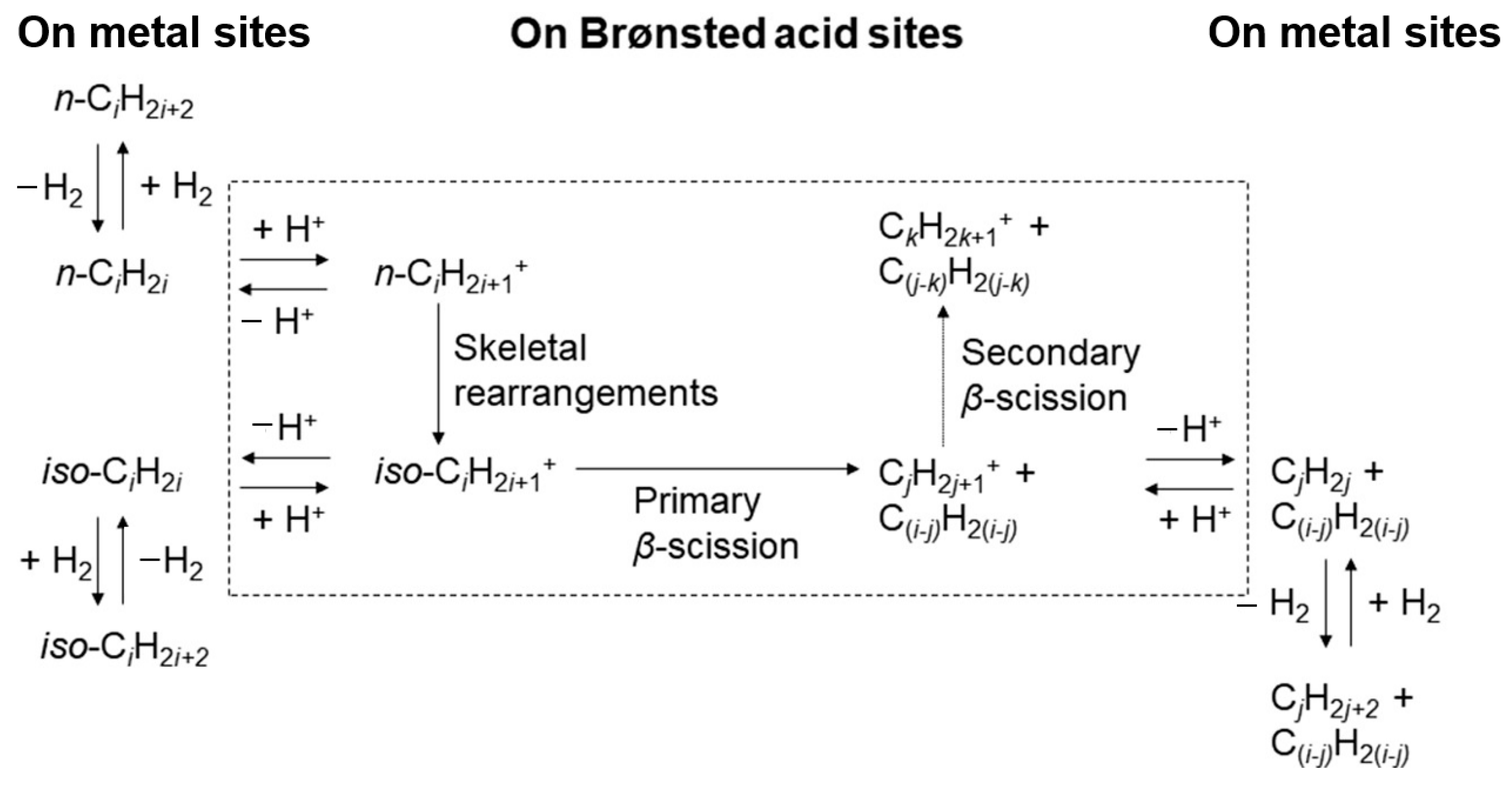

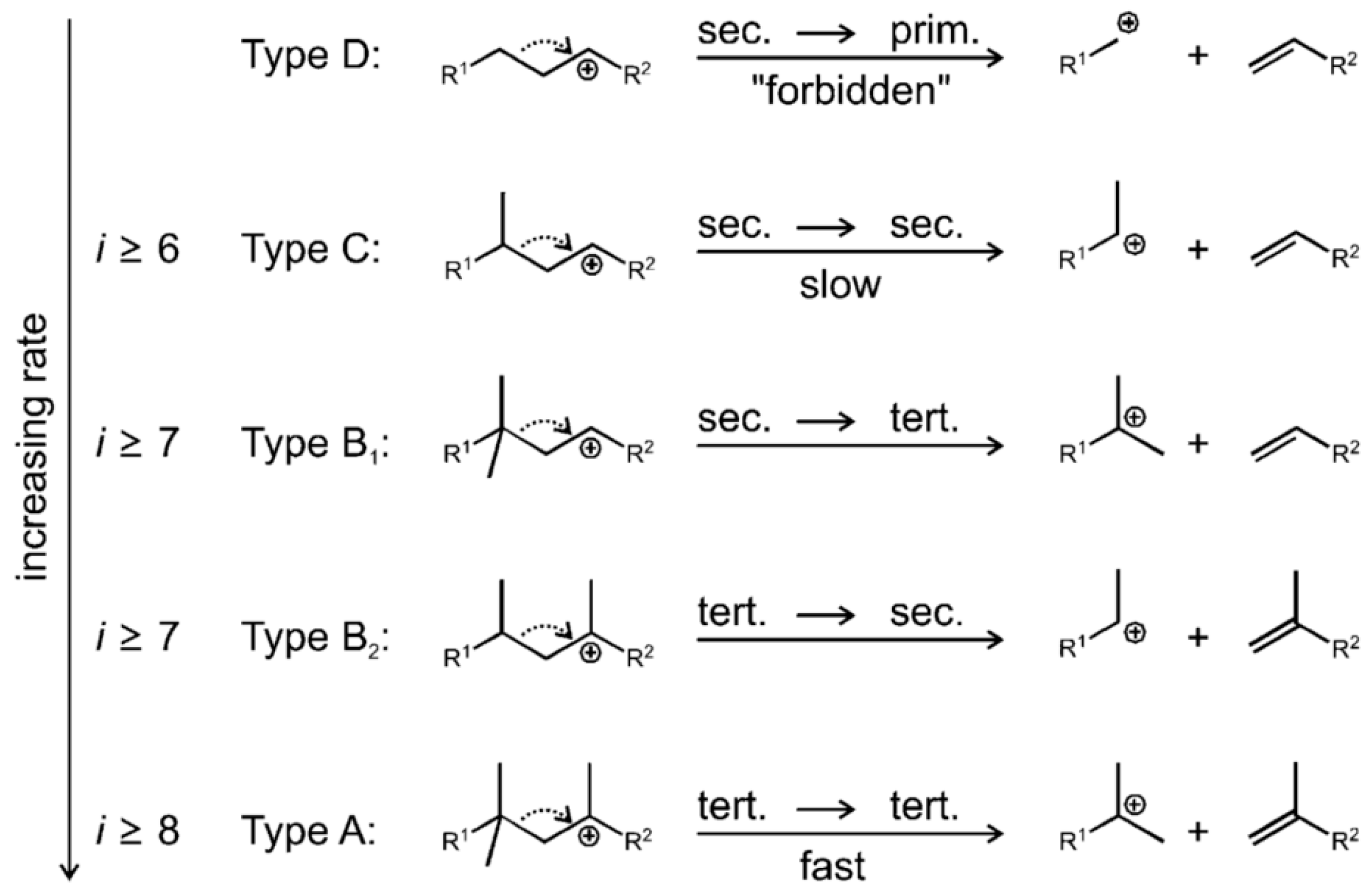

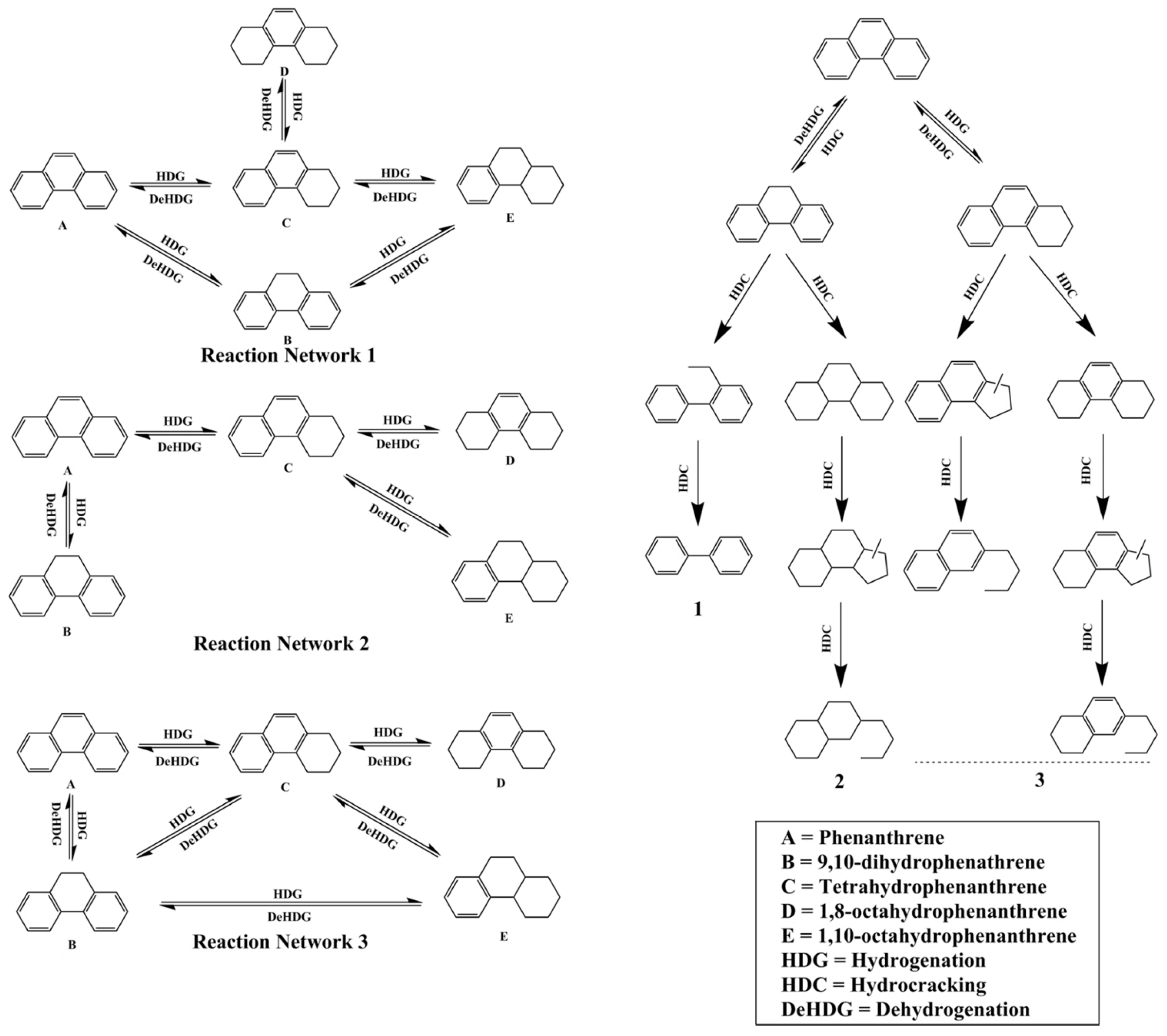

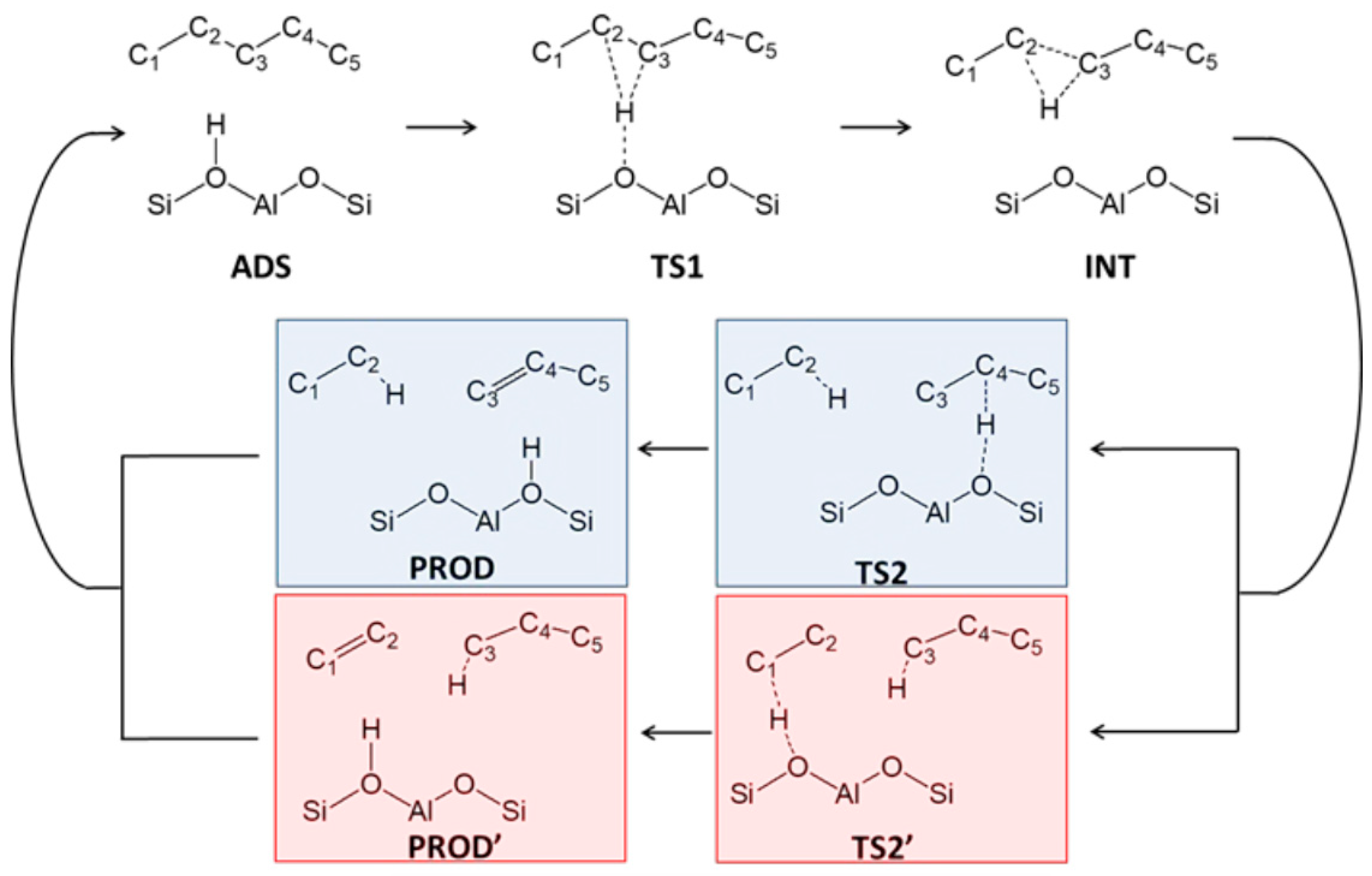

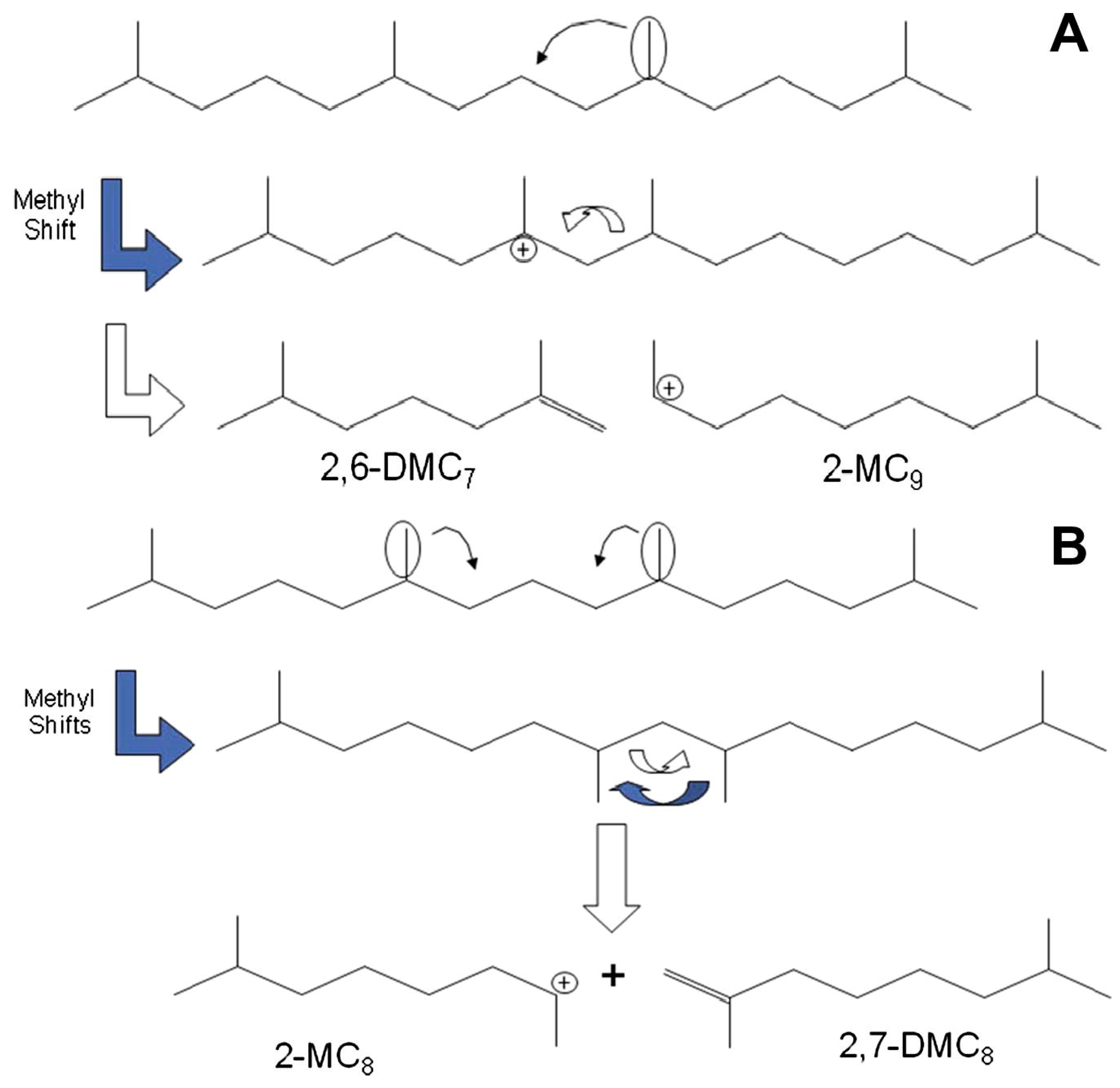

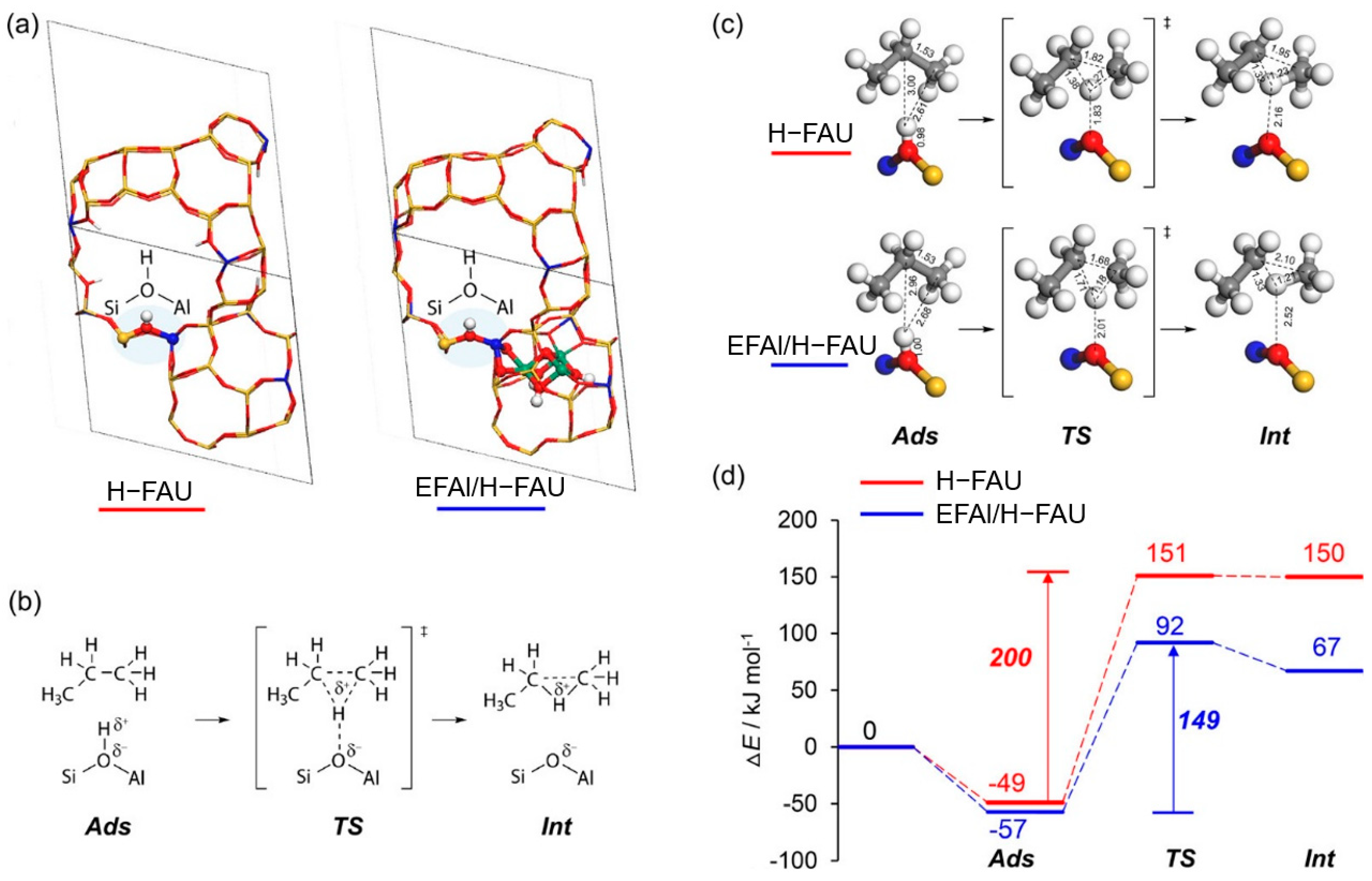

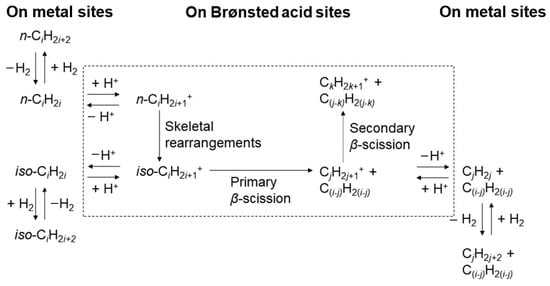

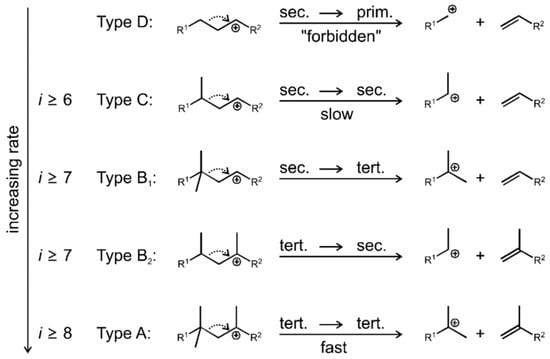

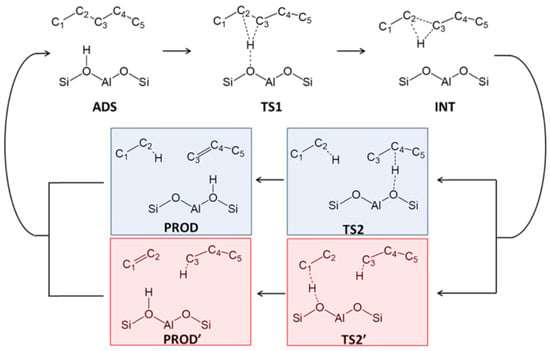

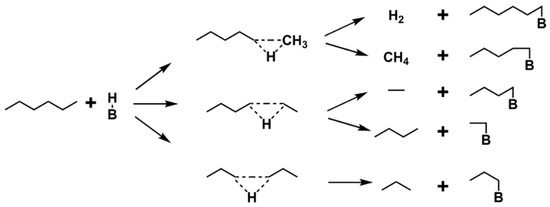

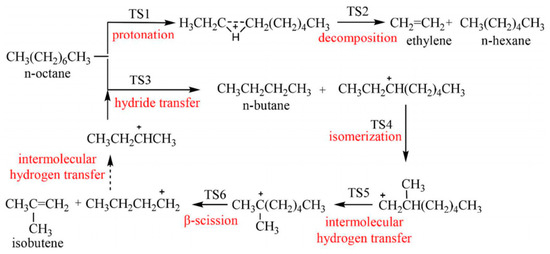

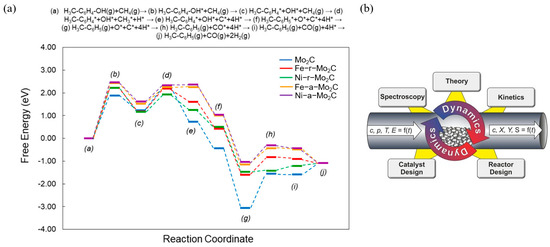

Figure 3 shows the classic hydrocracking mechanism of normal alkanes (n-alkanes) on a bifunctional catalyst. The catalyst has the following two main functions: 1. The metal active site is responsible for the dehydrogenation of the reactant (n-alkanes) to generate olefins and the hydrogenation of the intermediate product (olefins). The reaction reaches a balance between dehydrogenation and hydrogenation, and the generated olefins can desorb and diffuse to the acidic site. 2. The Brønsted acid sites (BAS) serves as an active site to protonate the olefin to generate a secondary carbocation. The secondary carbon cations generate cracking products through β-splitting or structural rearrangement reactions. Among the cracking products, the generation of light alkanes and branched alkanes is related to the type of carbon cation and the cracking path. This mechanism shows in detail the process of normal alkanes undergoing dehydrogenation, cracking, rearrangement, and hydrogenation steps on a bifunctional catalyst to generate light alkanes or branched alkanes. Through this catalytic effect, efficient generation of cracking products can be achieved [43].

Figure 3.

Classical mechanism of hydrocracking of an n-alkane on a bifunctional catalyst including metal sites for dehydrogenation/hydrogenation and Brønsted acid sites (BAS). i stands for the carbon number of the reactant, and j and k stand the carbon number of the cracked or hydrocracked products [43]. Reproduced with permission from Jens Weitkamp et al., ChemCatChem; published by John Wiley and Sons, 2012 [43].

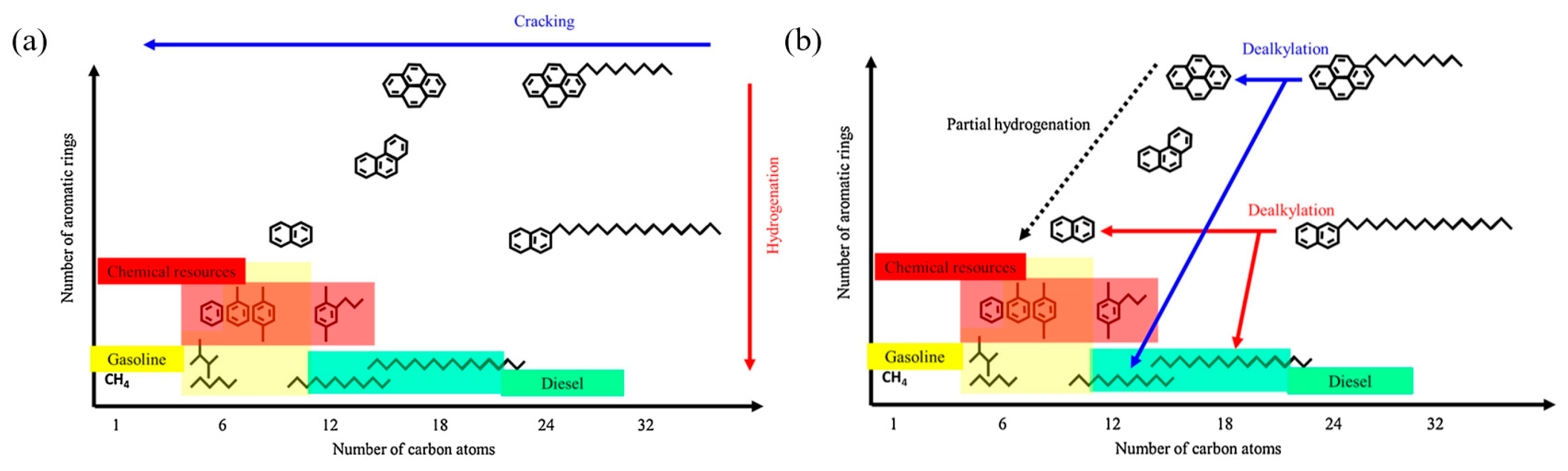

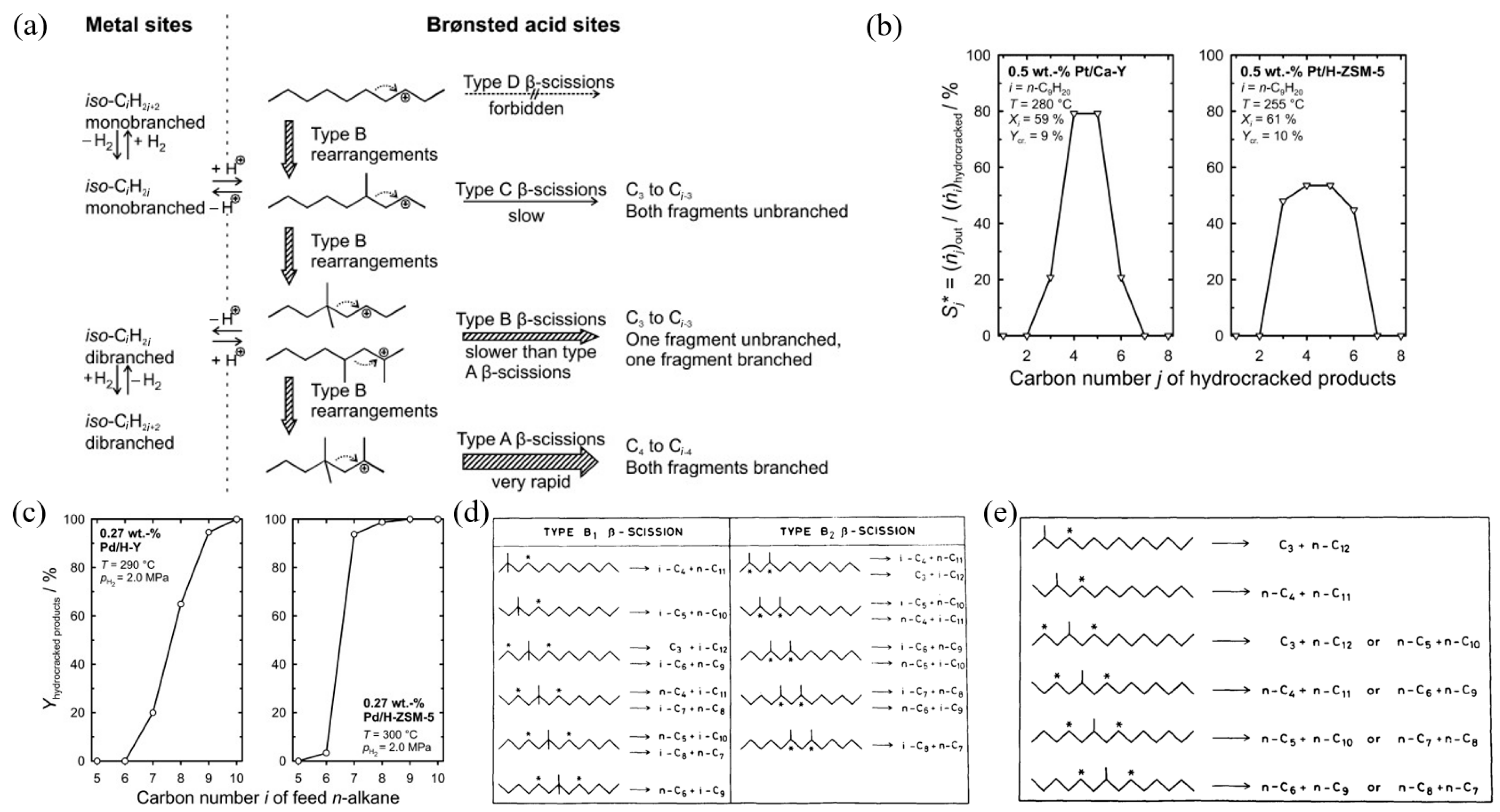

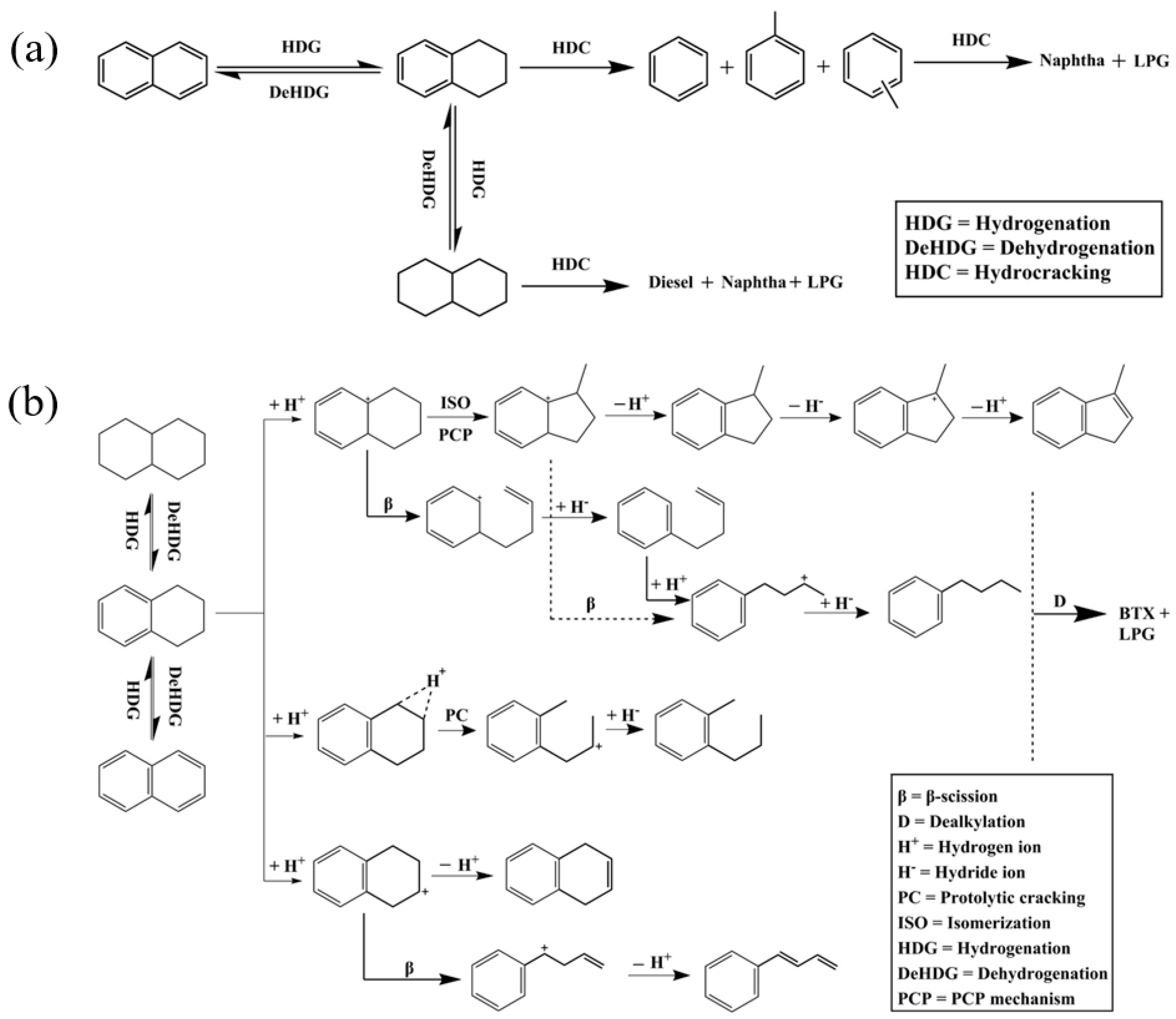

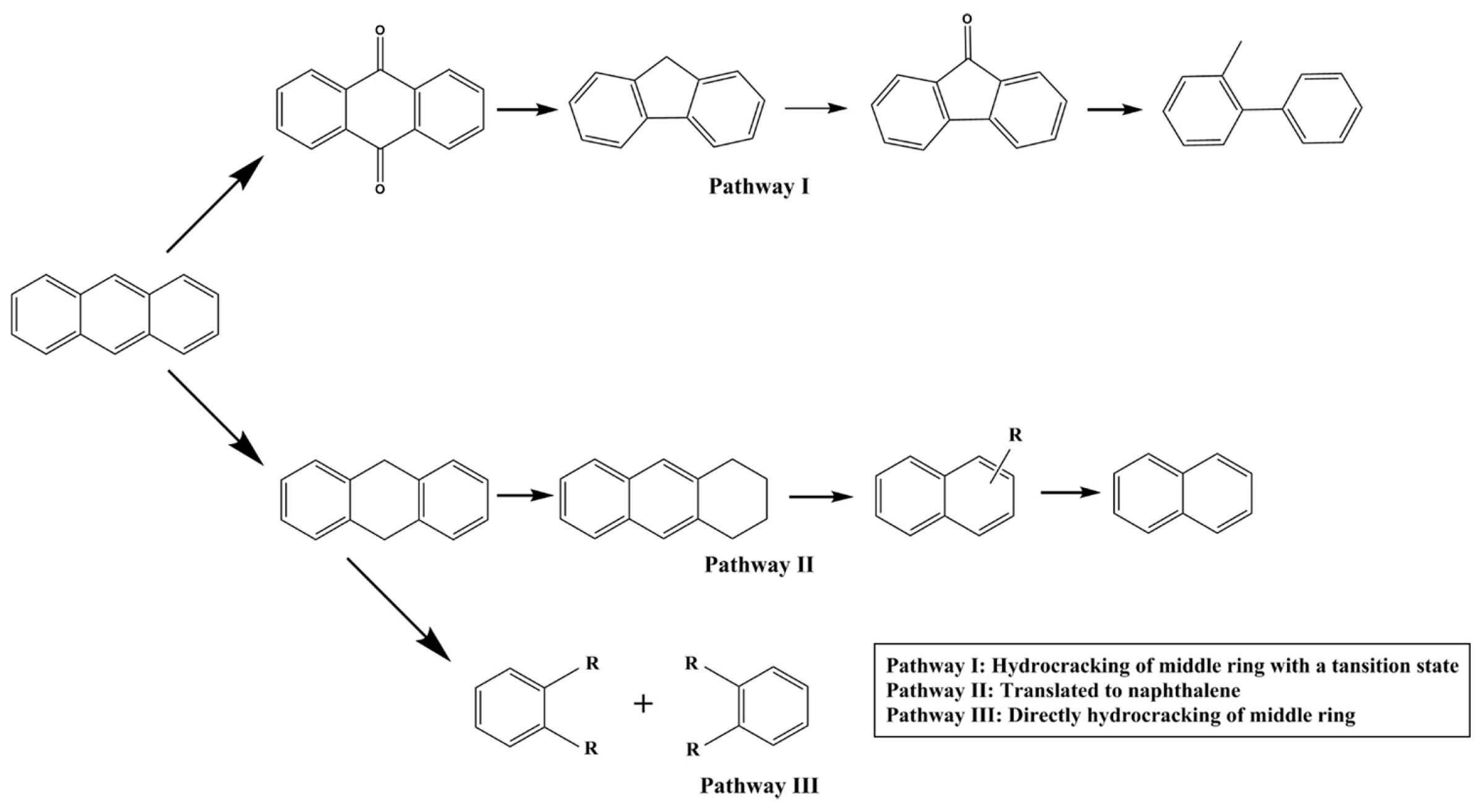

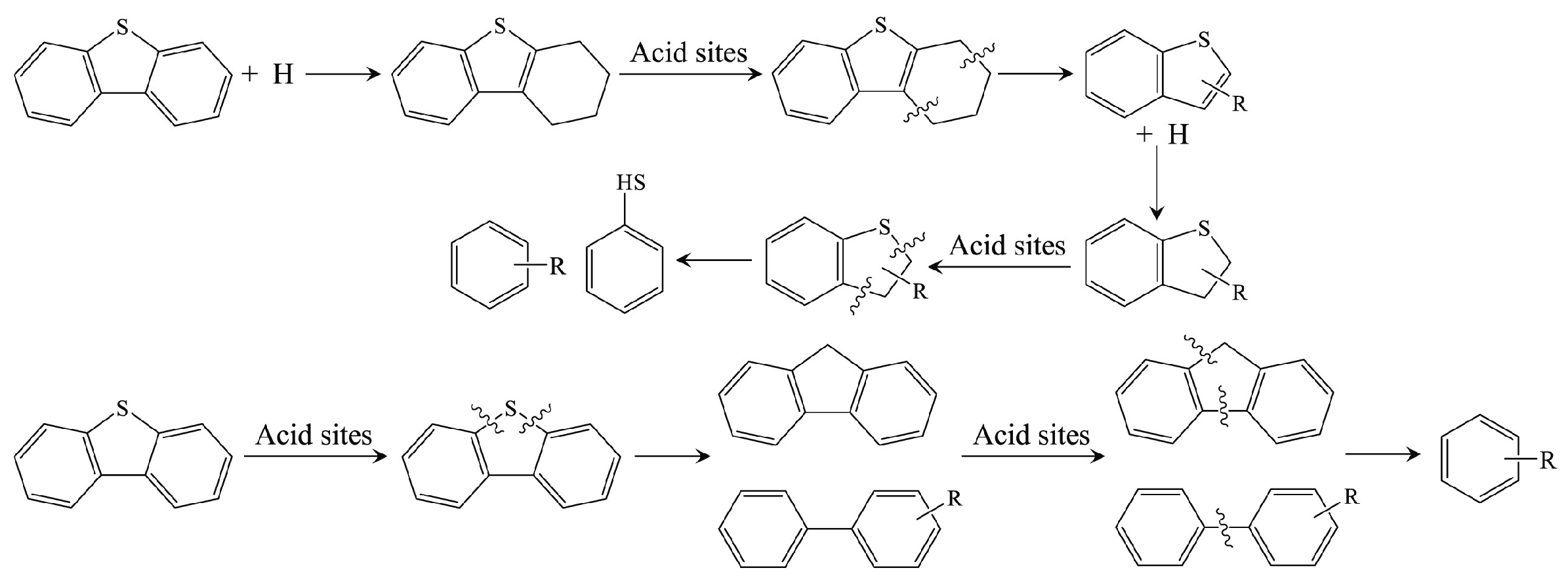

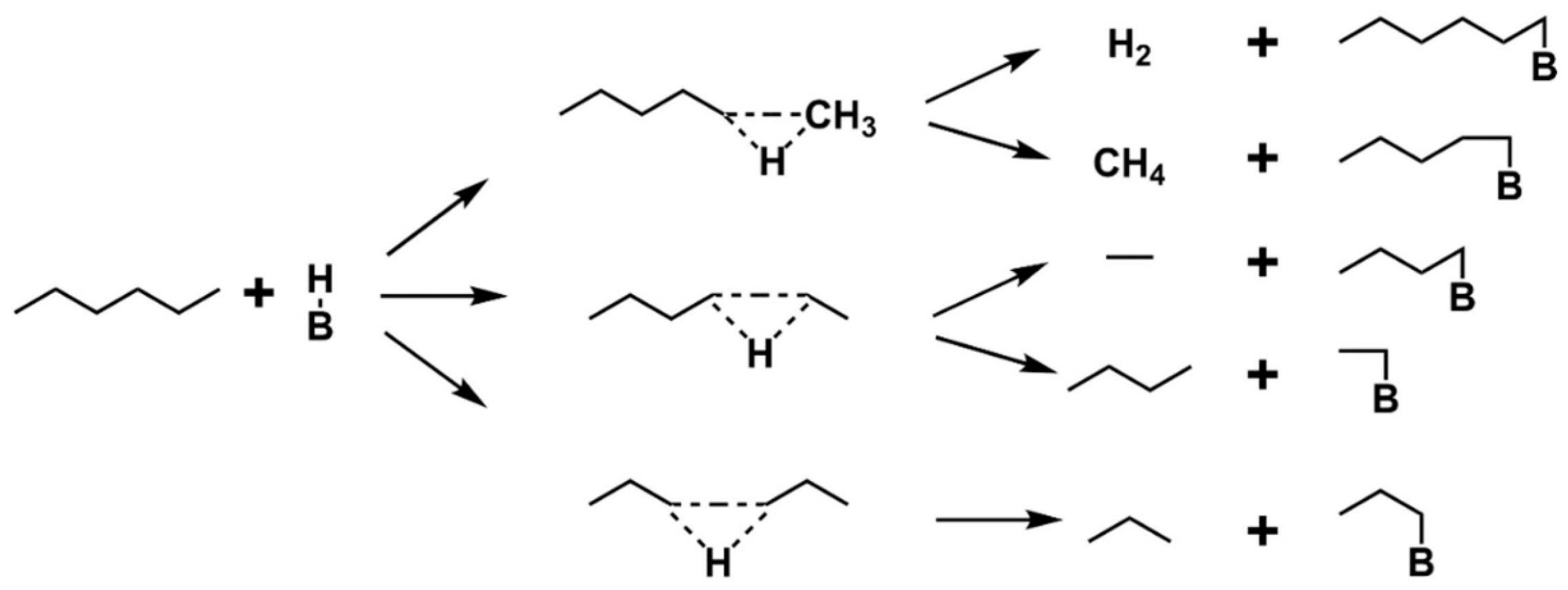

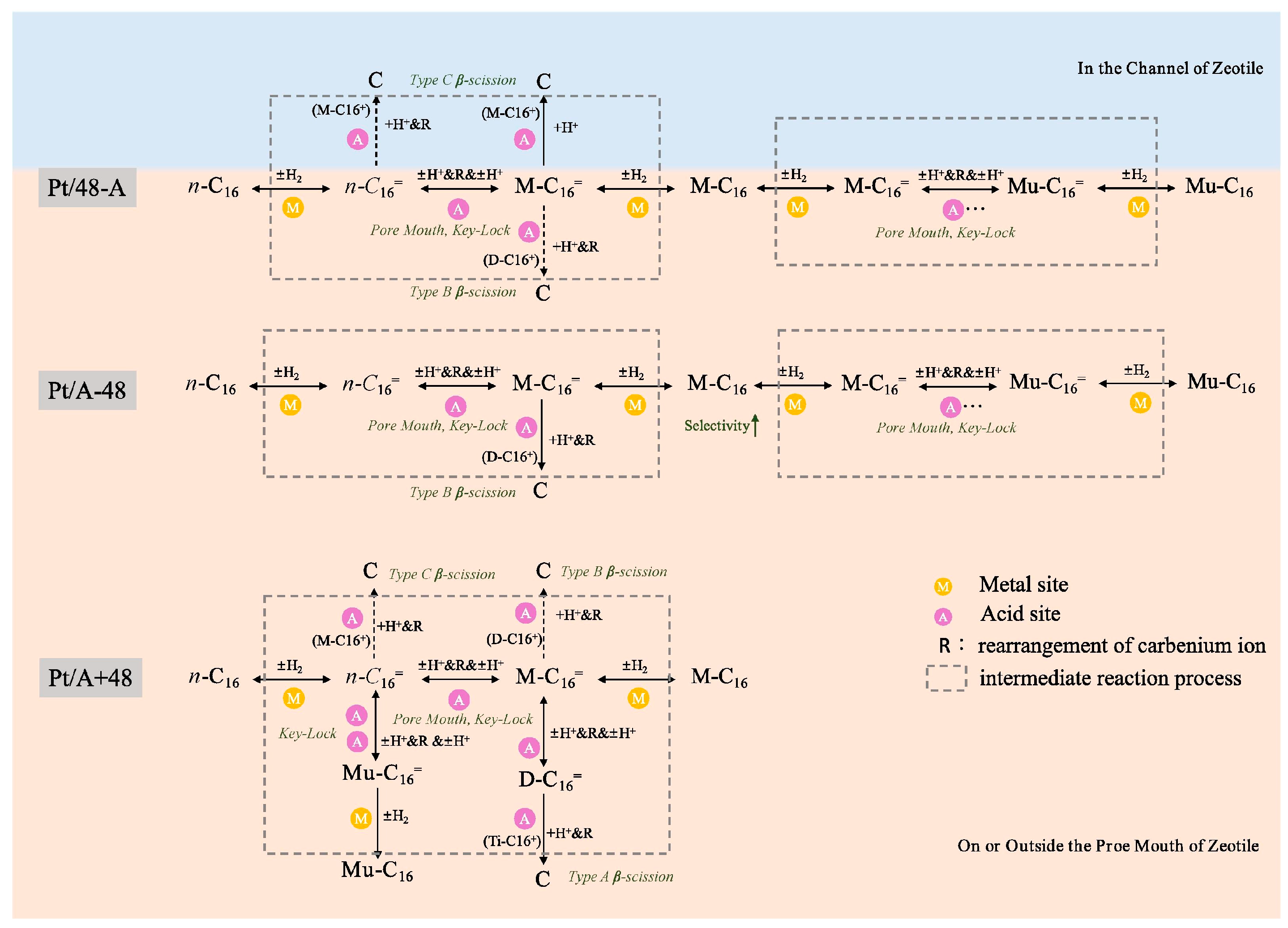

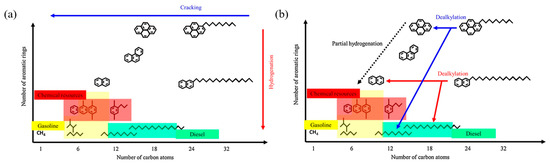

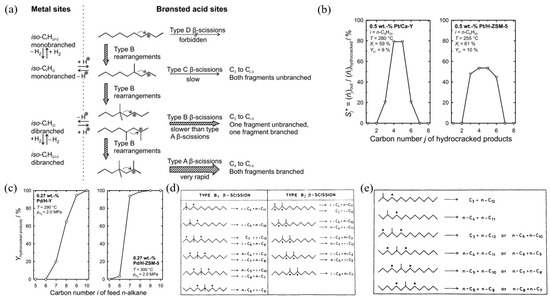

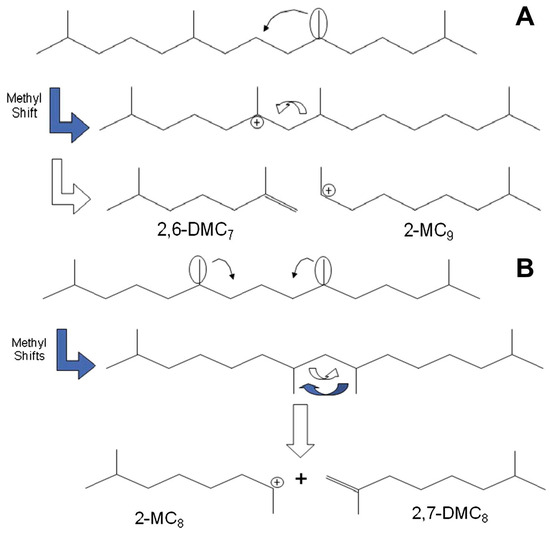

Figure 4 shows two schematic diagrams of processes involving alkyl aromatics. The conventional hydrocracking process (Figure 4a) describes the hydrogenation of aromatics, followed by the cracking of alkyl groups and aromatic rings. This process is achieved through a hydrogenation–dehydrogenation cycle and catalytic cracking to produce smaller hydrocarbon molecules. The process requires a large amount of hydrogen and is energy intensive, and typically produces a wide range of products, including alkanes and single-ring aromatics. The dealkylation followed by partial hydrogenation process (Figure 4b) focuses on a selective dealkylation process that removes alkyl groups from polycyclic aromatic hydrocarbons (PAHs) through BAS catalysis. Subsequently, partial hydrogenation is performed to stabilize the aromatic compounds after dealkylation. Compared with conventional hydrocracking, this method efficiently produces long-chain alkanes and single-ring aromatics (such as benzene, naphthalene, and their derivatives) with less hydrogen consumption. The two pathways compare the differences in energy consumption, selectivity, and product types between conventional hydrocracking and dealkylation technologies, highlighting the potential of dealkylation processes in the production of high-value-added fuels and petrochemical feedstocks [10].

Figure 4.

Schematic drawing of (a) conventional hydrocracking and (b) dealkylation followed by partial hydrogenation of polyaromatics of alkylaromatic hydrocarbons [10]. Reproduced with permission from Naonobu Katada et al., Applied Catalysis A: General; published by Elsevier, 2017 [10].

2.3. Catalysts in the Heavy Oil Cracking Process

Several typical processes for heavy oil upgrading are introduced above. This review focuses on heavy oil cracking, which mainly includes thermal cracking, catalytic cracking, and hydrocracking. Thermal cracking generally does not require the participation of catalysts, so this subsection only discusses catalysts related to catalytic cracking and hydrocracking. When talking about catalysts, catalysts can often be divided into homogeneous catalysts or heterogeneous catalysts based on whether the reactants and catalysts are in the same phase. In addition, they can also be divided into mineral catalysts, water-soluble catalysts, oil-soluble catalysts, dispersed catalysts, or solid acid catalysts based on the solubility of the catalyst. The catalysts used in the heavy oil cracking process are summarized in Table 3.

Table 3.

Catalysts used in heavy oil cracking process.

In the heavy oil cracking process, various catalysts have been widely used in different processes due to their characteristics and applicability. Mineral catalysts use natural minerals such as clay minerals and quartz. They have attracted much attention in early applications due to their large specific surface area and rich acid sites [44]. However, the activity of this type of catalyst is limited by the reservoir temperature, and its performance is slightly insufficient compared with modern synthetic catalysts [45]. As one of the earliest cracking catalysts used [46], water-soluble catalysts rely on the catalytic action of transition metal ions (such as Ru, Fe, Mo, etc.) and have the characteristics of low cost and a significant desulfurization effect [47]. However, since water-soluble catalysts are difficult to fully contact with heavy oil, their industrial application effect is limited, especially in the in situ combustion (ISC) process involving complex reaction steps. Oil-soluble catalysts can effectively solve this problem. Oil-soluble catalysts have attracted widespread attention due to their good compatibility with heavy oil, such as nickel sulfonates [48], molybdenum oleates [49,50], and aromatic metal sulfonic acid complexes [51,52]. These catalysts can significantly reduce the viscosity of heavy oil and improve cracking efficiency, but their preparation process is complicated, and the cost is high. In addition, dispersed catalysts are composed of solid particles (heterogeneous phase) and water-soluble or oil-soluble catalysts (homogeneous phase). Their high contact area can effectively inhibit the diffusion of free radicals during the reaction, but they require complex dispersion and pretreatment processes and are difficult to regenerate [53,54].

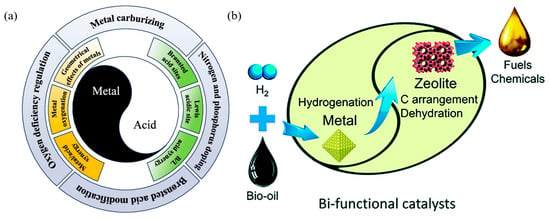

Solid acid catalysts are the most widely used in heavy oil cracking, and their types include zeolites, superacids, and heteropolyacids [55]. These catalysts have the advantages of strong acidity, high catalytic activity, and good selectivity. They can effectively catalyze the breaking of C-C bonds at lower reaction temperatures, thereby increasing the yield of light oil products. At the same time, solid acid catalysts can remove heteroatoms such as sulfur and nitrogen in heavy oil, reduce the viscosity of heavy oil, and improve product quality. However, solid acid catalysts are prone to the clogging of pores due to coke accumulation during use, and their sensitivity to metal impurities makes them easily deactivated. Compared with other heavy oil cracking processes, hydrocracking catalysts have unique properties—that is, the catalysts used in hydrocracking must be bifunctional catalysts. The so-called bifunctionality means that the catalyst has the function of cracking heavy oil, and also needs to have the functions of hydrogenation and dehydrogenation. Bifunctional catalysts are composed of metals (such as Pd, Ni-Mo) and acidic carriers (such as ZSM-5, Al2O3). The metal component is responsible for hydrogenation and dehydrogenation, and the acidic carrier provides cracking active sites and shape-selective catalytic ability. It has both cracking and hydrogenation functions, which can significantly improve the quality of light oil products and has strong stability. However, its precious metal components are susceptible to sulfur poisoning, and the raw material purity requirements are high, so pretreatment is required to ensure performance [56,57,58].

As the core representative of solid acid catalysts, zeolite catalysts have become the core technology in the field of heavy oil catalytic cracking due to their high efficiency, selectivity, and stability, especially showing significant advantages in the production of light oil products and heavy oil upgrading. Their microporous structure not only gives them excellent shape-selective catalytic ability, but also can effectively control product distribution and improve the selectivity of light oil products. It can also reduce energy consumption and optimize the catalytic effect by adjusting the pore size and acid sites. Commonly used zeolites such as ZSM-5 and Y-type zeolite can be used for catalytic cracking and can achieve the synergistic effect of hydrogenation and cracking in a bifunctional catalyst system. In addition, zeolite catalysts are an ideal choice for economical catalysts because of their abundant resources and relatively low preparation costs. Zeolite occupies an important position in the future development and improvement of catalysts, and also provides important support for promoting green and efficient heavy oil cracking technology [59,60].

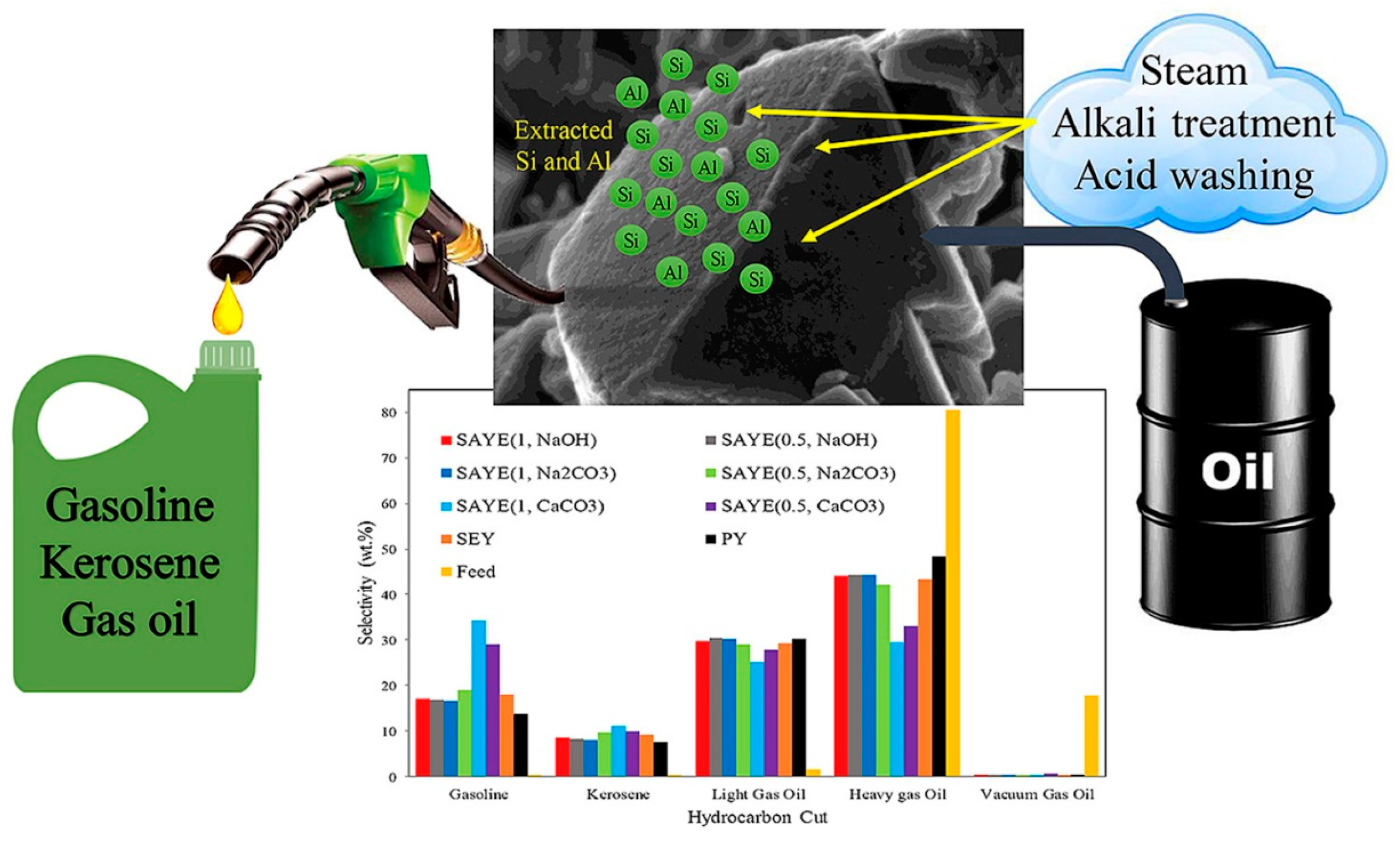

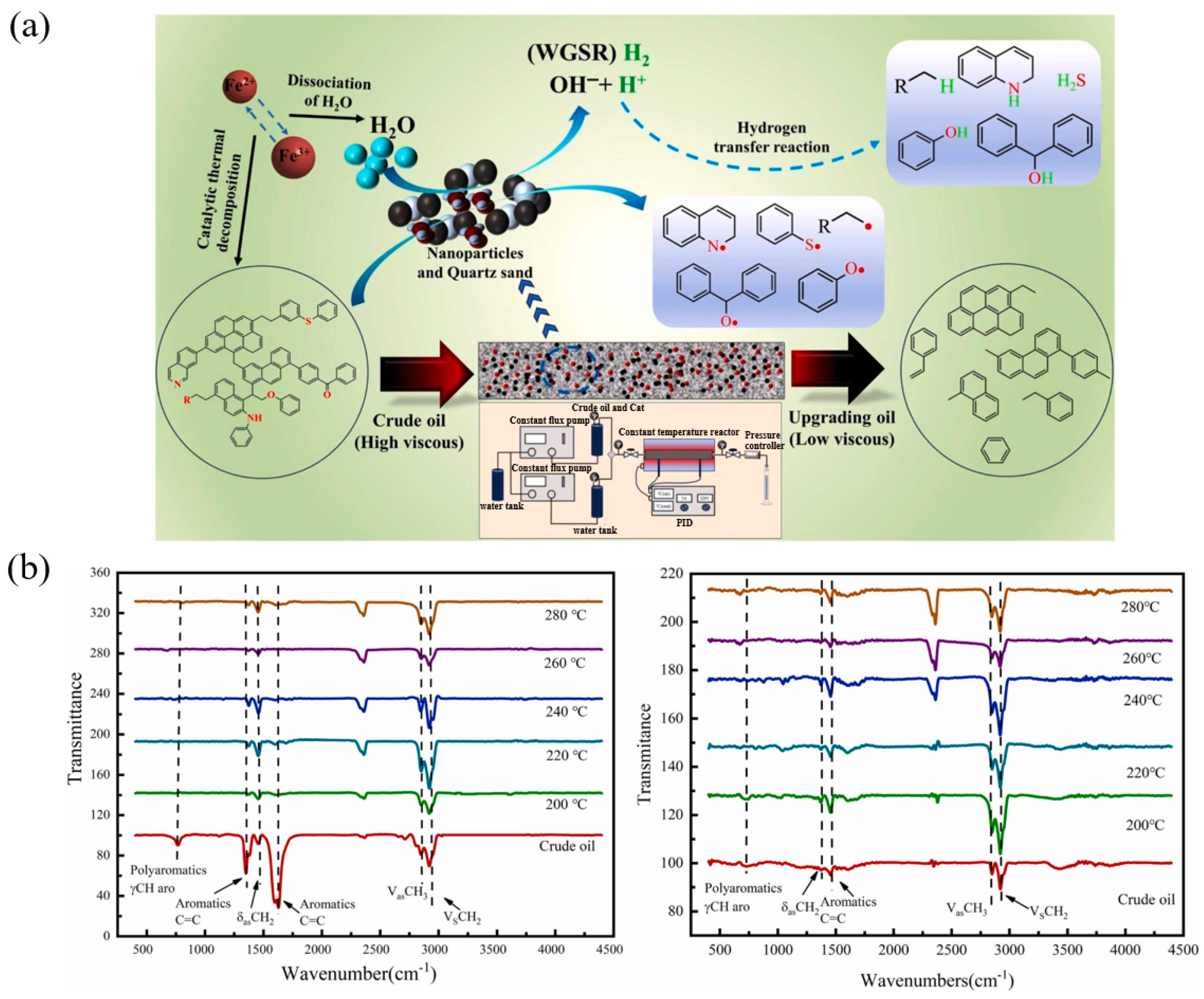

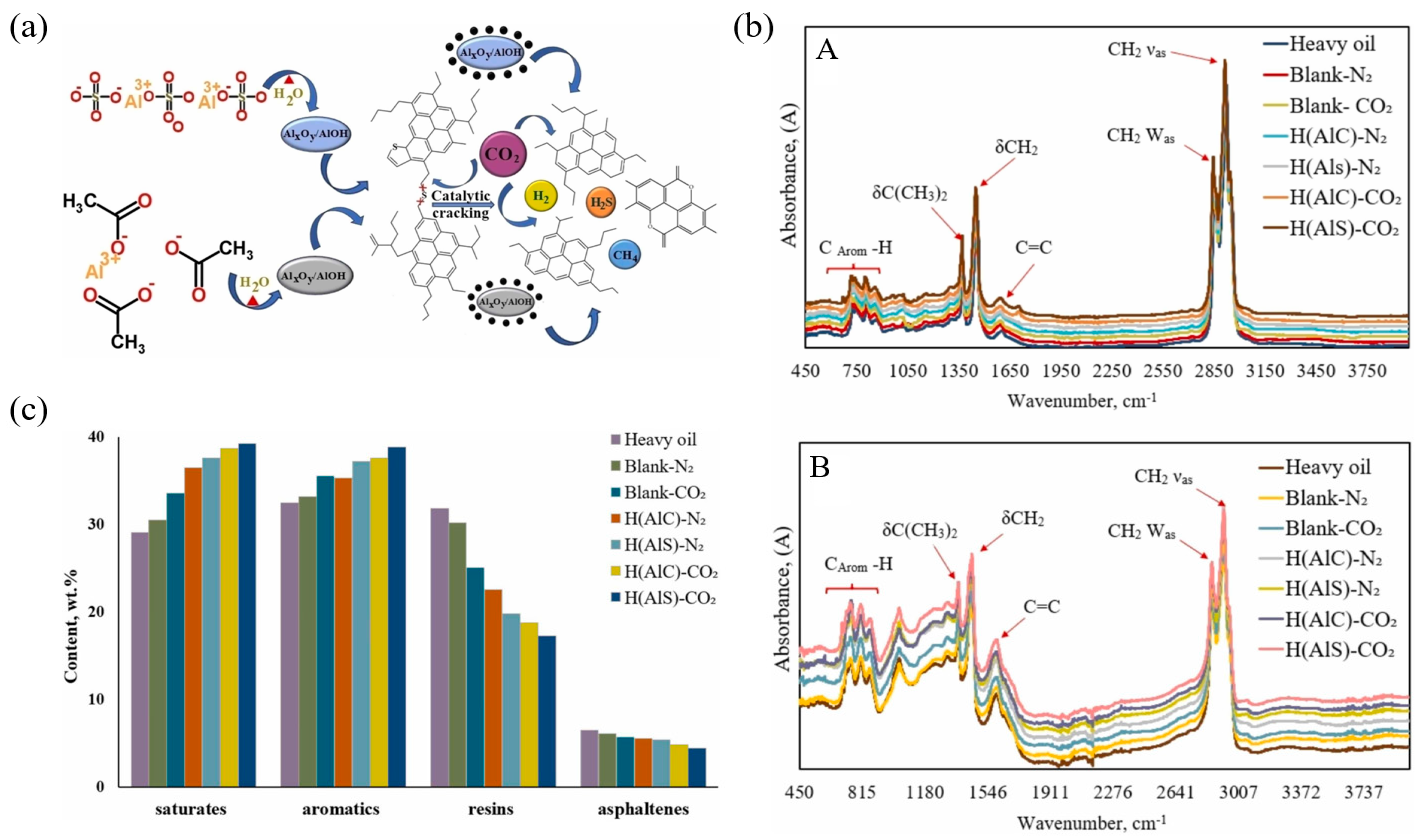

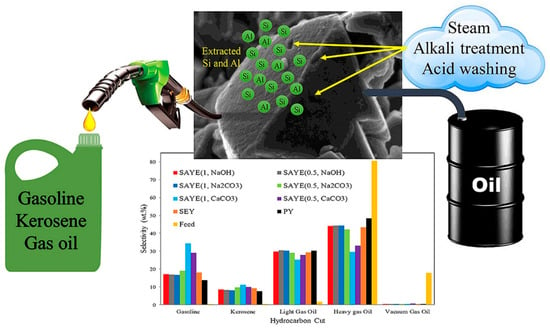

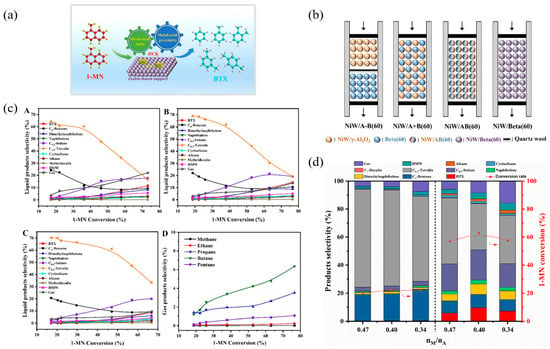

Figure 5 shows the modification of a Y-type zeolite catalyst by continuous steam, alkaline, and acid washing treatments to improve its catalytic performance in heavy oil cracking. The modification process aims to optimize the physicochemical properties of the catalyst by gradually adjusting the silicon–aluminum ratio, acid site distribution, and pore structure. The bar graph illustrates the selectivity effects of the catalysts treated with different alkaline reagents (such as NaOH, Na2CO3, and CaCO3) on various products (such as gasoline, kerosene, light gas oil, etc.), among which the CaCO3-modified catalyst shows better gasoline and kerosene yields. The modified Y-type zeolite catalyst shows higher light oil output efficiency and lower coke generation in heavy oil cracking, providing efficient technical support for heavy oil upgrading and petrochemical product optimization [61].

Figure 5.

Improving the physicochemical properties of Y zeolite for catalytic cracking of heavy oil via sequential steam–alkali–acid treatments [61]. Reproduced with permission from Erfan Aghaei et al., Microporous and Mesoporous Materials; published by Elsevier, 2020 [61].

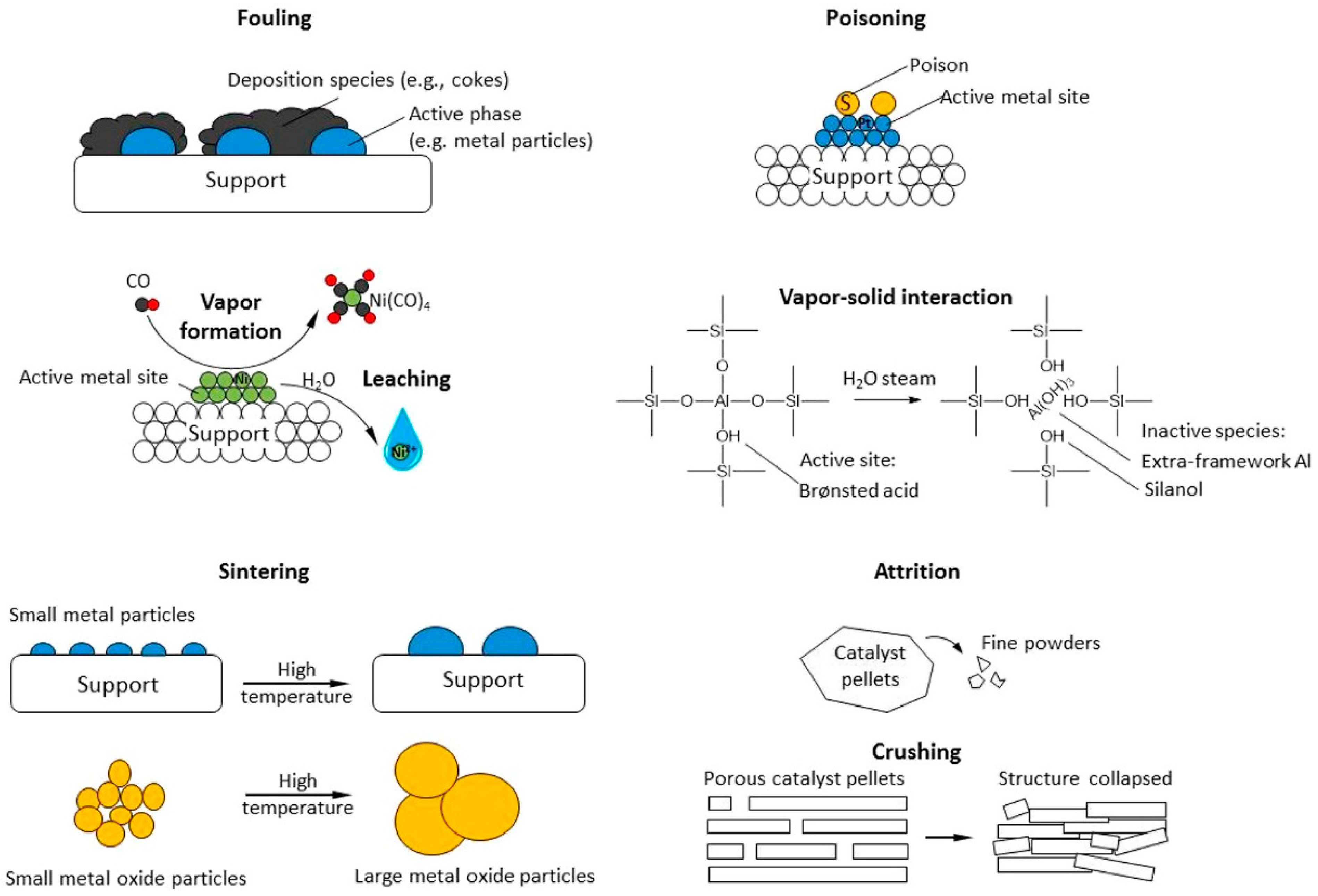

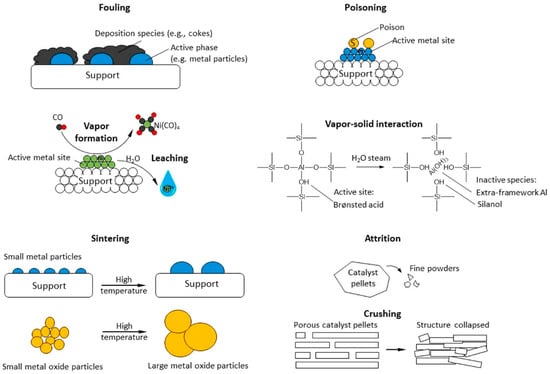

However, catalysts still face many challenges in the heavy oil cracking process: first, polycyclic aromatic hydrocarbons and asphaltene in heavy oil easily form coke on the catalyst surface, resulting in pore blockages and catalyst deactivation; second, metal impurities such as nickel and vanadium contained in heavy oil will react irreversibly with the catalyst, causing catalyst poisoning [62,63]. In response to these problems, researchers have improved the anti-coking and anti-metal poisoning properties of catalysts by introducing mesoporous structures, rare earth metal modification, and dealuminization treatment, thereby extending the service life of catalysts and improving catalytic efficiency. Figure 6 shows the typical mechanisms of heterogeneous catalyst deactivation, which mainly include the following categories: 1. Fouling: reactants or intermediates are deposited on the catalyst surface or in the pores, blocking active sites and affecting catalytic efficiency. 2. Poisoning: certain chemicals (such as sulfur or nitrogen compounds) are strongly adsorbed on the active sites of the catalyst, hindering the catalytic reaction. 3. Vapor Formation/Leaching: the active components in the catalyst react with gas or liquid to form volatile compounds or dissolve into the liquid phase, resulting in the loss of active substances. 4. Vapor–Solid Interaction: the active components in the catalyst react with vapor to form an inactive phase, resulting in reduced activity. 5. Thermal Degradation/Sintering: high temperature causes the catalyst surface or pores to shrink, reducing the active surface area. 6. Attrition/Crushing: mechanical wear or external force causes the catalyst particles to break and lose the internal active surface area. These deactivation mechanisms are important challenges in catalyst research and industrial applications. Studying their causes and mitigation measures is of great significance for improving the life and stability of catalysts. And in industrial practice, effectively slowing down these deactivation processes is also a major challenge—especially for high-acidity zeolite catalysts operating under non-hydrogenation conditions. Therefore, proper feedstock pretreatment (such as deasphalting or demetallization) is often necessary to maintain catalyst stability and prolong service life [62].

Figure 6.

Examples of heterogeneous catalyst deactivation mechanisms [62]. Reproduced with permission from Fan Lin et al., ACS Catalysis; published by American Chemical Society, 2022 [62].

3. Structure and Application of Zeolite Catalysts

Catalysts are the core of the heavy oil cracking process, and their performance directly determines the activity, selectivity, and stability of the reaction. Zeolite catalysts have significant advantages in heavy oil cracking due to their unique microporous structure and adjustable acidity [37,61]. The main functions of zeolite catalysts in heavy oil cracking include the following: providing evenly distributed acid sites, promoting the breakage and recombination of C-C bonds, and improving the selectivity of target products; improving the diffusion properties of heavy oil macromolecular hydrocarbons and reducing the occurrence of side reactions through pore structure optimization. In addition, the high thermal stability and resistance to metal poisoning of zeolite catalysts enable them to maintain high catalytic activity under high-temperature cracking conditions [15,61,64].

Zeolites are widely used as catalysts for cracking components [65,66,67,68]. The activity and selectivity for different fractions (natural gas, naphtha, kerosene, and diesel) depend on their acidity (including micropores and mesopores), which is directly related to the framework Si/Al ratio and the extra-framework Al content [66]. Most industrial applications of zeolites rely on BAS [69]. Therefore, many studies are devoted to determining the number, nature, and strength of acid sites and further studying the effect of acidity on catalytic activity [70,71,72,73]. Catalytic (hydro)cracking is an important type of acid-catalyzed reaction. The study of the effect of acid strength of zeolite catalysts on catalytic activity can guide actual industrial production and improve cracking efficiency, and has attracted widespread attention in the petrochemical field [74,75].

3.1. Structural Characteristics and Classification of Zeolites

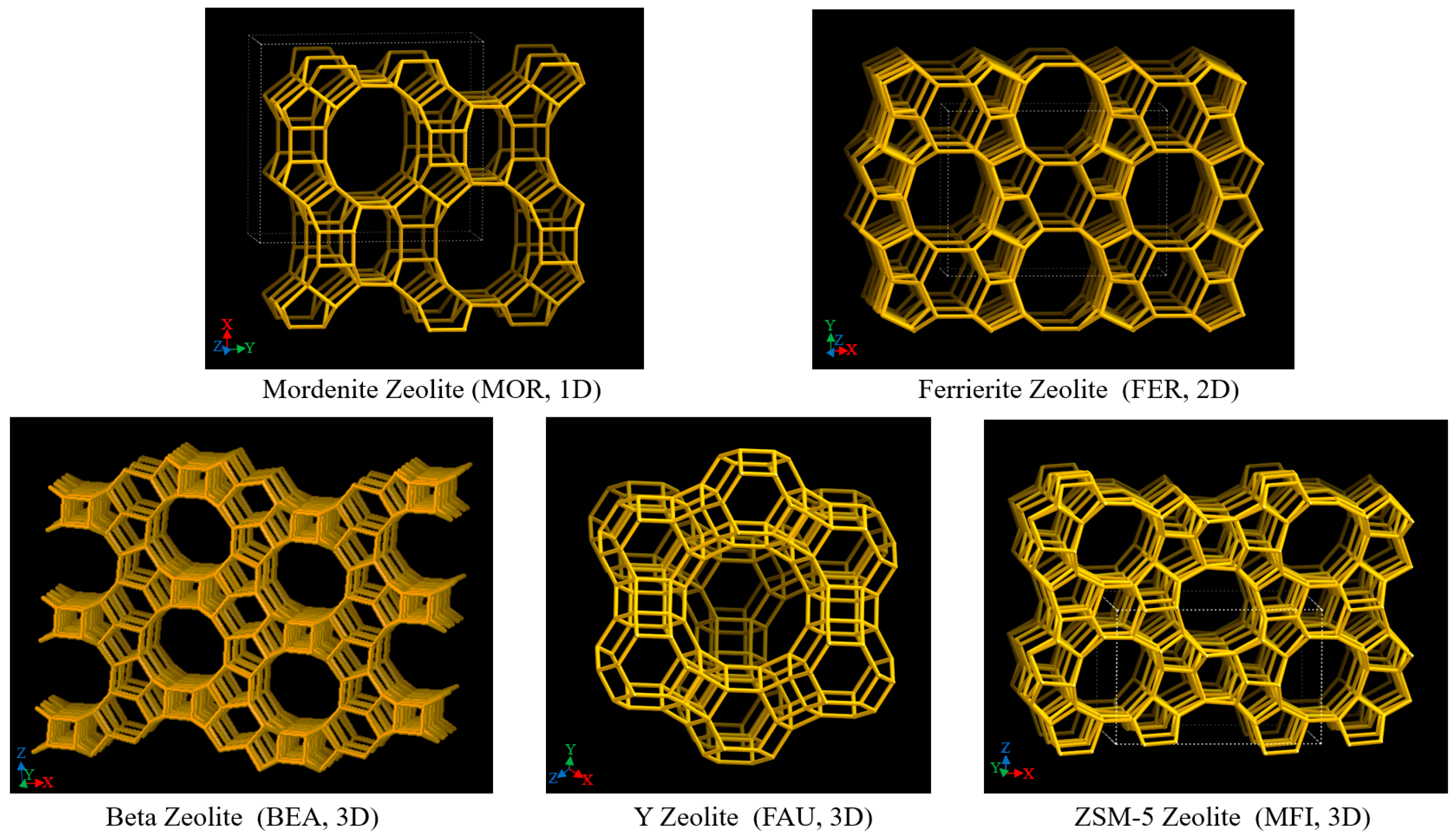

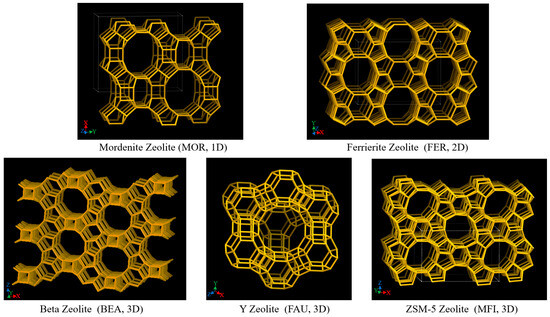

Zeolite is a type of aluminosilicate material with a regular microporous structure. Its skeleton structure is formed by a silicon–oxygen tetrahedron (SiO4) and aluminum–oxygen tetrahedron (AlO4) connected by oxygen bridge bonds. The structural characteristics of zeolite determine its unique catalytic performance, mainly including pore structure, acidity, and thermal stability [76,77]. According to the different pore dimensions, zeolite can be divided into one-dimensional, two-dimensional, and three-dimensional pore structures. These pores provide ideal space for the diffusion of reactant molecules and catalytic reactions. Schematic diagrams of one-dimensional, two-dimensional, and three-dimensional pore structures are shown in Figure 7 [78].

Figure 7.

Schematic diagram of one-dimensional, two-dimensional, and three-dimensional pore structures [78].

3.1.1. One-Dimensional, Two-Dimensional, and Three-Dimensional Pore Structures

Mordenite zeolite (MOR) is a typical representative of one-dimensional pore structure zeolites. Its pores are arranged linearly, and it has strong acidity and high stability, but its diffusion performance is limited [79,80]. This structure is suitable for cracking and isomerization reactions of long-chain alkanes, but it is easily affected by diffusion limitations during heavy oil cracking, which affects the reaction rate. In addition, due to the linear arrangement of the one-dimensional pores, after the reactant molecules react on the catalyst surface, the product discharge rate is slow, which makes it easy to induce side reactions, such as the formation of coke, thereby accelerating the deactivation of the catalyst [81].

Zeolites with two-dimensional pore structures, such as Ferrierite zeolite (FER), have a pore system composed of ten-membered straight pores and eight-membered cross-pores. This structure facilitates the transport of reactants and products, reduces diffusion resistance, and improves catalytic efficiency. The two-dimensional structure of FER zeolite provides a larger reaction space, improves the diffusion performance of large molecular hydrocarbons in the catalyst pores, and reduces the effect of diffusion limitation on the reaction rate. In the cracking of heavy oil and the hydrocracking of polycyclic aromatic hydrocarbons, FER zeolite exhibits high catalytic activity and good anti-deactivation performance. In addition, the pore structure and acidity distribution of FER zeolite can be further optimized through post-treatment and metal modification, thereby further improving its catalytic performance and stability [82,83].

Three-dimensional pore structures include Beta zeolite (BEA), Y-type zeolite (FAU), and ZSM-5 zeolite (MFI). These three types of zeolites show significant advantages in catalytic cracking reactions. The three-dimensional pore structure provides a larger diffusion space for the zeolite, reduces the diffusion resistance of reactants and products in the pores, and thus improves the catalytic efficiency [84]. Y-type zeolite has a supercage structure (12-membered ring), which provides a larger pore size and reaction space, and is suitable for cracking and recombination reactions of large molecular hydrocarbons, especially exhibiting excellent performance in the fluid catalytic cracking (FCC) process. ZSM-5 zeolite has excellent shape-selective catalytic performance due to its unique ten-membered ring pore structure and is suitable for the cracking and aromatization reactions of light hydrocarbons. Its high silicon–aluminum ratio gives it good hydrothermal stability, making it suitable for catalytic reactions under high-temperature conditions. In addition, Beta zeolite has a three-dimensional cross-12-membered ring macropore system with a large pore diameter (about 6.6 Å × 6.4 Å), which is conducive to the diffusion and transmission of large molecular hydrocarbons, thereby reducing diffusion limitations and improving catalytic efficiency. Beta zeolite is particularly suitable for heavy oil cracking and hydrocracking of polycyclic aromatic hydrocarbons. In addition, through post-treatment and metal modification, the acid distribution and pore structure of Beta zeolite can be further optimized, thereby enhancing its anti-deactivation performance and catalytic selectivity [85,86].

3.1.2. Common Zeolite Types and Their Applications in Heavy Oil Cracking

Zeolite catalysts are widely used in heavy oil catalytic cracking reactions due to their unique pore structure, adjustable acidity, and good thermal stability. Different types of zeolites have different structural characteristics and catalytic properties, showing significant advantages and challenges in the heavy oil cracking and upgrading process. Common zeolites mainly include Y-type zeolite, ZSM-5 zeolite, Beta zeolite, Ferrierite zeolite, and Mordenite zeolite. The comparison of the characteristics and applications of these five zeolites is shown in Table 4.

Table 4.

Comparison of properties and applications of five zeolites.

Y-Type Zeolite and Its Applications

As shown in Figure 7, Y-type zeolite is an important large-pore zeolite belonging to the FAU structure type, in which sodalite cages and hexagonal prism cages are arranged and connected according to the diamond structure, and multiple sodalite cages form a unique three-dimensional cavity structure, namely a supercage. The diameter of the supercage cavity is about 1.2 nm, and the supercages are connected to each other through a twelve-membered ring pore structure with a diameter of about 0.74 nm. Thanks to the large cavity and three-dimensional pores of Y-type zeolite, a variety of molecules can enter the supercage and react. Therefore, Y-type zeolite is an excellent solid–acid catalyst and is widely used in the field of petroleum refining [87]. Y-type zeolite can usually be synthesized by hydrothermal synthesis, hydrothermal conversion, and ion exchange. In addition, high-silicon–aluminum-ratio Y-type zeolite, heteroatom Y-type zeolite, and mesoporous Y-type zeolite have attracted much attention due to their higher stability, better stability and catalytic performance, and better transport performance, respectively [88].

The framework silicon–aluminum ratio of Y-type zeolite directly determines its acidic characteristics. Y-type zeolite with a low silicon–aluminum ratio contains a large number of BAS, which can effectively promote the breakage of C-C bonds in heavy oil, thereby improving the activity of the cracking reaction. However, strong acidity can also easily lead to coke formation, affecting the service life of the catalyst [89]. The acid distribution and strength of Y-type zeolite can be effectively regulated by dealumination treatment and rare earth metal ion exchange modification. For example, dealumination treatment can increase the silicon–aluminum ratio, reduce strong acid sites, and inhibit the formation of coke; rare earth modification can enhance the thermal stability of the acid center, thereby improving the stability and activity of the catalyst under high-temperature conditions [89,90].

Y-type zeolite is widely used in the fluidized catalytic cracking (FCC) process of heavy oil. Its supercage structure enables it to process large molecular hydrocarbons in heavy oil and produce high value-added products such as light oil and low-carbon olefins. In the FCC reaction, Y-type zeolite exhibits high activity, high selectivity, and good stability [87]. However, Y-type zeolite also faces some challenges in practical applications, such as catalyst deactivation, coke formation, and metal contamination [89]. Catalyst deactivation is mainly caused by coke deposition and heavy metal (such as Ni, V) contamination. The formation of coke is closely related to the acid strength of Y-type zeolite. Excessive acidity will lead to carbon cation polymerization and form coke that is difficult to remove. Metal contamination reacts with acid sites, resulting in poisoning of acid centers and decreased catalyst activity. Therefore, these problems can be effectively solved, and the service life of the catalyst can be extended by acidity regulation, rare earth metal modification, and the introduction of anti-metal contamination additives [90,91].

ZSM-5 Zeolite and Its Applications

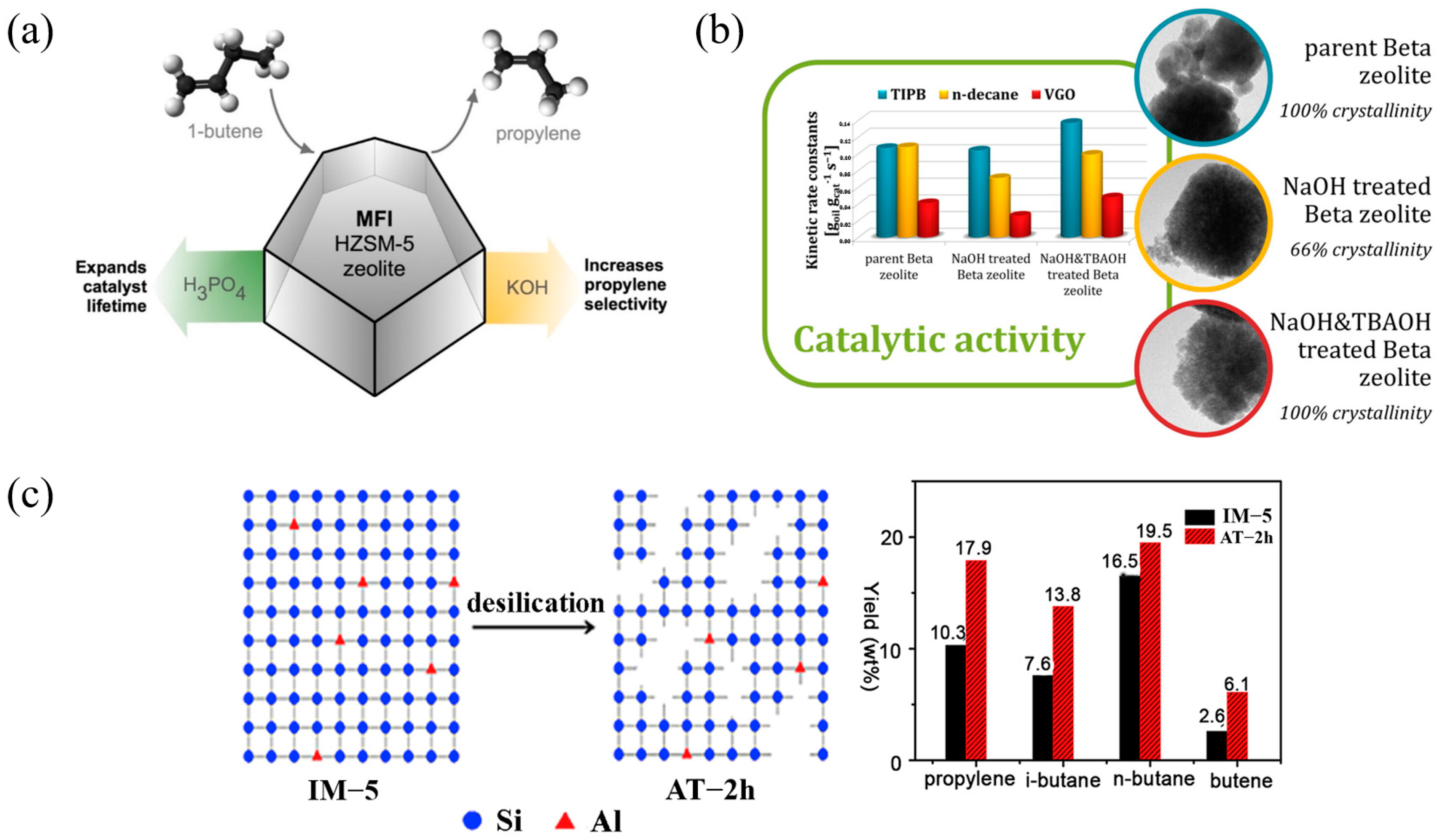

As shown in Figure 7, ZSM-5 zeolite belongs to the MFI structure type and has a unique ten-membered ring pore structure with a pore size of about 0.55 nm, presenting a three-dimensional pore system. This structure gives ZSM-5 zeolite excellent shape-selective catalytic performance, enabling it to effectively improve the selectivity of light olefins and aromatics in heavy oil cracking reactions. Since its pore size is close to the diameter of small molecular hydrocarbons, ZSM-5 zeolite has unique advantages in light hydrocarbon cracking and aromatization reactions, and is particularly suitable for highly selective catalysis of target products [92]. In addition, the high silicon–aluminum ratio of ZSM-5 zeolite gives it good hydrothermal stability, which can maintain structural integrity under high-temperature conditions and is suitable for high-temperature catalytic cracking reactions [37]. In addition, the acidic characteristics of ZSM-5 zeolite are mainly determined by the silicon–aluminum ratio in the framework. High silicon–aluminum ratio ZSM-5 has weaker acidity, which is suitable for selective catalytic reactions and reduces the occurrence of side reactions. The microporous structure of ZSM-5 zeolite is suitable for the generation of small molecular products but has certain limitations on the diffusion of large molecular hydrocarbons. To solve this problem, researchers have introduced mesoporous structures through post-treatment methods such as alkali treatment to improve the diffusion properties of reactants and products, thereby increasing the overall activity of the catalyst [93].

Due to its excellent shape-selective catalytic performance, ZSM-5 zeolite exhibits high activity and selectivity in the cracking reaction of long-chain alkanes. In the cracking process of long-chain alkanes, ZSM-5 zeolite can promote the uniform breaking of C-C bonds to produce high value-added products such as low-carbon olefins and aromatics. However, the strong acid sites of ZSM-5 zeolite may lead to side reactions and promote the formation of coke, thereby affecting the stability and service life of the catalyst. In order to improve this problem, the formation of coke can be effectively reduced by regulating the acid strength, introducing metal additives (such as Pt, Ni), and optimizing the pore structure, further improving the conversion rate and selectivity of long-chain alkane cracking, and extending the service life of the catalyst [94,95].

Beta Zeolite and Its Applications

As shown in Figure 7, Beta zeolite belongs to the *BEA structure type and has a three-dimensional cross-porous macroporous structure with a pore size of about 0.66 nm. This structure not only facilitates the diffusion and transport of macromolecular hydrocarbons, but also gives Beta zeolite good catalytic performance, making it particularly suitable for the cracking and hydrogenation of polycyclic aromatic hydrocarbons and macromolecular hydrocarbons. Beta zeolite exhibits high catalytic efficiency in heavy oil hydrocracking, which is beneficial for improving the yield of light oil products [96]. In addition, Beta zeolite has high acidity and strong thermal stability, which enables it to exhibit excellent catalytic performance under high-temperature conditions.

Polycyclic aromatic hydrocarbons are important components of heavy oil and have a highly stable structure that is difficult to crack under normal conditions. Beta zeolite, with its three-dimensional large pore structure and strong acidity, can effectively promote the cracking reaction of polycyclic aromatic hydrocarbons to produce light oil products and low-carbon olefins [96]. By regulating the acid distribution and pore structure of Beta zeolite through metal loading and post-treatment modification, its catalytic performance, catalytic selectivity, and anti-deactivation ability can be further improved, while effectively reducing coke formation and extending the service life of the catalyst [97].

Ferrierite Zeolite and Its Applications

As shown in Figure 7, Ferrierite zeolite belongs to the FER structure type and is a zeolite with a two-dimensional pore structure. It has a unique ten-membered ring straight pore (pore diameter of about 0.54 nm) and an eight-membered ring cross pore (pore diameter of about 0.42 nm), forming a dual-pore system. The unique pore structure of Ferrierite zeolite gives it excellent shape-selective catalytic performance, which can effectively and selectively catalyze small molecular reactants and perform well in isomerization reactions and light hydrocarbon conversions, but it has certain obstacles to the diffusion of large molecular hydrocarbons and polycyclic aromatic hydrocarbons [98,99].

Ferrierite zeolite is widely used in reactions such as light hydrocarbon isomerization and long-chain alkane conversion due to its unique pore structure and strong acidity. In light hydrocarbon isomerization, Ferrierite zeolite exhibits excellent shape-selective catalytic performance and can effectively promote the isomerization reaction of straight-chain alkanes to generate branched alkanes to increase the octane number. For example, Ferrierite zeolite exhibits high activity and selectivity for the isomerization of n-butene, while inhibiting the formation of by-products [100]. In the conversion of long-chain alkanes, Ferrierite zeolite exhibits good diffusion performance and thermal stability in the cracking reaction of long-chain alkanes and is suitable for the production of high-value-added products such as light olefins and aromatics. In addition, by introducing precious metal additives such as Pt and Pd, Ferrierite zeolite can be endowed with hydrogenation function, further improving the efficiency of the cracking reaction and the yield of the target product [101].

Although Ferrierite zeolite performs well in isomerization and alkane conversion, it still faces some challenges, such as pore diffusion limitation, catalyst deactivation, and metal contamination. Pore diffusion can be improved by alkali treatment or template-assisted synthesis of mesoporous structures to improve the diffusion efficiency of reactants and products. The catalyst’s anti-deactivation ability can be enhanced by adding metal additives and anti-coking technology, and the catalyst’s stability and durability can be improved. Green synthesis technology can be achieved by promoting environmentally friendly solvents and renewable templates, and sustainable synthesis and application of Ferrierite zeolite can be achieved [102].

Mordenite Zeolite and Its Applications

As shown in Figure 7, Mordenite zeolite belongs to the MOR structure type, has a one-dimensional linear pore structure, a pore size of about 0.65 nm, and has strong acidity. Due to its unique pore structure, Mordenite zeolite has high activity in heavy oil cracking and hydrocarbon isomerization reactions [103]. However, due to its relatively linear pore structure and poor diffusion performance, it is easy for reactants and products to be retained in the pores, affecting the catalytic efficiency.

Mordenite zeolite exhibits excellent catalytic performance in the isomerization and cracking reactions of long-chain alkanes. Its strong acid sites can effectively promote the breaking of C-C bonds to generate high-octane isohydrocarbons and low-carbon olefins. However, its strong acidity can also easily cause coke formation, resulting in catalyst deactivation [81]. However, by introducing mesoporous structures, rare earth metal ions, and other post-treatment methods, the diffusion properties, pore structure, acid distribution, and anti-coke formation ability of Mordenite zeolite can be improved, thereby improving its catalytic performance and stability in heavy oil cracking reactions [104,105].

In general, Y-type zeolite, ZSM-5 zeolite, Beta zeolite, Ferrierite zeolite, and Mordenite zeolite have their own characteristics and have different application advantages in different catalytic cracking reactions. Y-type zeolite and Beta zeolite are suitable for processing large molecular hydrocarbons in heavy oil and are widely used in cracking and hydrogenation reactions. ZSM-5 zeolite has outstanding performance in the generation of low-carbon olefins and aromatics due to its excellent shape-selective catalytic performance. Ferrierite zeolite and Mordenite zeolite are more suitable for the selective catalytic reaction of small molecules and long-chain alkanes. Different zeolites have differentiated application values in heavy oil cracking due to their unique pore structure and acidic characteristics. By rationally selecting and modifying these zeolites, the catalyst performance can be optimized, and the target product can be efficiently produced for different heavy oil components and reaction conditions.

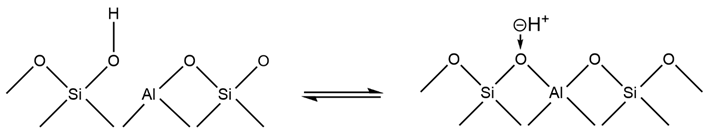

3.2. Acidic Characteristics of Zeolites

The acidity of zeolites comes from Brønsted acid sites (BAS) and Lewis acid sites (LAS). BAS are formed by the combination of framework aluminum atoms and protons and can provide protons to participate in catalytic cracking reactions. LAS are mainly derived from extra-framework aluminum or metal cations and can accept electron pairs. The acidity strength, acid site distribution, and pore structure of zeolites directly affect their catalytic performance. The two acid sites, BAS and LAS, generally work synergistically to jointly determine the catalytic activity, selectivity, and stability of zeolites. The strength, quantity, distribution, and type of zeolite acidity are closely related to its silicon–aluminum ratio, framework structure, and subsequent modification methods. The regulation of zeolite acidity is an important way to optimize catalytic performance and adapt to different reaction conditions. For the complex reaction process of heavy oil cracking, the rational regulation of acid characteristics can not only help improve the selectivity of the target product, but also inhibit the formation of side reactions such as coke [106].

3.2.1. Brønsted Acid Sites (BAS) and Lewis Acid Sites (LAS)

There are two main sources of zeolite acidity. One is the BAS formed by the combination of framework aluminum atoms and hydroxyl groups, which can donate protons to the outside. The other is the LAS formed by cations outside the framework or unsaturated aluminum atoms on the framework, which can accept external electron pairs. BAS and LAS can be converted into each other under certain conditions.

BAS are negatively charged sites generated by the aluminum–oxygen tetrahedrons in the zeolite framework, which are formed by combining with protons (H+). These acid sites are mainly distributed in the micropores of zeolites and are one of the most important active centers in catalytic cracking reactions. BAS provide protons to protonate hydrocarbon molecules in heavy oil to form highly active carbon cations. This intermediate is unstable and will rapidly undergo cracking or recombination reactions to produce target products such as light oil products and low-carbon olefins [107]. At the same time, the lower the silicon–aluminum ratio of the zeolite, the higher the aluminum content in the framework, and the greater the number of BAS. However, too many acid sites will lead to overreaction, increase the probability of side reactions, and ultimately generate a large amount of coke, which will block the pores of the zeolite and reduce the activity and life of the catalyst [108]. Katsuki et al. [109] used NH3 infrared mass spectrometry and programmed temperature desorption (TPD) technology to study the acid strength of in situ-prepared HNaY zeolite [Si/Al = 2.55, NaNH4Y (96% NH4+/4% Na+)] and found that NH3 molecules were adsorbed at the -O2H position, while ammonium ions (NH4+) were formed at the -O1H, -O3H, and -O4H positions, and that the formation of NH4+ was more favorable than the adsorption of NH3 molecules from an energetic point of view. Dedecek et al. [110] found that Al/Si substitution reduced the 29Si chemical shift of the nearest neighbor Si atom and increased the 27Al chemical shift of the next nearest neighbor Al atom (NNN-Al), while the effect of more distant Al/Si substitution on acid strength was not obvious. Huang et al. [111] found, based on the cluster model at the BLYP/DNP level, that the order of acid strength of the acidic sites determined by the alkaline probe molecules (NH3 and pyridine) is different from the order of the intrinsic acid strength (OH deprotonation energy), and that the alkaline probe molecules generally tend to adsorb on the acidic sites in the supercage.

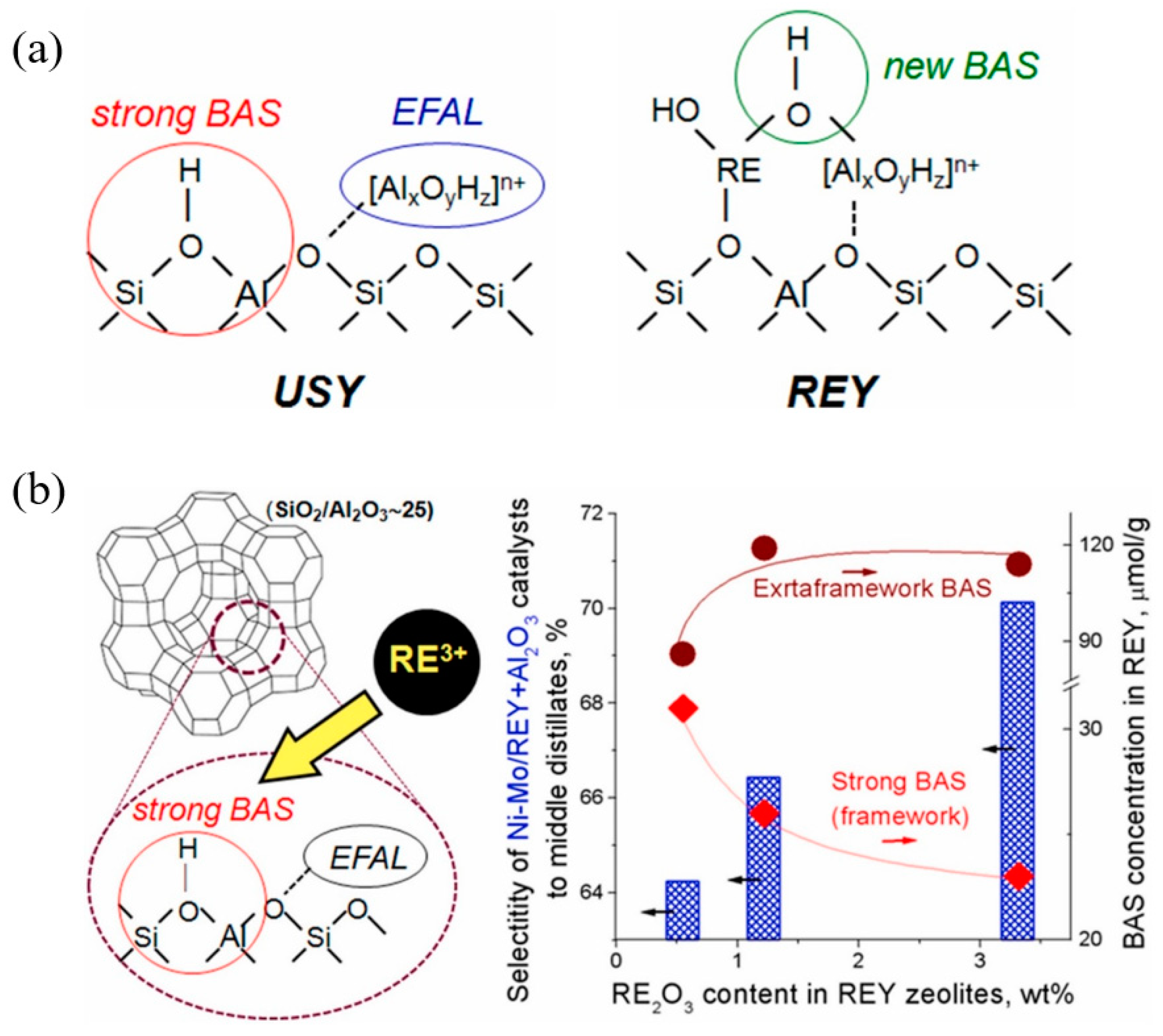

LAS are mainly formed by non-framework aluminum or exchange cations, such as metal ions, defect sites generated by dealumination treatment, etc. The characteristic of LAS is that they can accept electron pairs, especially playing a key role in hydrocracking and isomerization reactions. In particular, in zeolites modified by metal ion exchange, LAS can synergize with metal active centers to promote the occurrence of hydrogenation reactions. For example, when metals such as Ni, Mo, and Pt are introduced into zeolites, LAS can achieve hydrogenation ring-opening reactions of polycyclic aromatic hydrocarbons in the presence of these metals, significantly reducing the content of unsaturated components in the product and improving the quality and yield of light oil products [112].

In addition, BAS and LAS can be converted into each other under certain specific zeolite modification conditions. For example, through metal ion exchange or high-temperature calcination, some BAS will be converted into LAS. This acidity regulation can optimize the activity and selectivity of the catalyst to meet the needs of different reaction conditions [113].

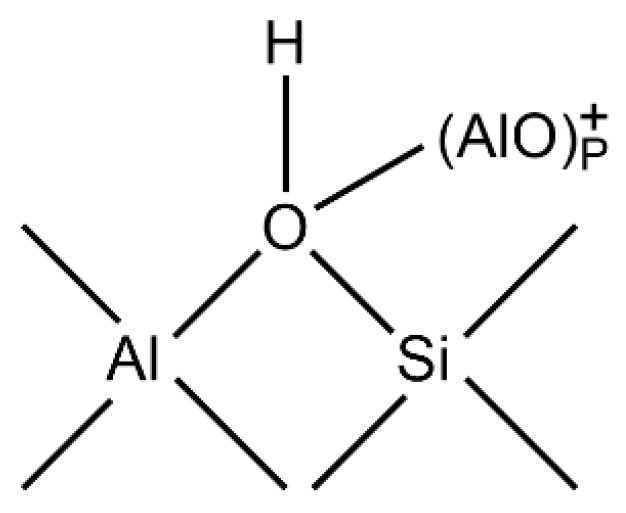

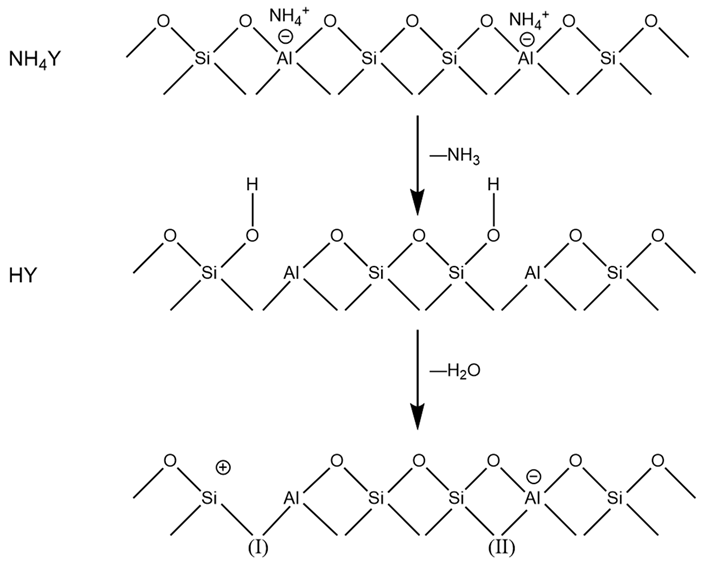

People have long recognized that the acidity of zeolites is affected by their structure—that is, the distribution of Al. The aluminum content of zeolites can be controlled by post-synthesis treatment (such as dealumination) or by changing the synthesis conditions. The following uses HY zeolite as an example to introduce the formation of acid sites and intrinsic catalytic performance of Y-type zeolites.

The OH group of HY zeolite is the acid center and can be expressed by the following equilibrium formula:

When the temperature rises, the equilibrium of the above formula moves to the right, resulting in a decrease in the number of OH groups, so the intensity of its infrared band decreases. When the temperature is above 770 K, LAS centers begin to appear, which are associated with tri-coordinated aluminum atoms and are formed by further dehydration of H-Y.

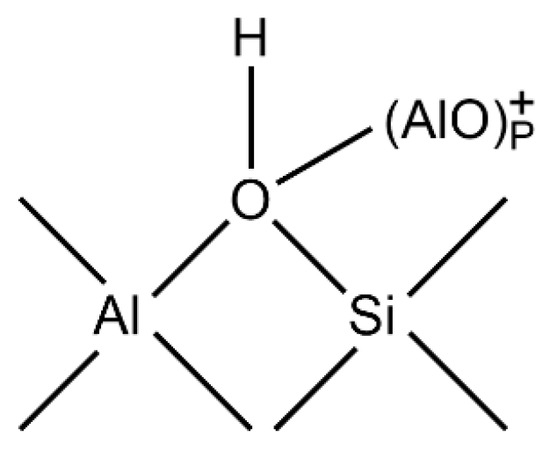

The extra-framework aluminum ions will strengthen the acid sites and form LAS center, as shown in Figure 8:

Figure 8.

Schematic diagram of the structure of extra-framework aluminum ions.

Multivalent cations may also produce OH acid sites, such as [Ca(OH2)]2+ → [Ca(OH)]+ + H+.

Reduction in transition metal ions can also form acid centers, such as Cu2+ + H2 → Cu0 + 2H+ and Ag+ + 1/2H2 → Ag0 + H+.

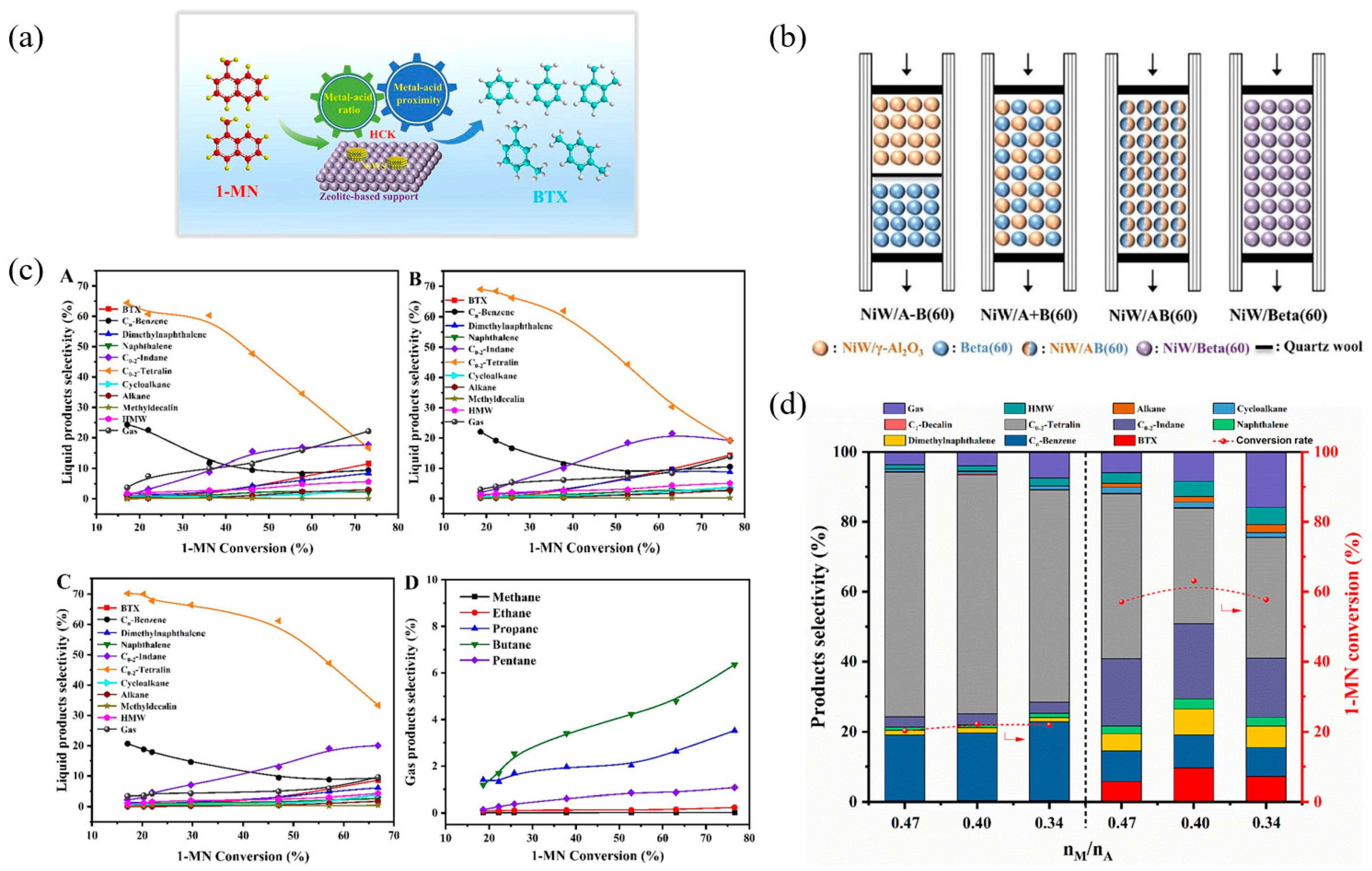

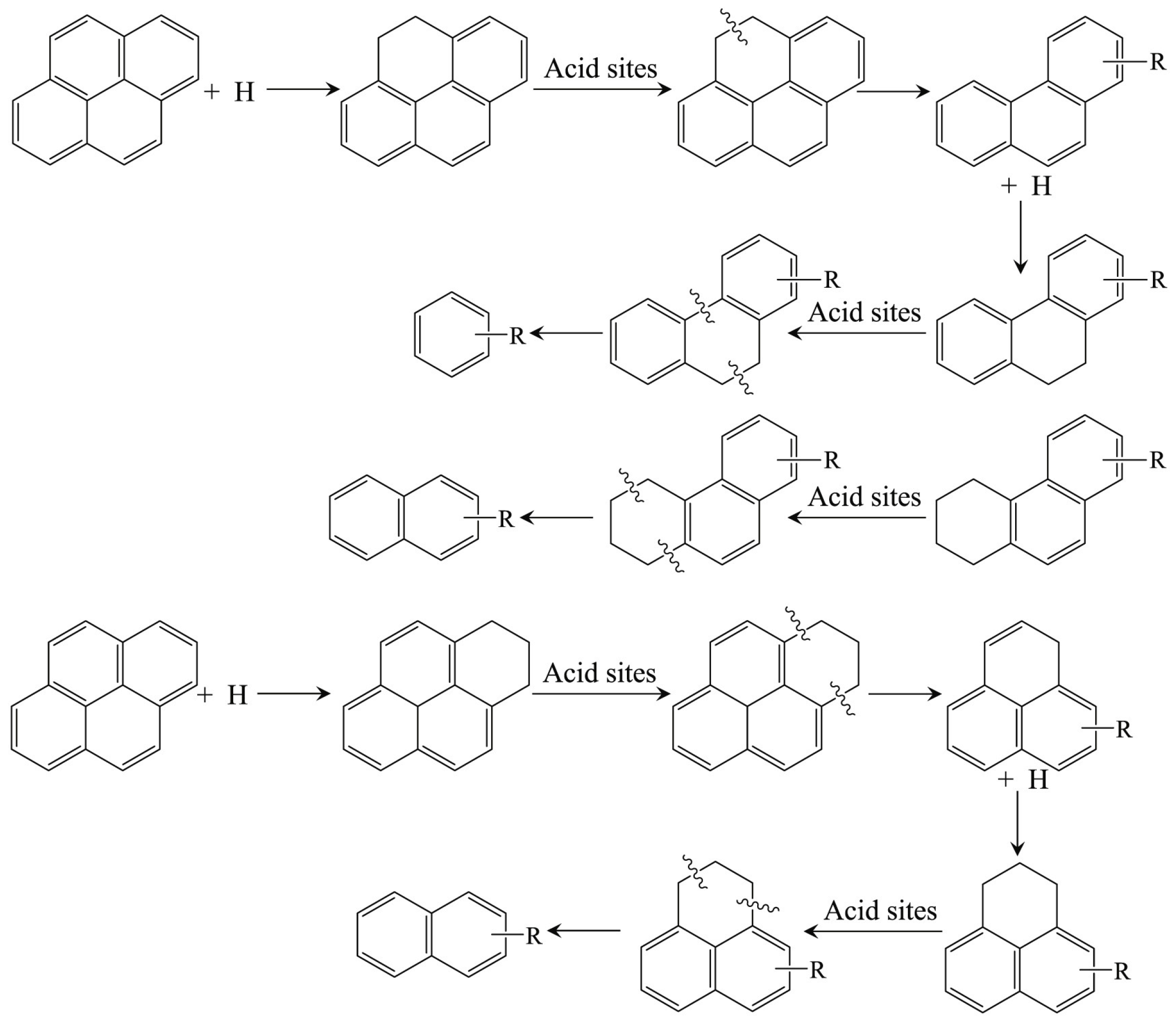

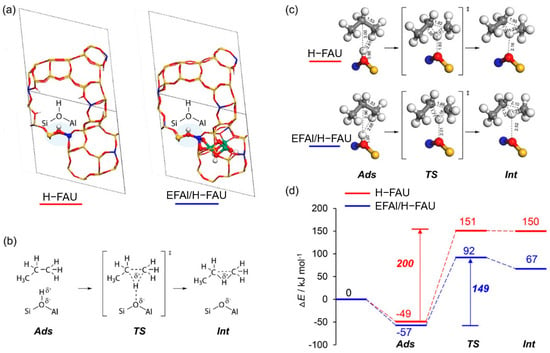

3.2.2. Effect of Acidity on Catalytic Performance

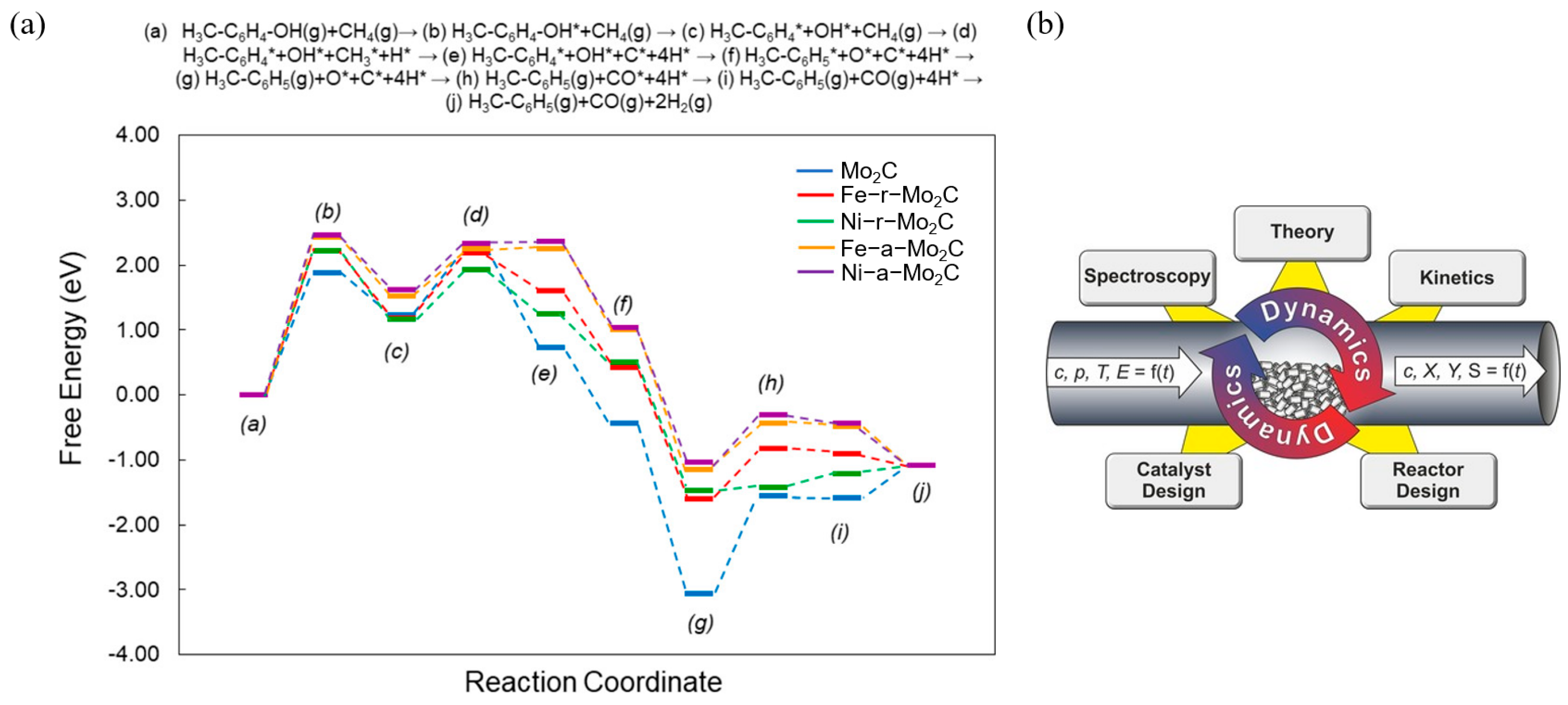

Hydrocracking catalysts are typically bifunctional, combining metal hydrogenation sites with zeolite acidic sites to enable the breaking and transformation of heavy hydrocarbon molecules. The Brønsted acid sites (BAS) in zeolites play a vital role in facilitating C-C bond cleavage and determining product distribution [7,114,115]. Arribas et al. [116] demonstrated that the BAS acidity of Pt/USY zeolite significantly influenced both the yield and selectivity in the ring-opening hydrogenation of 1-methylnaphthalene. Dealuminated forms such as HTY and HTY-Al were superior to NaY and HY zeolites in producing light aromatics due to their optimized acid strength and wider pore size distribution [117]. Additionally, Lemberton et al. [118] found that the cleavage of the saturated central ring in dihydrophenanthrene may occur through an acidic mechanism. These studies highlighted the significant effect of zeolite acidity on hydrocracking catalytic activity, which was confirmed by similar studies by other researchers [10,119,120,121].

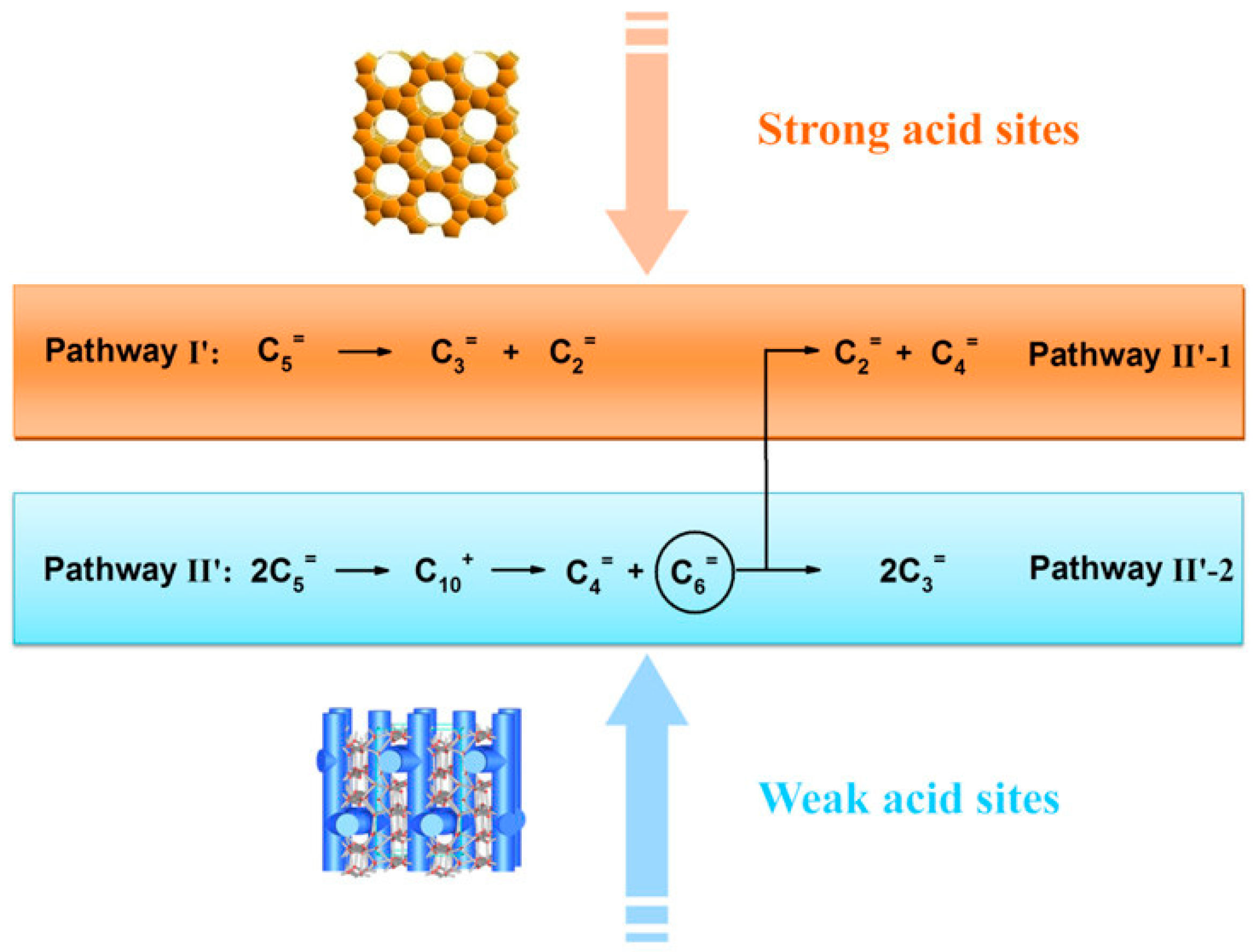

A key parameter affecting catalytic activity in alkane cracking is the framework aluminum content, which directly determines the number and strength of acid sites. Studies have shown that increasing framework Al in Y-type zeolite or ZSM-5 correlates with increased catalytic activity for cracking hexane and isobutane [122,123,124,125,126]. Moreover, acid strength influences not only activity but also the selectivity of products like light olefins [127,128]. For example, Bai et al. [129] established the relationship between the reaction pathway of naphtha catalytic pyrolysis and catalyst acid strength, showing that reducing BAS acidity suppresses secondary reactions of light olefins—such as hydrogen transfer, oligomerization, cyclization, and aromatization—and significantly enhances light olefin yield. Similarly, Zhai et al. [130] investigated n-hexane catalytic pyrolysis over HZSM-5 and found that both the Si/Al ratio and catalyst-to-oil ratio positively correlated with propylene selectivity, while lower acid density favored unimolecular cracking. In line with these findings, Xue et al. [131] employed 1-hexene cracking as a probe reaction to evaluate the acid site distribution in Sn-modified ZSM-5, demonstrating that tailored Al siting and acid strength significantly influence cracking pathways and the selectivity of hydrocarbon products.

However, overly strong acidity can accelerate side reactions including coke formation and excessive cracking, particularly in the processing of heavy oils rich in polycyclic aromatics and long-chain alkanes. This leads to rapid catalyst deactivation due to pore blockage. Therefore, regulating the strength, amount, and distribution of acidity is crucial to maintain catalyst efficiency, selectivity, and longevity [89].

To address this, several strategies have been proposed: Increasing Si/Al ratio: reduces acid strength, suppresses coke formation, and enhances selectivity—commonly applied in Y-type zeolites via dealumination [89]. Acid or alkali post-treatment: acid leaching removes framework aluminum, moderating strong acid sites and improving metal tolerance; alkali treatment creates mesoporosity, reducing diffusion barriers and enhancing activity [93]. Metal ion exchange and heteroatom introduction: rare earth metals like La or Ce, and noble metals such as Pt and Pd, can stabilize acid centers and improve resistance to deactivation. Acid site distribution optimization: achieved through nanocrystallization or mesoporous engineering to reduce side reactions and improve product selectivity [91,132]. In summary, the tailored regulation of acidity—through structural modification, post-treatment, and metal loading—is fundamental to optimizing the catalytic performance of zeolites for complex reactions such as heavy oil cracking and hydrocracking.

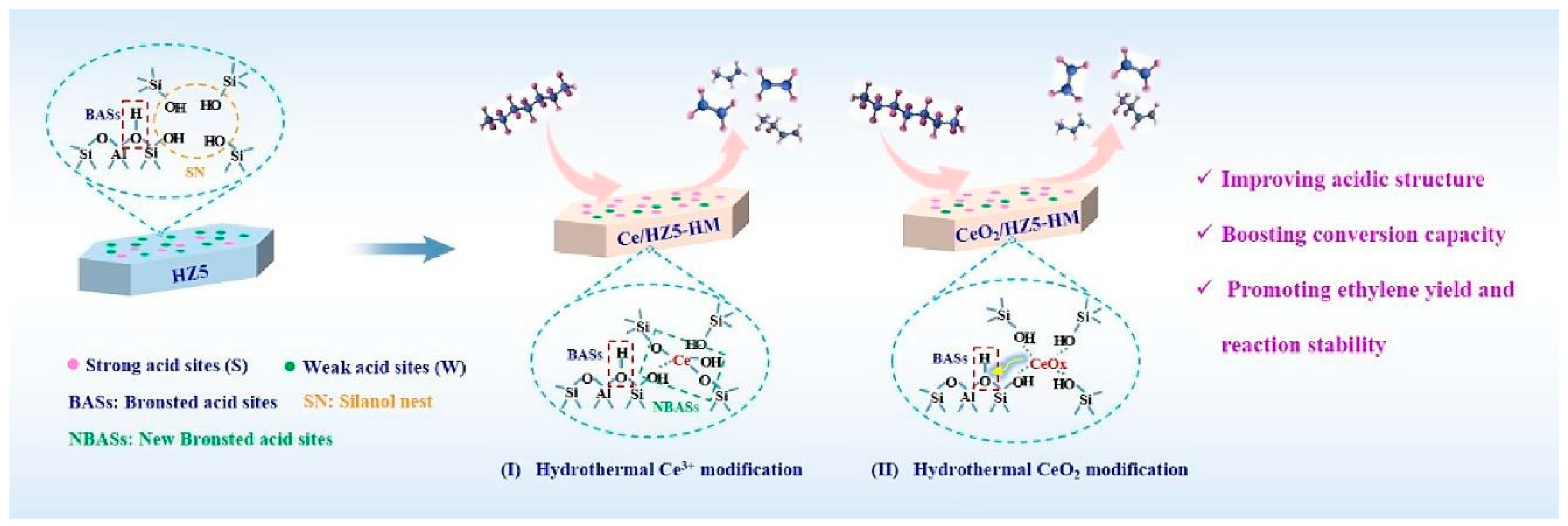

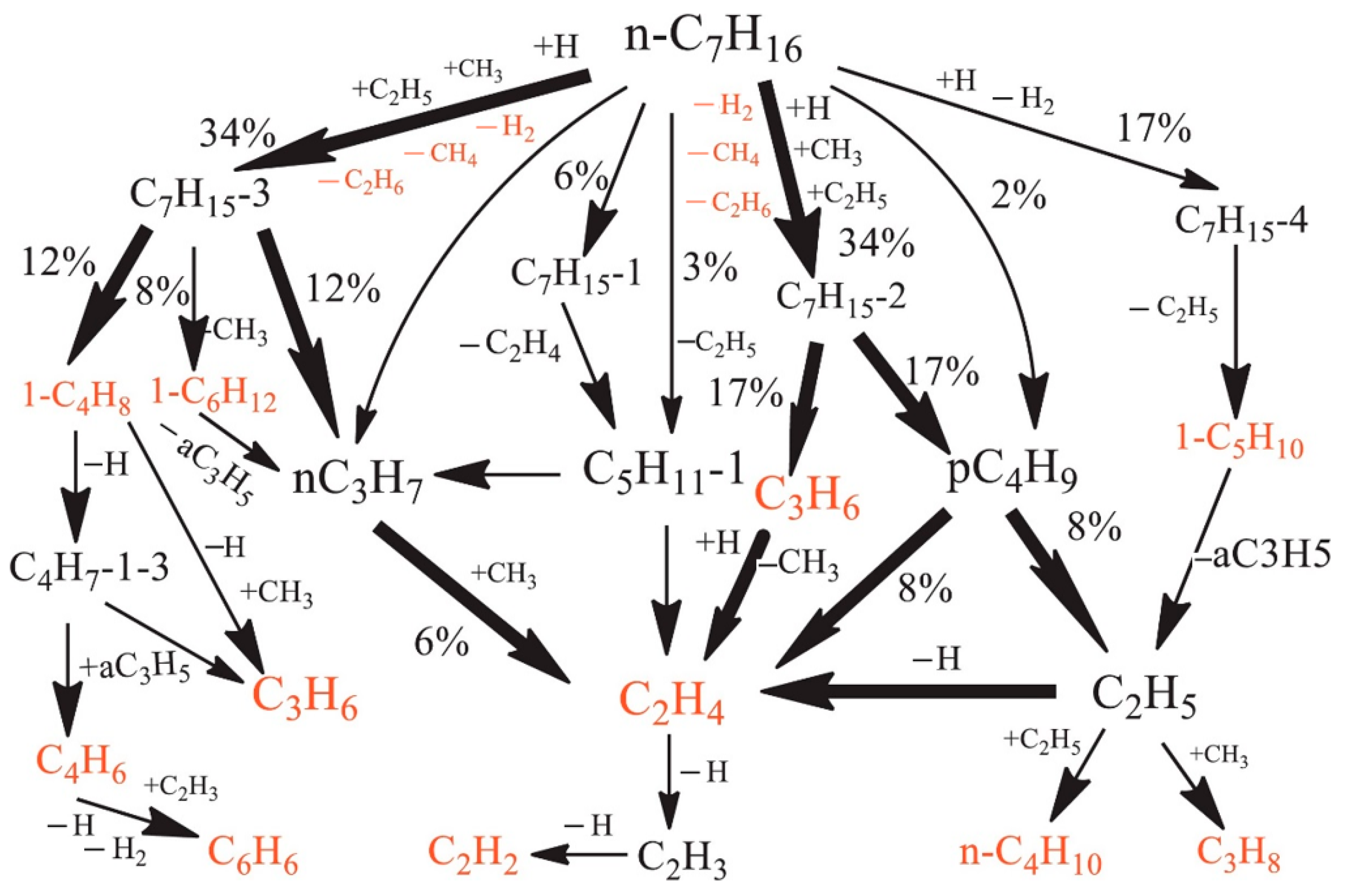

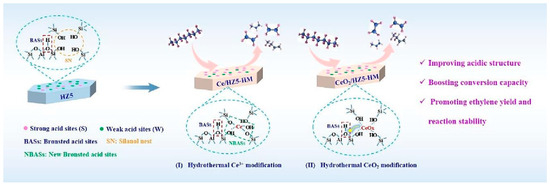

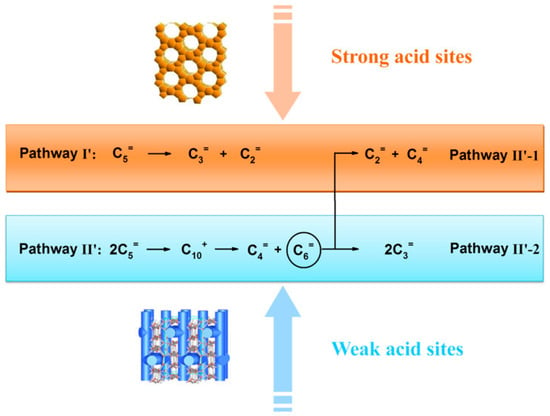

Figure 9 shows the improvement of catalytic performance after rare earth cerium (Ce) modification of HZSM-5 zeolite by the hydrothermal method. Two modification methods are shown in the figure, namely 1. Ce3+ modification: Ce3+ ions interact with silanol groups (Si-OH) on the surface of zeolite to generate new BAS and repair defective sites in zeolite. This modification method significantly enhances the acid strength and acid density of the catalyst. 2. CeO2 modification: CeO2 clusters are introduced into the pore structure of zeolite to form stable CeOx clusters. These clusters further enhance the acid stability of zeolite and the stability of the framework structure. Both modification methods can significantly improve the selectivity of HZSM-5 zeolite for ethylene (C2H4) and propylene (C3H6) in the catalytic cracking reaction of n-heptane, as well as the reaction stability. At the same time, the modified catalyst has a lower coke deposition rate, which prolongs the service life of the catalyst. These modified catalysts significantly increased the yield of light olefins in the cracking reaction by optimizing the strong acid/weak acid and BAS/LAS (B/L) ratios and improved the catalyst stability and resistance to deactivation [106].

Figure 9.

Hydrothermally Ce-modified HZSM-5 zeolite enhancing its strong acidity and BAS/LAS ratio: stably boosting ethylene/propylene ratio for cracking n-heptane [106]. Reproduced with permission from Qi Liu et al., Fuel; published by Elsevier, 2024 [106].

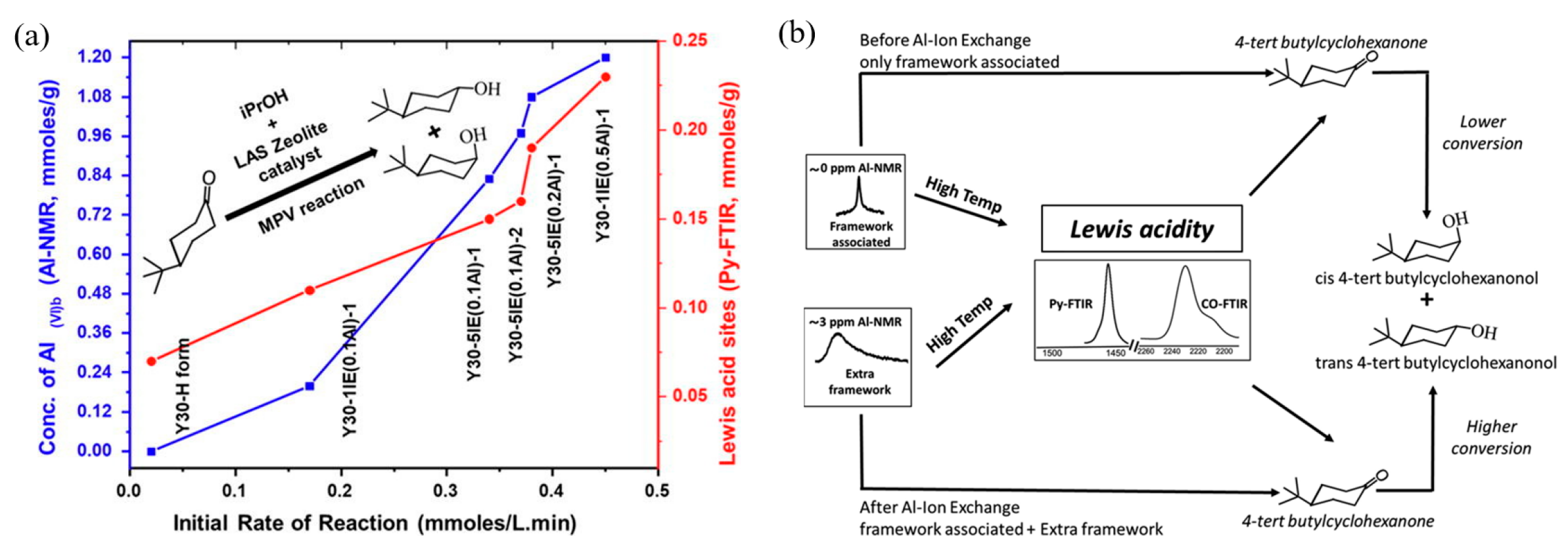

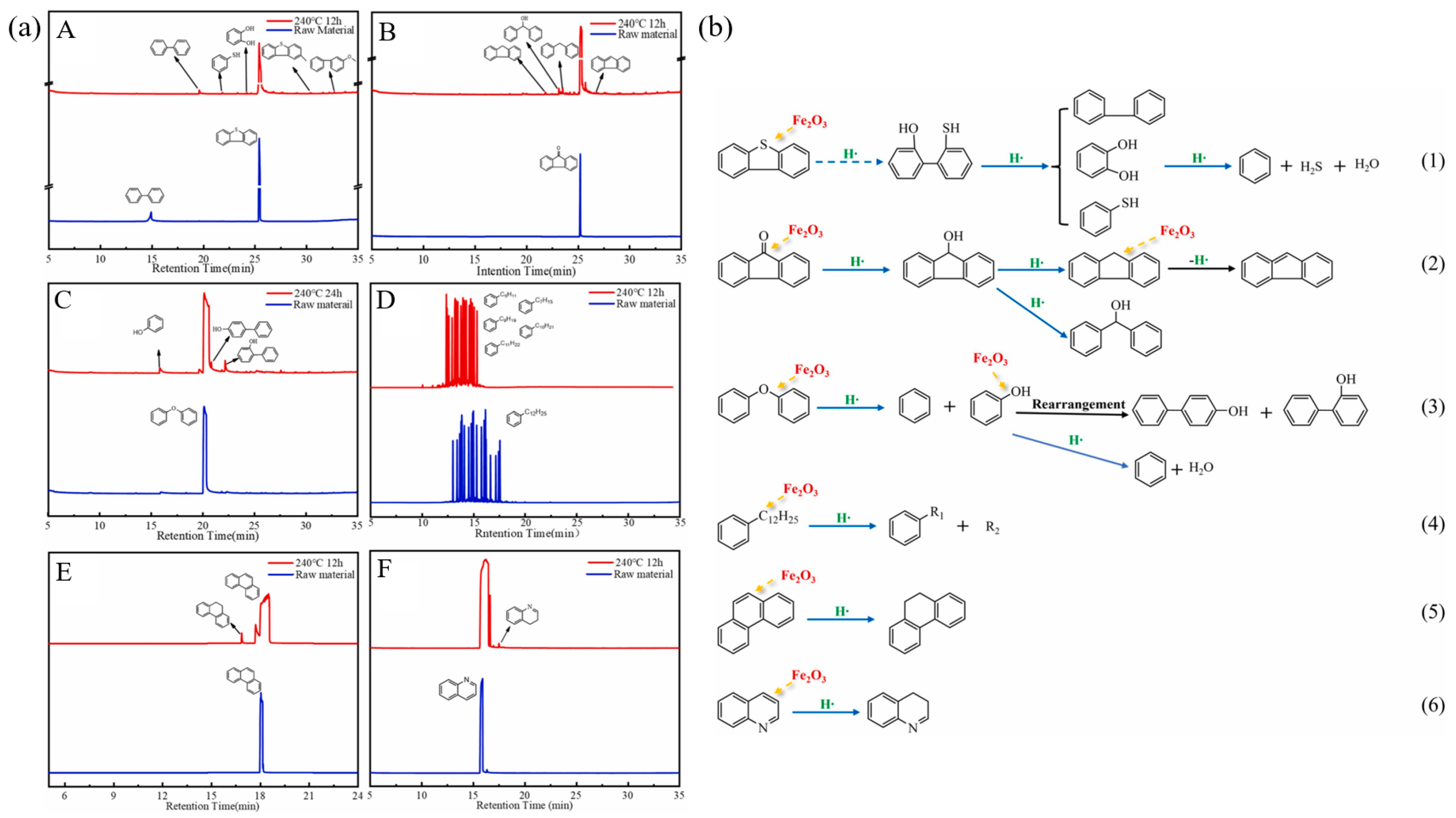

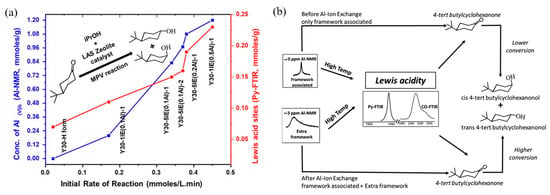

Figure 10a depicts the correlation between the catalytic performance of modified Y zeolite catalysts in the Meerwein–Ponndorf–Verley (MPV) reaction and the LAS concentration. The red line in the figure represents the LAS concentration (measured by pyridine-FTIR), while the blue line represents the initial rate of the reaction. As the concentration of extra-framework aluminum (EFAl) in the catalyst increases, the LAS concentration increases significantly, and at the same time, the reaction rate also increases synchronously, indicating the key role of LAS in the reaction. Isopropyl alcohol (iPrOH) and ketone compounds (such as 4-tert-butylcyclohexanone) are catalyzed by LAS to produce alcohols (such as 4-tert-butylcyclohexanol) through MPV reaction. This improvement in catalytic performance is mainly attributed to the extra-framework aluminum species introduced into the catalyst after ion exchange, which significantly enhance the LAS acidity of the catalyst. The figure further indicates that the generation of these extra-framework aluminum species is achieved through simple aluminum ion exchange, which does not destroy the zeolite framework and significantly improves the LAS catalytic activity, providing potential high-efficiency catalysts for important industrial reactions such as fluid catalytic cracking (FCC) and biomass conversion. Figure 10b shows the mechanism of LAS acidity induced by aluminum species in different coordination states before and after ion exchange. Before ion exchange, the framework-associated aluminum (Al(VIa)) of Y zeolite mainly exists in octahedral coordination, and these aluminum species provide the basis for the formation of LAS. After ion exchange, the LAS acidity is further increased by introducing additional extra-framework aluminum (Al(VIb)). These extra-framework aluminums mainly exist in the form of neutral aluminum oxide or aluminum hydroxide clusters, indicating that their octahedral coordination structure has strong catalytic activity. Aluminum ion exchange not only increases the number of LAS, but also retains the original BAS. This feature optimizes the acid distribution of the catalyst, thereby significantly enhancing the catalytic performance. In addition, the figure shows that after appropriate ion exchange, the zeolite structure remains intact, which lays the foundation for its application in catalytic reactions with high activity and stability. These modified LAS show high reaction rates and efficiencies in catalytic reactions including the Meerwein–Ponndorf–Verley (MPV) reduction reaction. In this way, aluminum can be introduced into Y zeolite through a simple post-treatment process, thereby developing more efficient LAS catalysts [113].

Figure 10.

(a) Correlating the concentration of extra-framework Al(VIb) species to catalytic rate of reaction and total content of LAS obtained from pyridine-probed FTIR quantitative analysis; (b) summary of results illustrating aluminum species in different coordinations responsible for LAS acidity before and after aluminum ion-exchange [113]. Reproduced with permission from Syeda R. Batool et al., Journal of Catalysis; published by Elsevier, 2022 [113].

3.2.3. Catalytic Performance of Low-Acidity Aluminosilicates

While zeolites with strong acidity are widely used for heavy oil cracking due to their high activity, they also suffer from rapid deactivation caused by coke formation and sensitivity to metal impurities. In this context, low-acidity aluminosilicates have emerged as promising alternatives, particularly for processing feeds with high concentrations of heteroatoms and heavy metals. These materials—such as amorphous silica-alumina (ASA), mesoporous Al-MCM-41, and other low-crystallinity aluminosilicates—exhibit moderate acidity that allows sufficient catalytic activity for cracking reactions while greatly enhancing resistance to coke deposition and deactivation.

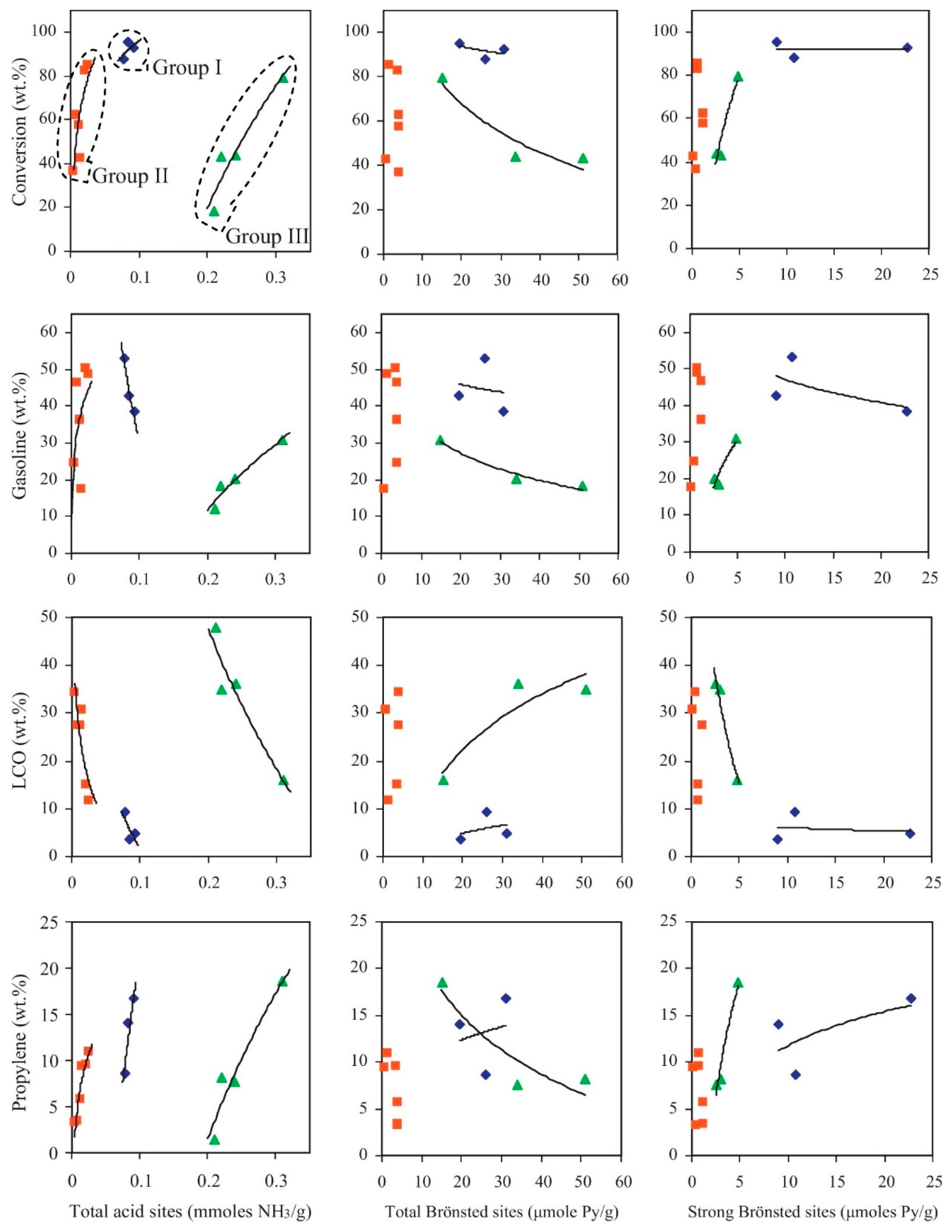

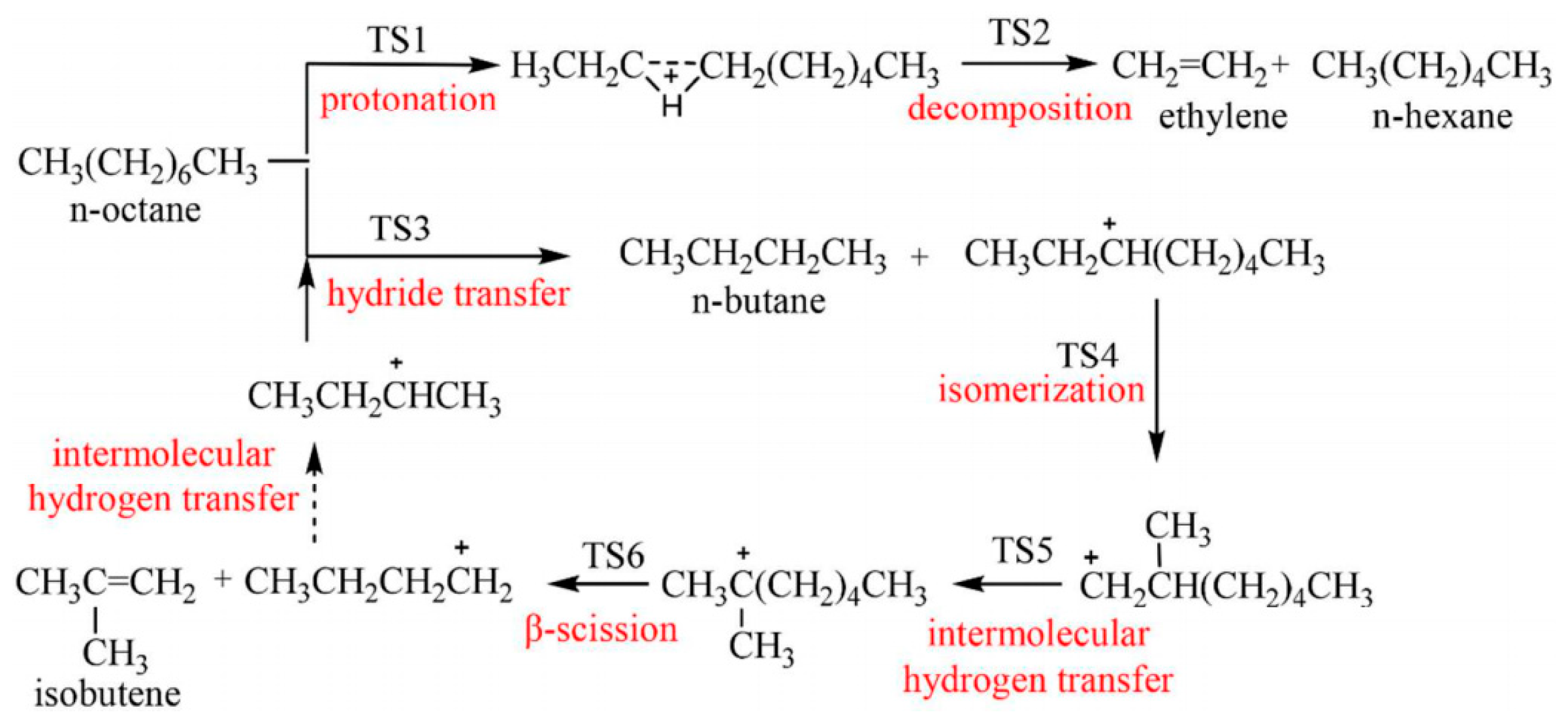

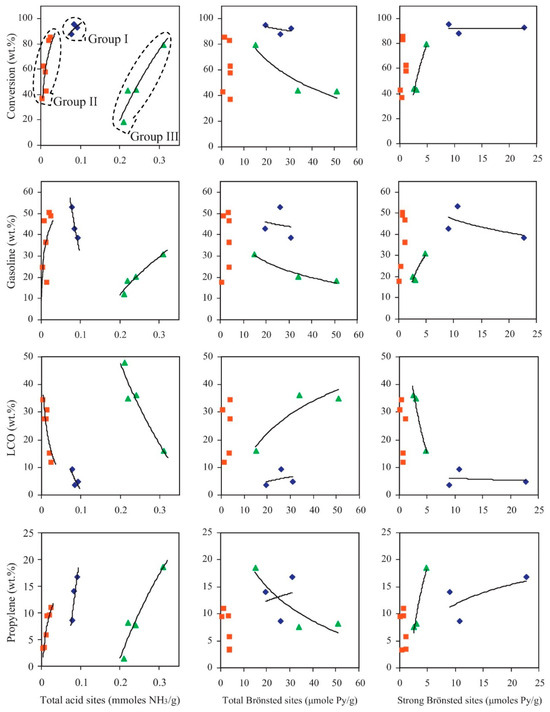

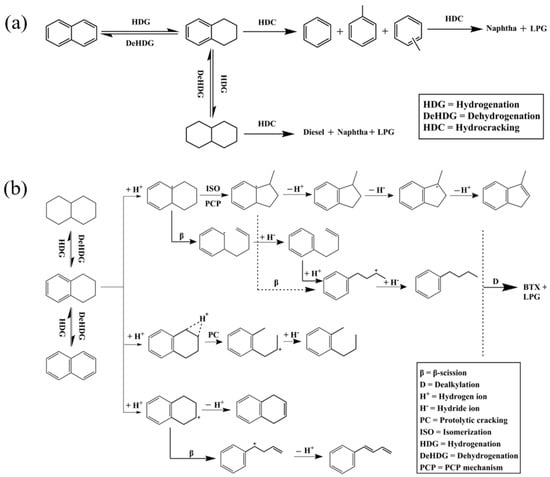

Figure 11 illustrates the relationship between the acidic properties and pore structures of various zeolitic and mesoporous aluminosilicate catalysts, and their influence on the conversion and product distribution during Fischer–Tropsch (F-T) wax cracking. The catalysts are classified into three groups. Group 1 includes freshly calcined zeolites such as H-Y, H-ZSM-5, and H-Beta, characterized by high acidity and crystallinity. These catalysts demonstrate high F-T wax conversion rates and significant gasoline yields, along with a notable proportion of light olefins. Group 2 consists of severely steamed zeolites (e.g., metal-modified steam-treated types), which undergo partial dealumination, leading to reduced BAS acidity. Despite this, they maintain considerable cracking activity, with a product distribution that favors light olefins and light cycle oil (LCO). Group 3 encompasses low-crystallinity or amorphous mesoporous materials such as low-crystallinity ZSM-5, amorphous Beta-derived structures, ordered mesoporous materials (such as Al-MCM-41), and commercial amorphous silica–alumina (ASA). Although these materials exhibit weaker acidity, their large pore structures enhance diffusion of bulky hydrocarbon molecules and reduce deactivation. They tend to favor LCO formation and suppress excessive secondary cracking, highlighting their advantages in scenarios where product selectivity and catalyst stability are prioritized over maximum conversion. Overall, Figure 11 underscores that both acid strength and pore architecture are critical factors influencing catalytic efficiency and product selectivity in F-T wax upgrading processes [89].

Figure 11.

Correlation between F–T wax conversion and product yields with the acidic properties of the various zeolitic and mesoporous aluminosilicate catalytic materials (group I: fresh-calcined zeolites H-Y, H-ZSM-5, and H-Beta; group II: severely steamed zeolites (including the metal modified steamed zeolites); group III: 3% crystalline ZSM-5-based, amorphous Beta-based, ordered mesoporous Al-MCM-41, and commercial ASA catalyst) [89]. Reproduced with permission from V.G. Komvokis et al., Catalysis Today; published by Elsevier, 2012 [89].

Notably, Yang et al. [133] found that the acidity distribution of aluminosilicate catalysts is largely governed by the Si/Al ratio, and catalysts with increased porosity and reduced acidity exhibited lower coke deposition during lignin pyrolysis. Another notable development involves embedding alumina into HZSM-5 to create mesoporous matrices with moderate acidity, enhancing thermal stability and improving conversion of bulky bio-oils [134]. In addition, Hou et al. [135] reported that acid-modified kaolin, a natural aluminosilicate, exhibited promising performance in the upgrading of coal pyrolysis volatiles, offering a cost-effective and thermally stable alternative to traditional zeolites, which are often limited by high cost and coke deposition.

Overall, low-acidity aluminosilicates represent a valuable class of materials in the evolving landscape of catalytic systems for heavy oil upgrading, offering a trade-off between activity and operational stability. Their role is particularly pronounced in integrated petrochemical refining systems aiming for longer cycle life and cleaner fuel production.

3.3. Synthesis and Modification of Zeolites

The synthesis and modification of zeolites are key means to improve their catalytic performance, mainly including hydrothermal synthesis methods, post-treatment and modification methods, as well as metal ion exchange and heteroatom introduction. By regulating the structure, acidity, and stability of zeolites, their application performance in reactions such as catalytic cracking and hydrocracking can be significantly improved to meet the needs under different reaction conditions. The synthesis and modification methods of zeolites are summarized in Table 5, revealing the optimization effects and applicable scenarios of different methods. Dealumination and metal ion exchange are essential for improving the thermal stability and heavy oil conversion performance of catalysts, while alkali treatment and heteroatom introduction can significantly improve the diffusion performance of macromolecules and product selectivity. The combined application of these modification strategies can achieve precise regulation of catalyst performance according to industrial needs, thereby meeting production requirements under different reaction conditions.

Table 5.

Summary of zeolite synthesis and modification methods.

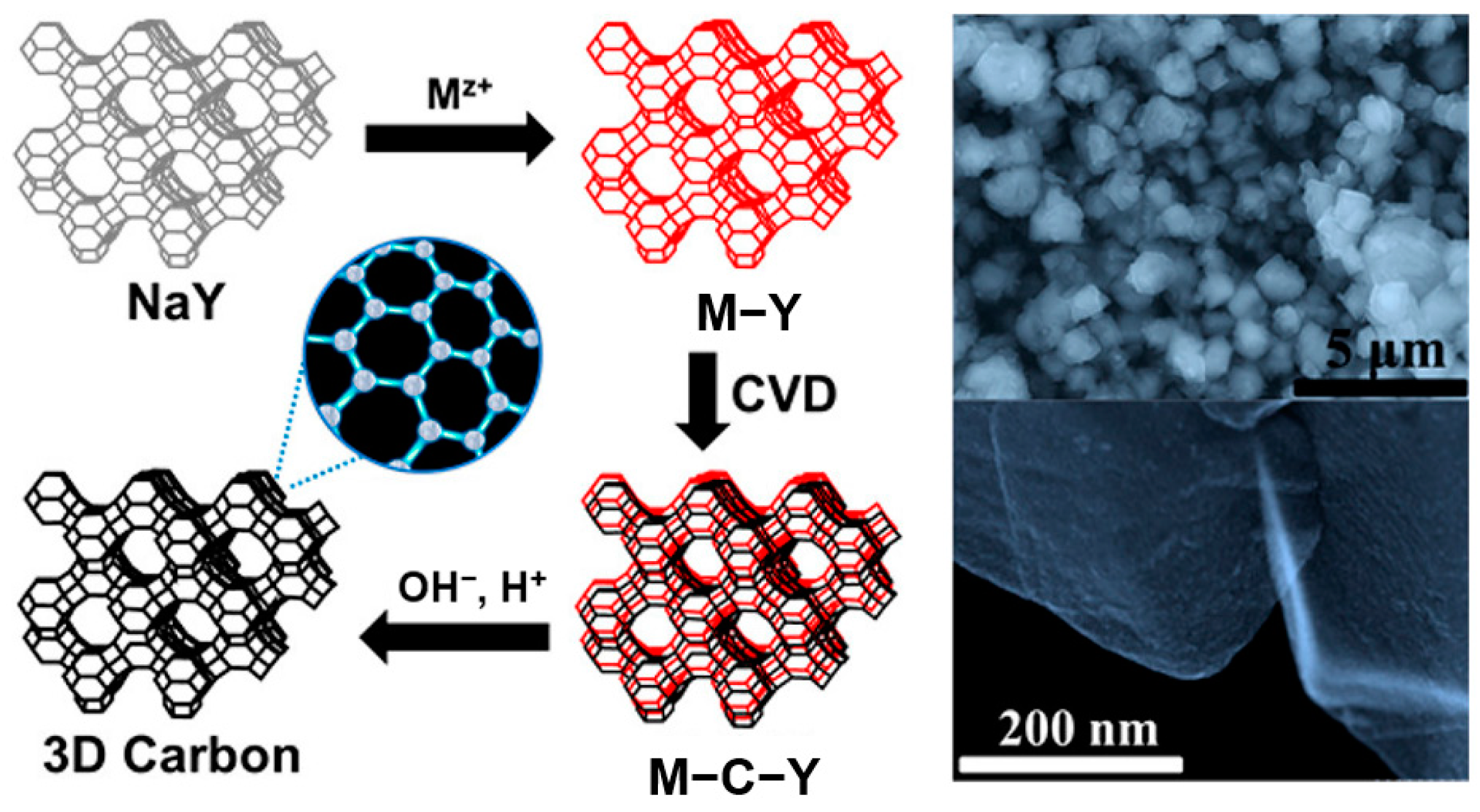

3.3.1. Hydrothermal Synthesis Method

The hydrothermal synthesis method is a classic method for preparing zeolites and is widely used to synthesize different types of zeolites, such as Y-type, ZSM-5, Beta, etc. This method uses a silicon source (such as silica sol, sodium silicate), an aluminum source (such as sodium aluminate, aluminum sulfate), a template (such as tetrapropylammonium hydroxide), and an alkali source (such as sodium hydroxide, potassium hydroxide) to undergo a crystallization reaction under high-temperature and high-pressure conditions to form a zeolite material with a regular pore structure [136,137].

During the hydrothermal synthesis process, multiple factors have an important influence on the structure and properties of zeolites. First, the reaction temperature is an important parameter for controlling the crystallization rate and crystal size of zeolites. Too high a temperature may lead to excessive crystal growth and increased pore structure defects; too low a temperature may delay the crystallization process and affect the purity and crystallinity of the product [138]. Secondly, the pH value has a significant effect on the formation of the silicon–aluminum ratio of the zeolite framework. Under alkaline conditions, it is conducive to the introduction of framework aluminum to form zeolites with high aluminum content, but too high an aluminum content may lead to uneven acidity distribution. In addition, the silicon–aluminum ratio is an important factor in regulating the acidity of zeolites. Zeolites with a high silicon–aluminum ratio have lower acid strength and are suitable for catalytic reactions with lower acidity requirements [139].

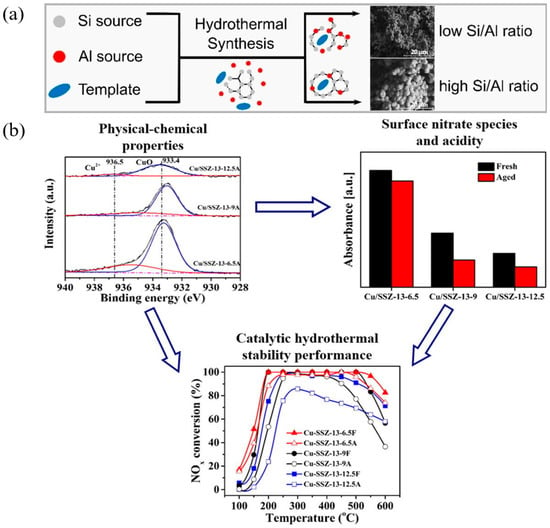

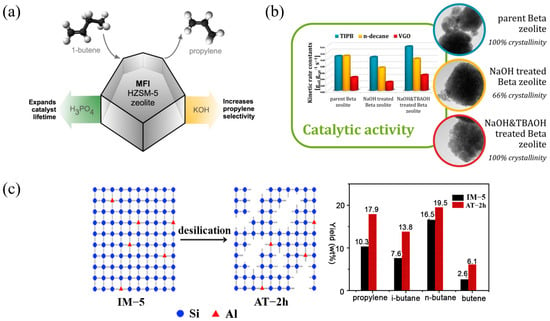

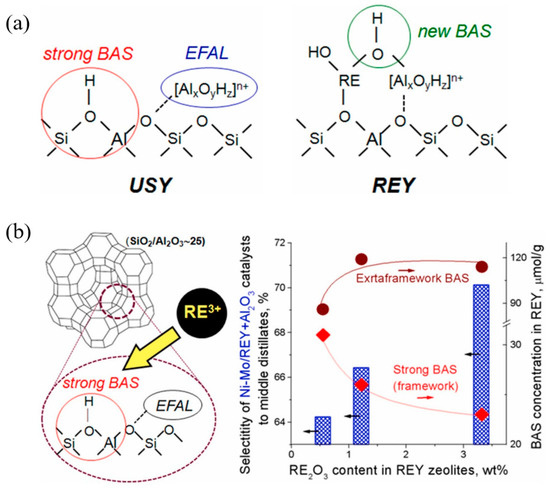

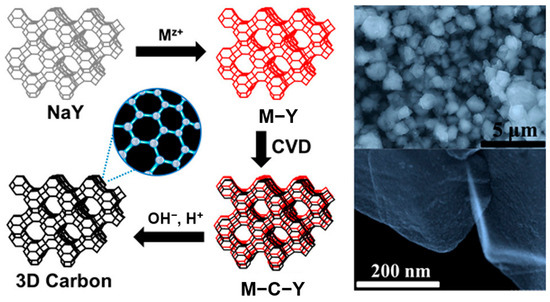

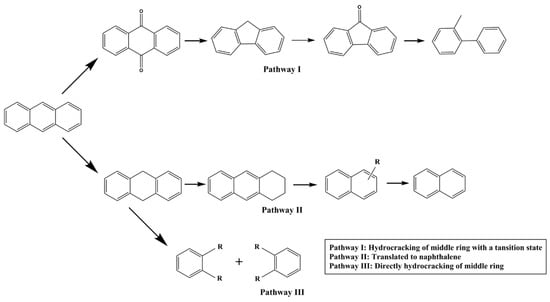

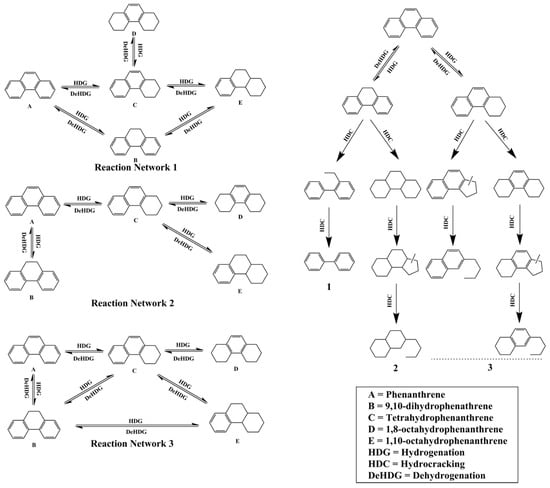

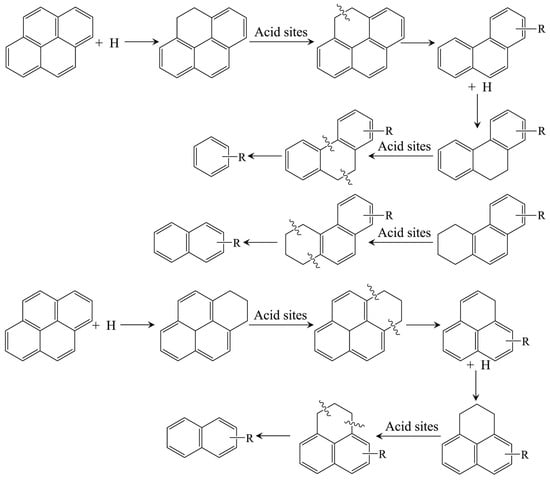

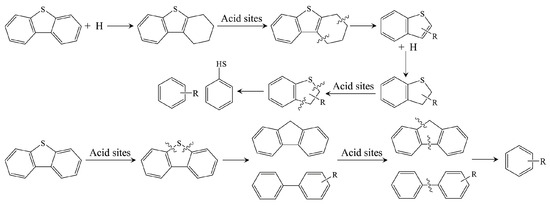

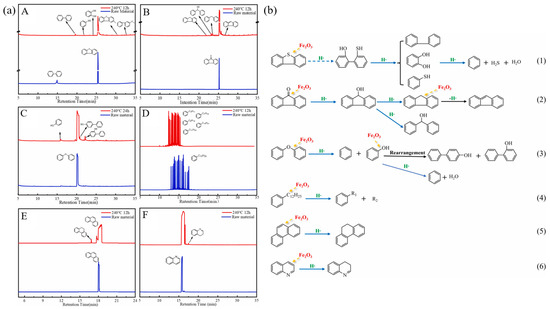

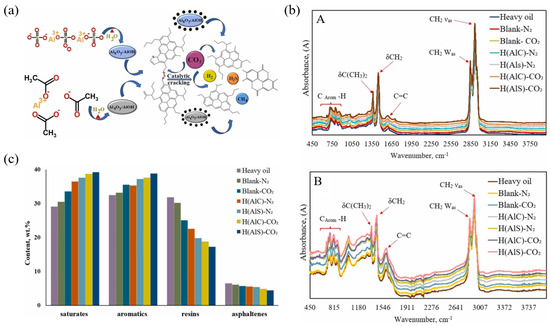

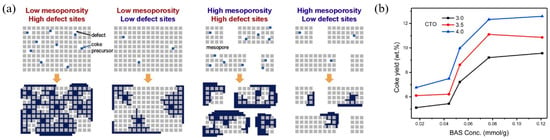

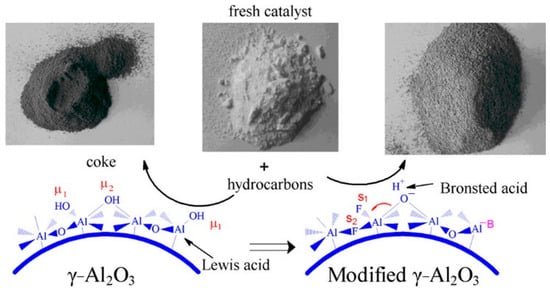

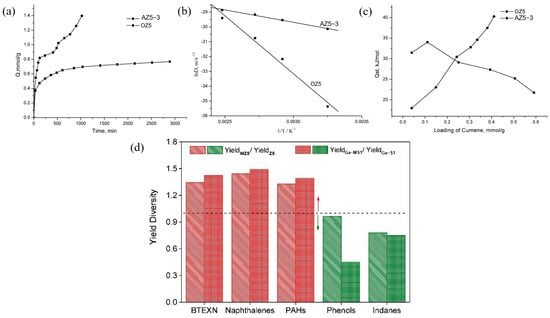

The selection and dosage of templates are crucial to the pore structure of zeolites. Different templates will lead to the formation of different pore structures and crystal morphologies. For example, tetrapropylammonium hydroxide (TPAOH) is often used to synthesize ZSM-5 zeolite, which can induce the formation of a ten-membered ring pore structure. However, excessive use of templates not only increases costs but also affects environmental friendliness. Therefore, in recent years, green synthesis technology has gradually attracted attention, and sustainable synthesis is achieved by introducing recyclable templates and regulating reaction conditions [140].