Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review

Abstract

:1. Introduction

2. Laser–Solid Interactions

2.1. Metals

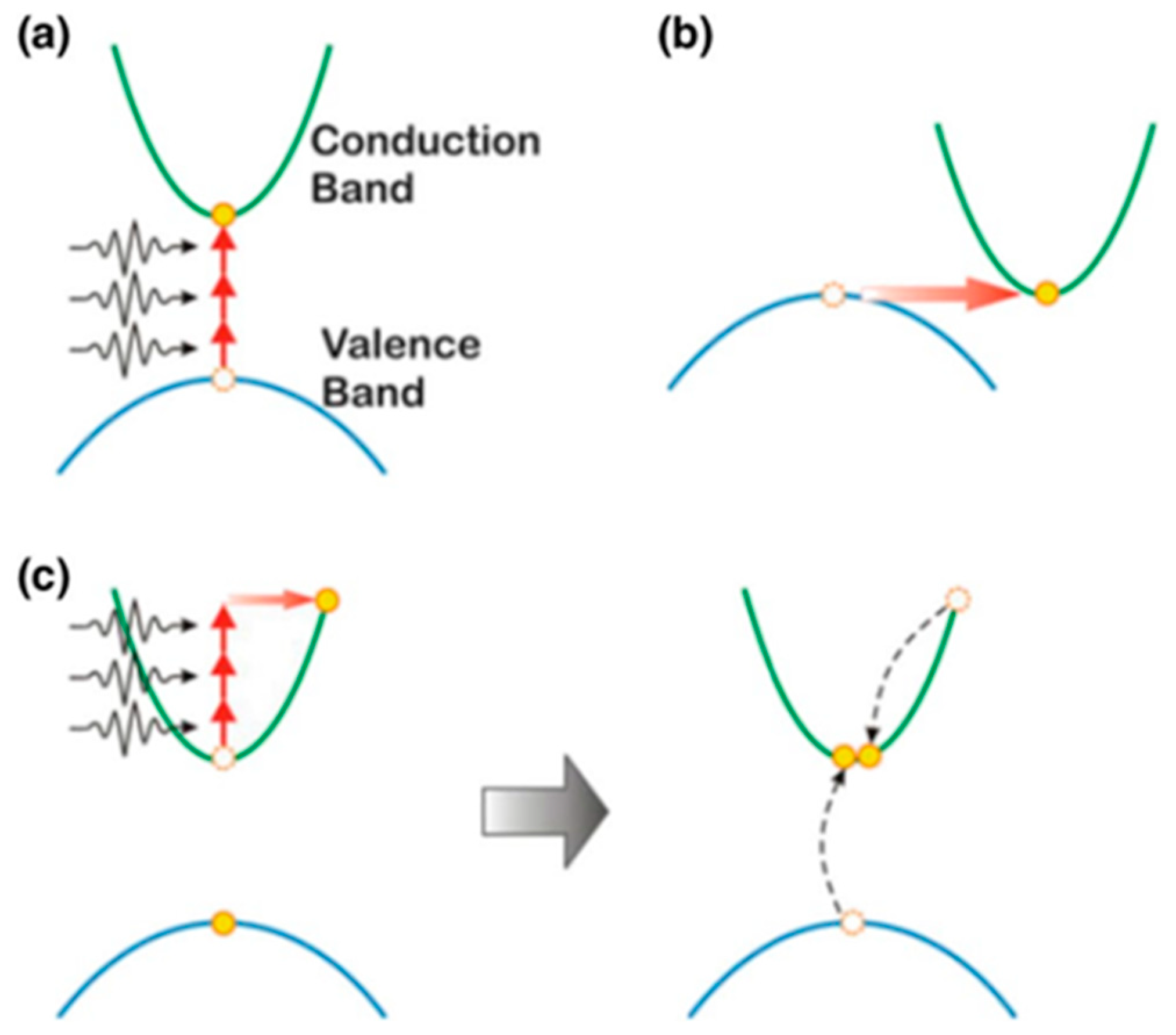

2.2. Semiconductors

2.3. Insulators

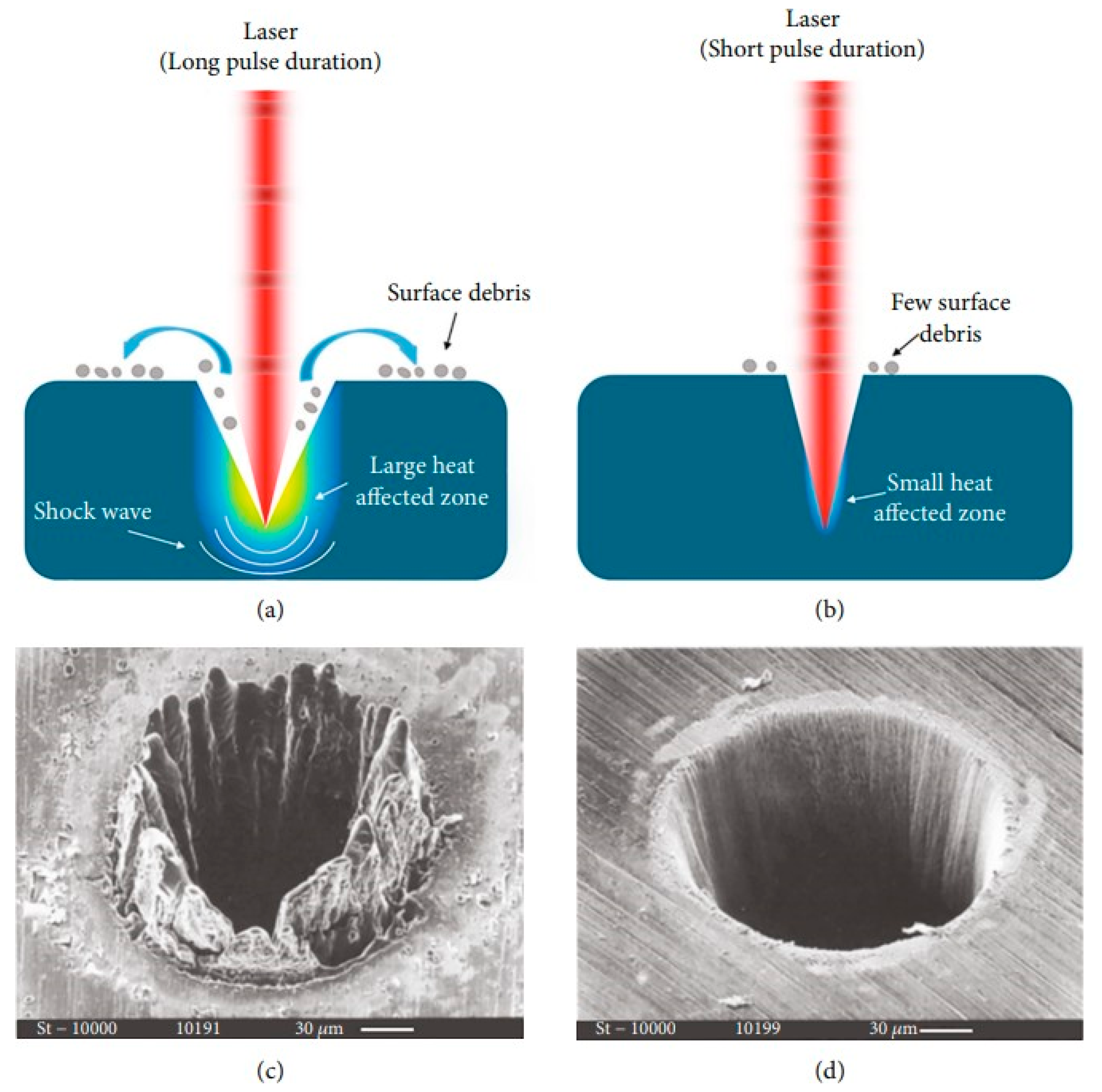

3. Ultrashort-Pulsed-Laser Ablation

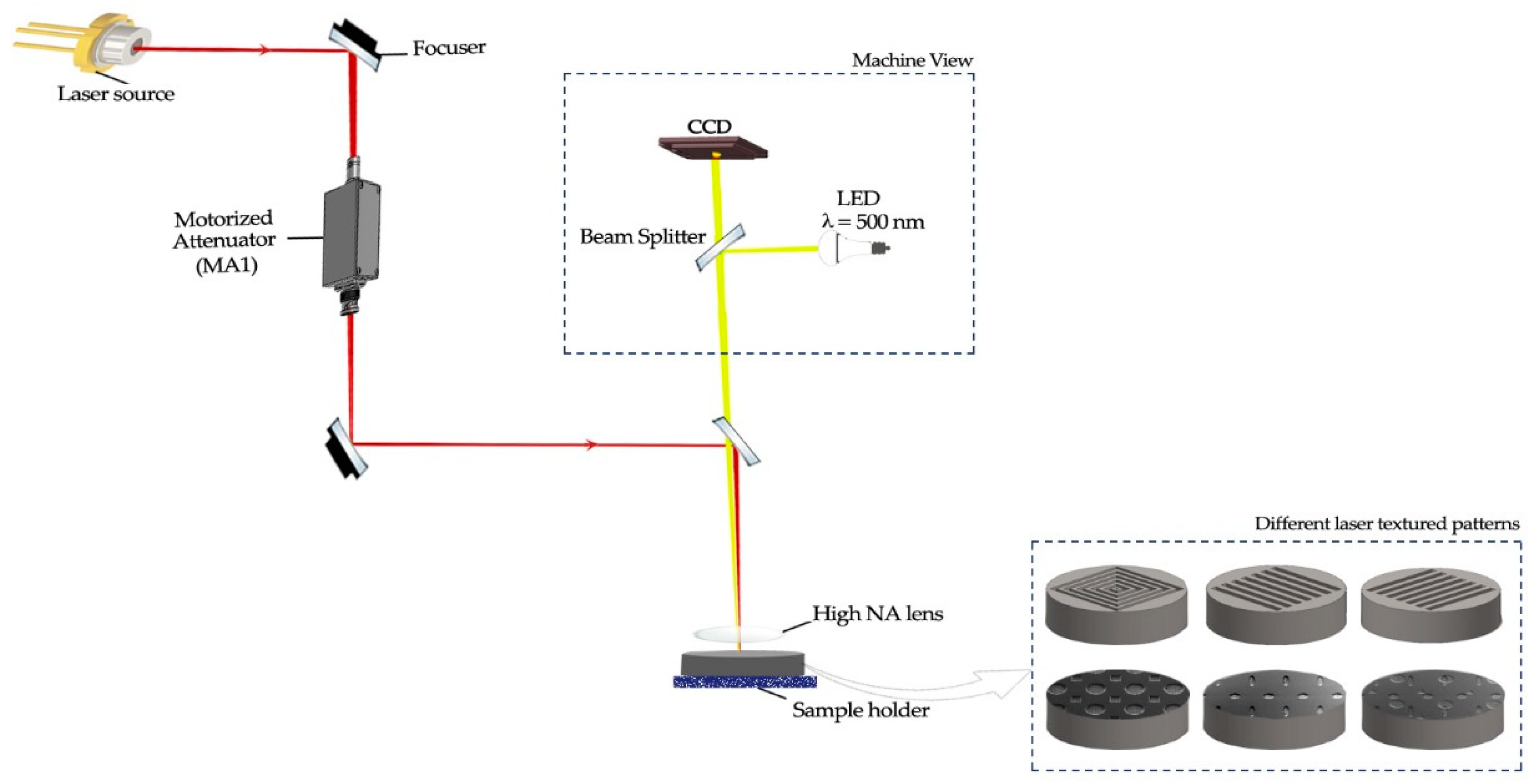

4. Ultrashort-Pulsed-LST

5. Wettability and Surface Roughness

6. COF and Wear Resistance

6.1. Effects of Laser Parameters on Surface Roughness and Wettability

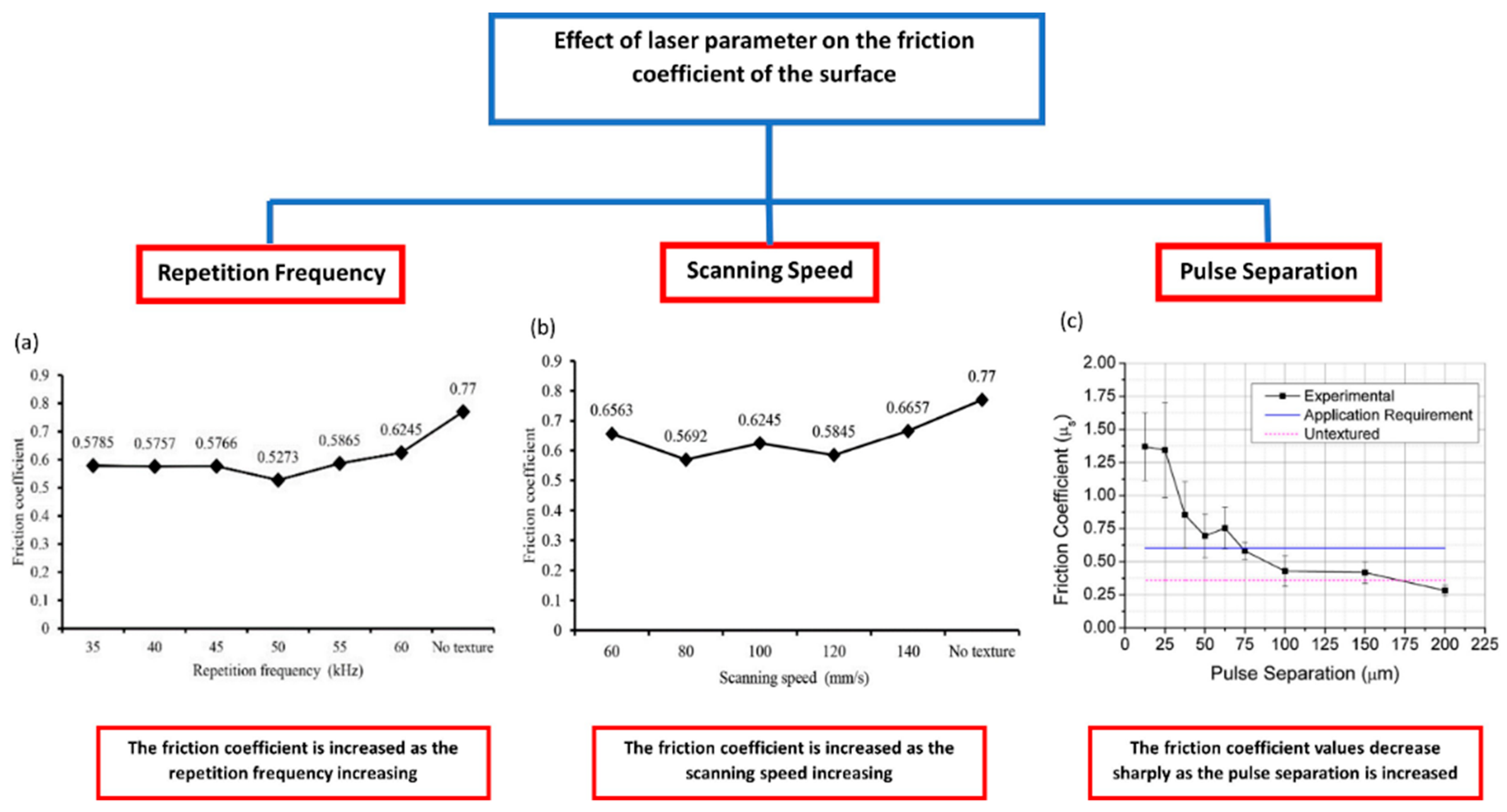

6.2. Effects of Laser Parameters on Surface COF and Wear Resistance

7. Summary and Outlook

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, B.; Sun, J.; Hua, Y.; Zhan, N.; Jia, J.; Chu, K. Femtosecond laser micro/nano-manufacturing: Theories, measurements, methods, and applications. Nanomanuf. Metrol. 2020, 3, 26–67. [Google Scholar] [CrossRef]

- Tan, D.; Sharafudeen, K.N.; Yue, Y.; Qiu, J. Femtosecond laser induced phenomena in transparent solid materials: Fundamentals and applications. Prog. Mater. Sci. 2016, 76, 154–228. [Google Scholar] [CrossRef]

- Bharatish, A.; Soundarapandian, S. Influence of femtosecond laser parameters and environment on surface texture characteristics of metals and nonmetals—State of the art. Lasers Manuf. Mater. Process. 2018, 5, 143–167. [Google Scholar] [CrossRef]

- Shugaev, M.V.; Wu, C.; Armbruster, O.; Naghilou, A.; Brouwer, N.; Ivanov, D.S.; Derrien, T.J.-Y.; Bulgakova, N.M.; Kautek, W.; Rethfeld, B.; et al. Fundamentals of ultrafast laser–material interaction. MRS Bull. 2016, 41, 960–968. [Google Scholar] [CrossRef]

- Lin, Z.; Hong, M. Femtosecond Laser Precision Engineering: From Micron, Submicron, to Nanoscale. Ultrafast Sci. 2021, 2021. [Google Scholar] [CrossRef]

- Sundaram, S.K.; Mazur, E. Inducing and probing non-thermal transitions in semiconductors using femtosecond laser pulses. Nat. Mater. 2002, 1, 217–224. [Google Scholar] [CrossRef] [PubMed]

- Balling, P.; Schou, J. Femtosecond-laser ablation dynamics of dielectrics: Basics and applications for thin films. Rep. Prog. Phys. Phys. Soc. 2013, 76, 036502. [Google Scholar] [CrossRef] [PubMed]

- Stuart, B.C.; Feit, M.D.; Herman, S.; Rubenchik, A.M.; Shore, B.W.; Perry, M.D. Nanosecond-to-femtosecond laser-induced breakdown in dielectrics. Phys. Rev. B Condens. Matter 1996, 53, 1749–1761. [Google Scholar] [CrossRef] [PubMed]

- Rousse, A.; Rischel, C.; Fourmaux, S.; Uschmann, I.; Sebban, S.; Grillon, G.; Balcou, P.; Forster, E.; Geindre, J.; Audebert, P.; et al. Non- thermal melting in semiconductors measured at femtosecond resolution. Nature 2001, 410, 65–68. [Google Scholar] [CrossRef]

- Hase, M.; Fons, P.; Mitrofanov, K.; Kolobov, A.V.; Tominaga, J. Femtosecond structural transformation of phase-change materials far from equilibrium monitored by coherent phonons. Nat. Commun. 2015, 6, 8367. [Google Scholar] [CrossRef]

- Brown, M.S.; Arnold, C.B. Fundamentals laser-material interaction and application to multiscale surface modification. In Laser Precision Microfabrication; Springer: Berlin/Heidelberg, Germany, 2010; pp. 91–120. [Google Scholar]

- Moskal, D.; Martan, J.; Honner, M. Scanning strategies in laser surface texturing: A review. Micromachines 2023, 14, 1241. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Lin, N.; Zou, J.; Lin, X.; Liu, Z.; Yuan, S.; Yu, Y.; Wang, Z.; Zeng, Q.; Chen, W.; et al. Super-hydrophobicity and corrosion resistance of laser surface textured AISI 304 stainless steel decorated with hexadecyltrimethoxysilane (HDTMS). Opt. Laser Technol. 2020, 127, 106146. [Google Scholar] [CrossRef]

- Luo, X.; Tian, Z.; Chen, C.; Jiang, G.; Hu, X.; Wang, L.; Peng, R.; Zhang, H.; Zhong, M. Laser-textured high-throughput hydrophobic/superhydrophobic SERS platform for fish drugs residue detection. Opt. Laser Technol. 2022, 152, 108075. [Google Scholar] [CrossRef]

- He, C.; Yang, S.; Zheng, M. Analysis of synergistic friction reduction effect on micro-textured cemented carbide surface by laser processing. Opt. Laser Technol. 2022, 155, 108343. [Google Scholar] [CrossRef]

- Chen, X.; Lei, Z.; Chen, Y.; Jiang, M.; Jiang, N.; Bi, J.; Lin, S. Enhanced wetting behavior using femtosecond laser-textured surface in laser welding-brazing of Ti/Al butt joint. Opt. Laser Technol. 2021, 142, 107212. [Google Scholar] [CrossRef]

- Mahayuddin, N.; Wahab, J.A.; Salleh, M.; Roduan, S.F.; Chen, H.K. Surface texturing method and roughness effect on the substrate performance: A short review. J. Tribol. 2020, 27, 8–18. [Google Scholar]

- Moldovan, E.R.; Doria, C.C.C.; Ocaña, J.L.; Baltes, L.S.; Stanciu, E.M.; Croitoru, C.; Pascu, A.; Roata, I.C.; Tierean, M.H. Wettability and surface roughness analysis of laser surface texturing of AISI 430 stainless steel. Materials 2022, 15, 2955. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, Y.S.S.; DePaiva, J.M.; Amorim, F.L.; Torres, R.D.; de Rossi, W.; Veldhuis, S.C. Laser surface texturing and characterization of austenitic stainless steel for the improvement of its surface properties. Int. J. Adv. Manuf. Technol. 2021, 115, 1795–1808. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, H.; Zhu, Z.; Xiang, N.; Wang, Z.; Sun, G. Switchable wettability control of titanium via facile nanosecond laser-based surface texturing. Surf. Interfaces 2021, 24, 101122. [Google Scholar] [CrossRef]

- Prakash, F.P.; Jeyaprakash, N.; Duraiselvam, M.; Prabu, G.; Yang, C.-H. Droplet spreading and wettability of laser textured c-263 based nickel superalloy. Surf. Coat. Technol. 2020, 397, 126055. [Google Scholar] [CrossRef]

- Sierra, D.R.; Edwardson, S.; Dearden, G. Laser surface texturing of titanium with thermal post-processing for improved wettability properties. Procedia CIRP 2018, 74, 362–366. [Google Scholar] [CrossRef]

- Bizi-Bandoki, P.; Benayoun, S.; Valette, S.; Beaugiraud, B.; Audouard, E. Modifications of roughness and wettability properties of metals induced by femtosecond laser treatment. Appl. Surf. Sci. 2011, 257, 5213–5218. [Google Scholar] [CrossRef]

- Gemini, L.; Faucon, M.; Romoli, L.; Kling, R. High throughput laser texturing of super-hydrophobic surfaces on steel. In Proceedings of the Laser-Based Micro-and Nanoprocessing XI, San Francisco, CA, USA, 31 January–2 February 2017. [Google Scholar]

- Yusuf, Y.; Ghazali, M.J.; Abdollah, M.F.B.; Otsuka, Y.; Nakamura, S.; Pembuatan, F.T.K.M.d. Superhydrophilicity of laser surface textured TiO2 coating for self-cleaning surfaces. In Proceedings of Mechanical Engineering Research Day 2019; Centre for Advanced Research on Energy: Melaka, Malaysia, 2019; pp. 342–343. [Google Scholar]

- Baron, C.F.; Mimidis, A.; Puerto, D.; Skoulas, E.; Stratakis, E.; Solis, J.; Siegel, J. Biomimetic surface structures in steel fabricated with femtosecond laser pulses: Influence of laser rescanning on morphology and wettability. Beilstein J. Nanotechnol. 2018, 9, 2802–2812. [Google Scholar] [CrossRef] [PubMed]

- Chen, N.; Li, Z.; Wu, Y.; Zhao, G.; Li, L.; He, N. Investigating the ablation depth and surface roughness of laser-induced nano-ablation of CVD diamond material. Precis. Eng. 2019, 57, 220–228. [Google Scholar] [CrossRef]

- Kumar, B.; Soni, R.K. Submicrometre periodic surface structures in InP induced by nanosecond UV laser pulses. J. Phys. D 2008, 41, 155303. [Google Scholar] [CrossRef]

- Jalil, S.A.; Akram, M.; Bhat, J.A.; Hayes, J.J.; Singh, S.C.; ElKabbash, M.; Guo, C. Creating superhydrophobic and antibacterial surfaces on gold by femtosecond laser pulses. Appl. Surf. Sci. 2020, 506, 144952. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Rancan, M.; Gambaro, S.; Cirisano, F.; Armelao, L.; Tuissi, A. Ultrashort laser texturing of superelastic NiTi: Effect of laser power and scanning speed on surface morphology, composition and wettability. Metals 2023, 13, 381. [Google Scholar] [CrossRef]

- Oberli, L.; Caruso, D.; Hall, C.; Fabretto, M.; Murphy, P.J.; Evans, D. Condensation and freezing of droplets on superhydrophobic surfaces. Adv. Colloid Interface Sci. 2014, 210, 47–57. [Google Scholar] [CrossRef] [PubMed]

- Dunn, A.; Wlodarczyk, K.L.; Carstensen, J.V.; Hansen, E.B.; Gabzdyl, J.; Harrison, P.M.; Shephard, J.D.; Hand, D.P. Laser surface texturing for high friction contacts. Appl. Surf. Sci. 2015, 357, 2313–2319. [Google Scholar] [CrossRef]

- Lu, L.; Zhang, Z.; Guan, Y.; Zheng, H. Comparison of the effect of typical patterns on friction and wear properties of chromium alloy prepared by laser surface texturing. Opt. Laser Technol. 2018, 106, 272–279. [Google Scholar] [CrossRef]

- Segu, D.Z.; Hwang, P. Effectiveness of multi-shape laser surface texturing in the reduction of friction under lubrication regime. Ind. Lubr. Tribol. 2016, 68, 116–124. [Google Scholar] [CrossRef]

- Shi, Z.; Shum, P.; Wasy, A.; Zhou, Z.; Li, L.K.-Y. Tribological performance of few layers graphene on textured m2 steel surfaces. Surf. Coat. Technol. 2016, 296, 164–170. [Google Scholar] [CrossRef]

- Arenas, M.A.; Ahuir-Torres, J.I.; García, I.; Carvajal, H.; de Damborenea, J. Tribological behaviour of laser textured Ti–6Al–4V alloy coated with MoS2 and graphene. Tribol. Int. 2018, 128, 240–247. [Google Scholar] [CrossRef]

- Li, X.; Li, G.; Lei, Y.; Gao, L.; Zhang, L.; Yang, K. Influence of laser surface texture on the anti-friction properties of 304 stainless steel. Machines 2023, 11, 473. [Google Scholar] [CrossRef]

- Mishra, S.K.; Ghosh, S.; Aravindan, S. Investigations into friction and wear behavior of AlTiN and AlCrN coatings deposited on laser textured WC/co using novel open tribometer tests. Surf. Coat. Technol. 2020, 387, 125513. [Google Scholar] [CrossRef]

- Rufuss, S.A.D.D.W.; Jain, A.; Kandasamy, J.; Singhal, M. Laser processing techniques for surface property enhancement: Focus on material advancement. Surf. Interfaces 2023, 42, 103293. [Google Scholar]

- Mao, B.; Siddaiah, A.; Liao, Y.; Menezes, P.L. Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J. Manuf. Process. 2020, 53, 153–173. [Google Scholar] [CrossRef]

- Liang, C.; Wang, H.; Yang, J.; Li, B.; Yang, Y.; Li, H. Biocompatibility of the micro-patterned NiTi surface produced by femtosecond laser. Appl. Surf. Sci. 2012, 261, 337–342. [Google Scholar] [CrossRef]

- Liu, Z.; Niu, T.; Lei, Y.; Luo, Y. Metal surface wettability modification by nanosecond laser surface texturing: A review. Biosurf. Biotribol. 2022, 8, 95–120. [Google Scholar] [CrossRef]

- MacGregor-Ramiasa, M.N.; Vasilev, K. Questions and answers on the wettability of nano-engineered surfaces. Adv. Mater. Interfaces 2017, 4, 1700381. [Google Scholar] [CrossRef]

- Sarbada, S.; Shin, Y.C. Superhydrophobic contoured surfaces created on metal and polymer using a femtosecond laser. Appl. Surf. Sci. 2017, 405, 465–475. [Google Scholar] [CrossRef]

- Yang, C.j.; Mei, X.s.; Tian, Y.l.; Zhang, D.w.; Li, Y.; Liu, X.p. Modification of wettability property of titanium by laser texturing. Int. J. Adv. Manuf. Technol. 2016, 87, 1663–1670. [Google Scholar] [CrossRef]

- Cunha, A.; Serro, A.P.; Oliveira, V.; Almeida, A.; Vilar, R.; Durrieu, M.-C. Wetting behaviour of femtosecond laser textured ti–6al–4v surfaces. Appl. Surf. Sci. 2013, 265, 688–696. [Google Scholar] [CrossRef]

- Li, B.; Li, H.; Huang, L.j.; Ren, N.f.; Kong, X. Femtosecond pulsed laser textured titanium surfaces with stable superhydrophilicity and superhydrophobicity. Appl. Surf. Sci. 2016, 389, 585–593. [Google Scholar] [CrossRef]

| Material | Laser Fluence (J/cm2) or Power | Wavelength (nm) | Repetition (kHz) | Pulse Duration | Contact Angle | Type | Conclusion | Ref |

|---|---|---|---|---|---|---|---|---|

| Stainless steel | - | 1046 | - | 9 ns | - | Groove-type | The surface of the microstructure became hydrophobic as the repetition number increased while the frequency was maintained. | [18] |

| - | - | - | 30 fs | 22.2°, 22.8°, 23.2° | Three textures: square, parallel, and perpendicular | Surface hydrophilicity increased. LST demonstrated a clear ability to reduce wear rate and COF. | [19] | |

| 2.04/- | - | 5 | 150 fs | 116.5° | Nanoperiodic and microperiodic ripples | Materials became hydrophobic as the number of pulses increased. | [23] | |

| 0.36, 1.14, 2.33/- | - | 1000 | - | 120° | Microgrooves | The surface changed from hydrophilic to hydrophobic and became superhydrophobic when laser processing was performed with the highest repetition rate. | [24] | |

| Titanium surface | - | 355 | 30 | 20 ns | 153.2° | Crosshatch pattern | Wettability could be effectively shifted between superhydrophobicity and superhydrophobicity several times. | [20] |

| Nickel-based superalloy (C-263) | - | 532 | - | - | - | Four waviness patterns | A hydrophobic surface was obtained, and the surface roughness of the textured surface increased by 92%. | [21] |

| Ti–6Al–4V | 4.07, 5.09, 6.11, 7.13, 8.14, 9.17/- | - | 65 | 65 ns | - | Micropillars | The most effective topography construction for a superhydrophobic regime was pillar-based with fluences of 5.09 and 6.11 J/cm2 | [22] |

| 2.04 | - | 5 | 150 fs | 116.5° | Nanoperiodic and microperiodic ripples | Materials became hydrophobic as the number of pulses increased | [23] | |

| TiO2 | - | - | - | - | Low CA of <4° | Microdimples | After laser texturing, all samples displayed superhydrophilic behavior | [25] |

| steel | 0.12, 0.2, 0.5, 1 | 1030 | 500, 1000, 2000 | 340 fs | 92° ± 2° to 136°± 6°; some surfaces presented CAs of >150° | Ripples, grooves, and spikes | A hydrophobic surface was obtained | [26] |

| CVD diamond material | - | 1064 | 200 | 100 ns | - | - | The surface roughness values of Sa and Sz increased with the increase in the average laser power and decreased with the increase in laser filling pitch and scanning speed; an exception occurred at a scanning speed of 30 mm/s and filling pitch of 3 m | [27] |

| crystalline InP | 125/- | 266 | 0.010 | 5 ns | - | Ripple | Roughness increased with the increase in laser shots, and the duration of ripple pattern decreased | [28] |

| gold | 0.08–3 | 800 | 1 | 30 fs | 10 8°–15 4° | Microstructure/nanostructure | The surface changed from hydrophilic to hydrophobic | [29] |

| NiT | 15 | 1028 | Single pulse: 200 kHz | 210 fs–10 ps | 131° | Microstructure/nanostructure | The surface changed from hydrophilic to hydrophobic | [30] |

| Material | Laser Fluence (J/cm2) or Power | Wavelength (nm) | Pulse Duration | COF | Type | Conclusion | Ref |

|---|---|---|---|---|---|---|---|

| 316 stainless steel | 167/- | 1064 | 220 ns | 1.25 | - | A very high static COF of >1.25 was obtained. | [32] |

| Chromium alloys | -/15.6 W | - | 600 ps | Lower COF than the as-received surfaces | - | Under dry conditions, the wear rate and COF of the textured samples and were lower than those of the sample received. | [33] |

| Steel | -/24 W | 1064 | 200 ns | Less extreme and more stable than the unpatterned surface | Circle and ellipse, circle and triangle, and circle and square | The multishaped pattern surface performed better than the unpatterned surface in terms of stability and COF under dry and lubricated conditions. | [34] |

| M2 steel surfaces | -/350 W | 1064 | - | Low COF of approximately 0.22 | Parallel microgrooves | With a percentage of 35% groove areas, there was enough graphene to minimize friction, and an 80% reduction in the wear rate considerably enhanced the wear resistance. | [35] |

| Ti–6Al–4V | - | 1064 | - | Low COF of approximately 0.2 | Cross-groove patterns | The COF dropped to approximately 0.2 for patterned surfaces coated with graphene or MoS2. | [36] |

| 304 stainless steel | -/20 W | 1064 | 200 ns | Low COF | - | A low COF was obtained. | [37] |

| WC/Co | - | - | - | COF decreased | Microholes | COF decreased for coated patterned surfaces under high and low load conditions. | [38] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsaigh, R.A. Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review. Crystals 2024, 14, 353. https://doi.org/10.3390/cryst14040353

Alsaigh RA. Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review. Crystals. 2024; 14(4):353. https://doi.org/10.3390/cryst14040353

Chicago/Turabian StyleAlsaigh, Reem A. 2024. "Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review" Crystals 14, no. 4: 353. https://doi.org/10.3390/cryst14040353

APA StyleAlsaigh, R. A. (2024). Enhancement of Surface Properties Using Ultrashort-Pulsed-Laser Texturing: A Review. Crystals, 14(4), 353. https://doi.org/10.3390/cryst14040353