High-Temperature Energy Storage Properties of Bi0.5Na0.5TiO3-0.06BaTiO3 Thin Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

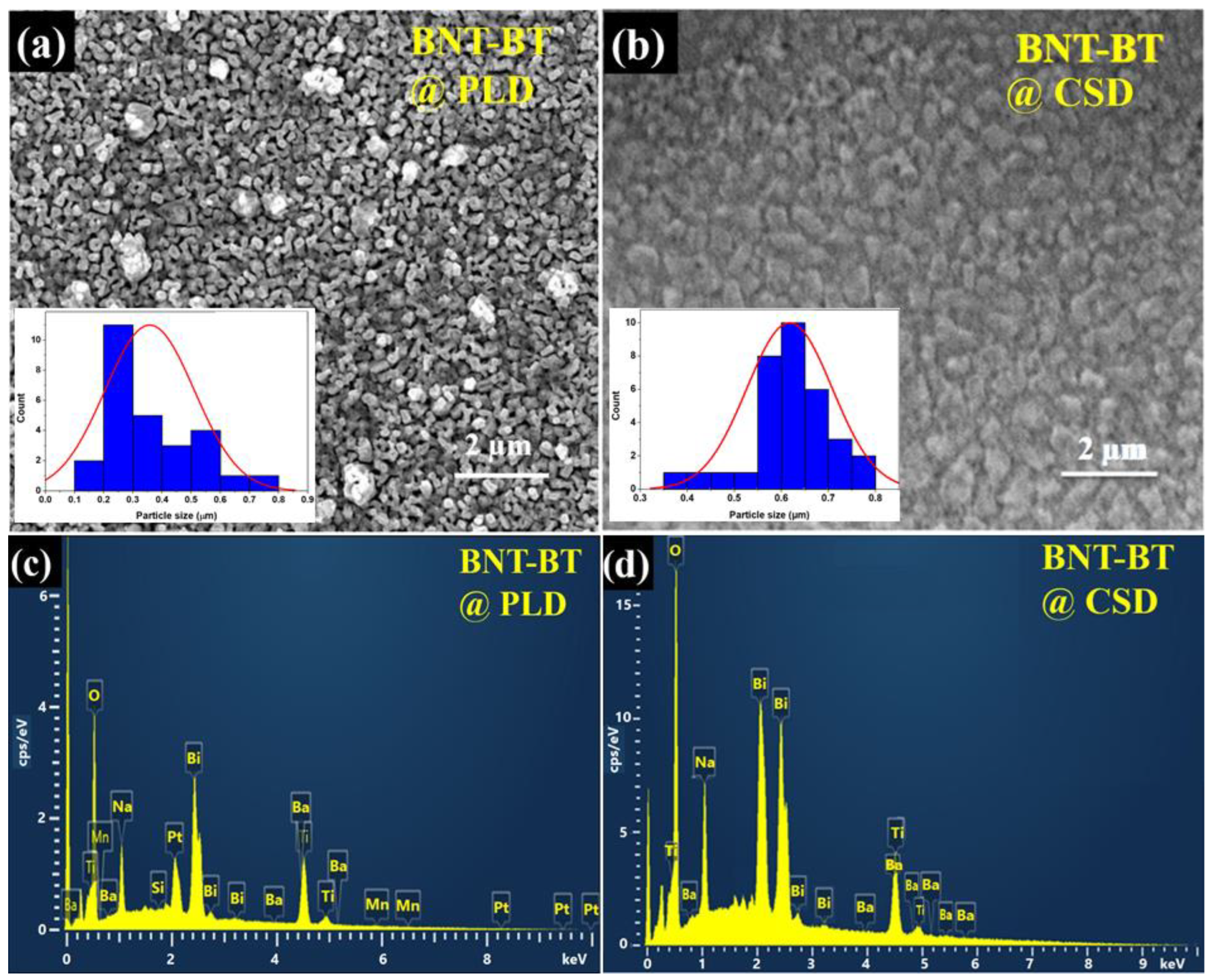

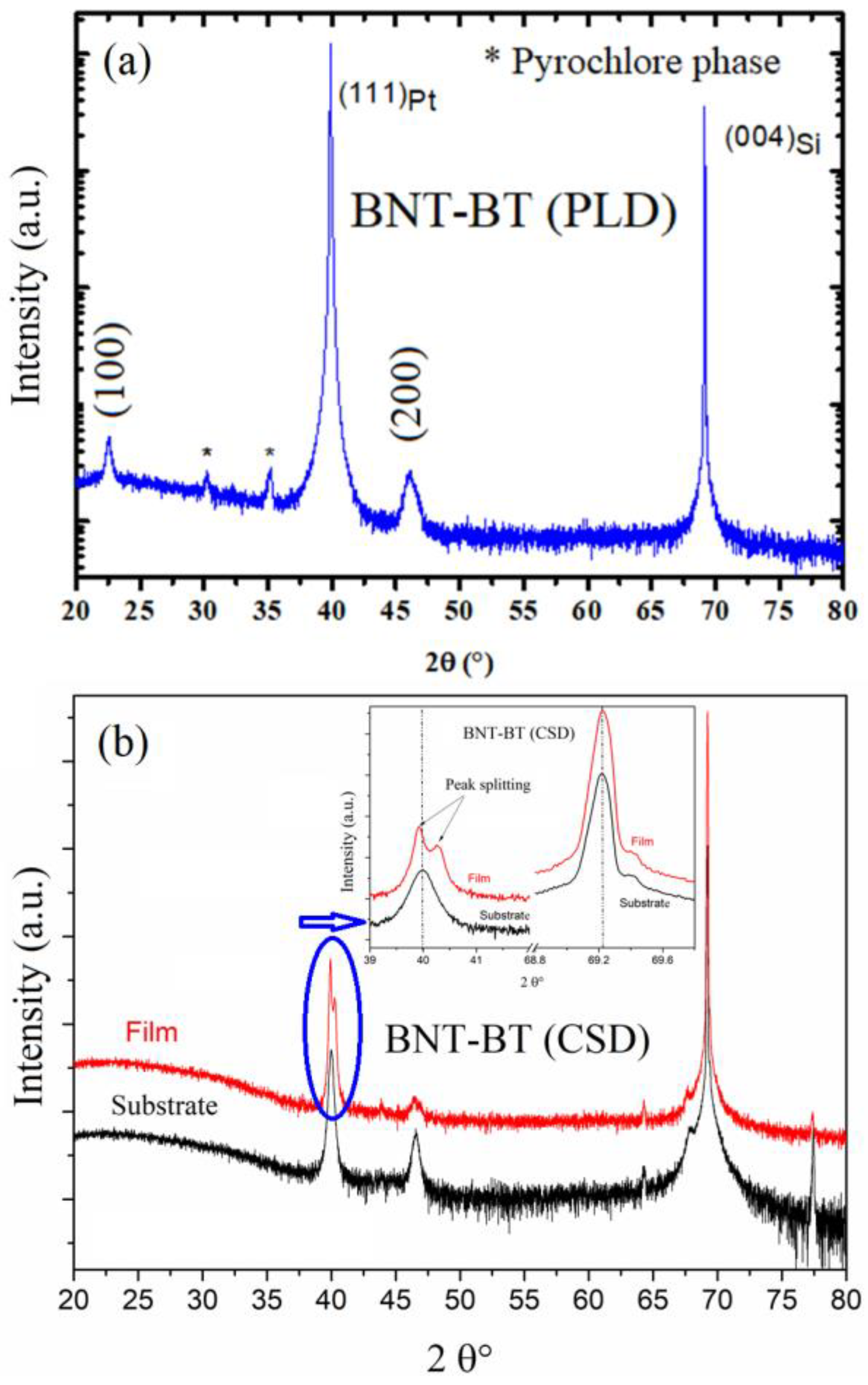

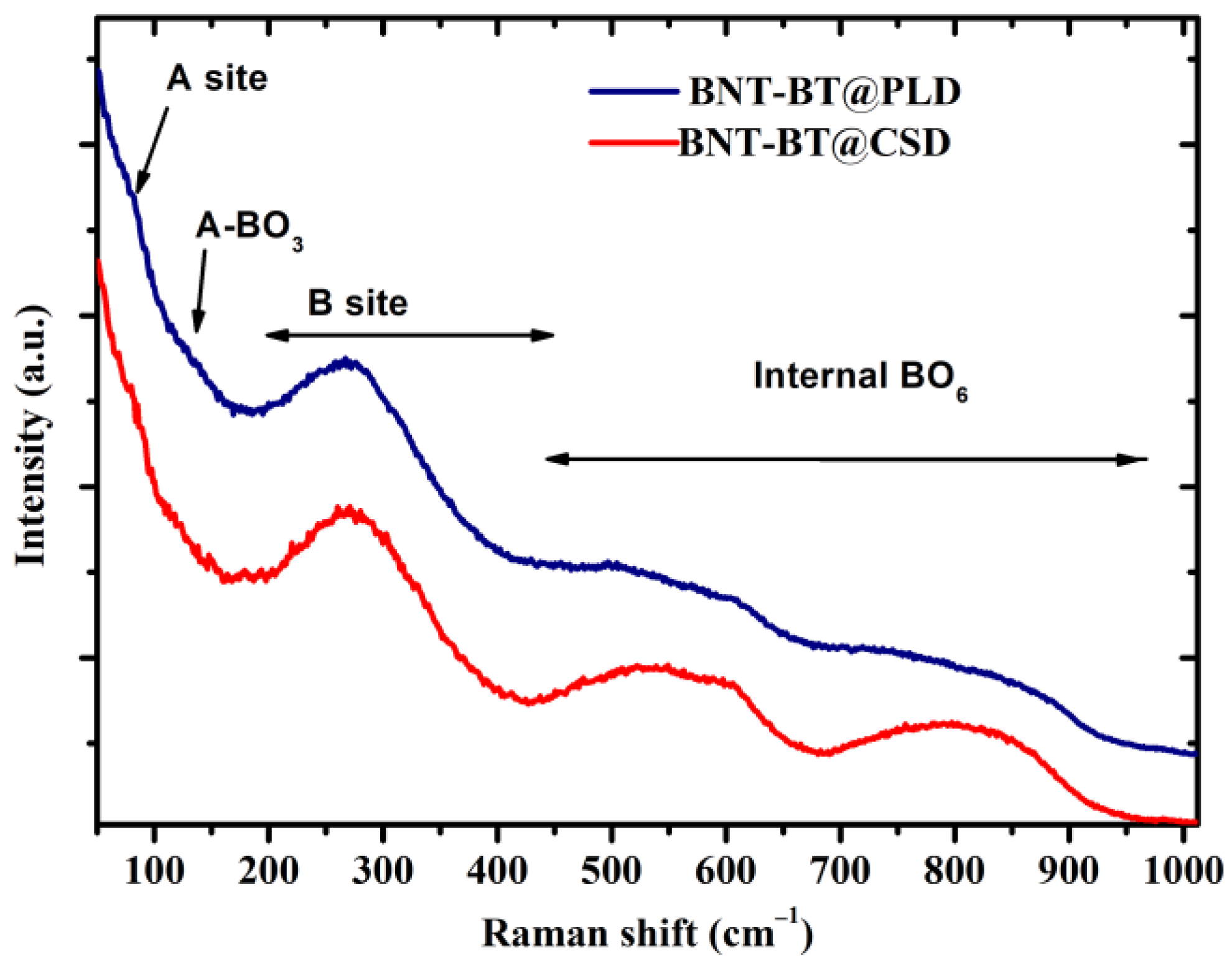

3.1. Microstructural and Structural Investigations

3.2. Dielectric Investigation and Thermal Permittivity Stability

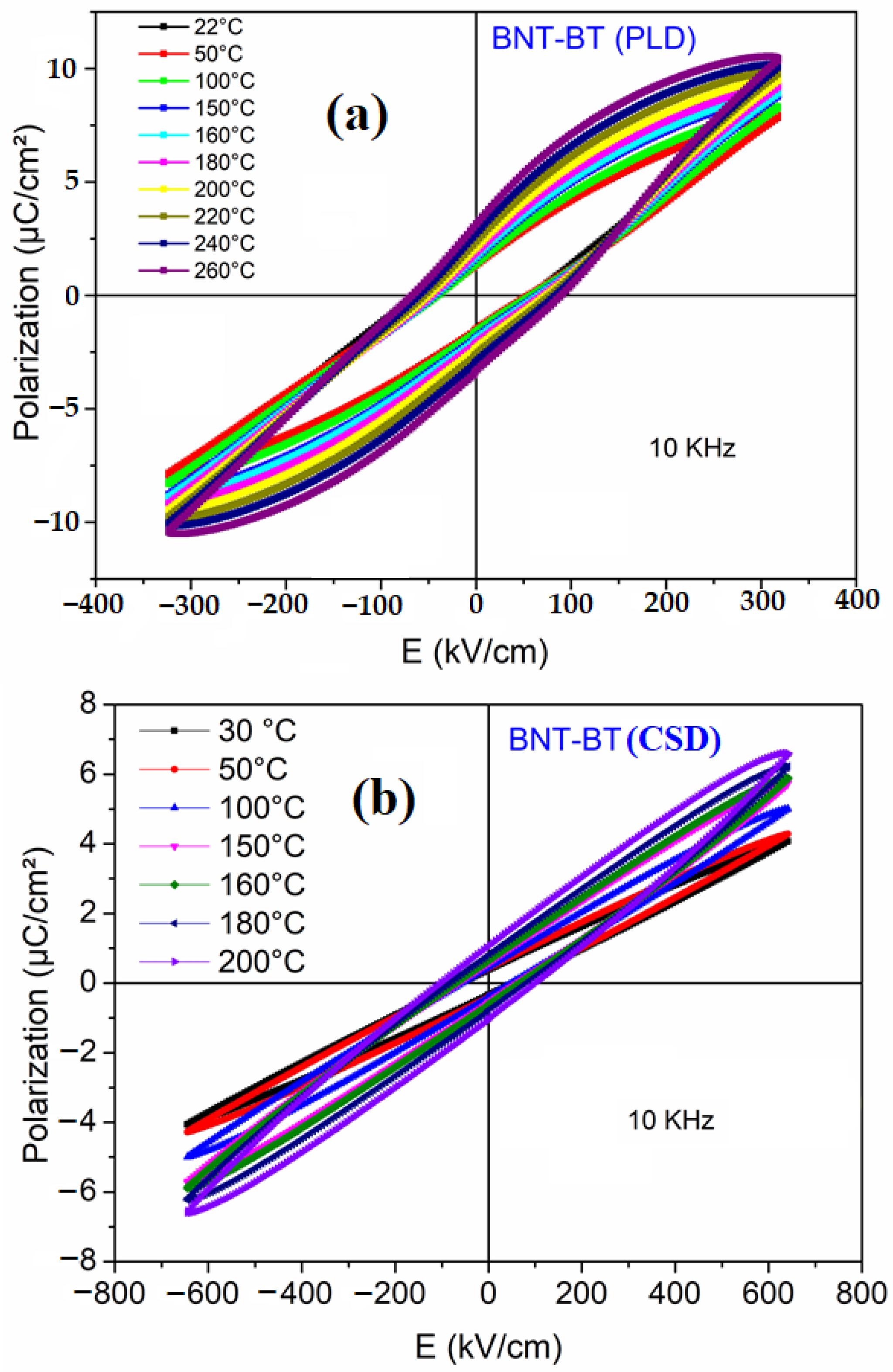

3.3. Leakage Current, Ferroelectric, and Energy Storage Investigations

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yao, K.; Chen, S.; Rahimabady, M.; Mirshekarloo, M.S.; Yu, S.; Tay, F.E.H.; Sritharan, T.; Lu, L. Nonlinear dielectric thin films for high-power electric storage with energy density comparable with electrochemical supercapacitors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2011, 58, 1968–1974. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.; Song, Z.; Hao, H.; Yu, Z.; Cao, M.; Zhang, S.; Lanagan, M.T.; Liu, H. Homogeneous/Inhomogeneous-Structured Dielectrics and their Energy-Storage Performances. Adv. Mater. 2017, 29, 1601727. [Google Scholar] [CrossRef] [PubMed]

- Prateek; Thakur, V.K.; Gupta, R.K. Recent Progress on Ferroelectric Polymer-Based Nanocomposites for High Energy Density Capacitors: Synthesis, Dielectric Properties, and Future Aspects. Chem. Rev. 2016, 116, 4260–4317. [Google Scholar] [CrossRef]

- Xu, B.; Íñiguez, J.; Bellaiche, L. Designing lead-free antiferroelectrics for energy storage. Nat. Commun. 2017, 8, 15682. [Google Scholar] [CrossRef] [Green Version]

- Xu, Q.; Lanagan, M.T.; Huang, X.; Xie, J.; Zhang, L.; Hao, H.; Liu, H. Dielectric behavior and impedance spectroscopy in lead-free BNT–BT–NBN perovskite ceramics for energy storage. Ceram. Int. 2016, 42, 9728–9736. [Google Scholar] [CrossRef]

- Lu, X.; Xu, J.; Yang, L.; Zhou, C.; Zhao, Y.; Yuan, C.; Li, Q.; Chen, G.-H.; Wang, H. Energy storage properties of (Bi0.5Na0.5)0.93Ba0.07TiO3 lead-free ceramics modified by La and Zr co-doping. J. Materiomics 2016, 2, 87–93. [Google Scholar] [CrossRef] [Green Version]

- Zeb, A.; Milne, S.J. High temperature dielectric ceramics: A review of temperature-stable high-permittivity perovskites. J. Mater. Sci. Mater. Electron. 2015, 26, 9243–9255. [Google Scholar] [CrossRef]

- Scott, J.F.; de Araujo, C.A.P. Ferroelectric Memories. Science 1989, 246, 1400–1405. [Google Scholar] [CrossRef]

- Jaffe, H. Piezoelectric Ceramics. J. Am. Ceram. Soc. 1958, 41, 494–498. [Google Scholar] [CrossRef]

- Katzke, H.; Dietze, M.; Lahmar, A.; Es-Souni, M.; Neumann, N.; Lee, S.-G. Dielectric, ultraviolet/visible, and Raman spectroscopic investigations of the phase transition sequence in 0.71Pb(Mg1/3Nb2/3)O3-0.29PbTiO3 crystals. Phys. Rev. B 2011, 83, 174115. [Google Scholar] [CrossRef] [Green Version]

- Parliament, T.H.E.E.; Council, T.H.E.; The, O.F.; Union, E. Directive 2011/83/EU of the European Parliament and of the Council. Fundam. Texts Eur. Priv. Law 2020, 88–110. [Google Scholar] [CrossRef]

- Sherrill, S.A.; Banerjee, P.; Rubloff, G.W.; Lee, S.B. High to ultra-high power electrical energy storage. Phys. Chem. Chem. Phys. 2011, 13, 20714–20723. [Google Scholar] [CrossRef]

- Siny, I.G.; Tu, C.-S.; Schmidt, V.H. Schmidt, Critical acoustic behavior of the relaxor ferroelectric (Bi0.5Na0.5)TiO3 in the intertransition region. Phys. Rev. B 1995, 51, 5659–5665. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shvartsman, V.V.; Lupascu, D.C. Lead-Free Relaxor Ferroelectrics. J. Am. Ceram. Soc. 2011, 95, 1–26. [Google Scholar] [CrossRef]

- Suchanicz, J.; Ptak, W.S. On the phase transition in Na0.5Bi0.5TiO3. Ferroelectr. Lett. Sect. 1990, 12, 71–78. [Google Scholar] [CrossRef]

- Hiruma, Y.; Nagata, H.; Takenaka, T. Thermal depoling process and piezoelectric properties of bismuth sodium titanate ceramics. J. Appl. Phys. 2009, 105, 084112. [Google Scholar] [CrossRef]

- Fan, Z.; Yu, Y.; Huang, J.; Zhang, Q.; Lu, Y.; He, Y. Excellent energy storage properties over a wide temperature range under low driving electric fields in NBT-BSN lead-free relaxor ferroelectric ceramics. Ceram. Int. 2020, 47, 4715–4721. [Google Scholar] [CrossRef]

- Verma, A.; Yadav, A.K.; Kumar, S.; Srihari, V.; Jangir, R.; Poswal, H.K.; Liu, S.-W.; Biring, S.; Sen, S. Improvement of energy storage properties with the reduction of depolarization temperature in lead-free (1 − x)Na0.5Bi0.5TiO3-xAgTaO3 ceramics. J. Appl. Phys. 2019, 125, 054101. [Google Scholar] [CrossRef]

- Rahman, J.U.; Hussain, A.; Maqbool, A.; Ryu, G.H.; Song, T.K.; Kim, W.-J.; Kim, M.H. Field induced strain response of lead-free BaZrO3-modified Bi0.5Na0.5TiO3–BaTiO3 ceramics. J. Alloys Compd. 2014, 593, 97–102. [Google Scholar] [CrossRef]

- Cho, J.-H.; Jeong, Y.-H.; Nam, J.-H.; Yun, J.-S.; Park, Y.-J. Phase transition and piezoelectric properties of lead-free (Bi1/2Na1/2)TiO3–BaTiO3 ceramics. Ceram. Int. 2014, 40, 8419–8425. [Google Scholar] [CrossRef]

- Zannen, M.; Lahmar, A.; Dietze, M.; Khemakhem, H.; Kabadou, A.; Es-Souni, M. Structural, optical, and electrical properties of Nd-doped Na0.5Bi0.5TiO3. Mater. Chem. Phys. 2012, 134, 829–833. [Google Scholar] [CrossRef]

- Mishra, A.; Majumdar, B.; Ranjan, R. A complex lead-free (Na, Bi, Ba)(Ti, Fe)O3 single phase perovskite ceramic with a high energy-density and high discharge-efficiency for solid state capacitor applications. J. Eur. Ceram. Soc. 2017, 37, 2379–2384. [Google Scholar] [CrossRef] [Green Version]

- Yang, H.; Yan, F.; Lin, Y.; Wang, T.; Wang, F. High energy storage density over a broad temperature range in sodium bismuth titanate-based lead-free ceramics. Sci. Rep. 2017, 7, 8726. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zannen, M.; Belhadi, J.; Benyoussef, M.; Khemakhem, H.; Zaidat, K.; El Marssi, M.; Lahmar, A. Electrostatic energy storage in antiferroelectric like perovskite. Superlattices Microstruct. 2019, 127, 43–48. [Google Scholar] [CrossRef]

- Cao, W.; Li, W.; Dai, X.; Zhang, T.; Sheng, J.; Hou, Y.; Fei, W. Large electrocaloric response and high energy-storage properties over a broad temperature range in lead-free NBT-ST ceramics. J. Eur. Ceram. Soc. 2015, 36, 593–600. [Google Scholar] [CrossRef]

- Cao, W.; Li, W.; Zhang, T.; Sheng, J.; Hou, Y.; Feng, Y.; Yu, Y.; Fei, W. High-Energy Storage Density and Efficiency of (1−x)[0.94 NBT-0.06 BT]-xST Lead-Free Ceramics. Energy Technol. 2015, 3, 1198–1204. [Google Scholar] [CrossRef]

- Zannen, M.; Lahmar, A.; Kutnjak, Z.; Belhadi, J.; Khemakhem, H.; El Marssi, M. Electrocaloric effect and energy storage in lead free Gd0.02Na0.5Bi0.48TiO3 ceramic. Solid State Sci. 2017, 66, 31–37. [Google Scholar] [CrossRef]

- Benyoussef, M.; Zannen, M.; Belhadi, J.; Manoun, B.; Kutnjak, Z.; Vengust, D.; Spreitzer, M.; El Marssi, M.; Lahmar, A. Structural, dielectric, and ferroelectric properties of Na0.5(Bi1−xNdx)0.5TiO3 ceramics for energy storage and electrocaloric applications. Ceram. Int. 2021, 47, 26539–26551. [Google Scholar] [CrossRef]

- Zhang, T.; Li, W.; Hou, Y.; Yu, Y.; Song, R.; Cao, W.; Fei, W. High-energy storage density and excellent temperature stability in antiferroelectric/ferroelectric bilayer thin films. Am. Ceram. Soc. 2017, 100, 3080–3087. [Google Scholar] [CrossRef]

- Wu, M.; Yu, S.; Wang, X.; Li, L. Ultra-high energy storage density and ultra-wide operating temperature range in Bi2Zn2/3Nb4/3O7 thin film as a novel lead-free capacitor. J. Power Sources 2021, 497, 229879. [Google Scholar] [CrossRef]

- Alaoui, I.H.; Moussa, M.; Lemée, N.; Le Marrec, F.; Cantaluppi, A.; Favry, D.; Lahmar, A. Influence of the Addition of Rare Earth Elements on the Energy Storage and Optical Properties of Bi0.5Na0.5TiO3–0.06BaTiO3 Polycrystalline Thin Films. Materials 2023, 16, 2197. [Google Scholar] [CrossRef] [PubMed]

- de la Flor, G.; Malcherek, T.; Gorfman, S.; Mihailova, B. Structural transformations in (1−x)Na0.5Bi0.5TiO3−xBaTiO3 single crystals studied by Raman spectroscopy. Phys. Rev. B 2017, 96, 214102. [Google Scholar] [CrossRef]

- Xie, Y.; Hao, H.; Xie, J.; Zhang, S.; Cao, M.; Yao, Z.; Liu, H. Ultra-high energy storage density and enhanced dielectric properties in BNT-BT based thin film. Ceram. Int. 2021, 47, 23259–23266. [Google Scholar] [CrossRef]

- Bhattarai, M.K.; Mishra, K.K.; Instan, A.A.; Bastakoti, B.P.; Katiyar, R.S. Enhanced energy storage density in Sc3+ substituted Pb(Zr0.53Ti0.47)O3 nanoscale films by pulse laser deposition technique. Appl. Surf. Sci. 2019, 490, 451–459. [Google Scholar] [CrossRef]

- Zhao, Z.; Buscaglia, V.; Viviani, M.; Nygren, M.; Johnsson, M.; Nanni, P. Grain-size effects on the ferroelectric behavior of dense nanocrystalline BaTiO3 ceramics. Phys. Rev. B 2004, 70, 24107. [Google Scholar] [CrossRef]

- Acosta, M.; Zang, J.; Jo, W.; Rödel, J. High-temperature dielectrics in CaZrO3-modified Bi1/2Na1/2TiO3-based lead-free ceramics. J. Eur. Ceram. Soc. 2012, 32, 4327–4334. [Google Scholar] [CrossRef]

- Park, S.-E.; Chung, S.-J.; Kim, I.-T.; Hong, K.S. Nonstoichiometry and the Long-Range Cation Ordering in Crystals of (Na1/2Bi1/2) TiO3. J. Am. Ceram. Soc. 1994, 77, 2641–2647. [Google Scholar] [CrossRef]

- Liu, X.; Du, H.; Liu, X.; Shi, J.; Fan, H. Energy storage properties of BiTi0.5Zn0.5O3-Bi0.5Na0.5TiO3-BaTiO3 relaxor ferroelectrics. Ceram. Int. 2016, 42, 17876–17879. [Google Scholar] [CrossRef]

- Ashkani, O.; Tavighi, M.R.; Karamimoghadam, M.; Moradi, M.; Bodaghi, M.; Rezayat, M. Influence of Aluminum and Copper on Mechanical Properties of Biocompatible Ti-Mo Alloys: A Simulation-Based Investigation. Micromachines 2023, 14, 1081. [Google Scholar] [CrossRef]

- Rezayat, M.; Sani, A.A.; Noghani, M.T.; Yazdi, M.S.; Taheri, M.; Moghanian, A.; Mohammadi, M.A.; Moradi, M.; García, A.M.M.; Besharatloo, H. Effect of Lateral Laser-Cladding Process on the Corrosion Performance of Inconel 625. Metals 2023, 13, 367. [Google Scholar] [CrossRef]

- Wang, R.; Chu, W.; Gao, K.; Su, W.; Qiao, L. Stress corrosion cracking of a BaTiO3 ferroelectric ceramics. Mater. Lett. 2003, 58, 1811–1814. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alaoui, I.H.; Lemée, N.; Belhadi, J.; Le Marrec, F.; Cantaluppi, A.; Lahmar, A. High-Temperature Energy Storage Properties of Bi0.5Na0.5TiO3-0.06BaTiO3 Thin Films. Crystals 2023, 13, 1244. https://doi.org/10.3390/cryst13081244

Alaoui IH, Lemée N, Belhadi J, Le Marrec F, Cantaluppi A, Lahmar A. High-Temperature Energy Storage Properties of Bi0.5Na0.5TiO3-0.06BaTiO3 Thin Films. Crystals. 2023; 13(8):1244. https://doi.org/10.3390/cryst13081244

Chicago/Turabian StyleAlaoui, Ilham Hamdi, Nathalie Lemée, Jamal Belhadi, Françoise Le Marrec, Anna Cantaluppi, and Abdelilah Lahmar. 2023. "High-Temperature Energy Storage Properties of Bi0.5Na0.5TiO3-0.06BaTiO3 Thin Films" Crystals 13, no. 8: 1244. https://doi.org/10.3390/cryst13081244

APA StyleAlaoui, I. H., Lemée, N., Belhadi, J., Le Marrec, F., Cantaluppi, A., & Lahmar, A. (2023). High-Temperature Energy Storage Properties of Bi0.5Na0.5TiO3-0.06BaTiO3 Thin Films. Crystals, 13(8), 1244. https://doi.org/10.3390/cryst13081244