Uncommon Cold-Rolling Faults in an Fe–Mn–Si–Cr Shape-Memory Alloy

Abstract

:1. Introduction

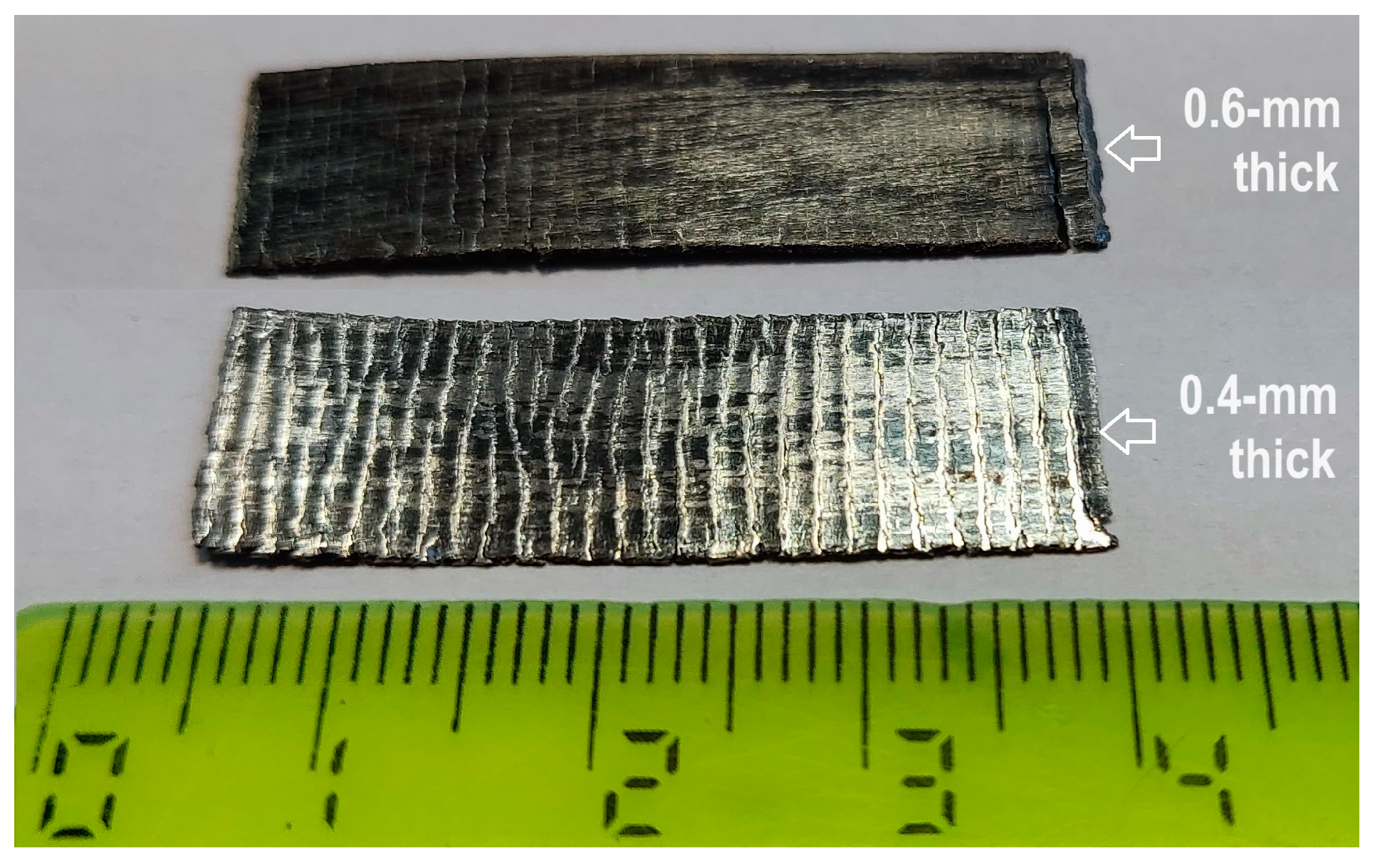

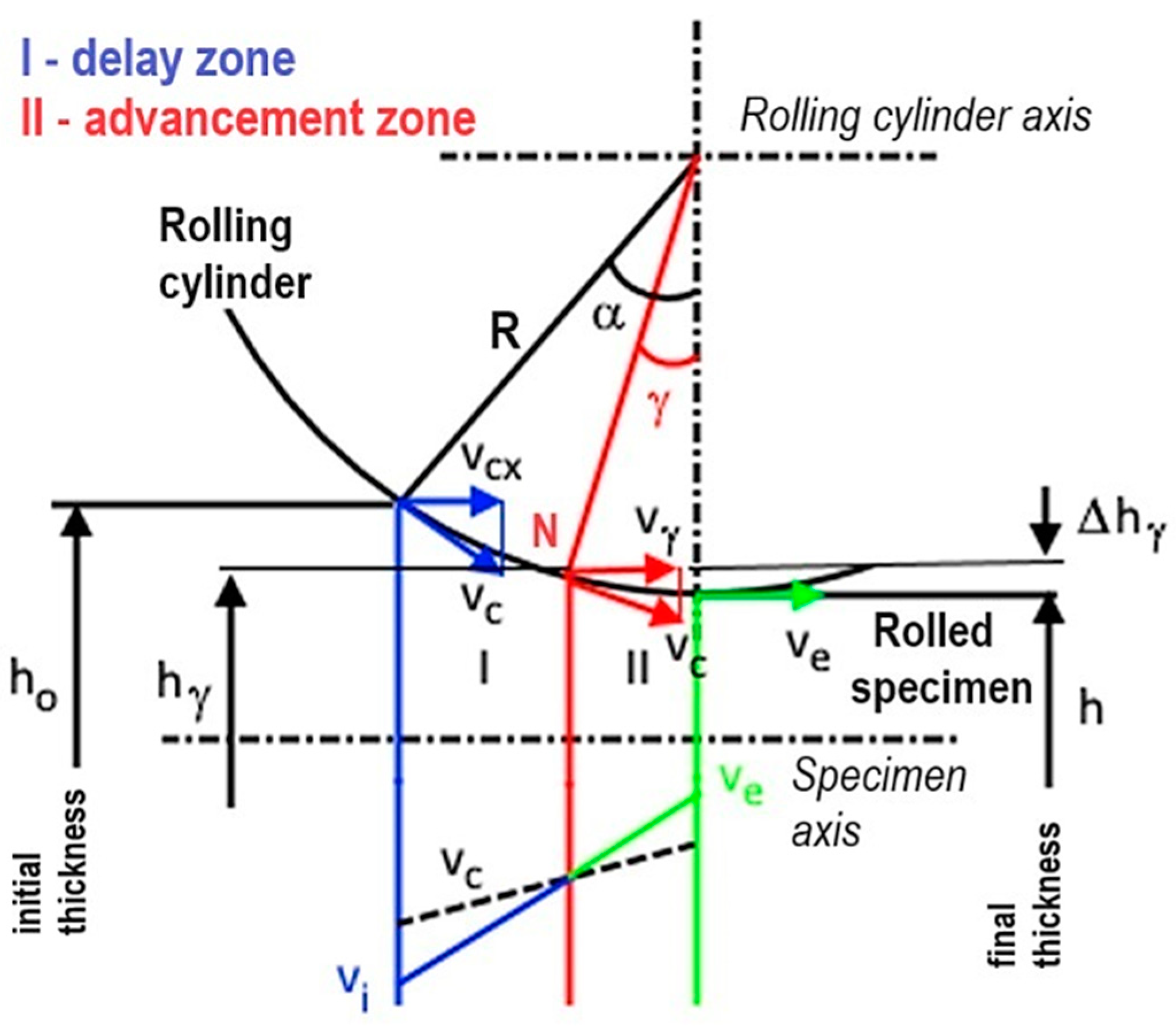

2. Materials and Methods

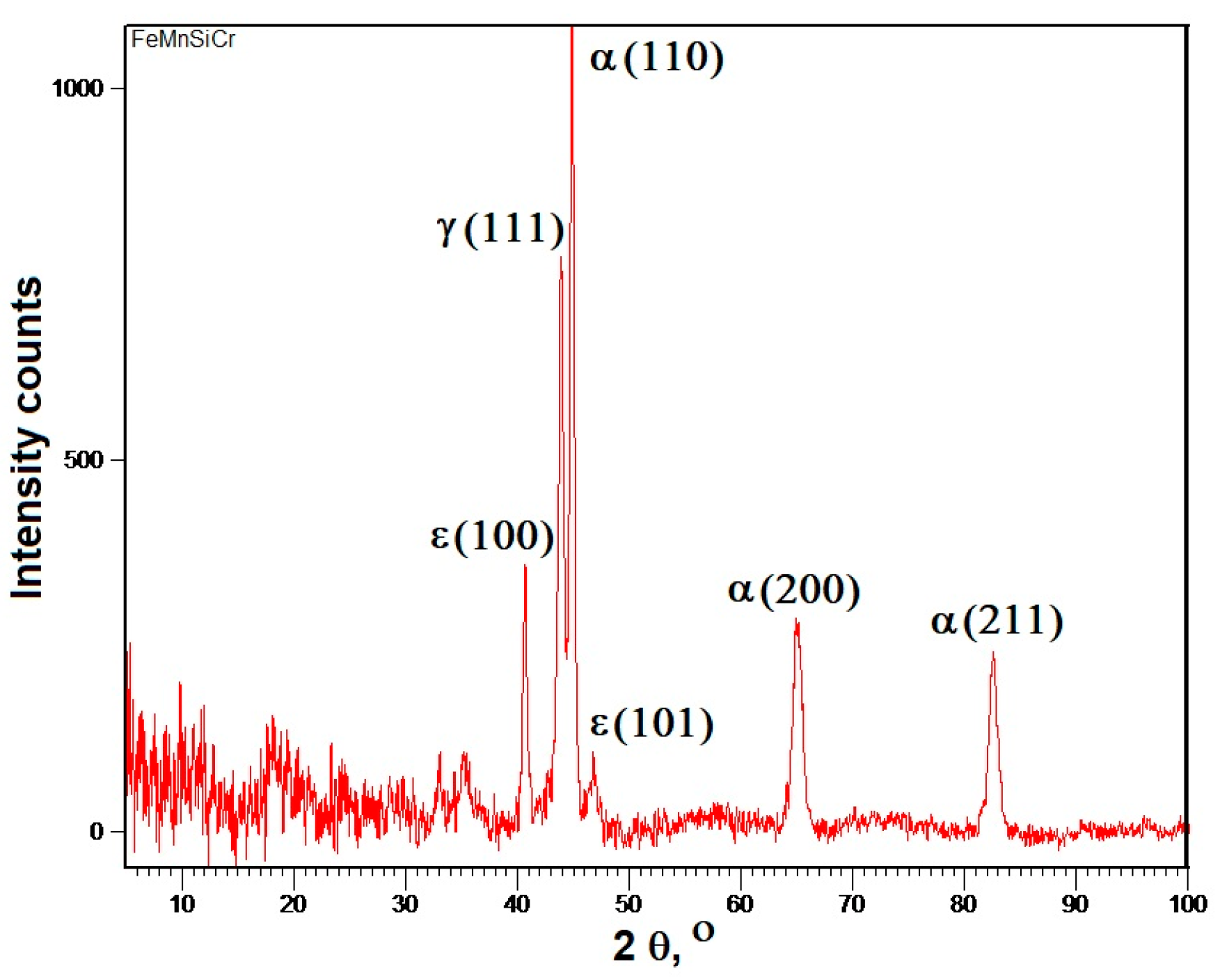

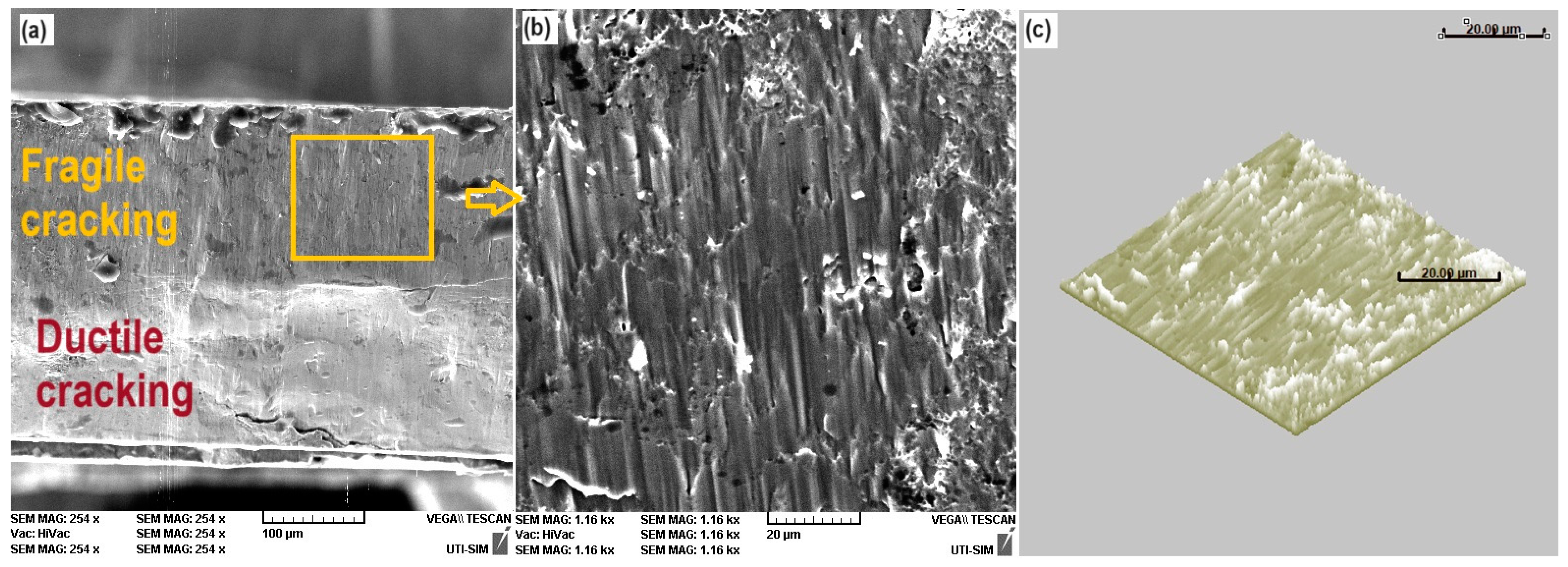

3. Results and Discussion

4. Summary and Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Y.; Bahador, S.D.; Lihua, T.; Lei, Z. Strain transfer models for macrofiber-composite strain actuators. Mater. Manuf. Proc. 2010, 25, 237–242. [Google Scholar] [CrossRef]

- Sun, L.; Huang, W.M.; Ding, Z.; Zhao, Y.; Wang, C.C.; Purnawali, H.; Tang, C. Stimulus-responsive shape memory materials: A review. Mater. Design 2012, 33, 577–640. [Google Scholar] [CrossRef]

- Ma, J.; Karaman, I. Expanding the repertoire of shape memory alloys. Science 2010, 327, 1468–1469. [Google Scholar] [CrossRef] [PubMed]

- Kamila, S. Introduction, classification and applications of smart materials: An overview. Am. J. Appl. Sci. 2013, 10, 876–880. [Google Scholar] [CrossRef]

- Wayman, C.M.; Duerig, T.W. An introduction to martensite and shape memory. In Engineering Aspects of Shape Memory Alloys; Duerig, T.W., Melton, K.N., Stöckel, D., Wayman, C.M., Eds.; Butterworth-Heinemann: London, UK, 1990; pp. 3–20. [Google Scholar]

- Otsuka, K.; Wayman, C.M. Introduction. In Shape Memory Materials; Otsuka, K., Wayman, C.M., Eds.; Cambridge University Press: Cambridge, UK, 1998; pp. 1–26. [Google Scholar]

- Kumar, P.K.; Lagoudas, D.C. Introduction to Shape Memory Alloys. In Shape Memory Alloys. Modelling and Engineering Applications; Lagoudas, D.C., Ed.; Springer: Berlin/Heidelberg, Germany, 2008; pp. 1–51. [Google Scholar]

- Oliveira, J.P.; Zeng, Z.; Berveiller, S.; Bouscaud, D.; Fernandes, F.B.; Miranda, R.M.; Zhou, N. Laser Welding of Cu-Al-Be Shape Memory Alloys: Microstructure and Mechanical Properties. Mater. Design 2018, 148, 145–152. [Google Scholar] [CrossRef]

- Gao, Z.Y.; Yang, S.; Zhang, H.J.; Dong, G.F.; Cai, W. Effect of aging on phase transformation, thermoelastic and fracture behaviour of Mn53Ni25Ga22 ferromagnetic shape memory alloy. Mat. Sci. Eng. A 2014, 594, 1–6. [Google Scholar] [CrossRef]

- Saedi, S.; Acar, E.; Raji, H.; Saghaian, S.E.; Mirsayar, M. Energy damping in shape memory alloys: A review. J. Alloys Compd. 2023, 956, 170286. [Google Scholar] [CrossRef]

- Amadi, A.; Mohyaldinn, M.; Ridha, S.; Ola, V. Advancing engineering frontiers with NiTi shape memory alloys: A multifaceted review of properties, fabrication, and application potentials. J. Alloys Compd. 2024, 976, 173227. [Google Scholar] [CrossRef]

- Mehta, K.; Gupta, K. Fabrication and Processing of Shape Memory Alloys; Springer: Berlin/Heidelberg, Germany, 2019; pp. 9–37. [Google Scholar] [CrossRef]

- Dasgupta, R. A look into Cu-based shape memory alloys: Present scenario and future prospects. J. Mater. Res. 2014, 29, 1681–1698. [Google Scholar] [CrossRef]

- James, R.D.; Hane, K.F. Martensitic transformations and shape-memory materials. Acta Mater. 2000, 48, 197–222. [Google Scholar] [CrossRef]

- Murakami, M.; Otsuka, H.; Suzuki, H.G.; Matsuda, S. Complete shape memory effect in polycrystalline Fe-Mn-Si alloys. In Proceedings of the International Conference on Martensitic Transformation (Japan Institute of Metals), Nara, Japan, 26–30 August 1986; pp. 985–990. [Google Scholar]

- Dunne, D. Diffusionless transformations, high strength steels, modelling and advanced analytical techniques. In Phase Transformations in Steels; Pereloma, E., Edmonds, D.V., Eds.; Woodhead: Cambridge, MA, USA, 2012; Volume 2, pp. 83–125. [Google Scholar]

- Tanaka, Y.; Himuro, Y.; Kainuma, R.; Sutou, Y.; Omori, T.; Ishida, K. Ferrous Polycrystalline Shape-Memory Alloy Showing Huge Superelasticity. Science 2010, 327, 1488–1490. [Google Scholar] [CrossRef] [PubMed]

- Omori, T.; Ando, K.; Okano, M.; Xu, X.; Tanaka, Y.; Ohnuma, I.; Kainuma, R.; Ishida, K. Superelastic Effect in Polycrystalline Ferrous Alloys. Science 2011, 333, 68–71. [Google Scholar] [CrossRef]

- Shimpo, Y.; Seki, H.; Wongsatanawarid, A.; Taniguchi, S.; Maruyama, T.; Kurita, T.; Murakami, M. The improvement of the superconducting Y–Ba–Cu–O magnet characteristics through shape recovery strain of Fe–Mn–Si alloys. Phys. C 2010, 470, 1170–1172. [Google Scholar] [CrossRef]

- Kajiwara, S. Characteristic features of shape memory effect and related transformation behavior in Fe-based alloys. Mater. Sci. Eng. A 1999, 273–275, 67–88. [Google Scholar] [CrossRef]

- Bracke, L.; Mertens, G.; Penning, J.; De Cooman, B.C.; Liebeherr, M.; Akdut, N. Influence of phase transformations on the mechanical properties of high-strength austenitic Fe-Mn-Cr steel. Metall. Mater. Trans. A 2006, 37A, 307–317. [Google Scholar] [CrossRef]

- Arruda, G.J.; Buono, V.T.L.; Andrade, M.S. The influence of deformation on the microstructure and transformation temperatures of Fe–Mn–Si–Cr–Ni shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 528–532. [Google Scholar] [CrossRef]

- Li, J.C.; Zhao, M.; Jiang, Q. Alloy design of Fe-Mn-Si-Cr-Ni shape memory alloys related to stacking-fault energy. Metall. Mater. Trans. A 2000, 31, 581–584. [Google Scholar] [CrossRef]

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ ↔ ε transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183. [Google Scholar] [CrossRef]

- Murakami, M.; Otsuka, H.; Suzuki, H.; Matsuda, S. Effect of alloying content, phase and magnetic transformation on shape memory effect of Fe-Mn-Si alloys. Trans. Iron Steel Inst. Jpn. 1987, 27, B88. [Google Scholar]

- Otsuka, H.; Yamada, H.; Maruyama, T.; Tanahashi, H.; Matsuda, S.; Murakami, M. Effects of alloying additions on Fe-Mn-Si shape memory alloys. ISIJ Int. 1990, 30, 675–679. [Google Scholar] [CrossRef]

- Moriya, Y.; Kimura, H.; Ishizaki, S.; Hashizume, S.; Suzuki, S.; Suzuki, H.; Sampei, T. Properties of Fe-Cr-Ni-Mn-Si (-Co) shape memory alloys. J. Phys. IV C 1991, 4, 433–437. [Google Scholar] [CrossRef]

- Berns, H.; Theisen, W. Ferrous Materials: Steel and Cast Iron; Springer: Berlin/Heidelberg, Germany, 2008; pp. 26–30. [Google Scholar] [CrossRef]

- Manjaiah, M.; Narendranath, S.; Basavarajappa, S. Review on non-conventional machining of shape memory alloys. Trans. Nonferrous Met. Soc. China 2014, 24, 12–21. [Google Scholar] [CrossRef]

- Kubo, H.; Otsuka, H.; Farjami, S.; Maruyama, T. Characteristics of Fe–Mn–Si–Cr shape memory alloys in centrifugal casting. Scr. Mater. 2006, 55, 1059–1062. [Google Scholar] [CrossRef]

- Druker, A.V.; Sobrero, C.; Malarría, J.; Garbe, U.; Brokmeier, H.-G.; Bolmaro, R.E. Effect of texture heterogeneities on the shape memory properties of rolled Fe-Mn-Si SMA. Z. Kristallogr Suppl. 2009, 30, 297–302. [Google Scholar] [CrossRef]

- Ginzburg, V.B. Steel-Rolling Technology: Theory and Practice; Marcel Dekker Inc.: New York, NY, USA, 1989; pp. 187–198. [Google Scholar]

- Zhi, Y.; Wang, X.; Wang, S.; Liu, X. A review on the rolling technology of shape flat products. Int. J. Adv. Manuf. Technol. 2018, 94, 4507–4518. [Google Scholar] [CrossRef]

- Lee, C. Stresses and Defects in Roll Products: A Review of Stress Models and Control Techniques. Int. J. Precis. Eng. Manuf. 2018, 19, 781–789. [Google Scholar] [CrossRef]

- Zhao, R.-J.; Fu, J.-X.; Wu, Y.-X.; Yang, Y.-J.; Zhu, Y.-Y.; Zhang, M. Representative Technologies for Hot Charging and Direct Rolling in Global Steel Industry. ISIJ Int. 2015, 55, 1816–1821. [Google Scholar] [CrossRef]

- Wang, D.-C.; Liu, H.-M.; Liu, J. Research and Development Trend of Shape Control for Cold Rolling Strip. Chin. J. Mech. Eng. 2017, 30, 1248–1261. [Google Scholar] [CrossRef]

- Li, L.; Ding, S.X. Optimal Detection Schemes for Multiplicative Faults in Uncertain Systems With Application to Rolling Mill Processes. IEEE Trans. Control Syst. Technol. 2020, 28, 2432–2444. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, D.; Qiu, G.; Li, X.; Jiang, Z.; Zhang, H. Inclusion evolution in solid steel during rolling deformation: A review. J. Mater. Res. Technol. 2022, 18, 5103–5115. [Google Scholar] [CrossRef]

- Elsilä, U.; Röning, J. Defect prediction in hot strip rolling. Ironmak. Steelmak. 2004, 31, 241–248. [Google Scholar] [CrossRef]

- Ma, H.; Chen, C.; Qi, X.; Li, J.; Lv, B.; Zhang, F. Effect of rolling temperature on microstructure evolution and mechanical properties of high carbon high manganese steel. J. Mater. Res. Technol. 2022, 21, 319–329. [Google Scholar] [CrossRef]

- Muley, A.; Mundlik, A.; Nairale, S. Defects in rolled sheets-A paper review. Int. Res. J. Eng. Technol. 2022, 9, 248–252. [Google Scholar]

- Suru, M.-G.; Lohan, N.M.; Pricop, B.; Spiridon, I.P.; Mihalache, E.; Comăneci, R.I.; Bujoreanu, L.-G. Structural effects of high-temperature plastic deformation process on martensite plate morphology in a Fe-Mn-Si-Cr SMA. Int. J. Mater. Prod. Technol. 2015, 50, 276–288. [Google Scholar] [CrossRef]

- Popa, M.; Popa, F.; Pricop, B.; Cimpoeșu, N.; Lohan, N.-M.; Kicsi, G.; Istrate, B.; Bujoreanu, L.-G. Heat Treatment and Dynamic Mechanical Analysis Strain Sweep Effects on the Phase Structure and Morphology of an Fe-28Mn-6Si-5Cr Shape Memory Alloy. Nanomaterials 2023, 13, 1250. [Google Scholar] [CrossRef] [PubMed]

- Spiridon, I.-P.; Lohan, N.-M.; Suru, M.-G.; Mihalache, E.; Bujoreanu, L.-G.; Pricop, B. A study of free recovery in a Fe–Mn–Si–Cr shape memory alloy. Met. Sci. Heat. Treat. 2016, 57, 548–552. [Google Scholar] [CrossRef]

- Paleu, V.; Gurău, G.; Comăneci, R.I.; Sampath, V.; Gurău, C.; Bujoreanu, L.G. A new application of Fe-28Mn-6Si-5Cr (mass%) shape memory alloy, for self adjustable axial preloading of ball bearings. Smart Mater. Struct. 2018, 27, 75026. [Google Scholar] [CrossRef]

- Pricop, B.; Söyler, A.U.; Özkal, B.; Bujoreanu, L.-G. Powder Metallurgy: An Alternative for FeMnSiCrNi Shape Memory Alloys Processing. Front. Mater. 2020, 7, 247. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Bujoreanu, L.-G.; Kikuchi, T.; Ogawa, K.; Yin, F. Effects of Nb and C in Solution and in NbC Form on the Transformation-related Internal Friction of Fe–17Mn (mass%) Alloys. ISIJ Int. 2008, 48, 99–106. [Google Scholar] [CrossRef]

- Wen, Y.H.; Peng, H.B.; Sun, P.P.; Liu, G.; Li, N. A novel training-free cast Fe–18Mn–5.5Si–9.5Cr–4Ni shape memory alloy with lathy delta ferrite. Scr. Mater. 2010, 62, 55–58. [Google Scholar] [CrossRef]

- Kim, D.; Ferretto, I.; Leinenbach, C.; Lee, W.; Kim, W. Effect of direct aging on microstructure, mechanical properties and shape memory behavior of Fe-17Mn-5Si-10Cr-4Ni-(V, C) shape memory alloy fabricated by laser powder bed fusion. Mater. Char 2023, 197, 112705. [Google Scholar] [CrossRef]

- Zou, Q.; Ye, X.; Li, Y.; Luo, W.; Luo, Y. Preparation and properties of Fe–Mn–Si–Cr–Ni shape memory alloy. J. Mater. Sci. 2023, 58, 3346–3359. [Google Scholar] [CrossRef]

- Zhang, Z.-X.; Zhang, J.; Wu, H.; Ji, Y.; Kumar, D.D. Iron-Based Shape Memory Alloys in Construction: Research, Applications and Opportunities. Materials 2022, 15, 1723. [Google Scholar] [CrossRef]

- Mohri, M.; Ferretto, I.; Khodaverdi, H.; Leinenbach, C.; Ghafoori, E. Influence of thermomechanical treatment on the shape memory effect and pseudoelasticity behavior of conventional and additive manufactured FeeMneSieCreNi-(V,C) shape memory alloys. J. Mater. Res. Technol. 2023, 24, 5922–5933. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Tomota, Y.; Yoshinaka, F.; Harjo, S. Evidence supporting reversible martensitic transformation under cyclic loading on Fe–Mn–Si–Al alloys using in situ neutron diffraction. Acta Mater. 2023, 242, 118494. [Google Scholar] [CrossRef]

- Singh, D.; Tasaki, W.; Yoshinaka, F.; Takamori, S.; Emura, S.; Tsuchiya, K.; Sawaguchi, T. Unveiling the transformation pathways of hierarchical γ90–εtwin–α′ triple phase structure formation at ε-ε martensite intersection. Mater. Charact. 2023, 205, 113358. [Google Scholar] [CrossRef]

- Pricop, B.; Grigoras, M.; Borza, F.; Özkal, B.; Bujoreanu, L.-G. On the Possible Cause of Sudden Storage Modulus Increase during the Heating of PM FeMnSiCrNi SMAs. Nanomaterials 2022, 12, 2342. [Google Scholar] [CrossRef] [PubMed]

- Maruschak, P.; Konovalenko, I.; Sorochak, A. Methods for evaluating fracture patterns of polycrystalline materials based on the parameter analysis of ductile separation dimples: A review. Eng. Fail. Anal. 2023, 153, 107587. [Google Scholar] [CrossRef]

- Bulzak, T.; Pater, Z.; Tomczak, J.; Wojcik, L.; Murillo-Marrodan, A. Internal crack formation in cross wedge rolling: Fundamentals and rolling methods. J. Mater. Proc. Technol. 2022, 307, 117681. [Google Scholar] [CrossRef]

- Wusatowski, Z. Fundamentals of Rolling; Pergament Press: Oxford, UK, 1969; pp. 69–202. [Google Scholar]

- Mocanu, M.; Mihalache, E.; Comăneci, R.-I.; Pricop, B.; Özkal, B.; Bujoreanu, L.-G. Tensile Stress-Induced Structural Changes Associated with Martensite Transformations in Fe-Mn-Si Based Shape Memory Alloys. Mater. Sci. Forum 2017, 907, 25–30. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Bujoreanu, L.-G.; Kikuchi, T.; Ogawa, K.; Koyama, M.; Murakami, M. Mechanism of reversible transformation-induced plasticity of Fe–Mn–Si shape memory alloys. Scr. Mater. 2008, 59, 826–829. [Google Scholar] [CrossRef]

| 2θ, ° | I (a.u.) | Miller Indices | Phase | ||

|---|---|---|---|---|---|

| h | k | l | |||

| 41.166 | 268 | 1 | 0 | 0 | ε (hcp) |

| 43.608 | 999 | 1 | 1 | 1 | γ (fcc) |

| 44.381 | 274 | 0 | 0 | 2 | ε (hcp) |

| 44.485 | 100 | 1 | 1 | 0 | α′ (bcc) |

| 47.041 | 999 | 1 | 0 | 1 | ε (hcp) |

| 50.795 | 420 | 2 | 0 | 0 | γ (fcc) |

| 62.128 | 112 | 1 | 0 | 2 | ε (hcp) |

| 64.779 | 20 | 2 | 0 | 0 | α′ (bcc) |

| 74.681 | 172 | 2 | 2 | 0 | γ (fcc) |

| 75.025 | 100 | 1 | 1 | 0 | ε (hcp) |

| 81.986 | 50 | 2 | 1 | 1 | α′ (bcc) |

| 83.634 | 98 | 1 | 0 | 3 | ε (hcp) |

| 89.358 | 13 | 2 | 0 | 0 | ε (hcp) |

| 90.673 | 158 | 3 | 1 | 1 | γ (fcc) |

| 91.541 | 94 | 1 | 1 | 2 | ε (hcp) |

| 93.446 | 65 | 2 | 0 | 1 | ε (hcp) |

| 95.953 | 43 | 2 | 2 | 2 | γ (fcc) |

| 98.117 | 12 | 0 | 0 | 4 | ε (hcp) |

| 98.475 | 18 | 2 | 2 | 0 | α′ (bcc) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bădărău, G.; Popa, M.; Stoian, G.; Roman, A.-M.; Comăneci, R.-I.; Pricop, B.; Cimpoeșu, N.; Bujoreanu, L.-G. Uncommon Cold-Rolling Faults in an Fe–Mn–Si–Cr Shape-Memory Alloy. Crystals 2024, 14, 250. https://doi.org/10.3390/cryst14030250

Bădărău G, Popa M, Stoian G, Roman A-M, Comăneci R-I, Pricop B, Cimpoeșu N, Bujoreanu L-G. Uncommon Cold-Rolling Faults in an Fe–Mn–Si–Cr Shape-Memory Alloy. Crystals. 2024; 14(3):250. https://doi.org/10.3390/cryst14030250

Chicago/Turabian StyleBădărău, Gheorghe, Mihai Popa, George Stoian, Ana-Maria Roman, Radu-Ioachim Comăneci, Bogdan Pricop, Nicanor Cimpoeșu, and Leandru-Gheorghe Bujoreanu. 2024. "Uncommon Cold-Rolling Faults in an Fe–Mn–Si–Cr Shape-Memory Alloy" Crystals 14, no. 3: 250. https://doi.org/10.3390/cryst14030250

APA StyleBădărău, G., Popa, M., Stoian, G., Roman, A.-M., Comăneci, R.-I., Pricop, B., Cimpoeșu, N., & Bujoreanu, L.-G. (2024). Uncommon Cold-Rolling Faults in an Fe–Mn–Si–Cr Shape-Memory Alloy. Crystals, 14(3), 250. https://doi.org/10.3390/cryst14030250