Phase Structure and Electrical Properties of 0.28PIN-0.32PZN–(0.4-x) PT-xPZ Piezoelectric Ceramics

Abstract

:1. Introduction

2. Experimental Procedure

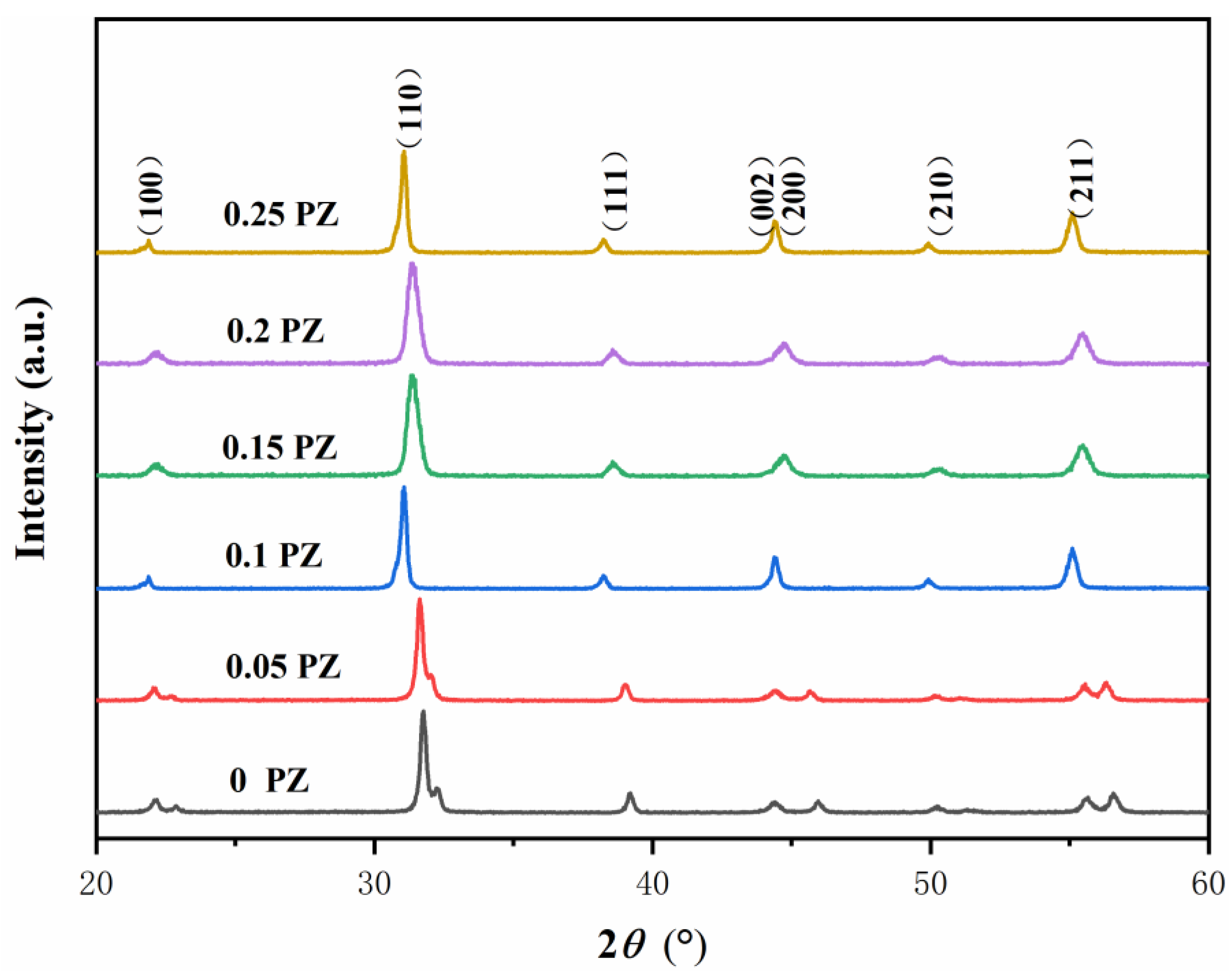

3. Results and Discussion

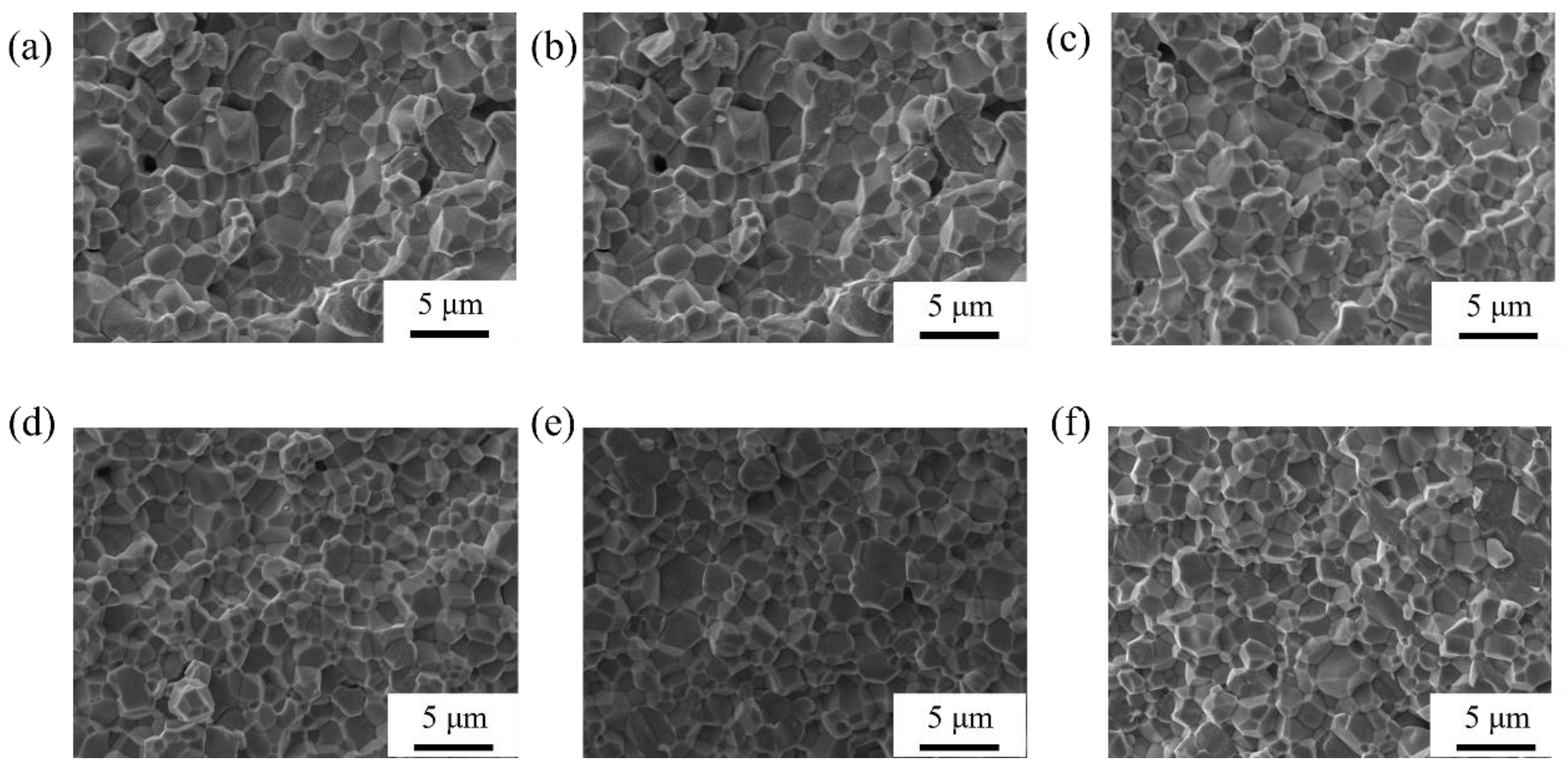

3.1. Microstructure of Ceramics

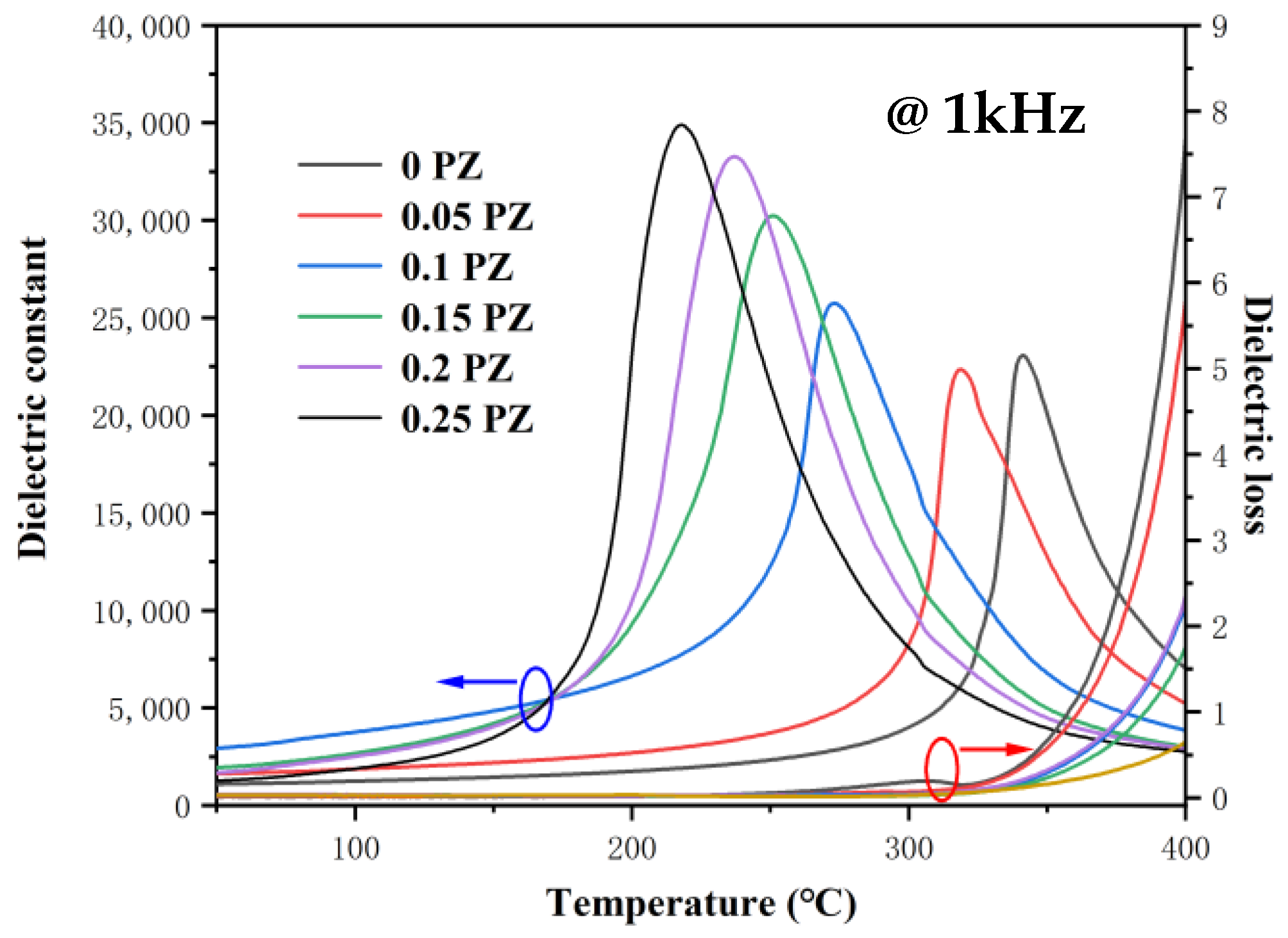

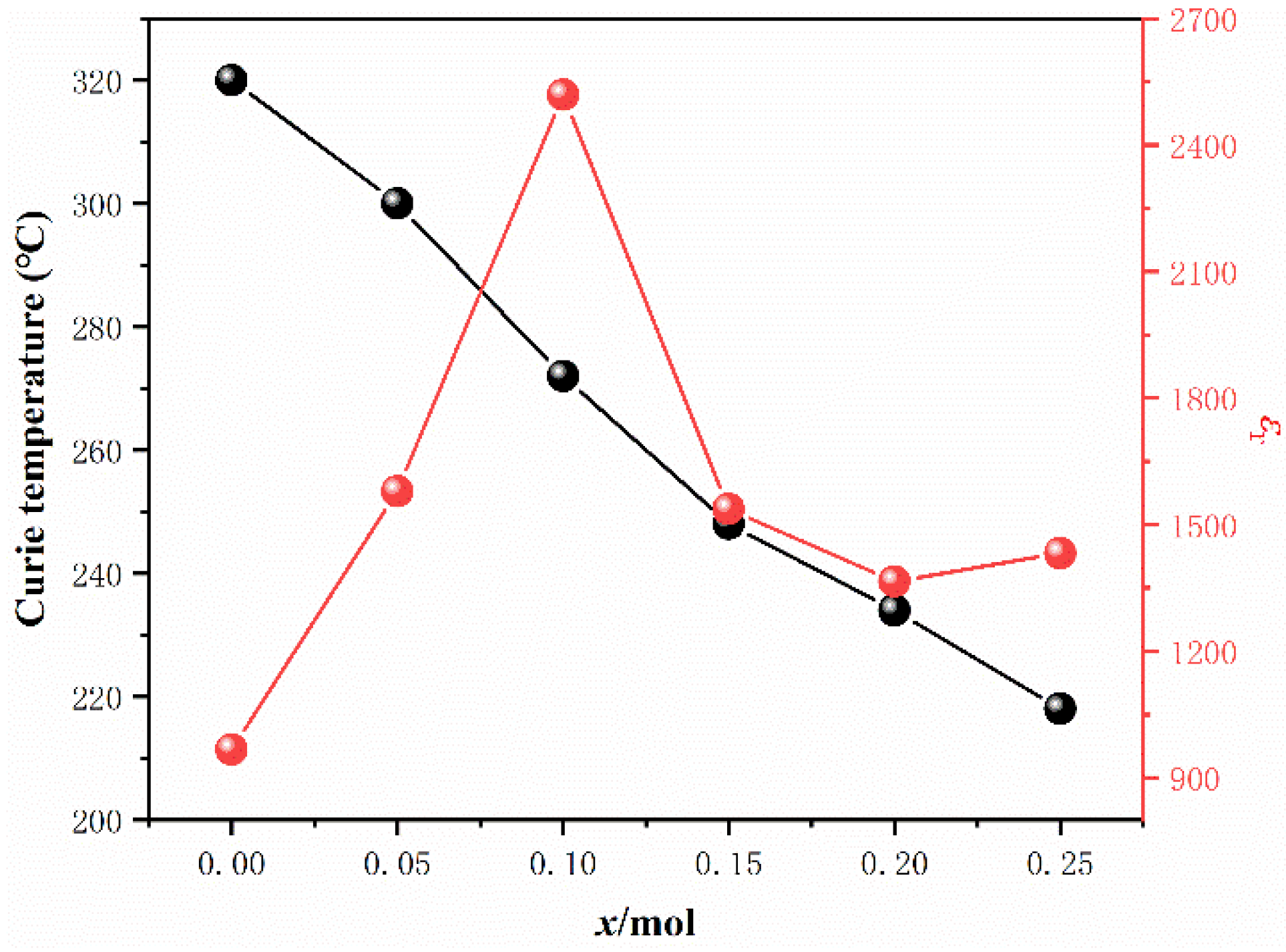

3.2. Dielectric Properties of Ceramics

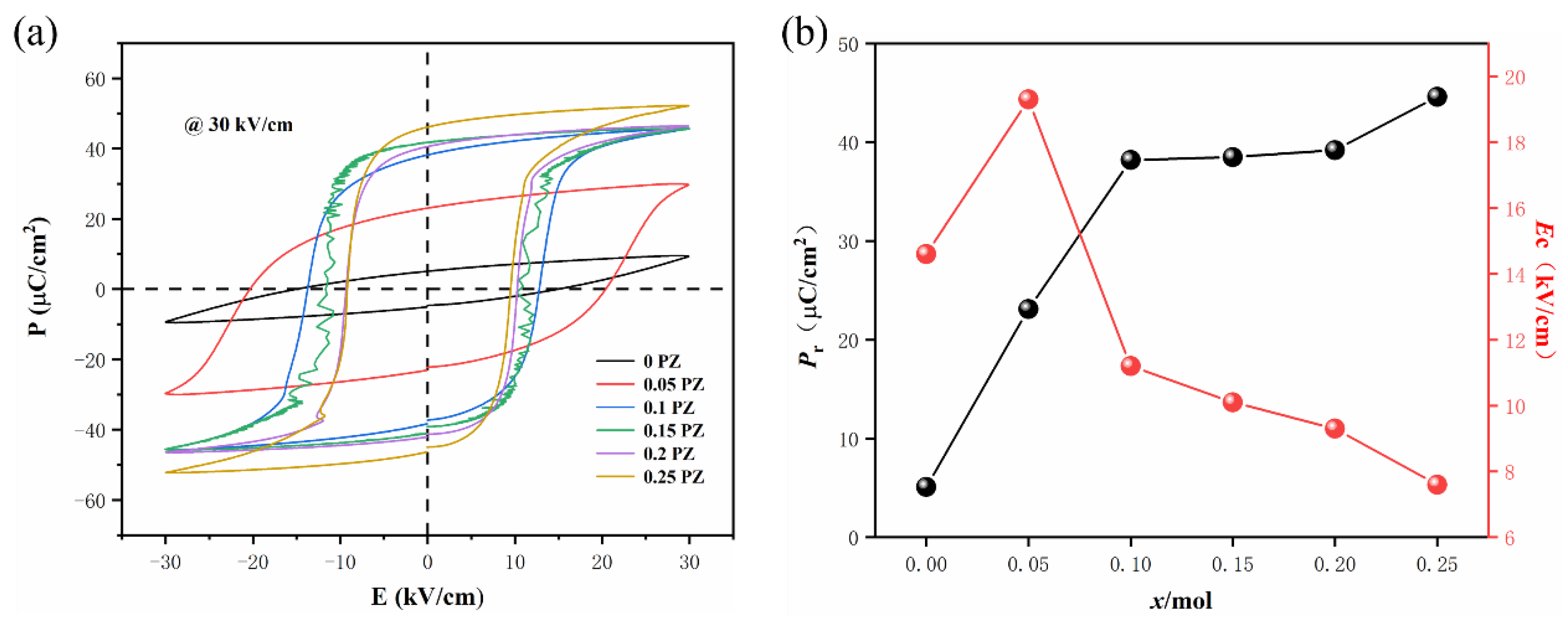

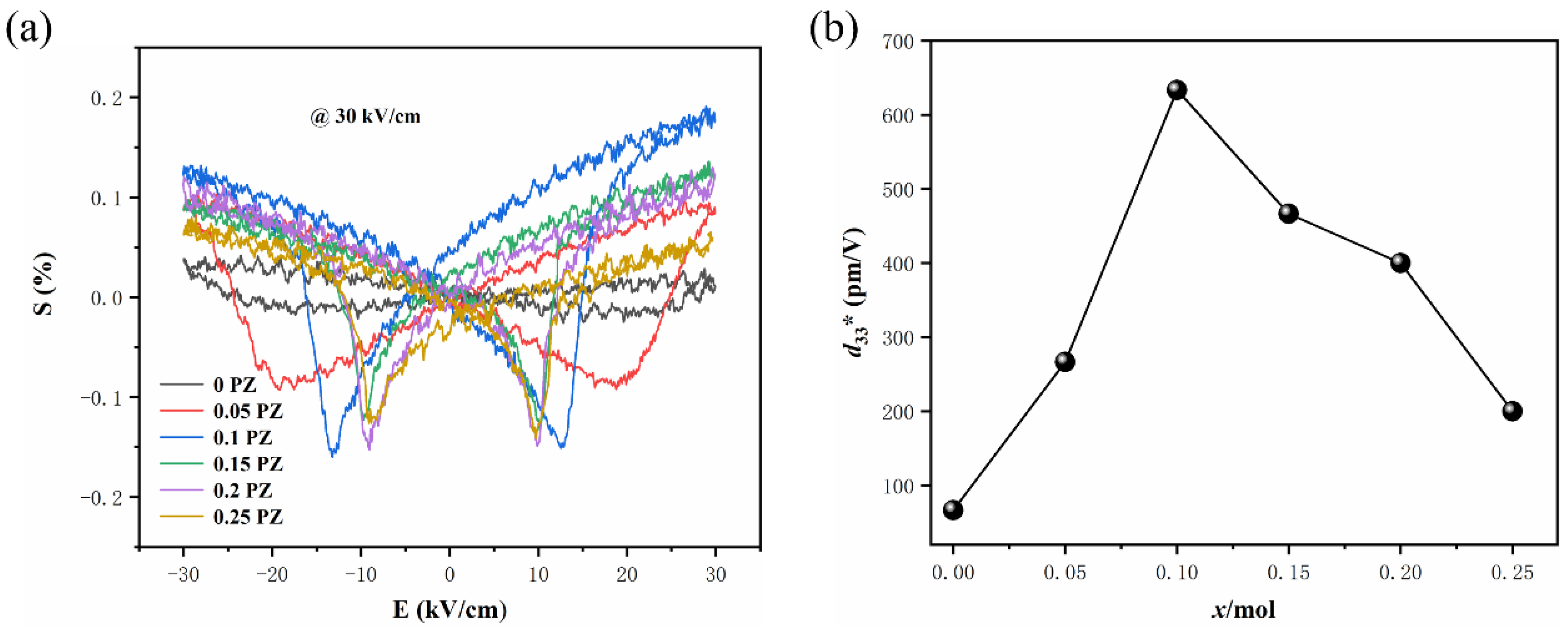

3.3. Ferroelectric and Piezoelectric Properties of Ceramics

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Q.; Xu, X.; Gottlieb, E.; Sun, L.; Cannata, J.; Ameri, H.; Humayun, M.; Han, P.; Shung, S. PMN–PT single crystal, high-frequency ultrasonic needle transducers for pulsed-wave Doppler application. IEEE Trans. Ultra Ferr. Freq. Cont. 2007, 54, 668–675. [Google Scholar] [CrossRef] [PubMed]

- Kim, K.; Hsu, D.; Ahn, B.; Kim, Y.; Barnard, D. Fabrication and comparison of PMN-PT single crystal, PZT and PZT-based 1-3 composite ultrasonic transducers for NDE applications. Ultrasonics 2010, 50, 790–797. [Google Scholar] [CrossRef] [PubMed]

- Hall, A.; Allahverdi, M.; Akdogan, E.; Safari, A. Piezoelectric/electrostrictive multimaterial PMN–PT monomorph actuators. J. Eur. Ceram. Soc. 2005, 25, 2991–2997. [Google Scholar] [CrossRef]

- Yamamoto, N.; Yamashita, Y.; Hosono, Y.; Itsumi, K. Electrical and physical properties of repoled PMN–PT single crystal sliver transducer. Sens. Actuators A-Phys. 2013, 200, 16–20. [Google Scholar] [CrossRef]

- Feng, X.; Liu, J.; Teng, D.; Yang, Y.; Liao, L.; Liu, W.; Chen, Q.; Xu, J.; Gao, F. Effect of sintering atmosphere on the microstructure and electrical properties of Pb(Zr1/2Ti1/2)O3-Pb(Zn1/3Nb2/3)O3-Pb(Ni1/3Nb2/3)O3 ceramics. J. Mater. Sci. Mater. Electron. 2022, 33, 11613–11622. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, S.; Kim, D.; Lee, H.; Shrout, T. Electromechanical properties of PMN-PZT piezoelectric single crystals near morphotropic phase boundary compositions. J. Am. Ceram. Soc. 2007, 90, 3859–3862. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Cao, S.; Xu, J.; Wu, C.; Pawlikowska, E.; Szafran, M.; Gao, F. Microstructure evolution and reaction mechanisms of Pb(Zr0.5Ti0.5)O3-Pb(Zn1/3Nb2/3)O3-Pb(Ni1/3Nb2/3)O3 piezoelectric ceramics with plate-like PbTiO3 template. Ceram. Int. 2021, 47, 470–478. [Google Scholar] [CrossRef]

- Li, L.; Liu, J.; Xu, J.; Cao, S.; Chen, Q.; Pawlikowska, E.; Szafran, M.; Gao, F.; Reece, M.; Yan, H. Effect of MnO2 on the microstructure and electrical properties of 0.83Pb(Zr0.5Ti0.5)O3-0.11Pb(Zn1/3Nb2/3)O3-0.06Pb(Ni1/3Nb2/3)O3 piezoelectric ceramics. Ceram. Int. 2020, 46, 180–185. [Google Scholar] [CrossRef]

- Ananta, S.; Thomas, N. Fabrication of PMN and PFN ceramic by a two-stage sintering technique. J. Eur. Ceram. Soc. 1999, 19, 2917–2930. [Google Scholar] [CrossRef]

- Zhu, Z.; Zheng, N.; Li, G.; Yin, Q. Dielectric and electrical conductivity properties of PMS-PZT ceramics. J. Am. Ceram. Soc. 2006, 89, 717–719. [Google Scholar] [CrossRef]

- Wang, D.; Cao, M.; Zhang, S. Phase diagram and properties of Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 polycrystalline ceramics. J. Eur. Ceram. Soc. 2012, 32, 433–439. [Google Scholar] [CrossRef]

- Wu, J.; Chang, Y.; Yang, B.; Zhang, S.; Sun, Y.; Guo, F.; Cao, W. Phase transitional behavior and electrical properties of Pb(In1/2Nb1/2)O3-Pb(Mg1/3Nb2/3)O3-PbTiO3 ternary ceramics. J. Mater. Sci. Mater. Electron. 2015, 26, 1874–1880. [Google Scholar] [CrossRef]

- Hussain, A.; Jabeen, N.; Hassan, N.; Rasheed, S.; Idress, A.; Eldin, S.; Ouladsmane, M.; Khan, S.; Akkinepally, B.; Javed, S. Structural, piezoelectric and ferroelectric analysis of 0.96Bi0.5Na0.5TiO3-0.06BaTiO3: xwt%MnO2 ceramics for high-tech applications. Ceram. Int. 2023, 49, 27848–27854. [Google Scholar] [CrossRef]

- Jiang, L.; Chen, R.; Xing, J.; Lu, G.; Li, R.; Shung, K.; Zhu, J.; Zhou, Q. Fabrication of a (K,Na)NbO3-based lead-free 1-3 piezocomposite for high-sensitivity ultrasonic transducers application. J. Appl. Phys. 2019, 125, 214501. [Google Scholar] [CrossRef]

- Chen, J.; Li, X.; Zhao, X.; Wang, X.; Chen, C.; Deng, H. Compositional segregation, structural transformation and property-temperature relationship of high-Curie temperature Pb(In1/2Nb1/2)O3–Pb(Mg1/3Nb2/3)O3–PbTiO3 single crystals. J. Mater. Sci. Mater. Electron. 2015, 26, 9316–9328. [Google Scholar] [CrossRef]

- Lim, J.; Zhang, S.; Shrout, T. Modified Pb(Yb,Nb)O3-PbZrO3-PbTiO3 Ternary System for High Temperature Applications. Ceram. Int. 2012, 38, 277–282. [Google Scholar] [CrossRef]

- Dong, H.; Wang, J.; Chen, H.; Zhang, P.; Zhong, W.; Su, W. 0.08Pb(Fe1/3Sb2/3)O3-yPbTiO;(1-0.08-y)PbZrO3 Piezoelectric Ceramic. J. Funct. Mater. 2001, 32, 80–81. [Google Scholar]

- Shaw, J.; Liu, K.; Lin, I. Modification of piezoelectric characteristics of the Pb(Mg,Nb)O3-PbZrO3-PbTiO3 ternary system by aliovalent additives. J. Am. Ceram. Soc. 1995, 78, 178–182. [Google Scholar] [CrossRef]

- Wu, L.; Liang, C.; Shieu, C. Piezoelectric properties of (Pb,Sr)(Zr,Ti,Mn,Zn,Nb)O3 piezoelectric ceramic. J. Mater. Sci. 1991, 26, 4439–4444. [Google Scholar] [CrossRef]

- Luo, N.; Zhang, S.; Li, Q.; Xu, C.; Shrout, T. New Pb(Mg1/3Nb2/3)O3-Pb(In1/2Nb1/2)O3-PbZrO3-PbTiO3 quaternary ceramics: Morphotropic phase boundary design and electrical properties. ACS Appl. Mater. 2016, 8, 15506–15517. [Google Scholar] [CrossRef] [PubMed]

- Jin, L. Broadband Dielectric Response in Hard and Soft PZT: Understanding Softening and Hardening Mechanisms. Ph.D. Thesis, École Polytechnique Fédérale de Lausanne, Lausanne, Switzerland, 2011. [Google Scholar]

- Li, F.; Lin, D.; Chen, Z.; Cheng, Z.; Wang, J.; Li, C.; Xu, Z.; Huang, Q.; Liao, X.; Chen, L.; et al. Ultrahigh piezoelectricity in ferroelectric ceramics by design. Nat. Mater. 2018, 17, 349. [Google Scholar] [CrossRef]

- Wang, T.; Song, K.; Li, Z. Electrical properties and temperature stability of high TC/TR-T Pb(In1/2Nb1/2)O3–Pb(Zn1/3Nb2/3)O3–PbTiO3 piezoelectric ceramics with compositions near the morphotropic phase boundary. J. Mater. Sci. Mater Electron. 2020, 31, 20411–20422. [Google Scholar] [CrossRef]

- Du, J.; Qiu, J.; Zhu, K.; Hong, L. Enhanced piezoelectric properties of 0.55Pb(Ni1/3Nb2/3)O3-0.135PbZrO3-0.315PbTiO3 ternary ceramics by optimizing sintering temperature. J. Electroceram. 2014, 32, 234–239. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, M.F.; Zhang, S.J.; Feng, Y.J.; Li, F.; Shrout, T.R. Investigation of dielectric and piezoelectric properties in Pb(Ni1/3Nb2/3)O3-PbHfO3-PbTiO3 ternary system. J. Eur. Ceram. Soc. 2013, 33, 2491–2497. [Google Scholar] [CrossRef]

- Kalem, V.; Wan, Y.; Shih, W. Dielectric and piezoelectric properties of PMN-PT ceramics doped with strontium. Ceram. Int. 2018, 44, 2835–2842. [Google Scholar] [CrossRef]

- Guo, Q.; Li, F.; Xia, F.; Gao, X.; Wang, P.; Hao, H.; Zhang, S. High-Performance Sm-Doped Pb(Mg1/3Nb2/3)O3-PbZrO3-PbTiO3-Based Piezoceramics. ACS Appl. Mater. Interfaces 2019, 11, 43359–43367. [Google Scholar] [CrossRef] [PubMed]

| Samples | 0 PZ | 0.05 PZ | 0.1 PZ | 0.15 PZ | 0.2 PZ | 0.25 PZ |

|---|---|---|---|---|---|---|

| Rhombohedral phase content | 0.12 | 0.13 | 0.41 | 0.51 | 0.61 | 0.83 |

| Tetragonal phase content | 0.88 | 0.87 | 0.59 | 0.49 | 0.39 | 0.17 |

| Samples | Ɛr (Before Polarization) | Tc (°C) | Pr (μC/cm2) | Ec (kV/cm) | d33 (pC/N) | kp | Qm |

|---|---|---|---|---|---|---|---|

| x = 0 | 966 | 320 | 5.10 | 14.6 | 90 | 0.26 | 140.8 |

| x = 0.05 | 1578 | 300 | 23.05 | 19.3 | 204 | 0.28 | 129.5 |

| x = 0.1 | 2402 | 272 | 38.22 | 11.2 | 452 | 0.53 | 66.8 |

| x = 0.15 | 1536 | 248 | 38.32 | 10.1 | 190 | 0.3 | 94.8 |

| x = 0.2 | 1364 | 234 | 39.15 | 9.3 | 145 | 0.382 | 99.1 |

| x = 0.25 | 1432 | 218 | 44.63 | 7.6 | 125 | 0.33 | 117.9 |

| Designation | Tc (°C) | d33 (pC/N) | kp | εr | Tanδ (%) | Ref. |

|---|---|---|---|---|---|---|

| PMN-PT | 159 | 663 | / | 5260 | 1.8 | [22] |

| PMN-PIN-PT | 245 | 450 | 0.49 | 2970 | 1.1 | [11] |

| PMN-PIN-PZT | 231 | 580 | 0.53 | 3830 | 1.5 | [20] |

| PZN-PIN-PT | 245 | 589 | 0.59 | 2143 | 1.9 | [23] |

| PNN-PZ-PT | 115 | 986 | 0.693 | 9015 | [24] | |

| PNN-PH-PT | 110 | 970 | 0.65 | 6000 | 1.5 | [25] |

| Sr-PMN-PT | 210 | 630 | 0.52 | 4000 | [26] | |

| Sm-PMN-PT | 89 | 1510 | / | 13,000 | 3.5 | [27] |

| PIZZT (0.1 PZ) | 272 | 450 | 0.53 | 2402 | 1.5 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Feng, X.; Zhou, L.; Wang, H.; Yan, B.; Lu, M.; Chen, C.; Mei, H.; Xu, J.; Gao, F. Phase Structure and Electrical Properties of 0.28PIN-0.32PZN–(0.4-x) PT-xPZ Piezoelectric Ceramics. Crystals 2023, 13, 1362. https://doi.org/10.3390/cryst13091362

Xu X, Feng X, Zhou L, Wang H, Yan B, Lu M, Chen C, Mei H, Xu J, Gao F. Phase Structure and Electrical Properties of 0.28PIN-0.32PZN–(0.4-x) PT-xPZ Piezoelectric Ceramics. Crystals. 2023; 13(9):1362. https://doi.org/10.3390/cryst13091362

Chicago/Turabian StyleXu, Xiaoyu, Xiaoying Feng, Liyang Zhou, Hui Wang, Bin Yan, Mingxin Lu, Chao Chen, Hui Mei, Jie Xu, and Feng Gao. 2023. "Phase Structure and Electrical Properties of 0.28PIN-0.32PZN–(0.4-x) PT-xPZ Piezoelectric Ceramics" Crystals 13, no. 9: 1362. https://doi.org/10.3390/cryst13091362

APA StyleXu, X., Feng, X., Zhou, L., Wang, H., Yan, B., Lu, M., Chen, C., Mei, H., Xu, J., & Gao, F. (2023). Phase Structure and Electrical Properties of 0.28PIN-0.32PZN–(0.4-x) PT-xPZ Piezoelectric Ceramics. Crystals, 13(9), 1362. https://doi.org/10.3390/cryst13091362