Synthesis of Samarium Nitride Thin Films on Magnesium Oxide (001) Substrates Using Molecular Beam Epitaxy

Abstract

1. Introduction

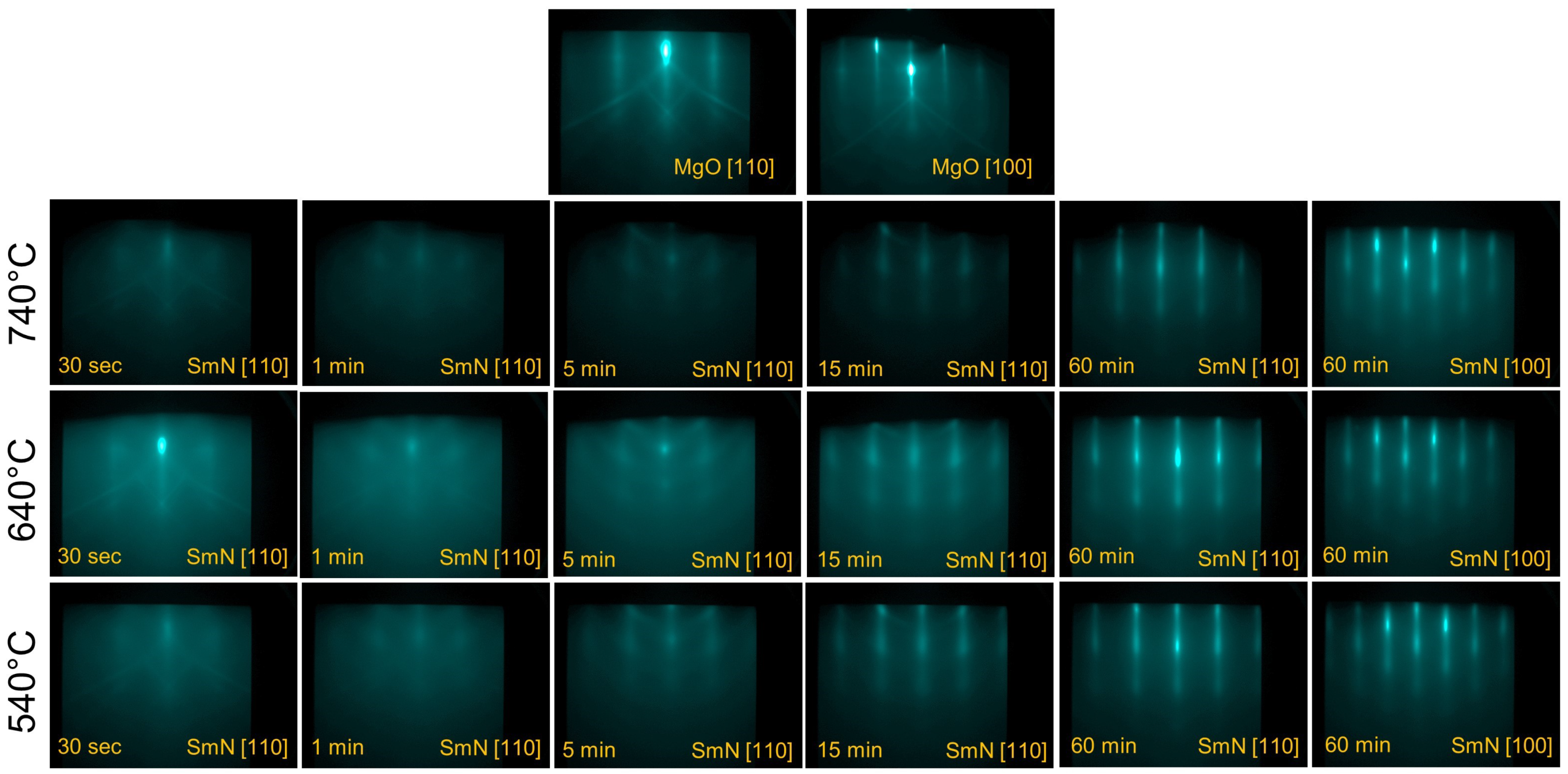

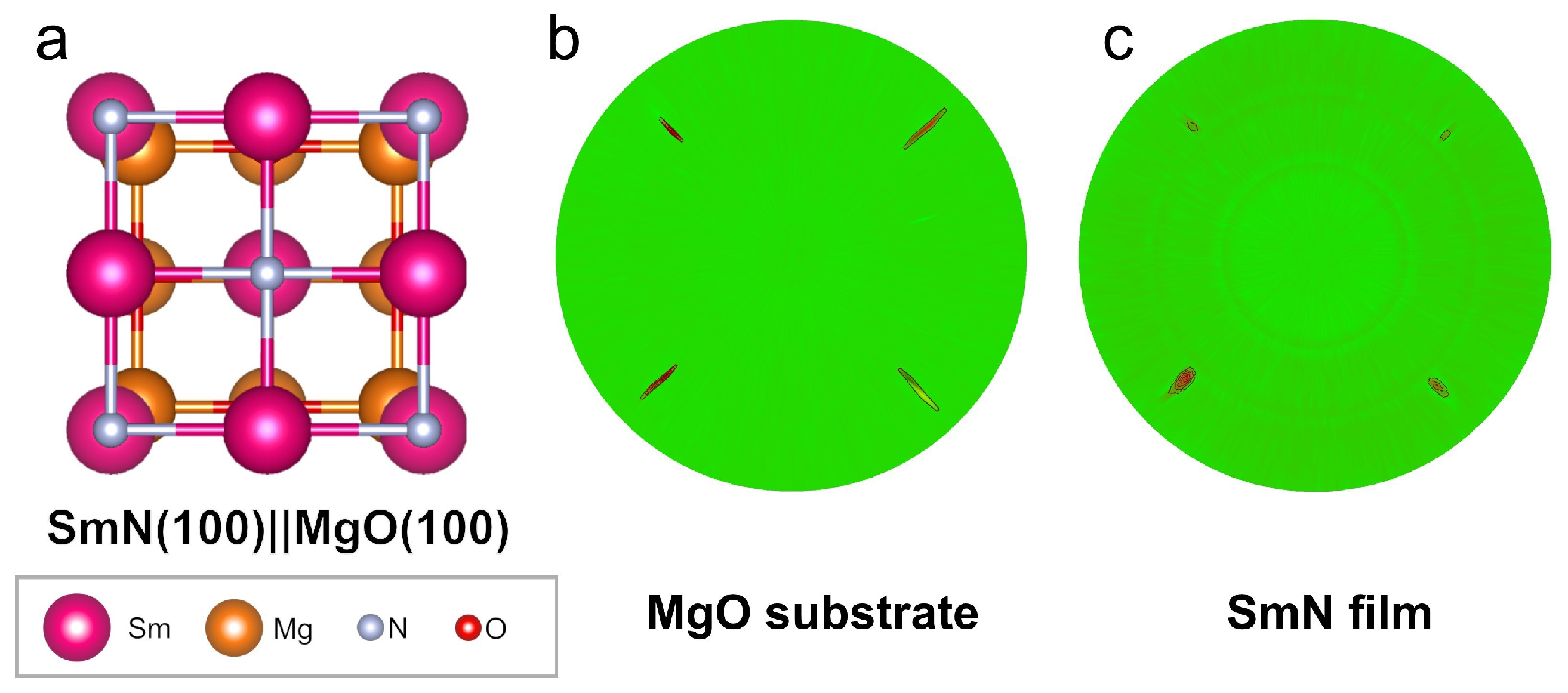

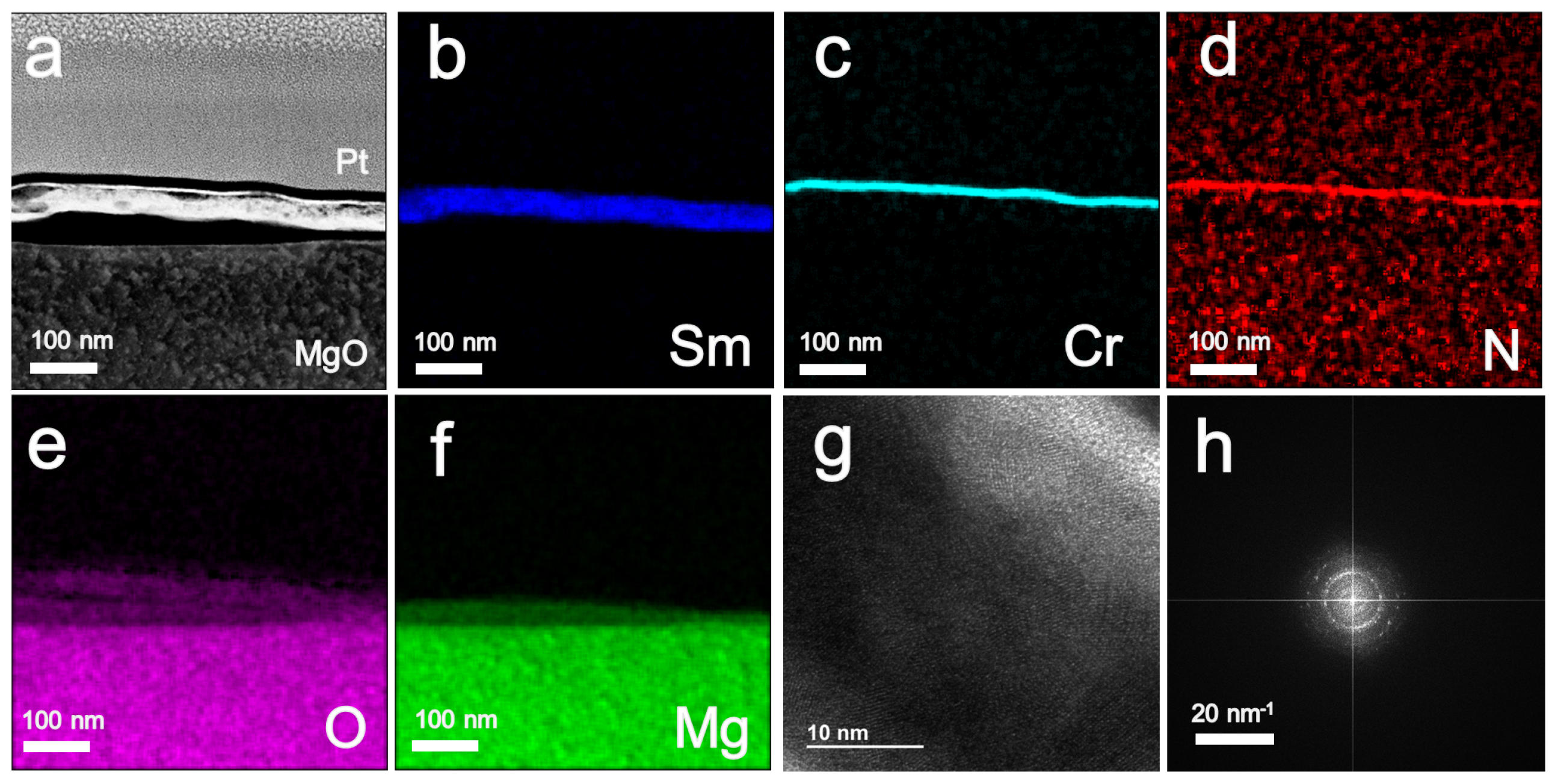

2. Materials and Methods

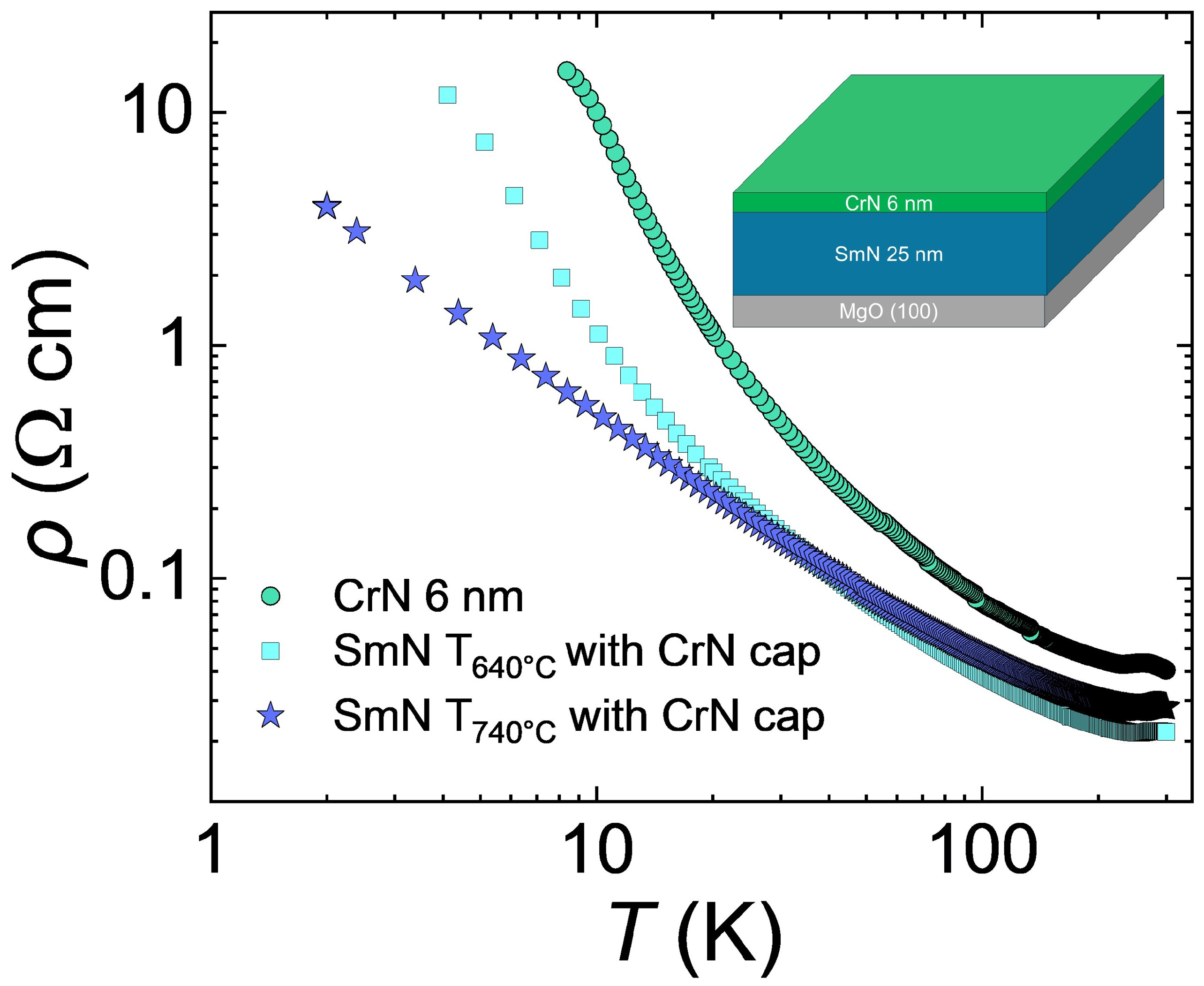

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Natali, F.; Ruck, B.J.; Plank, N.O.; Trodahl, H.J.; Granville, S.; Meyer, C.; Lambrecht, W.R. Rare-earth mononitrides. Prog. Mater. Sci. 2013, 58, 1316–1360. [Google Scholar] [CrossRef]

- Anton, E.M.; Granville, S.; Engel, A.; Chong, S.V.; Governale, M.; Zülicke, U.; Moghaddam, A.G.; Trodahl, H.J.; Natali, F.; Vézian, S.; et al. Superconductivity in the ferromagnetic semiconductor samarium nitride. Phys. Rev. B 2016, 94, 024106. [Google Scholar] [CrossRef]

- Moon, R.; Koehler, W. Magnetic properties of SmN. J. Magn. Magn. Mater. 1979, 14, 265–269. [Google Scholar] [CrossRef]

- Preston, A.; Granville, S.; Housden, D.; Ludbrook, B.; Ruck, B.; Trodahl, H.; Bittar, A.; Williams, G.; Downes, J.; DeMasi, A.; et al. Comparison between experiment and calculated band structures for DyN and SmN. Phys. Rev. B Condens. Matter Mater. Phys. 2007, 76, 245120. [Google Scholar] [CrossRef]

- Anton, E.M.; Ruck, B.J.; Meyer, C.; Natali, F.; Warring, H.; Wilhelm, F.; Rogalev, A.; Antonov, V.N.; Trodahl, H.J. Spin/orbit moment imbalance in the near-zero moment ferromagnetic semiconductor SmN. Phys. Rev. B Condens. Matter Mater. Phys. 2013, 87, 134414. [Google Scholar] [CrossRef]

- Holmes-Hewett, W.F.; Ullstad, F.H.; Ruck, B.J.; Natali, F.; Trodahl, H.J. Anomalous Hall effect in SmN: Influence of orbital magnetism and 4f -band conduction. Phys. Rev. B 2018, 98, 235201. [Google Scholar] [CrossRef]

- Azeem, M. On the optical energy gap of SmN. Chin. J. Phys. 2018, 56, 1925–1930. [Google Scholar] [CrossRef]

- Holmes-Hewett, W.F.; Buckley, R.G.; Ruck, B.J.; Natali, F.; Trodahl, H.J. Optical spectroscopy of SmN: Locating the 4f conduction band. Phys. Rev. B 2019, 99, 205131. [Google Scholar] [CrossRef]

- Azeem, M. Quantitative measure of nitrogen vacancy related effects in SmN and EuN. Adv. Nat. Sci. Nanosci. Nanotechnol. 2019, 10, 015003. [Google Scholar] [CrossRef]

- Morari, C.; Beiuşeanu, F.; Marco, I.D.; Peters, L.; Burzo, E.; Mican, S.; Chioncel, L. Magnetism and electronic structure calculation of SmN. J. Phys. Condens. Matter 2015, 27, 115503. [Google Scholar] [CrossRef] [PubMed]

- McNulty, J.F.; Ruck, B.J.; Trodahl, H.J. On the ferromagnetic ground state of SmN. Phys. Rev. B 2016, 93, 054413. [Google Scholar] [CrossRef]

- Som, N.N.; Mankad, V.H.; Dabhi, S.D.; Patel, A.; Jha, P.K. Magnetic behavior study of samarium nitride using density functional theory. J. Magn. Magn. Mater. 2018, 448, 186–191. [Google Scholar] [CrossRef]

- Aynyas, M.; Panwar, Y.S.; Pataiya, J.; Makode, C.; Sanyal, S.P. Properties of samarium nitride: First principle calculations. AIP Conf. Proc. 2016, 1728, 020015. [Google Scholar] [CrossRef]

- Holmes-Hewett, W.F. Electronic structure of nitrogen-vacancy doped SmN: Intermediate valence and 4f transport in a ferromagnetic semiconductor. Phys. Rev. B 2021, 104, 075124. [Google Scholar] [CrossRef]

- Hao, A.M.; Bai, J.; Luo, S.H.; Qi, X.W. First Principles Investigation of Electronic Property and High Pressure Phase Stability of SmN. Chin. J. Chem. Phys. 2016, 29, 219–222. [Google Scholar] [CrossRef]

- Holmes-Hewett, W.F.; Buckley, R.G.; Butler, T.J.; Pot, C.; Koughnet, K.V.; Ruck, B.J.; Trodahl, H.J. TO(Γ) mode resonances in the rare-earth nitrides. AIP Adv. 2022, 12, 075120. [Google Scholar] [CrossRef]

- Natali, F.; Ludbrook, B.; Galipaud, J.; Plank, N.; Granville, S.; Preston, A.; Do, B.L.; Richter, J.; Farrell, I.; Reeves, R.; et al. Epitaxial growth and properties of GdN, EuN and SmN thin films. Phys. Status Solidi (C) Curr. Top. Solid State Phys. 2012, 9, 605–608. [Google Scholar] [CrossRef]

- McNulty, J.F.; Anton, E.M.; Ruck, B.J.; Natali, F.; Warring, H.; Wilhelm, F.; Rogalev, A.; Soares, M.M.; Brookes, N.B.; Trodahl, H.J. Twisted phase of the orbital-dominant ferromagnet SmN in a GdN/SmN heterostructure. Phys. Rev. B Condens. Matter Mater. Phys. 2015, 91, 174426. [Google Scholar] [CrossRef]

- McNulty, J.F.; Temst, K.; Bael, M.J.V.; Vantomme, A.; Anton, E.M. Epitaxial growth of (100)-oriented SmN directly on (100)Si substrates. Phys. Rev. Mater. 2021, 5, 113404. [Google Scholar] [CrossRef]

- Petroff, P.M.; Lorke, A.; Imamoglu, A. Epitaxially self-assembled quantum dots. Phys. Today 2001, 54, 46–52. [Google Scholar] [CrossRef]

- Vallejo, K.D.; Cabrera-Perdomo, C.I.; Garrett, T.A.; Drake, M.D.; Liang, B.; Grossklaus, K.A.; Simmonds, P.J. Tunable mid-infrared interband emission from tensile-strained InGaAs quantum dots. ACS Nano 2023, 17, 2318–2327. [Google Scholar] [CrossRef]

- Vallejo, K.D.; Garrett, T.A.; Cabrera, C.I.; Liang, B.; Grossklaus, K.A.; Simmonds, P.J. Tensile-strained self-assembly of InGaAs on InAs (111) A. J. Vac. Sci. Technol. B 2021, 39, 062809. [Google Scholar] [CrossRef]

- Haidet, B.B.; Nordin, L.; Muhowski, A.J.; Vallejo, K.D.; Hughes, E.T.; Meyer, J.; Simmonds, P.J.; Wasserman, D.; Mukherjee, K. Interface structure and luminescence properties of epitaxial PbSe films on InAs (111) A. J. Vac. Sci. Technol. A Vac. Surf. Film. 2021, 39, 023404. [Google Scholar] [CrossRef]

- May, B.J.; Sarwar, A.; Myers, R.C. Nanowire LEDs grown directly on flexible metal foil. Appl. Phys. Lett. 2016, 108, 141103. [Google Scholar] [CrossRef]

- May, B.J.; Hettiaratchy, E.C.; Wang, B.; Selcu, C.M.; Esser, B.D.; McComb, D.W.; Myers, R.C. Efficiency limits in coalesced AlGaN nanowire ultraviolet LEDs. Phys. Status Solidi (RRL)–Rapid Res. Lett. 2024, 18, 2300399. [Google Scholar] [CrossRef]

- Chan, J.R.; Vézian, S.; Trodahl, J.; Khalfioui, M.A.; Damilano, B.; Natali, F. Temperature-Induced Four-Fold-on-Six-Fold Symmetric Heteroepitaxy, Rocksalt SmN on Hexagonal AlN. Cryst. Growth Des. 2016, 16, 6454–6460. [Google Scholar] [CrossRef]

- Vézian, S.; Damilano, B.; Natali, F.; Khalfioui, M.A.; Massies, J. AlN interlayer to improve the epitaxial growth of SmN on GaN (0001). J. Cryst. Growth 2016, 450, 22–27. [Google Scholar] [CrossRef]

- Natali, F.; Trodahl, J.; Vézian, S.; Traverson, A.; Damilano, B.; Ruck, B. Epitaxial GdN/SmN-based superlattices grown by molecular beam epitaxy. MRS Adv. 2017, 2, 189–194. [Google Scholar] [CrossRef]

- Anton, E.M.; Trewick, E.; Holmes-Hewett, W.F.; Chan, J.R.; McNulty, J.F.; Butler, T.; Ruck, B.J.; Natali, F. Growth of epitaxial (100)-oriented rare-earth nitrides on (100)LaAlO3. Appl. Phys. Lett. 2023, 123, 262401. [Google Scholar] [CrossRef]

- Meléndez-Sans, A.; Pereira, V.; Chang, C.; Kuo, C.Y.; Chen, C.; Tjeng, L.; Altendorf, S. Influence of nitrogen stoichiometry and the role of Sm 5 d states in SmN thin films. Phys. Rev. B 2024, 110, 045120. [Google Scholar] [CrossRef]

- Shaib, A.; Holmes-Hewett, W.F.; Chan, J.; Murmu, P.P.; Ruck, B.J.; Trodahl, H.J.; Natali, F. SmN and DyN: Effect of the nitrogen to rare earth flux ratio on the structural, transport, and magnetic properties. AIP Adv. 2021, 11, 015125. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Gerlach, J.; Mennig, J.; Rauschenbach, B. Epitaxial gadolinium nitride thin films. Appl. Phys. Lett. 2007, 90, 061919. [Google Scholar] [CrossRef]

- Jin, Q.; Cheng, H.; Wang, Z.; Zhang, Q.; Lin, S.; Roldan, M.A.; Zhao, J.; Wang, J.O.; Chen, S.; He, M.; et al. Strain-Mediated High Conductivity in Ultrathin Antiferromagnetic Metallic Nitrides. Adv. Mater. 2021, 33, 2005920. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vallejo, K.D.; Cresswell, Z.E.; Buturlim, V.; Newell, B.S.; Gofryk, K.; May, B.J. Synthesis of Samarium Nitride Thin Films on Magnesium Oxide (001) Substrates Using Molecular Beam Epitaxy. Crystals 2024, 14, 765. https://doi.org/10.3390/cryst14090765

Vallejo KD, Cresswell ZE, Buturlim V, Newell BS, Gofryk K, May BJ. Synthesis of Samarium Nitride Thin Films on Magnesium Oxide (001) Substrates Using Molecular Beam Epitaxy. Crystals. 2024; 14(9):765. https://doi.org/10.3390/cryst14090765

Chicago/Turabian StyleVallejo, Kevin D., Zachery E. Cresswell, Volodymyr Buturlim, Brian S. Newell, Krzysztof Gofryk, and Brelon J. May. 2024. "Synthesis of Samarium Nitride Thin Films on Magnesium Oxide (001) Substrates Using Molecular Beam Epitaxy" Crystals 14, no. 9: 765. https://doi.org/10.3390/cryst14090765

APA StyleVallejo, K. D., Cresswell, Z. E., Buturlim, V., Newell, B. S., Gofryk, K., & May, B. J. (2024). Synthesis of Samarium Nitride Thin Films on Magnesium Oxide (001) Substrates Using Molecular Beam Epitaxy. Crystals, 14(9), 765. https://doi.org/10.3390/cryst14090765