Influence of Rapid Thermal Annealing on the Characteristics of Sn-Doped Ga2O3 Films Fabricated Using Plasma-Enhanced Atomic Layer Deposition

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

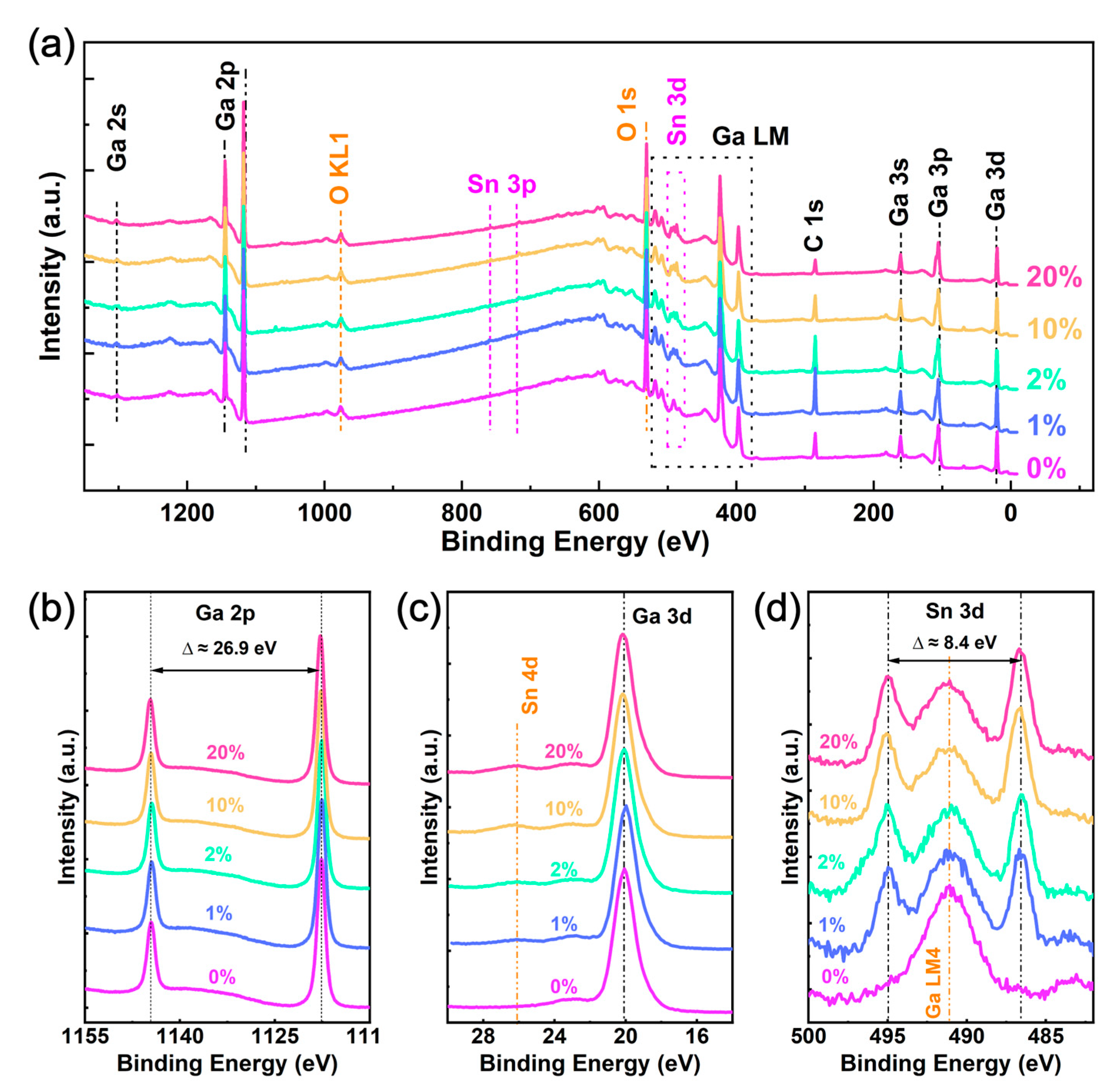

3.1. Chemical Composition

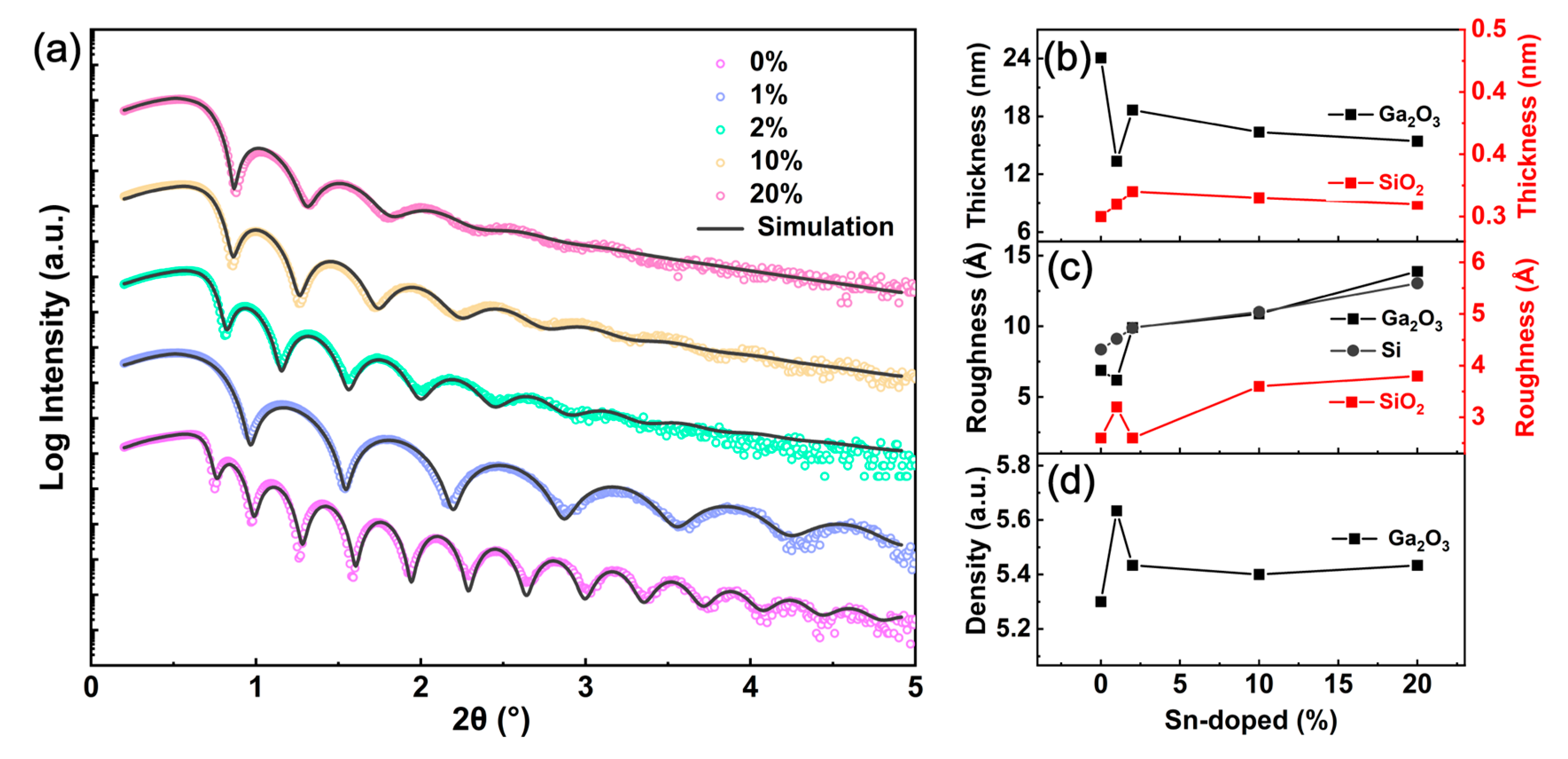

3.2. Surface Topography and Microstructure

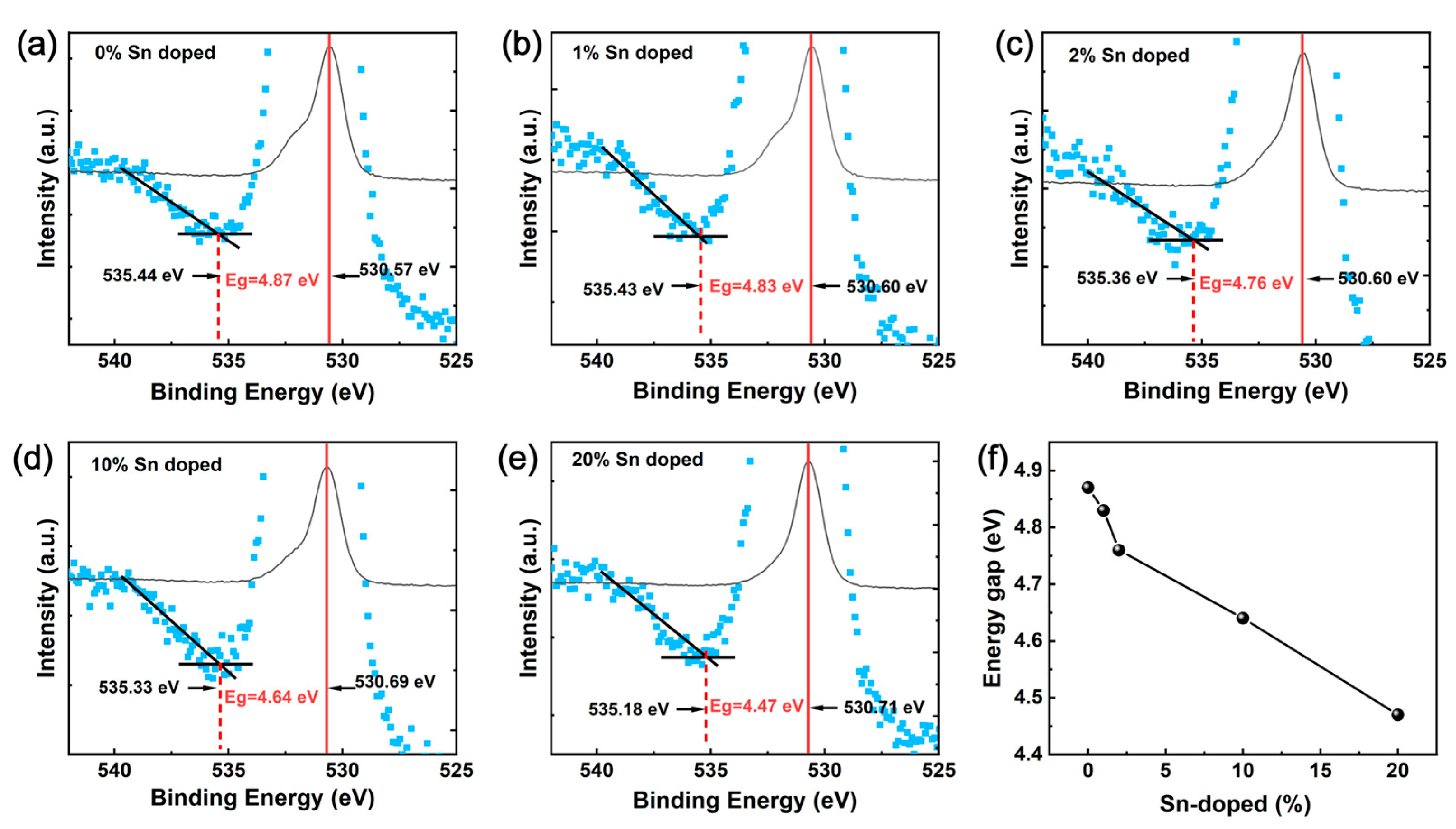

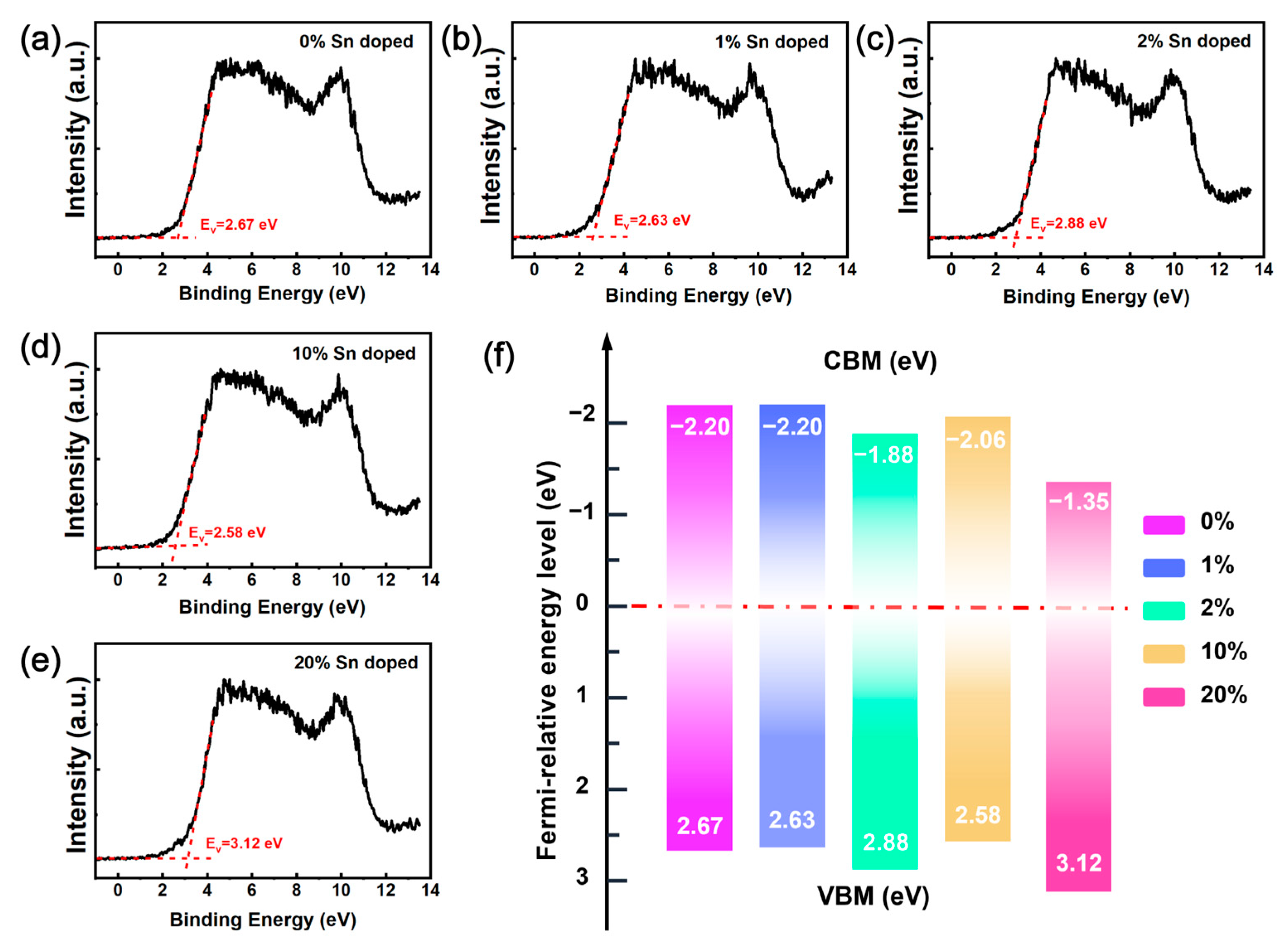

3.3. Energy Band Structure

3.4. Electrical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Higashiwaki, M.; Sasaki, K.; Kuramata, A.; Masui, T.; Yamakoshi, S. Gallium oxide (Ga2O3) metal-semiconductor field-effect transistors on single-crystal β-Ga2O3 (010) substrates. Appl. Phys. Lett. 2012, 100, 013504. [Google Scholar] [CrossRef]

- Fan, M.-M.; Lu, Y.-J.; Xu, K.-L.; Cui, Y.-X.; Cao, L.; Li, X.-Y. Growth and characterization of Sn-doped β-Ga2O3 thin films by chemical vapor deposition using solid powder precursors toward solar-blind ultraviolet photodetection. Appl. Surf. Sci. 2020, 509, 144867. [Google Scholar] [CrossRef]

- Ogita, M.; Higo, K.; Nakanishi, Y.; Hatanaka, Y. Ga2O3 thin film for oxygen sensor at high temperature. Appl. Surf. Sci. 2001, 175, 721–725. [Google Scholar] [CrossRef]

- Stepanov, S.I.; Nikolaev, V.I.; Bougrov, V.E.; Romanov, A.E. Gallium oxide: Properties and applications-a review. Rev. Adv. Mater. Sci. 2016, 44, 63–86. [Google Scholar]

- Gu, L.; Ma, H.-P.; Shen, Y.; Zhang, J.; Chen, W.-J.; Yang, R.-Y.; Wu, F.; Yang, L.; Zeng, Y.-X.; Wang, X.-R.; et al. Temperature-dependent oxygen annealing effect on the properties of Ga2O3 thin film deposited by atomic layer deposition. J. Alloys Compd. 2022, 925, 166727. [Google Scholar] [CrossRef]

- Shen, Y.; Ma, H.-P.; Gu, L.; Zhang, J.; Huang, W.; Zhu, J.-T.; Zhang, Q.-C. Atomic-Level Sn Doping Effect in Ga2O3 Films Using Plasma-Enhanced Atomic Layer Deposition. Nanomaterials 2022, 12, 4256. [Google Scholar] [CrossRef] [PubMed]

- Rogers, D.J.; Look, D.C.; Teherani, F.H.; Magill, B.A.; Park, J.-H.; Rogers, D.J.; McClintock, R.; Razeghi, M.; Pavlidis, D.; Dravid, V.P.; et al. A review of the growth, doping, and applications of Beta-Ga2O3 thin films. Oxide-Based Mater. Devices IX 2018, 10533, R1–R24. [Google Scholar]

- Baji, Z.; Cora, I.; Horváth, Z.; Agócs, E.; Szabó, Z. Atomic layer deposition and characterization of Zn-doped Ga2O3 films. J. Vac. Sci. Technol. A 2021, 39, 032411. [Google Scholar] [CrossRef]

- Wang, F.H.; Chen, K.N.; Hsu, C.M.; Liu, M.C.; Yang, C.F. Investigation of the Structural, Electrical, and Optical Properties of the Nano-Scale GZO Thin Films on Glass and Flexible Polyimide Substrates. Nanomaterials 2016, 6, 88. [Google Scholar] [CrossRef]

- Tadjer, M.J.; Freitas, J.A.; Culbertson, J.C.; Weber, M.H.; Glaser, E.R.; Mock, A.L.; Mahadik, N.A.; Schmieder, K.; Jackson, E.; Gallagher, J.C.; et al. Structural and electronic properties of Si- and Sn-doped (−201) β-Ga2O3 annealed in nitrogen and oxygen atmospheres. J. Phys. D: Appl. Phys. 2020, 53, 88. [Google Scholar] [CrossRef]

- Mandal, P.; Singh, U.P.; Roy, S. Optical performance of europium-doped β gallium oxide PVD thin films. J. Mater. Sci. Mater. Electron. 2021, 32, 3958–3965. [Google Scholar] [CrossRef]

- Zhang, D.; Du, Z.; Ma, M.; Zheng, W.; Liu, S.; Huang, F. Enhanced performance of solar-blind ultraviolet photodetector based on Mg-doped amorphous gallium oxide film. Vacuum 2019, 159, 204–208. [Google Scholar] [CrossRef]

- Mandal, P.; Roy, S.; Singh, U.P. Investigation on the optical and electrical performance of aluminium doped gallium oxide thin films. Opt. Quantum Electron. 2022, 54, 476. [Google Scholar] [CrossRef]

- Biyikli, N.; Haider, A. Atomic layer deposition: An enabling technology for the growth of functional nanoscale semiconductors. Semicond. Sci. Technol. 2017, 32, 093002. [Google Scholar] [CrossRef]

- Ma, H.-P.; Yang, J.-H.; Tao, J.-J.; Yuan, K.-P.; Cheng, P.-H.; Huang, W.; Wang, J.-C.; Guo, Q.-X.; Lu, H.-L.; Zhang, D.W. Low-temperature epitaxial growth of high-quality GaON films on ZnO nanowires for superior photoelectrochemical water splitting. Nano Energy 2019, 66, 104089. [Google Scholar] [CrossRef]

- Ma, H.-P.; Gu, L.; Shen, Y.; Huang, W.; Liu, Y.-H.; Zhu, J.-T.; Zhang, Q.-C. Annealing effect on SiNx/SiO2 superlattice with ultrathin sublayer fabricated using plasma-enhanced atomic layer deposition. Ceram. Int. 2022, 48, 22164–22171. [Google Scholar] [CrossRef]

- Kim, H.W.; Kim, N.H. Annealing effects on the properties of Ga2O3 thin films grown on sapphire by the metal organic chemical vapor deposition. Appl. Surf. Sci. 2004, 230, 301–306. [Google Scholar] [CrossRef]

- Wu, J.; Mi, W.; Yang, Z.; Chen, Y.; Li, P.; Zhao, J.; Zhang, K.; Zhang, X.; Luan, C. Influence of annealing on the structural and optical properties of gallium oxide films deposited on c-sapphire substrate. Vacuum 2019, 167, 6–9. [Google Scholar] [CrossRef]

- Li, S.; Yue, J.; Ji, X.; Lu, C.; Yan, Z.; Li, P.; Guo, D.; Wu, Z.; Tang, W. Oxygen vacancies modulating the photodetector performances in ε-Ga2O3 thin films. J. Mater. Chem. C 2021, 9, 5437–5444. [Google Scholar] [CrossRef]

- Kim, H.W.; Kim, N.H. Influence of postdeposition annealing on the properties of Ga2O3 films on SiO2 substrates. J. Alloys Compd. 2005, 389, 177–181. [Google Scholar] [CrossRef]

- Hill, C.; Jones, S.K.; Boys, D.R. Rapid thermal annealing-theory and practice. In Reduced Thermal Processing for ULSI; Springer: Berlin/Heidelberg, Germany, 1989; pp. 143–180. [Google Scholar]

- Vignaud, G.; Gibaud, A. REFLEX: A program for the analysis of specular X-ray and neutron reflectivity data. J. Appl. Crystallogr. 2019, 52, 201–213. [Google Scholar] [CrossRef]

- Mi, W.; Li, Z.; Luan, C.; Xiao, H.; Zhao, C.; Ma, J. Transparent conducting tin-doped Ga2O3 films deposited on MgAl2O4, substrates by MOCVD. Ceram. Int. 2015, 41, 2572–2575. [Google Scholar] [CrossRef]

- Tidswell, I.M.; Ocko, B.M.; Pershan, P.S.; Wasserman, S.R.; Whitesides, G.M.; Axe, J.D. X-ray specular reflection studies of silicon coated by organic monolayers (alkylsiloxanes). Phys. Rev. B 1990, 41, 1111–1128. [Google Scholar] [CrossRef]

- Kiessig, H. Interferenz von Röntgenstrahlen an dünnen Schichten. Ann. Der Phys. 1931, 402, 769–788. [Google Scholar] [CrossRef]

- Chen, Z.; Nishihagi, K.; Wang, X.; Saito, K.; Tanaka, T.; Nishio, M.; Arita, M.; Guo, Q. Band alignment of Ga2O3/Si heterojunction interface measured by X-ray photoelectron spectroscopy. Appl. Phys. Lett. 2016, 109, 102106. [Google Scholar] [CrossRef]

- Zhang, F.; Saito, K.; Tanaka, T.; Nishio, M.; Arita, M.; Guo, Q. Wide bandgap engineering of (AlGa)2O3 films. Appl. Phys. Lett. 2014, 105, 162107. [Google Scholar] [CrossRef]

- Nichols, M.T.; Li, W.; Pei, D.; Antonelli, G.A.; Lin, Q.; Banna, S.; Nishi, Y.; Shohet, J.L. Measurement of bandgap energies in low-k organosilicates. J. Appl. Phys. 2014, 115, 094105. [Google Scholar] [CrossRef]

- Mohamed, M.; Janowitz, C.; Unger, I.; Manzke, R.; Galazka, Z.; Uecker, R.; Fornari, R.; Weber, J.; Varley, J.; Van de Walle, C. The electronic structure of β-Ga2O3. Appl. Phys. Lett. 2010, 97, 211903. [Google Scholar] [CrossRef]

- Kavan, L. Conduction band engineering in semiconducting oxides (TiO2, SnO2): Applications in perovskite photovoltaics and beyond. Catal. Today 2019, 328, 50–56. [Google Scholar] [CrossRef]

- Ravi, V.K.; Markad, G.B.; Nag, A. Band Edge Energies and Excitonic Transition Probabilities of Colloidal CsPbX3 (X = Cl, Br, I) Perovskite Nanocrystals. ACS Energy Lett. 2016, 1, 665–671. [Google Scholar] [CrossRef]

- Vequizo, J.J.M.; Ichimura, M. Fabrication of Electrodeposited SnS/SnO2 Heterojunction Solar Cells. Jpn. J. Appl. Phys. 2012, 51, 10NC38. [Google Scholar] [CrossRef]

- Mohamed, H.F.; Xia, C.; Sai, Q.; Cui, H.; Pan, M.; Qi, H. Growth and fundamentals of bulk β-Ga2O3 single crystals. J. Semicond. 2019, 40, 011801. [Google Scholar] [CrossRef]

- Hughes, R. High field electronic properties of SiO2. Solid-State Electron. 1978, 21, 251–258. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, Y.; Ma, H.-P.; Wang, Z.-Y.; Gu, L.; Zhang, J.; Li, A.; Yang, M.-Y.; Zhang, Q.-C. Influence of Rapid Thermal Annealing on the Characteristics of Sn-Doped Ga2O3 Films Fabricated Using Plasma-Enhanced Atomic Layer Deposition. Crystals 2023, 13, 301. https://doi.org/10.3390/cryst13020301

Shen Y, Ma H-P, Wang Z-Y, Gu L, Zhang J, Li A, Yang M-Y, Zhang Q-C. Influence of Rapid Thermal Annealing on the Characteristics of Sn-Doped Ga2O3 Films Fabricated Using Plasma-Enhanced Atomic Layer Deposition. Crystals. 2023; 13(2):301. https://doi.org/10.3390/cryst13020301

Chicago/Turabian StyleShen, Yi, Hong-Ping Ma, Zhen-Yu Wang, Lin Gu, Jie Zhang, Ao Li, Ming-Yang Yang, and Qing-Chun Zhang. 2023. "Influence of Rapid Thermal Annealing on the Characteristics of Sn-Doped Ga2O3 Films Fabricated Using Plasma-Enhanced Atomic Layer Deposition" Crystals 13, no. 2: 301. https://doi.org/10.3390/cryst13020301

APA StyleShen, Y., Ma, H.-P., Wang, Z.-Y., Gu, L., Zhang, J., Li, A., Yang, M.-Y., & Zhang, Q.-C. (2023). Influence of Rapid Thermal Annealing on the Characteristics of Sn-Doped Ga2O3 Films Fabricated Using Plasma-Enhanced Atomic Layer Deposition. Crystals, 13(2), 301. https://doi.org/10.3390/cryst13020301