Multifunctional Experimental Studies of Sm-Ion-Influenced Pseudo-Cubic Morphotropic Phase Boundary Regional BiFeO3-xSrTiO3 Ceramics for High-Temperature Applications

Abstract

:1. Introduction

2. Fabrication and Characterization

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Cao, J.; Ji, Y.; Shao, Z. Perovskites for protonic ceramic fuel cells: A review. Energy Environ. Sci. 2022, 15, 2200–2232. [Google Scholar] [CrossRef]

- Hussain, A.; Jabeen, N.; Rahman, A.U.; Qaiser, M.A.; Tariq, Z.; Abd El-Gawad, H.H. Experimental and theoretical study of Gd2O3 added pseudo-tetragonal Bi3TaTiO9-based ceramics for ferroelectric, electric and high-temperature piezoelectric applications. Ceram. Int. 2024, 50, 18177–18184. [Google Scholar] [CrossRef]

- Assirey, E.A.R. Perovskite synthesis, properties and their related biochemical and industrial application. Saudi Pharm. J. 2019, 27, 817–829. [Google Scholar] [CrossRef] [PubMed]

- Goel, P.; Sundriyal, S.; Shrivastav, V.; Mishra, S.; Dubal, D.P.; Kim, K.H.; Deep, A. Perovskite materials as su-perior and powerful platforms for energy conversion and storage applications. Nano Energy 2021, 80, 105552. [Google Scholar] [CrossRef]

- Chen, L.; Liu, H.; Qi, H.; Chen, J. High-electromechanical performance for high-power piezoelectric applications: Fundamental, progress, and perspective. Prog. Mater. Sci. 2022, 127, 100944. [Google Scholar] [CrossRef]

- Meng, Y.; Chen, G.; Huang, M. Piezoelectric materials: Properties, advancements, and design strategies for high-temperature applications. Nanomaterials 2022, 12, 1171. [Google Scholar] [CrossRef] [PubMed]

- Lv, X.; Wang, X.; Ma, Y.; Zhang, X.X.; Wu, J. Temperature stability of perovskite-structured lead-free piezoceramics: Evaluation methods, improvement strategies, and future perspectives. Mater. Sci. Eng. R Rep. 2024, 159, 100793. [Google Scholar] [CrossRef]

- Chen, K.-H.; Cheng, C.-M.; Chen, Y.-J.; Chen, M.-L. Lead-Free Piezoelectric Ceramic Micro-Pressure Thick Films. Crystals 2023, 13, 201. [Google Scholar] [CrossRef]

- Bell, A.J.; Deubzer, O. Lead-free piezoelectrics—The environmental and regulatory issues. MRS Bull. 2018, 43, 581–587. [Google Scholar] [CrossRef]

- Catalan, G.; Scott, J.F. Physics and applications of bismuth ferrite. Adv. Mater. 2009, 21, 2463–2485. [Google Scholar] [CrossRef]

- Lv, J.; Wu, J.; Wu, W. Enhanced Electrical Properties of Quenched (1 − x)Bi1−ySmyFeO3–xBiScO3 Lead-Free Ceramics. J. Phys. Chem. C 2015, 119, 21105–21115. [Google Scholar]

- Narayan, B.; Adhikari, S.; Madras, G.; Ranjan, R. Trapping a metastable ferroelectric phase by size reduction in semiconducting ferroelectric BiFeO3−PbTiO3 and its implications for photocatalytic response. Phys. Rev. Appl. 2017, 7, 024018. [Google Scholar] [CrossRef]

- Wang, D.; Wang, G.; Murakami, S.; Fan, Z.; Feteira, A.; Zhou, D.; Sun, S.; Zhao, Q.; Reaney, I.M. BiFeO3-BaTiO3: A new gen-eration of lead-free electroceramics. J. Adv. Dielectr. 2018, 8, 1830004. [Google Scholar] [CrossRef]

- Zheng, L.; Niu, Z.; Zheng, P.; Zhang, K.; Luo, C.; Zhang, J.; Wang, N.; Bai, W.; Zhang, Y. Simultaneously achieving high energy storage performance and remarkable thermal stability in Bi0.5K0.5TiO3-based ceramics. Mater. Today Energy 2022, 28, 101078. [Google Scholar] [CrossRef]

- Cheng, S.; Zhang, B.P.; Zhao, L.; Wang, K.K. Enhanced insulating and piezoelectric properties of BiFeO3-BaTiO3-Bi0.5Na0.5TiO3 ceramics with high Curie temperature. J. Am. Ceram. Soc. 2019, 102, 7355–7365. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, H.; Yan, T.; Zhao, J.; Guo, S.; Sun, R.; Lu, Z.; Wang, D. Microstructure and electrical properties of Nb-doped SrTiO3-BiFeO3 based lead-free ceramics. J. Am. Ceram. Soc. 2022, 105, 2020–2028. [Google Scholar] [CrossRef]

- Saad, Y.; Álvarez-Serrano, I.; López, M.; Hidouri, M. Structural and dielectric characterization of new lead-free perovskites in the (SrTiO3)–(BiFeO3) system. Ceram. Int. 2016, 42, 8962–8973. [Google Scholar] [CrossRef]

- Wang, Z.; Cao, M.; Yao, Z.; Zhang, Q.; Song, Z.; Hu, W.; Xu, Q.; Hao, H.; Liu, H.; Yu, Z. Giant permittivity and low dielectric loss of SrTiO3 ceramics sintered in nitrogen atmosphere. J. Eur. Ceram. Soc. 2014, 34, 1755–1760. [Google Scholar] [CrossRef]

- Haeni, J.H.; Irvin, P.; Chang, W.; Uecker, R.; Reiche, P.; Li, Y.L.; Choudhury, S.; Tian, W.; Hawley, M.E.; Craigo, B.; et al. Room-temperature ferroe-lectricity in strained SrTiO3. Nature 2004, 430, 758–761. [Google Scholar] [CrossRef]

- Makarovic, M.; Bencan, A.; Walker, J.; Malic, B.; Rojac, T. Processing, piezoelectric and ferroelectric properties of (x)BiFeO3-(1 − x)SrTiO3 ceramics. J. Eur. Ceram. Soc. 2019, 39, 3693–3702. [Google Scholar]

- Wang, S.; Liu, H.; Wang, Y.; Qin, H.; Zhao, J.; Lu, Z.; Mao, Z.; Wang, D. Microstructure, dielectric, and piezoelectric properties of BiFeO3–SrTiO3 lead-free ceramics. J. Am. Ceram. Soc. 2024, 107, 205–213. [Google Scholar] [CrossRef]

- Arman, M.M. The effect of the rare earth A-site cation on the structure, morphology, physical properties, and application of perovskite AFeO3. Mater. Chem. Phys. 2023, 304, 127852. [Google Scholar] [CrossRef]

- Zeng, Z.; Xu, Y.; Zhang, Z.; Gao, Z.; Luo, M.; Yin, Z.; Zhang, C.; Xu, J.; Huang, B.; Luo, F.; et al. Rare-earth-containing perovskite nanomaterials: Design, synthesis, properties and applications. Chem. Soc. Rev. 2020, 49, 1109–1143. [Google Scholar] [CrossRef]

- Jang, S.; Lim, H.; Wi, S.; Park, J.; Jeong, Y.; Chung, J.-S.; Kang, W.; Kwark, Y.-J.; Kim, I.W.; Noh, H.; et al. A-site and B-site substitutions and the emission properties of Eu3+ ions in ABO3–type cubic perovskite: A case study of BaZrO3. Curr. Appl. Phys. 2020, 20, 1110–1117. [Google Scholar] [CrossRef]

- Firdaus, M. Oxidation of Rare Earth Permanent Magnets. Ph.D. Thesis, Swinburne University of Technology Melbourne, Melbourne, Australia, 2018. [Google Scholar]

- Jabeen, N.; Hussain, A.; Nawaz, S.; Qaiser, M.A.; Zafar, R.; Ishtiaq, S.; Ahmed, F.; Masud, U.; Sultan, T.; Muntaha, S.T. Thermally stable piezoelectric performance of MnO2 inserted pseudo-tetragonal phase existent CaBi2Nb2O9-based ceramics. Mater. Technol. 2022, 37, 2702–2710. [Google Scholar] [CrossRef]

- Hussain, A.; Jabeen, N.; Hassan, N.U.; Rahman, A.U.; Khan, M.U.; Naz, A.; Yousef, E.S. Influence of Mn Ions’ Insertion in Pseudo-Tetragonal Phased CaBi4Ti4O15-Based Ceramics for Highly Efficient Energy Storage Devices and High-Temperature Piezoelectric Applications. Int. J. Mol. Sci. 2022, 23, 12723. [Google Scholar] [CrossRef] [PubMed]

- Heron, J.T.; Bosse, J.L.; He, Q.; Gao, Y.; Trassin, M.; Ye, L.; Clarkson, J.D.; Wang, C.; Liu, J.; Salahuddin, S.; et al. Deterministic switching of ferro-magnetism at room temperature using an electric field. Nature 2014, 516, 370–373. [Google Scholar] [CrossRef] [PubMed]

- Abedi, M.; Fangueiro, R.; Correia, A.G. Effects of electrodes layout and filler scale on percolation threshold and piezoresistivity performances of a cementitious-based geocomposite. Nanomaterials 2022, 12, 1734. [Google Scholar] [CrossRef]

- Hiruma, Y.; Aoyagi, R.; Nagata, H.; Takenaka, T. Ferroelectric and piezoelectric properties of (Bi1/2K1/2) TiO3 ceramics. Jpn. J. Appl. Phys. 2005, 44, 5040. [Google Scholar] [CrossRef]

- Liu, H.; Chen, J. Effect of Li2CO3 addition on structural and electrical properties of 0.7BiFeO3–0.3BaTiO3 piezo-electric ceramic. J. Adv. Dielectr. 2022, 12, 2241003. [Google Scholar] [CrossRef]

- Qin, H.; Zhao, J.; Chen, X.; Li, H.; Wang, S.; Du, Y.; Li, P.; Zhou, H.; Wang, D. Investigation of lead-free BiFeO3–BaTiO3 piezoelectric ceramics through precise composition control. J. Adv. Dielectr. 2023, 13, 2350018. [Google Scholar] [CrossRef]

- Li, S.; Wang, F.; Tang, L.; Tan, D.Q.; Chen, Y. Structures, dielectric properties and AC impedance characteristics of BiFeO3–BaTiO3 high-temperature lead-free piezoceramics synthesized by the hydrothermal method. J. Adv. Dielectr. 2023, 13, 2340006. [Google Scholar] [CrossRef]

- Cui, Y.; Li, C.; Lei, X.; Li, F.; Sun, H.; Wang, Z.; Wang, S.; Peng, B.; Wang, D.; Yan, F.; et al. Achieving high Curie temperature and prominent piezoelectric response via site engineering for BiFeO3-BaTiO3 ceramics. J. Alloys Compd. 2023, 943, 169137. [Google Scholar] [CrossRef]

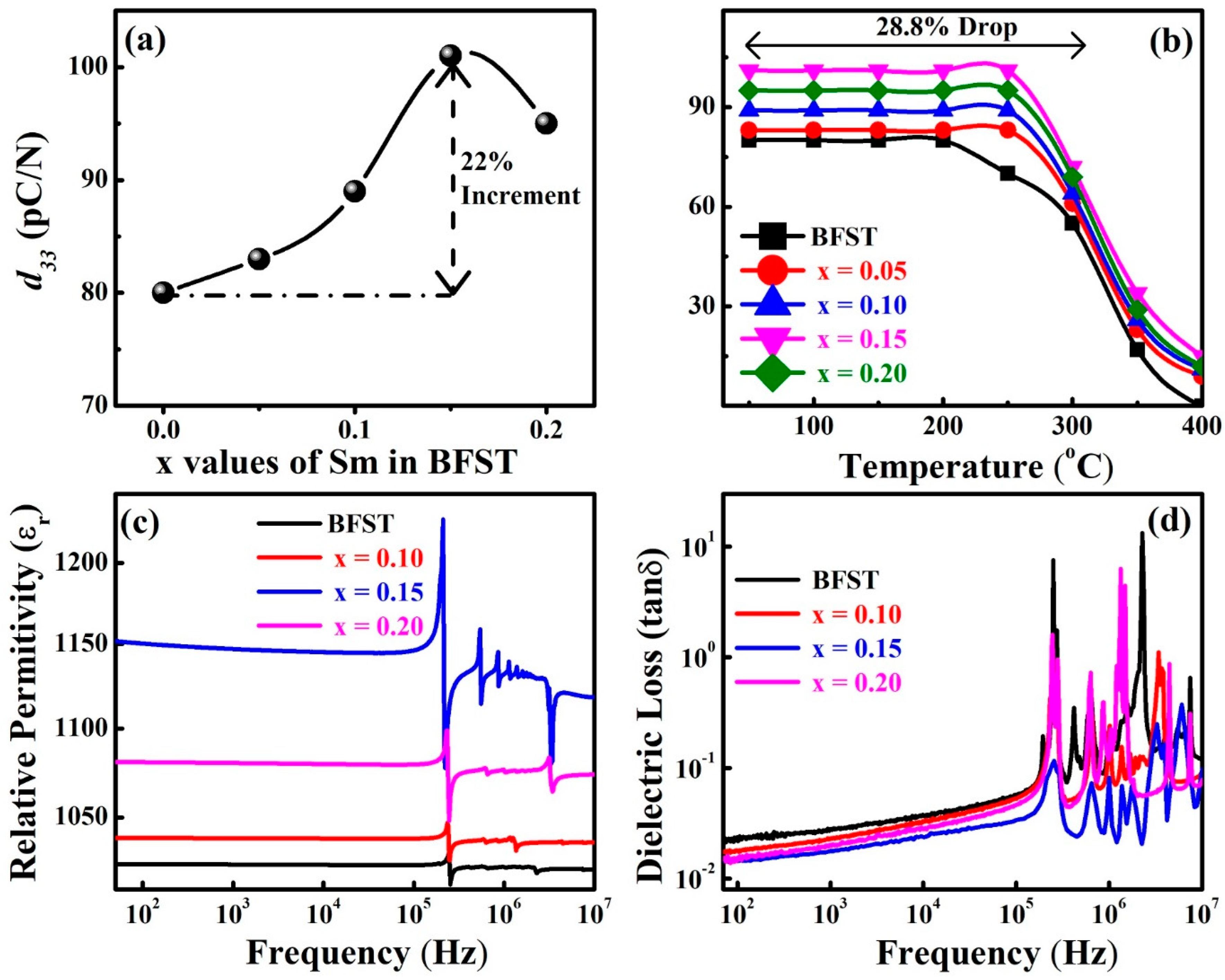

| Sr. No | Material | Fabrication Technique | Piezoelectric Coefficient d33 (pC/N) | Ref. |

|---|---|---|---|---|

| 1 | (1 − x)Bi1−ySmyFeO3–xBiScO3 | Rapid thermal quenching | 51 | [16] |

| 2 | 0.625BiFeO3–0.375SrTiO3 | Conventional solid-state synthesis | 69 | [20] |

| 3 | 0.62BiFeO3–0.38SrTiO3 | Conventional solid-state synthesis | 72 | [21] |

| 4 | 0.66BiFeO3–0.34BaTiO3 | Conventional solid-state synthesis | 217 | [32] |

| 5 | K+ and Nb5+ co-doped (0.75 − x)BiFeO3–0.25BaTiO3 | Conventional solid-state synthesis | 163 | [34] |

| 6 | 0.62BiFeO3–0.38SrTiO3:0.15wt%Sm2O3 | Conventional solid-state synthesis | 101 | This work |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, A.; Jabeen, N.; Tabassum, A.; Khan, M.U.; Basharat, L.; El Azab, I.H. Multifunctional Experimental Studies of Sm-Ion-Influenced Pseudo-Cubic Morphotropic Phase Boundary Regional BiFeO3-xSrTiO3 Ceramics for High-Temperature Applications. Crystals 2024, 14, 540. https://doi.org/10.3390/cryst14060540

Hussain A, Jabeen N, Tabassum A, Khan MU, Basharat L, El Azab IH. Multifunctional Experimental Studies of Sm-Ion-Influenced Pseudo-Cubic Morphotropic Phase Boundary Regional BiFeO3-xSrTiO3 Ceramics for High-Temperature Applications. Crystals. 2024; 14(6):540. https://doi.org/10.3390/cryst14060540

Chicago/Turabian StyleHussain, Ahmad, Nawishta Jabeen, Aasma Tabassum, Muhammad Usman Khan, Laiba Basharat, and Islam H. El Azab. 2024. "Multifunctional Experimental Studies of Sm-Ion-Influenced Pseudo-Cubic Morphotropic Phase Boundary Regional BiFeO3-xSrTiO3 Ceramics for High-Temperature Applications" Crystals 14, no. 6: 540. https://doi.org/10.3390/cryst14060540