Study on Texture Formation of Sb2Te Thin Films for Phase Change Memory Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Texture Characterization

2.3. Electrical Property Measurement

2.4. Interface Mismatch Calculation

3. Results

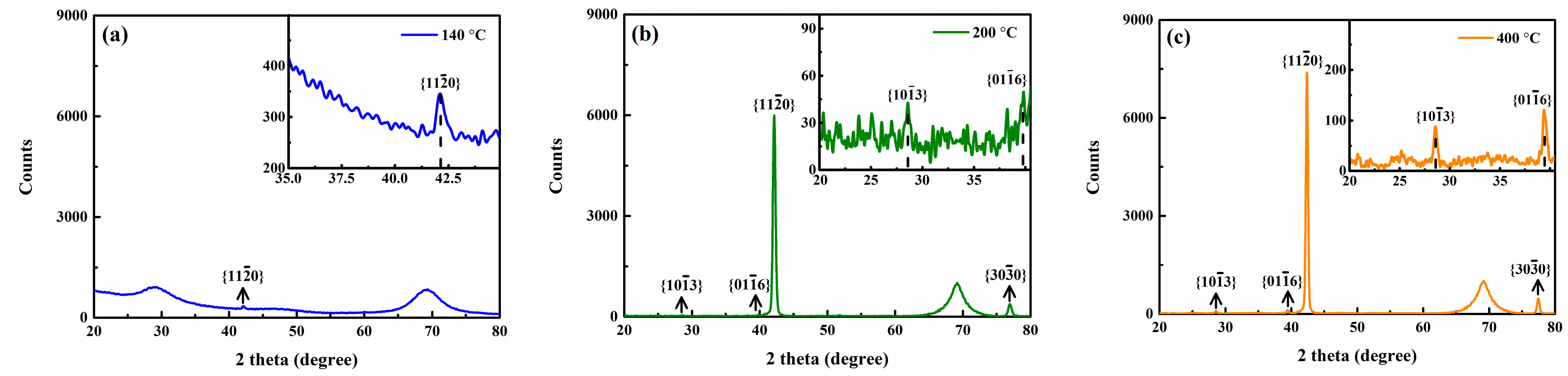

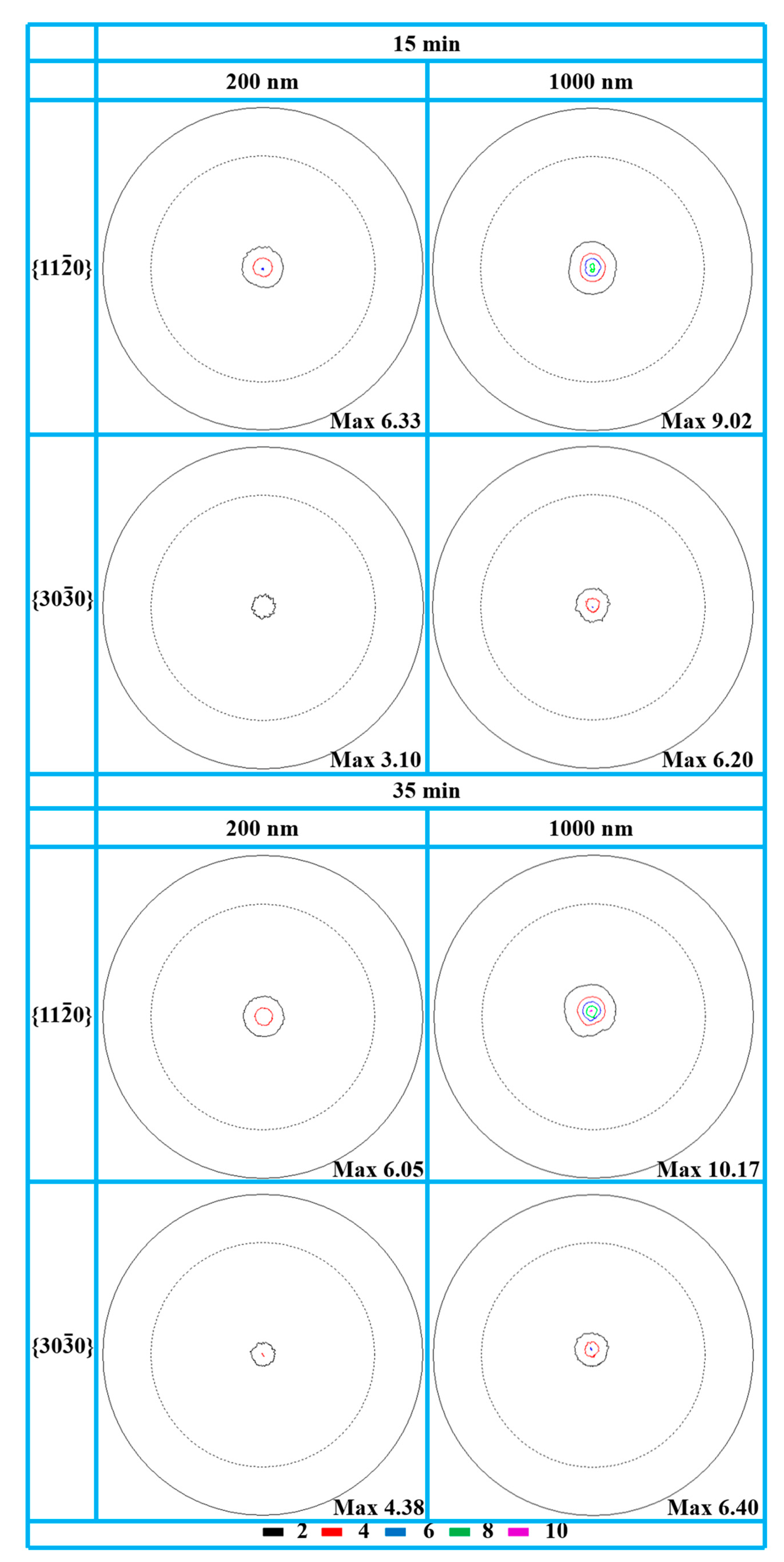

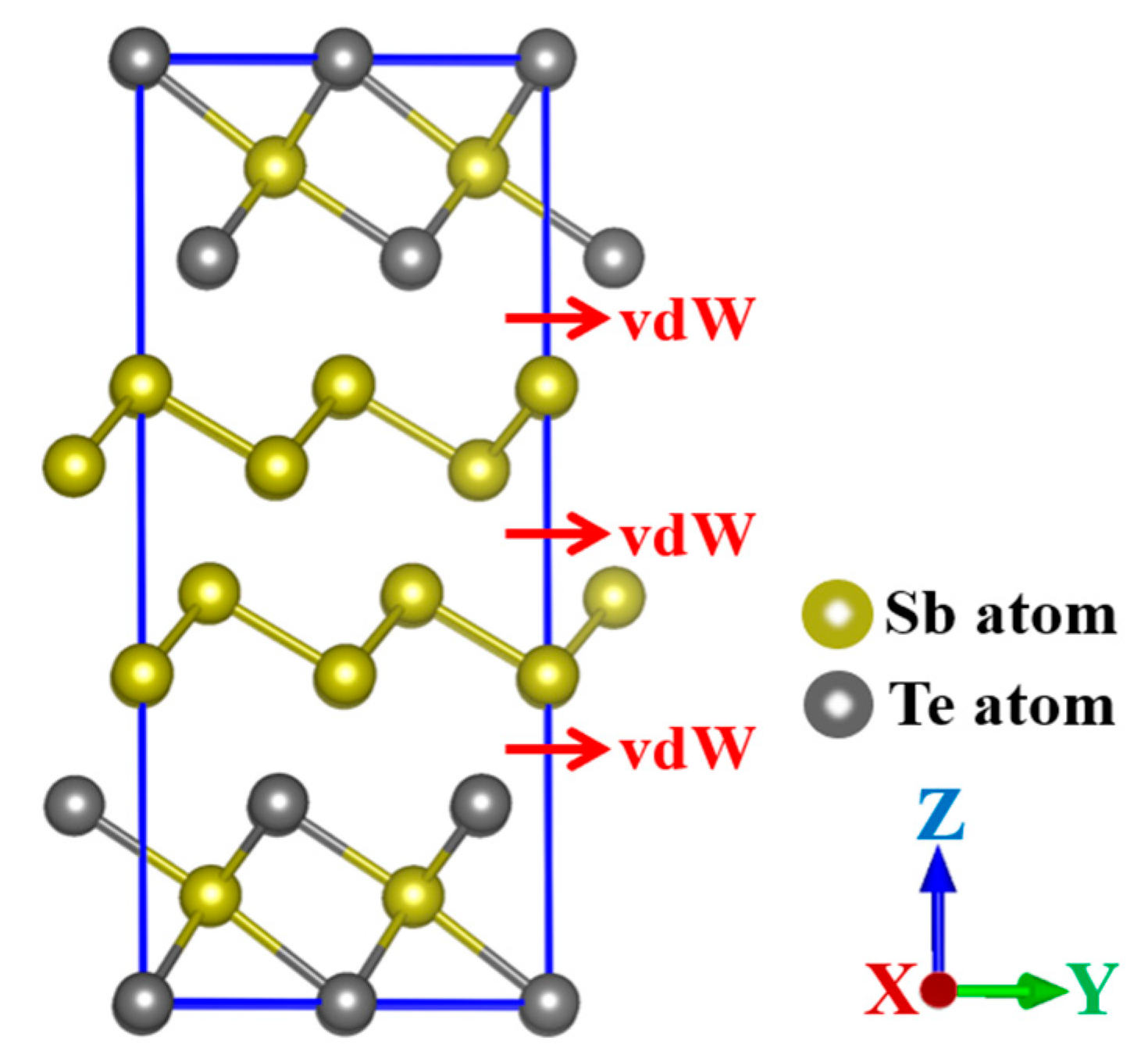

3.1. Texture Characterization of Sb2Te Thin Films

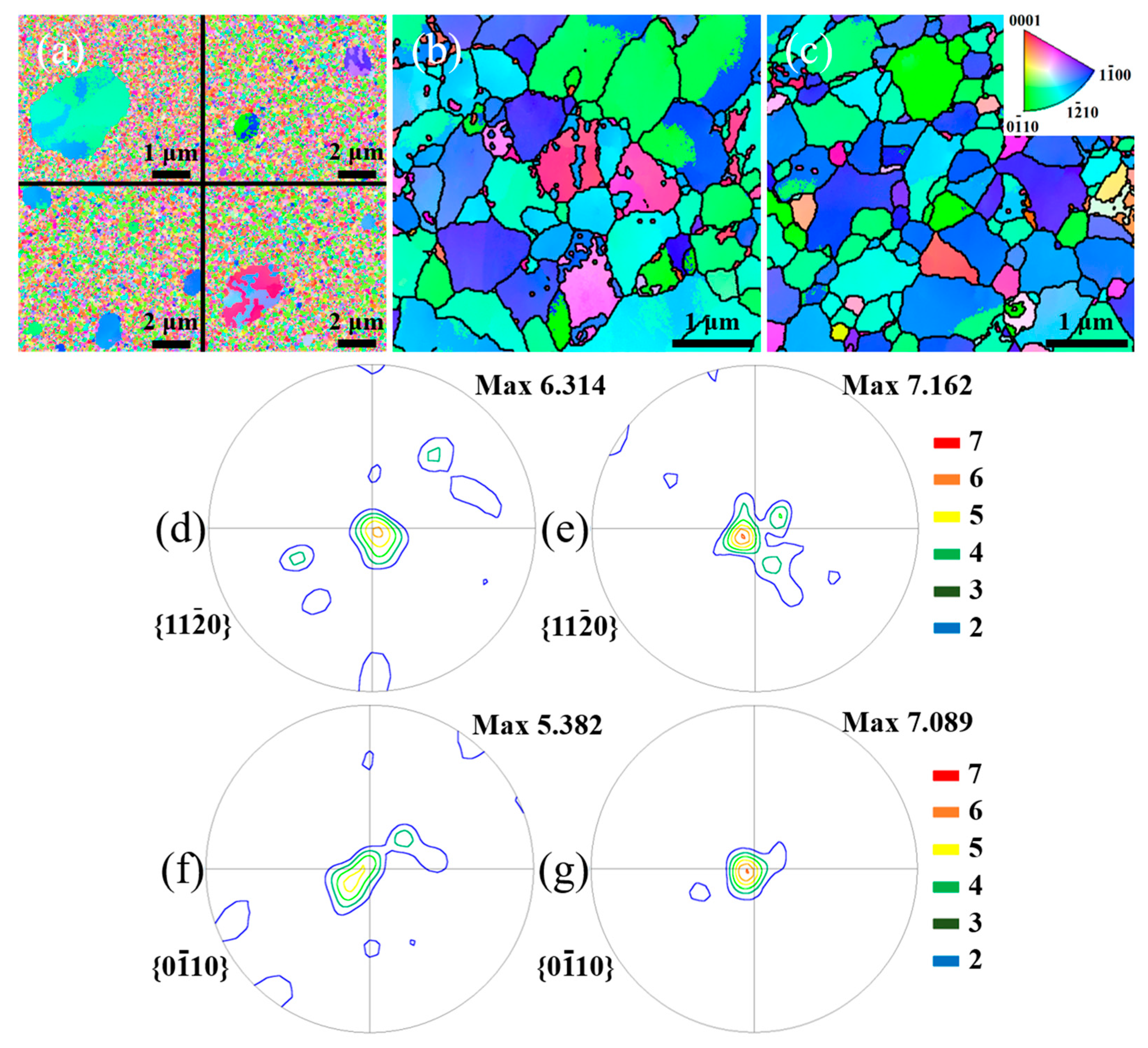

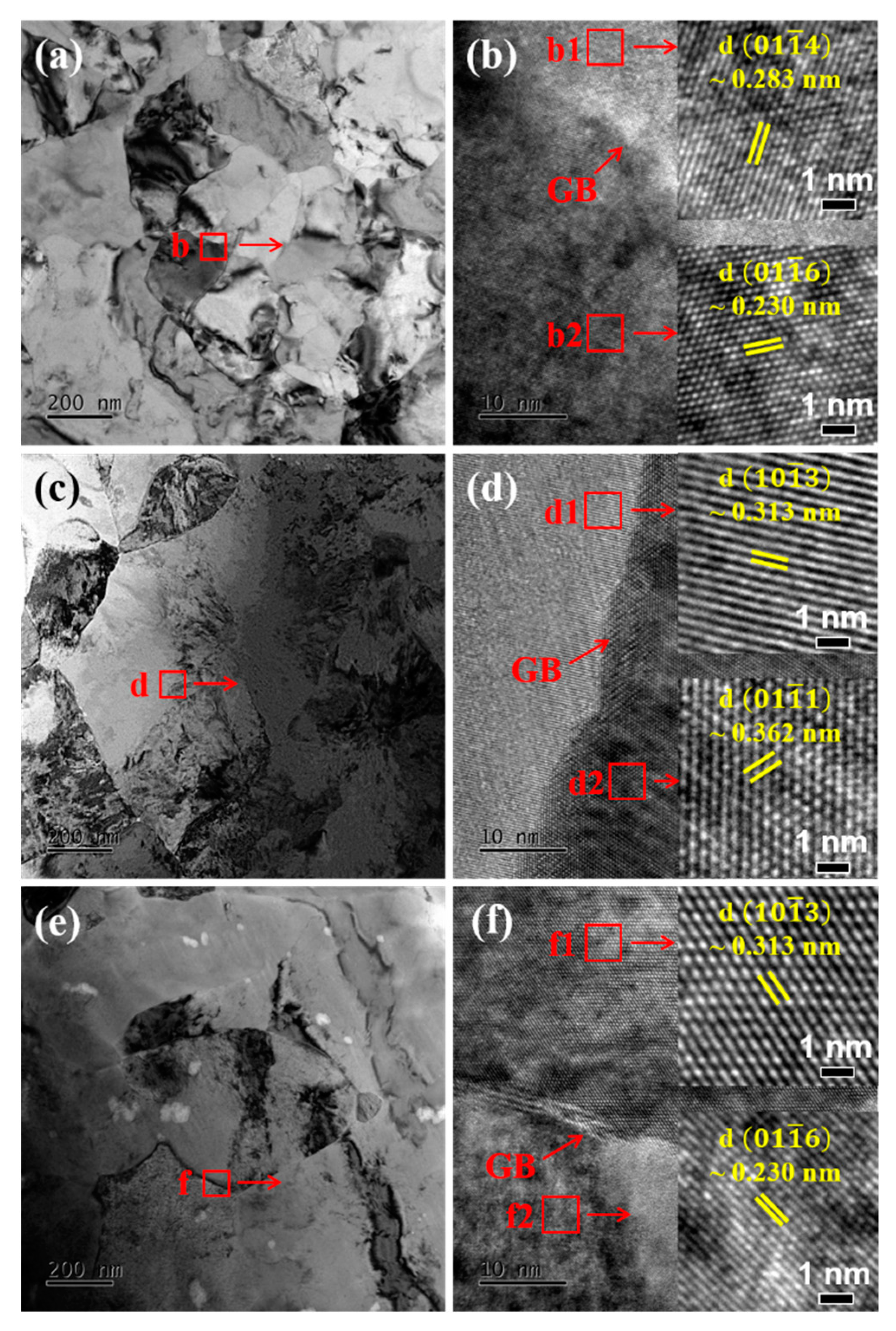

3.2. Formation Mechanism of Prismatic Texture

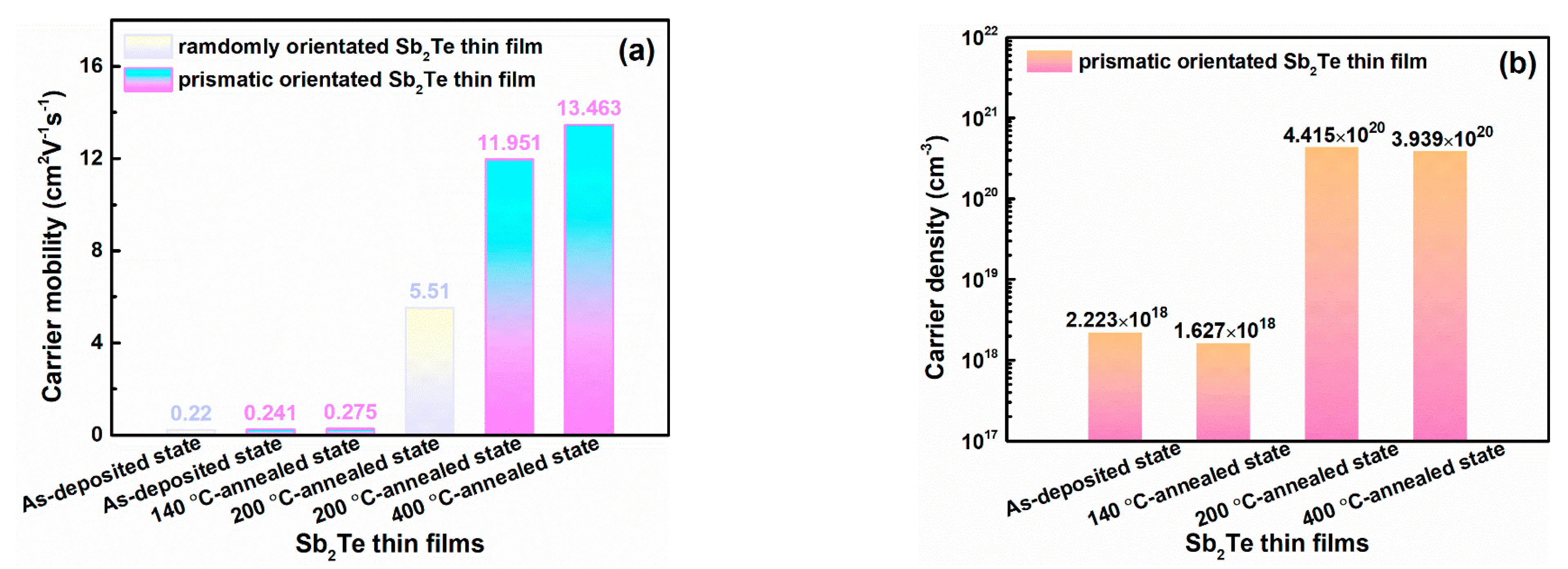

3.3. Electrical Properties of Prismatic Textured Sb2Te Thin Film

3.4. Interface Stability of Prismatic Orientated Sb2Te Thin Film

4. Conclusions

- 1.

- The single-phase Sb2Te thin films exhibit and prismatic texture.

- 2.

- The and prismatic preference is induced by the lattice strain, surface energy of the crystal plane, and coarse grain, where the lattice strain is a major contributor.

- 3.

- The prismatic-preferred Sb2Te thin film exhibits higher carrier mobility compared with its randomly orientated counterparts. The increase of carrier mobility results from the reduction of grain boundary potential energy and grain coarsening in the prismatic-textured Sb2Te thin film.

- 4.

- The prismatic-preferred Sb2Te thin films have higher mismatches with (100), (110), and (111) oriented silicon wafers, which reduces the stability of the thin film–substrate interface.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ovshinsky, S.R. Reversible electrical switching phenomena in disordered structures. Phys. Rev. Lett. 1968, 21, 1450–1453. [Google Scholar] [CrossRef]

- Lencer, D.; Salinga, M.; Grabowski, B.; Hickel, T.; Neugebauer, J.; Wuttig, M. A map for phase-change materials. Nat. Mater. 2008, 7, 972–977. [Google Scholar] [CrossRef]

- Wuttig, M.; Yamada, N. Phase-change materials for rewriteable data storage. Nat. Mater. 2007, 6, 824–832. [Google Scholar] [CrossRef]

- Hosseini, P.; Wright, C.D.; Bhaskaran, H. An optoelectronic framework enabled by low-dimensional phase-change films. Nature 2014, 511, 206–211. [Google Scholar] [CrossRef]

- Li, X.-B.; Chen, N.-K.; Wang, X.-P.; Sun, H.-B. Phase-change superlattice materials toward low power consumption and high density data storage: Microscopic picture, working principles, and optimization. Adv. Funct. Mater. 2018, 28, 1803380. [Google Scholar] [CrossRef]

- Wright, C.D.; Liu, Y.; Kohary, K.I.; Aziz, M.M.; Hicken, R.J. Arithmetic and biologically-inspired computing using phase-change materials. Adv. Mater. 2011, 23, 3408–3413. [Google Scholar] [CrossRef]

- Behera, J.K.; Zhou, X.; Ranjan, A.; Simpson, R.E. Sb2Te3 and its superlattices: Optimization by statistical design. ACS Appl. Mater. Interfaces 2018, 10, 15040–15050. [Google Scholar] [CrossRef]

- Ie, S.Y.; Bea, B.T.; Ahn, Y.-K.; Chang, M.Y.; You, D.G.; Cho, M.H.; Jeong, K. Texture formation of GeSbTe thin films prepared by multilayer deposition of modulating constituent elements. Appl. Phys. Lett. 2007, 90, 251917. [Google Scholar] [CrossRef]

- Simpson, R.E.; Fons, P.; Kolobov, A.V.; Krbal, M.; Tominaga, J. Enhanced crystallization of GeTe from an Sb2Te3 template. Appl. Phys. Lett. 2012, 100, 021911. [Google Scholar] [CrossRef]

- Simpson, R.E.; Fons, P.; Kolobov, A.V.; Fukaya, T.; Krbal, M.; Yagi, T.; Tominaga, J. Interfacial phase-change memory. Nat. Nanotechnol. 2011, 6, 501–505. [Google Scholar]

- Sun, C.W.; Lee, J.Y.; Youm, M.S.; Kim, Y.T. Crystal structure and atomic arrangement of δ-phase Sb-Te binary alloy. Jpn. J. Appl. Phys. 2006, 45, 9157–9161. [Google Scholar] [CrossRef]

- Atwood, G. Phase-change materials for electronic memories. Science 2008, 321, 210–211. [Google Scholar] [CrossRef]

- Liu, G.; Wu, L.; Zhu, M.; Song, Z.; Rao, F.; Song, S.; Cheng, Y. The investigations of characteristics of Sb2Te as a base phase-change material. Solid-State Electron. 2017, 135, 31–36. [Google Scholar] [CrossRef]

- Zhang, M.-X.; Kelly, P.M.; Easton, M.A.; Taylor, J.A. Crystallographic study of grain refinement in aluminum alloys using the edge-to-edge matching model. Acta Mater. 2005, 53, 1427–1438. [Google Scholar] [CrossRef]

- Ali, Y.; Qiu, D.; Jiang, B.; Pan, F.; Zhang, M.-X. Current research progress in grain refinement of cast magnesium alloys: A review article. J. Alloys Compd. 2015, 619, 639–651. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, M.S.; Kim, R.-Y.; Kim, K.S.; Kim, H.G. Characterization of Agx(Ge2Sb2Te5)1-x thin film by RF magnetron sputtering. Mater. Charact. 2007, 58, 479–484. [Google Scholar] [CrossRef]

- Daymond, M.R.; Holt, R.A.; Cai, S.; Mosbrucker, P.; Vogel, S.C. Texture inheritance and variant selection through an hcp–bcc–hcp phase transformation. Acta Mater. 2010, 58, 4053–4066. [Google Scholar] [CrossRef]

- Romero, J.; Preuss, M.; Quinta da Fonseca, J. Texture memory and variant selection during phase transformation of a zirconium alloy. Acta Mater. 2009, 57, 5501–5511. [Google Scholar] [CrossRef]

- Yu, Y.N. Fundamentals of Materials Science, 2nd ed.; China Higher Education Press: Beijing, China, 2012; pp. 428–435. [Google Scholar]

- Zhou, X.; Kalikka, J.; Ji, X.; Wu, L.; Song, Z.; Simpson, R.E. Phase-change memory materials by design: A strain engineering approach. Adv. Mater. 2016, 28, 3007–3016. [Google Scholar] [CrossRef]

- Agafonov, V.; Rodier, N.; Céolin, R.; Bellissent, R.; Bergman, C.; Gaspard, J.P. Structure of Sb2Te. Acta Crystallogr. 1991, C47, 1141–1143. [Google Scholar] [CrossRef]

- Mitra, M.; Jung, Y.; Gianola, D.S.; Agarwal, R. Extremely low drift of resistance and threshold voltage in amorphous phase change nanowire devices. Appl. Phys. Lett. 2010, 96, 222111. [Google Scholar] [CrossRef]

- Raoux, S.; Rettner, C.T.; Jordan-Sweet, J.L.; Kellock, A.J.; Topuria, T.; Rice, P.M.; Miller, D.C. Direct observation of amorphous to crystalline phase transitions in nanoparticle arrays of phase change materials. J. Appl. Phys. 2007, 102, 094305. [Google Scholar] [CrossRef]

- Chang, C.-C.; Chao, C.-T.; Wu, J.-C.; Yew, T.-R.; Tsai, M.-J.; Chin, T.-S. The use of Ga16Sb84 alloy for electronic phase-change memory. Scr. Mater. 2011, 64, 801–804. [Google Scholar] [CrossRef]

- Wu, W.; Chen, S.; Zhai, J. Study on the physical properties and structure of titanium antimony thin films for phase change memory application. J. Mater. Sci. 2017, 52, 11598–11607. [Google Scholar] [CrossRef]

- Takagaki, Y.; Giussani, A.; Tominaga, J.; Jahn, U.; Calarco, R. Transport properties in a Sb–Te binary topological-insulator system. J. Phys. Condens. Matter 2013, 25, 345801. [Google Scholar] [CrossRef]

- Peng, C.; Wu, L.; Rao, F.; Song, Z.; Yang, P.; Song, H.; Ren, K.; Zhou, X.; Zhu, M.; Liu, B.; et al. W-Sb-Te phase-change material: A candidate for the trade-off between programming speed and data retention. Appl. Phys. Lett. 2012, 101, 122108. [Google Scholar] [CrossRef]

- Tong, H.; Yu, N.N.; Yang, Z.; Cheng, X.M.; Miao, X.S. Disorder-induced anomalously signed hall effect in crystalline GeTe/Sb2Te3 superlattice-like materials. J. Appl. Phys. 2015, 118, 075704. [Google Scholar] [CrossRef]

- Findikoglu, A.T.; Choi, W.; Matias, V.; Holesinger, T.G.; Jia, Q.X.; Peterson, D.E. Well-oriented silicon thin films with high carrier mobility on polycrystalline substrates. Adv. Mater. 2005, 17, 1527–1531. [Google Scholar] [CrossRef]

- Cojocaru-Mirédin, O.; Hollermann, H.; Mio, A.M.; Wang, A.Y.-T.; Wuttig, M. Role of grain boundaries in Ge-Sb-Te based chalcogenide superlattices. J. Phys. Condens. Matter 2019, 31, 204002. [Google Scholar] [CrossRef]

- Tsurekawa, S.; Kido, K.; Watanabe, T. Interfacial state and potential barrier height associated with grain boundaries in polycrystalline silicon. Mater. Sci. Eng. A 2007, 462, 61–67. [Google Scholar] [CrossRef]

- Kasper, J.S.; Richards, S.M. The crystal structures of new forms of silicon and germanium. Acta Crystallogr. 1964, 17, 752–755. [Google Scholar] [CrossRef]

- Yin, Q.; Chen, L. Enhanced optical properties of Sn-doped Ge2Sb2Te5 thin film with structural evolution. J. Alloys Compd. 2019, 770, 692–700. [Google Scholar] [CrossRef]

- Gao, Q.; Chen, L. Effect of Cu doping on microstructure and thermal stability of Ge2Sb2Te5 thin film. Appl. Phys. A 2019, 125, 564. [Google Scholar] [CrossRef]

- Behrens, M.; Lotnyk, A.; Roß, U.; Griebel, J.; Schumacher, P.; Gerlach, J.W.; Rauschenbach, B. Impact of disorder on optical reflectivity contrast of epitaxial Ge2Sb2Te5 thin films. CrystEngComm 2018, 20, 3688–3695. [Google Scholar] [CrossRef]

| Crystal Plane | (0001) | ||||

|---|---|---|---|---|---|

| Interplanar Spacing (nm) | 0.3131 | 0.2301 | 0.2360 | 0.1233 | 1.7633 |

| Annealing Time | 15 min (35 min) | |||

|---|---|---|---|---|

| Diffraction plane | ||||

| Diffraction intensity (1000 nm) | 30,646 (30,895) | 1653 (1794) | 233 (205) | 257 (332) |

| Diffraction intensity (200 nm) | 6603 (6353) | 367 (357) | 159 (173) | 183 (198) |

| Sb2Te Thin Film | ||||||

|---|---|---|---|---|---|---|

| 2θ (°) | d (nm) | a (nm) | 2θ (°) | d (nm) | a (nm) | |

| 200 nm | 42.170 (42.232) | 0.2141 (0.2138) | 0.4282 (0.4276) | 77.010 (77.078) | 0.1237 (0.1236) | 0.4286 (0.4283) |

| 1000 nm | 42.054 (42.150) | 0.2147 (0.2142) | 0.4294 (0.4284) | 76.757 (76.854) | 0.1241 (0.1239) | 0.4298 (0.4294) |

| Matching Relation | |||||

|---|---|---|---|---|---|

| Mismatch | 0.624 | 1.119 | 1.884 | 2.107 | 4.381 |

| Matching Relation | |||||

|---|---|---|---|---|---|

| Mismatch | 0.734 | 0.499 | 1.039 | 1.197 | 2.805 |

| Matching Relation | |||||

|---|---|---|---|---|---|

| Mismatch | 0.783 | 0.224 | 0.665 | 0.794 | 2.107 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, L.; Chen, L. Study on Texture Formation of Sb2Te Thin Films for Phase Change Memory Applications. Crystals 2023, 13, 377. https://doi.org/10.3390/cryst13030377

Kang L, Chen L. Study on Texture Formation of Sb2Te Thin Films for Phase Change Memory Applications. Crystals. 2023; 13(3):377. https://doi.org/10.3390/cryst13030377

Chicago/Turabian StyleKang, Lei, and Leng Chen. 2023. "Study on Texture Formation of Sb2Te Thin Films for Phase Change Memory Applications" Crystals 13, no. 3: 377. https://doi.org/10.3390/cryst13030377

APA StyleKang, L., & Chen, L. (2023). Study on Texture Formation of Sb2Te Thin Films for Phase Change Memory Applications. Crystals, 13(3), 377. https://doi.org/10.3390/cryst13030377