Influence of the γ′ Volume Fraction on the High-Temperature Strength of Single Crystalline Co–Al–W–Ta Superalloys

Abstract

:1. Introduction

2. Experimental Procedures

3. Results and Discussion

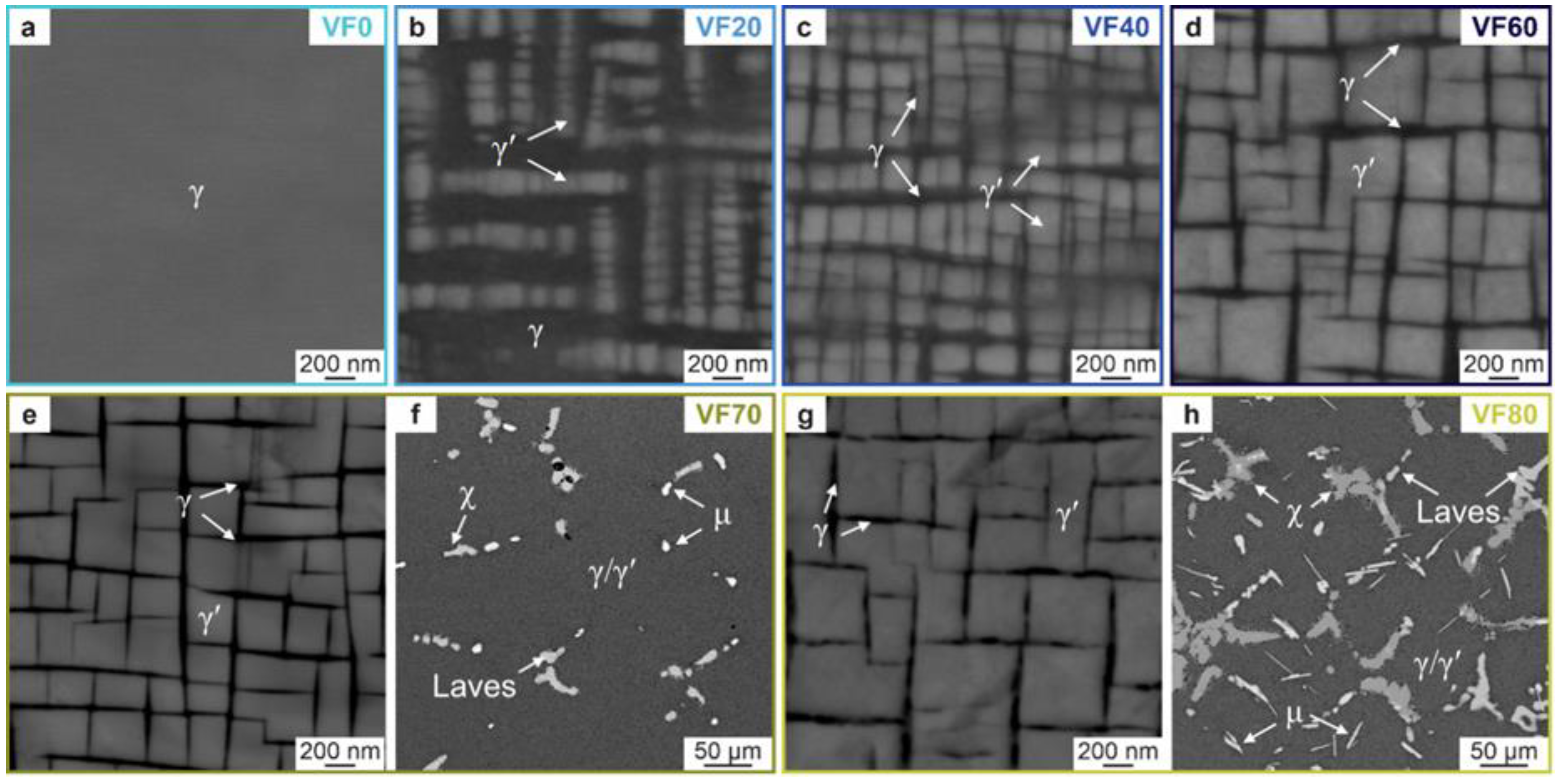

3.1. Microstructure

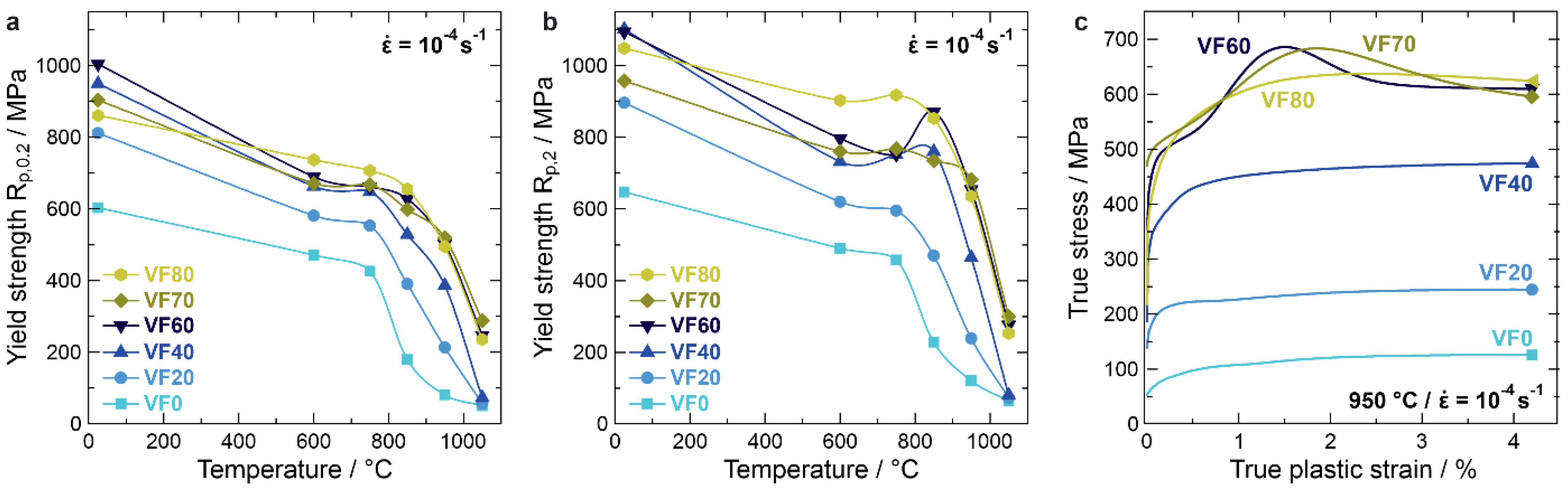

3.2. Compressive Yield Strength and Anomalous Work-Hardening

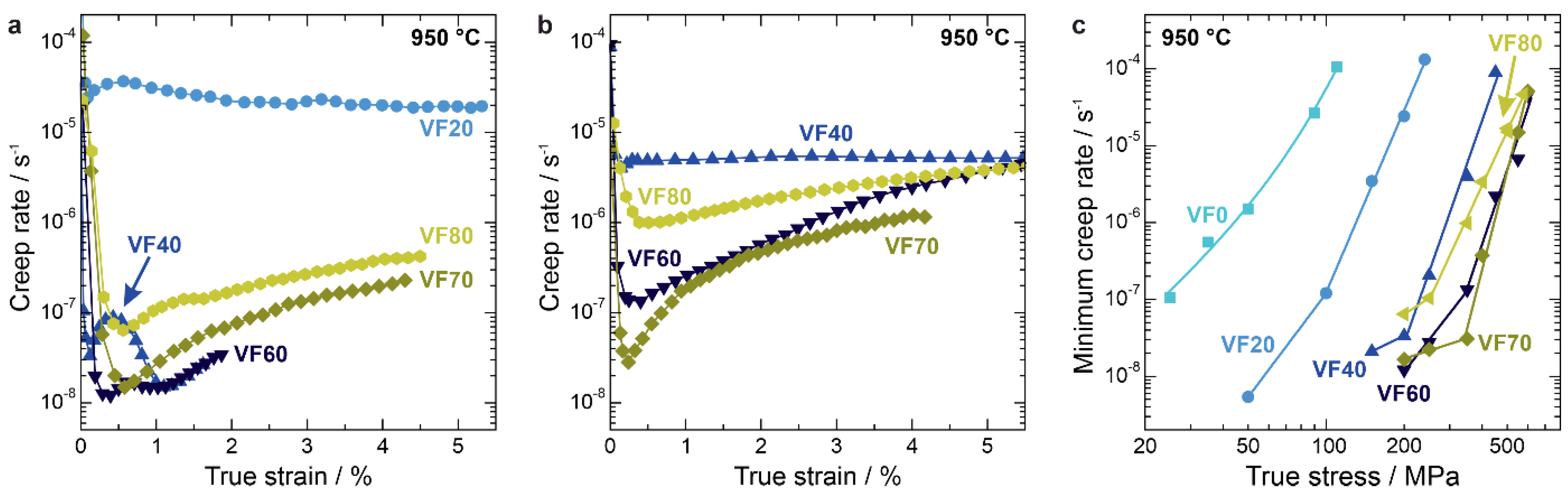

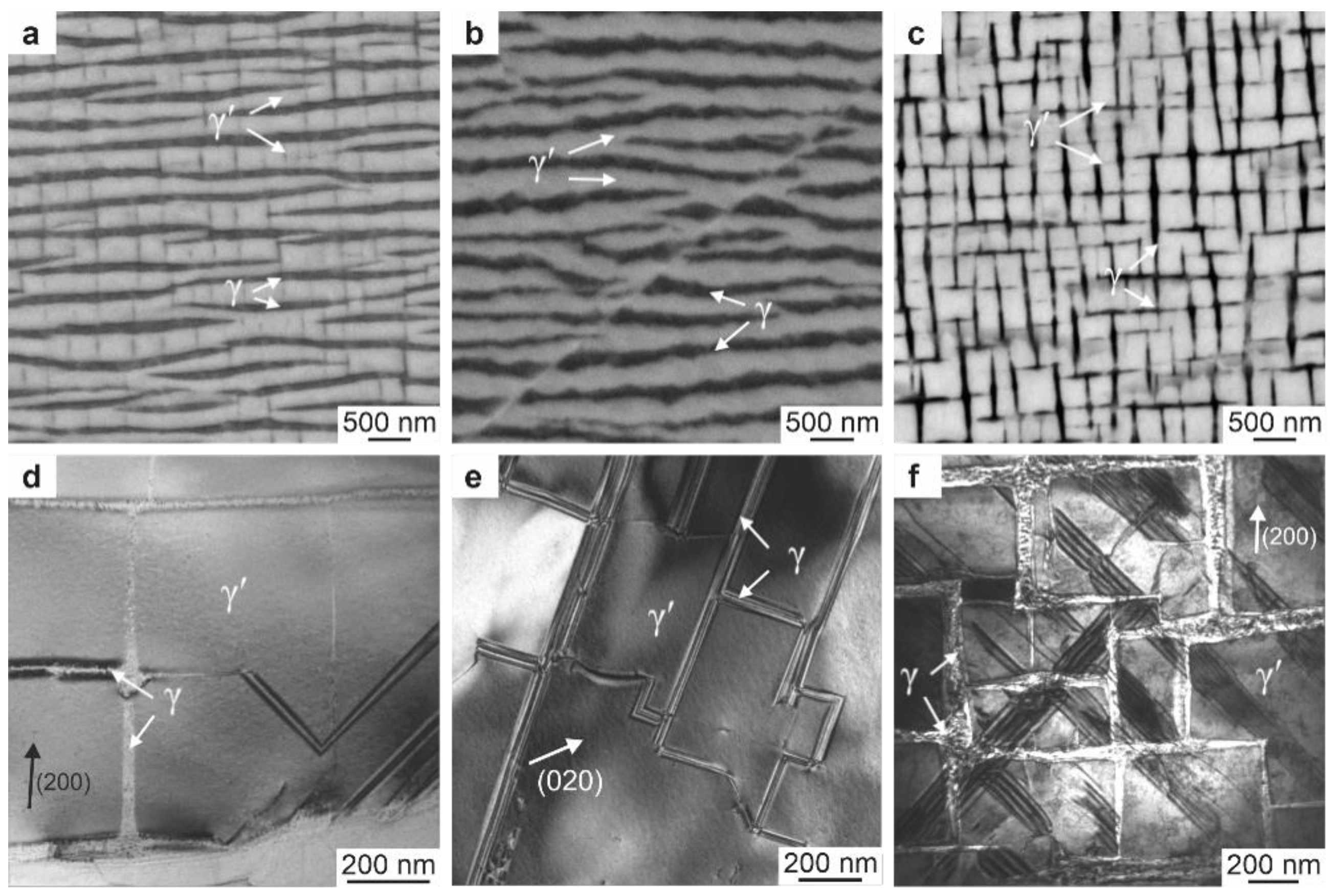

3.3. Compressive Creep Behavior at 950 °C

4. Conclusions

- A 0.2% yield stress increased with increasing γ′ volume fraction from 0% up to ~70% in the VF0–VF60 alloys from room temperature to 1050 °C. The additional formation of secondary phases with a volume fraction of up to 15% did not significantly decrease the yield strength.

- Strong strain-hardening was found in the VF60 and VF70 alloys with a high γ′ volume fractions at 950 °C, but not in the low-γ′ volume fraction VF0–VF40 alloys during compression tests. The additional 2% area fraction of the secondary phases in VF70 did not decrease the compression strength, but led to a longer, less steep work-hardening behavior, while the 15% area fraction of the secondary phases in VF80 suppressed the anomalous work-hardening behavior.

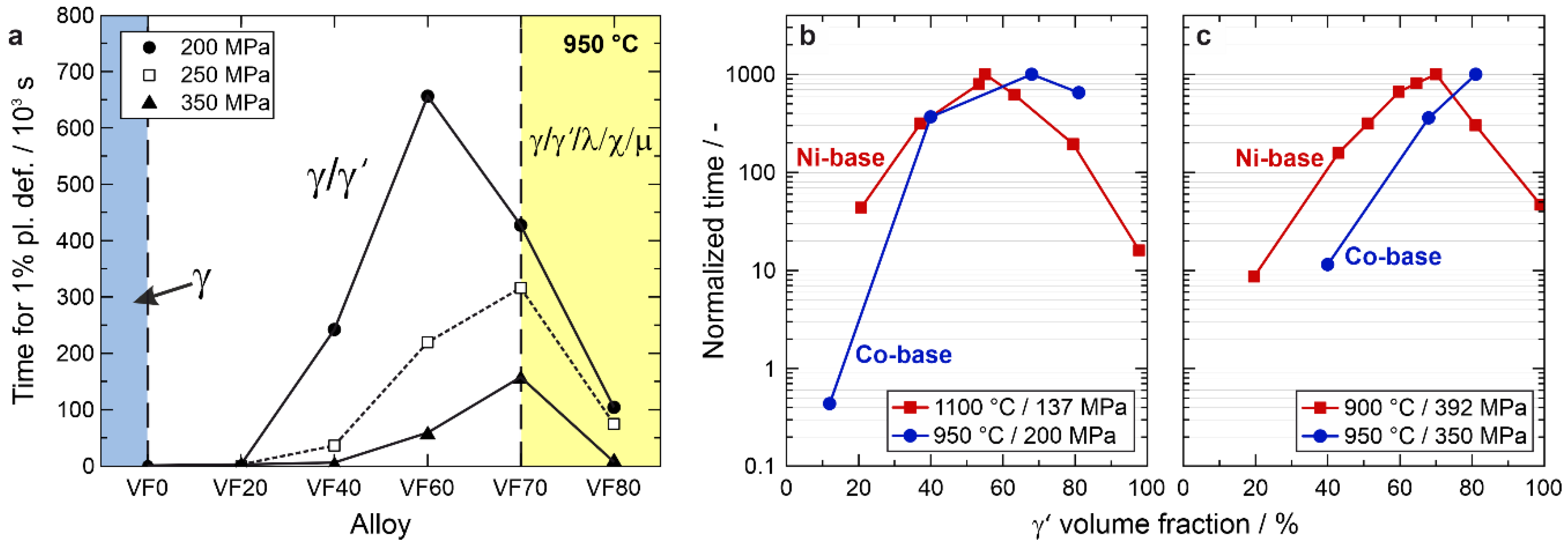

- The creep strength consistently improved with an increasing γ′ volume fraction from 0% to 70% in VF0–VF60 at 950 °C. However, the creep properties in VF70 and VF80 gradually decreased at 200 MPa, while VF70 exhibited the best creep resistance at higher stresses of 250 and 350 MPa.

- A creep curve with two creep rate minima was found in the VF40 and VF60 alloys with γ′ volume fractions from 50% to 70% at 950 °C and 200 MPa. The second minimum was associated with rafting at early creep stages. At higher applied stresses from 250 to 350 MPa, a single minimum creep behavior was evident in all experimental alloys, because extensive γ′ shearing occurred in the early creep stages.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sato, J.; Omori, T.; Oikawa, K.; Ohnuma, I.; Karinuma, R.; Ishida, K. Cobalt-Base High-Temperature Alloys. Science 2006, 312, 90–91. [Google Scholar] [CrossRef] [PubMed]

- Suzuki, A.; Pollock, T.M. High-Temperature Strength and Deformation of γ/γ′ Two-Phase Co-Al-W-base Alloys. Acta Mater. 2008, 56, 1288–1297. [Google Scholar] [CrossRef]

- Bauer, A.; Neumeier, S.; Pyczak, F.; Göken, M. Microstructure and Creep Strength of Different γ/γ′-Strengthened Co-base Superalloy Variants. Scr. Mater. 2010, 63, 1197–1200. [Google Scholar] [CrossRef] [Green Version]

- Xue, F.; Wang, M.; Feng, Q. Alloying Effects on Heat-Treated Microstructure in Co-Al-W-base Superalloys at 1300 °C and 900 °C. In Proceedings of the Superalloys 2012, Seven Springs, PA, USA, 9 September 2012; Huron, E.S., Reed, R.C., Hardy, M.C., Mills, M.J., Montero, R.E., Portella, P.D., Telesman, J., Eds.; TMS: Warrendale, PA, USA, 2012; pp. 813–821. [Google Scholar]

- Yan, H.-Y.; Coakley, J.; Vorontsov, V.A.; Jones, N.G.; Stone, H.J.; Dye, D. Alloying and the Micromechanics of Co–Al–W–X Quaternary Alloys. Mater. Sci. Eng. A 2014, 613, 201–208. [Google Scholar] [CrossRef]

- Makineni, S.K.; Nithin, B.; Chattopadhyay, K. Synthesis of a New Tungsten-Free γ–γ′ Cobalt-based Superalloy by Tuning Alloying Additions. Acta Mater. 2015, 85, 85–94. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, C.; Ruan, J.; Omori, T.; Kainuma, R.; Ishida, K.; Liu, X. High-Strength Co–Al–V-base Superalloys Strengthened by γ′-Co3(Al,V) with High Solvus Temperature. Acta Mater. 2019, 170, 62–74. [Google Scholar] [CrossRef]

- Bocchini, P.J.; Sudbrack, C.K.; Sauza, D.J.; Noebe, R.D.; Seidman, D.N.; Dunand, D.C. Effect of Tungsten Concentration on Microstructures of Co-10Ni-6Al-(0,2,4,6)W-6Ti (at%) Cobalt-based Superalloys. Mater. Sci. Eng. A 2017, 700, 481–486. [Google Scholar] [CrossRef]

- Li, W.; Li, L.; Antonov, S.; Lu, F.; Feng, Q. Effects of Cr and Al/W Ratio on the Microstructural Stability, Oxidation Property and γ′ Phase Nano-Hardness of Multi-Component Co–Ni-base Superalloys. J. Alloys Compd. 2020, 826, 154182. [Google Scholar] [CrossRef]

- Liu, P.; Huang, H.; Antonov, S.; Wen, C.; Xue, D.; Chen, H.; Li, L.; Feng, Q.; Omori, T.; Su, Y. Machine Learning Assisted Design of γ′-Strengthened Co-base Superalloys with Multi-Performance Optimization. Npj Comput. Mater 2020, 6, 62. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, C.; Ruan, J.; Yang, S.; Omori, T.; Kainuma, R.; Ishida, K.; Han, J.; Lu, Y.; Liu, X. Development of Low-Density γ/γ′ Co–Al–Ta-based Superalloys with High Solvus Temperature. Acta Mater. 2020, 188, 652–664. [Google Scholar] [CrossRef]

- Yan, H.Y.; Vorontsov, V.A.; Dye, D. Alloying Effects in Polycrystalline γ′ Strengthened Co–Al–W Base Alloys. Intermetallics 2014, 48, 44–53. [Google Scholar] [CrossRef] [Green Version]

- Shinagawa, K.; Omori, T.; Sato, J.; Oikawa, K.; Ohnuma, I.; Kainuma, R.; Ishida, K. Phase Equilibria and Microstructure on γ′ Phase in Co-Ni-Al-W System. Mater. Trans. 2008, 49, 1474–1479. [Google Scholar] [CrossRef] [Green Version]

- Xue, F.; Zhou, H.J.; Ding, X.F.; Wang, M.L.; Feng, Q. Improved High Temperature γ′ Stability of Co-Al-W-base Alloys Containing Ti and Ta. Mater. Lett. 2013, 112, 215–218. [Google Scholar] [CrossRef]

- Zenk, C.H.; Neumeier, S.; Kolb, M.; Volz, N.; Fries, S.G.; Dolotko, O.; Povstugar, I.; Raabe, D.; Göken, M. The Role of the Base Element in γ′ Strengthened Cobalt/Nickel-base Superalloys. In Proceedings of the Superalloys 2016, Seven Springs, PA, USA, 11–15 September 2016; Hardy, M., Huron, E., Glatzel, U., Griffin, B., Lewis, B., Rae, C., Seetharaman, V., Tin, S., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2016; pp. 969–980, ISBN 978-1-119-07564-6. [Google Scholar]

- Shinagawa, K.; Omori, T.; Oikawa, K.; Kainuma, R.; Ishida, K. Ductility Enhancement by Boron Addition in Co-Al-W High-Temperature Alloys. Scr. Mater. 2009, 61, 612–615. [Google Scholar] [CrossRef]

- Titus, M.S.; Eggeler, Y.M.; Suzuki, A.; Pollock, T.M. Creep-Induced Planar Defects in L12-Containing Co- and CoNi-base Single-Crystal Superalloys. Acta Mater. 2015, 82, 530–539. [Google Scholar] [CrossRef]

- Eggeler, Y.M.; Müller, J.; Titus, M.S.; Suzuki, A.; Pollock, T.M.; Spiecker, E. Planar Defect Formation in the γ′ Phase during High Temperature Creep in Single Crystal CoNi-base Superalloys. Acta Mater. 2016, 113, 335–349. [Google Scholar] [CrossRef]

- Murray, S.P.; Pusch, K.M.; Polonsky, A.T.; Torbet, C.J.; Seward, G.G.E.; Zhou, N.; Forsik, S.A.J.; Nandwana, P.; Kirka, M.M.; Dehoff, R.R.; et al. A Defect-Resistant Co–Ni Superalloy for 3D Printing. Nat. Commun. 2020, 11, 4975. [Google Scholar] [CrossRef]

- Xue, F.; Zhou, H.J.; Shi, Q.Y.; Chen, X.H.; Chang, H.; Wang, M.L.; Feng, Q. Creep Behavior in a γ′ Strengthened Co-Al-W-Ta-Ti Single Crystal Alloy at 1000 °C. Scr. Mater. 2015, 97, 37–40. [Google Scholar] [CrossRef]

- Neumeier, S.; Freund, L.P.; Göken, M. Novel Wrought γ/γ′ Cobalt Base Superalloys with High Strength and Improved Oxidation Resistance. Scr. Mater. 2015, 109, 104–107. [Google Scholar] [CrossRef]

- Davies, R.G.; Stoloff, N. On the Yield Stress of Aged Ni-Al Alloys. Trans. Metall. Soc. AIME 1965, 233, 714–719. [Google Scholar]

- Beardmore, P.; Davies, R.G.; Johnston, T.L. On Temperature Dependence of Flow Stress of Nickel-base Alloys. Met. Soc. AIME-Trans. 1969, 245, 1537–1545. [Google Scholar]

- Ro, Y.; Koizumi, Y.; Harada, H. High Temperature Tensile Properties of a Series of Nickel-base Superalloys on a γ/γ′ Tie Line. Mater. Sci. Eng. A 1997, 223, 59–63. [Google Scholar] [CrossRef]

- Murakumo, T.; Kobayashi, T.; Koizumi, Y.; Harada, H. Creep Behaviour of Ni-base Single-Crystal Superalloys with Various γ′ Volume Fraction. Acta Mater. 2004, 52, 3737–3744. [Google Scholar] [CrossRef]

- Titus, M.S.; Mottura, A.; Babu Viswanathan, G.; Suzuki, A.; Mills, M.J.; Pollock, T.M. High Resolution Energy Dispersive Spectroscopy Mapping of Planar Defects in L12-Containing Co-base Superalloys. Acta Mater. 2015, 89, 423–437. [Google Scholar] [CrossRef]

- Eggeler, Y.M.; Titus, M.S.; Suzuki, A.; Pollock, T.M. Creep Deformation-Induced Antiphase Boundaries in L12-Containing Single-Crystal Cobalt-base Superalloys. Acta Mater. 2014, 77, 352–359. [Google Scholar] [CrossRef]

- Freund, L.P.; Messé, O.M.D.M.; Barnard, J.S.; Göken, M.; Neumeier, S.; Rae, C.M.F. Segregation Assisted Microtwinning during Creep of a Polycrystalline L12-Hardened Co-base Superalloy. Acta Mater. 2017, 123, 295–304. [Google Scholar] [CrossRef]

- Xue, F.; Zenk, C.H.; Freund, L.P.; Neumeier, S.; Göken, M. Understanding Raft Formation and Precipitate Shearing during Double Minimum Creep in a γ′-Strengthened Single Crystalline Co-base Superalloy. Philos. Mag. 2021, 101, 326–353. [Google Scholar] [CrossRef]

- Lu, S.; Antonov, S.; Xue, F.; Li, L.; Feng, Q. Segregation-Assisted Phase Transformation and Anti-Phase Boundary Formation during Creep of a γ′-Strengthened Co-based Superalloy at High Temperatures. Acta Mater. 2021, 215, 117099. [Google Scholar] [CrossRef]

- Lu, S.; Antonov, S.; Li, L.; Liu, C.; Zhang, X.; Zheng, Y.; Fraser, H.L.; Feng, Q. Atomic Structure and Elemental Segregation Behavior of Creep Defects in a Co-Al-W-based Single Crystal Superalloys under High Temperature and Low Stress. Acta Mater. 2020, 190, 16–28. [Google Scholar] [CrossRef]

- Lenz, M.; Eggeler, Y.M.; Müller, J.; Zenk, C.H.; Volz, N.; Wollgramm, P.; Eggeler, G.; Neumeier, S.; Göken, M.; Spiecker, E. Tension/Compression Asymmetry of a Creep Deformed Single Crystal Co-base Superalloy. Acta Mater. 2019, 166, 597–610. [Google Scholar] [CrossRef]

- Bezold, A.; Volz, N.; Xue, F.; Göken, M.; Neumeier, S. Anomalous Work Hardening Behavior of a Single Crystalline Co-base Superalloy. Alloys 2022, 1, 243–253. [Google Scholar] [CrossRef]

- Xue, F.; Zhou, H.J.; Feng, Q. Improved High-Temperature Microstructural Stability and Creep Property of Novel Co-base Single-Crystal Alloys Containing Ta and Ti. JOM 2014, 66, 2486–2494. [Google Scholar] [CrossRef]

- Nystrom, J.; Pollock, T.; Murphy, W.; Garg, A. Discontinuous Cellular Precipitation in a High-Refractory Nickel-base Superalloy. Metall. Mater. Trans. A 1997, 28, 2443–2452. [Google Scholar] [CrossRef]

- Wilson, A.S. Formation and Effect of Topologically Close-Packed Phases in Nickel-base Superalloys. Energy Mater. 2016, 11, 1108–1118. [Google Scholar] [CrossRef]

- Titus, M.S.; Suzuki, A.; Pollock, T.M. High Temperature Creep of New L12 Containing Cobalt-base Superalloys; Huron, E.S., Reed, R.C., Hardy, M.C., Mills, M.J., Montero, R.E., Portella, P.D., Telesman, J., Eds.; TMS: Warrendale, PA, USA, 2012; pp. 823–832. [Google Scholar]

- Volz, N.; Xue, F.; Bezold, A.; Zenk, C.H.; Fries, S.G.; Schreuer, J.; Neumeier, S.; Göken, M. Design of a Co–Al–W–Ta Alloy Series with Varying γ′ Volume Fraction and Their Thermophysical Properties. Met. Mater. Trans. A 2021, 52, 3931–3944. [Google Scholar] [CrossRef]

- Bezold, A.; Volz, N.; Xue, F.; Zenk, C.H.; Neumeier, S.; Göken, M. On the Precipitation-Strengthening Contribution of the Ta-Containing Co3(Al,W)-Phase to the Creep Properties of γ/γ′ Cobalt-base Superalloys. Met. Mater. Trans. A 2020, 51, 1567–1574. [Google Scholar] [CrossRef] [Green Version]

- Heckl, A.; Rettig, R.; Singer, R.F. Solidification Characteristics and Segregation Behavior of Nickel-base Superalloys in Dependence on Different Rhenium and Ruthenium Contents. Met. Mater. Trans. A 2010, 41, 202. [Google Scholar] [CrossRef]

- Maier, H.J.; Niendorf, T.; Bürgel, R. Handbuch Hochtemperatur-Werkstofftechnik: Grundlagen, Werkstoffbeanspruchungen, Hochtemperaturlegierungen und -Beschichtungen; Springer: Berlin/Heidelberg, Germany, 2015; ISBN 978-3-658-10591-4. [Google Scholar]

- Xue, F.; Zenk, C.H.; Freund, L.P.; Hoelzel, M.; Neumeier, S.; Göken, M. Double Minimum Creep in the Rafting Regime of a Single-Crystal Co-base Superalloy. Scr. Mater. 2018, 142, 129–132. [Google Scholar] [CrossRef]

- Pollock, T.M.; Argon, A.S. Directional Coarsening in Nickel-base Single Crystals with High Volume Fractions of Coherent Precipitates. Acta Metall. Mater. 1994, 42, 1859–1874. [Google Scholar] [CrossRef]

- Tanaka, K.; Ooshima, M.; Tsuno, N.; Sato, A.; Inui, H. Creep Deformation of Single Crystals of New Co–Al–W-based Alloys with fcc/L12 Two-Phase Microstructures. Philos. Mag. 2012, 92, 4011–4027. [Google Scholar] [CrossRef]

- Matan, N.; Cox, D.C.; Carter, P.; Rist, M.A.; Rae, C.M.F.; Reed, R.C. Creep of CMSX-4 Superalloy Single Crystals: Effects of Misorientation and Temperature. Acta Mater. 1999, 47, 1549–1563. [Google Scholar] [CrossRef]

| Alloy | Nominal Composition | |||

|---|---|---|---|---|

| Co | Al | W | Ta | |

| ERBOCo–2Ta | 81.5 | 9.0 | 7.5 | 2.0 |

| VF0 | 86.7 | 8.8 | 4.0 | 0.5 |

| VF20 | 84.4 | 8.8 | 5.7 | 1.1 |

| VF40 | 82.1 | 8.9 | 7.3 | 1.7 |

| VF60 | 79.8 | 8.9 | 9.0 | 2.3 |

| VF70 | 78.7 | 9.0 | 9.8 | 2.6 |

| VF80 | 77.5 | 9.0 | 10.6 | 2.9 |

| VF100 | 75.2 | 9.0 | 12.3 | 3.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, F.; Bezold, A.; Volz, N.; Kirchmayer, A.; Zenk, C.H.; Neumeier, S.; Göken, M. Influence of the γ′ Volume Fraction on the High-Temperature Strength of Single Crystalline Co–Al–W–Ta Superalloys. Crystals 2023, 13, 1095. https://doi.org/10.3390/cryst13071095

Xue F, Bezold A, Volz N, Kirchmayer A, Zenk CH, Neumeier S, Göken M. Influence of the γ′ Volume Fraction on the High-Temperature Strength of Single Crystalline Co–Al–W–Ta Superalloys. Crystals. 2023; 13(7):1095. https://doi.org/10.3390/cryst13071095

Chicago/Turabian StyleXue, Fei, Andreas Bezold, Nicklas Volz, Andreas Kirchmayer, Christopher H. Zenk, Steffen Neumeier, and Mathias Göken. 2023. "Influence of the γ′ Volume Fraction on the High-Temperature Strength of Single Crystalline Co–Al–W–Ta Superalloys" Crystals 13, no. 7: 1095. https://doi.org/10.3390/cryst13071095