Study and Design of the Mitigation Structure of a Shell PBX Charge under Thermal Stimulation

Abstract

:1. Introduction

2. Shell Mitigation Structure Design

2.1. Pressure Relief Area Design

2.2. Design of the Pressure Relief Hole Distribution

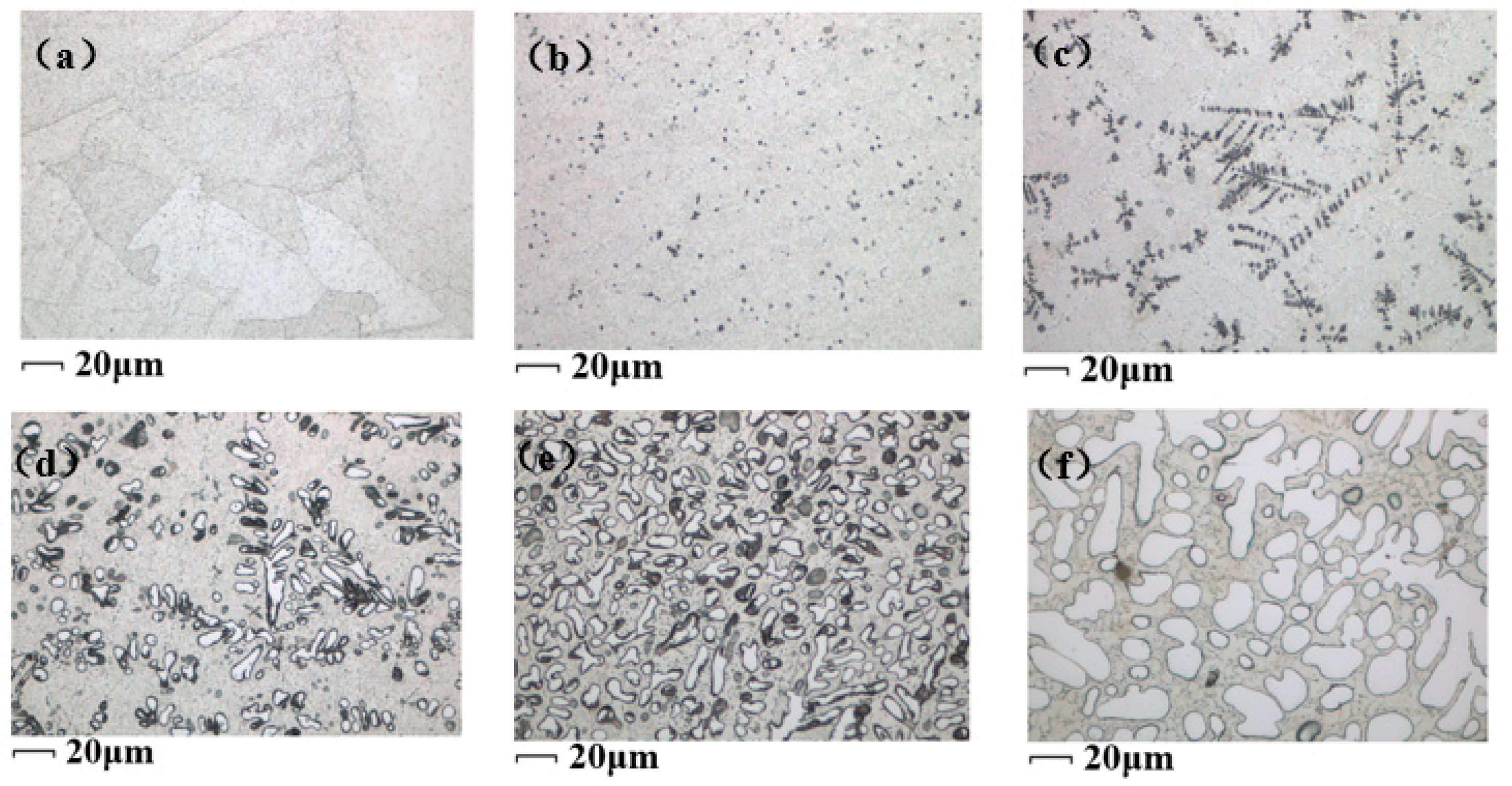

2.3. Design of Pressure Relief Hole Filling Material Design

- (1)

- These structures have sufficient strength under storage and transportation conditions and do not affect the normal use requirements of ammunition.

- (2)

- When the ammunition is subjected to unexpected thermal stimulation, such as high temperature, before reaching the lowest ignition point or explosion point of the ammunition, the mitigation structure must lose most of the strength, and the exhaust channel must be opened to reduce the reaction strength of the ammunition and improve the safety.

3. Analysis of Factors Affecting the Pressure Relief Effect

3.1. Simulation Model

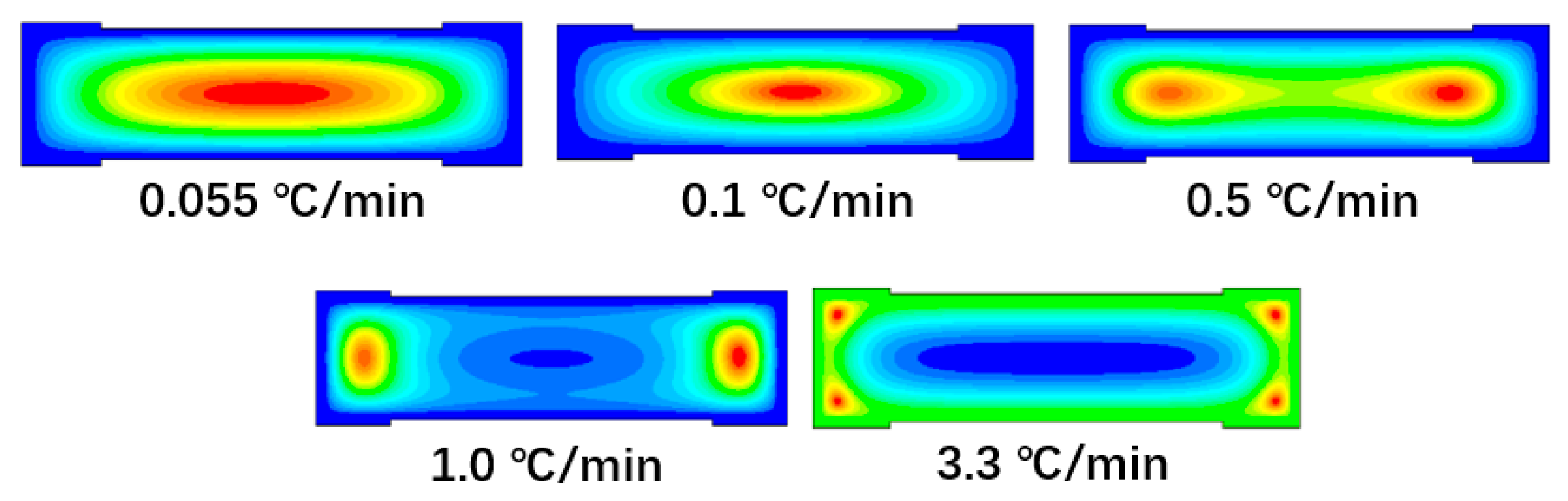

3.2. Simulation Results

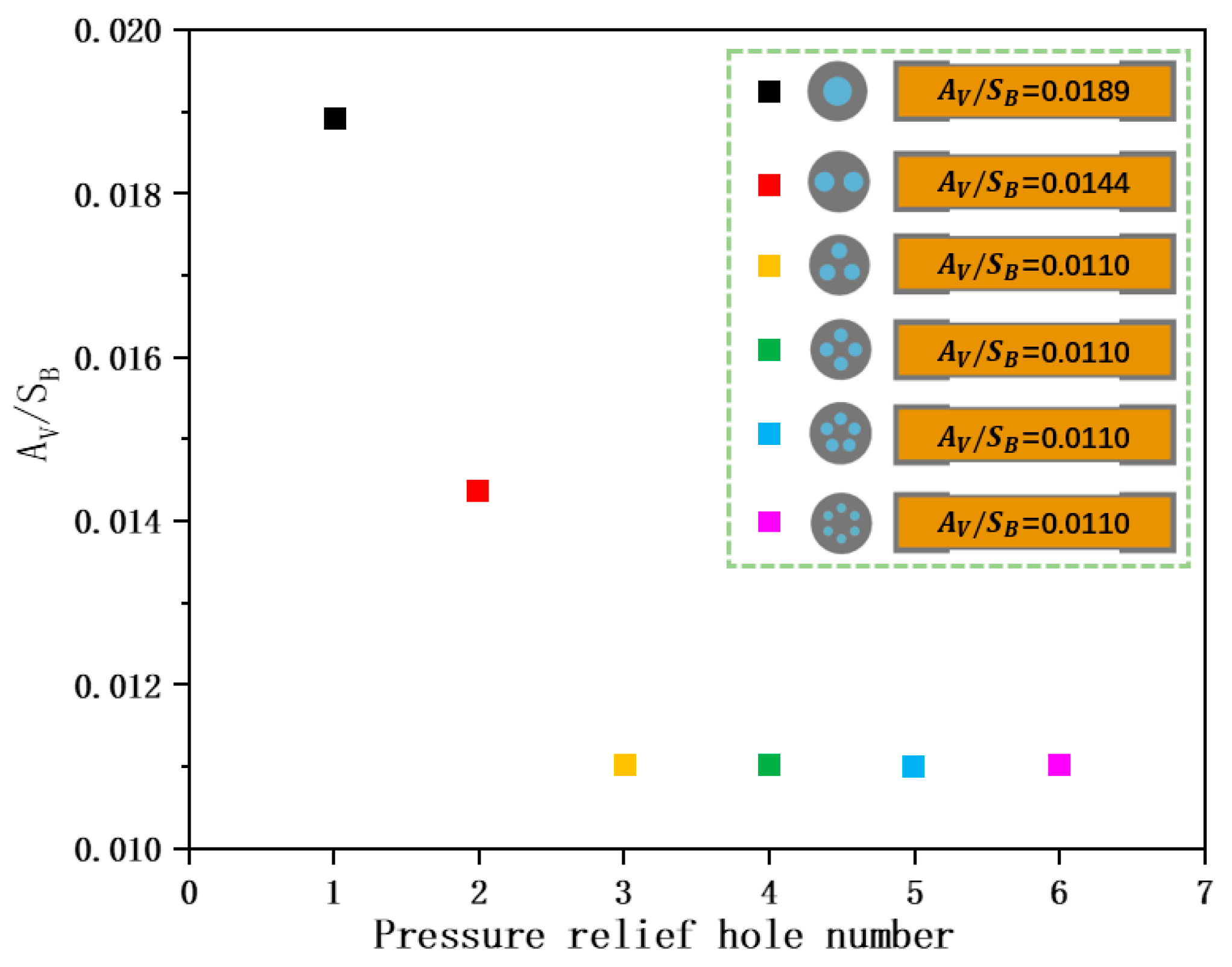

3.2.1. Influence of the Number of Pressure Relief Holes

3.2.2. Influence of Pressure Relief Area

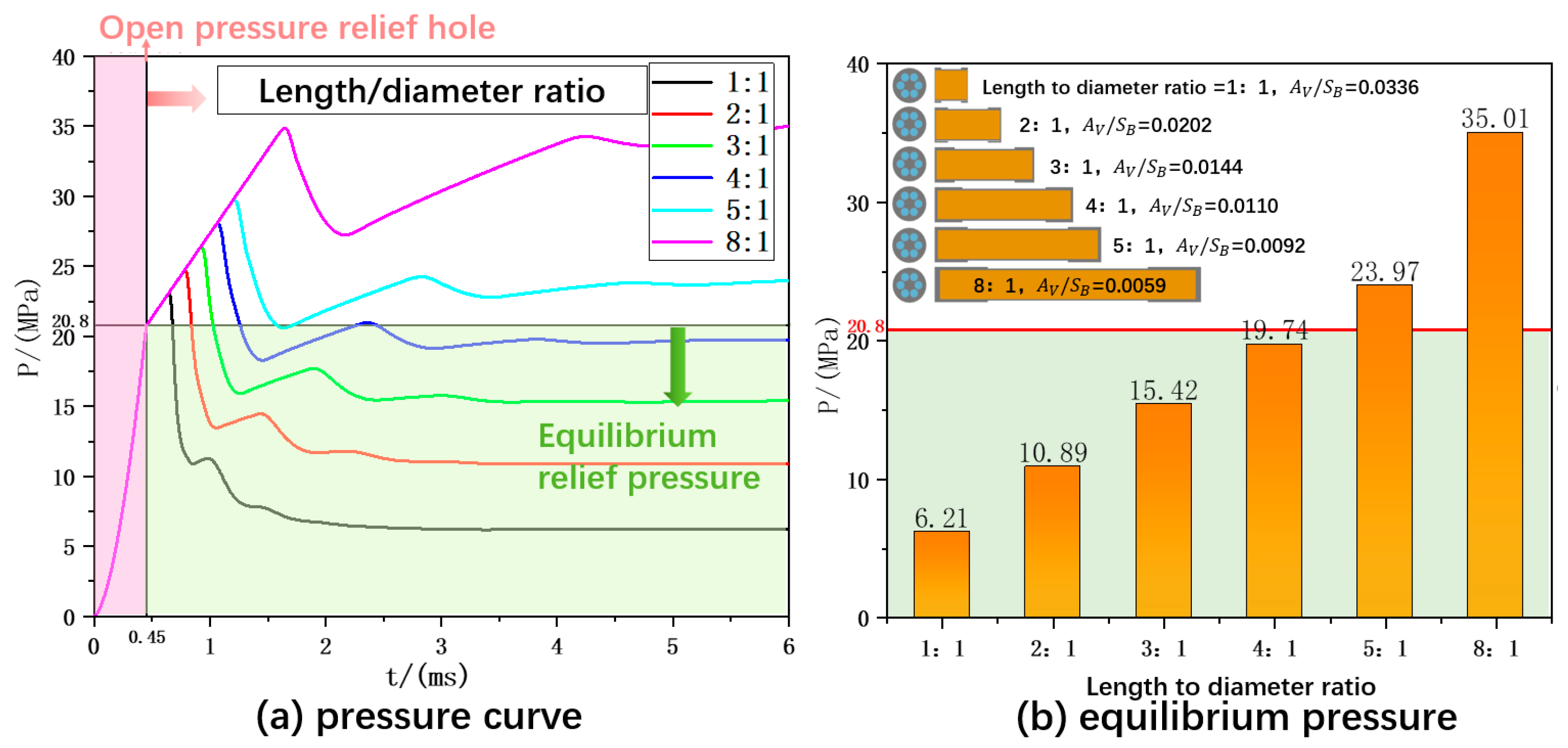

3.2.3. Influence of the Length/Diameter Ratio

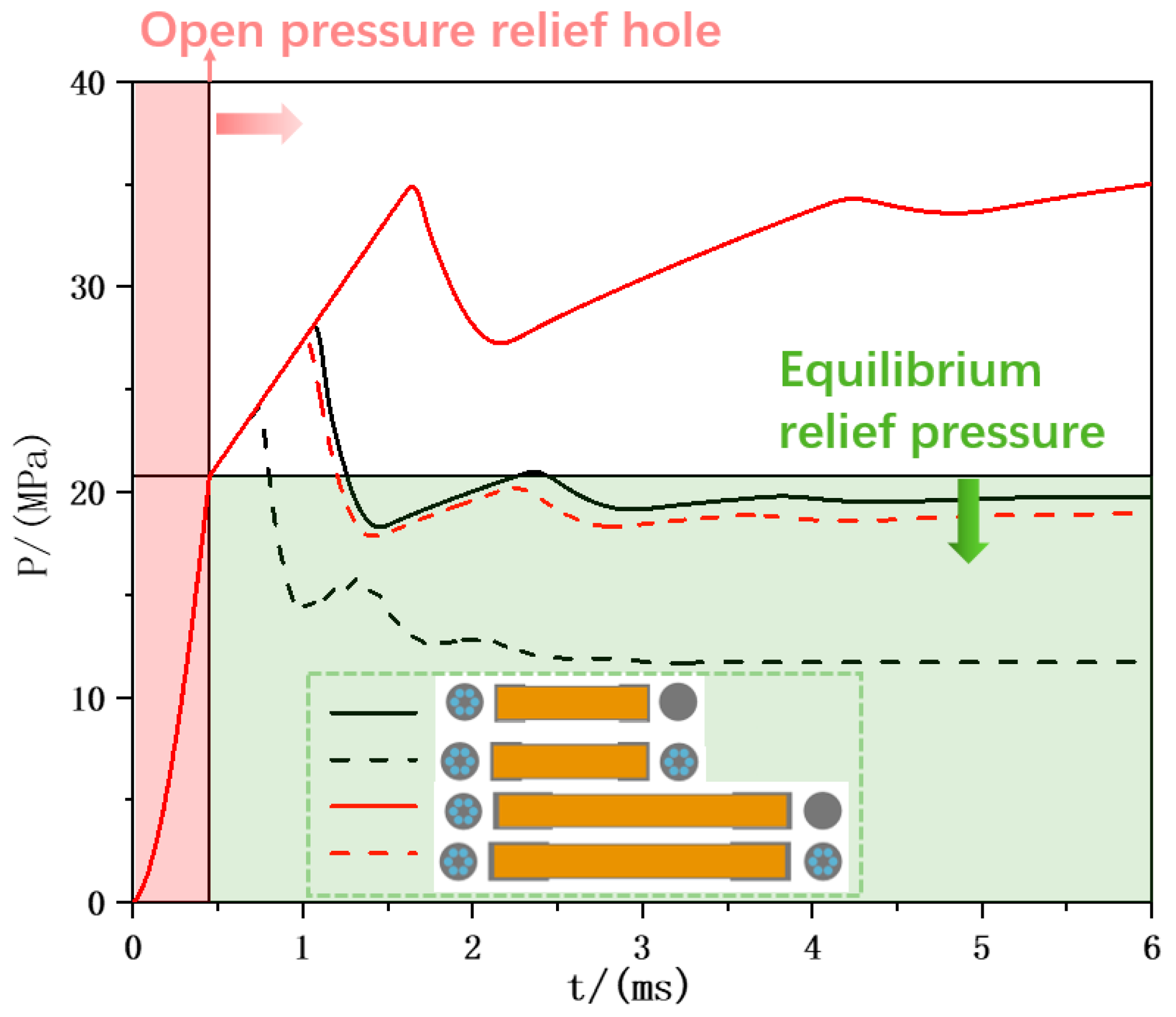

3.2.4. Influence of the Pressure Relief Hole Location

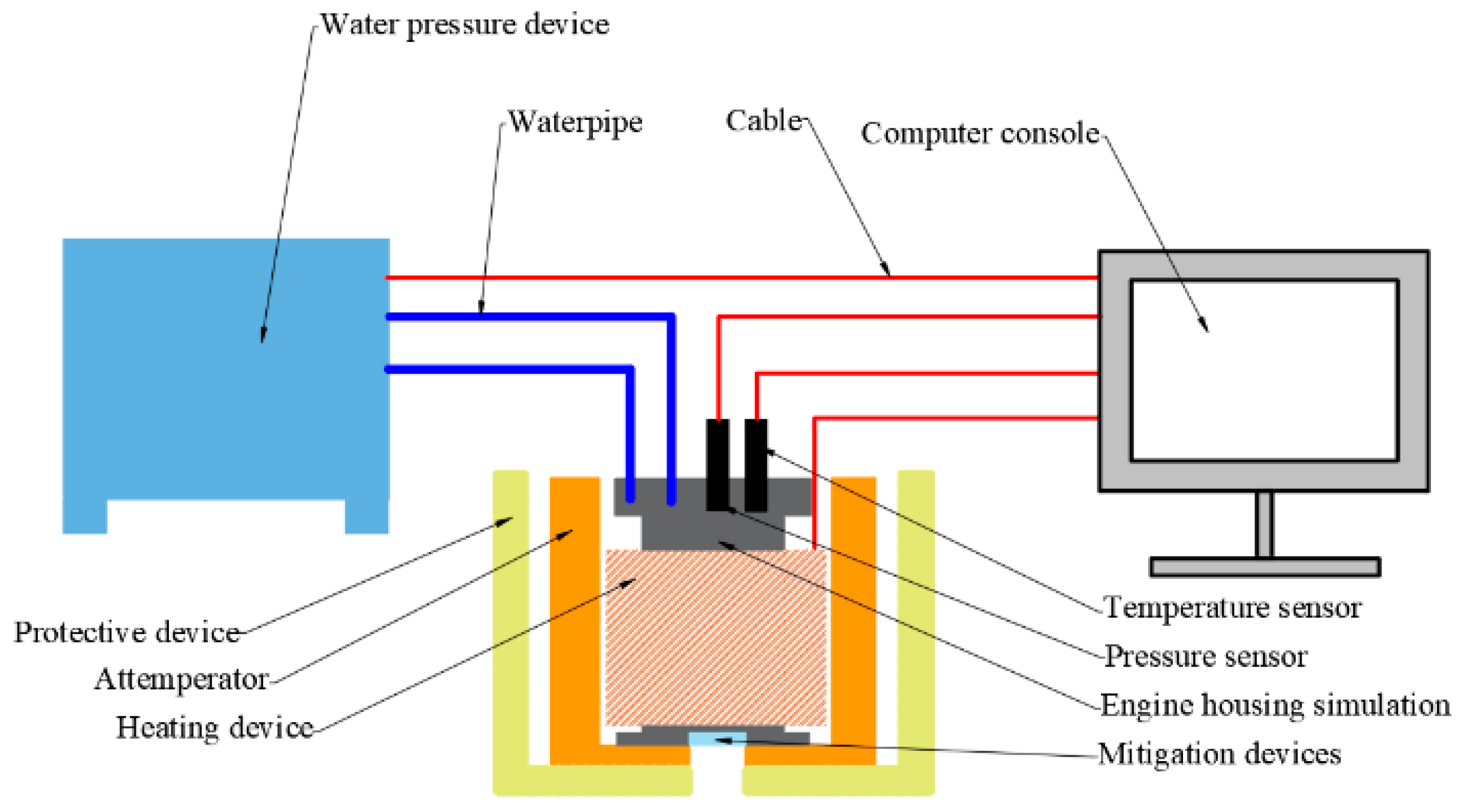

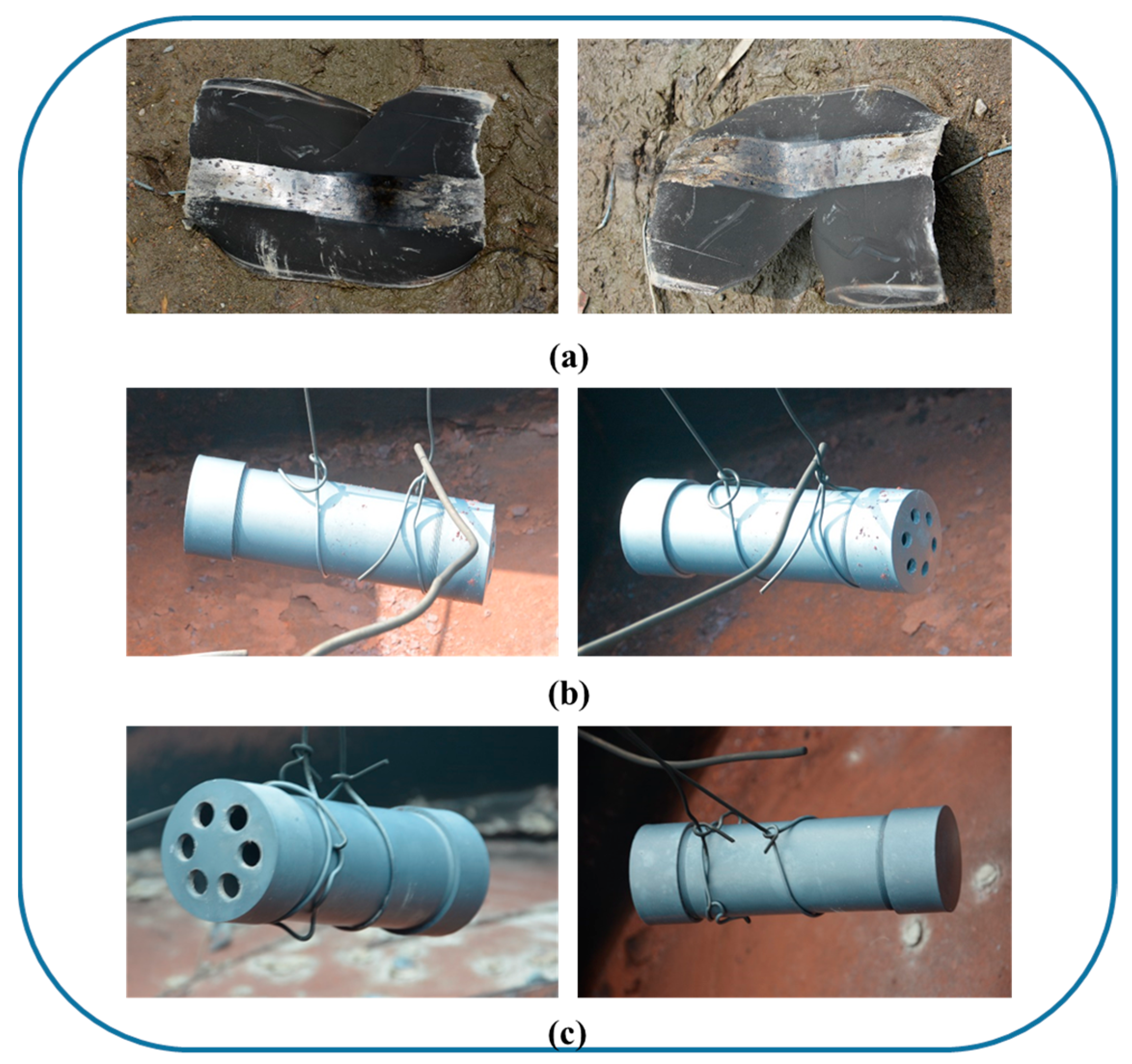

4. Test of Pressure Relief Hole Plugging Structure Strength

4.1. Hydrostatic Pressure in the High-Temperature Test

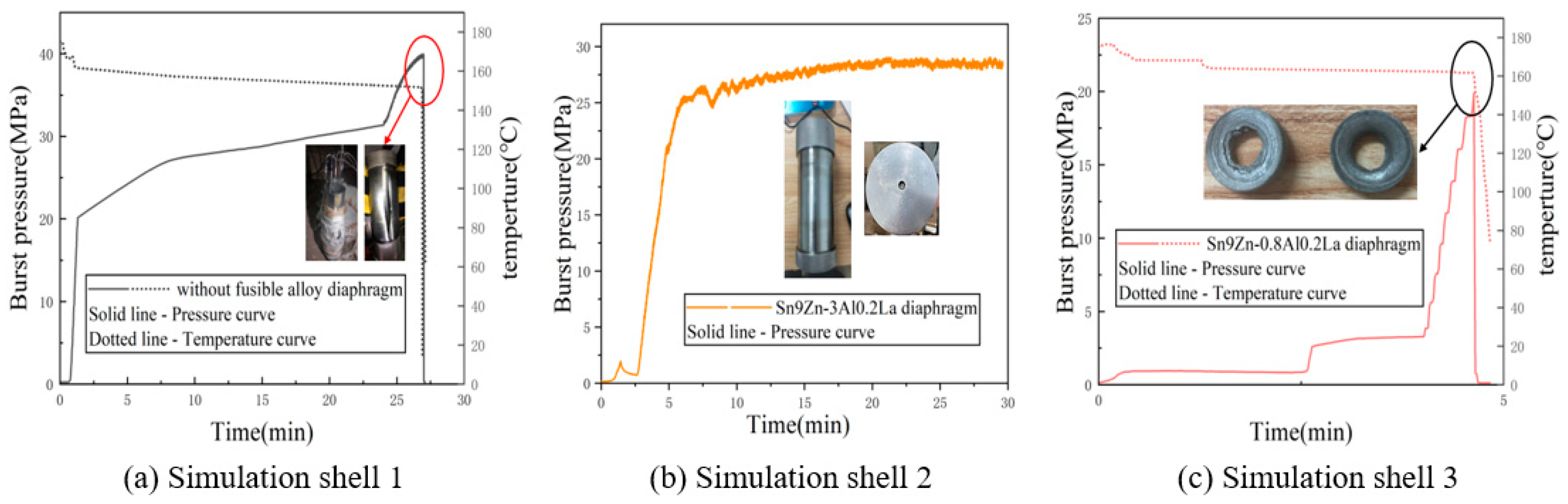

4.2. Results of the Low-Melting-Point Alloy Plug Strength Test

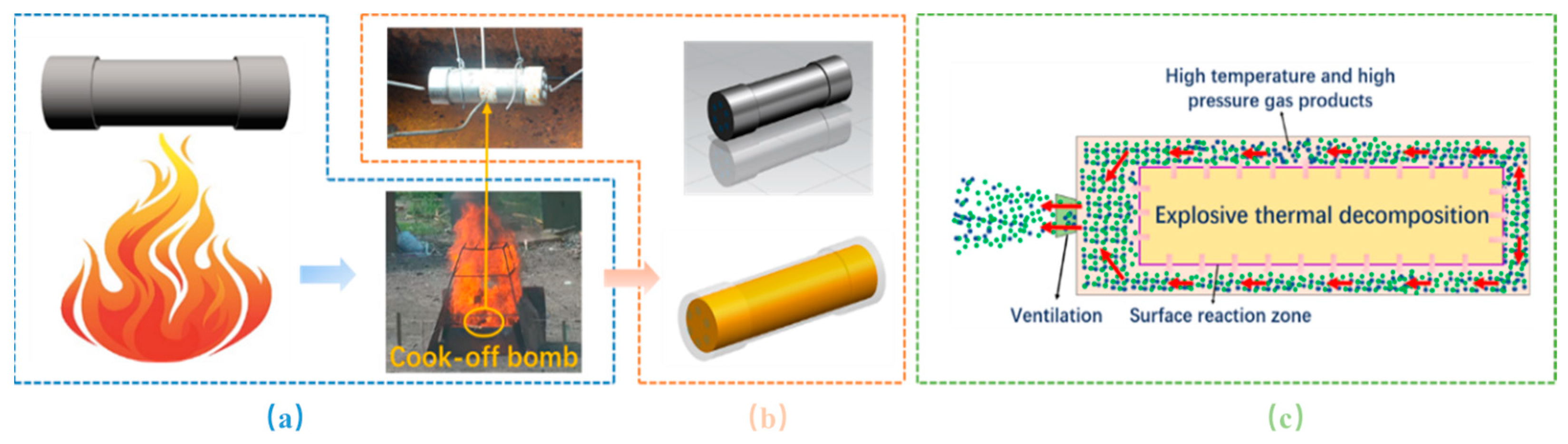

5. Mitigation Design and Cook-Off Test of the Cook-Off Bomb

5.1. Design of the Mitigation Structure of the Shelled PBX Charge

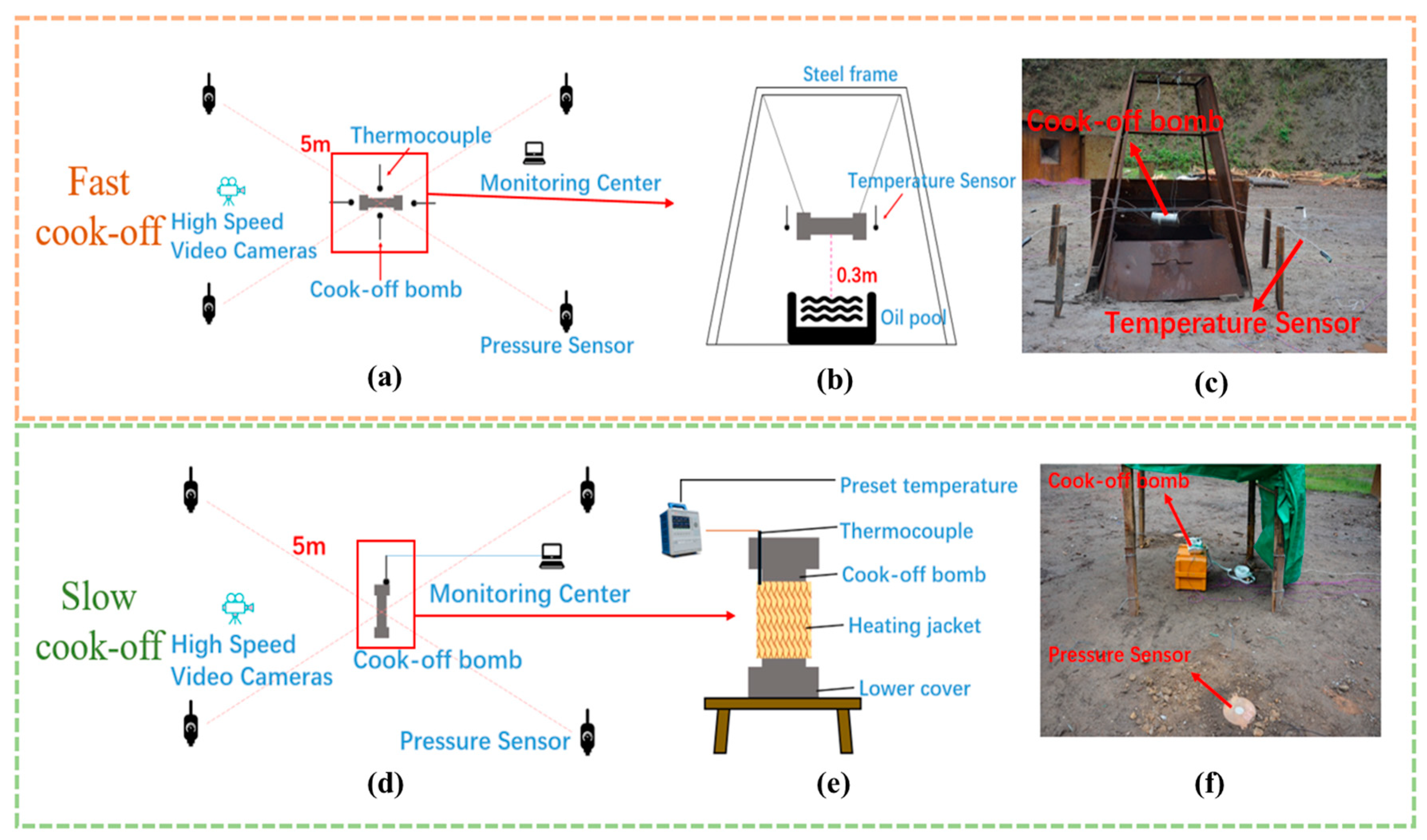

5.2. Test Conditions

5.3. Results and Analysis

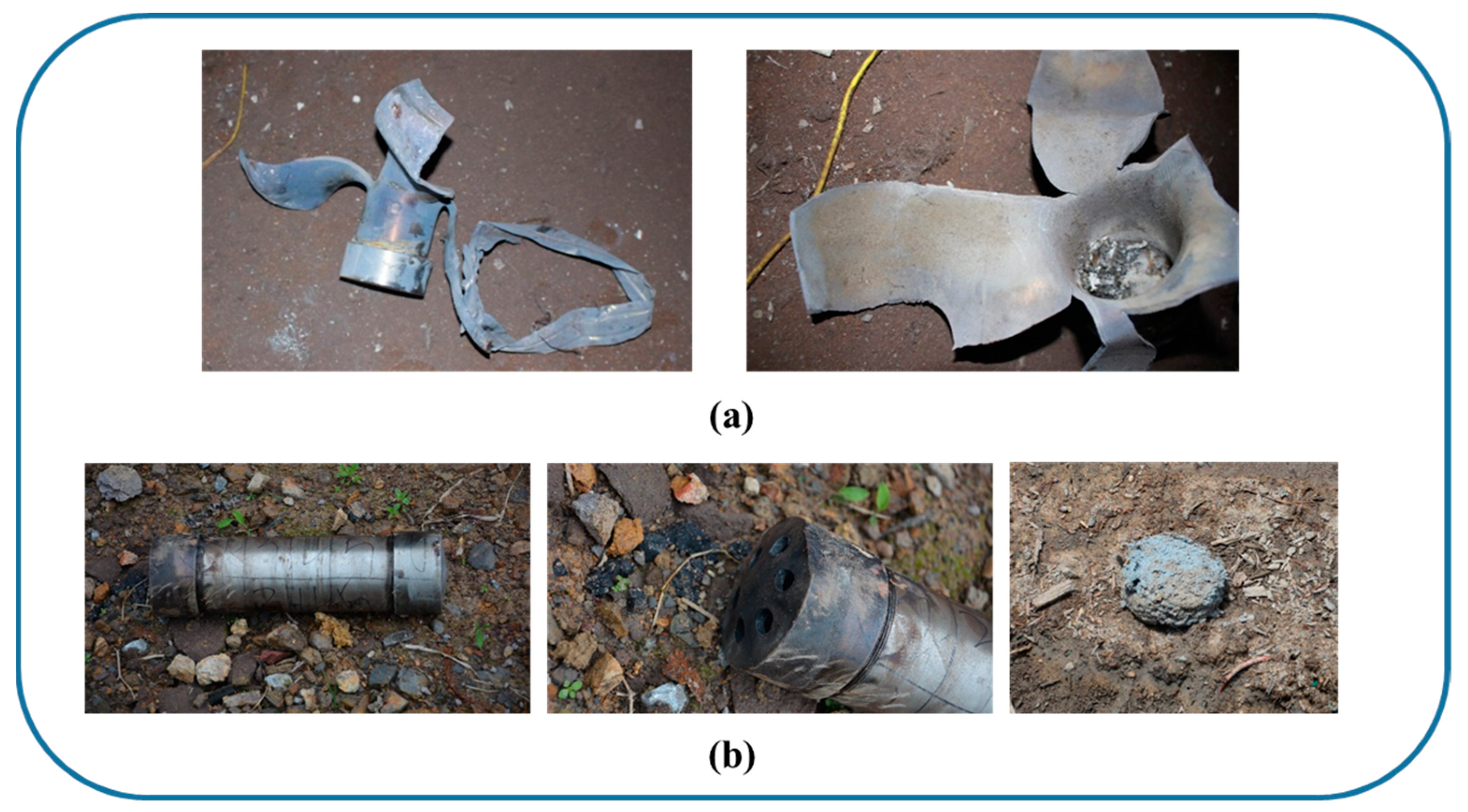

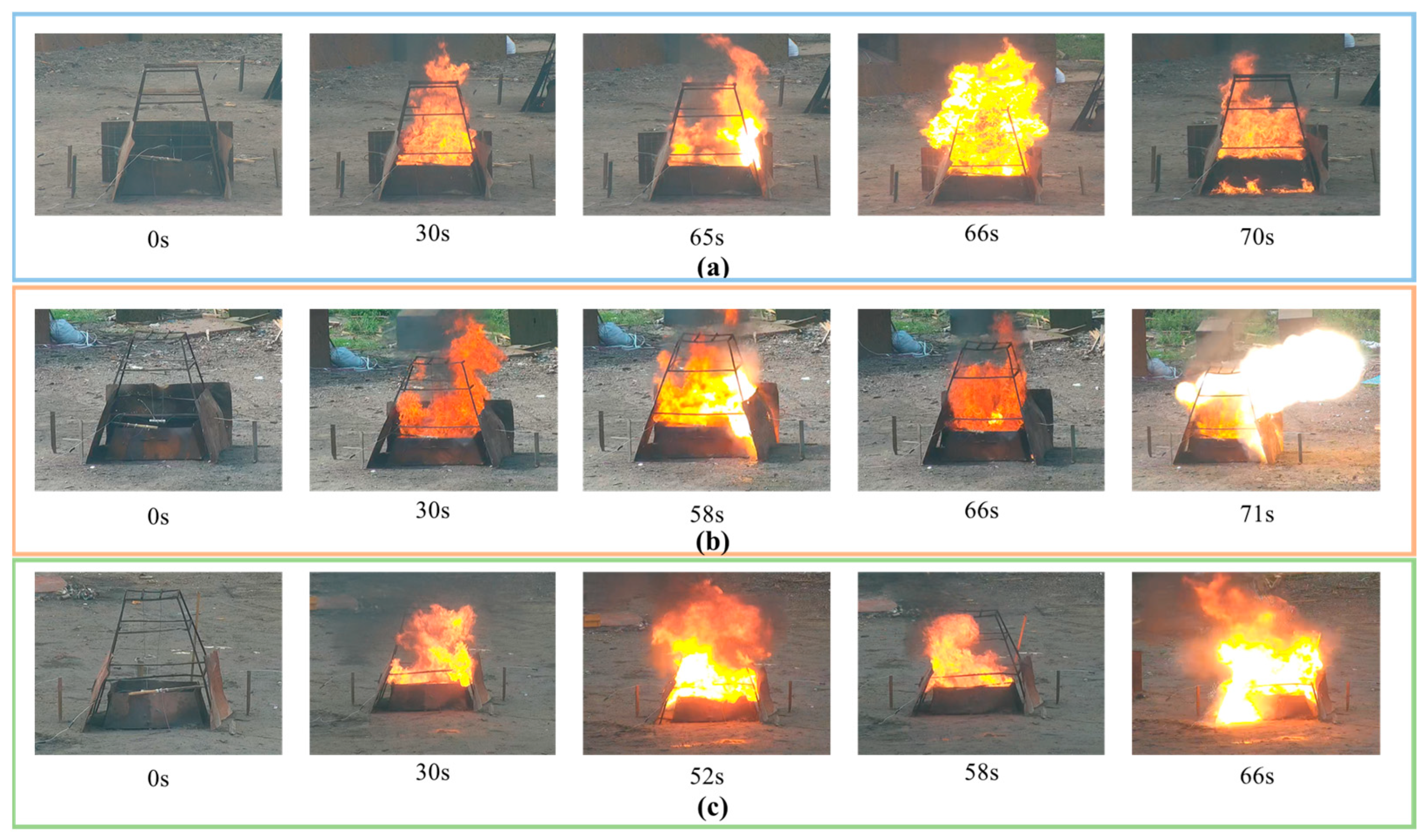

5.3.1. Slow Cook-Off Test

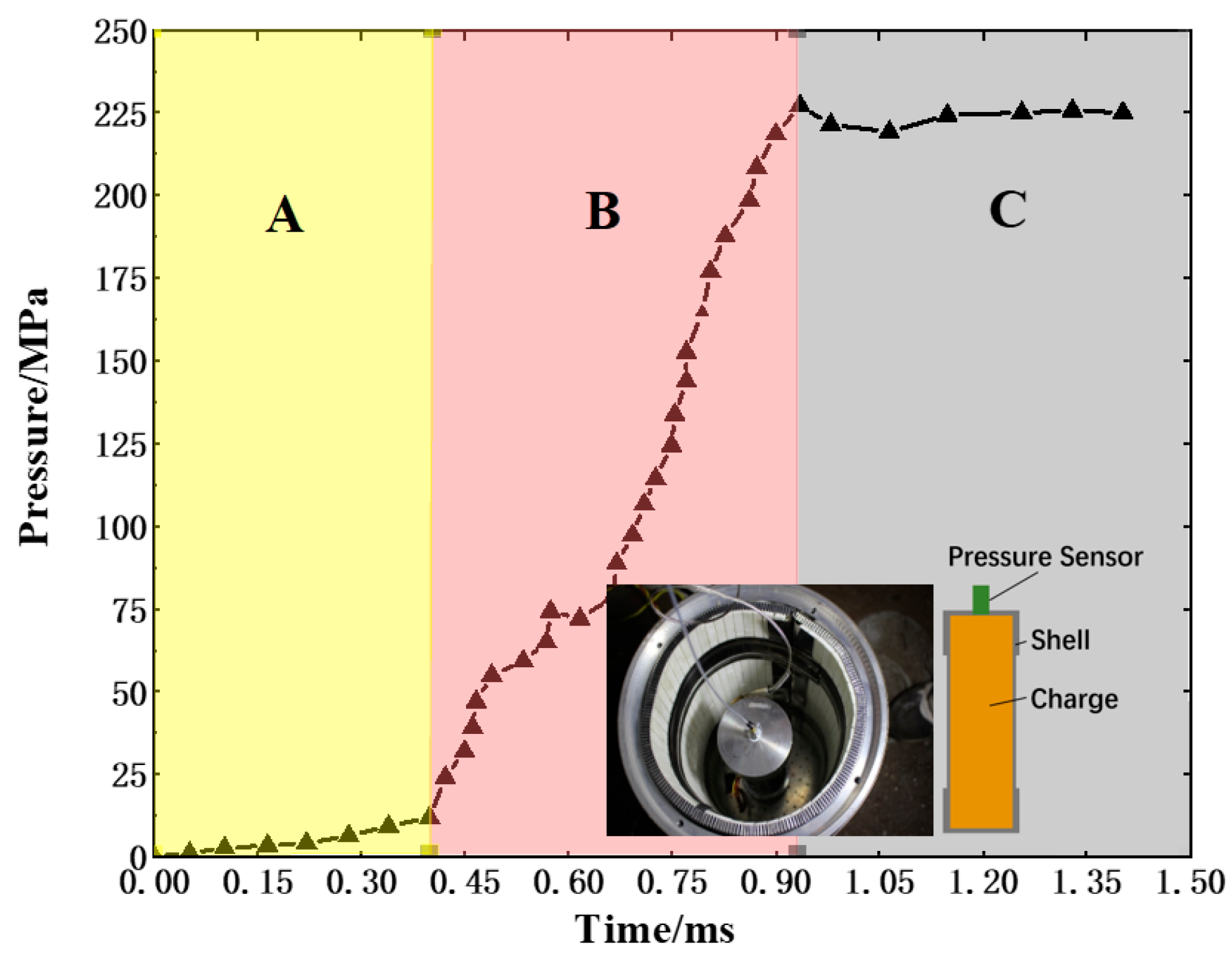

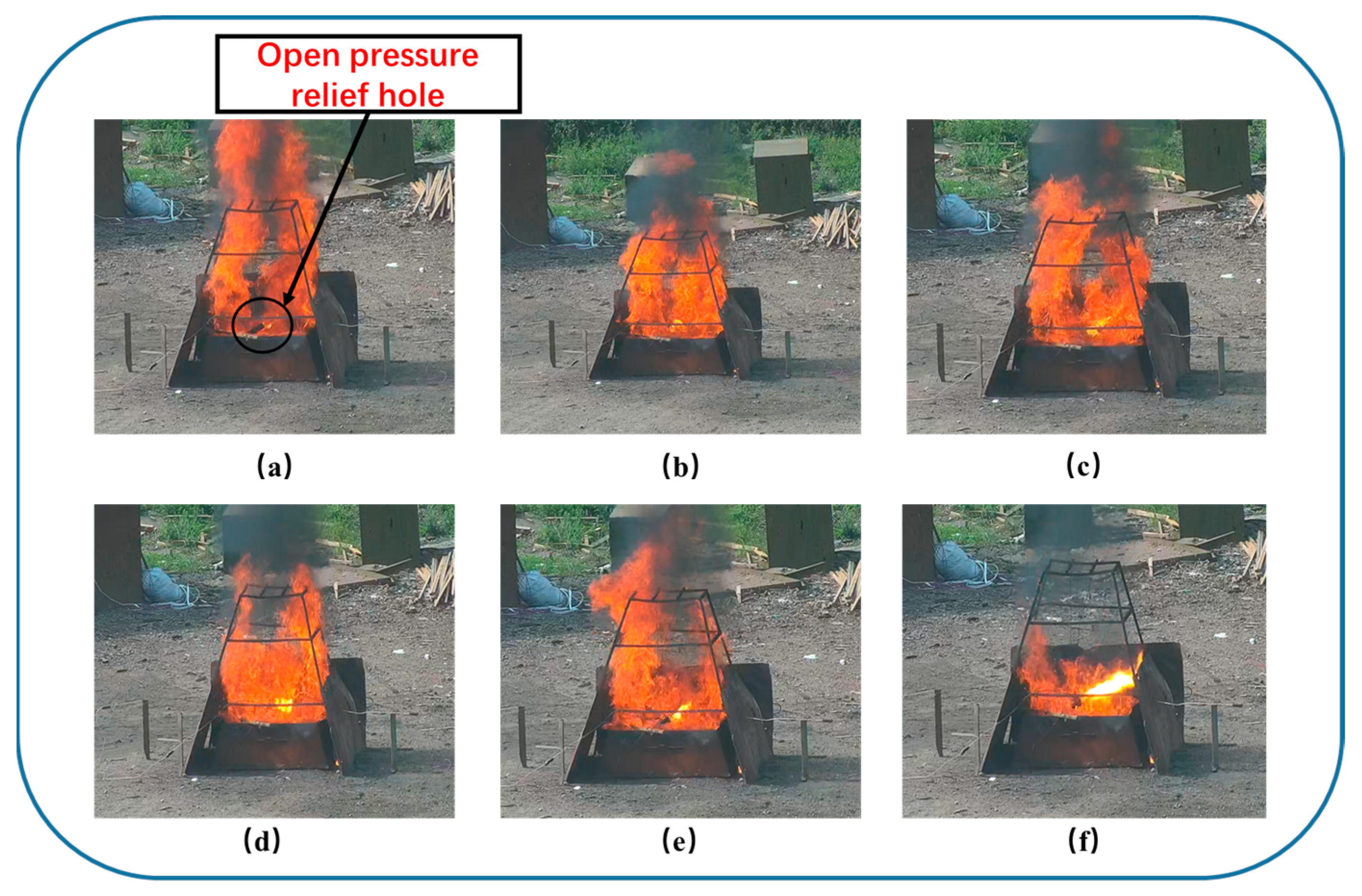

5.3.2. Fast Cook-Off Test

6. Conclusions

- (1)

- For PBX explosives, when the length/diameter ratio is 4 and AV/SB = 0.0189, the reaction intensity can be effectively reduced.

- (2)

- As the number of relief holes increases, the required relief area will decrease. When the number of relief holes is 6, AV/SB = 0.0110 is the equilibrium pressure relief size.

- (3)

- When AV/SB ≤ 0.011, the balanced pressure relief of the shell pressure relief process can be effectively realized, and as the pressure relief area of the mitigation structure is larger, the reaction intensity is smaller.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Powell, I.J. Insensitive Munitions—Design Principles and Technology Developments. Propellants Explos. Pyrotech. 2016, 41, 409–413. [Google Scholar] [CrossRef]

- Wang, Q.; Zhi, X.; Xiao, Y. Analysis of the effect of a venting structure on slow cookoff of Comp-B based on a universal cookoff mode. Explos. Shock Waves 2022, 42, 61–69. [Google Scholar] [CrossRef]

- Robert, H.; Zachary, A. Spears Matthew Sanford. Advanced Precision Kill Weapon System (APKWS) IM Solutions. In Proceedings of the Insensitive Munitions & Energetic Materials Technology Symposium (2006), Bristol, UK, 24–28 April 2006. [Google Scholar]

- Stephen, K.; Fred, B. Joint General Purpose Bomb Insensitive Munitions Program. In Proceedings of the Insensitive Munitions & Energetic Materials Technology Symposium (2006), Bristol, UK, 24–28 April 2006. [Google Scholar]

- Tony, W. General Purpose Bomb Fast Cook-off Mitigation Techniques. In Proceedings of the Insensitive Munitions & Energetic Materials Technology Symposium (2010), Munich, Germany, 11–14 October 2010. [Google Scholar]

- Stephen, K. Venting Techniques for Penetrator Warheads. In Proceedings of the Insensitive Munitions & Energetic Materials Technology Symposium (2010), Munich, Germany, 11–14 October 2010. [Google Scholar]

- Stephen, K. Success in Venting Penetrator Warheads. In Proceedings of the Insensitive Munitions & Energetic Materials Technology Symposium (2012), Las Vegas, NV, USA, 14–17 May 2012. [Google Scholar]

- William, C.; Enic, E.; Adcl, S. Fast Cook-off Tests Report; Center for the Simulation of Accidental Fires & Explosions: Salt Lake City, UT, USA, 2003. [Google Scholar]

- Glascoe, E.; Dehaven, M.; McClelland, M.; Greenwood, D.; Springer, H.; Maienschein, J. Mechanisms of Comp-B Thermal Explosions. In Proceedings of the 15th International Detonation Symposium (2014), San Francisco, CA, USA, 13–18 July 2014. [Google Scholar]

- Kinney, G.; Sewell, R. Venting of Explosions; NWC TM 2448; Naval Weapons Center: China Lake, CA, USA, 1974. [Google Scholar]

- Sahin, H.; Narin, B.; Kurtulus, F.D. Development of a design methodology against fast cook-off threat for insensitive munitions. Propellants Explos. Pyrotech. 2016, 41, 580–587. [Google Scholar] [CrossRef]

- Wardell, J.; Maienschein, J. The Scaled Thermal Explosion Experiment. In Proceedings of the 12th International Detonation Symposium (2002), San Diego, CA, USA, 11–16 August 2002. [Google Scholar]

- Niu, G. Experimental study on the fast cook-off of ammunition with pressure mitigation structure at head. In Proceedings of the Symposium on Energetic Materials and Insensitive Munitions (2016), Nashville, TN, USA, 12–15 September 2016. [Google Scholar]

- Madsen, T.; Fisher, S.; Baker, E.; Suarez, D.; Fuchs, B. Explosive Venting Technology for Cook-off Response Mitigation; Technical Report ARMET-TR-10003; Army Armament Research Development and Engineering Center Picatinny Arsenal nj Energetics Warheads and Manufacturing Technology Directorate: Picatinny Arsenal, NJ, USA, 2010. [Google Scholar]

- Mcchristian, L.; Cistano, J.; Foxx, C.; Hartmann, W.; Murphy, W.; Stauner, R.; Takata, A. Vulnerability of Nuclear Weapon Systems to Fire Studies of Burning Explosives; Report RTD-TDR-63-3086; IIT Research Institute: Chicago, IL, USA, 1963. [Google Scholar]

- Hu, R.; Zhao, F.; Gao, H.; Yao, E. Estimation of detonation performances of explosives using M, ρ, ∆fHmθ, Cp, Tig or b of C-H-O-N explosives and ∆fHmθ of detonation products. Chin. J. Explos. Propellants 2013, 36, 20–23. [Google Scholar] [CrossRef]

- Graham, J. Mitigation of Fuel Fire Threat to Large Rocket Motors by Venting. In Proceedings of the 2010 Insensitive Munitions & Energetic Materials Technology Symposium (2010), Munich, Germany, 11–14 October 2010. [Google Scholar]

- Sinditskii, V.; Levshenkov, I.; Egorshev, Y.; Serushkin, V. Study on Combustion and Thermal Decomposition of 1,1-Diamino-2,2-dinitroethylene (FOX-7). In Proceedings of the Inter Seminar Europyro & Inter Pyrotechnics Seminar, Saint-Malo (2003), Saint-Malo, France, 23–27 June 2003. [Google Scholar]

- Chen, K.; Huang, H.; Lu, Z.; Nie, S.; Jiang, Z. Experimental Study on Cook-Off Test for Melt-Cast and Cast-Cured Explosive at Strong Constraint. J. Sichuan Ordnance 2015, 36, 133–136. [Google Scholar] [CrossRef]

- Kou, Y.; Chen, L.; Ma, X.; Zhao, P.; Lu, J.; Wu, J. Cook-off experimental and numerical simulation of RDX-based aluminized explosives. Acta Armamentarii 2019, 40, 978–989. [Google Scholar] [CrossRef]

- Fisher, M. Shape Memory Polymer (SMP) Venting Mechanism for Munitions. In Proceedings of the NDIA/MSIAC Insensitive Munitions & Energetic Materials Technology Symposium (2010), Munich, Germany, 11–14 October 2010. [Google Scholar]

- Strickland, A. Development of IM Brimstone rocket motor; An IM, minimum smoke, air-launched system. In Proceedings of the 2015 Insensitive Munitions & Energetic Materials Technology Symposium (2015), Rome, Italy, 18–21 May 2015. [Google Scholar]

- Wei, T.; Li, N.; Nie, J.; Liang, J.; Guo, Z.; Yan, S.; Zhang, T.; Jiao, Q. The properties of Sn–Zn–Al–La fusible alloy for mitigation devices of solid propellant rocket motors. Def. Technol. 2022, 18, 1688–1696. [Google Scholar] [CrossRef]

- Nie, J.; Li, X.; Guo, X.; Zhang, H.; Yan, S.; Zhang, T. Study on Response Characteristics of Insensitive PBX Explosive in Shell under Slow Cook-off. J. Saf. Environ. 2022, 23, 1085–1092. [Google Scholar] [CrossRef]

- Nie, J.; Wei, Z.; Guo, X.; Yan, S.; Jiao, Q.; Fan, W.; Liang, X. A Temperature Controllable Engine Casing Hydraulic Blasting Experiment System and Method. CN112748013A, 10 June 2022. [Google Scholar]

- MIL-STD-2105D; Hazard Assessment Tests for Non-Nuclear Munitions. The Department of National Defense of USA: Washington, DC, USA, 2011.

| Temperature/°C | |

|---|---|

| 160 [19] | 0.0100 |

| 177 [19] | 0.0128 |

| 237 * | 0.0189 |

| Alloy | High and Low Temperature Mechanical Properties/MPa | Melting Point/°C | ||||

|---|---|---|---|---|---|---|

| −50 °C | 25 °C | 70 °C | 125 °C | 175 °C | ||

| Sn9Zn-3Al0.2La | 133.61 | 67.18 | 60.4 | 31.59 | 9 | 205.6 |

| Label | Mitigation Structure | Experimental Conditions | Experimental Method |

|---|---|---|---|

| 1 | - | high temperature | ① Pressurize the shell to 20 MPa and maintain the pressure. ② Heat the shell; set the temperature to approximately 150 °C. ③ Pressurize; the maximum pressure is set to 60 MPa, until the shell bursts. |

| 2 | Sn9Zn-3Al0.2La | normal temperature | ① Pressurize the shell to 2 MPa and keep the pressure for 0.5 min. ② Pressure; the maximum pressure is set to 31.5 MPa. |

| 3 | Sn9Zn-3Al0.2La | high temperature | ① Pressurize the shell to 2 MPa and keep the pressure for 0.5 min. ② Heat the shell to 175 °C. ③ Pressurize; the maximum pressure is set to 31.5 MPa. |

| Test Name | Test Condition Number | Diameter/mm | |

|---|---|---|---|

| Slow cook-off | S-1 | 0 | - |

| S-2 | 0.0110 | 11 | |

| Fast cook-off | F-1 | 0.0045 | 7 |

| F-2 | 0.0110 | 11 | |

| F-3 | 0.0180 | 14 |

| Cook-Off Bomb | Reaction Temperature/°C | Shock Wave Overpressure at 5 m/MPa | Response Level | |

|---|---|---|---|---|

| S-1 | 0 | 237.0 | Not detected | Deflagration |

| S-2 | 1.10 | 193.6 | Not detected | Combustion and below |

| Cook-Off Bomb | Time of the Pressure Relief Channel Is Open/s | Time of Charge Reaction/s | Shock Wave Overpressure at 5 m/MPa | Response Level | |

|---|---|---|---|---|---|

| F-1 | 0.45 | — | 65 | Not detected | Deflagration |

| F-2 | 1.10 | 58 | 71 | Not detected | Combustion |

| F-3 | 1.80 | 52 | 66 | Not detected | Combustion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, J.; Nie, J.; Liu, R.; Han, M.; Jiao, G.; Sun, X.; Wang, X.; Huang, B. Study and Design of the Mitigation Structure of a Shell PBX Charge under Thermal Stimulation. Crystals 2023, 13, 914. https://doi.org/10.3390/cryst13060914

Liang J, Nie J, Liu R, Han M, Jiao G, Sun X, Wang X, Huang B. Study and Design of the Mitigation Structure of a Shell PBX Charge under Thermal Stimulation. Crystals. 2023; 13(6):914. https://doi.org/10.3390/cryst13060914

Chicago/Turabian StyleLiang, Jiahao, Jianxin Nie, Rui Liu, Ming Han, Gangling Jiao, Xiaole Sun, Xiaoju Wang, and Bo Huang. 2023. "Study and Design of the Mitigation Structure of a Shell PBX Charge under Thermal Stimulation" Crystals 13, no. 6: 914. https://doi.org/10.3390/cryst13060914

APA StyleLiang, J., Nie, J., Liu, R., Han, M., Jiao, G., Sun, X., Wang, X., & Huang, B. (2023). Study and Design of the Mitigation Structure of a Shell PBX Charge under Thermal Stimulation. Crystals, 13(6), 914. https://doi.org/10.3390/cryst13060914