Microstructure and Mechanical Properties of Platinum Fiber Fabricated by Unidirectional Solidification

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

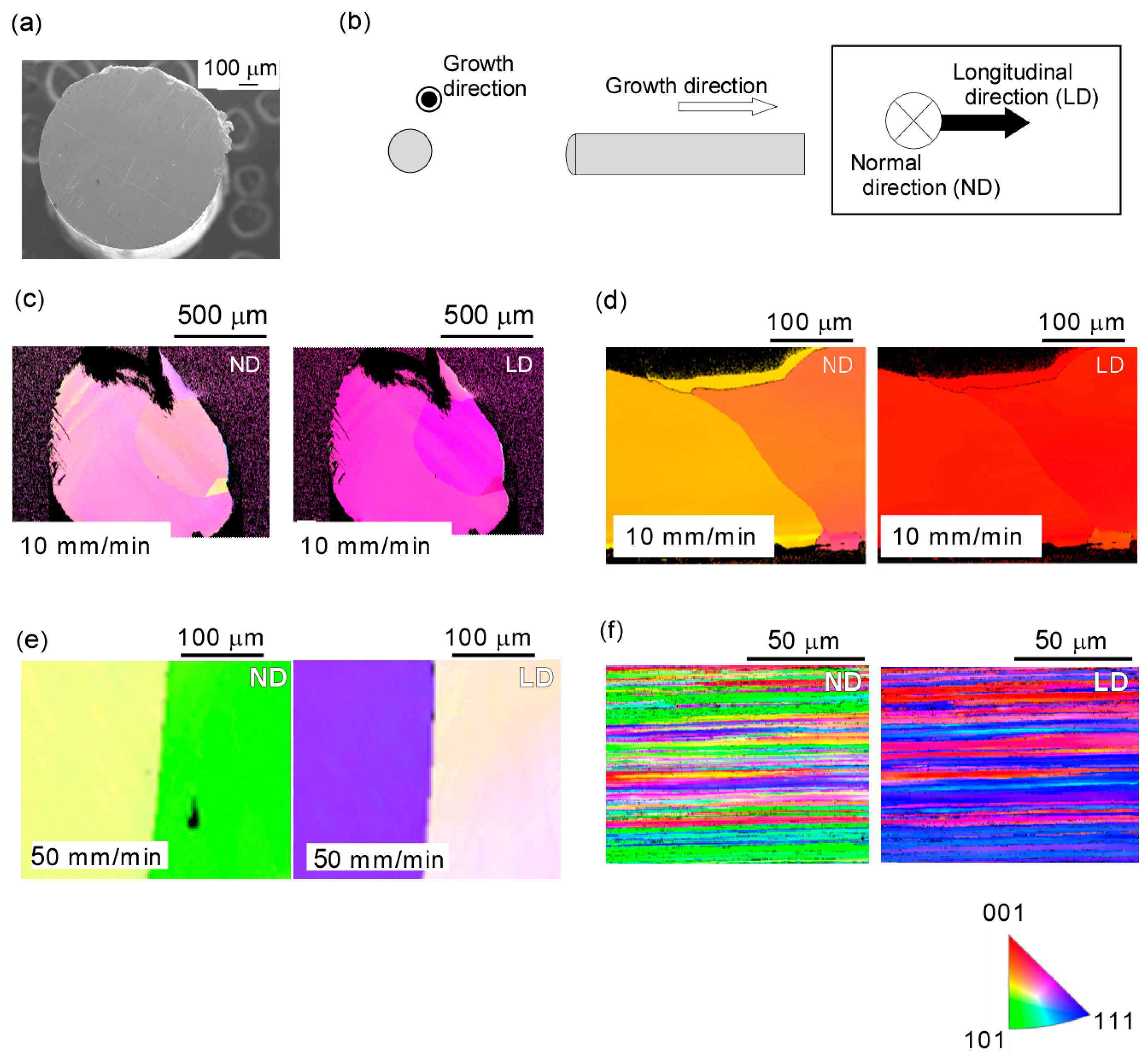

3.1. Microstructure

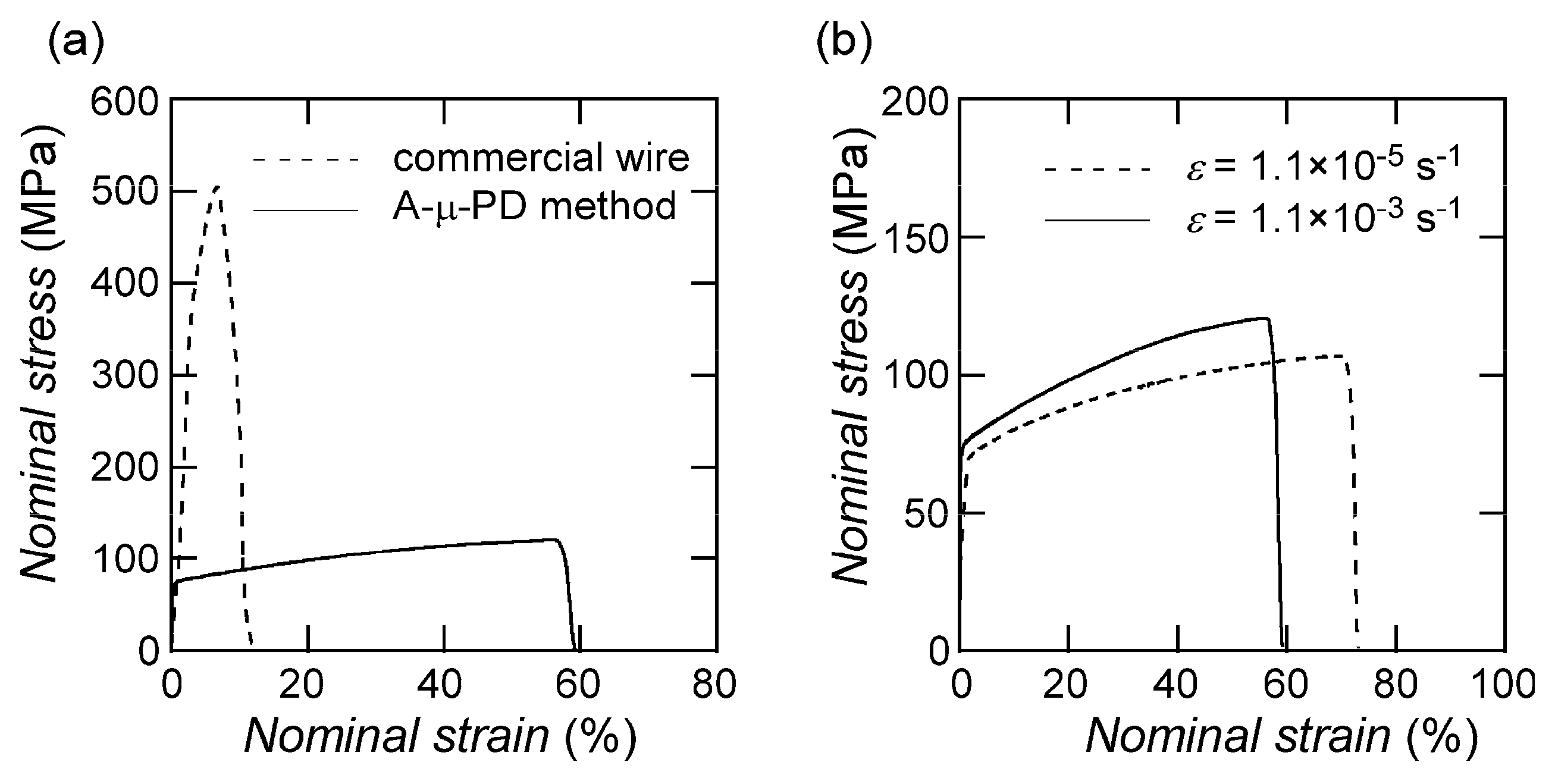

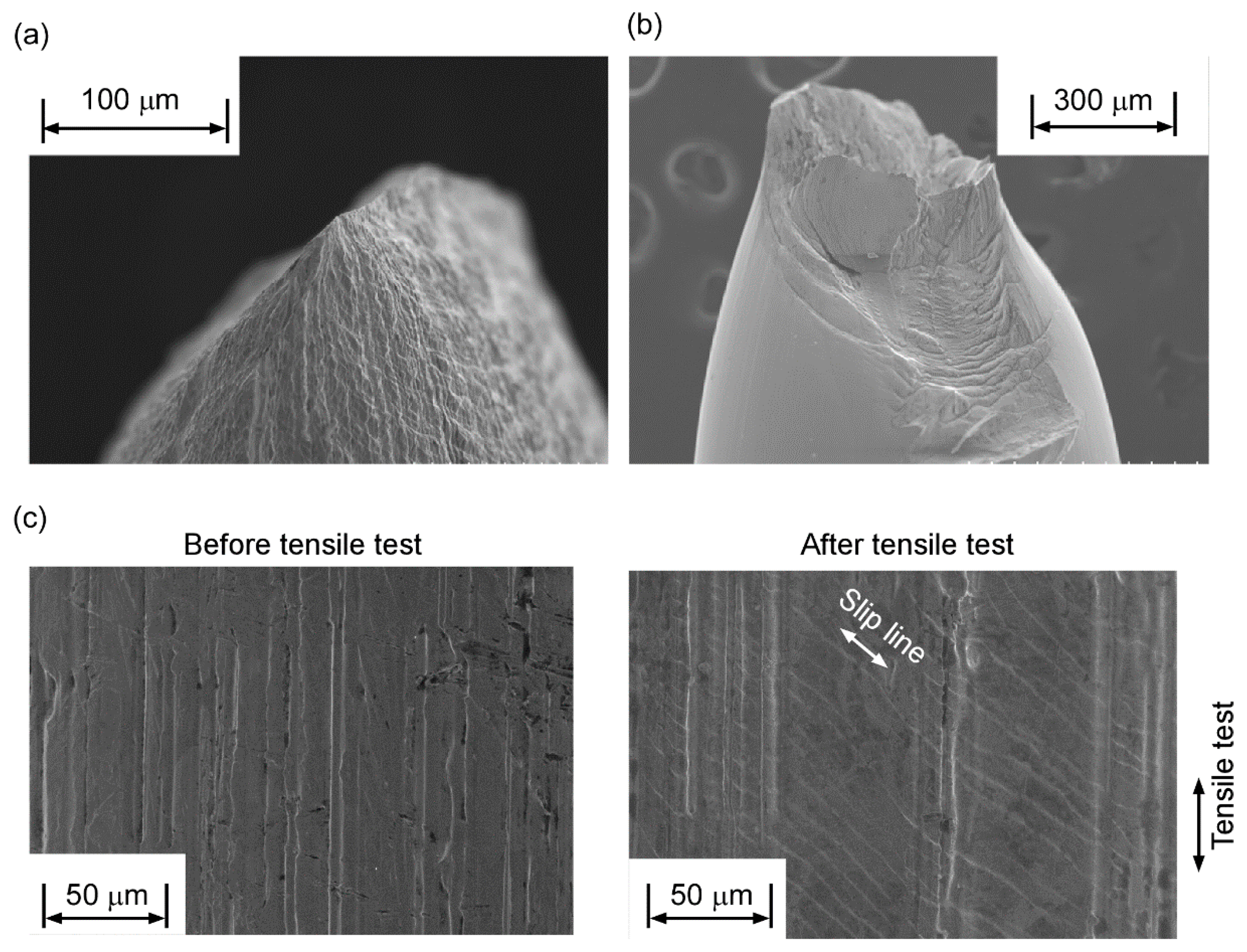

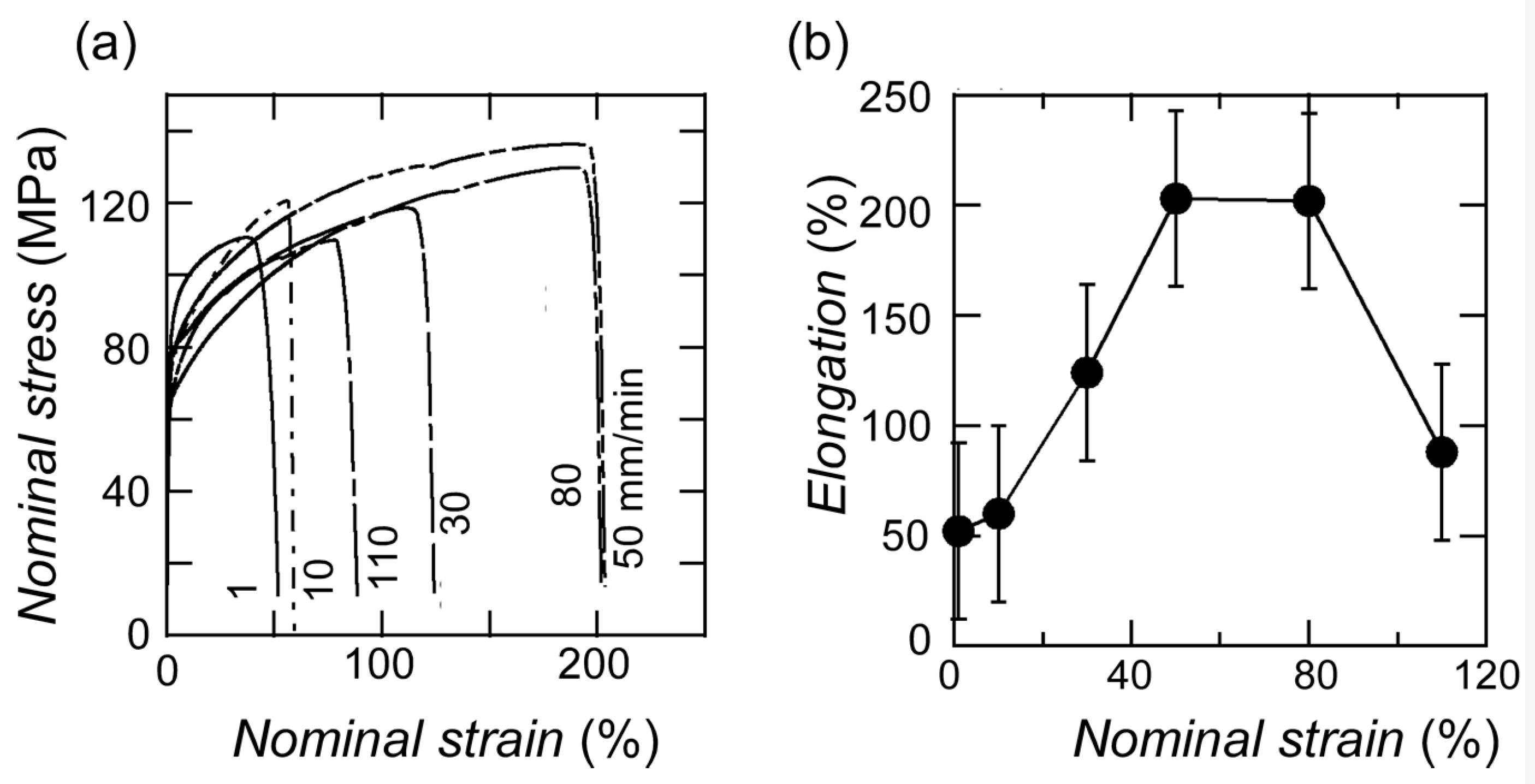

3.2. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hamada, T.; Hitomi, S.; Ikematsu, Y.; Nasu, S. High-temperature creep of pure platinum. Mater. Trans. JIM 1996, 37, 353–358. [Google Scholar] [CrossRef] [Green Version]

- Kamada, K.; Shoji, Y.; Kochurikhin, V.V.; Okumura, S.; Yamamoto, S.; Nagura, A.; Yeom, J.Y.; Kurosawa, S.; Yokota, Y.; Yoshikawa, A. Growth and scintillation properties of 3 in. diameter Ce doped Gd3Ga3Al2O12 scintillation single crystal. J. Cryst. Growth 2016, 452, 81–84. [Google Scholar] [CrossRef] [Green Version]

- Yokota, Y.; Kudo, T.; Ohashi, Y.; Medvedev, A.; Kurosawa, S.; Kamada, K.; Yoshikawa, A. Growth and piezoelectric properties of Ca3Nb(Ga1-xAlx)3Si2O14 (x = 0.25 and 0.50) single crystals. Jpn. J. Appl. Phys. 2015, 54, 10ND13. [Google Scholar] [CrossRef]

- Yokota, Y.; Ito, T.; Shoji, Y.; Kurosawa, S.; Ohashi, Y.; Kamada, K.; Yoshikawa, A. Growth of 1.5-In Eu:SrI2 Single Crystal and Scintillation Properties. IEEE Trans. Nucl. Sci. 2015, 63, 467–470. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Shoji, Y.; Yokota, Y.; Kurosawa, S.; Hayasaka, S.; Chani, V.; Ito, T.; Kamada, K.; Ohashi, Y.; Kochurikhin, V. Growth of 2 inch Eu-doped SrI2 single crystals for scintillator applications. J. Cryst. Growth 2016, 452, 73–80. [Google Scholar] [CrossRef] [Green Version]

- Yoshikawa, A.; Nikl, M.; Boulon, G.; Fukuda, T. Challenge and study for developing of novel single crystalline optical materials using micro-pulling-down method. Opt. Mater. 2007, 30, 6–10. [Google Scholar] [CrossRef]

- Yokota, Y.; Fujimoto, Y.; Yanagida, T.; Takahashi, H.; Yonetani, M.; Hayashi, K.; Park, I.; Kawaguchi, N.; Fukuda, K.; Yamaji, A.; et al. Crystal growth of Na co-doped Ce:LiCaAlF6 single crystals and their optical, scintillation and physical properties. Cryst. Growth Des. 2011, 11, 4775–4779. [Google Scholar] [CrossRef]

- Yoshikawa, A.; Chani, V. Growth of optical crystals by the micro-pulling-down method. Mater. Res. Bull. 2009, 34, 266–270. [Google Scholar] [CrossRef]

- Yokota, Y.; Kurosawa, S.; Shoji, Y.; Ohashi, Y.; Kamada, K.; Yoshikawa, A. Development of novel growth methods for halide single crystals. Opt. Mater. 2017, 65, 46–51. [Google Scholar] [CrossRef]

- Yokota, Y.; Chani, V.; Sato, M.; Tota, K.; Onodera, K.; Yanagida, T.; Yoshikawa, A. Growth and crystallinity of shaped and multiple sapphire crystals by a micro-pulling-down method. J. Cryst. Growth 2011, 318, 983–986. [Google Scholar] [CrossRef]

- Yokota, Y.; Yoshikawa, A.; Futami, Y.; Sato, M.; Tota, K.; Onodera, K.; Yanagida, T. Shaped crystal growth of langasite-type piezoelectric single crystals and their physical properties. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2012, 59, 1868–1871. [Google Scholar] [CrossRef] [PubMed]

- Chani, V.; Yoshikawa, A.; Kuwano, Y.; Hasegawa, K.; Fukuda, T. Growth of Y3Al5O12:Nd fiber crystals by micro-pulling-down technique. J. Cryst. Growth 1999, 204, 155–162. [Google Scholar] [CrossRef]

- Sato, H.; Chani, V.; Yoshikawa, A.; Kagamitani, Y.; Machida, H.; Fukuda, T. Micro-pulling-down growth and characterization of Tb3-xTmxAl5O12 fiber crystals for Faraday rotator applications. J. Cryst. Growth 2004, 264, 253–259. [Google Scholar] [CrossRef]

- Zhuravleva, M.; Chani, V.; Yanagida, T.; Yoshikawa, A. The micro-pulling-down growth of Bi4Si3O12 (BSO) and Bi4Ge3O12 (BGO) fiber crystals and their scintillation efficiency. J. Cryst. Growth 2008, 310, 2152–2156. [Google Scholar] [CrossRef]

- Yokota, Y.; Nihei, T.; Ohashi, Y.; Kurosawa, S.; Kamada, K.; Yoshikawa, A. Fabrication of Metallic Fibers with High Melting Point and Poor Workability by Unidirectional Solidification. Adv. Eng. Mater. 2018, 20, 1700506. [Google Scholar] [CrossRef]

- Nihei, T.; Yokota, Y.; Arakawa, M.; Ohashi, Y.; Kurosawa, S.; Kamada, K.; Chani, V.; Yoshikawa, A. Growth of platinum fibers using the micro-pulling-down method. J. Cryst. Growth 2016, 468, 403–406. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yokota, Y.; Nihei, T.; Yoshino, M.; Yamaji, A.; Toyoda, S.; Sato, H.; Ohashi, Y.; Kurosawa, S.; Kamada, K.; Yoshikawa, A. Microstructure and Mechanical Properties of Platinum Fiber Fabricated by Unidirectional Solidification. Crystals 2020, 10, 216. https://doi.org/10.3390/cryst10030216

Yokota Y, Nihei T, Yoshino M, Yamaji A, Toyoda S, Sato H, Ohashi Y, Kurosawa S, Kamada K, Yoshikawa A. Microstructure and Mechanical Properties of Platinum Fiber Fabricated by Unidirectional Solidification. Crystals. 2020; 10(3):216. https://doi.org/10.3390/cryst10030216

Chicago/Turabian StyleYokota, Yuui, Takayuki Nihei, Masao Yoshino, Akihiro Yamaji, Satoshi Toyoda, Hiroki Sato, Yuji Ohashi, Shunsuke Kurosawa, Kei Kamada, and Akira Yoshikawa. 2020. "Microstructure and Mechanical Properties of Platinum Fiber Fabricated by Unidirectional Solidification" Crystals 10, no. 3: 216. https://doi.org/10.3390/cryst10030216

APA StyleYokota, Y., Nihei, T., Yoshino, M., Yamaji, A., Toyoda, S., Sato, H., Ohashi, Y., Kurosawa, S., Kamada, K., & Yoshikawa, A. (2020). Microstructure and Mechanical Properties of Platinum Fiber Fabricated by Unidirectional Solidification. Crystals, 10(3), 216. https://doi.org/10.3390/cryst10030216