β-Ga2O3 Schottky Barrier Diode with Ion Beam Sputter-Deposited Semi-Insulating Layer

Abstract

:1. Introduction

2. Experimental Methods and Materials

- Choosing of the samples region to produce the lamella and its orientation;

- Deposition of a Pt layer to protect the samples surface against ion etching by means of a gas injection system at an accelerating voltage of U1 = 30 kV and a current of I1 = 24 pA;

- Formation of two trapezoidal depressions on either side of the protective Pt layer by means of an FIB at U1 = 30 kV and I1 = 0.23 pA;

- Cutting of lamellae along the perimeter by means of an FIB at U1 = 30 kV and I1 = 0.79 pA;

- Bringing and welding the Pt probe of the nanomanipulator to the lamella and then removing it from the sample;

- Moving the lamella with the nanomanipulator onto the grid for TEM and then welding it with Pt using a gas injection system;

- FIB thinning of a lamella welded to a grid at U1 = 30 kV and I1 = 80 pA;

- Final polishing of the lamella surface with an ion beam at U1 = 30 kV and I1 = 24 pA.

3. Results and Discussion

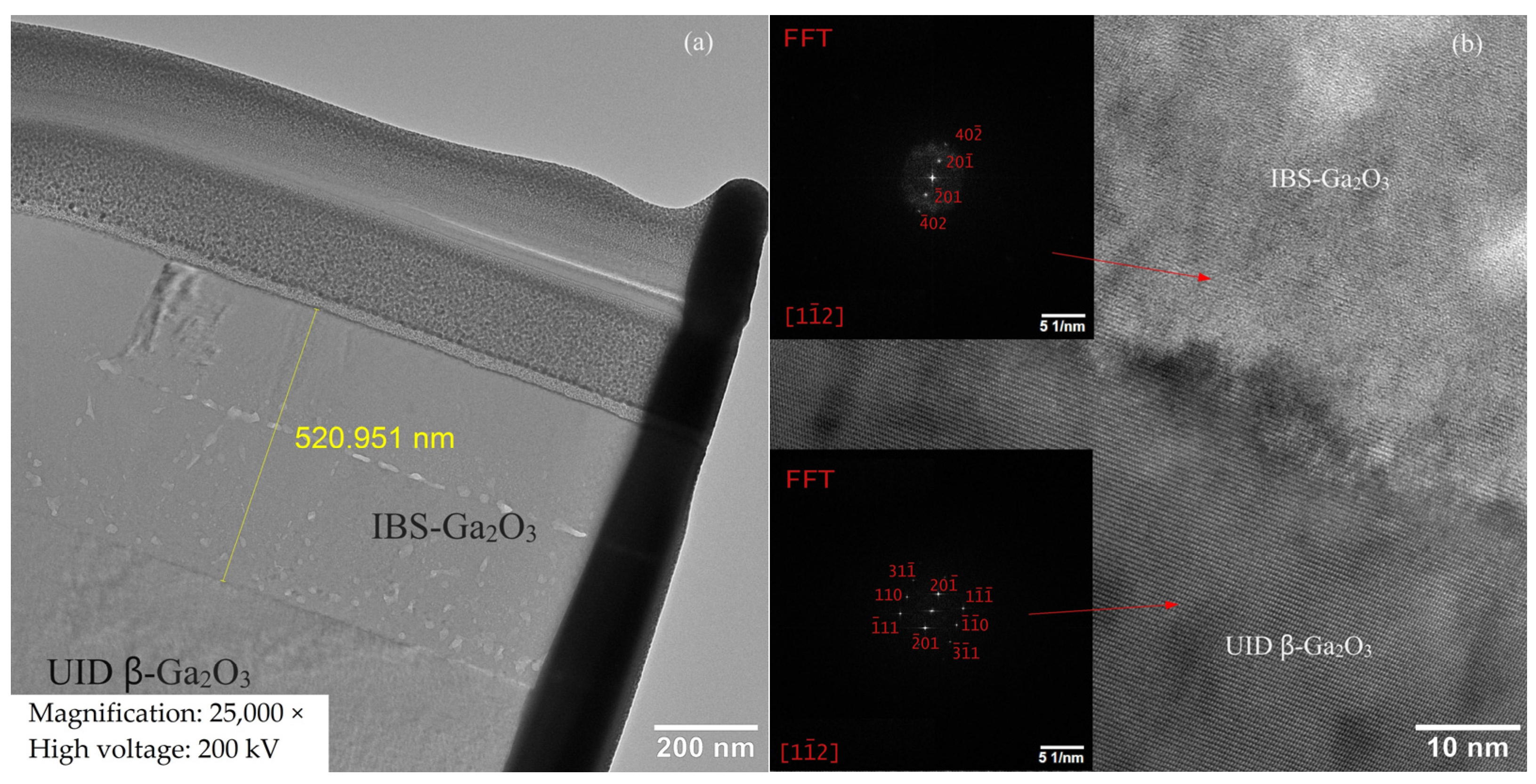

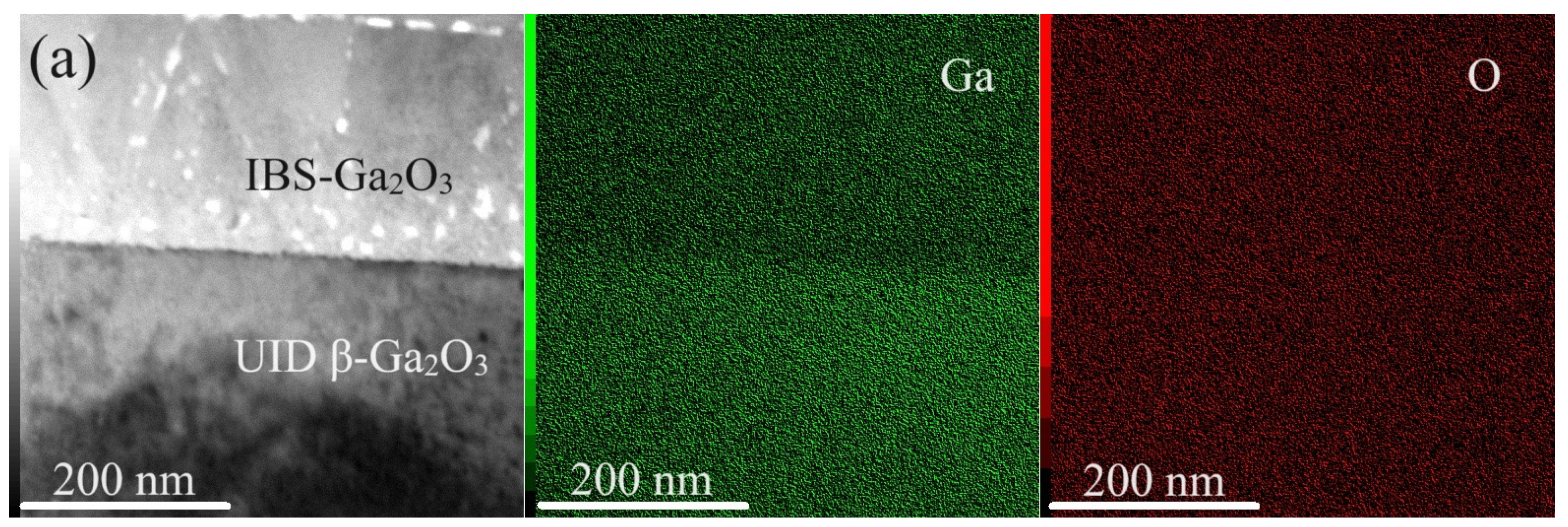

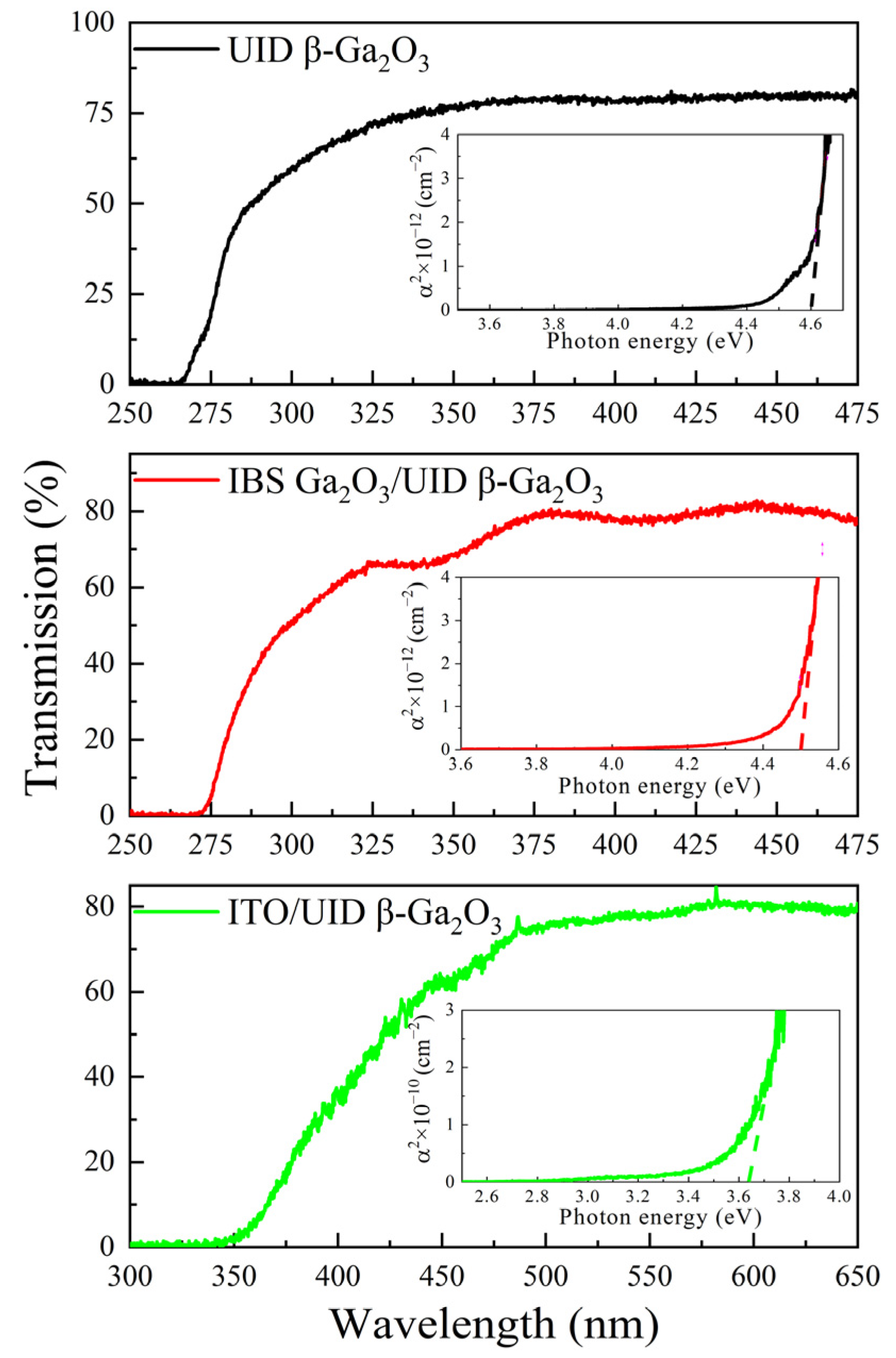

3.1. Structural Properties of IBS Ga2O3/UID β-Ga2O3 and ITO/UID β-Ga2O3 Structures

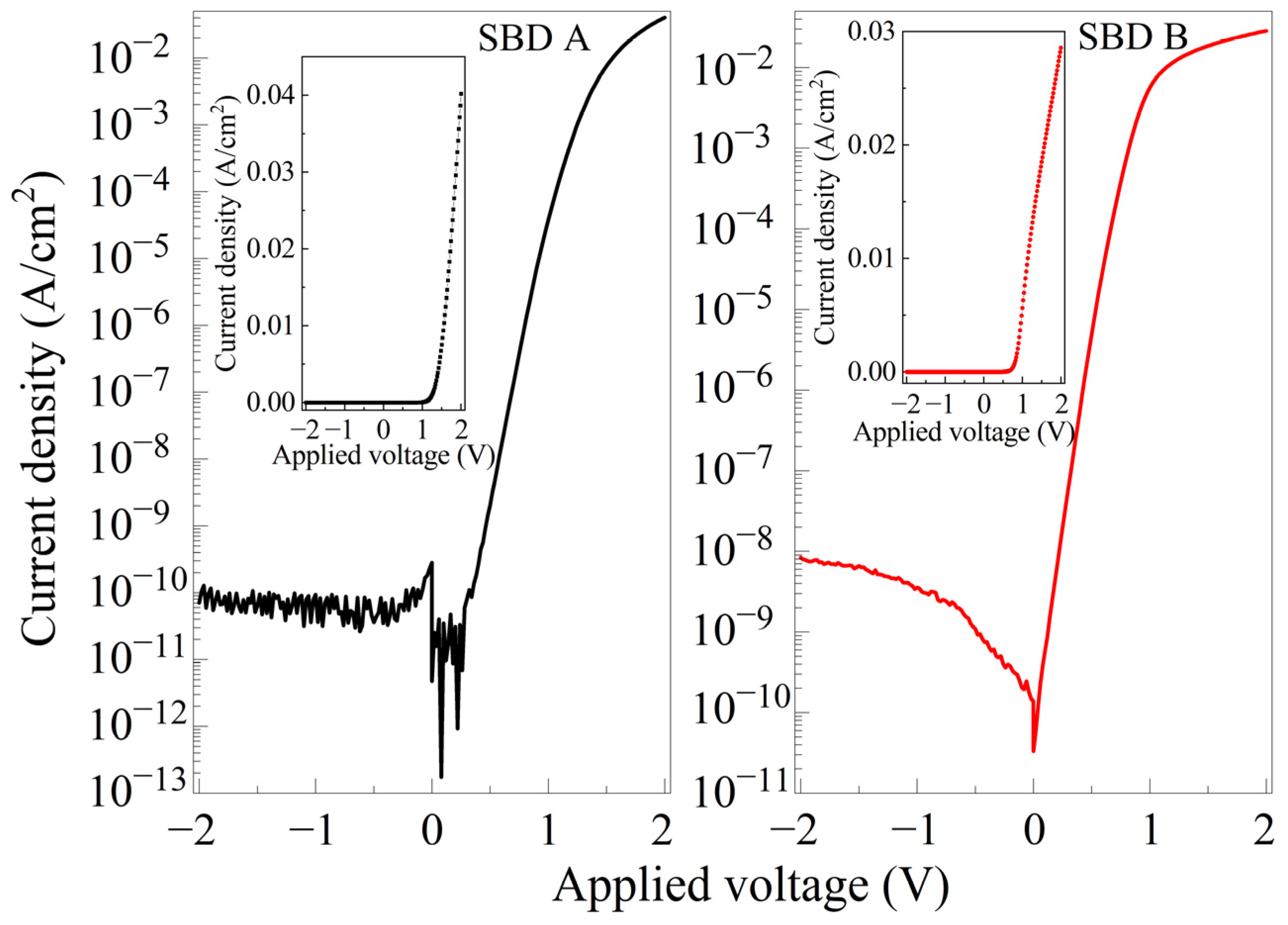

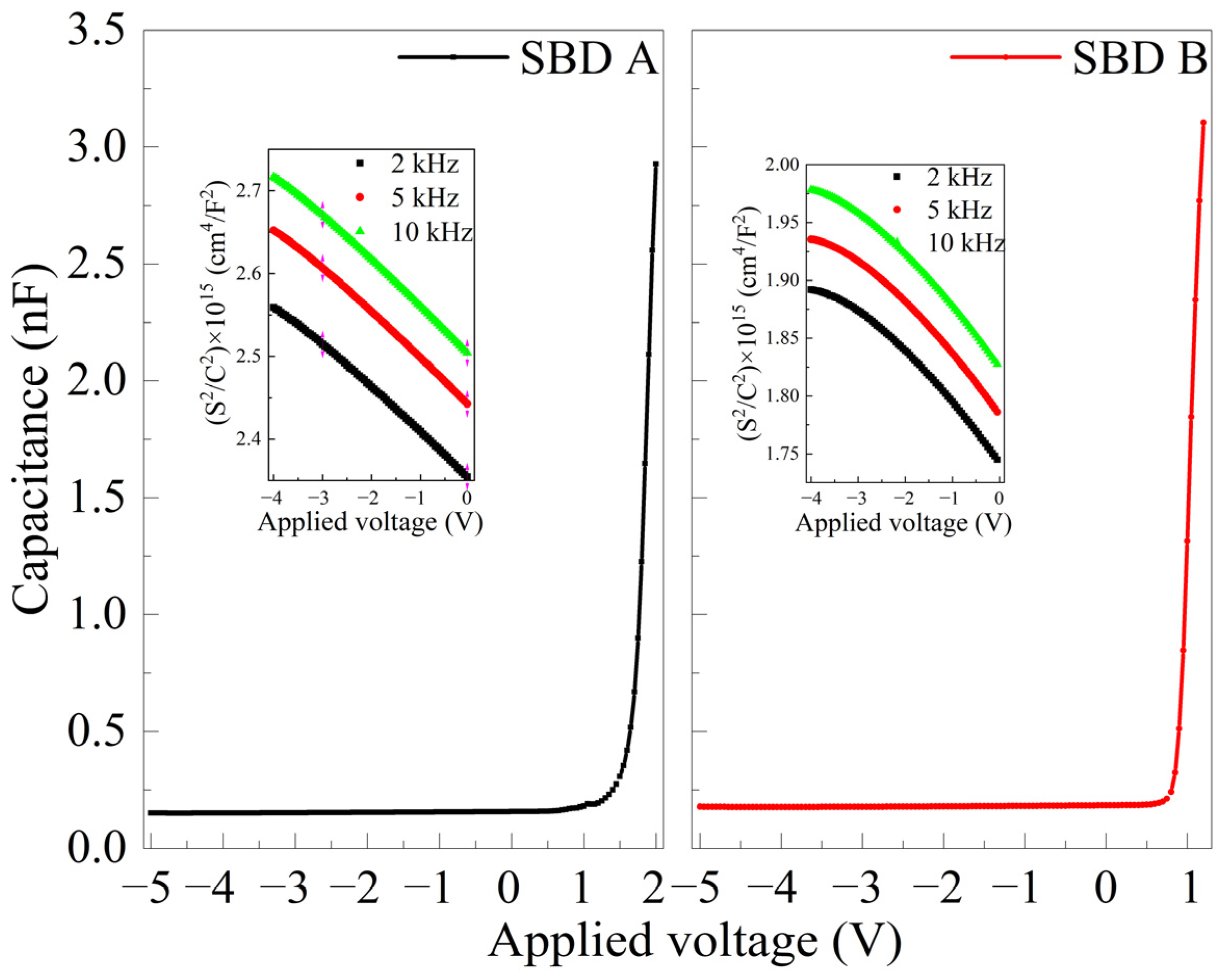

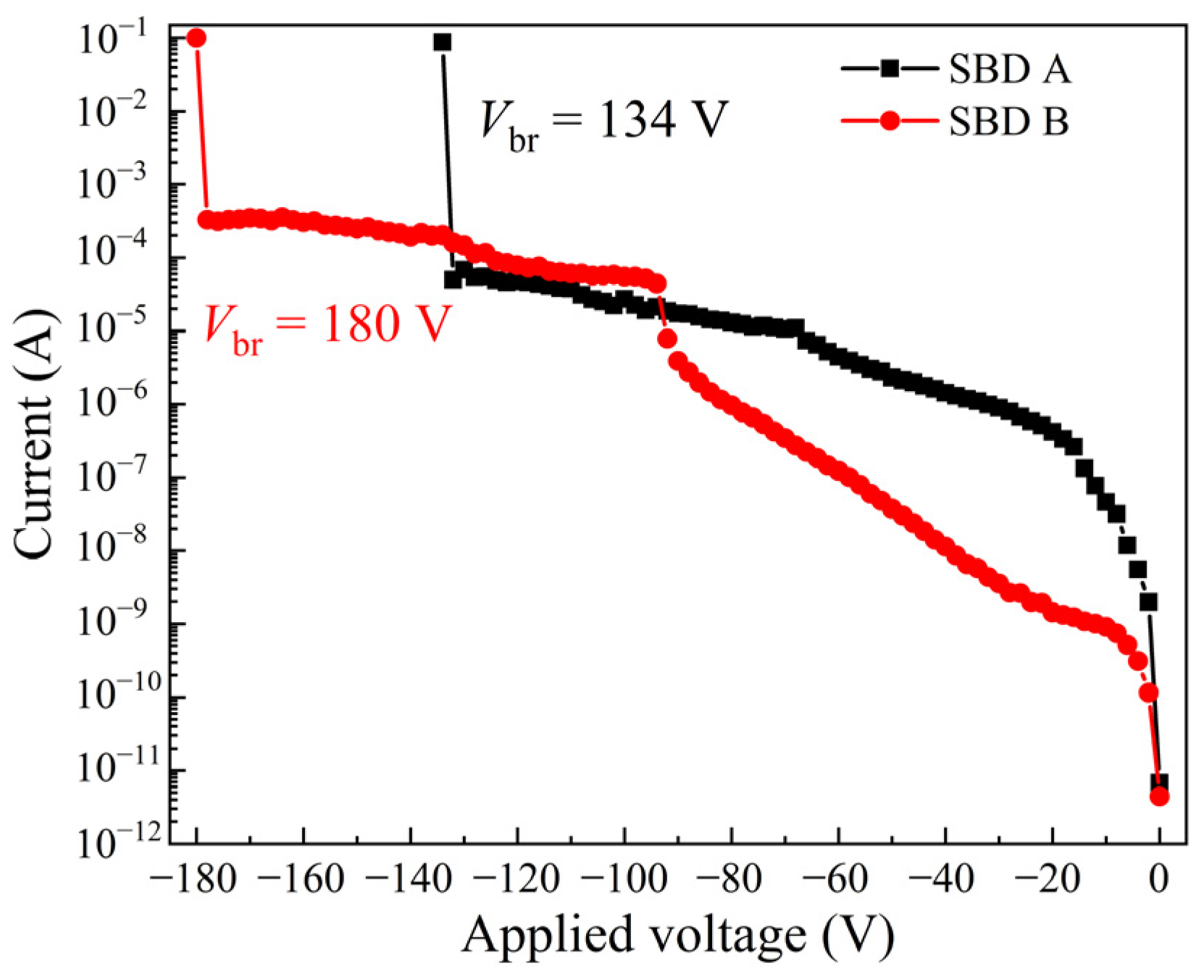

3.2. Electrically Conductive Characteristics of Diodes Based on IBS Ga2O3/UID β-Ga2O3 and IBS Ga2O3/UID β-Ga2O3/ITO Structures with Ni Gate

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Pearton, S.J.; Yang, J.; Cary, P.H.; Ren, F.; Kim, J.; Tadjer, M.J.; Mastro, M.A. A review of Ga2O3 materials, processing, and devices. Appl. Phys. Rev. 2018, 5, 011301. [Google Scholar] [CrossRef]

- Polyakov, A.Y.; Smirnov, N.B.; Shchemerov, I.V.; Yakimov, E.B.; Pearton, S.J.; Ren, F.; Chernykh, A.V.; Gogova, D.; Kochkova, A.I. Electrical Properties, Deep Trap and Luminescence Spectra in Semi-Insulating, Czochralski β-Ga2O3 (Mg). ECS J. Solid State Sci. Technol. 2019, 8, Q3019. [Google Scholar] [CrossRef]

- Tairov, Y.M. Growth of bulk SiC. Mater. Sci. Eng. B 1995, 29, 83–89. [Google Scholar] [CrossRef]

- Akasaki, I.; Amano, H.; Murakami, H.; Sassa, M.; Kato, H.; Manabe, K. Growth of GaN and AlGaN for UV/blue p-n junction diodes. J. Cryst. Growth 1993, 128, 379–383. [Google Scholar] [CrossRef]

- Yazdi, G.R.; Persson, P.O.Å.; Gogova, D.; Fornari, R.; Hultman, L.; Syväjärvi, M.; Yakimova, R. Aligned AlN nanowires by self-organized vapor–solid growth. Nanotechnology 2009, 20, 495304. [Google Scholar] [CrossRef] [PubMed]

- Sheoran, H.; Kumar, V.; Singh, R. A Comprehensive Review on Recent Developments in Ohmic and Schottky Contacts on Ga2O3 for Device Applications. ACS Appl. Electron. Mater. 2022, 4, 2589–2628. [Google Scholar] [CrossRef]

- Fu, B.; Jia, Z.; Mu, W.; Yin, Y.; Zhang, J.; Tao, X. A review of β-Ga2O3 single crystal defects, their effects on device performance and their formation mechanism. J. Semicond. 2019, 40, 011804. [Google Scholar] [CrossRef]

- Ueda, O.; Ikenaga, N.; Koshi, K.; Iizuka, K.; Kuramata, A.; Hanada, K.; Moribayashi, T.; Yamakoshi, S.; Kasu, M. Structural evaluation of defects in β-Ga2O3 single crystals grown by edge-defined film-fed growth process. Jpn. J. Appl. Phys. 2016, 55, 1202B. [Google Scholar] [CrossRef]

- Nikolaev, V.I.; Polyakov, A.Y.; Krymov, V.M.; Shapenkov, S.; Butenko, P.; Yakimov, E.B.; Vasilev, A.A.; Shchemerov, I.V.; Chernykh, A.V.; Matros, N.R.; et al. Trap States and Carrier Diffusion in Czochralski (100) Single Crystal β-Ga2O3. ECS J. Solid State Sci. Technol. 2024, 13, 015003. [Google Scholar] [CrossRef]

- Hoshikawa, K.; Ohba, E.; Kobayashi, T.; Yanagisawa, J.; Miyagawa, C.; Nakamura, Y. Growth of β-Ga2O3 single crystals using vertical Bridgman method in ambient air. J. Cryst. Growth 2016, 447, 36–41. [Google Scholar] [CrossRef]

- Kuramata, A.; Koshi, K.; Watanabe, S.; Yamaoka, Y.; Masui, T.; Yamakoshi, S. High-quality β-Ga2O3 single crystals grown by edge-defined film-fed growth. Jpn. J. Appl. Phys. 2016, 55, 1202A2. [Google Scholar] [CrossRef]

- Gogova, D.; Kasic, A.; Larsson, H.; Pécz, B.; Yakimova, R.; Magnusson, B.; Monemar, B.; Tuomisto, F.; Saarinen, K.; Miskys, C.; et al. Optical and Structural Characteristics of Virtually Unstrained Bulk-Like GaN. Jpn. J. Appl. Phys. 2004, 43, 1264. [Google Scholar] [CrossRef]

- Gogova, D.; Larsson, H.; Kasic, A.; Yazdi, G.R.; Ivanov, I.; Yakimova, R.; Monemar, B.; Aujol, E.; Frayssinet, E.; Faurie, J.-P.; et al. High-Quality 2″ Bulk-Like Free-Standing GaN Grown by HydrideVapour Phase Epitaxy on a Si-doped Metal Organic Vapour Phase Epitaxial GaN Template with an Ultra Low Dislocation Density. Jpn. J. Appl. Phys. 2005, 44, 1181. [Google Scholar] [CrossRef]

- Hermann, M.; Gogova, D.; Siche, D.; Schmidbauer, M.; Monemar, B.; Stutzmann, M.; Eickhoff, M. Nearly stress-free substrates for GaN homoepitaxy. J. Cryst. Growth 2006, 293, 462–468. [Google Scholar] [CrossRef]

- Morgan, N.N.; Zhizhen, Y.; Yabou, X. Evaluation of GaN growth improvement techniques. Mater. Sci. Eng. B 2002, 90, 201–205. [Google Scholar] [CrossRef]

- Malinauskas, T.; Jarašiūnas, K.; Aleksiejunas, R.; Gogova, D.; Monemar, B.; Beaumont, B.; Gibart, P. Contribution of dislocations to carrier recombination and transport in highly excited ELO and HVPE GaN layers. Phys. Stat. Sol. B 2006, 243, 1426–1430. [Google Scholar] [CrossRef]

- Gogova, D.; Petrov, P.P.; Buegler, M.; Wagner, M.R.; Nenstiel, C.; Callsen, G.; Schmidbauer, M.; Kucharski, R.; Zajac, M.; Dwilinski, R.; et al. Structural and optical investigation of non-polar (1-100) GaN grown by the ammonothermal method. J. Appl. Phys. 2013, 113, 203513. [Google Scholar] [CrossRef]

- Bennett, S.E. Dislocations and their reduction in GaN. Mater. Sci. Technol. 2010, 26, 1017–1028. [Google Scholar] [CrossRef]

- Nakamura, S. The roles of structural imperfections in InGaN based blue light emitting diodes and laser diodes. Science 1998, 281, 956–961. [Google Scholar] [CrossRef]

- Heying, B.; Tarsa, E.J.; Elsass, C.R.; Fini, P.; DenBaars, S.P.; Speck, J.S. Dislocation mediated surface morphology of GaN. J. Appl. Phys. 1999, 85, 6470–6476. [Google Scholar] [CrossRef]

- Speck, J.S.; Rosner, S.J. The role of threading dislocations in the physical properties of GaN and its alloys. Phys. B Condens. 1999, 273–274, 24–32. [Google Scholar] [CrossRef]

- Kuznetsov, N.I.; Mynbaeva, M.G.; Melnychuk, G.; Dmitriev, V.A.; Saddow, S.E. Electrical characterization of Schottky diodes fabricated on SiC epitaxial layers grown on porous SiC substrates. Appl. Surf. Sci. 2001, 184, 483–486. [Google Scholar] [CrossRef]

- Zollner, C.J.; Almogbel, A.; Yao, Y.; SaifAddin, B.K.; Wu, F.; Iza, M.; DenBaars, S.P.; Speck, J.S.; Nakamura, S. Reduced dislocation density and residual tension in AlN grown on SiC by metalorganic chemical vapor deposition. Appl. Phys. Lett. 2019, 115, 161101. [Google Scholar] [CrossRef]

- Kitagawa, S.; Miyake, H.; Hiramatsu, K. High-quality AlN growth on 6H-SiC substrate using three dimensional nucleation by low-pressure hydride vapor phase epitaxy. Jpn. J. Appl. Phys. 2014, 53, 05FL03. [Google Scholar] [CrossRef]

- Okumura, H.; Kimoto, T.; Suda, J. Formation mechanism of threading-dislocation array in AlN layers grown on 6H-SiC (0001) substrates with 3-bilayer-high surface steps. Appl. Phys. Lett. 2014, 105, 071603. [Google Scholar] [CrossRef]

- Solís-Cisneros, H.I.; Vilchis, H.; Hernández-Trejo, R.; Melchor-Tovilla, A.L.; Guillén-Cervantes, A.; Hernández Gutiérrez, C.A. Study and characterization of the nanotextured Ga2O3-GaOOH formations synthesized via thermal oxidation of GaAs in ambient air. Semicond. Sci. Technol. 2023, 38, 105004. [Google Scholar] [CrossRef]

- Kaneko, K.; Suzuki, K.; Ito, Y.; Fujita, S. Growth characteristics of corundum-structured α-(AlxGa1−x)2O3/Ga2O3 heterostructures on sapphire substrates. J. Cryst. Growth 2016, 436, 150–154. [Google Scholar] [CrossRef]

- Zeng, K.; Vaydai, A.; Singisetti, U. 1.85 kV Breakdown Voltage in Lateral Field-Plated Ga2O3 MOSFETs. IEEE Electron Device Lett. 2018, 39, 1385–1388. [Google Scholar] [CrossRef]

- Dong, L.; Jia, R.; Xin, B.; Peng, B.; Zhang, Y. Effects of oxygen vacancies on the structural and optical properties of β-Ga2O3. Sci. Rep. 2017, 7, 40160. [Google Scholar] [CrossRef]

- Orita, M.; Ohta, H.; Hirano, M.; Hosono, H. Deep-ultraviolet transparent conductive β-Ga2O3 thin films. Appl. Phys. Lett. 2000, 77, 4166–4168. [Google Scholar] [CrossRef]

- He, H.; Orland, R.; Blanco, M.A.; Pandey, R.; Amzallag, E.; Baraille, I.; Rérat, M. First-principles study of the structural, electronic, and optical properties of Ga2O3 in its monoclinic and hexagonal phases. Phys. Rev. B. 2006, 74, 195123. [Google Scholar] [CrossRef]

- Onuma, T.; Saito, S.; Sasaki, K.; Masui, T.; Yamaguchi, T.; Honda, T.; Higashiwaki, M. Valence band ordering in β-Ga2O3 studied by polarized transmittance and reflectance spectroscopy. Jpn. J. Appl. Phys. 2015, 54, 112601. [Google Scholar] [CrossRef]

- Hu, Z.; Nomoto, K.; Li, W.; Tanen, N.; Sasaki, K.; Kuramata, A.; Nakamura, T.; Jena, D.; Xing, H.G. Enhancement-Mode Ga2O3 Vertical Transistors with Breakdown Voltage >1 kV. IEEE Electron Device Lett. 2018, 39, 869–872. [Google Scholar] [CrossRef]

- Yan, X.; Esqueda, I.S.; Ma, J.; Tice, J.; Wang, H. High breakdown electric field in β-Ga2O3/graphene vertical barristor heterostructure. Appl. Phys. Lett. 2018, 112, 032101. [Google Scholar] [CrossRef]

- Tetelbaum, D.; Nikolskaya, A.; Korolev, D.; Mullagaliev, T.; Belov, A.; Trushin, V.; Dudin, Y.; Nezhdanov, A.; Mashin, A.; Mikhaylov, A.; et al. Ion-beam modification of metastable gallium oxide polymorphs. Mater. Lett. 2021, 302, 130346. [Google Scholar] [CrossRef]

- Almaev, A.V.; Nikolaev, V.I.; Stepanov, S.I.; Pechnikov, A.I.; Chikiryaka, A.V.; Yakovlev, N.N.; Kalygina, V.M.; Kopyev, V.V.; Chernikov, E.V. Hydrogen influence on electrical properties of Pt-contacted α-Ga2O3/ε-Ga2O3 structures grown on patterned sapphire substrates. J. Phys. D Appl. Phys. 2020, 53, 414004. [Google Scholar] [CrossRef]

- Almaev, A.; Yakovlev, N.; Kopyev, V.; Nikolaev, V.; Butenko, P.; Deng, J.; Pechnikov, A.; Korusenko, P.; Koroleva, A.; Zhizhin, E. High Sensitivity Low-Temperature Hydrogen Sensors Based on SnO2/κ(ε)-Ga2O3:Sn Heterostructure. Chemosensors 2023, 11, 325. [Google Scholar] [CrossRef]

- Nikolskaya, A.; Okulich, E.; Korolev, D.; Stepanov, A.; Nikolichev, D.; Mikhaylov, A.; Tetelbaum, D.; Almaev, A.; Bolzan, C.A.; Buaczik, A.; et al. Ion implantation in β-Ga2O3: Physics and technology. J. Vac. Sci. Technol. A 2021, 39, 030802. [Google Scholar] [CrossRef]

- Yang, J.; Ren, F.; Tadjer, M.; Pearton, S.J.; Kuramata, A. 2300 V Reverse Breakdown Voltage Ga2O3 Schottky Rectifiers. ECS J. Solid State Sci. Technol. 2016, 7, 92–96. [Google Scholar] [CrossRef]

- Qin, Y.; Xiao, M.; Porter, M.; Ma, Y.; Spencer, J.; Du, Z.; Jacobs, A.G.; Sasaki, K.; Wang, H.; Tadjer, M.; et al. 10-kV Ga2O3 Charge-Balance Schottky Rectifier Operational at 200 °C. IEEE Electron Device Lett. 2023, 44, 1268–1271. [Google Scholar] [CrossRef]

- Hu, Z.; Zhou, H.; Feng, Q.; Zhang, C.; Dang, K.; Cai, Y.; Feng, Z.; Gao, Y.; Kang, X.; Hao, Y. Field-Plated Lateral β-Ga2O3 Schottky Barrier Diode with High Reverse Blocking Voltage of More Than 3 kV and High DC Power Figure-of-Merit of 500 MW/cm2. IEEE Electron Device Lett. 2018, 39, 1564–1567. [Google Scholar] [CrossRef]

- Huang, X.; Liao, F.; Li, L.; Liang, X.; Liu, Q.; Zhang, C.; Hu, X. 3.4 kV Breakdown Voltage Ga2O3 Trench Schottky Diode with Optimized Trench Corner Radius. ECS J. Solid State Sci. Technol. 2020, 9, 045012. [Google Scholar] [CrossRef]

- Sekhar Reddy, P.R.; Janardhanam, V.; Shim, K.-H.; Rajagopal Reddy, V.; Lee, S.-N.; Park, S.-J.; Choi, C.-J. Temperature-dependent Schottky barrier parameters of Ni/Au on n-type (001) β-Ga2O3 Schottky barrier diode. Vacuum 2020, 171, 109012. [Google Scholar] [CrossRef]

- Yao, Y.; Gangireddy, R.; Kim, J.; Das, K.K.; Davis, R.F.; Porter, L.M. Electrical behavior of β-Ga2O3 Schottky diodes with different Schottky metals. J. Vac. Sci. Technol. B 2017, 35, 03D113. [Google Scholar] [CrossRef]

- Carey, P.H.; Yang, J.; Ren, F.; Hays, D.C.; Pearton, S.J.; Jang, S.; Kuramata, A.; Kravchenko, I.I. Ohmic contacts on n-type β-Ga2O3 using AZO/Ti/Au. AIP Adv. 2017, 7, 095313. [Google Scholar] [CrossRef]

- Oshima, T.; Wakabayashi, R.; Hattori, M.; Hashiguchi, A.; Kawano, N.; Sasaki, K.; Masui, T.; Kuramata, A.; Yamakoshi, S.; Yoshimatsu, K.; et al. Formation of indium-tin oxide ohmic contacts for β-Ga2O3. Jpn. J. Appl. Phys. 2016, 55, 1202B7. [Google Scholar] [CrossRef]

- Kim, S.J.; Park, S.Y.; Kim, K.H.; Kim, S.W.; Kim, T.G. Ga2O3:ITO Transparent Conducting Electrodes for Near-Ultraviolet Light-Emitting Diodes. IEEE Electron Device Lett. 2014, 35, 232. [Google Scholar] [CrossRef]

- Carey, P.H.; Yang, J.; Ren, F.; Hays, D.C.; Pearton, S.J.; Kuramata, A.; Kravchenko, I.I. Improvement of Ohmic contacts on Ga2O3 through use of ITO-interlayers. J. Vac. Sci. Technol. B 2017, 35, 061201. [Google Scholar] [CrossRef]

- Xia, X.; Xian, M.; Ren, F.; Rasel, M.A.J.; Haque, A.; Pearton, S.J. Thermal stability of transparent ITO/n-Ga2O3/n+-Ga2O3/ITO rectifiers. ECS J. Solid State Sci. Technol. 2021, 10, 115005. [Google Scholar] [CrossRef]

- Bundesmann, C.; Neumann, H. Tutorial: The systematics of ion beam sputtering for deposition of thin films with tailored properties. J. Appl. Phys. 2018, 124, 231102. [Google Scholar] [CrossRef]

- Kalanov, D.; Anders, A.; Bundesmann, C. Properties of secondary ions in ion beam sputtering of Ga2O3. J. Vac. Sci. Technol. A 2021, 39, 053409. [Google Scholar] [CrossRef]

- Kalanov, D.; Unutulmazsoy, Y.; Spemann, D.; Bauer, J.; Anders, A.; Bundesmann, C. Properties of gallium oxide thin films grown by ion beam sputter deposition at room temperature. J. Vac. Sci. Technol. A 2022, 40, 033409. [Google Scholar] [CrossRef]

- Becker, M.; Benz, S.L.; Chen, L.; Polity, A.; Klar, P.J.; Chatterjee, S. Controlled thin-film deposition of α or β Ga2O3 by ion-beam sputtering. J. Vac. Sci. Technol. A 2020, 38, 063412. [Google Scholar] [CrossRef]

- Poliakov, M.; Kovalev, D.; Vadchenko, S.; Moskovskikh, D.; Kiryukhantsev-Korneev, P.; Volkova, L.; Dudin, A.; Orlov, A.; Goryachev, A.; Rogachev, A. Amorphous/Nanocrystalline High-Entropy CoCrFeNiTix Thin Films with Low Thermal Coefficient of Resistivity Obtained via Magnetron Deposition. Nanomaterials 2023, 13, 2004. [Google Scholar] [CrossRef] [PubMed]

- Cuong, P.K. Nano-Structured Carbon Materials for Energy Generation and Storage. Ph.D. Thesis, National University of Singapore, Singapore, 2015. [Google Scholar] [CrossRef]

- Available online: https://www.tamura-ss.co.jp/en/gao/pdf/150210.pdf (accessed on 10 January 2024).

- Tadjer, M.J.; Lyons, J.L.; Nepal, N.; Freitas, J.A., Jr.; Koehler, A.D.; Foster, G.M. Review—Theory and Characterization of Doping and Defects in β-Ga2O3. ECS J. Solid State Sci. Technol. 2019, 8, Q3187–Q3194. [Google Scholar] [CrossRef]

- Wang, Z.; Chen, X.; Ren, F.-F.; Gu, S.; Ye, J. Deep-level defects in gallium oxide. J. Phys. D Appl. Phys. 2021, 54, 043002. [Google Scholar] [CrossRef]

- Zhang, Z.; Farzana, E.; Arehart, A.R.; Ringel, S.A. Deep level defects throughout the bandgap of (010) β-Ga2O3 detected by optically and thermally stimulated defect spectroscopy. Appl. Phys. Lett. 2016, 108, 052105. [Google Scholar] [CrossRef]

- Sdoeung, S.; Sasaki, K.; Kawasaki, K.; Hirabayashi, J.; Kuramata, A.; Oishi, T.; Kasu, M. Origin of reverse leakage current path in edge-defined film-fed growth (001) β-Ga2O3 Schottky barrier diodes observed by high-sensitive emission microscopy. Appl. Phys. Lett. 2020, 117, 022106. [Google Scholar] [CrossRef]

- Xu, M.; Biswas, A.; Li, T.; He, Z.; Luo, S.; Mei, Z.; Zhou, J.; Chang, C.; Puthirath, A.B.; Vajtai, R.; et al. Vertical β-Ga2O3 metal–insulator–semiconductor diodes with an ultrathin boron nitride interlayer. Appl. Phys. Lett. 2023, 123, 232107. [Google Scholar] [CrossRef]

| SBD Type | A | B |

|---|---|---|

| Ideality factor * n | 1.43 | 1.24 |

| Schottky barrier height * Φb (eV) | 1.80 | 1.67 |

| Saturation current density * Js (A/cm2) | 6.69 × 10−14 | 6.24 × 10−11 |

| Leakage current density at –2 V(A/cm2) | 7.01 × 10−11 | 8.38 × 10−9 |

| Rectification ratio at ±2 V (arb. un.) | 3.9 × 108 | 3.4 × 106 |

| Breakdown voltage Vbr (V) | 134 | 180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yakovlev, N.N.; Almaev, A.V.; Kushnarev, B.O.; Verkholetov, M.G.; Poliakov, M.V.; Zinovev, M.M. β-Ga2O3 Schottky Barrier Diode with Ion Beam Sputter-Deposited Semi-Insulating Layer. Crystals 2024, 14, 123. https://doi.org/10.3390/cryst14020123

Yakovlev NN, Almaev AV, Kushnarev BO, Verkholetov MG, Poliakov MV, Zinovev MM. β-Ga2O3 Schottky Barrier Diode with Ion Beam Sputter-Deposited Semi-Insulating Layer. Crystals. 2024; 14(2):123. https://doi.org/10.3390/cryst14020123

Chicago/Turabian StyleYakovlev, Nikita N., Aleksei V. Almaev, Bogdan O. Kushnarev, Maksim G. Verkholetov, Maksim V. Poliakov, and Mikhail M. Zinovev. 2024. "β-Ga2O3 Schottky Barrier Diode with Ion Beam Sputter-Deposited Semi-Insulating Layer" Crystals 14, no. 2: 123. https://doi.org/10.3390/cryst14020123

APA StyleYakovlev, N. N., Almaev, A. V., Kushnarev, B. O., Verkholetov, M. G., Poliakov, M. V., & Zinovev, M. M. (2024). β-Ga2O3 Schottky Barrier Diode with Ion Beam Sputter-Deposited Semi-Insulating Layer. Crystals, 14(2), 123. https://doi.org/10.3390/cryst14020123