Critical Aluminum Etch Material Amount for Local Droplet-Etched Nanohole-Based GaAs Quantum Dots

Abstract

1. Introduction

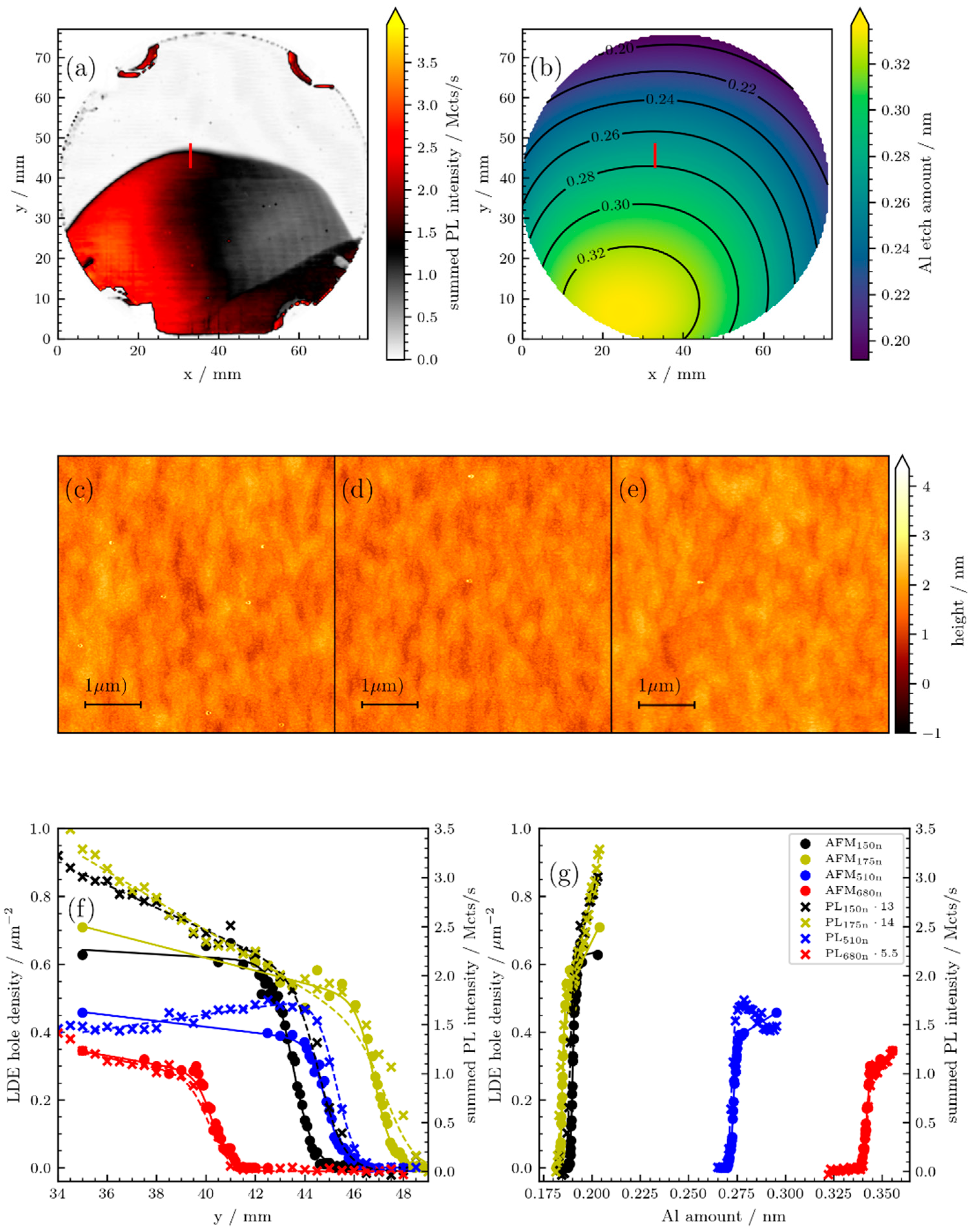

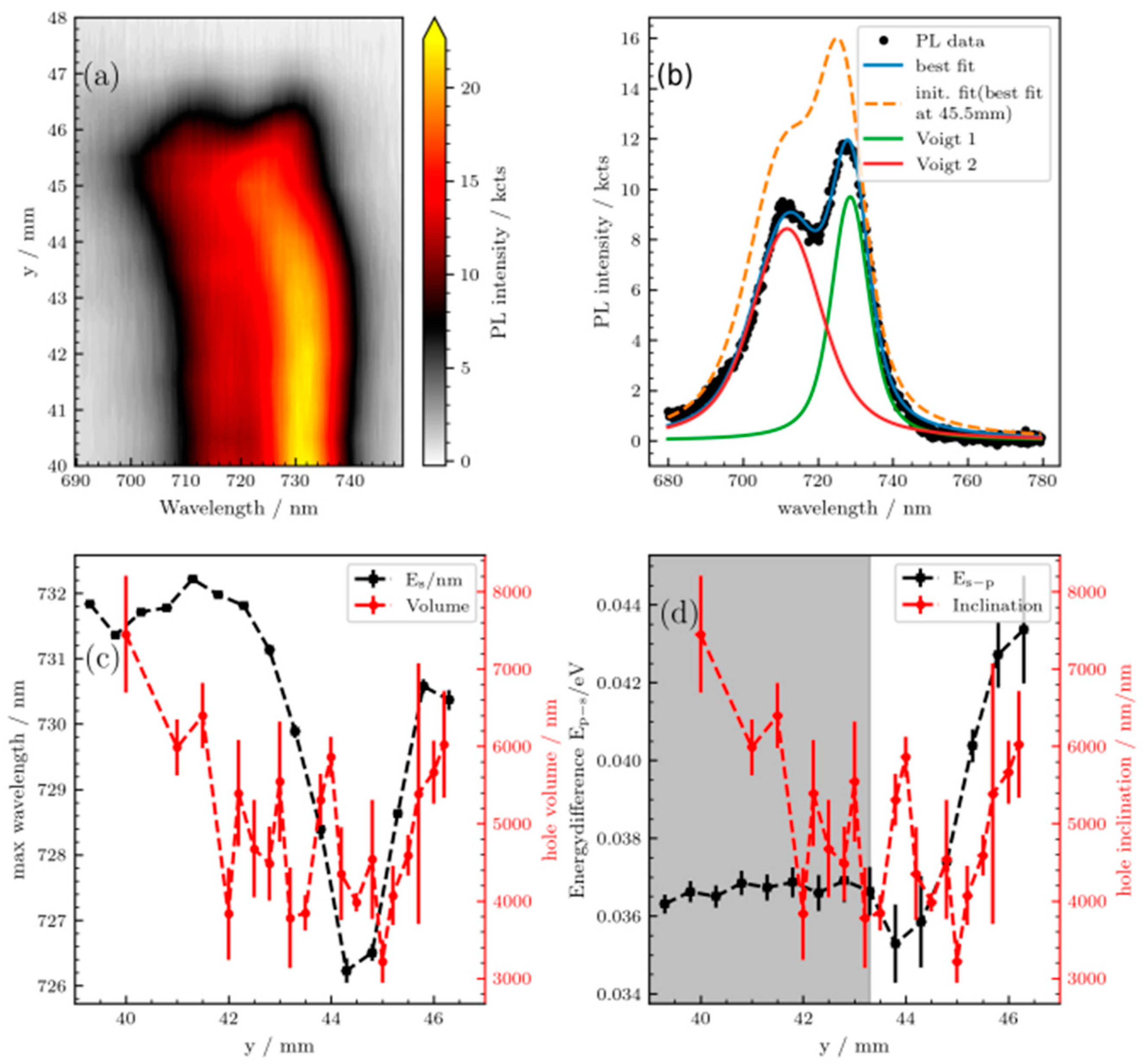

2. Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Senellart, P.; Solomon, G.; White, A. High-performance semiconductor quantum-dot single-photon sources. Nat. Nanotechnol. 2017, 12, 1026–1039. [Google Scholar] [CrossRef]

- Zhai, L.; Löbl, M.C.; Nguyen, G.N.; Ritzmann, J.; Javadi, A.; Spinnler, C.; Wieck, A.D.; Ludwig, A.; Warburton, R.J. Low-noise GaAs quantum dots for quantum photonics. Nat. Commun. 2020, 11, 4745. [Google Scholar] [CrossRef] [PubMed]

- Tomm, N.; Javadi, A.; Antoniadis, N.O.; Najer, D.; Löbl, M.C.; Korsch, A.R.; Schott, R.; Valentin, S.R.; Wieck, A.D.; Ludwig, A.; et al. A bright and fast source of coherent single photons. Nat. Nanotechnol. 2021, 16, 399–403. [Google Scholar] [CrossRef]

- Kuhlmann, A.V.; Houel, J.; Ludwig, A.; Greuter, L.; Reuter, D.; Wieck, A.D.; Poggio, M.; Warburton, R.J. Charge noise and spin noise in a semiconductor quantum device. Nat. Phys. 2013, 9, 570–575. [Google Scholar] [CrossRef]

- Leonard, D.; Krishnamurthy, M.; Reaves, C.M.; Denbaars, S.P.; Petroff, P.M. Direct formation of quantum-sized dots from uniform coherent islands of InGaAs on GaAs surfaces. Appl. Phys. Lett. 1993, 63, 3203–3205. [Google Scholar] [CrossRef]

- Heyn, C.; Stemmann, A.; Schramm, A.; Welsch, H.; Hansen, W.; Nemcsics, Á. Faceting during GaAs quantum dot self-assembly by droplet epitaxy. Appl. Phys. Lett. 2007, 90, 203105. [Google Scholar] [CrossRef]

- Gurioli, M.; Wang, Z.; Rastelli, A.; Kuroda, T.; Sanguinetti, S. Droplet epitaxy of semiconductor nanostructures for quantum photonic devices. Nat. Mater. 2019, 18, 799–810. [Google Scholar] [CrossRef]

- Babin, H.-G.; Bart, N.; Schmidt, M.; Spitzer, N.; Wieck, A.D.; Ludwig, A. Full wafer property control of local droplet etched GaAs quantum dots. J. Cryst. Growth 2022, 591, 126713. [Google Scholar] [CrossRef]

- Atkinson, P.; Zallo, E.; Schmidt, O.G. Independent wavelength and density control of uniform GaAs/AlGaAs quantum dots grown by infilling self-assembled nanoholes. J. Appl. Phys. 2012, 112, 054303. [Google Scholar] [CrossRef]

- Wolters, J.; Buser, G.; Horsley, A.; Béguin, L.; Jöckel, A.; Jahn, J.-P.; Warburton, R.J.; Treutlein, P. Simple Atomic Quantum Memory Suitable for Semiconductor Quantum Dot Single Photons. Phys. Rev. Lett. 2017, 119, 60502. [Google Scholar] [CrossRef] [PubMed]

- Keil, R.; Zopf, M.; Chen, Y.; Höfer, B.; Zhang, J.; Ding, F.; Schmidt, O.G. Solid-state ensemble of highly entangled photon sources at rubidium atomic transitions. Nat. Commun. 2017, 8, 15501. [Google Scholar] [CrossRef] [PubMed]

- Sukachev, D.D.; Sipahigil, A.; Nguyen, C.T.; Bhaskar, M.K.; Evans, R.E.; Jelezko, F.; Lukin, M.D. Silicon-Vacancy Spin Qubit in Diamond: A Quantum Memory Exceeding 10 ms with Single-Shot State Readout. Phys. Rev. Lett. 2017, 119, 223602. [Google Scholar] [CrossRef]

- Heyn, C.; Stemmann, A.; Köppen, T.; Strelow, C.; Kipp, T.; Grave, M.; Mendach, S.; Hansen, W. Highly uniform and strain-free GaAs quantum dots fabricated by filling of self-assembled nanoholes. Appl. Phys. Lett. 2009, 94, 183113. [Google Scholar] [CrossRef]

- Nguyen, G.N.; Spinnler, C.; Hogg, M.R.; Zhai, L.; Javadi, A.; Schrader, C.A.; Erbe, M.; Wyss, M.; Ritzmann, J.; Babin, H.-G.; et al. Enhanced Electron-Spin Coherence in a GaAs Quantum Emitter. Phys. Rev. Lett. 2023, 131, 210805. [Google Scholar] [CrossRef] [PubMed]

- Zaporski, L.; Shofer, N.; Bodey, J.H.; Manna, S.; Gillard, G.; Appel, M.H.; Schimpf, C.; Da Covre Silva, S.F.; Jarman, J.; Delamare, G.; et al. Ideal refocusing of an optically active spin qubit under strong hyperfine interactions. Nat. Nanotechnol. 2023, 18, 257–263. [Google Scholar] [CrossRef] [PubMed]

- Millington-Hotze, P.; Dyte, H.E.; Manna, S.; Da Covre Silva, S.F.; Rastelli, A.; Chekhovich, E.A. Approaching a fully-polarized state of nuclear spins in a solid. Nat. Commun. 2024, 15, 985. [Google Scholar] [CrossRef] [PubMed]

- Gillard, G.; Clarke, E.; Chekhovich, E.A. Harnessing many-body spin environment for long coherence storage and high-fidelity single-shot qubit readout. Nat. Commun. 2022, 13, 4048. [Google Scholar] [CrossRef] [PubMed]

- Chekhovich, E.A.; da Silva, S.F.C.; Rastelli, A. Nuclear spin quantum register in an optically active semiconductor quantum dot. Nat. Nanotechnol. 2020, 15, 999–1004. [Google Scholar] [CrossRef] [PubMed]

- Heyn, C.; Gräfenstein, A.; Pirard, G.; Ranasinghe, L.; Deneke, K.; Alshaikh, A.; Bester, G.; Hansen, W. Dot-Size Dependent Excitons in Droplet-Etched Cone-Shell GaAs Quantum Dots. Nanomaterials 2022, 12, 2981. [Google Scholar] [CrossRef]

- Huber, D.; Reindl, M.; Huo, Y.; Huang, H.; Wildmann, J.S.; Schmidt, O.G.; Rastelli, A.; Trotta, R. Highly indistinguishable and strongly entangled photons from symmetric GaAs quantum dots. Nat. Commun. 2017, 8, 15506. [Google Scholar] [CrossRef]

- Zhai, L.; Nguyen, G.N.; Spinnler, C.; Ritzmann, J.; Löbl, M.C.; Wieck, A.D.; Ludwig, A.; Javadi, A.; Warburton, R.J. Quantum interference of identical photons from remote GaAs quantum dots. Nat. Nanotechnol. 2022, 17, 829–833. [Google Scholar] [CrossRef]

- Kerbst, J.; Heyn, C.; Slobodskyy, T.; Hansen, W. Density limits of high temperature and multiple local droplet etching on AlAs. J. Cryst. Growth 2014, 389, 18–22. [Google Scholar] [CrossRef]

- Heyn, C.; Feddersen, S. Modeling of Al and Ga Droplet Nucleation during Droplet Epitaxy or Droplet Etching. Nanomaterials 2021, 11, 468. [Google Scholar] [CrossRef]

- Langbein, W.; Borri, P.; Woggon, U.; Stavarache, V.; Reuter, D.; Wieck, A. Radiatively limited dephasing in InAs quantum dots. Phys. Rev. B 2004, 70, 033301. [Google Scholar] [CrossRef]

- Strobel, T.; Weber, J.H.; Schmidt, M.; Wagner, L.; Engel, L.; Jetter, M.; Wieck, A.D.; Portalupi, S.L.; Ludwig, A.; Michler, P. A Unipolar Quantum Dot Diode Structure for Advanced Quantum Light Sources. Nano Lett. 2023, 23, 6574–6580. [Google Scholar] [CrossRef] [PubMed]

- Löbl, M.C.; Spinnler, C.; Javadi, A.; Zhai, L.; Nguyen, G.N.; Ritzmann, J.; Midolo, L.; Lodahl, P.; Wieck, A.D.; Ludwig, A.; et al. Radiative Auger process in the single-photon limit. Nat. Nanotechnol. 2020, 15, 558–562. [Google Scholar] [CrossRef] [PubMed]

- Kurzmann, A.; Ludwig, A.; Wieck, A.D.; Lorke, A.; Geller, M. Auger Recombination in Self-Assembled Quantum Dots: Quenching and Broadening of the Charged Exciton Transition. Nano Lett. 2016, 16, 3367–3372. [Google Scholar] [CrossRef]

- Ageev, O.A.; Solodovnik, M.S.; Balakirev, S.V.; Mikhaylin, I.A. Monte Carlo simulation of V/III flux ratio influence on GaAs island nucleation during MBE. J. Phys. Conf. Ser. 2016, 681, 012036. [Google Scholar] [CrossRef]

- Fuster, D.; González, Y.; González, L. Fundamental role of arsenic flux in nanohole formation by Ga droplet etching on GaAs(001). Nanoscale Res. Lett. 2014, 9, 309. [Google Scholar] [CrossRef][Green Version]

- Heyn, C.; Bartsch, T.; Sanguinetti, S.; Jesson, D.; Hansen, W. Dynamics of mass transport during nanohole drilling by local droplet etching. Nanoscale Res. Lett. 2015, 10, 67. [Google Scholar] [CrossRef]

- Heyn, C.; Schnüll, S.; Hansen, W. Scaling of the structural characteristics of nanoholes created by local droplet etching. J. Appl. Phys. 2014, 115, 024309. [Google Scholar] [CrossRef]

- Balakirev, S.V.; Chernenko, N.E.; Eremenko, M.M.; Ageev, O.A.; Solodovnik, M.S. Independent Control Over Size and Surface Density of Droplet Epitaxial Nanostructures Using Ultra-Low Arsenic Fluxes. Nanomaterials 2021, 11, 1184. [Google Scholar] [CrossRef]

- Heyn, C.; Stemmann, A.; Eiselt, R.; Hansen, W. Influence of Ga coverage and AS pressure on local droplet etching of nanoholes and quantum rings. J. Appl. Phys. 2009, 105, 054316. [Google Scholar] [CrossRef]

- Bart, N.; Dangel, C.; Zajac, P.; Spitzer, N.; Ritzmann, J.; Schmidt, M.; Babin, H.G.; Schott, R.; Valentin, S.R.; Scholz, S.; et al. Wafer-scale epitaxial modulation of quantum dot density. Nat. Commun. 2022, 13, 1633. [Google Scholar] [CrossRef]

- Schmidt, M. Optische Untersuchung Ganzer 3 Zoll Wafer zur Optimierung Von III-V Halbleiter-Quantenpunkten Hergestellt Mittels Molekularstrahlepitaxie. Ph.D. Thesis, Ruhr-Universität Bochum, Bochum, Germany, 2022. [Google Scholar]

- Ranasinghe, L.; Heyn, C.; Deneke, K.; Zocher, M.; Korneev, R.; Hansen, W. Luminescence from Droplet-Etched GaAs Quantum Dots at and Close to Room Temperature. Nanomaterials 2021, 11, 690. [Google Scholar] [CrossRef]

- Zhou, X.L.; Chen, Y.H.; Ye, X.L.; Xu, B.; Wang, Z.G. Abnormal temperature dependent photoluminescence of excited states of InAs/GaAs quantum dots: Carrier exchange between excited states and ground states. J. Appl. Phys. 2011, 109, 113540. [Google Scholar] [CrossRef]

- Bacher, G.; Schweizer, H.; Kovac, J.; Forchel, A.; Nickel, H.; Schlapp, W.; Lösch, R. Influence of barrier height on carrier dynamics in strained InxGa1-xAs/GaAs quantum wells. Phys. Rev. B Condens. Mater. 1991, 43, 9312–9315. [Google Scholar] [CrossRef]

- Yin, H.; Li, G.; Jiang, C. Temperature effect of activation energy for GaSb quantum dots using variable temperature photoluminescence. J. Nanosci. Nanotechnol. 2013, 13, 1022–1025. [Google Scholar] [CrossRef]

- Heyn, C.; Zocher, M.; Schnüll, S.; Hansen, W. Role of Arsenic During Aluminum Droplet Etching of Nanoholes in AlGaAs. Nanoscale Res. Lett. 2016, 11, 428. [Google Scholar] [CrossRef]

- Wang, Y.; Jiang, C.; Huang, Y.; Ding, Z.; Luo, Z.; Wang, J.; Guo, X. Mechanism of Aluminum Droplet Nucleation and Ripening on GaAs(001) Surface by Molecular Beam Epitaxy. J. Electron. Mater. 2023, 52, 463–470. [Google Scholar] [CrossRef]

- Zocher, M.; Heyn, C.; Hansen, W. Alloying during local droplet etching of AlGaAs surfaces with aluminium. J. Appl. Phys. 2019, 125, 025306. [Google Scholar] [CrossRef]

- Reyes, K.; Smereka, P.; Nothern, D.; Millunchick, J.M.; Bietti, S.; Somaschini, C.; Sanguinetti, S.; Frigeri, C. Unified model of droplet epitaxy for compound semiconductor nanostructures: Experiments and theory. Phys. Rev. B 2013, 87, 165406. [Google Scholar] [CrossRef]

- Patella, F.; Arciprete, F.; Fanfoni, M.; Sessi, V.; Balzarotti, A.; Placidi, E. Reflection high energy electron diffraction observation of surface mass transport at the two- to three-dimensional growth transition of InAs on GaAs(001). Appl. Phys. Lett. 2005, 87, 252101. [Google Scholar] [CrossRef]

- Lysenko, O.V.; Stepanyuk, V.S.; Hergert, W.; Kirschner, J. Interlayer mass transport in homoepitaxy on the atomic scale. Phys. Rev. B 2003, 68, 33409. [Google Scholar] [CrossRef]

- Chen, C.; Yan, J.-Y.; Babin, H.-G.; Wang, J.; Xu, X.; Lin, X.; Yu, Q.; Fang, W.; Liu, R.-Z.; Huo, Y.-H.; et al. Wavelength-tunable high-fidelity entangled photon sources enabled by dual Stark effects. Nat. Commun. 2024, 15, 5792. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.-Y.; Chen, C.; Zhang, X.-D.; Wang, Y.-T.; Babin, H.-G.; Wieck, A.D.; Ludwig, A.; Meng, Y.; Hu, X.; Duan, H.; et al. Coherent control of a high-orbital hole in a semiconductor quantum dot. Nat. Nanotechnol. 2023, 18, 1139–1146. [Google Scholar] [CrossRef] [PubMed]

- Yan, J.-Y.; Zhai, L.; Babin, H.-G.; Li, Y.; Pei, S.-H.; Cygorek, M.; Fang, W.; Gao, F.; Wieck, A.D.; Ludwig, A.; et al. Complete Quantum Control of Orbital Qubits by Phase-Controlled Stimulated Raman Transitions. arXiv 2024, arXiv:2403.15295. [Google Scholar] [CrossRef]

- Löbl, M.C.; Zhai, L.; Jahn, J.-P.; Ritzmann, J.; Huo, Y.; Wieck, A.D.; Schmidt, O.G.; Ludwig, A.; Rastelli, A.; Warburton, R.J. Correlations between optical properties and Voronoi-cell area of quantum dots. Phys. Rev. B 2019, 100, 155402. [Google Scholar] [CrossRef]

- Mulheran, P.A.; Blackman, J.A. Capture zones and scaling in homogeneous thin-film growth. Phys. Rev. B Condens. Mater. 1996, 53, 10261–10267. [Google Scholar] [CrossRef]

| Sample | Al Etch Amount/nm | ||

|---|---|---|---|

| 150n/15367 | 0.15 | 0.20 | 1.8 |

| 175n/15369 | 0.18 | 0.20 | 1.8 |

| 510n/15389 | 0.51 | 0.29 | 0.44 |

| 680n/15385 | 0.68 | 0.35 | 1.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kruck, T.; Babin, H.G.; Wieck, A.D.; Ludwig, A. Critical Aluminum Etch Material Amount for Local Droplet-Etched Nanohole-Based GaAs Quantum Dots. Crystals 2024, 14, 714. https://doi.org/10.3390/cryst14080714

Kruck T, Babin HG, Wieck AD, Ludwig A. Critical Aluminum Etch Material Amount for Local Droplet-Etched Nanohole-Based GaAs Quantum Dots. Crystals. 2024; 14(8):714. https://doi.org/10.3390/cryst14080714

Chicago/Turabian StyleKruck, Timo, Hans Georg Babin, Andreas D. Wieck, and Arne Ludwig. 2024. "Critical Aluminum Etch Material Amount for Local Droplet-Etched Nanohole-Based GaAs Quantum Dots" Crystals 14, no. 8: 714. https://doi.org/10.3390/cryst14080714

APA StyleKruck, T., Babin, H. G., Wieck, A. D., & Ludwig, A. (2024). Critical Aluminum Etch Material Amount for Local Droplet-Etched Nanohole-Based GaAs Quantum Dots. Crystals, 14(8), 714. https://doi.org/10.3390/cryst14080714