Stepwise Evolution of AgCl Microcrystals from Octahedron into Hexapod with Mace Pods and their Visible Light Photocatalytic Activity

Abstract

:1. Introduction

2. Materials and Methods

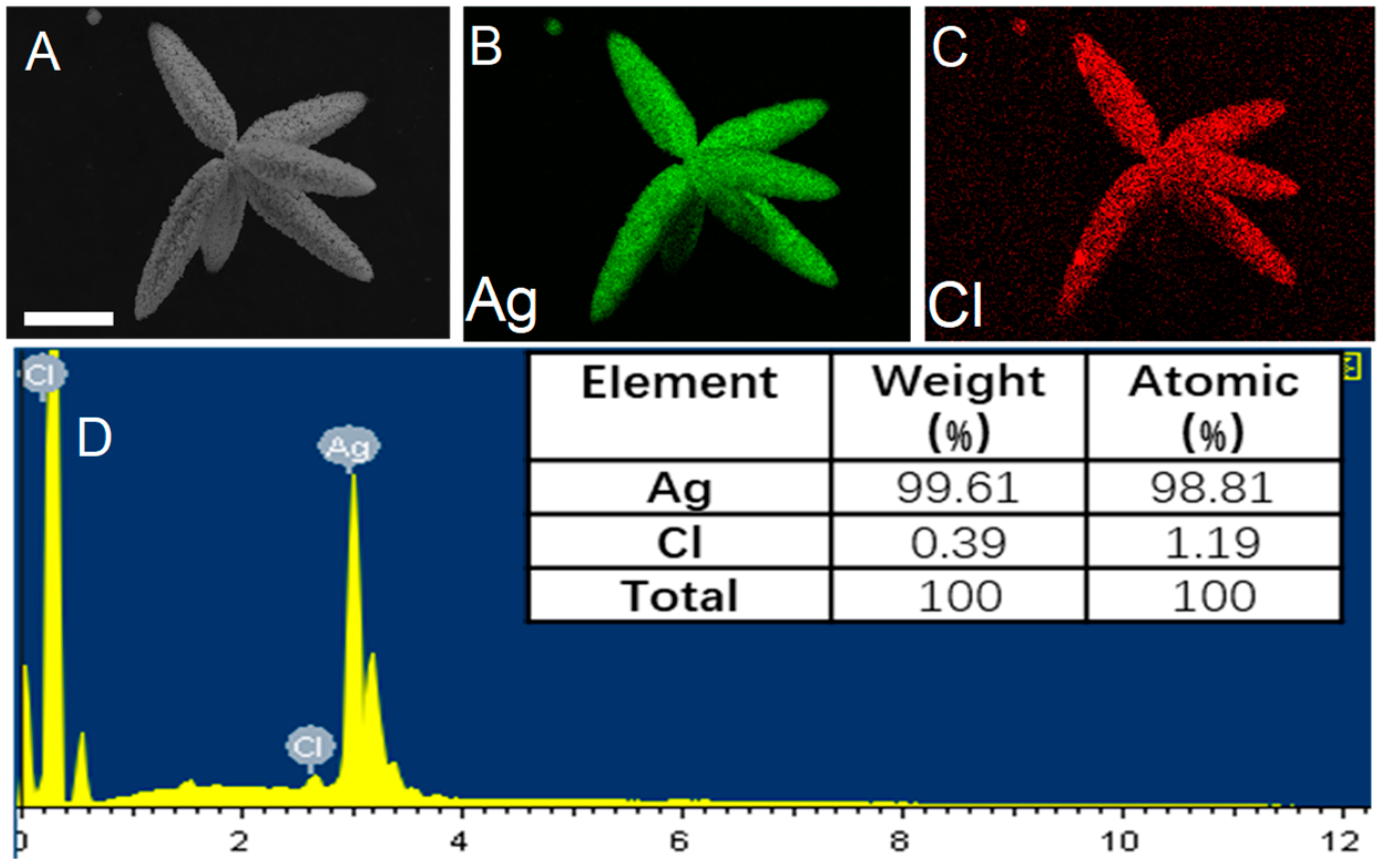

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Leonardi, A.; Engel, M. Particle Shape Control via Etching of Core@Shell Nanocrystals. ACS Nano 2018, 12, 9186–9195. [Google Scholar] [CrossRef] [PubMed]

- Qin, Y.Z.; Pan, W.F.; Yu, D.D.; Lu, Y.X.; Wu, W.H.; Zhou, J.G. Stepwise evolution of Au micro/nanocrystals from an octahedron into a truncated ditetragonal prism. Chem. Commun. 2018, 54, 3411–3414. [Google Scholar] [CrossRef]

- Satyavolu, N.S.R.; Tan, L.H.; Lu, Y. DNA-Mediated Morphological Control of Pd−Au Bimetallic Nanoparticles. J. Am. Chem. Soc. 2016, 138, 16542–16548. [Google Scholar] [CrossRef]

- Liu, P.; Qin, R.; Fu, G.; Zheng, N. Surface Coordination Chemistry of Metal Nanomaterials. J. Am Chem. Soc. 2017, 139, 2122–2131. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, P.; Wang, T.; Gong, J. Monoclinic WO3 nanomultilayers with preferentially exposed (002) facets for photoelectrochemical waters plitting. Nano Energy 2015, 11, 189–195. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Ma, Y.Y.; Zeng, J.; Zhong, X.L.; Jin, M.S.; Li, Z.Y.; Xia, Y.N. Seed-Mediated Synthesis of Single-Crystal Gold Nanospheres with Controlled Diameters in the Range 5–30 nm and their Self-Assembly upon Dilution. Chem. Asian J. 2013, 8, 792–799. [Google Scholar] [CrossRef]

- Zheng, Y.Q.; Zhong, X.L.; Li, Z.Y.; Xia, Y.N. Successive, Seed-Mediated Growth for the Synthesis of Single-Crystal Gold Nanospheres with Uniform Diameters Controlled in the Range of 5–150 nm. Part. Part. Syst. Charact. 2013, 31, 266–273. [Google Scholar] [CrossRef]

- Ruditskiy, A.; Xia, Y.N. Toward the Synthesis of Sub-15 nm Ag Nanocubes with Sharp Corners and Edges: The Roles of Heterogeneous Nucleation and Surface Capping. J. Am. Chem. Soc. 2016, 138, 3161–3167. [Google Scholar] [CrossRef]

- Zhou, S.; Li, J.H.; Gilroy, K.D.; Tao, J.; Zhu, C.L.; Yang, X.; Sun, X.J.; Xia, Y.N. Facile Synthesis of Silver Nanocubes with Sharp Corners and Edges in an Aqueous Solution. ACS Nano 2016, 10, 9861–9870. [Google Scholar] [CrossRef] [PubMed]

- Xiong, Y.J.; Chen, J.; Wiley, B.; Xia, Y.N.; Yin, Y.D.; Li, Z.Y. Size-Dependence of Surface Plasmon Resonance and Oxidation for Pd Nanocubes Synthesized via a Seed Etching Process. Nano Lett. 2005, 5, 1237–1242. [Google Scholar] [CrossRef]

- Liu, H.P.; Zhong, P.; Liu, K.; Han, L.; Zheng, H.Q.; Yin, Y.D.; Gao, C.B. Synthesis of ultrathin platinum nanoplates for enhanced oxygen reduction activity. Chem. Sci. 2018, 9, 398–404. [Google Scholar] [CrossRef]

- Yin, X.; Shi, M.; Kwok, K.S.; Zhao, H.D.; Gray, D.L.; Bertke, J.A.; Yang, H. Dish-like higher-ordered palladium nanostructures through metal ion-ligand complexation. Nano Res. 2018, 11, 3442–3452. [Google Scholar] [CrossRef]

- Zeng, J.; Xia, X.H.; Rycenga, M.; Henneghan, P.; Li, Q.G.; Xia, Y.N. Successive Deposition of Silver on Silver Nanoplates: Lateral versus Vertical Growth. Angew. Chem. 2011, 123, 258–263. [Google Scholar] [CrossRef]

- Rubio, G.G.; Oliveira, T.M.; Altantzis, T.; Porta, A.L.; Guerrero-Martínez, A.; Bals, S.; Scarabelli, L.; Marzan, L.M.L. Disentangling the effect of seed size and crystal habit on gold nanoparticle seeded growth. Chem. Commun. 2017, 53, 11360–11363. [Google Scholar] [CrossRef] [Green Version]

- Ge, Y.J.; Duan, X.D.; Zhang, M.; Mei, L.; Hu, J.W.; Hu, W.; Duan, X.F. Direct Room Temperature Welding and Chemical Protection of Silver Nanowire Thin Films for High Performance Transparent Conductors. J. Am. Chem. Soc. 2018, 140, 193–199. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, W.F.; Li, X.L.; Chen, W.; Fan, N.N.; Zou, C.; Chen, X.; Xu, X.J.; Zhang, L.J.; Huang, S.M. Controlled Growth of Ag/Au Bimetallic Nanorods through Kinetics Control. Chem. Mater. 2013, 25, 34–41. [Google Scholar] [CrossRef]

- Lee, S.; Bae, C.; Lee, J.; Lee, S.; Oh, S.H.; Kim, J.Y.; Park, G.S.; Jung, H.S.; Shin, H. Fabrication of a Stable New Polymorph Gold Nanowire with Sixfold Rotational Symmetry. Adv. Mater. 2018, 30, 1706261. [Google Scholar] [CrossRef]

- Rubio, G.G.; Núñez, P.D.; Rivera, A.; Prada, A.; Tardajos, G.; Izquierdo, J.G.; Bañares, L.; Llombart, P.; Macdowell, L.G.; Palafox, M.A.; et al. Femtosecond laser reshaping yields gold nanorods with ultranarrow surface plasmon resonances. Science 2017, 358, 640–644. [Google Scholar] [CrossRef]

- Xie, J.; Zhang, Q.; Lee, J.Y.; Wang, D.I.C. The Synthesis of SERS-Active Gold Nanoflower Tags for In Vivo Applications. ACS Nano 2008, 2, 2473–2480. [Google Scholar] [CrossRef]

- Song, C.Y.; Zhou, N.; Yang, B.Y.; Yang, Y.J.; Wang, L.H. Facile synthesis of hydrangea flower-like hierarchical gold nanostructures with tunable surface topographies for single-particle surface enhanced Raman scattering. Nanoscale 2015, 7, 17004–17011. [Google Scholar] [CrossRef]

- Martınez, A.G.; Barbosa, S.; Santos, I.P.; Marzan, L.M.L. Nanostars shine bright for you Colloidal synthesis, properties and applications of branched metallic nanoparticles. Curr. Opin. Colloid Interface Sci. 2011, 16, 118–127. [Google Scholar]

- Cheong, S.; Watt, J.; Ingham, B.; Toney, M.F.; Tilley, R.D. In Situ and Ex Situ Studies of Platinum Nanocrystals: Growth and Evolution in Solution. J. Am. Chem. Soc. 2009, 131, 14590–14595. [Google Scholar] [CrossRef] [Green Version]

- Mulvihill, M.J.; Ling, X.Y.; Henzie, J.; Yang, P. Anisotropic Etching of Silver Nanoparticles for Plasmonic Structures Capable of Single-Particle SERS. J. Am. Chem. Soc. 2009, 132, 268–274. [Google Scholar] [CrossRef]

- Maksimuk, S.; Teng, X.; Yang, H. Roles of Twin Defects in the Formation of Platinum Multipod Nanocrystals. J. Phys. Chem. C 2007, 111, 14312–14319. [Google Scholar] [CrossRef]

- Yu, T.; Kim, D.Y.; Zhang, H.; Xia, Y. Platinum Concave Nanocubes with High-Index Facets and Their Enhanced Activity for Oxygen Reduction Reaction. Angew. Chem. Int. Ed. 2011, 50, 2773–2777. [Google Scholar] [CrossRef]

- Jin, M.; Zhang, H.; Xie, Z.; Xia, Y. Palladium Concave Nanocubes with High-Index Facets and Their Enhanced Catalytic Properties. Angew. Chem. Int. Ed. 2011, 50, 7850–7854. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Herricks, T.; Xia, Y. Polyol Synthesis of Platinum Nanostructures: Control of Morphology through the Manipulation of Reduction Kinetics. Angew. Chem. Int. Ed. 2005, 117, 2645–2648. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, Y.G.; Liu, H.; Fang, J.Z. One-pot synthesis of high-index faceted AgCl nanocrystals with trapezohedral, concave hexoctahedral structures and their photocatalytic activity. Nanoscale 2015, 7, 11591–11601. [Google Scholar] [CrossRef]

- Dong, R.; Tian, B.; Zeng, C.; Li, T.; Wang, T.; Zhang, J. Ecofriendly Synthesis and Photocatalytic Activity of Uniform Cubic Ag@AgCl Plasmonic Photocatalyst. J. Phys. Chem. C 2012, 117, 213–220. [Google Scholar] [CrossRef]

- Cheng, L.; Ma, C.; Yang, G.; You, H.; Fang, J. Hierarchical silver mesoparticles with tunable surface topographies for highly sensitive surface enhanced Raman spectroscopy. J. Mater. Chem. A 2014, 2, 4534–4542. [Google Scholar] [CrossRef]

- Zhang, Q.; Ge, J.; Pham, T.; Goebl, J.; Hu, Y.; Lu, Z.; Yin, Y. Reconstruction of Silver Nanoplates by UV Irradiation: Tailored Optical Properties and Enhanced Stability. Angew. Chem. Int. Ed. 2009, 48, 3516–3519. [Google Scholar] [CrossRef]

- Wang, P.; Huang, B.B.; Lou, Z.Z.; Zhang, X.Y.; Qin, X.Y.; Dai, Y.; Zheng, Z.K.; Wang, X.N. Synthesis of Highly Efficient Ag@AgCl Plasmonic Photocatalysts with Various Structures. Chem. Eur. J. 2010, 16, 538–544. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, P.; Liu, M. High-Performance Visible-Light-Driven Plasmonic Photocatalysts Ag/AgCl with Controlled Size and Shape Using Graphene Oxide as Capping Agent and Catalyst Promoter. Langmuir 2013, 29, 9259–9268. [Google Scholar] [CrossRef]

- Kimijima, K.I.; Sugimoto, T. Growth Mechanism of AgCl Nanoparticles in a Reverse Micelle System. J. Phys. Chem. B 2004, 108, 3735–3738. [Google Scholar] [CrossRef]

- Lou, Z.; Huang, B.; Wang, Z.; Qin, X.; Zhang, X.; Liu, Y.; Zhang, R.; Dai, Y.; Whangbo, M.-H. Interface kinetic diffusion reaction leading to fast and continuous generation of AgCl nanocubes in NaCl solution. Dalton Trans. 2013, 42, 15219–15225. [Google Scholar] [CrossRef]

- An, C.; Peng, S.; Sun, Y. Facile Synthesis of Sunlight-Driven AgCl:Ag Plasmonic Nanophotocatalyst. Adv. Mater. 2010, 22, 2570–2574. [Google Scholar] [CrossRef]

- Tang, Y.; Jiang, Z.; Xing, G.; Li, A.; Kanhere, P.D.; Zhang, Y.; Sum, T.C.; Li, S.; Chen, X.; Dong, Z.; et al. Efficient Ag@AgCl Cubic Cage Photocatalysts Profit from Ultrafast Plasmon-Induced Electron Transfer Processes. Adv. Funct. Mater. 2013, 23, 2932–2940. [Google Scholar] [CrossRef]

- Han, S.H.; Liu, H.M.; Sun, C.C.; Jin, P.J.; Chen, Y. Photocatalytic performance of AgCl@Ag core–shell nanocubes for the hexavalent chromium reduction. J. Mater. Sci. 2018, 53, 12030–12039. [Google Scholar] [CrossRef]

- Guo, X.Y.; Deng, D.; Tian, Q.H. One pot controllable synthesis of AgCl nanocrystals with different morphology and their photocatalytic activity. Powder Technol. 2017, 308, 206–213. [Google Scholar] [CrossRef]

- Ao, Y.H.; Bao, J.Q.; Wang, P.F.; Wang, C. A novel heterostructured plasmonic photocatalyst with high photocatalytic activity: Ag@AgCl nanoparticles modified titanium phosphate nanoplates. J. Alloy. Comp. 2017, 698, 410–419. [Google Scholar] [CrossRef]

- Bi, Y.P.; Ye, J.H. In situ oxidation synthesis of Ag/AgCl core–shell nanowires and their photocatalytic properties. Chem. Commun. 2009, 6551–6553. [Google Scholar] [CrossRef]

- Bi, Y.P.; Ye, J.H. Heteroepitaxial growth of platinum nanocrystals on AgCl nanotubes via galvanic replacement reaction. Chem. Commun. 2010, 46, 1532–1534. [Google Scholar] [CrossRef]

- Hu, H.Y.; Jiao, Z.B.; Lu, G.X.; Ye, J.H.; Bi, Y.P. Enhanced photocatalytic properties of biomimetic Ag/AgCl heterostructures. RSC Adv. 2014, 4, 31795–31798. [Google Scholar] [CrossRef]

- Lou, Z.; Huang, B.; Qin, X.; Zhang, X.; Cheng, H.; Liu, Y.; Wang, S.; Wang, J.; Dai, Y. One-step synthesis of AgCl concave cubes by preferential overgrowth along <111> and <110> directions. Chem. Commun. 2012, 48, 3488–3490. [Google Scholar] [CrossRef]

- Lou, Z.; Huang, B.; Ma, X.; Zhang, X.; Qin, X.; Wang, Z.; Dai, Y.; Liu, Y. A 3D AgCl Hierarchical Superstructure Synthesized by a Wet Chemical Oxidation Method. Chem. Eur. J. 2012, 18, 16090–16096. [Google Scholar] [CrossRef]

- Gatemala, H.; Thammacharoen, C.; Ekgasit, S. 3D AgCl microstructures selectively fabricated via Cl− induced precipitation from [Ag(NH3)2]+. CrystEngComm 2014, 16, 6688–6696. [Google Scholar] [CrossRef]

- Gatemala, H.; Ekgasit, S.; Pienpinijtham, P. 3D structure-preserving galvanic replacement to create hollow Au microstructures. CrystEngComm 2017, 19, 3808–3816. [Google Scholar] [CrossRef]

- Abeyweera, S.C.; Rasamani, K.D.; Sun, Y. Ternary Silver Halide Nanocrystals. Acc. Chem. Res. 2017, 50, 1754–1761. [Google Scholar] [CrossRef]

- Shuford, K.L.; Chen, M.; Lee, E.J.; Cho, S.O. A Facile Polyol Route to Uniform Gold Octahedra with Tailorable Size and Their Optical Properties. ACS Nano 2008, 2, 1760–1769. [Google Scholar]

- Li, C.; He, G.; Jin, M.; Zhang, H.; Lu, N.; Wang, J.; Kim, M.J.; Xia, Y. A Mechanistic Study on the Nucleation and Growth of Au on Pd Seeds with a Cubic or Octahedral Shape. ChemCatChem 2012, 4, 1668–1674. [Google Scholar]

- Wang, P.; Huang, B.; Qin, X.; Zhang, X.; Dai, Y.; Wei, J.; Whangbo, M. Ag@AgCl: A Highly Efficient and Stable Photocatalyst Active under Visible Light. Angew. Chem. Int. Ed. 2008, 47, 7931. [Google Scholar] [CrossRef]

- Devi, T.B.; Begum, S.; Ahmaruzzaman, M. Photo-catalytic activity of Plasmonic Ag@AgCl nanoparticles (synthesized via a green route) for the effective degradation of Victoria Blue B from aqueous phase. J. Photochem. Photobiol. B Biol. 2016, 160, 260–270. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, Y.; Qin, Y.; Yu, D.; Zhou, J. Stepwise Evolution of AgCl Microcrystals from Octahedron into Hexapod with Mace Pods and their Visible Light Photocatalytic Activity. Crystals 2019, 9, 401. https://doi.org/10.3390/cryst9080401

Lu Y, Qin Y, Yu D, Zhou J. Stepwise Evolution of AgCl Microcrystals from Octahedron into Hexapod with Mace Pods and their Visible Light Photocatalytic Activity. Crystals. 2019; 9(8):401. https://doi.org/10.3390/cryst9080401

Chicago/Turabian StyleLu, Yuxiang, Yazhou Qin, Dongdong Yu, and Jianguang Zhou. 2019. "Stepwise Evolution of AgCl Microcrystals from Octahedron into Hexapod with Mace Pods and their Visible Light Photocatalytic Activity" Crystals 9, no. 8: 401. https://doi.org/10.3390/cryst9080401

APA StyleLu, Y., Qin, Y., Yu, D., & Zhou, J. (2019). Stepwise Evolution of AgCl Microcrystals from Octahedron into Hexapod with Mace Pods and their Visible Light Photocatalytic Activity. Crystals, 9(8), 401. https://doi.org/10.3390/cryst9080401