Ancient Metallurgical Iron Slags—Chemical, Powder X-ray Diffraction and Mössbauer Spectroscopic Study

Abstract

1. Introduction

2. Materials and Methods

3. Results

3.1. XRF

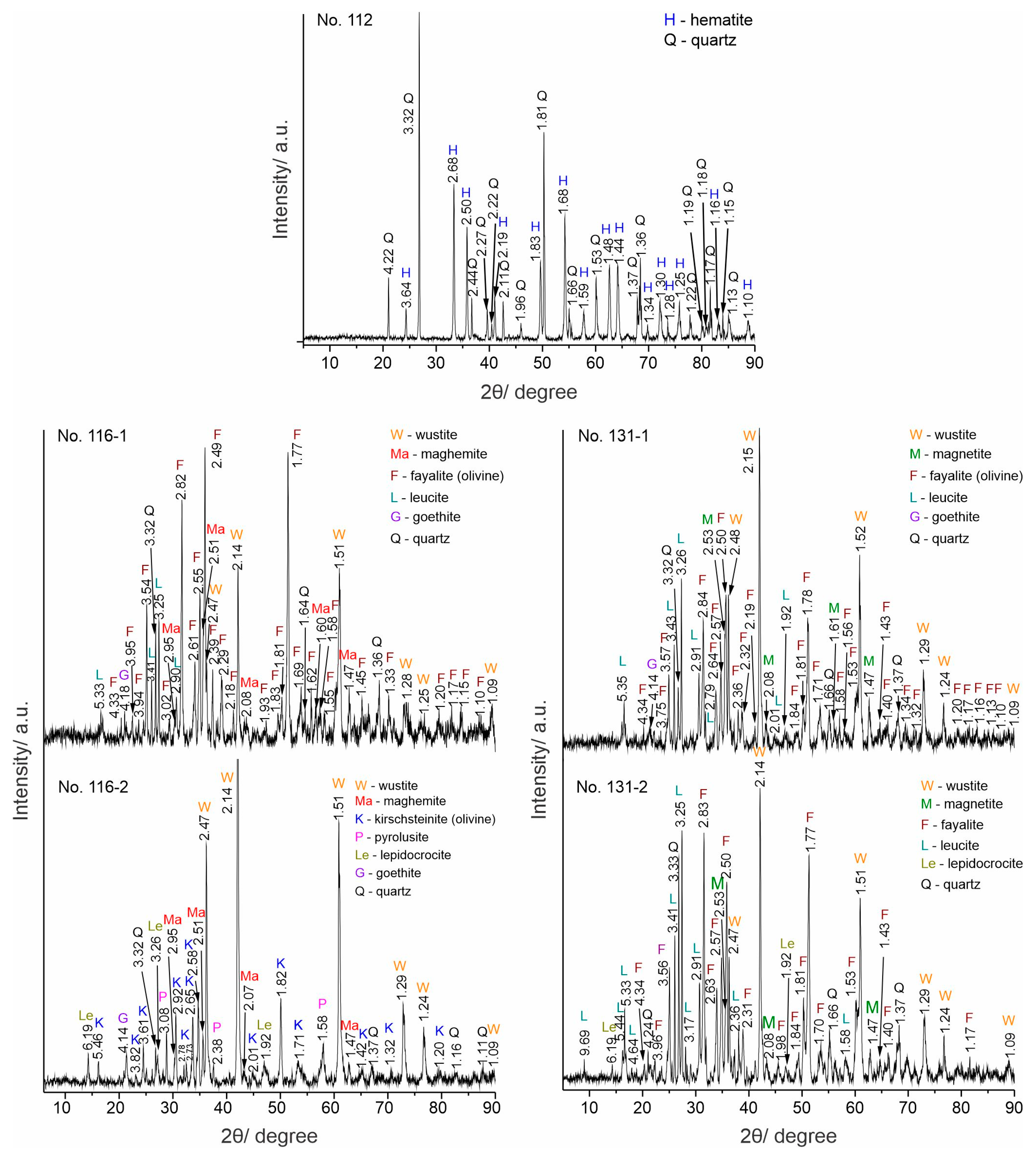

3.2. PXRD

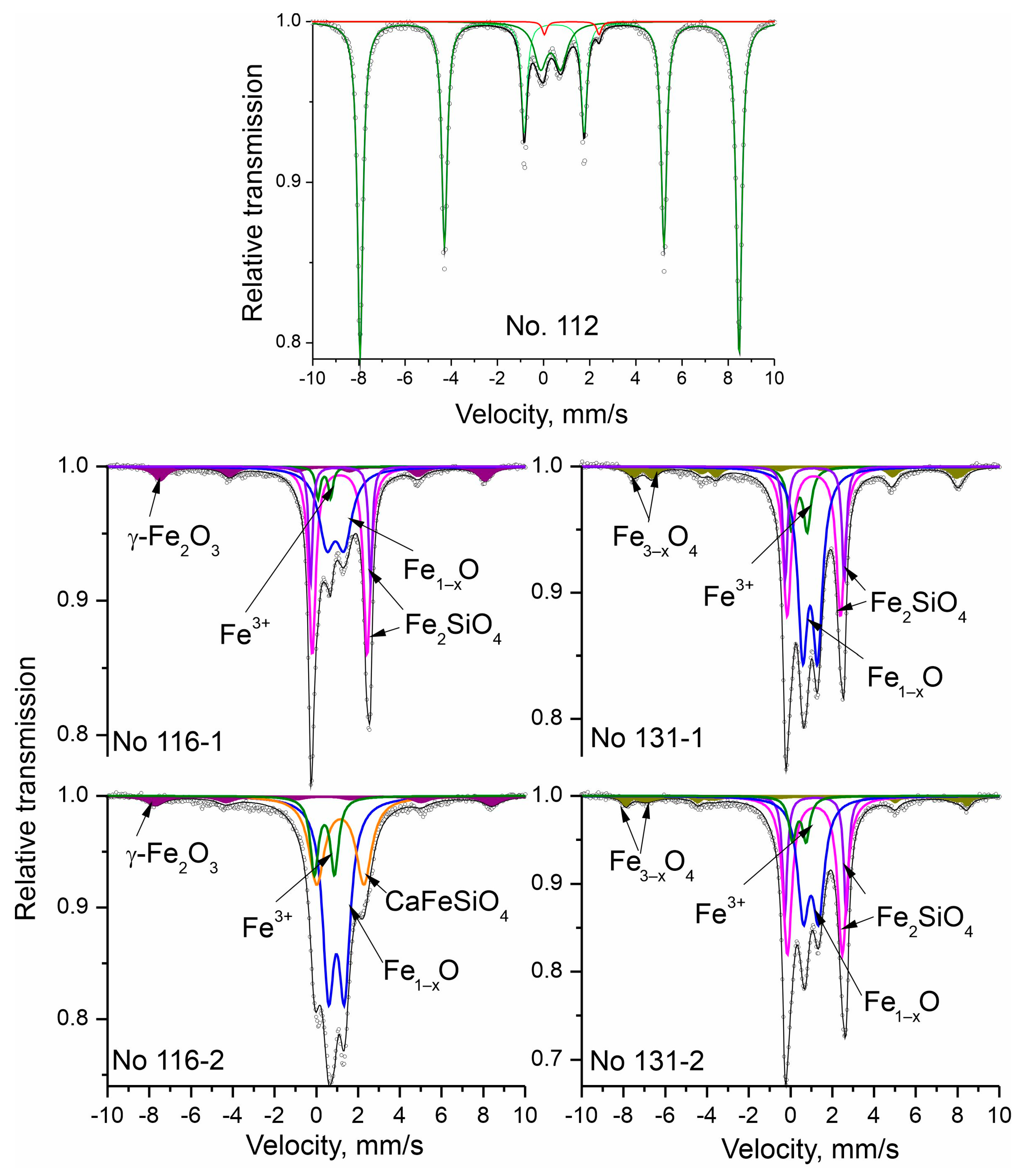

3.3. Mössbauer Spectroscopy

4. Discussion

4.1. Slag Type

4.2. Slag Phase Composition

4.3. Produced Iron

4.4. Factors Determining Produced Iron

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bayley, J.; Dungworth, D.; Paynter, S.C. Archaeometallurgy: Guidelines for Best Practice; Historic England: England, UK, 2015. [Google Scholar]

- Williams, A. The Knight and the Blast Furnace: A Histoty of the Metallurgy of Armour in the Middle Ages and the Early Modern Period; Brill: Leiden, The Netherlands, 2003. [Google Scholar]

- Larreina-Garcia, D.; Li, Y.; Liu, Y.; Martinón-Torres, M. Bloomery iron smelting in the Daye County (Hubei): Technological traditions in Qing China. Archaeol. Res. Asia 2018, 16, 148–165. [Google Scholar] [CrossRef]

- Portillo, H.; Zuluaga, M.C.; Ortega, L.A.; Alonso-Olazabal, A.; Murelaga, X.; Martinez-Salcedo, A. XRD, SEM/EDX and micro-Raman spectroscopy for mineralogical and chemical characterization of iron slags from the Roman archaeological site of Forua (Biscay, North Spain). Microchem. J. 2018, 138, 246–254. [Google Scholar] [CrossRef]

- Portillo-Blanco, H.; Zuluaga, M.C.; Ortega, L.A.; Alonso-Olazabal, A.; Cepeda-Ocampo, J.J.; Martínez Salcedo, A. Mineralogical characterization of slags from the Oiola site (Biscay, Spain) to assess the development in bloomery iron smelting technology from the Roman period to the Middle Ages. Minerals 2020, 10, 321. [Google Scholar] [CrossRef]

- Roberts, B.W.; Thornton, C.P. Archaeometallurgy in Global Perspective: Methods and Syntheses; Springer: New York, NY, USA, 2014. [Google Scholar] [CrossRef]

- Bitay, E.; Kacsó, I.; Tănăselia, C.; Toloman, D.; Borodi, G.; Pánczél, S.-P.; Kisfaludi-Bak, Z.; Veress, E. Spectroscopic characterization of iron slags from the archaeological sites of Brâncoveneşti, Călugăreni and Vătava located on the Mureş County (Romania) Sector of the Roman Limes. Appl. Sci. 2020, 10, 5373. [Google Scholar] [CrossRef]

- Manasse, A.; Mellini, M. Chemical and textural characterisation of medieval slags from the Massa Marittima smelting sites (Tuscany, Italy). J. Cult. Herit 2002, 3, 187–198. [Google Scholar] [CrossRef]

- Tylecote, R.F. A History of Metallurgy, 2nd ed.; Maney: For the institute of material: London, UK, 2002. [Google Scholar]

- Friede, H.; Hejja, A.; Koursaris, A. Arhaeo-metallurgical studies of iron smelting slags from prehistoric sites in Southern Africa. J. S. Afr. Inst. Min. Metall. 1982, 82, 38–48. [Google Scholar]

- Török, B.; Gallina, Z.; Kovács, Á.F. Kristály, Early medieval iron bloomery centre at Zamárdi (Hungary), Complex archaeometrical examinations of the slags. Archeol. Rozhl. 2018, 70, 404–420. [Google Scholar]

- Di Bella, M.; Aleo Nero, C.; Chiovaro, M.; Italiano, F.; Leonetti, F.; Marcianò, G.; Quartieri, S.; Romano, D.; Sabatino, G. Archaeometric study of the Hellenistic metallurgy in Sicily: Mineralogical and chemical characterization of iron slags from Punic Panormos (Palermo, Italy). Mediterr. Archaeol. Archaeom. 2018, 18, 127–139. [Google Scholar] [CrossRef]

- Chernih, E.N. Mining and Metallurgy in Ancient BULGARIA; BAS Publishing House: Sofia, Bulgaria, 1978. [Google Scholar]

- Dumanov, B. Archaeology of the Old Iron Mining on the Lower Danube and in the Stara Planina Mountain Region—Roman Imperial Epoch-End of the XVIII Century; New Bulgarian University: Sofia, Bulgaria, 2021. [Google Scholar]

- Tsankov, T.; Philipov, L.; Katskov, N. Explanatory Note to a Geological Map of Bulgaria M 1:100,000, Kazanlak Map Sheet; ET Avers: Sofia, Bulgaria, 1995. [Google Scholar]

- Kanurkov, G. Iron Ore Deposits in Bulgaria; Tehnika: Sofia, Bulgaria, 1988. [Google Scholar]

- Uzunov, Z.; Dimitrova, I.; Dumanov, B. Results from the field archeological excavations of archeological sites in the working area. In SARCHUS-AIR. Localization and Experimental Reconstruction of Ancient Roads and Habitats; Dumanov, B., Ed.; Askoni Izdat.: Sofia, Bulgaria, 2017; pp. 37–49. [Google Scholar]

- PDF (Powder Diffraction File); ICDD: Newtown Square, PA, USA, 2001.

- Wyckoff, R.W.G. Crystal Structures; Interscience Publishers: New York, NY, USA, 1963. [Google Scholar]

- Cornell, R.M.; Schwertmann, U. The Iron Oxides: Structure, Properties, Reactions, Occurrences and Uses, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2003. [Google Scholar] [CrossRef]

- Geiger, C.A.; Vielreicher, N.M.; Dachs, E. Are the thermodynamic properties of natural and synthetic Mg2SiO4-Fe2SiO4 olivines the same? Am. Miner. 2021, 106, 317–321. [Google Scholar] [CrossRef]

- Eibschütz, M.; Ganiel, U. Mössbauer studies of Fe2+ in paramagnetic fayalite (Fe2SiO4). Solid State Commun. 1967, 5, 267–270. [Google Scholar] [CrossRef]

- Kramar, S.; Lux, J.; Pristacz, H.; Mirtič, B.; Rogan-Šmuc, N. Mineralogical and geochemical characterization of Roman slag from the archaeological site near Mosnje (Slovenia). Mater. Technol. 2015, 49, 343–348. [Google Scholar] [CrossRef]

- Davidson, P.M.; Mukhopadhyay, D.K. Ca-Fe-Mg olivines: Phase relations and a solution model. Contrib. Miner. Pet. 1984, 86, 256–263. [Google Scholar] [CrossRef]

- Dyar, M.D.; Sklute, E.C.; Menzies, O.N.; Bland, P.A.; Lindsley, D.; Glotch, T.; Lane, M.D.; Schaefer, M.W.; Wopenka, B.; Klima, R.; et al. Spectroscopic characteristics of synthetic olivine: An integrated multi-wavelength and multi-technique approach. Am. Mineral. 2009, 94, 883–898. [Google Scholar] [CrossRef]

- Wyderko, M.; Mazanek, E. The mineralogical characteristics of calcium-iron olivines. Mineral. Mag. J. Mineral. Soc. 1968, 36, 955–961. [Google Scholar] [CrossRef]

- Tošić, M.B.; Mitrović, M.M.; Dimitrijević, R.Ž. Crystallization of leucite as the main phase in aluminosilicate glass with low fluorine content. J. Mater. Sci. 2000, 35, 3659–3667. [Google Scholar] [CrossRef]

- Allibert, M. Slag Atlas, 2nd ed.; Verlag Stahleisen GmbH: Düsseldorf, Germany, 1995. [Google Scholar]

- Bachmann, H.G. The Identification of Slags from Archeological Sites; Occasional Publication No. 6; Institute of Archeology: London, UK, 1982; pp. 1–37. [Google Scholar]

| Sample | Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | MnO | Fe2O3 | Fe * |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No 112 | <LOD | 0.73 | 6.03 | 34.50 | 0.37 | <LOD | 0.95 | 0.70 | 0.27 | 0.09 | 56.31 | 39.37 |

| No. 116-1 | 0.52 | 0.48 | 9.54 | 32.55 | 0.68 | 0.09 | 4.40 | 6.28 | 0.34 | 0.11 | 44.90 | 31.39 |

| No. 116-2 | 0.70 | 0.88 | 5.94 | 26.80 | 1.42 | 0.11 | 6.07 | 9.75 | 0.16 | 0.16 | 47.75 | 33.39 |

| No. 131-1 | 0.42 | 0.40 | 7.12 | 28.75 | 0.60 | 0.13 | 5.02 | 5.61 | 0.24 | 0.10 | 51.46 | 35.98 |

| No. 131-2 | 0.75 | 0.78 | 8.94 | 32.58 | 0.70 | 0.08 | 5.32 | 6.39 | 0.25 | 0.11 | 43.93 | 30.72 |

| Minerals/Phases | Sample | |||||||

|---|---|---|---|---|---|---|---|---|

| Origin | Name | Chemical formula | Ore | Slags | ||||

| No. 112 | No. 116-1 | No. 116-2 | No. 131-1 | No. 131-2 | ||||

| Ore-forming raw/relict | H—hematite | Fe3+2O3 | H | - | - | - | - | |

| Q—quartz | SiO2 | Q | Q | Q | Q | Q | ||

| New-formed metallurgical phases | olivine group | F—fayalite | Fe2+2SiO4 | - | F | - | F | F |

| K— kirschsteinite | CaFe2+SiO4 | - | - | K | - | - | ||

| feldspatoid group | L—leucite | K(AlSi2O6) | - | L | - | L | L | |

| Fe-oxides | W—wüstite | Fe2+O | - | W | W | W | W | |

| P—pyrolusite | Mn4+O2 | - | - | P | - | - | ||

| New-formed during liquid slag cooling | Fe— oxides | Ma— maghemite | γ-Fe3+2O3 | - | Ma | Ma | - | - |

| M—magnetite | Fe2+Fe3+2O4 | M | M | |||||

| New-formed weathering minerals | G—goethite | α-Fe3+O(OH) | - | G | G | G | - | |

| Le—lepidocrocite | γ-Fe3+O(OH) | - | - | Le | - | Le | ||

| Sample | Compounds | δ, mm/s | 2ε/Δ, mm/s | Bhf, T | Г, mm/s | A, % | Fe2+/Fe3+ |

|---|---|---|---|---|---|---|---|

| No. 112 | Sx- α-Fe2O3 - (Fe3+) Db1 - Fe2+ Db2 - (Fe3+) | 0.36 1.22 0.31 | -0.20 2.37 0.88 | 50.7 - - | 0.31 0.24 0.66 | 86 2 12 | 2/98 |

| No. 116-1 | Sx-γ-Fe2O3 - (Fe3+) Db1-Fe2SiO4 - (Fe2+)-M1 Db2-Fe2SiO4 - (Fe2+)-M2 Db3-Fe1-xO - (Fe2+) Db4- (Fe3+) | 0.33 1.12 1.16 0.92 0.38 | 0.01 2.63 2.87 0.84 0.61 | 48.3 - - - - | 0.78 0.41 0.25 0.92 0.43 | 11 39 13 33 4 | 85/15 |

| No. 116-2 | Sx -γ-Fe2O3 - (Fe3+) Db1-CaFeSiO4 - (Fe2+)-M1 Db2-Fe1-xO - (Fe2+) Db3- (Fe3+) | 0.34 1.15 0.97 0.39 | 0.01 2.26 0.77 0.97 | 49.9 - - - | 0.98 0.90 0.68 0.47 | 7 32 48 13 | 80/20 |

| No. 131-1 | Sx1 - Fe3-xO4- (Fe3+tetra) Sx2 - Fe3-xO4- (Fe2.5+octa) Db1-Fe2SiO4- (Fe2+)-M1 Db2-Fe2SiO4- (Fe2+)-M2 Db3-Fe1-xO- (Fe2+) Db4- (Fe3+) | 0.29 0.65 1.12 1.16 0.94 0.42 | 0.03 0.01 2.55 2.82 0.71 0.74 | 48.4 45.4 - - - - | 0.69 0.62 0.47 0.27 0.58 0.43 | 5 6 27 11 40 10 | 82/18 |

| No. 131-2 | Sx1 - Fe3-xO4- (Fe3+tetra) Sx2 - Fe3-xO4- (Fe2.5+octa) Db1-Fe2SiO4- (Fe2+)-M1 Db2-Fe2SiO4- (Fe2+)-M2 Db3-Fe1-xO- (Fe2+) Db4- (Fe3+) | 0.29 0.59 1.16 1.19 0.98 0.40 | 0.00 0.01 2.63 2.93 0.73 0.65 | 49.1 45.4 - - - - | 0.46 1.20 0.52 0.29 0.67 0.42 | 4 6 36 14 32 8 | 85/15 |

| Sample | Produced Fe, Equivalent Mass % | Fe2+ in W, % | Fe3+ in Ma + G + Le, % | Viscosity Index |

|---|---|---|---|---|

| No. 116-1 | 7.98 | 33 | 15 | 0.28 |

| No. 116-2 | 5.98 | 48 | 20 | 0.53 |

| No. 131-1 | 3.39 | 40 | 21 | 0.32 |

| No. 131-2 | 8.65 | 32 | 18 | 0.32 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kostova, B.; Paneva, D.; Cherkezova-Zheleva, Z.; Mihaylova, K.; Dumanov, B. Ancient Metallurgical Iron Slags—Chemical, Powder X-ray Diffraction and Mössbauer Spectroscopic Study. Crystals 2023, 13, 888. https://doi.org/10.3390/cryst13060888

Kostova B, Paneva D, Cherkezova-Zheleva Z, Mihaylova K, Dumanov B. Ancient Metallurgical Iron Slags—Chemical, Powder X-ray Diffraction and Mössbauer Spectroscopic Study. Crystals. 2023; 13(6):888. https://doi.org/10.3390/cryst13060888

Chicago/Turabian StyleKostova, Bilyana, Daniela Paneva, Zara Cherkezova-Zheleva, Katerina Mihaylova, and Boyan Dumanov. 2023. "Ancient Metallurgical Iron Slags—Chemical, Powder X-ray Diffraction and Mössbauer Spectroscopic Study" Crystals 13, no. 6: 888. https://doi.org/10.3390/cryst13060888

APA StyleKostova, B., Paneva, D., Cherkezova-Zheleva, Z., Mihaylova, K., & Dumanov, B. (2023). Ancient Metallurgical Iron Slags—Chemical, Powder X-ray Diffraction and Mössbauer Spectroscopic Study. Crystals, 13(6), 888. https://doi.org/10.3390/cryst13060888