Eco-Friendly and Highly Efficient Enzyme-Based Wool Shrinkproofing Finishing by Multiple Padding Techniques

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Enzyme Treatment

2.2.1. Exhaustion Process

2.2.2. Multiple Padding Process

2.3. Plant Treatment of Wool with the Chlorine-Hercosett Process and Multiple Padding Enzyme Process Respectively

2.4. Measurement

2.4.1. Felting Shrinkage

2.4.2. Directional Friction Effect

2.4.3. Mechanical Property

2.4.4. Fineness

2.4.5. Surface Morphology

2.4.6. Enzyme Adsorption

2.4.7. Amino Acid Content

2.4.8. Weight Loss

2.4.9. X-ray Photoelectron Spectroscopy (XPS)

2.4.10. Colorimetric Measurements

3. Result and Discussion

3.1. Effect of Different Enzyme Treatment Methods on Wool Fiber Properties

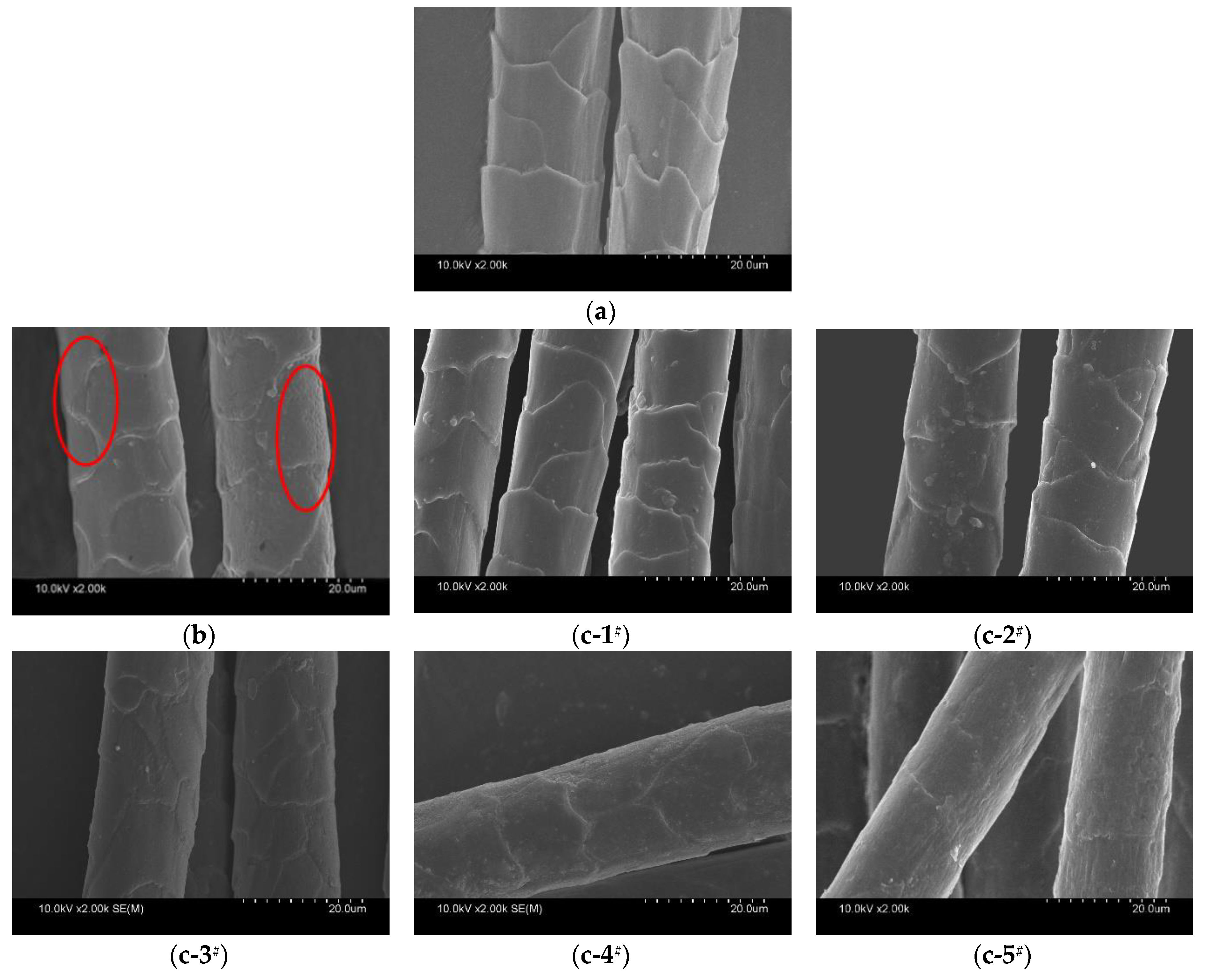

3.1.1. Shrinkproofing Performance and Surface Morphology

3.1.2. Fineness and Mechanical Properties

3.2. Effect of Different Enzyme Treatment Methods on Adsorption Performance of Enzyme

3.3. Effect of Different Enzyme Treatment Methods on Reaction Efficiency

3.4. XPS Characterization of Wool Fibers after Enzyme Treatment

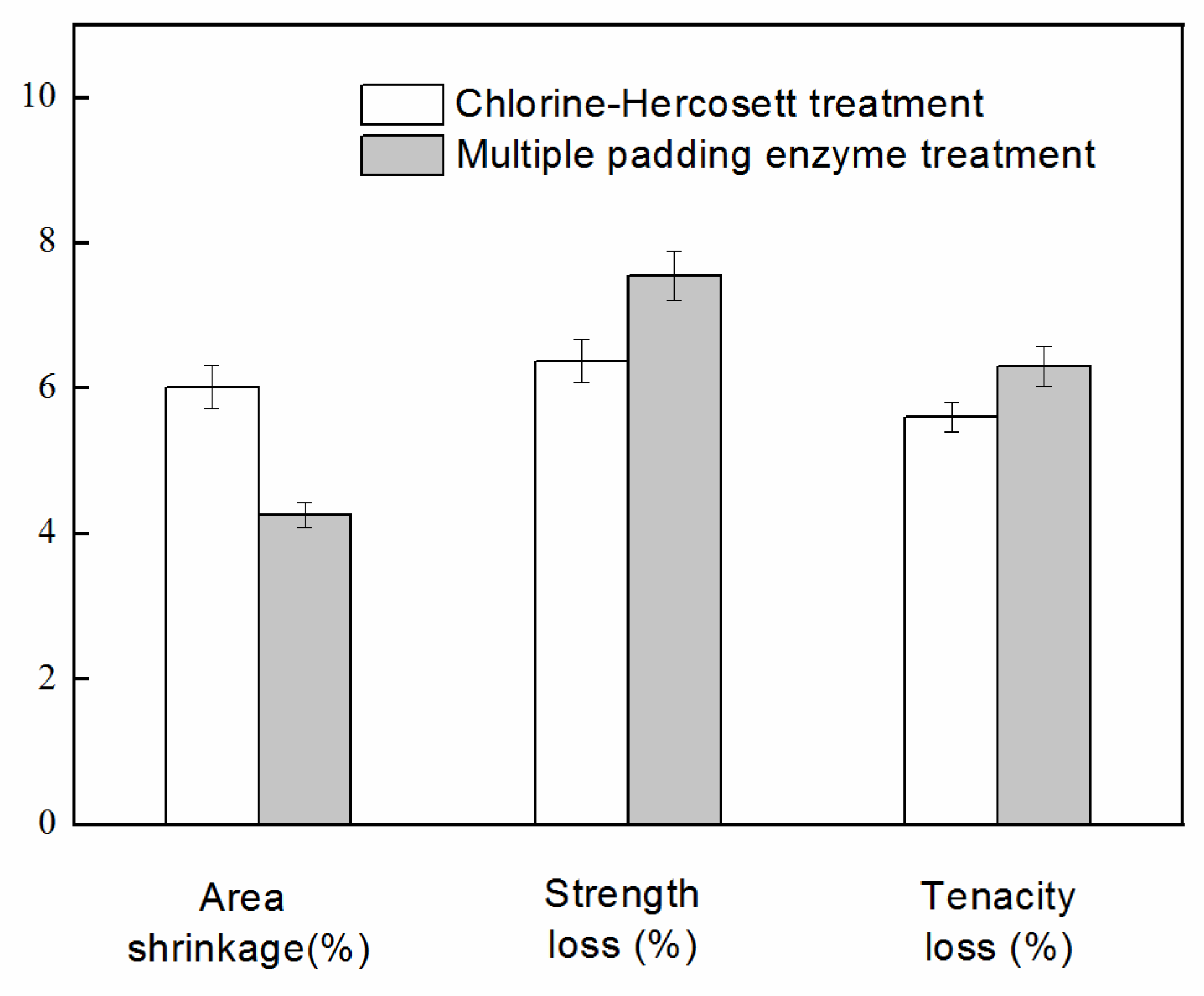

3.5. Performance Analysis of Chlorine-Hercosett Treated and Multiple Padding Enzyme Treated Wool

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Madhu, A.; Chakraborty, J.N. Developments in application of enzymes for textile processing. J. Clean. Prod. 2017, 145, 114–133. [Google Scholar] [CrossRef]

- El-Sayed, H.; Kantouch, A.; Heine, E.; Hocker, H. Developing a zero-AOX shrink-resist process for wool. Part 1: Preliminary results. Color. Technol. 2001, 117, 234–238. [Google Scholar] [CrossRef]

- Cui, L.; Chen, T.; Ding, C.; Li, Z.; Yan, J.; Liu, Y.; Niu, X.; Chen, A.; Yang, W. Spatial distribution of total halogenated organic compounds (TX), adsorbable organic halogens (AOX), and heavy metals in wetland soil irrigated with pulp and paper wastewater. Chem. Speciat. Bioavailab. 2017, 29, 15–24. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, A. Modification of wool by air plasma and enzymes as a cleaner and environmentally friendly process. J. Clean. Prod. 2015, 87, 961–965. [Google Scholar] [CrossRef]

- Canal, C.; Molina, R.; Bertran, E.; Erra, P. Polysiloxane softener coatings on plasma-treated wool: Study of the surface interactions. Macromol. Mater. Eng. 2007, 292, 817–824. [Google Scholar] [CrossRef]

- Karakawa, T.; Umehara, R.; Ichimura, H.; Nakase, K.; Ohshima, K. Continuous shrink-resist process of wool top sliver with ozone I performance. Sen-I Gakkaishi 2002, 58, 135–142. [Google Scholar] [CrossRef]

- Shen, J.; Smith, E.; Chizyuka, M.; Prajapati, C. Development of durable shrink-resist coating of wool with sol-gel polymer processing. Fibers Polym. 2017, 18, 1769–1779. [Google Scholar] [CrossRef]

- Shahid, M.; Mohammad, F.; Chen, G.; Tang, R.-C.; Xing, T. Enzymatic processing of natural fibres: White biotechnology for sustainable development. Green Chem. 2016, 18, 2256–2281. [Google Scholar] [CrossRef]

- Fu, J.; Su, J.; Wang, P.; Yu, Y.; Wang, Q.; Cavaco-Paulo, A. Enzymatic processing of protein-based fibers. Appl. Microbiol. Biotechnol. 2015, 99, 10387–10397. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mojsov, K. Enzymatic treatment of wool fabrics—Opportunity of the improvement on some physical and chemical properties of the fabrics. J. Text. Inst. 2017, 108, 1136–1143. [Google Scholar] [CrossRef]

- Iglesias, M.S.; Sequeiros, C.; Garcia, S.; Olivera, N.L. Newly isolated Bacillus sp. G51 from Patagonian wool produces an enzyme combination suitable for felt-resist treatments of organic wool. Bioprocess Biosyst. Eng. 2017, 40, 833–842. [Google Scholar] [CrossRef] [PubMed]

- Wang, P.; Yuan, J.; Ren, X.; Cui, L.; Wang, Q.; Fan, X. Bio-antifelting of wool based on mild methanolic potassium hydroxide pretreatment. Eng. Life Sci. 2013, 13, 102–108. [Google Scholar] [CrossRef]

- Zhang, Z.; Nie, Y.; Zhang, Q.; Liu, X.; Tu, W.; Zhang, X.; Zhang, S. Quantitative Change in Disulfide Bonds and Microstructure Variation of Regenerated Wool Keratin from Various Ionic Liquids. ACS Sustain. Chem. Eng. 2017, 5, 2614–2622. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Q.; Fan, X.; Cui, L.; Yuan, J.; Chen, S.; Wu, J. Effects of cutinase on the enzymatic shrink-resist finishing of wool fabrics. Enzyme Microb. Technol. 2009, 44, 302–308. [Google Scholar] [CrossRef]

- Lenting, H.B.M.; Schroeder, M.; Guebitz, G.M.; Cavaco-Paulo, A.; Shen, J. New enzyme-based process direction to prevent wool shrinking without substantial tensile strength loss. Biotechnol. Lett. 2006, 28, 711–716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Smith, E.; Shen, J. Enzymatic treatment of wool pre-treated with cetyltrimethylammonium bromide to achieve machine washability. Biocatal. Biotransform. 2012, 30, 38–47. [Google Scholar] [CrossRef]

- Kaur, A.; Chakraborty, J.N. Controlled eco-friendly shrink-resist finishing of wool using bromelain. J. Clean. Prod. 2015, 108, 503–513. [Google Scholar] [CrossRef]

- Kaur, A.; Chakraborty, J.N.; Dubey, K.K. Enzymatic Functionalization of Wool for Felting Shrink-Resistance. J. Nat. Fibers 2016, 13, 437–450. [Google Scholar] [CrossRef]

- Du, G.; Cui, L.; Zhu, Y.; Chen, J. Improvement of shrink-resistance and tensile strength of wool fabric treated with a novel microbial transglutaminase from Streptomyces hygroscopicus. Enzyme Microb. Technol. 2007, 40, 1753–1757. [Google Scholar] [CrossRef]

- Li, X.; Wang, Q.; Fan, X.; Wang, P.; Yuan, J.; Cui, L. Self-crosslinking and Grafting Reactions in mTGase-mediated Modification of Wool Fibers. Res. J. Biotechnol. 2014, 9, 70–74. [Google Scholar]

- Gaffar Hossain, K.M.; Diaz Gonzalez, M.; Riva Juan, A.; Tzanov, T. Enzyme-mediated coupling of a bi-functional phenolic compound onto wool to enhance its physical, mechanical and functional properties. Enzyme Microb. Technol. 2010, 46, 326–330. [Google Scholar] [CrossRef] [Green Version]

- Shen, J.; Rushforth, M.; Cavaco-Paulo, A.; Guebitz, G.; Lenting, H. Development and industrialisation of enzymatic shrink-resist process based on modified proteases for wool machine washability. Enzyme Microb. Technol. 2007, 40, 1656–1661. [Google Scholar] [CrossRef]

- Silva, C.J.S.M.; Zhang, Q.; Shen, J.; Cavaco-Paulo, A. Immobilization of proteases with a water soluble-insoluble reversible polymer for treatment of wool. Enzyme Microb. Technol. 2006, 39, 634–640. [Google Scholar] [CrossRef] [Green Version]

- Silva, C.; Prabaharan, M.; Gubitz, G.; Cavaco-Paulo, A. Treatment of wool fibres with subtilisin and subtilisin-PEG. Enzyme Microb. Technol. 2005, 36, 917–922. [Google Scholar] [CrossRef] [Green Version]

- Yin, X.; Liu, J.; Yao, J.; Liu, Y.; Wang, L. Application of synergetic protease catalytic system in wool treatment. In Proceedings of the 13th International Wool Research Conference, IWRC 2015 and AATCC Sustainability Symposium, AATCC-SS 2015, Hangzhou, China, 10–14 June 2015; Trans Tech Publications Ltd.: Hangzhou, China, 2015; pp. 19–24. [Google Scholar]

- Wang, L.J.; Lin, T.; Wang, X.G.; Kaynak, A. Frictional and tensile properties of conducting polymer coated wool and alpaca fibers. Fibers Polym. 2005, 6, 259–262. [Google Scholar] [CrossRef]

- Yang, M.; Yan, K.; Zhou, A. A Study on Xe-2* Excilamp Treatment of Wool Fibers. J. Appl. Polym. Sci. 2010, 118, 241–246. [Google Scholar] [CrossRef]

- Vilakazi, R.L.M.; Chikwembani, S. Surface structure study of shrink-resist treated wool fibres using atomic force microscopy. S. Afr. J. Sci. 2005, 101, 502–506. [Google Scholar]

- Li, X.; Yang, Z.; Peng, Y. The interaction of silver nanoparticles with papain and bromelain. New J. Chem. 2018, 42, 4940–4950. [Google Scholar] [CrossRef]

- Chakraborty, J.N.; Madan, P.P.S. Imparting anti-shrink functionality to wool by individual and simultaneous application of keratinase and papain. Indian J. Fibre Text. Res. 2014, 39, 411–417. [Google Scholar]

- Jovancic, P.; Jocic, D.; Molina, R.; Julia, M.R.; Erra, P. The combined low-temperature, plasma/enzyme wool shrink-resist treatment. AATCC Rev. 2003, 3, 25–28. [Google Scholar]

- Farouk, H.U.; Raman, A.A.A.; Daud, W.M.A.W. Surface transformations of TiO2 anatase deactivated in methylene blue solution with Cl- ions in the colloid. J. Taiwan Inst. Chem. Eng. 2017, 80, 203–214. [Google Scholar] [CrossRef]

- Okamoto, M.; Ishikawa, K.; Tanji, N.; Aoyagi, S. Investigation of the damage on the outermost hair surface using ToF-SIMS and XPS. Surf. Interface Anal. 2012, 44, 736–739. [Google Scholar] [CrossRef]

- Wang, P.; Wang, Q.; Cui, L.; Fan, X.; Yuan, J.; Gao, M. A Comparative Evaluation of the Action of Savinase and Papain to the Cutinase-pretreated Wool. Fibers Polym. 2010, 11, 586–592. [Google Scholar] [CrossRef]

- Kan, C.-W.; Wong, W.-Y. Color properties of cellulase-treated cotton denim fabric manufactured by torque-free ring spun yarn. Text. Res. J. 2011, 81, 875–882. [Google Scholar] [CrossRef]

| Samples | Area Shrinkage/% | Static D.F.E./% | Kinetic D.F.E./% |

|---|---|---|---|

| Control | 56.8 (0.53) | 26.5 (0.17) | 23.7 (0.43) |

| Exhaustion treatment | 49.2 (0.67) | 23.9 (0.33) | 21.8 (0.62) |

| Padding treatment | 2.4 (0.45) | 9.3 (0.18) | 8.1 (0.33) |

| Samples | Fineness/μm | Strength/cN | Tenacity/×10−2cN/μm2 | Retention Rate/% | ||

|---|---|---|---|---|---|---|

| Strength | Tenacity | |||||

| Control | 19.5 (0.21) | 6.6 (1.01) | 2.2 | -- | -- | |

| Exhaustion treatment | 19.4 (0.43) | 6.2 (1.57) | 2.1 | 94.1 | 94.6 | |

| Padding treatment | 1# | 19.4(0.20) | 6.5(1.21) | 2.2 | 97.6 | 99.5 |

| 2# | 19.3(0.33) | 6.3(0.85) | 2.1 | 94.7 | 97.6 | |

| 3# | 19.2(0.36) | 6.1(1.10) | 2.1 | 91.6 | 95.3 | |

| 4# | 19.0(0.31) | 5.9(0.83) | 2.1 | 88.3 | 94.2 | |

| 5# | 18.9 (0.20) | 5.7 (0.93) | 2.0 | 87.0 | 92.6 | |

| Samples | Concentration of Elements (At%) | |||

|---|---|---|---|---|

| C1s | N1s | O1s | S2p | |

| Control | 75.9 | 7.8 | 11.6 | 3.2 |

| Exhaustion treatment | 77.2 | 9.6 | 11.4 | 1.9 |

| Padding treatment | 76.3 | 7.3 | 15.1 | 1.3 |

| Samples | Relative Area of Different Chemical Bonds (%) | |

|---|---|---|

| –S–S– (164.48 eV) | –SO3H (168.5 eV) | |

| Control | 100.0 | <0.1 |

| Exhaustion treatment | 80.0 | 20.0 |

| Padding treatment | 19.6 | 80.4 |

| Sample | L* | a* | b* | ∆L* | ∆a* | ∆b* | CIE Whiteness |

|---|---|---|---|---|---|---|---|

| Control | 87.9 | −0.1 | 10.5 | — | — | — | 20.8 |

| Chlorine-Hercosett treatment | 90.7 | −1.2 | 11.2 | 2.8 | −1.1 | 0.7 | 24.6 |

| Multiple padding enzyme treatment | 90.4 | −1.0 | 9.4 | 2.5 | −0.9 | −1.1 | 32.5 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, L.; Yao, J.; Niu, J.; Liu, J.; Li, B.; Feng, M. Eco-Friendly and Highly Efficient Enzyme-Based Wool Shrinkproofing Finishing by Multiple Padding Techniques. Polymers 2018, 10, 1213. https://doi.org/10.3390/polym10111213

Wang L, Yao J, Niu J, Liu J, Li B, Feng M. Eco-Friendly and Highly Efficient Enzyme-Based Wool Shrinkproofing Finishing by Multiple Padding Techniques. Polymers. 2018; 10(11):1213. https://doi.org/10.3390/polym10111213

Chicago/Turabian StyleWang, Le, Jinbo Yao, Jiarong Niu, Jianyong Liu, Bo Li, and Mao Feng. 2018. "Eco-Friendly and Highly Efficient Enzyme-Based Wool Shrinkproofing Finishing by Multiple Padding Techniques" Polymers 10, no. 11: 1213. https://doi.org/10.3390/polym10111213

APA StyleWang, L., Yao, J., Niu, J., Liu, J., Li, B., & Feng, M. (2018). Eco-Friendly and Highly Efficient Enzyme-Based Wool Shrinkproofing Finishing by Multiple Padding Techniques. Polymers, 10(11), 1213. https://doi.org/10.3390/polym10111213