Research on Microstructure, Synthesis Mechanisms, and Residual Stress Evolution of Polycrystalline Diamond Compacts

Abstract

:1. Introduction

2. Experimental Materials and Methods

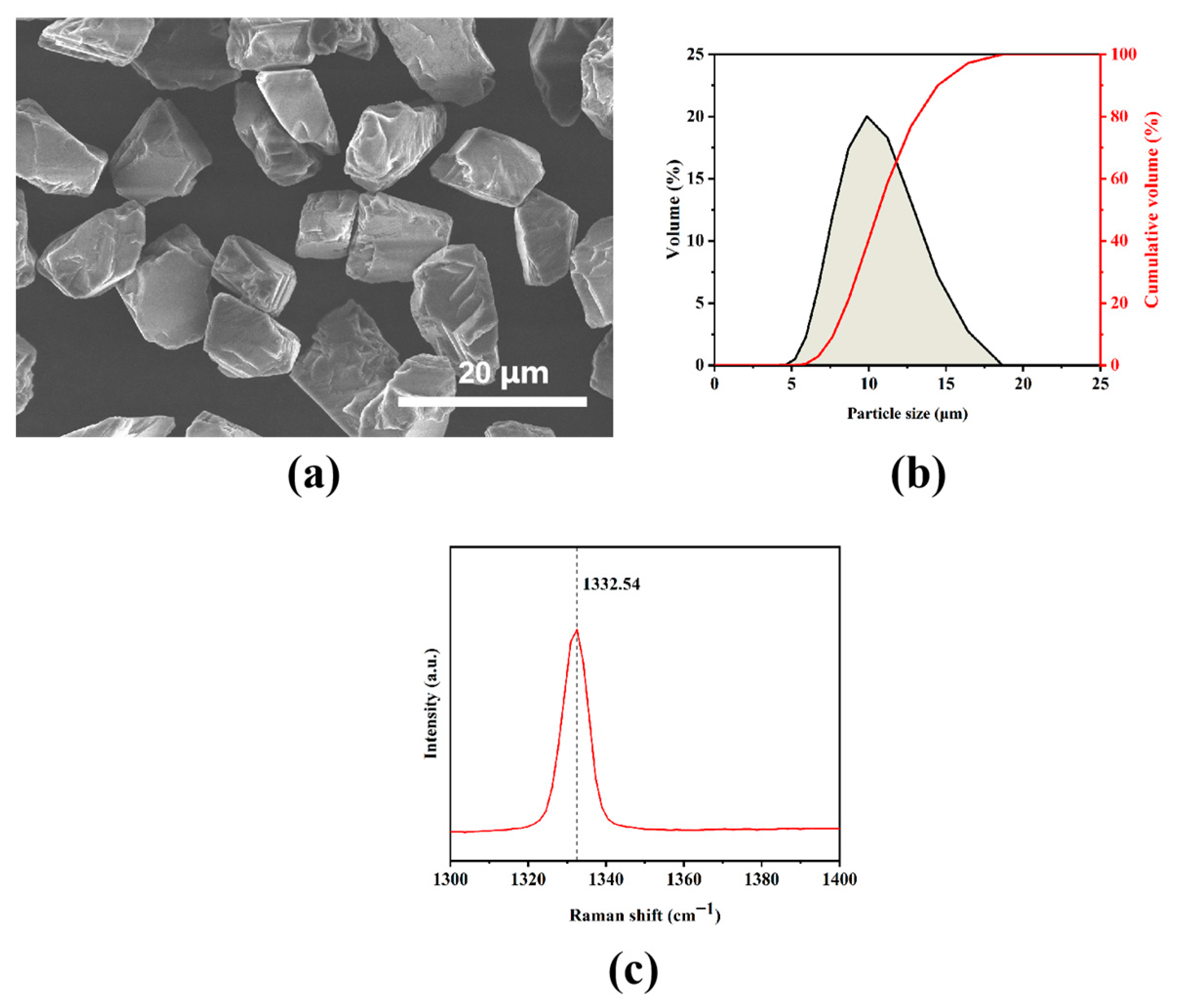

2.1. Experimental Materials

2.2. Experimental Methods

2.2.1. Preparation of Initial Powder of PDCs

2.2.2. HPHT Process

2.2.3. Residual Stress Evaluation

2.2.4. Property Characterization of Diamond Powder and Microstructure Analysis of PDCs

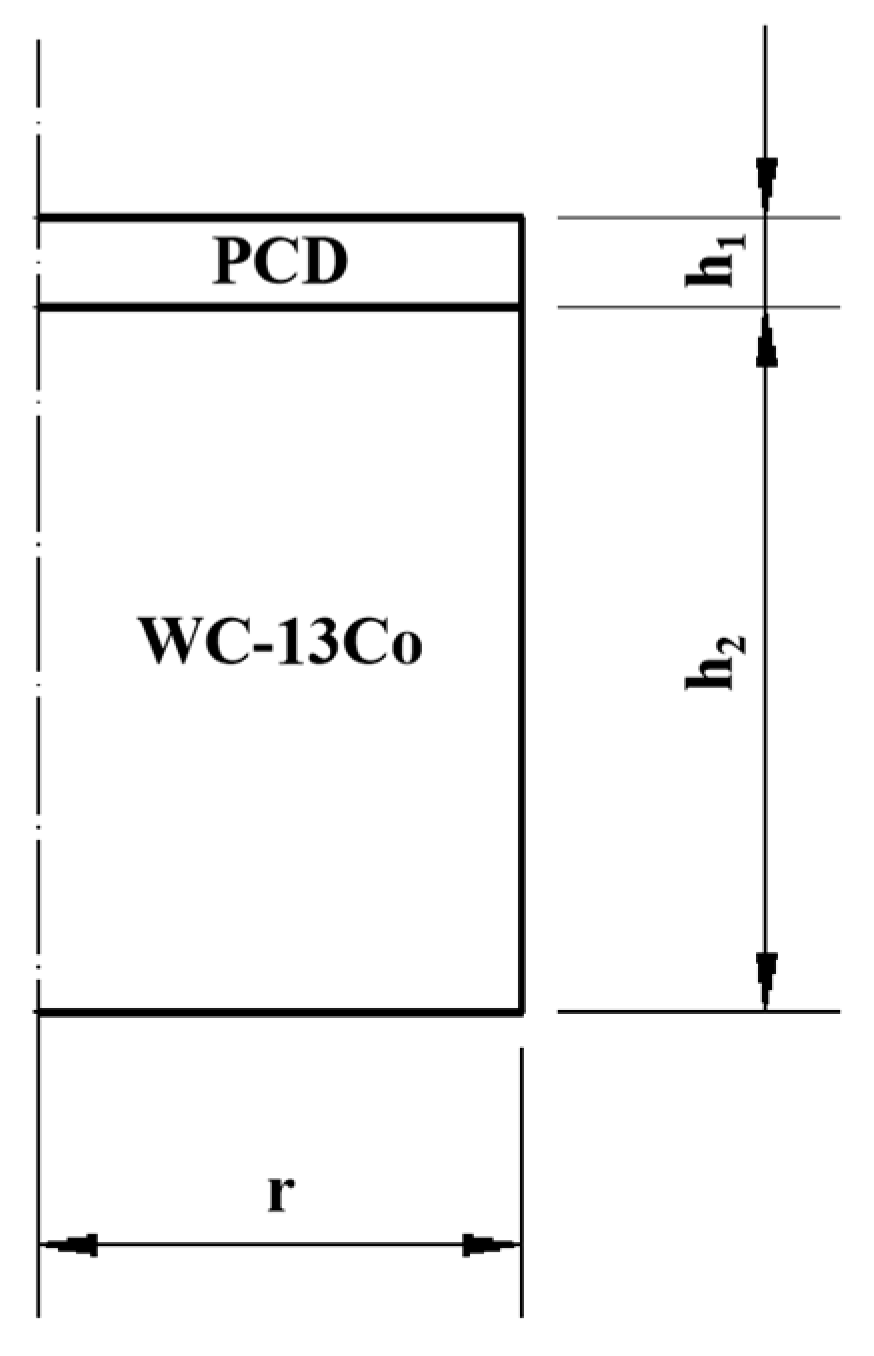

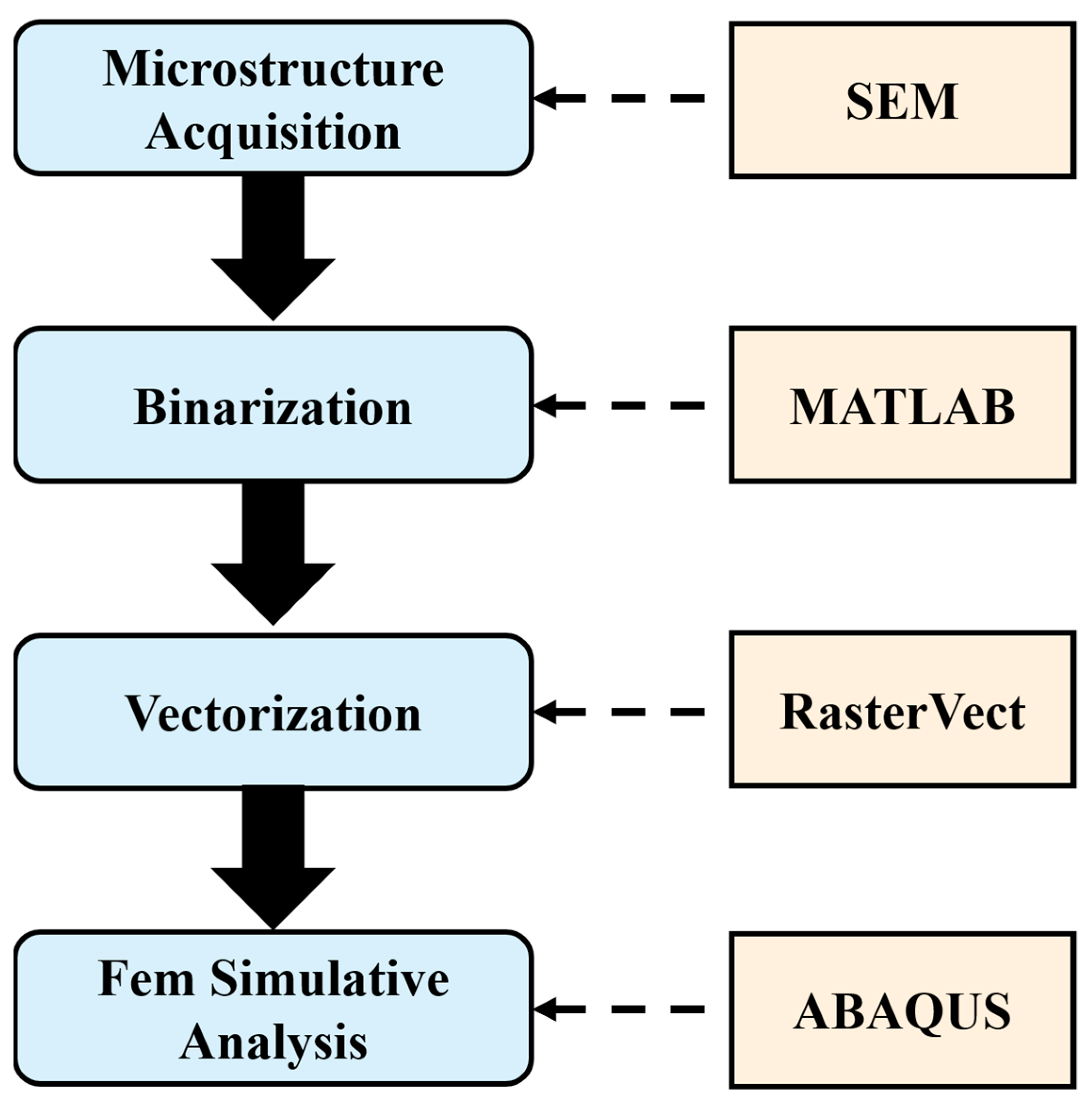

2.3. FEM Simulation of Residual Stress

3. Experimental Results and Discussion

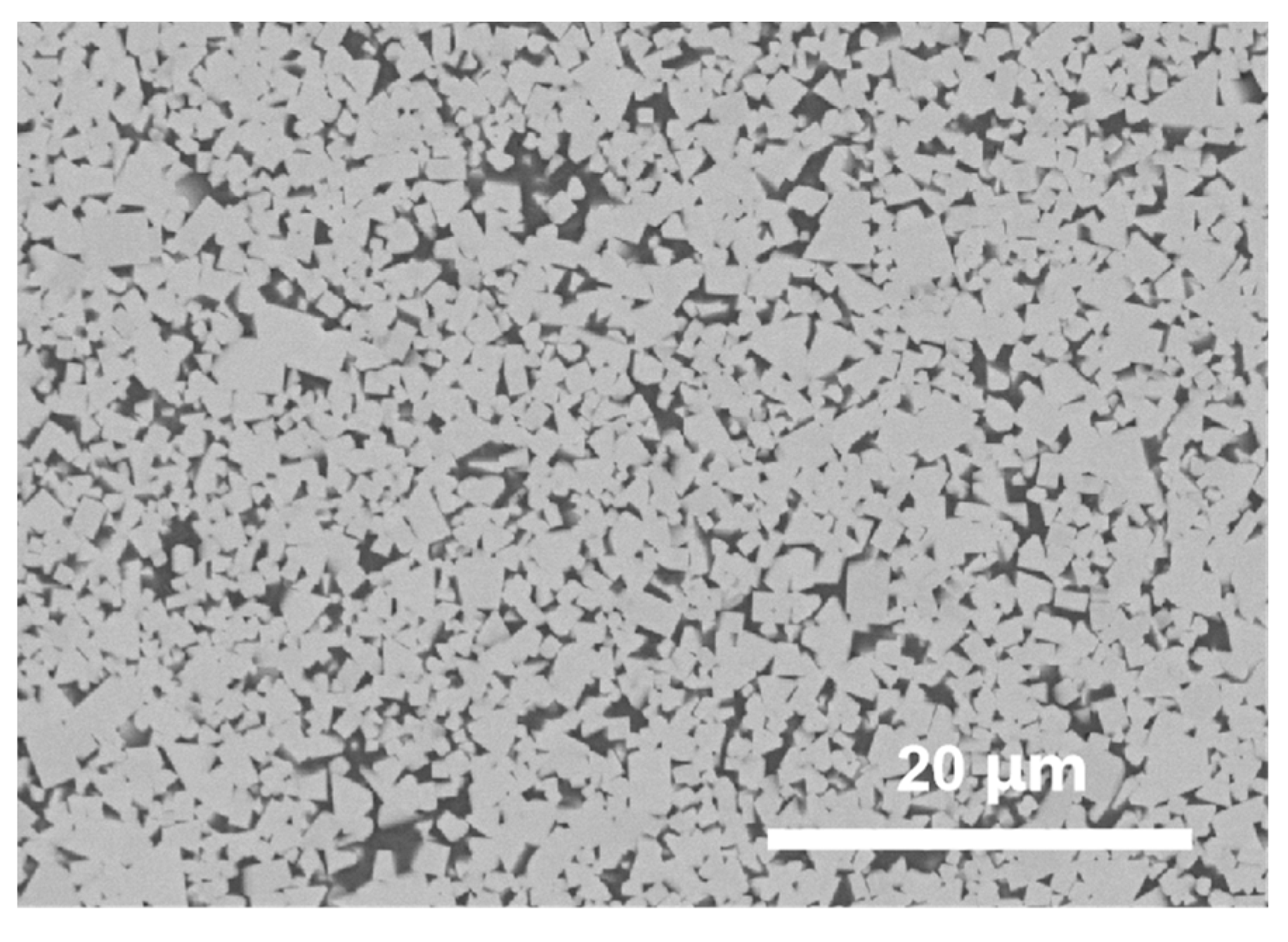

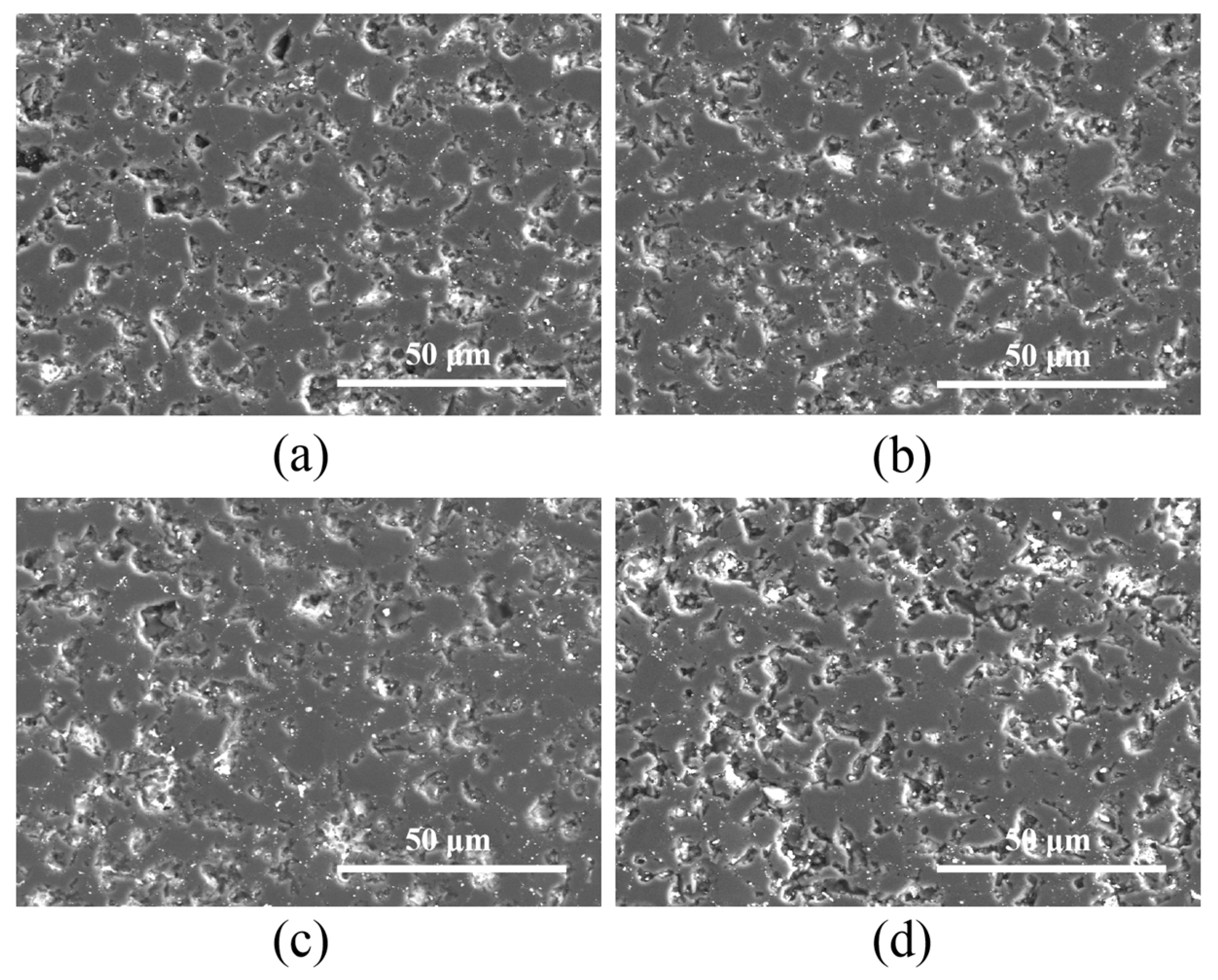

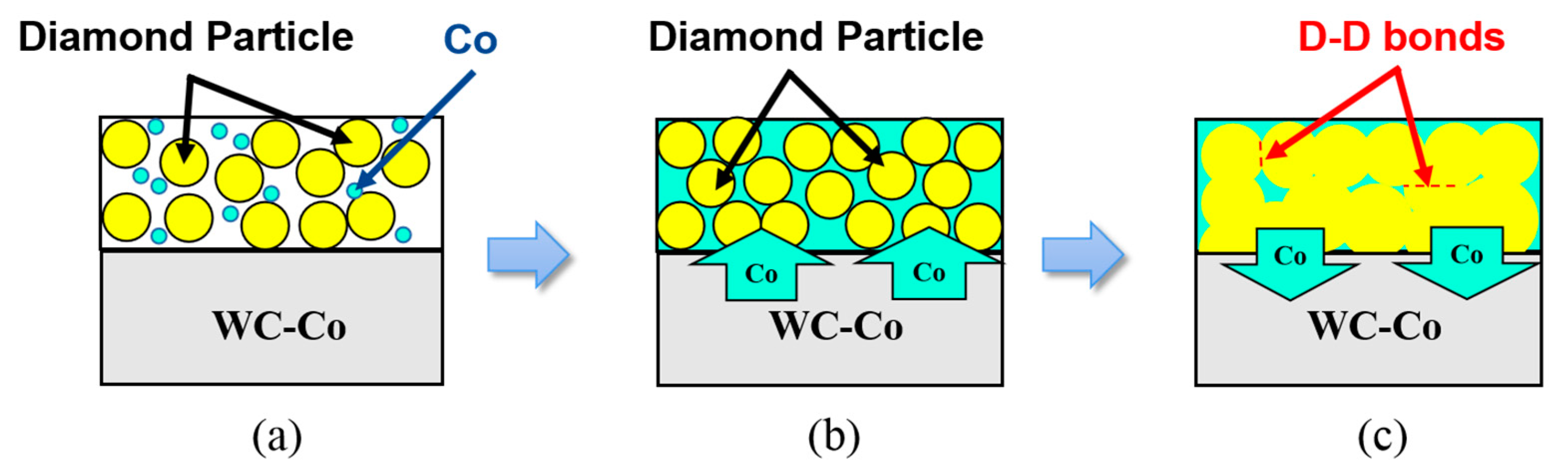

3.1. Microstructure of the PDCs

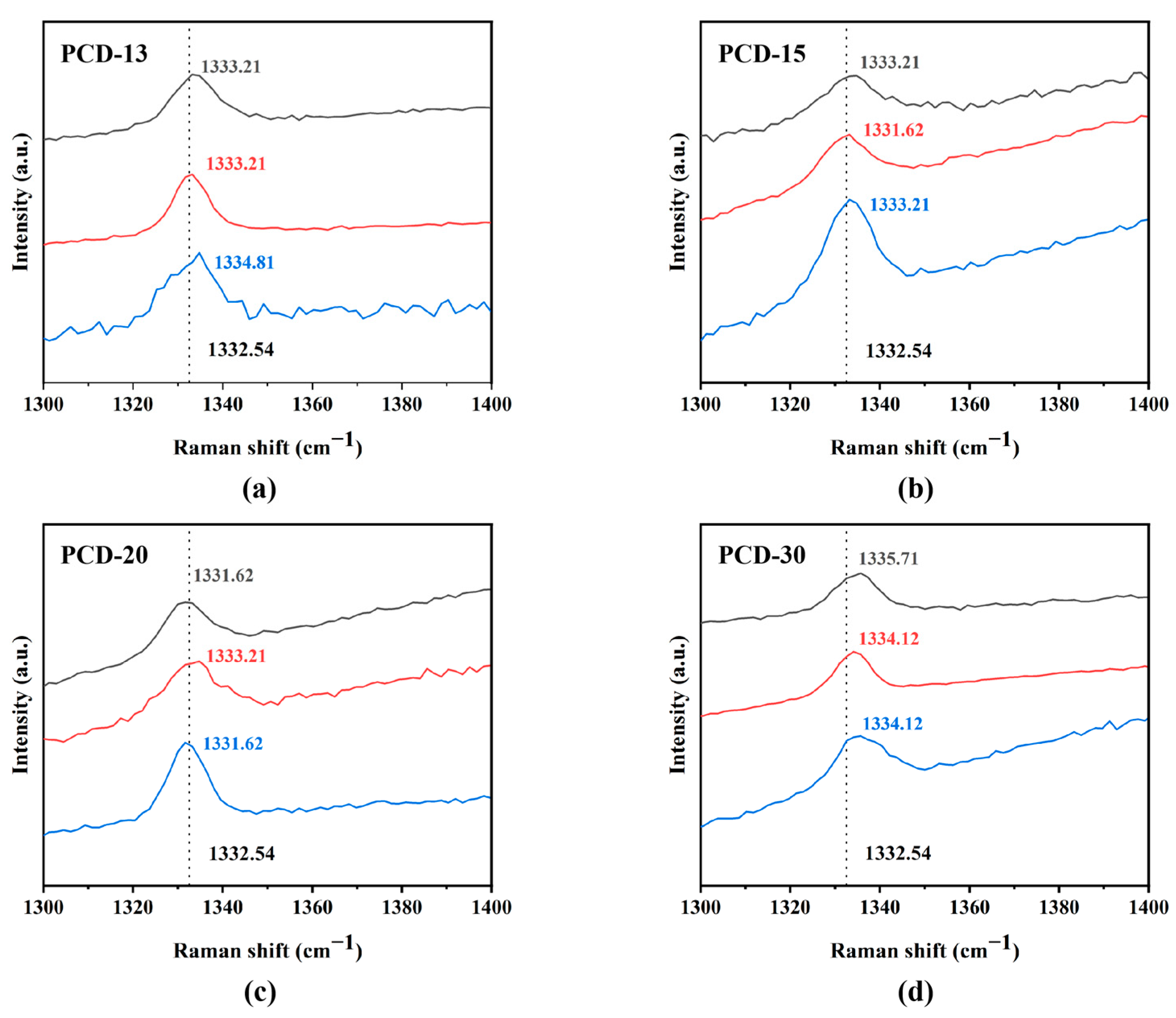

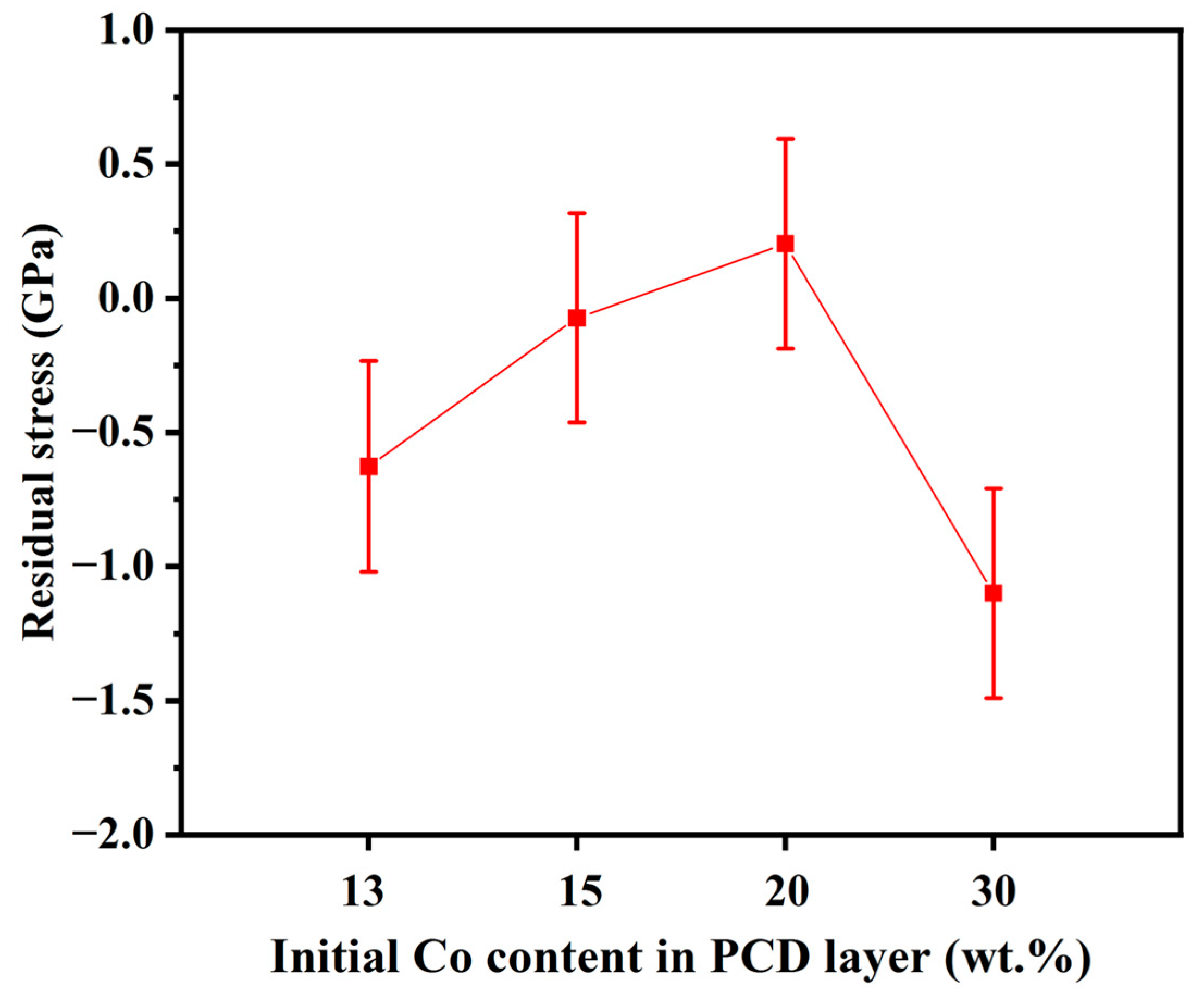

3.2. Raman Spectrum Analysis

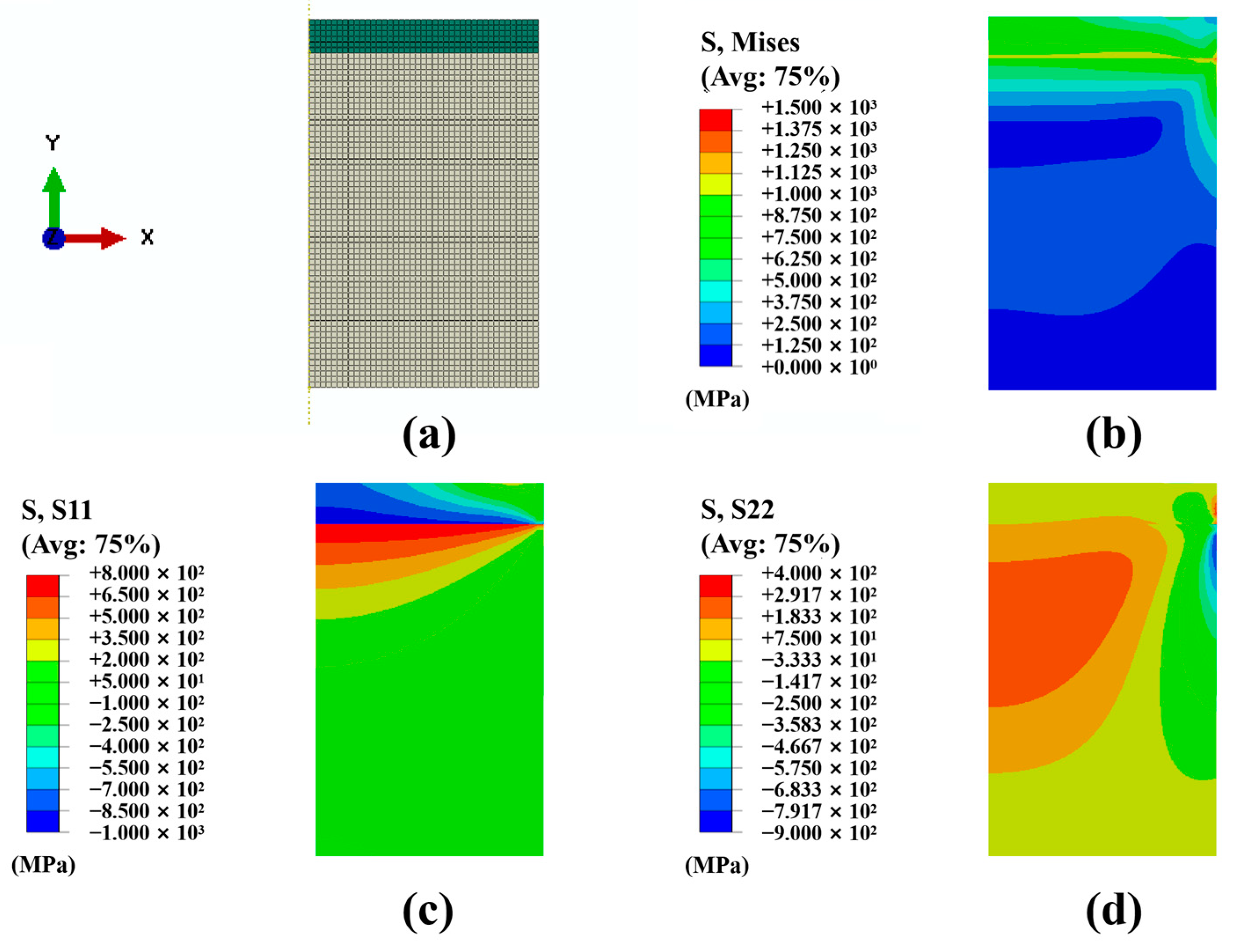

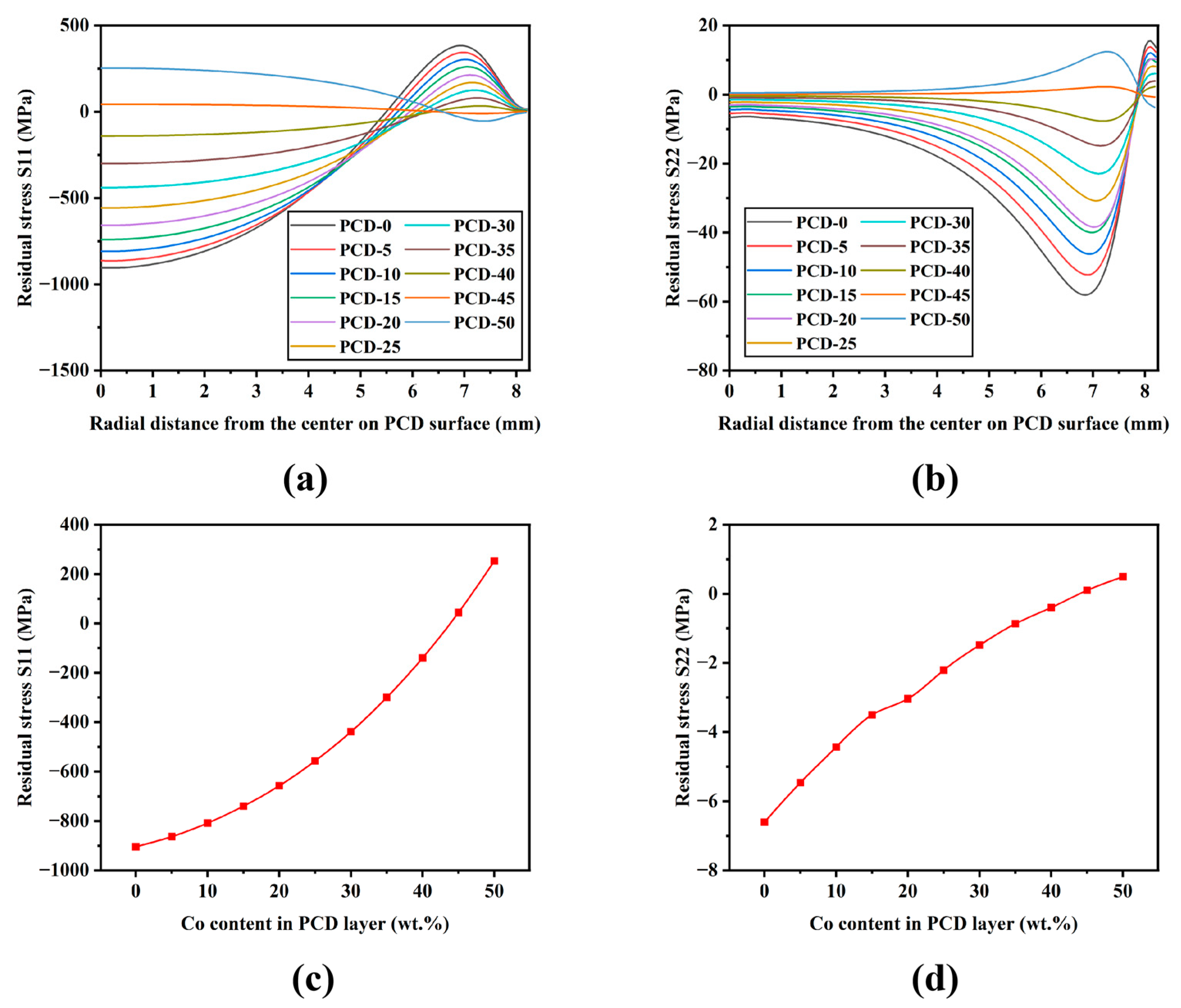

3.3. FEM Simulation of Residual Stress for PDCs

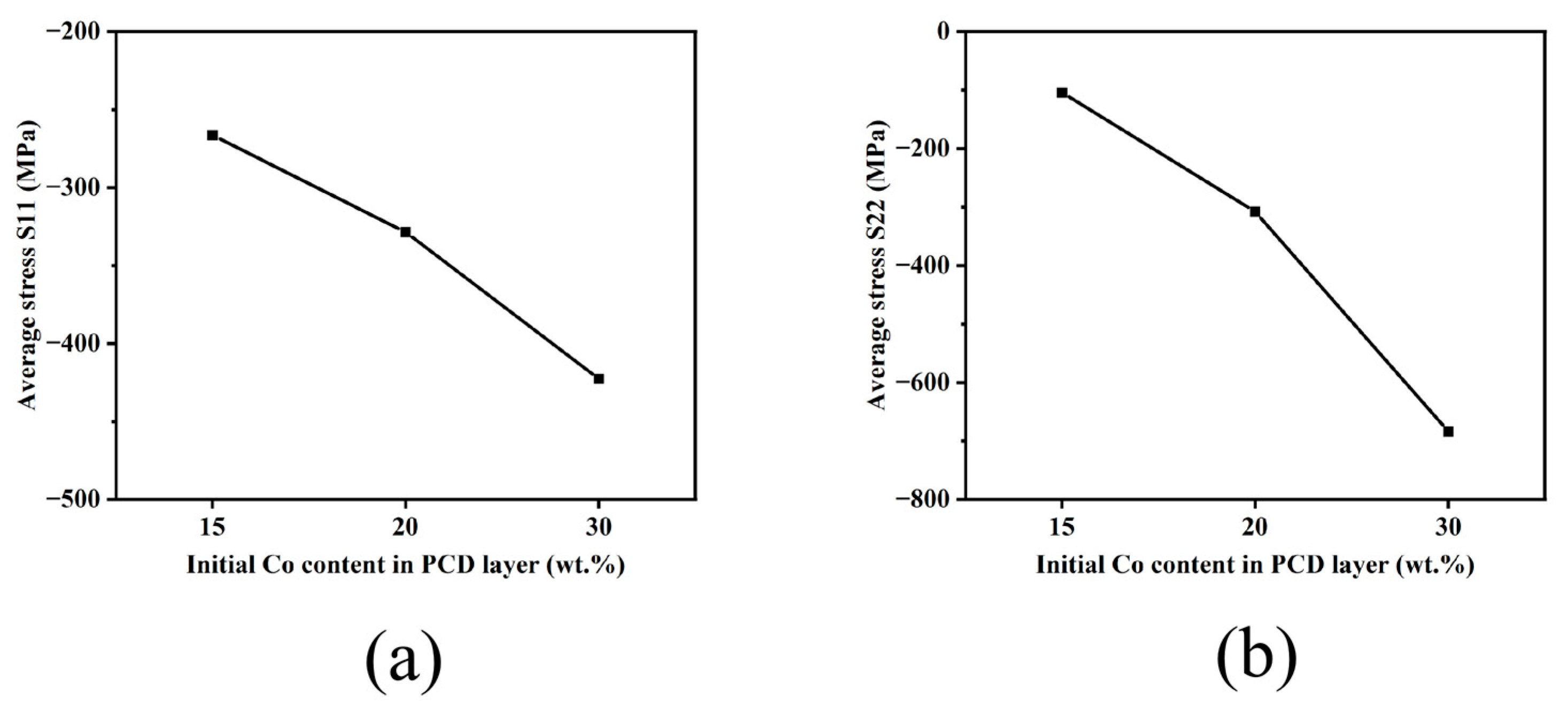

3.4. Micromechanical Simulation Based on Microstructure of PCD–Carbide Substrate Interface

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wentorf, R.H.; Devries, R.C.; Bundy, F.P. Sintered superhard materials. Science 1980, 208, 873. [Google Scholar] [CrossRef] [PubMed]

- Li, G.; Rahim, M.Z.; Pan, W.; Wen, C.; Ding, S. The manufacturing and the application of polycrystalline diamond tools—A comprehensive review. J. Manuf. Process. 2020, 56, 400. [Google Scholar] [CrossRef]

- Miyazaki, K.; Ohno, T.; Karasawa, H.; Takakura, S.; Eko, A. Performance evaluation of polycrystalline diamond compact percussion bits through laboratory drilling tests. Int. J. Rock Mech. Min. Sci. 2016, 87, 1. [Google Scholar] [CrossRef]

- Bochechka, O.O. Production of Polycrystalline Materials by Sintering of Nanodispersed Diamond Nanopowders at High Pressure. Review. J. Superhard Mater. 2018, 40, 325. [Google Scholar] [CrossRef]

- Miess, D.; Rai, G. Fracture toughness and thermal resistance of polycrystalline diamond compacts. Mater. Sci. Eng. A 1996, 209, 270. [Google Scholar] [CrossRef]

- Clark, I.; Bex, P. The use of PCD for petroleum and mining drilling. Ind. Diam. Rev. 1999, 59, 43. [Google Scholar]

- Abbas, R.K.; Musa, K.M. Using Raman shift and FT-IR spectra as quality indices of oil bit PDC cutters. Petroleum 2019, 5, 329. [Google Scholar] [CrossRef]

- Bellin, F.; Dourfaye, A.; King, W.; Thigpen, M. The current state of PDC bit technology. World Oil 2010, 231, 53. [Google Scholar]

- Kim, D.; Beal, A.; Kwon, P. Effect of Tool Wear on Hole Quality in Drilling of Carbon Fiber Reinforced Plastic-Titanium Alloy Stacks Using Tungsten Carbide and Polycrystalline Diamond Tools. J. Manuf. Sci. Eng.-Trans. Asme 2016, 138, 031006. [Google Scholar] [CrossRef]

- Chen, F.; Xu, G.; Ma, C.; Xu, G. Thermal residual stress of polycrystalline diamond compacts. Trans. Nonferrous Met. Soc. China 2010, 20, 227. [Google Scholar] [CrossRef]

- Paggett, J.; Drake, E.; Krawitz, A.; Winholtz, R.; Griffin, N. Residual stress and stress gradients in polycrystalline diamond compacts. Int. J. Refract. Met. Hard Mater. 2002, 20, 187. [Google Scholar] [CrossRef]

- McNamara, D.; Alveen, P.; Damm, S.; Carolan, D.; Rice, J.H.; Murphy, N.; Ivanković, A. A Raman spectroscopy investigation into the influence of thermal treatments on the residual stress of polycrystalline diamond. Int. J. Refract. Met. Hard Mater. 2015, 52, 114. [Google Scholar] [CrossRef]

- Erasmus, R.M.; Comins, J.D.; Mofokeng, V.; Martin, Z. Application of Raman spectroscopy to determine stress in polycrystalline diamond tools as a function of tool geometry and temperature. Diam. Relat. Mater. 2011, 20, 907. [Google Scholar] [CrossRef]

- Yue, T.; Yue, W.; Li, J.; Wang, C. Effect of vacuum annealing temperature on tribological behaviors of sintered polycrystalline diamond compact. Int. J. Refract. Met. Hard Mater. 2017, 64, 66. [Google Scholar] [CrossRef]

- Ni, P.; Zhao, Z.; Yang, W.; Deng, X.; Wu, S.; Qu, Z.; Jin, F. Effect of feedstock diamond powder property on microstructure and mechanical properties of polycrystalline diamond compacts. Int. J. Refract. Met. Hard Mater. 2023, 111, 106102. [Google Scholar] [CrossRef]

- Gu, J.; Huang, K.J.D.; Materials, R. Role of cobalt of polycrystalline diamond compact (PDC) in drilling process. Diam. Relat. Mater. 2016, 66, 98. [Google Scholar] [CrossRef]

- Kong, C.; Liang, Z.; Zhang, D.J.M. Failure analysis and optimum structure design of PDC cutter. Mechanics 2017, 23, 567. [Google Scholar] [CrossRef]

- Lin, T.; Hood, M.; Cooper, G.A.; Smith, R.H. Residual stresses in polycrystalline diamond compacts. J. Am. Ceram. Soc. 1994, 77, 1562. [Google Scholar] [CrossRef]

- Vhareta, M.; Erasmus, R.M.; Comins, J.D. Investigation of fatigue-type processes in polycrystalline diamond tools using Raman spectroscopy. Diam. Relat. Mater. 2014, 45, 34. [Google Scholar] [CrossRef]

- Yadav, V.; Jain, V.K.; Dixit, P.M. Thermal stresses due to electrical discharge machining. Int. J. Mach. Tools Manuf. 2002, 42, 877. [Google Scholar] [CrossRef]

- Catledge, S.A.; Vohra, Y.K.; Ladi, R.; Rai, G. Micro-Raman stress investigations and X-ray diffraction analysis of polycrystalline diamond (PCD) tools. Diam. Relat. Mater. 1996, 5, 1159. [Google Scholar] [CrossRef]

- Rats, D.; Bimbault, L.; Vandenbulcke, L.; Herbin, R.; Badawi, K.F. Crystalline quality and residual stresses in diamond layers by Raman and x-ray diffraction analyses. J. Appl. Phys. 1995, 78, 4994. [Google Scholar] [CrossRef]

- Krawitz, A.D.; Winholtz, R.A.; Drake, E.F.; Griffin, N. Residual stresses in polycrystalline diamond compacts. Int. J. Refract. Met. Hard Mater. 1999, 17, 117. [Google Scholar] [CrossRef]

- Mukhopadhyay, D. Identifying the causes of residual stress in polycrystalline diamond compact (PDC) cutters by X-ray diffraction technique. Results Mater. 2021, 11, 100216. [Google Scholar] [CrossRef]

- Chen, Z.; Ma, D.; Wang, S.; Dai, W.; Li, S.; Zhu, Y.; Liu, B. Effects of graphene addition on mechanical properties of polycrystalline diamond compact. Ceram. Int. 2020, 46, 11255. [Google Scholar] [CrossRef]

- Prawer, S.; Nemanich, R.J. Raman spectroscopy of diamond and doped diamond. Philos. Trans. R. Soc. Lond. Ser. A-Math. Phys. Eng. Sci. 2004, 362, 2537. [Google Scholar] [CrossRef]

- Zeng, P. Fundamentals of Finite Element Analysis; Higher Education Press: Beijing, China, 2009; p. 290. [Google Scholar]

- Kanyanta, V.; Ozbayraktar, S.; Maweja, K. Effect of manufacturing parameters on polycrystalline diamond compact cutting tool stress-state. Int. J. Refract. Met. Hard Mater. 2014, 45, 147. [Google Scholar] [CrossRef]

- Zhu, J.; Zhou, H.; Qin, B.; Zhao, Z. Design, fabrication and properties of TiB2/TiN/WC gradient ceramic tool materials. Ceram. Int. 2020, 46, 6497. [Google Scholar] [CrossRef]

- Shin, T.; Oh, J.; Oh, K.H.; Lee, D.N. The mechanism of abnormal grain growth in polycrystalline diamond during high pressure-high temperature sintering. Diam. Relat. Mater. 2004, 13, 488. [Google Scholar] [CrossRef]

- Vengrenovitch, R.D. On the ostwald ripening theory. Acta Metall. 1982, 30, 1079. [Google Scholar] [CrossRef]

- Kanyanta, V. Microstructure-Property Correlations for Hard, Superhard, and Ultrahard Materials; Springer: London, UK, 2016; p. 35. [Google Scholar]

| PDC Designation | Diamond Powder Content, wt.% | Co powder Content, wt.% |

|---|---|---|

| PCD-13 | 87 | 13 |

| PCD-15 | 85 | 15 |

| PCD-20 | 80 | 20 |

| PCD-30 | 70 | 30 |

| Property | Diamond | Cobalt | Carbide Substrate |

|---|---|---|---|

| Elastic modulus (GPa), | 900 | 200 | 579 |

| Density (kg/m3), | 3500 | 8500 | 15000 |

| Poisson’s ratio, | 0.07 | 0.33 | 0.22 |

| Thermal conductivity (W/(m·K)), k | 2000 | 69.2 | 100 |

| Specific Heat (J/(kg·K)), | 471 | 440 | 230 |

| Coefficient of thermal expansion (10−6·K−1), α | 3.2 | 14.4 | 5.2 |

| Designation of PDCs (Number Corresponds to wt.% of Co in PCD Layer) | Dimension of PDCs in Figure 3 | (kg/m3) | (GPa) | (10−6·K−1) | (J/(kg·K)) | (W/(m·K)) | |||

|---|---|---|---|---|---|---|---|---|---|

(mm) | (mm) | (mm) | |||||||

| PCD-0 | 8.25 | 1.645 | 12 | 3500.000 | 900.000 | 0.070 | 3.200 | 471.000 | 2000.000 |

| PCD-5 | 8.25 | 1.597 | 12 | 3606.061 | 877.762 | 0.076 | 3.362 | 470.342 | 1921.703 |

| PCD-10 | 8.25 | 1.548 | 12 | 3718.750 | 854.677 | 0.082 | 3.536 | 469.644 | 1841.776 |

| PCD-15 | 8.25 | 1.500 | 12 | 3838.710 | 830.693 | 0.089 | 3.724 | 468.900 | 1760.166 |

| PCD-20 | 8.25 | 1.452 | 12 | 3966.667 | 805.757 | 0.096 | 3.928 | 468.107 | 1676.821 |

| PCD-25 | 8.25 | 1.403 | 12 | 4103.448 | 779.808 | 0.103 | 4.150 | 467.259 | 1591.684 |

| PCD-30 | 8.25 | 1.355 | 12 | 4250.000 | 752.781 | 0.110 | 4.393 | 466.350 | 1504.697 |

| PCD-35 | 8.25 | 1.306 | 12 | 4407.407 | 724.606 | 0.119 | 4.659 | 465.374 | 1415.799 |

| PCD-40 | 8.25 | 1.258 | 12 | 4576.923 | 695.204 | 0.127 | 4.952 | 464.323 | 1324.926 |

| PCD-45 | 8.25 | 1.210 | 12 | 4760.000 | 664.488 | 0.137 | 5.276 | 463.188 | 1232.012 |

| PCD-50 | 8.25 | 1.161 | 12 | 4958.333 | 632.363 | 0.147 | 5.637 | 461.958 | 1136.986 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ni, P.; Chen, Y.; Yang, W.; Hu, Z.; Deng, X. Research on Microstructure, Synthesis Mechanisms, and Residual Stress Evolution of Polycrystalline Diamond Compacts. Crystals 2023, 13, 1286. https://doi.org/10.3390/cryst13081286

Ni P, Chen Y, Yang W, Hu Z, Deng X. Research on Microstructure, Synthesis Mechanisms, and Residual Stress Evolution of Polycrystalline Diamond Compacts. Crystals. 2023; 13(8):1286. https://doi.org/10.3390/cryst13081286

Chicago/Turabian StyleNi, Peishen, Yongxuan Chen, Wenxin Yang, Zijian Hu, and Xin Deng. 2023. "Research on Microstructure, Synthesis Mechanisms, and Residual Stress Evolution of Polycrystalline Diamond Compacts" Crystals 13, no. 8: 1286. https://doi.org/10.3390/cryst13081286

APA StyleNi, P., Chen, Y., Yang, W., Hu, Z., & Deng, X. (2023). Research on Microstructure, Synthesis Mechanisms, and Residual Stress Evolution of Polycrystalline Diamond Compacts. Crystals, 13(8), 1286. https://doi.org/10.3390/cryst13081286