High-Efficiency Vertical-Chip Micro-Light-Emitting Diodes via p-GaN Optimization and Surface Passivation

Abstract

:1. Introduction

2. Simulation Methods

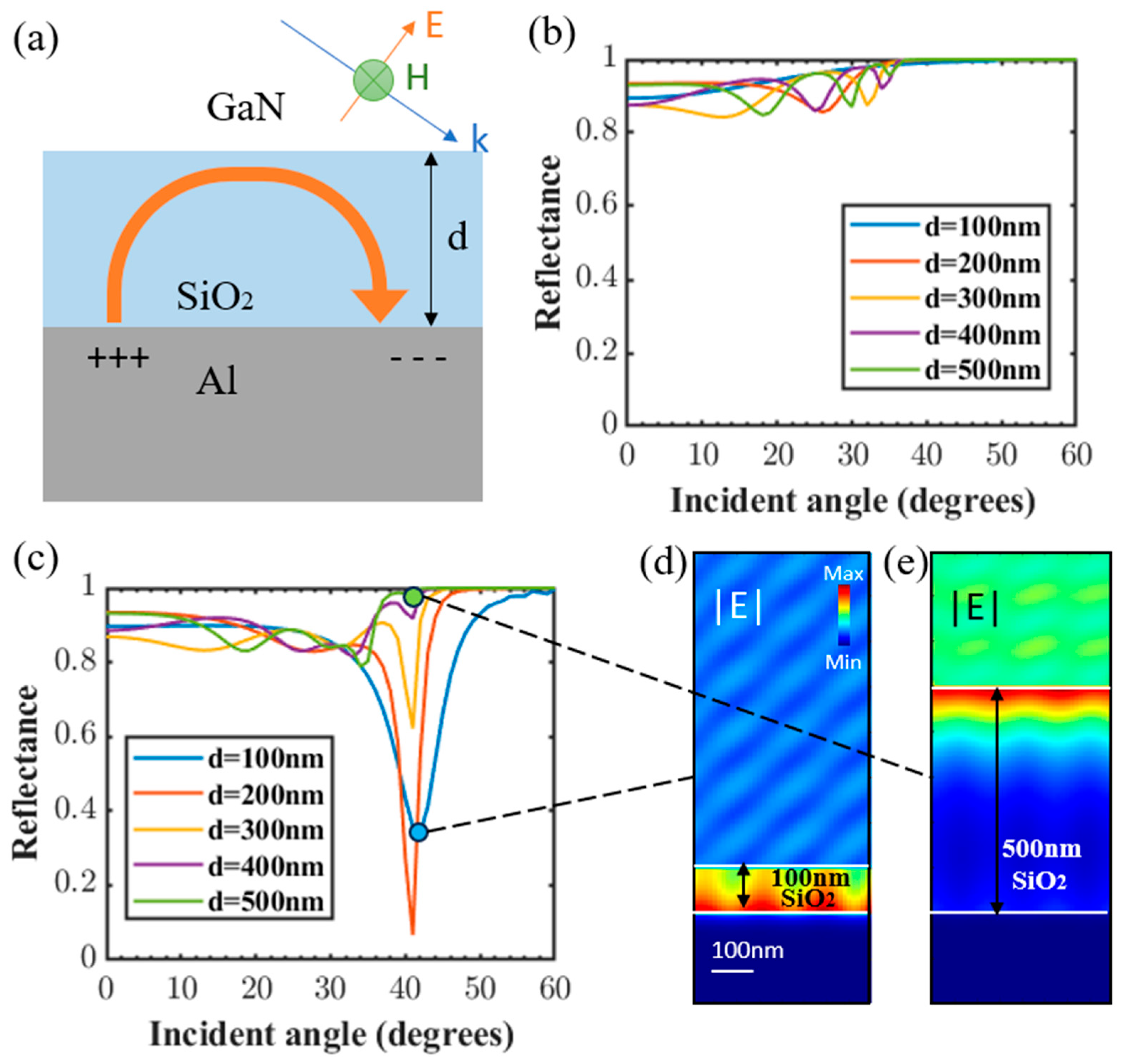

2.1. Optical Model for Blue InGaN/GaN CPC μLED

2.2. LEE Calculation

2.3. Electrical Model of CPC μLED

3. Results and Discussion

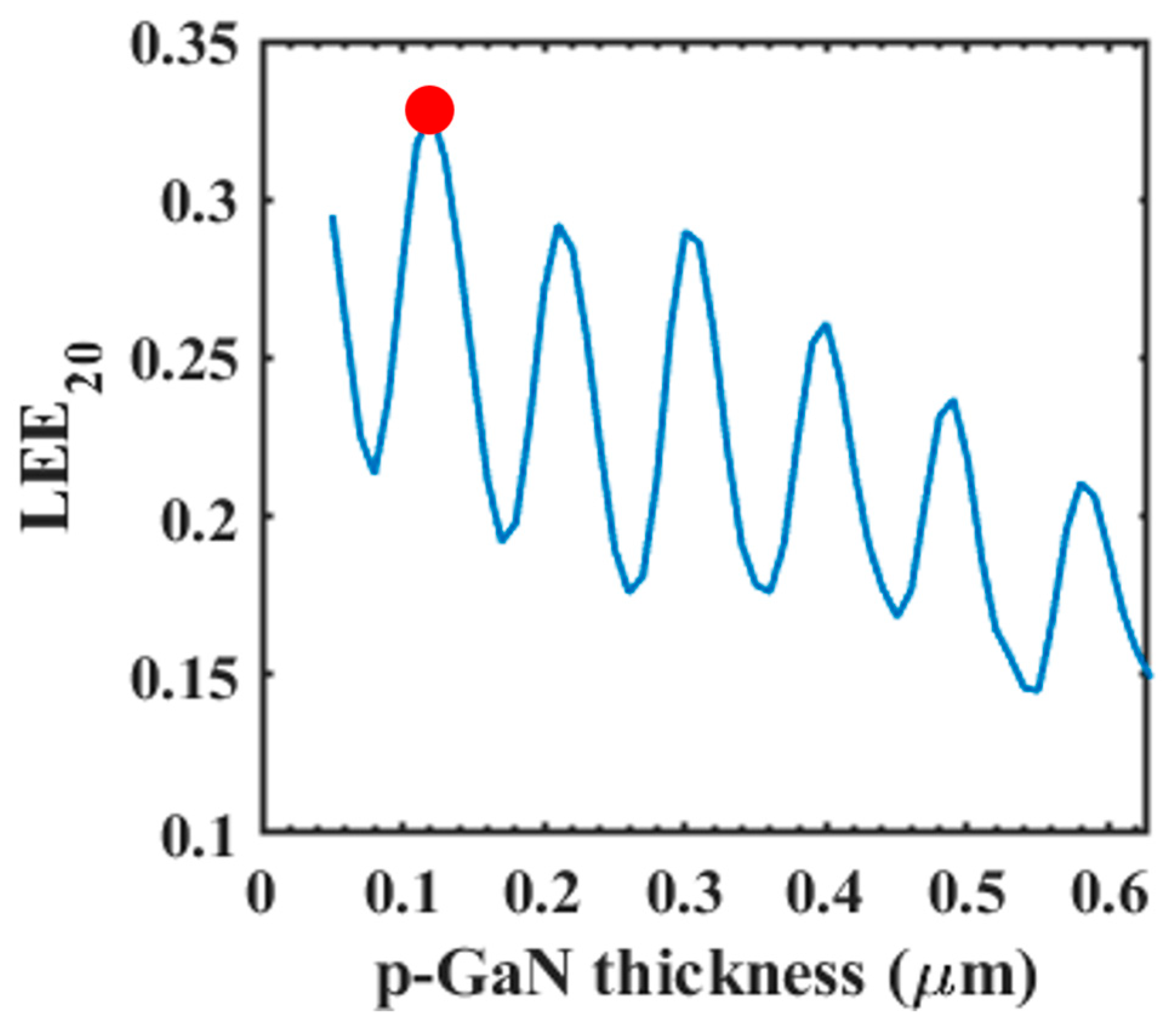

3.1. Reducing the Loss from Surface Plasmon

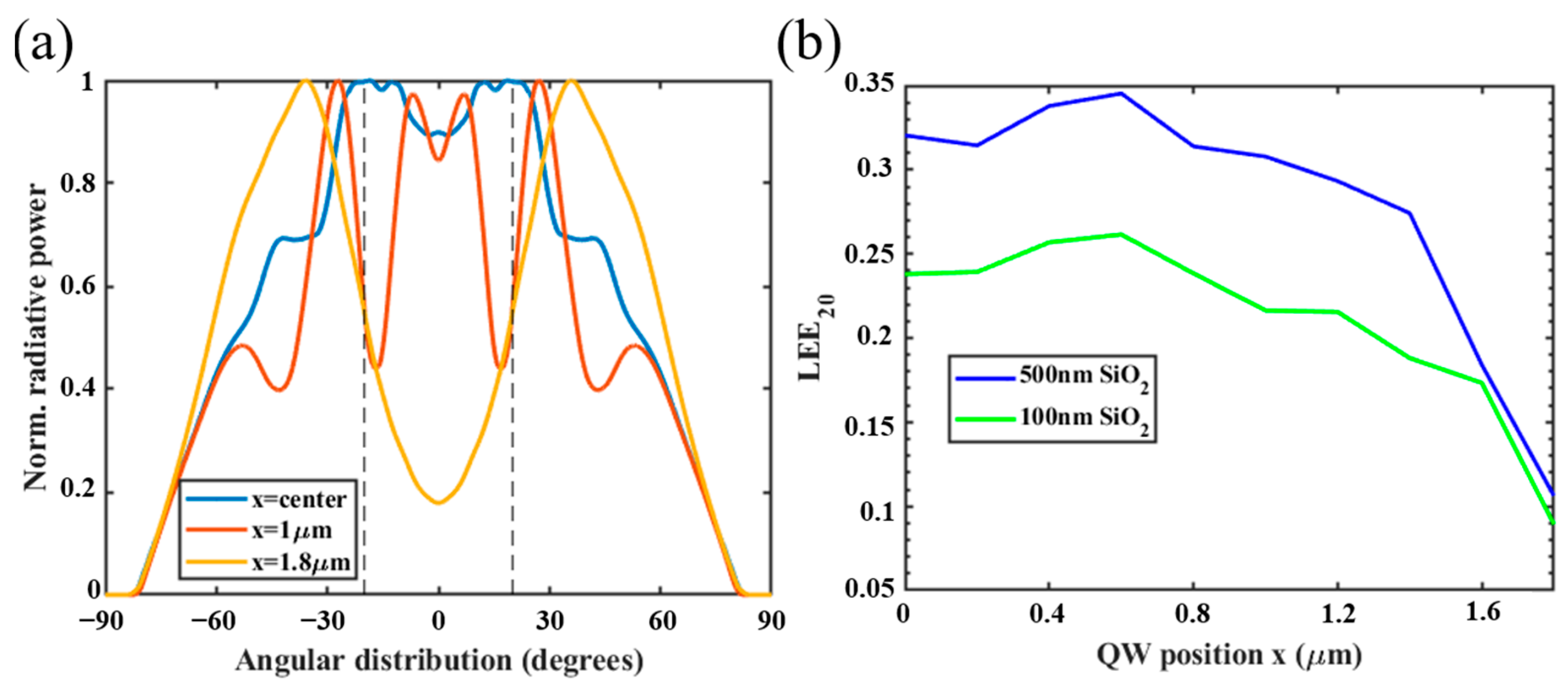

3.2. μLED Optical Performance

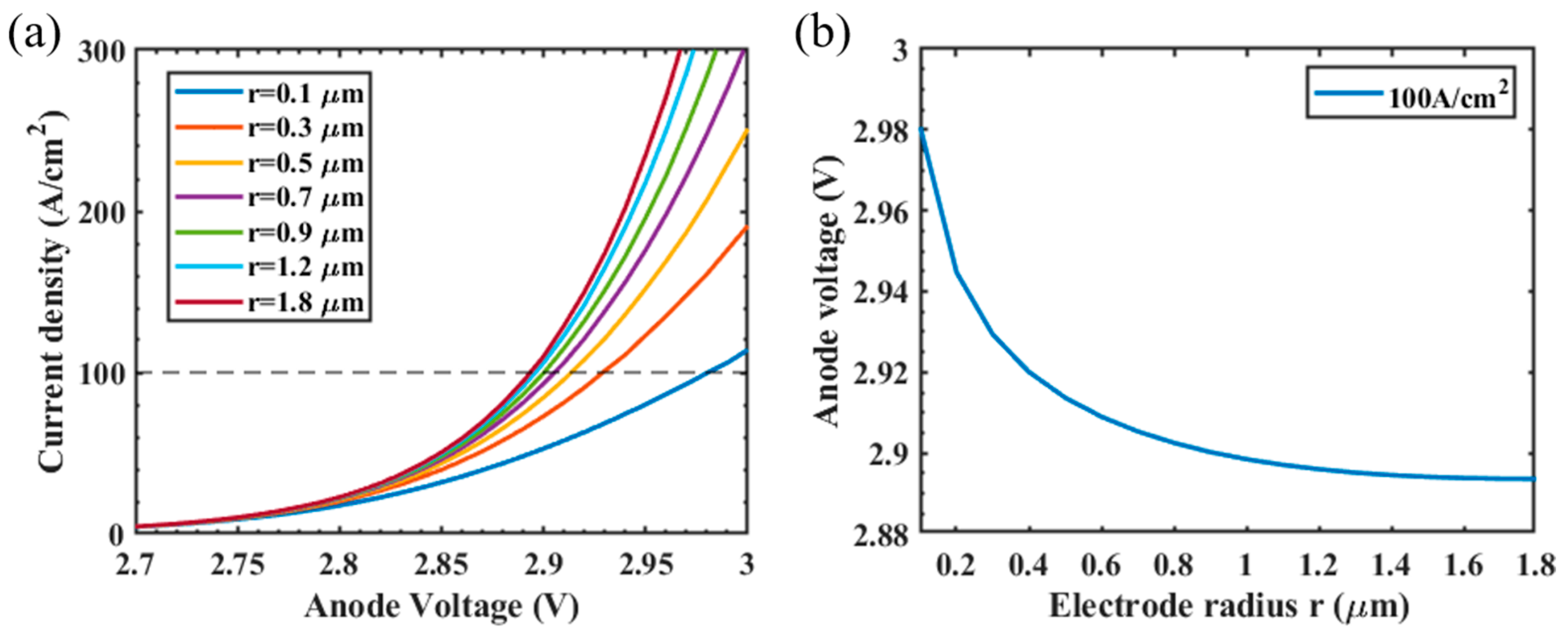

3.3. µLED Electrical Performance

3.4. EQE Improvement

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Biwa, G.; Aoyagi, A.; Doi, M.; Tomoda, K.; Yasuda, A.; Kadota, H. Technologies for the Crystal LED display system. J. Soc. Inf. Disp. 2021, 29, 435–445. [Google Scholar] [CrossRef]

- Huang, Y.; Hsiang, E.-L.; Deng, M.-Y.; Wu, S.-T. Mini-LED, Micro-LED and OLED displays: Present status and future perspectives. Light Sci. Appl. 2020, 9, 105. [Google Scholar] [CrossRef] [PubMed]

- Miao, W.C.; Hsiao, F.H.; Sheng, Y.; Lee, T.Y.; Hong, Y.H.; Tsai, C.W.; Chen, H.L.; Liu, Z.; Lin, C.L.; Chung, R.J. Microdisplays: Mini-LED, Micro-OLED, and Micro-LED. Adv. Opt. Mater. 2023, 12, 2300112. [Google Scholar] [CrossRef]

- Lin, C.-C.; Wu, Y.-R.; Kuo, H.-C.; Wong, M.S.; DenBaars, S.P.; Nakamura, S.; Pandey, A.; Mi, Z.; Tian, P.; Ohkawa, K.; et al. The micro-LED roadmap: Status quo and prospects. J. Phys. Photonics 2023, 5, 042502. [Google Scholar] [CrossRef]

- Chen, Z.; Yan, S.; Danesh, C. MicroLED technologies and applications: Characteristics, fabrication, progress, and challenges. J. Phys. D Appl. Phys. 2021, 54, 123001. [Google Scholar] [CrossRef]

- Lin, J.; Jiang, H. Development of microLED. Appl. Phys. Lett. 2020, 116, 100502. [Google Scholar] [CrossRef]

- Liu, Z.; Lin, C.-H.; Hyun, B.-R.; Sher, C.-W.; Lv, Z.; Luo, B.; Jiang, F.; Wu, T.; Ho, C.-H.; Kuo, H.-C. Micro-light-emitting diodes with quantum dots in display technology. Light Sci. Appl. 2020, 9, 83. [Google Scholar] [CrossRef] [PubMed]

- Anwar, A.R.; Sajjad, M.T.; Johar, M.A.; Hernández-Gutiérrez, C.A.; Usman, M.; Łepkowski, S. Recent progress in micro-LED-based display technologies. Laser Photonics Rev. 2022, 16, 2100427. [Google Scholar] [CrossRef]

- Zhou, X.; Tian, P.; Sher, C.-W.; Wu, J.; Liu, H.; Liu, R.; Kuo, H.-C. Growth, transfer printing and colour conversion techniques towards full-colour micro-LED display. Prog. Quant. Electron. 2020, 71, 100263. [Google Scholar] [CrossRef]

- Wu, Y.; Ma, J.; Su, P.; Zhang, L.; Xia, B. Full-color realization of micro-LED displays. Nanomaterials 2020, 10, 2482. [Google Scholar] [CrossRef]

- Qian, Y.; Yang, Z.; Hsiang, E.-L.; Yang, Q.; Nilsen, K.; Huang, Y.-H.; Lin, K.-H.; Wu, S.-T. Human Eye Contrast Sensitivity to Vehicle Displays under Strong Ambient Light. Crystals 2023, 13, 1384. [Google Scholar] [CrossRef]

- Hsiang, E.-L.; Yang, Z.; Yang, Q.; Lai, P.-C.; Lin, C.-L.; Wu, S.-T. AR/VR light engines: Perspectives and challenges. Adv. Opt. Photonics 2022, 14, 783–861. [Google Scholar] [CrossRef]

- Olivier, F.; Tirano, S.; Dupré, L.; Aventurier, B.; Largeron, C.; Templier, F. Influence of size-reduction on the performances of GaN-based micro-LEDs for display application. J. Lumin. 2017, 191, 112–116. [Google Scholar] [CrossRef]

- Boussadi, Y.; Rochat, N.; Barnes, J.-P.; Bakir, B.B.; Ferrandis, P.; Masenelli, B.; Licitra, C. Investigation of sidewall damage induced by reactive ion etching on AlGaInP MESA for micro-LED application. J. Lumin. 2021, 234, 117937. [Google Scholar] [CrossRef]

- Olivier, F.; Daami, A.; Licitra, C.; Templier, F. Shockley-Read-Hall and Auger non-radiative recombination in GaN based LEDs: A size effect study. Appl. Phys. Lett. 2017, 111, 022104. [Google Scholar] [CrossRef]

- Smith, J.M.; Ley, R.; Wong, M.S.; Baek, Y.H.; Kang, J.H.; Kim, C.H.; Gordon, M.J.; Nakamura, S.; Speck, J.S.; DenBaars, S.P. Comparison of size-dependent characteristics of blue and green InGaN microLEDs down to 1 μm in diameter. Appl. Phys. Lett. 2020, 116, 071102. [Google Scholar] [CrossRef]

- Ley, R.T.; Smith, J.M.; Wong, M.S.; Margalith, T.; Nakamura, S.; DenBaars, S.P.; Gordon, M.J. Revealing the importance of light extraction efficiency in InGaN/GaN microLEDs via chemical treatment and dielectric passivation. Appl. Phys. Lett. 2020, 116, 251104. [Google Scholar] [CrossRef]

- Yu, J.; Tao, T.; Liu, B.; Xu, F.; Zheng, Y.; Wang, X.; Sang, Y.; Yan, Y.; Xie, Z.; Liang, S. Investigations of sidewall passivation technology on the optical performance for smaller size GaN-based micro-LEDs. Crystals 2021, 11, 403. [Google Scholar] [CrossRef]

- Wong, M.S.; Kearns, J.A.; Lee, C.; Smith, J.M.; Lynsky, C.; Lheureux, G.; Choi, H.; Kim, J.; Kim, C.; Nakamura, S. Improved performance of AlGaInP red micro-light-emitting diodes with sidewall treatments. Opt. Express 2020, 28, 5787–5793. [Google Scholar] [CrossRef]

- Wong, M.S.; Lee, C.; Myers, D.J.; Hwang, D.; Kearns, J.A.; Li, T.; Speck, J.S.; Nakamura, S.; DenBaars, S.P. Size-independent peak efficiency of III-nitride micro-light-emitting-diodes using chemical treatment and sidewall passivation. Appl. Phys. Express 2019, 12, 097004. [Google Scholar] [CrossRef]

- Pandey, A.; Reddeppa, M.; Mi, Z. Recent progress on micro-LEDs. Light Adv. Manu. 2024, 4, 519–542. [Google Scholar] [CrossRef]

- Gilet, P.; Robin, I.-C. 52-1: Invited Paper: Nanostructures on Silicon to Solve the Active Display Paradigms. In SID Symposium Digest of Technical Papers; Wiley: Hoboken, NJ, USA, 2018; pp. 684–687. [Google Scholar]

- Pandey, A.; Xiao, Y.; Reddeppa, M.; Malhotra, Y.; Liu, J.; Min, J.; Wu, Y.; Mi, Z. A red-emitting micrometer scale LED with external quantum efficiency> 8%. Appl. Phys. Lett. 2023, 122, 151103. [Google Scholar] [CrossRef]

- Behrman, K.; Kymissis, I. Enhanced microLED efficiency via strategic pGaN contact geometries. Opt. Express 2021, 29, 14841–14852. [Google Scholar] [CrossRef] [PubMed]

- Qian, Y.; Yang, Z.; Huang, Y.-H.; Lin, K.-H.; Wu, S.-T. Directional high-efficiency nanowire LEDs with reduced angular color shift for AR and VR displays. Opto-Electron. Sci. 2022, 1, 220021. [Google Scholar] [CrossRef]

- Hsiang, E.-L.; He, Z.; Yang, Z.; Lan, Y.-F.; Wu, S.-T. Tailoring the light distribution of micro-LED displays with a compact compound parabolic concentrator and an engineered diffusor. Opt. Express 2021, 29, 39859–39873. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, K.; Luo, X.; Liu, S. Precise optical modeling of blue light-emitting diodes by Monte Carlo ray-tracing. Opt. Express 2010, 18, 9398–9412. [Google Scholar] [CrossRef]

- Konig, T.A.; Ledin, P.A.; Kerszulis, J.; Mahmoud, M.A.; El-Sayed, M.A.; Reynolds, J.R.; Tsukruk, V.V. Electrically tunable plasmonic behavior of nanocube–polymer nanomaterials induced by a redox-active electrochromic polymer. ACS Nano 2014, 8, 6182–6192. [Google Scholar] [CrossRef] [PubMed]

- Ryu, H.; Jeon, K.; Kang, M.; Yuh, H.; Choi, Y.; Lee, J. A comparative study of efficiency droop and internal electric field for InGaN blue lighting-emitting diodes on silicon and sapphire substrates. Sci. Rep. 2017, 7, 44814. [Google Scholar] [CrossRef] [PubMed]

- Maier, S.A. Plasmonics: Fundamentals and Applications; Springer: Berlin/Heidelberg, Germany, 2007. [Google Scholar]

- Pitarke, J.; Silkin, V.; Chulkov, E.; Echenique, P. Theory of surface plasmons and surface-plasmon polaritons. Rep. Prog. Phys. 2006, 70, 1–87. [Google Scholar] [CrossRef]

- Wang, L.; Sun, J.; Yan, Q.; Lin, J.; Guo, W.; Chen, E.; Xu, C.; Liu, Y. Issue of spatial coherence in MQW based micro-LED simulation. Opt. Express 2021, 29, 31520–31526. [Google Scholar] [CrossRef]

- Gou, F.; Hsiang, E.-L.; Tan, G.; Chou, P.-T.; Li, Y.-H.; Lan, Y.-F.; Wu, S.-T. Angular color shift of micro-LED displays. Opt. Express 2019, 12, A746–A757. [Google Scholar] [CrossRef] [PubMed]

- Hsu, Y.-H.; Lin, Y.-H.; Wu, M.-H.; Kuo, H.C.; Horng, R.-H. Current Confinement Effect on the Performance of Blue Light Micro-LEDs with 10 μm Dimension. ACS Omega 2023, 8, 35351–35358. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.; Ren, K.; Zhang, X.; An, Y.; Yin, L.; Lu, X.; Guo, A.; Zhang, J. Physical mechanisms on the size-effect in GaN-based Micro-LEDs. Micro Nanostruct. 2023, 177, 207542. [Google Scholar] [CrossRef]

- Hang, S.; Zhang, G.; Chu, C.; Zhang, Y.; Zheng, Q.; Li, Q.; Zhang, Z.-H. On the impact of the beveled mesa for GaN-based micro-light emitting diodes: Electrical and optical properties. Opt. Express 2022, 30, 37675–37685. [Google Scholar] [CrossRef]

- Finot, S.; Le Maoult, C.; Gheeraert, E.; Vaufrey, D.; Jacopin, G. Surface recombinations in III-nitride micro-LEDs probed by photon-correlation cathodoluminescence. ACS Photonics 2021, 9, 173–178. [Google Scholar] [CrossRef]

| Material | Thickness | Doping |

|---|---|---|

| Au | 100 nm | N/A |

| pGaN | 120 nm | 1 × 1020/cm3 |

| pAlGaN | 50 nm | 1 × 1020/cm3 |

| InGaN | 3 nm | N/A |

| nGaN | 2.83 μm | 1 × 1020/cm3 |

| ITO | 100 nm | N/A |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qian, Y.; Hsiang, E.-L.; Huang, Y.-H.; Lin, K.-H.; Wu, S.-T. High-Efficiency Vertical-Chip Micro-Light-Emitting Diodes via p-GaN Optimization and Surface Passivation. Crystals 2024, 14, 503. https://doi.org/10.3390/cryst14060503

Qian Y, Hsiang E-L, Huang Y-H, Lin K-H, Wu S-T. High-Efficiency Vertical-Chip Micro-Light-Emitting Diodes via p-GaN Optimization and Surface Passivation. Crystals. 2024; 14(6):503. https://doi.org/10.3390/cryst14060503

Chicago/Turabian StyleQian, Yizhou, En-Lin Hsiang, Yu-Hsin Huang, Kuan-Heng Lin, and Shin-Tson Wu. 2024. "High-Efficiency Vertical-Chip Micro-Light-Emitting Diodes via p-GaN Optimization and Surface Passivation" Crystals 14, no. 6: 503. https://doi.org/10.3390/cryst14060503