Experimental Study on Laser Lap Welding of Aluminum–Steel with Pre-Fabricated Copper–Nickel Binary Coating

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experimental Equipments

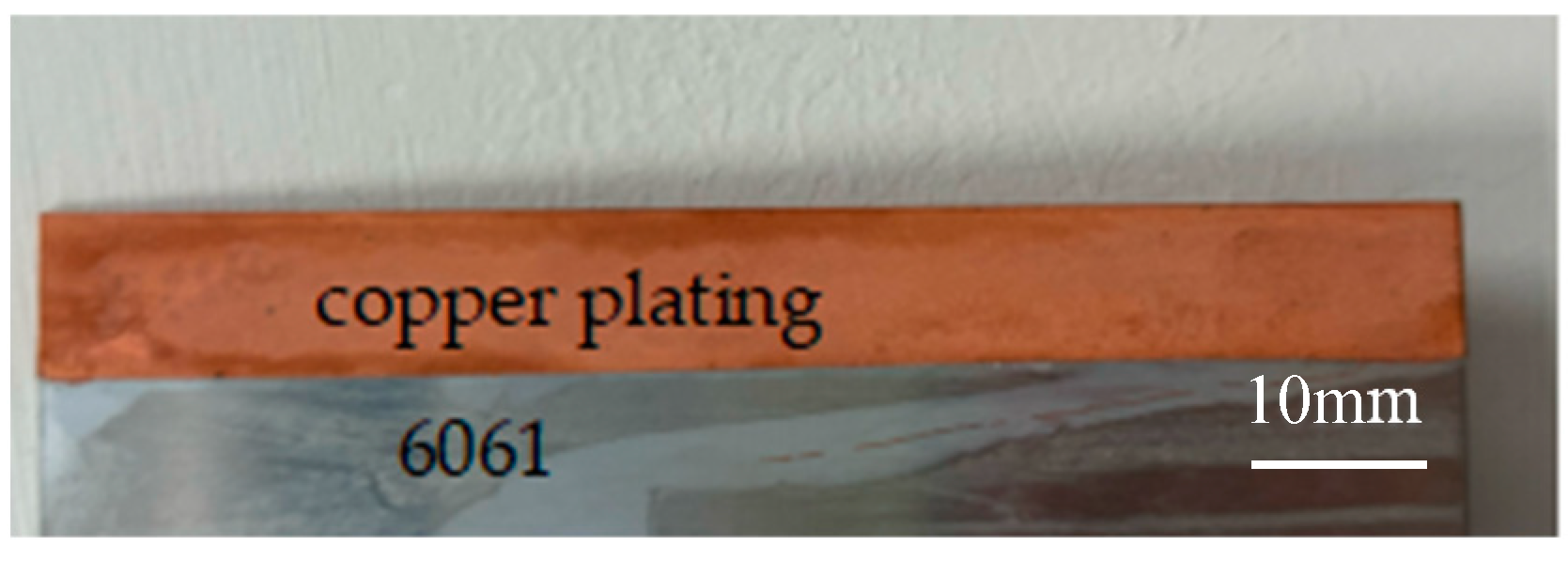

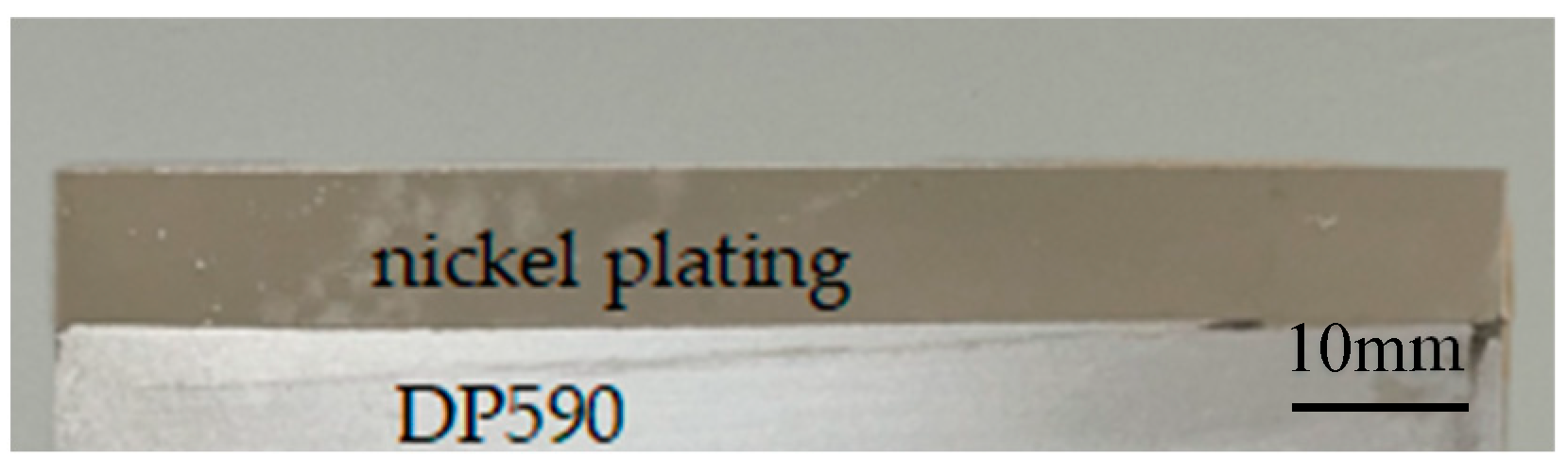

2.2. Experimental Materials

2.3. Pre-Deposited Copper–Nickel Binary Coating

2.4. Steel/Aluminum Laser Lap Welding Tests

2.5. Quality Assessment of Aluminum–Steel Lap Welds

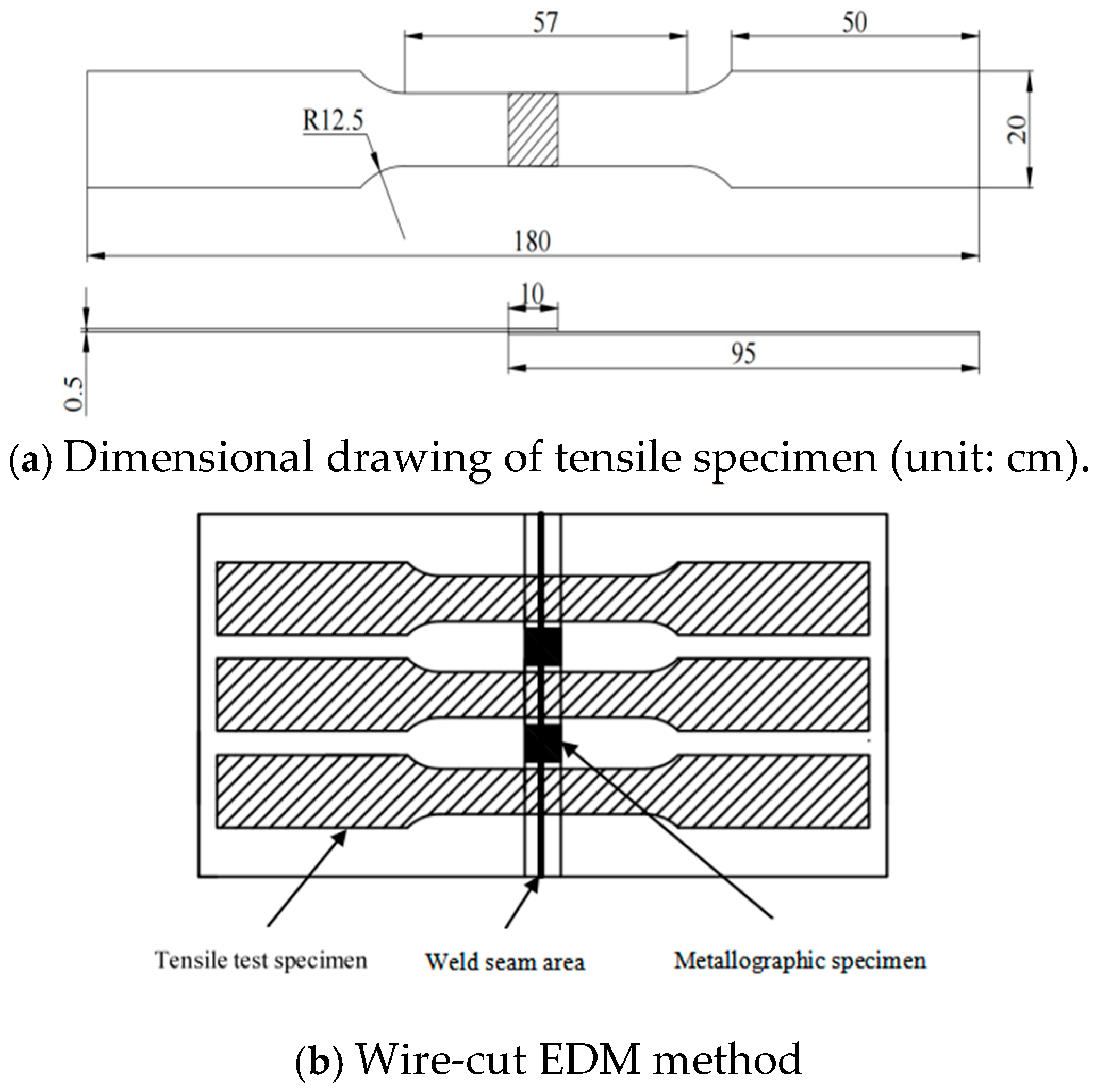

2.5.1. Mechanical Performance Testing

2.5.2. Microstructural Observation

3. Results and Analysis

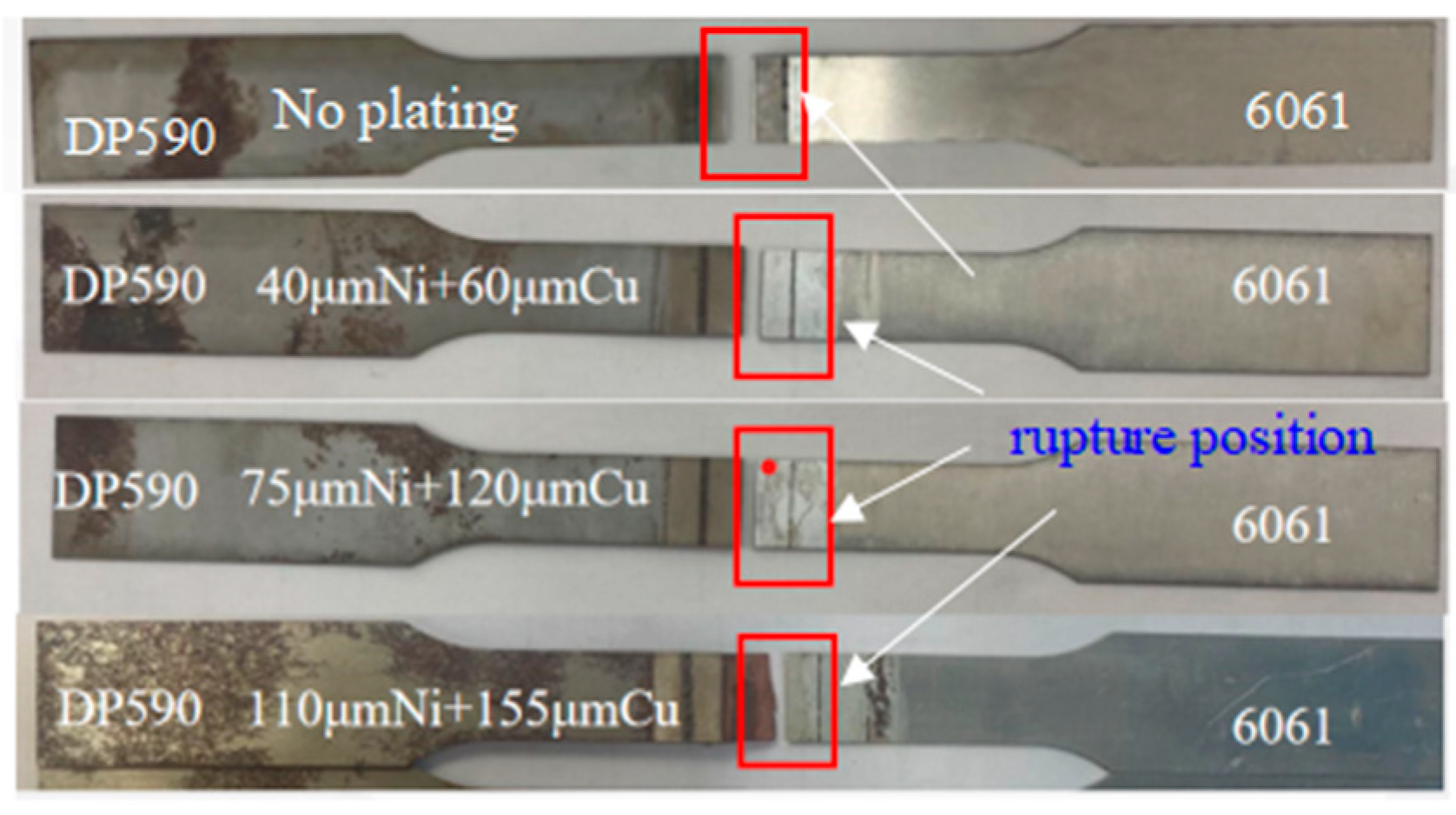

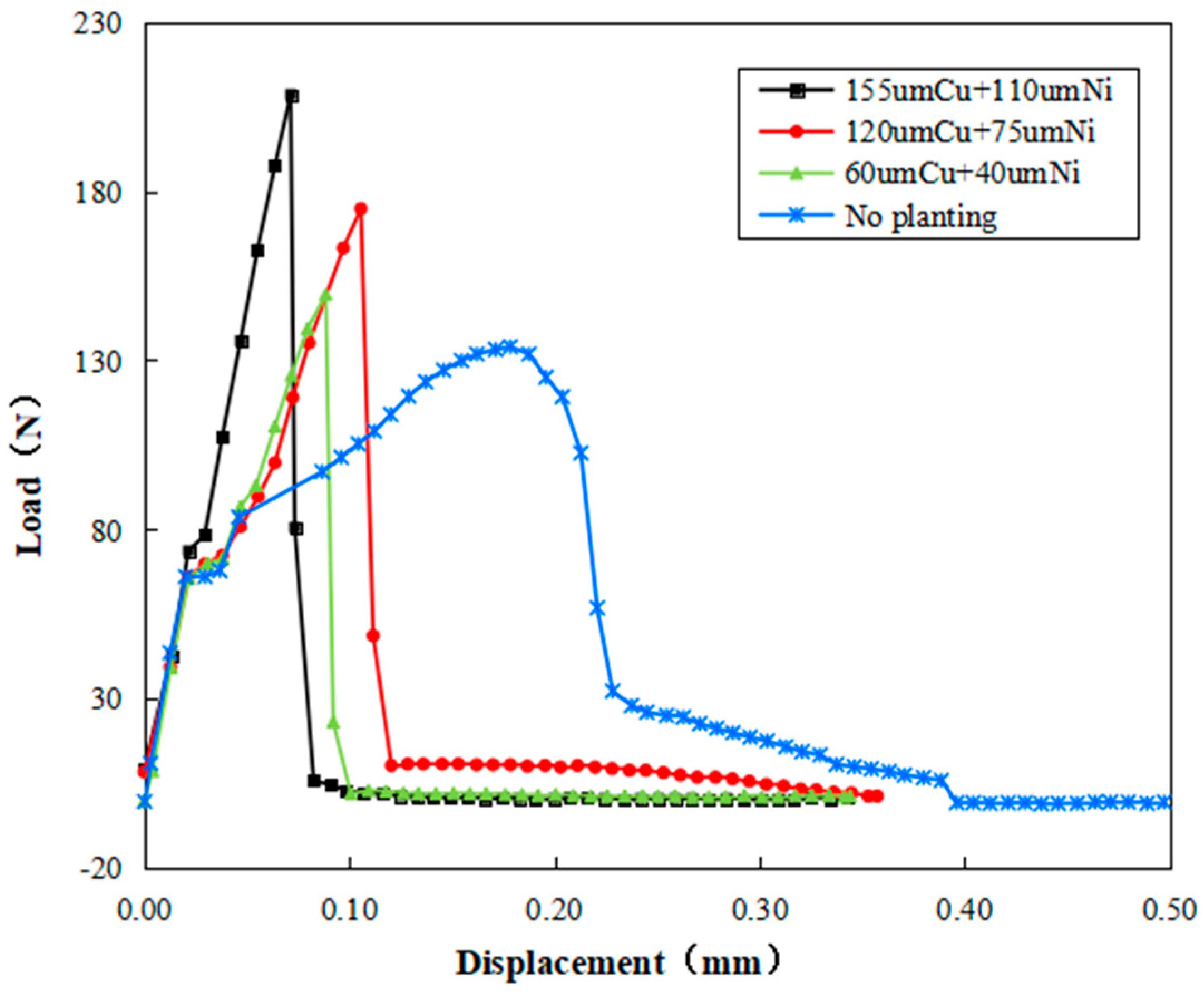

3.1. Mechanical Performance Analysis of Welds

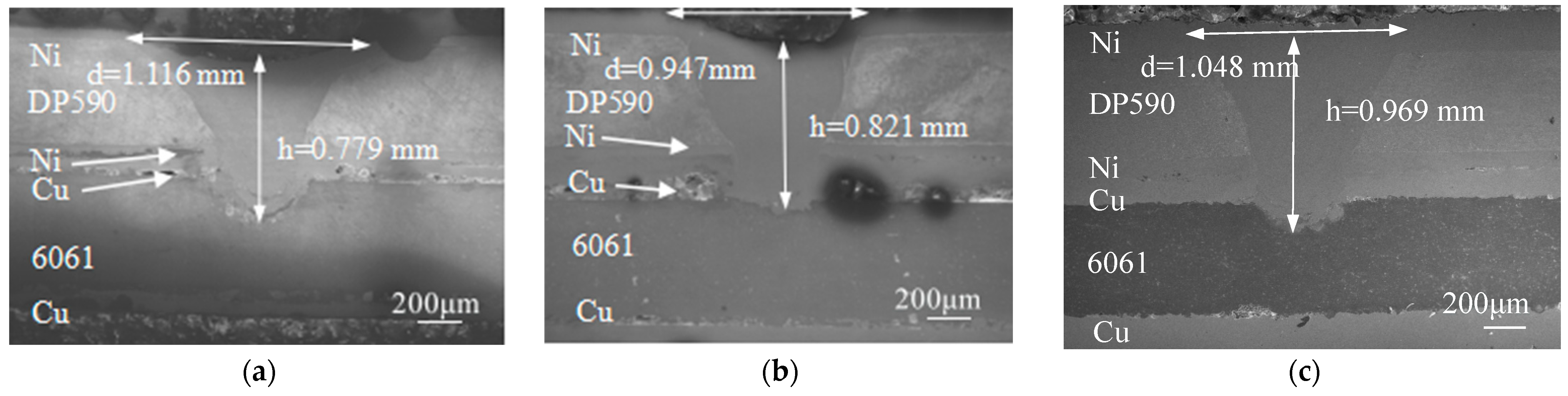

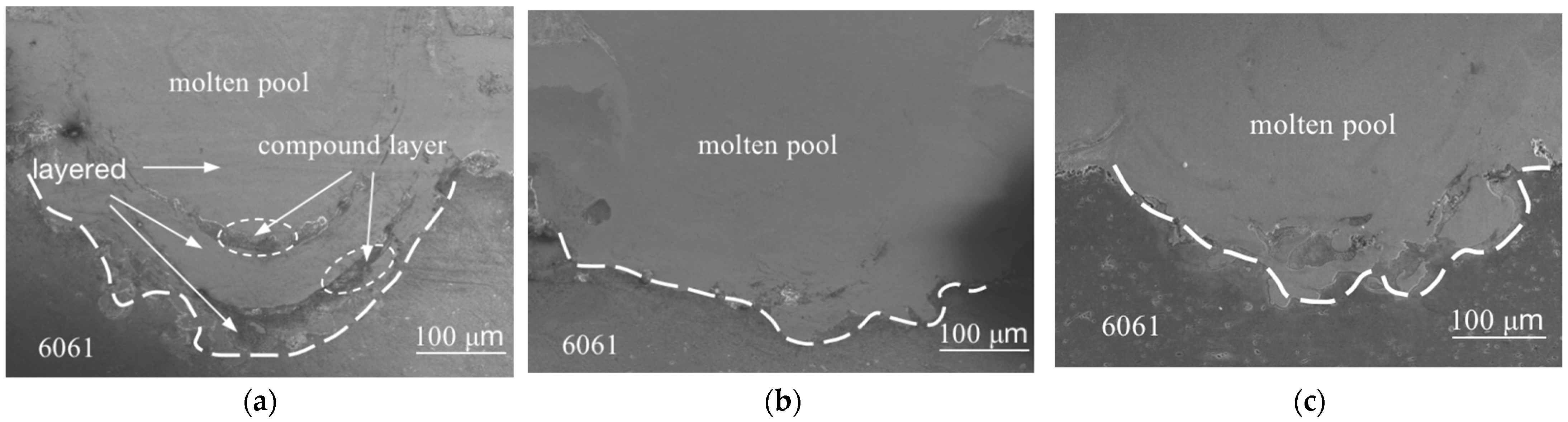

3.2. Morphology Analysis of Welds

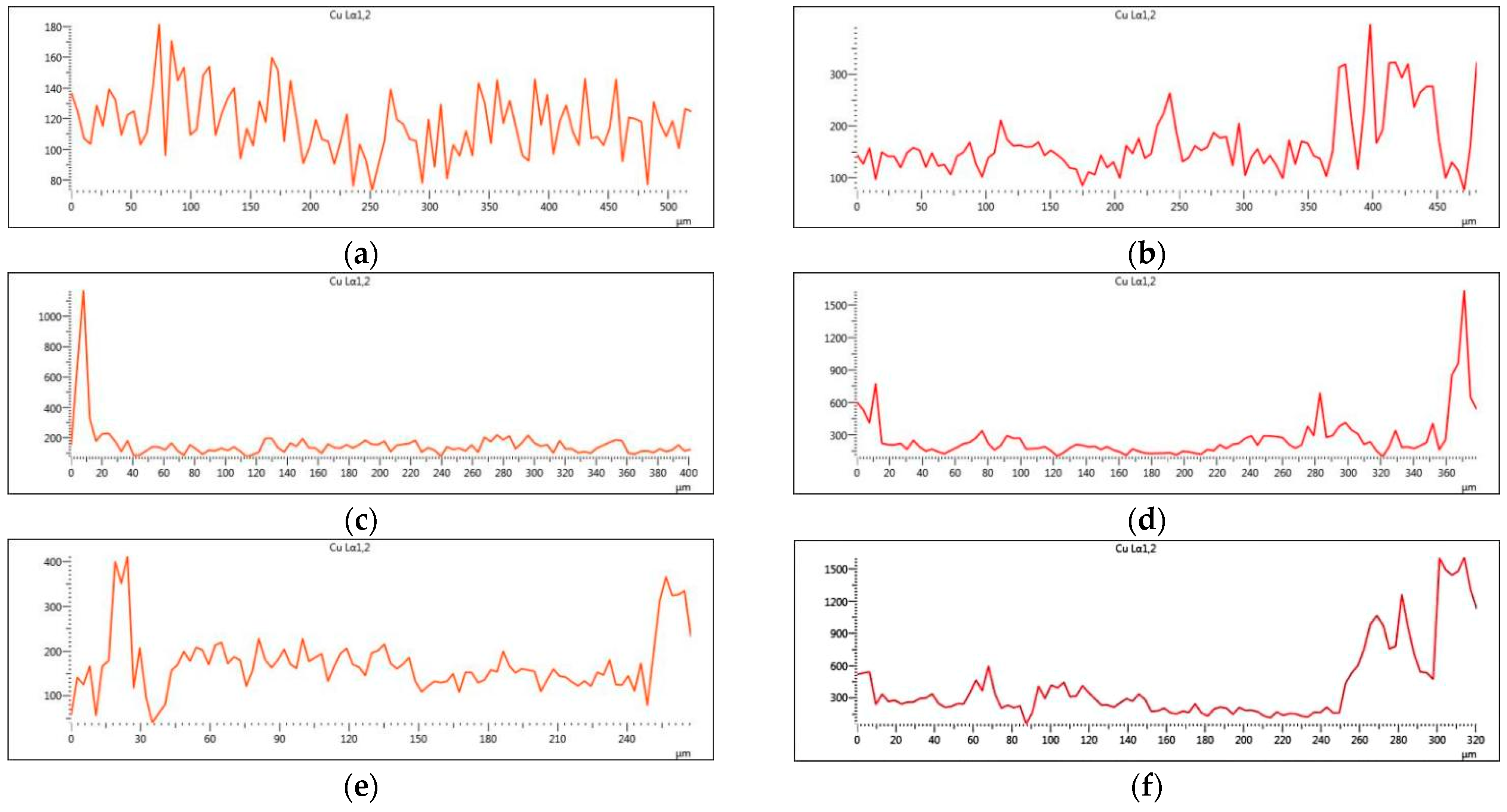

3.3. EDS Line Scan Analysis of Cu and Ni Elements in the Weld

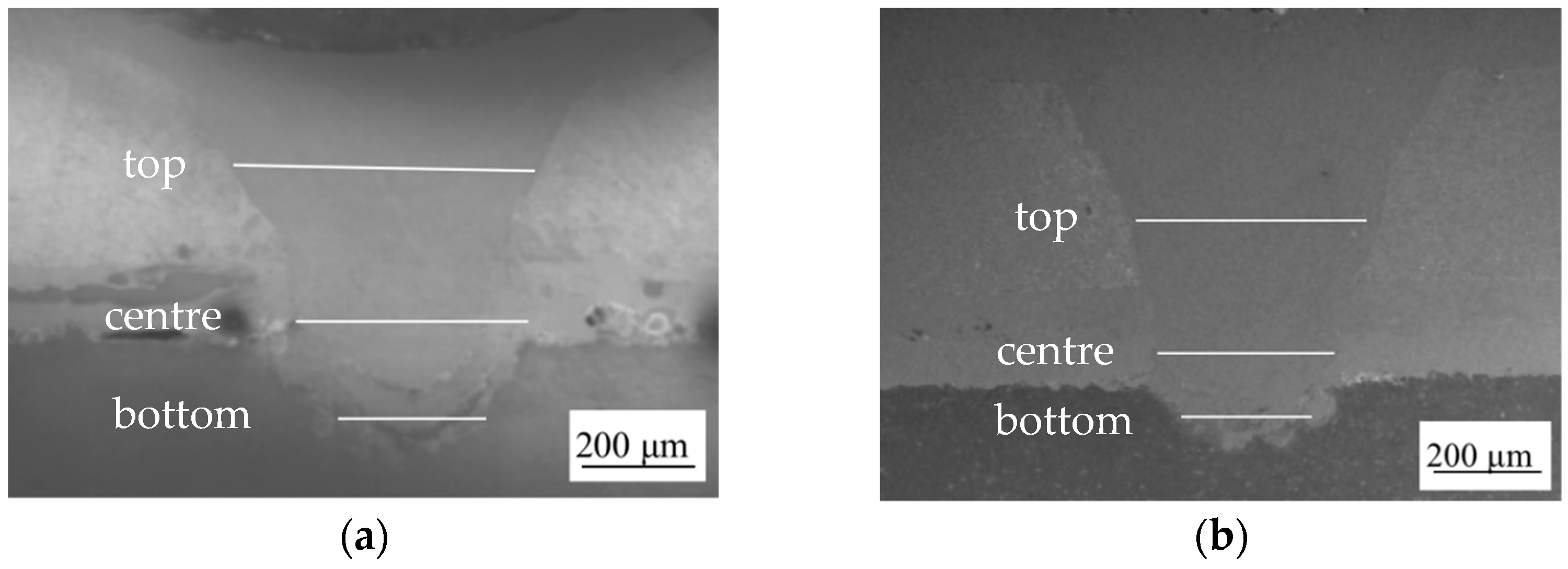

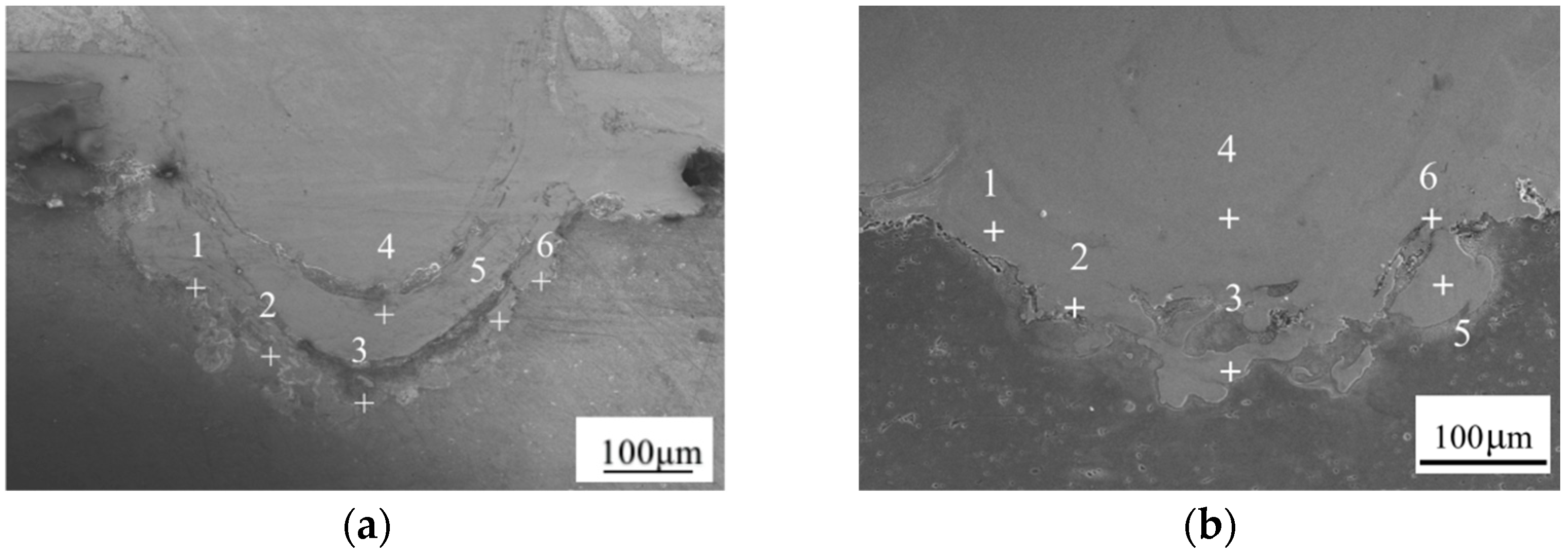

3.4. Compound and Microstructural Analysis of Welds

4. Conclusions

- 1

- The pre-deposition of a copper–nickel binary coating between aluminum and steel significantly improved the weld quality in aluminum–steel laser lap welding. It reduced the formation of cracks in the weld zone, resulted in a smoother fusion line interface, and greatly enhanced the mechanical performance of the welds. The weld exhibited optimal shear strength when the Cu and Ni coating thicknesses were 155 μm and 110 μm, respectively, achieving a maximum shear force of 208.09 N, which represents a 56% improvement compared to aluminum–steel lap welding without coatings.

- 2

- As the thickness of the copper–nickel binary coating increased, more Cu and Ni atoms entered the molten pool and reacted metallurgically with Fe and Al atoms, forming multi-element compounds such as (Fe, Cu, Ni)3Al, (Fe, Cu, Ni)Al3, and CuAl5. This effectively suppressed the formation of brittle Fe-Al intermetallic compounds, further enhancing the weld quality.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Schimek, M.; Springer, A.; Kaierle, S.; Kracht, D.; Wesling, V. Laser-welded dissimilar steel-aluminum seams for automotive lightweight construction. Phys. Procedia 2012, 39, 43–50. [Google Scholar]

- Wu, X.; Yan, H.; Zhou, Y.; Zhang, P.; Lu, Q.; Shi, H. Review of additive manufactured metallic metamaterials: Design, fabrication, property and application. Opt. Laser Technol. 2025, 182, 112066. [Google Scholar]

- Li, J.; Sun, Q.; Jia, J.; Zhu, W. Research on Pre-Compensation and Shape-Control Optimization of Hemming Structures with Dissimilar Materials Based on Forming Process Chain. Metals 2024, 14, 1063. [Google Scholar] [CrossRef]

- Marumoto, K.; Horai, T.; Morita, D.; Oda, C.; Fujii, T.; Yuzawa, T.; Koba, R.; Yamamoto, M. Development of Hot-Wire Laser Additive Manufacturing for Dissimilar Materials of Stainless Steel/Aluminum Alloys. J. Manuf. Mater. Process. 2024, 8, 93. [Google Scholar] [CrossRef]

- Wallerstein, D.; Salminen, A.; Lusquinos, F.; Comesaa, R.; Pou, J. Recent developments in laser welding of aluminum alloys to steel. Metals 2021, 11, 622. [Google Scholar] [CrossRef]

- Wu, L.; Oliveira, J.; Yang, J.; Xiao, M.; Zheng, M.; Xu, W.; Zhao, Y.; Wang, F.; Zhang, H. Effect of Al-Si Coating on the Interfacial Microstructure and Corrosion Resistance of Dissimilar Laser Al Alloy/22MnB5 Steel Joints. Metals 2024, 14, 328. [Google Scholar] [CrossRef]

- Jiang, F.; Wang, W.; Zhang, X.; Gong, W. Microstructure and Mechanical Properties of Friction Stir Lap Welding Joint of Al/CU Dissimilar Metals. Metals 2023, 13, 1969. [Google Scholar] [CrossRef]

- Shi, X.; Zhang, S.; Li, T.; Meng, X.; Cheng, C.; Pei, J.; Cao, T.; Zhao, J. Corrosion Behavior and Mechanical Property of 5182 Aluminum/DP780 Steel Resistance Spot Welding Joints. Materials 2024, 17, 2472. [Google Scholar] [CrossRef]

- Zhao, Y.; Long, Y.; Li, Z. Research progress of transition layer and filler wire for laser welding of steel and aluminum dissimilar metals. Int. J. Adv. Manuf. Technol. 2022, 119, 4149. [Google Scholar]

- Li, Y.; Liu, Y.; Yang, J. First principle calculations and mechanical properties of the intermetallic compounds in a laser welded steel/aluminum joint. Opt. Laser Technol. 2020, 122, 105875. [Google Scholar]

- Yang, J.; Su, J.; Gao, C.; Zhao, Y.; Liu, H.; Joao, P.; Tan, C.; Yu, Z. Effect of heat input on interfacial microstructure, tensile and bending properties of dissimilar Al/steel lap joints by laser Welding-brazing. Opt. Laser Technol. 2021, 142, 107218. [Google Scholar]

- Yu, J.; Fan, Y.; Zhang, H.; Cao, W.; Zhang, H.; Su, Z.; Gao, J. Interfacial evolution of thermo-compensated resistance diffusion welding of Al/steel joint with Ni interlayer via resistance seam welding. J. Mater. Eng. Perform. 2024, 33, 6480. [Google Scholar]

- Jiang, Q.; Yang, J.; Xiao, R.; Zheng, M.; Jiang, J.; Xue, J.; Xu, W.; Xu, J.; Zhang, H. Outstanding ductility of dissimilar laser Al/steel spot joint using a high entropy alloy interlayer. Mater. Lett. 2023, 349, 134707. [Google Scholar]

- Hu, X.; Xia, C.; Zhang, H.; Wan, G.; Liu, S.; Long, W. The microstructure and mechanical properties of aluminum/steel welded joint with Ni foil interlayers by FSLW. J. Adhes. Sci. Technol. 2024, 38, 1413. [Google Scholar]

- Li, B.; Han, S.; Ao, W.; Yang, Y.; Liu, D. Investigation on microstructure and mechanical properties of the dissimilar lap welding of Al alloy to steel with different filler materials and laser powers. Int. J. Adv. Manuf. Technol. 2024, 134, 935. [Google Scholar]

- Esmaily, H.; Habibolahzadeh, A.; Tajally, M. Improving pulsed laser weldability of duplex stainless steel to 5456 aluminum alloy via friction stir process reinforcing of aluminum by BNi-2 brazing alloy. Trans. Nonferrous Met. Soc. China 2019, 29, 1401. [Google Scholar]

- Yu, G.; Chen, S.; Zhao, Z.; Wen, Z.; Huang, J.; Yang, J.; Chen, S. Comparative study of laser swelding-brazing of aluminum alloy to galvanized steel butted joints using five different filler wires. Opt. Laser Technol. 2022, 147, 107618. [Google Scholar]

- Hu, Y.; Zhang, Y.; Mi, G.; Wang, C.; Zhang, W.; Zhang, X. Effects of Si contents in filling wires on microstructure evolution and properties of Al-steel dissimilar joint by laser welding-brazing. J. Mater. Res. Technol. 2021, 15, 1896–1904. [Google Scholar]

- Shi, Y.; Li, Z.; Yin, C.; Yu, X.; Kou, Y. Effect of alloying elements Cu and Ni on mechanical properties of steel/aluminum laser welded joints. Optik 2022, 255, 168707. [Google Scholar]

- Zhang, Y.; Wang, W.; Li, Z.; Huang, G.; Zhang, H.; Liu, F. Study of the brittleness mechanism of aluminum/steel laser welded joints with copper and vanadium interlayers. Opt. Laser Technol. 2023, 163, 109319. [Google Scholar]

- Li, T.; Zhou, D.; Yan, Y.; Liu, J. Effect of laser-Ti foil coupling on microstructure and mechanical property of steel/aluminum fusion welding joints. Opt. Laser Technol. 2021, 141, 107114. [Google Scholar]

- Guo, W.; Wu, M.; Teng, L.; Liu, L.; Wan, H. Effect of Filler-Wire Composition on Microstructure and Properties of Al/Steel-Welded Joints by Laser Welding–Brazing. Crystals 2025, 15, 266. [Google Scholar] [CrossRef]

| Material | C | Mn | P | Si | Ni | S | Cr | Fe |

|---|---|---|---|---|---|---|---|---|

| DP590 | 0.150 | 2.500 | 0.040 | 0.600 | - | 0.015 | 0.020 | Bal. |

| Material | Cu | Mn | Mg | Zn | Cr | Ti | Si | Fe | Al |

|---|---|---|---|---|---|---|---|---|---|

| 6061 | 0.15 | 0.15 | 0.8 | 0.25 | 0.04 | 0.15 | 0.4 | 0.7 | Bal. |

| Serial Number | Time (h) | Cu Coating Thickness (μm) | Ni Coating Thickness (μm) |

|---|---|---|---|

| 1 | 1 | 60 | 40 |

| 2 | 2 | 120 | 75 |

| 3 | 3 | 155 | 110 |

| Placement | Al (at%) | Fe (at%) | Cu (at%) | Ni (at%) | Polymetallic Phase (Chemistry) |

|---|---|---|---|---|---|

| 1 | 14.44 | 68.03 | 3.42 | 14.11 | (Fe, Cu, Ni)3Al |

| 2 | 21.05 | 63.5 | 3.05 | 12.4 | (Fe, Cu, Ni)3Al |

| 3 | 76.04 | 17.31 | 2.61 | 4.04 | (Fe, Cu, Ni)Al3 |

| 4 | 13.31 | 70.35 | 5.95 | 10.39 | (Fe, Cu, Ni)3Al |

| 5 | 20.11 | 59.36 | 8.75 | 11.78 | (Fe, Cu, Ni)3Al |

| 6 | 12.63 | 63.58 | 10.03 | 13.76 | (Fe, Cu, Ni)3Al |

| Placement | Al (at%) | Fe (at%) | Cu (at%) | Ni (at%) | Polymetallic Phase (Chemistry) |

|---|---|---|---|---|---|

| 1 | 10.09 | 61.05 | 12.12 | 16.74 | (Fe, Cu, Ni)3Al |

| 2 | 85.81 | 0 | 14.05 | 0.14 | CuAl5 |

| 3 | 12.52 | 45.29 | 12.95 | 29.24 | (Fe, Cu, Ni)3 Al |

| 4 | 7.29 | 57.56 | 8.13 | 27.02 | (Fe, Cu, Ni)3Al |

| 5 | 17.25 | 34.99 | 26.73 | 21.03 | (Fe, Cu, Ni)3Al |

| 6 | 20.19 | 41.70 | 8.35 | 29.76 | (Fe, Cu, Ni)3Al |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Gu, H.; Ma, D. Experimental Study on Laser Lap Welding of Aluminum–Steel with Pre-Fabricated Copper–Nickel Binary Coating. Crystals 2025, 15, 300. https://doi.org/10.3390/cryst15040300

Zhang H, Gu H, Ma D. Experimental Study on Laser Lap Welding of Aluminum–Steel with Pre-Fabricated Copper–Nickel Binary Coating. Crystals. 2025; 15(4):300. https://doi.org/10.3390/cryst15040300

Chicago/Turabian StyleZhang, Hua, Huiyan Gu, and Dong Ma. 2025. "Experimental Study on Laser Lap Welding of Aluminum–Steel with Pre-Fabricated Copper–Nickel Binary Coating" Crystals 15, no. 4: 300. https://doi.org/10.3390/cryst15040300

APA StyleZhang, H., Gu, H., & Ma, D. (2025). Experimental Study on Laser Lap Welding of Aluminum–Steel with Pre-Fabricated Copper–Nickel Binary Coating. Crystals, 15(4), 300. https://doi.org/10.3390/cryst15040300