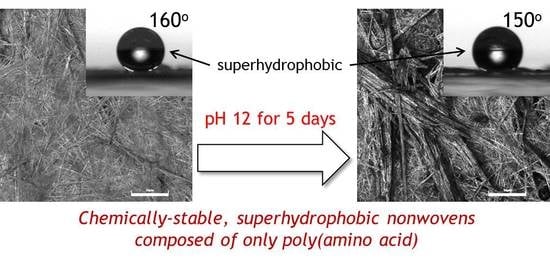

Creation of Superhydrophobic Poly(L-phenylalanine) Nonwovens by Electrospinning

Abstract

Share and Cite

Yoshida, H.; Yanagisawa, K. Creation of Superhydrophobic Poly(L-phenylalanine) Nonwovens by Electrospinning. Polymers 2018, 10, 1212. https://doi.org/10.3390/polym10111212

Yoshida H, Yanagisawa K. Creation of Superhydrophobic Poly(L-phenylalanine) Nonwovens by Electrospinning. Polymers. 2018; 10(11):1212. https://doi.org/10.3390/polym10111212

Chicago/Turabian StyleYoshida, Hiroaki, and Kazuhiro Yanagisawa. 2018. "Creation of Superhydrophobic Poly(L-phenylalanine) Nonwovens by Electrospinning" Polymers 10, no. 11: 1212. https://doi.org/10.3390/polym10111212

APA StyleYoshida, H., & Yanagisawa, K. (2018). Creation of Superhydrophobic Poly(L-phenylalanine) Nonwovens by Electrospinning. Polymers, 10(11), 1212. https://doi.org/10.3390/polym10111212