The Influence of Shape Memory Alloy Volume Fraction on the Impact Behavior of Polymer Composites

Abstract

:1. Introduction

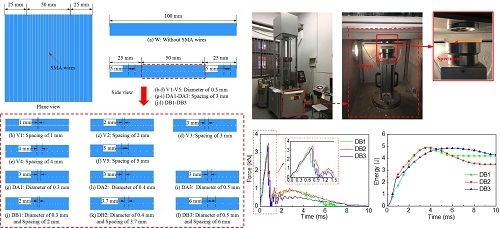

2. Experimental

2.1. Materials and Manufacturing

- (i)

- The treated SMA wire is arranged neatly according to the above design scheme (Figure 2), and the two ends of all SMA wires are fixed by using a scotch tape, respectively, and then they are placed in a silicon mold.

- (ii)

- The epoxy resin is mixed, the curing agent and the accelerator in a ratio of 100:1.5:0.15 is added, then they are uniformly stirred, and placed in a vacuum drying oven for about 4 min to extract the air. Note: The vacuum time should not be too long, otherwise the mixture will easily become gelled, resulting in the failure of the preparation.

- (iii)

- The air-free mixtures are poured into the mold with SMA wires, and the whole system is cured at room temperature for 12 h.

2.2. Low-Velocity Impact Test

3. Results and Discussion

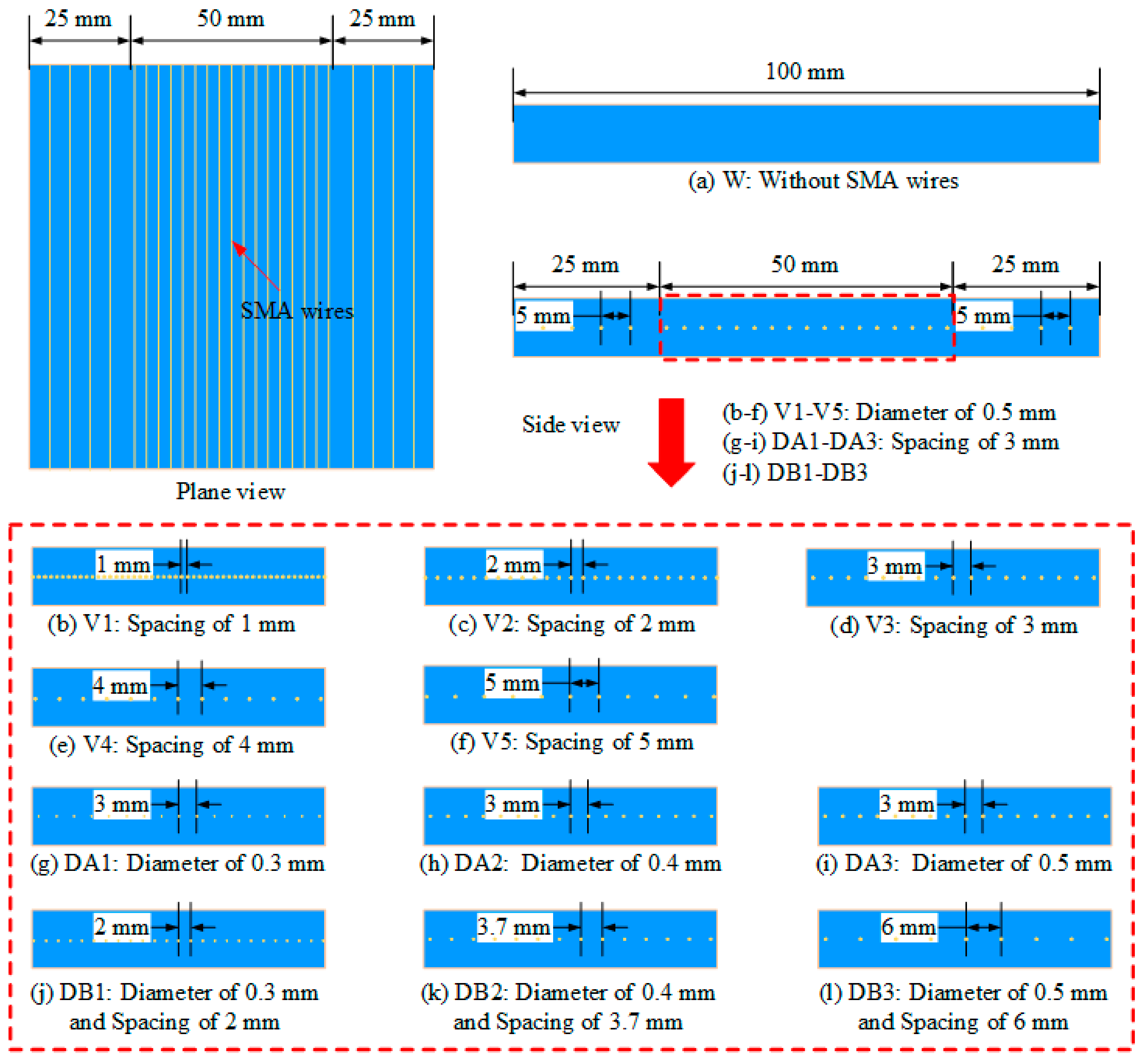

3.1. Failure Modes of Composites after the Low-Velocity Impact Test

3.1.1. Composites with Different SMA Layup Spacing Value

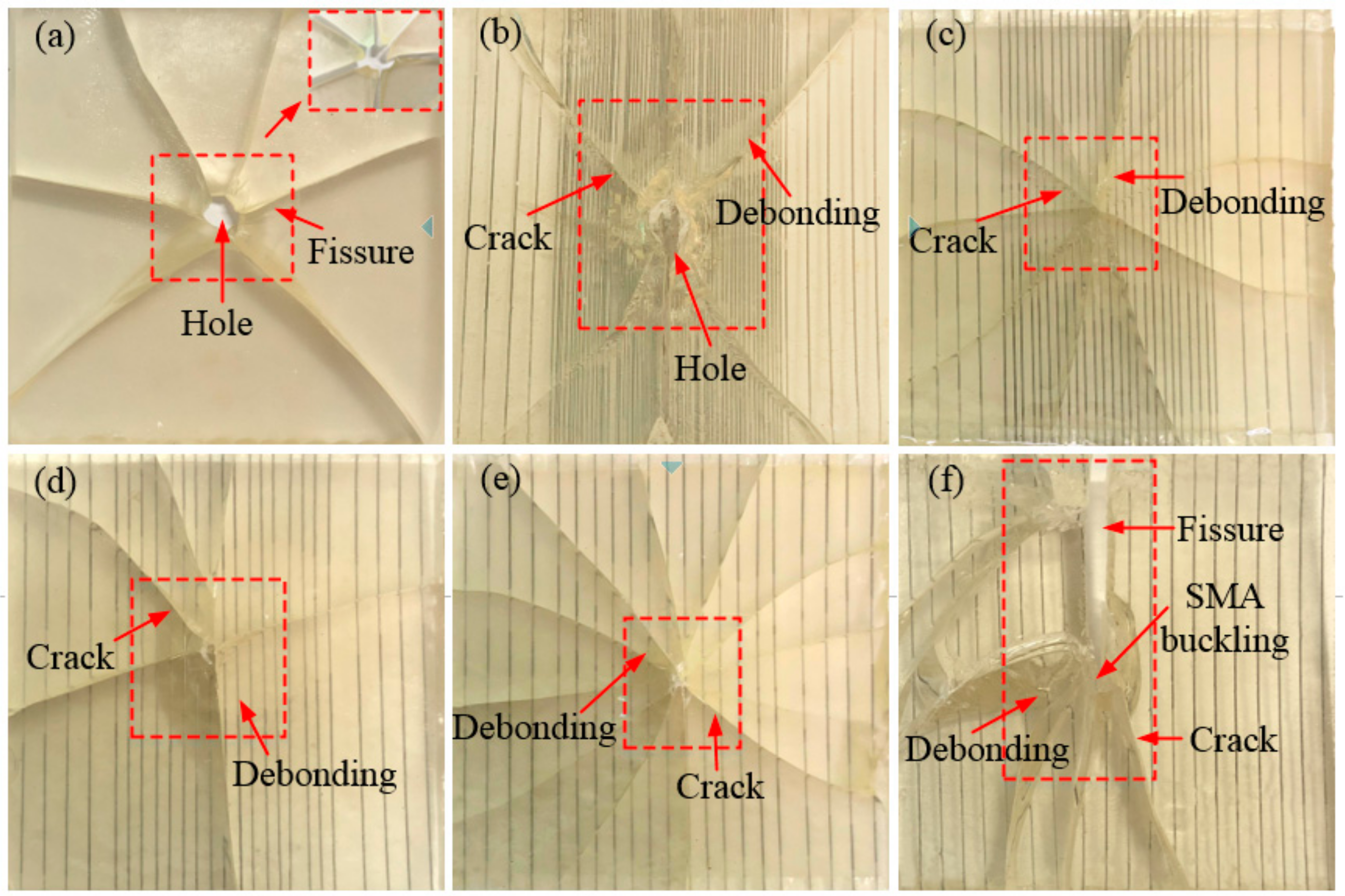

3.1.2. Composites with Different SMA Diameters

3.1.3. Composites with Different SMA Diameters and Layup Spacing Values

3.2. Influence of SMA Volume Fractions on Spacing Impact Behavior of spacing Composite

3.2.1. Different SMA Volume Fractions (Different SMA Layup Spacing)

3.2.2. Different SMA Volume Fractions (Different SMA Diameters)

3.2.3. Different SMA Volume Fractions (Different SMA Diameters and Layup Spacing)

4. Conclusions

- (1)

- Embedding the SMA wire into the pure polymer composites can effectively improve the bearing capacity and energy absorption characteristics of the entire test specimen and reduce the damage of the test specimen.

- (2)

- The SMA layup spacing has a great influence on the impact performance of the specimen. The specimen (V3) with a layup spacing of 3 mm has the best impact performance, the largest load carrying capacity and the smallest damage among six groups polymer composites. Here, the impact performance is the best when the volume fraction of the SMA wire in the test specimen is 0.49% in the 3 groups of polymer composites.

- (3)

- SMA diameter also has an effect on the impact properties of the specimen, which is the best for the specimen (DA3) with a diameter of 0.5 mm among the 3 group composite specimens. Here, the impact performance is the best when the volume fraction of the SMA wire in the test specimen is 0.49% in the 3 groups of polymer composites.

- (4)

- When the two factors of the SMA layup spacing and diameter are changed at the same time, the overall damage state of the test specimen, as well as the bearing capacity and energy absorption characteristics are also affected. Among the three test specimens, the impact resistance of the test specimen (DB2) with an SMA layup spacing of 3.7 mm and a diameter of 0.4 mm is the best, and the SMA layup spacing had a greater influence on the impact characteristics of the test specimen than the SMA diameter. Here, the impact performance is best when the volume fraction of the SMA wire in the test specimen is 0.28% in the 3 groups of polymer composites.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sevkat, E.; Liaw, B.; Delale, F. Drop-weight impact response of hybrid composites impacted by impactor of various geometries. Mater. Des. 2013, 52, 67–77. [Google Scholar] [CrossRef]

- Sayer, M.; Bektas, N.B.; Sayman, O. An experimental investigation on the impact behavior of hybrid composite plates. Compos. Struct. 2010, 92, 1256–1262. [Google Scholar] [CrossRef]

- Aktas, M.; Atas, C.; Içten, B.M.; Karakuzu, R. An experimental investigation of the impact response of composite laminates. Compos. Struct. 2009, 87, 307–313. [Google Scholar] [CrossRef]

- Atas, C.; Sayman, O. An overall view on impact response of woven fabric composite plates. Compos. Struct. 2008, 82, 336–345. [Google Scholar] [CrossRef]

- Baucom, J.N.; Zikry, M.A. Low-velocity impact damage progression in woven Eglass composite systems. Compos. Part A-Appl. Sci. Manuf. 2005, 36, 658–664. [Google Scholar] [CrossRef]

- Aslan, Z.; Karakuzu, R.; Okutan, B. The response of laminated composite plates under low-velocity impact loading. Compos. Struct. 2003, 59, 119–127. [Google Scholar] [CrossRef]

- De Moura, M.; Marques, A.T. Prediction of low velocity impact damage in carbonepoxy laminates. Compos. Part A-Appl. Sci. Manuf. 2002, 33, 361–368. [Google Scholar] [CrossRef]

- Palazotto, A.N.; Gummadi, L.N.B.; Vaidya, U.K.; Herup, E.J. Low velocity impact damage characteristics of Z-fiber reinforced sandwich panels-an experimental study. Compos. Struct. 1999, 43, 275–288. [Google Scholar] [CrossRef]

- Davies, G.A.O.; Zhang, X. Impact damage prediction in carbon composite structures. Int. J. Impact Eng. 1995, 16, 149–170. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of Low-Temperature Phase Changes on the Mechanical Properties of Alloys near Composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Sun, Q.P.; Li, Z.Q. Phase transformation in superelastic NiTi polycrystalline micro-tubes under tension and torsion––From localization to homogeneous deformation. Int. J. Solids Struct. 2002, 39, 3797–3809. [Google Scholar] [CrossRef]

- Xie, C.; Raghavan, J.; Yue, B.; Rajapakse, N. Stress-induced martensitic-transformation-related passive damping characteristics of TiNi fibres. Mater. Sci. Eng. A 2006, 438, 649–652. [Google Scholar] [CrossRef]

- John, S.; Hariri, M. Effect of shape memory alloy actuation on the dynamic response of polymeric composite plates. Compos. Part A-Appl. Sci. Manuf. 2008, 39, 769–776. [Google Scholar] [CrossRef]

- Aurrekoetxea, J.; Zurbitu, J.; Mendibil, I.O.D.; Agirregomezkorta, A.; Sanchez-Soto, M.; Sarrionandia, M. Effect of superelastic shape memory alloy wires on the impact behavior of carbon fiber reinforced in situ polymerized poly(butylene terephthalate) composites. Mater. Lett. 2011, 65, 863–865. [Google Scholar] [CrossRef]

- Zhang, R.; Ni, Q.Q.; Natsuki, T.; Iwamoto, M. Mechanical properties of composites filled with SMA particles and short fibers. Compos. Struct. 2007, 79, 90–96. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.; Lloyd, P. Design, manufacture and evaluation of bending behaviour of composite beams embedded with SMA wires. Compos. Sci. Technol. 2009, 69, 2034–2041. [Google Scholar] [CrossRef]

- Taheri-Behrooz, F.; Taheri, F.; Hosseinzadeh, R. Characterization of a shape memory alloy hybrid composite plate subject to static loading. Mater. Des. 2011, 32, 2923–2933. [Google Scholar] [CrossRef]

- Lei, H.S.; Wang, Z.Q.; Tong, L.Y.; Zhou, B.; Fu, J. Experimental and numerical investigation on the macroscopic mechanical behavior of shape memory alloy hybrid composite with weak interface. Compos. Struct. 2013, 101, 301–312. [Google Scholar] [CrossRef]

- Paine, J.S.N.; Rogers, C.A. The response of SMA hybrid composite materials to low velocity impact. J. Intell. Mater. Syst. Struct. 1994, 5, 530–535. [Google Scholar] [CrossRef]

- Roh, J.H.; Kim, J.H. Hybrid smart composite plate under low velocity impact. Compos. Struct. 2002, 56, 175–182. [Google Scholar] [CrossRef]

- Tsoi, K.A.; Stalmans, R.; Schrooten, J.; Wevers, M.; Mai, Y.W. Impact damage behaviour of shape memory alloy composites. Mater. Sci. Eng. A 2003, 342, 207–215. [Google Scholar] [CrossRef]

- Lau, K.T.; Ling, H.Y.; Zhou, L.M. Low velocity impact on shape memory alloy stitched composite plates. Smart. Mater. Struct. 2004, 13, 364–370. [Google Scholar] [CrossRef]

- Khalili, S.M.R.; Shokuhfar, A.; Malekzadeh, K.; Ghasemi, F.A. Low-velocity impact response of active thin-walled hybrid composite structures embedded with SMA wires. Thin-Walled Struct. 2007, 45, 799–808. [Google Scholar] [CrossRef]

- Pappadà, S.; Rametta, R.; Largo, A.; Maffezzoli, A. Low-velocity impact response in composite plates embedding shape memory alloy wires. Polym. Compos. 2012, 33, 655–664. [Google Scholar] [CrossRef]

- Sun, M.; Wang, Z.Q.; Yang, B.; Sun, X.K. Experimental investigation of GF/epoxy laminates with different SMAs positions subjected to low-velocity impact. Compos. Struct. 2017, 171, 170–184. [Google Scholar] [CrossRef]

- Meo, M.; Marulo, F.; Guida, M.; Russo, S. Shape memory alloy hybrid composites for improved impact properties for aeronautical applications. Compos. Struct. 2013, 95, 756–766. [Google Scholar] [CrossRef]

- Kang, K.W.; Kim, J.K. Effect of shape memory alloy on impact damage behavior and residual properties of glass/epoxy laminates under low temperature. Compos. Struct. 2009, 88, 455–460. [Google Scholar] [CrossRef]

- Raghavan, J.; Bartkiewicz, T.; Boyko, S.; Kupriyanov, M.; Rajapakse, N.; Yu, B. Damping, tensile, and impact properties of superelastic shape memory alloy (SMA) fiber-reinforced polymer composites. Compos. Part B-Eng. 2010, 41, 214–222. [Google Scholar] [CrossRef]

- Wang, Y.L.; Zhou, L.M.; Wang, Z.Q.; Huang, H.T.; Ye, L. Analysis of internal stresses induced by strain recovery in a single SMA fiber-matrix composite. Compos. Part B-Eng. 2011, 42, 1135–1143. [Google Scholar] [CrossRef]

- Wang, Y.L.; Zhou, L.M.; Wang, Z.Q.; Huang, H.T.; Ye, L. Stress distributions in single shape memory alloy fiber composites. Mater. Des. 2011, 32, 3783–3789. [Google Scholar] [CrossRef]

- Lei, H.S.; Wang, Z.Q.; Zhou, B.; Tong, L.Y.; Wang, X.Q. Simulation and analysis of shape memory alloy fiber reinforced composite based on cohesive zone model. Mater. Des. 2012, 40, 138–147. [Google Scholar] [CrossRef]

- Wang, Z.Q.; Liu, Y.F.; Lv, H.Q.; Yang, B. Enhancement of interface performance between shape memory alloy fiber and polymer matrix using silane coupling agent KH550 and Al2O3 nanoparticles. Polym. Compos. 2017, 39, 3040–3047. [Google Scholar] [CrossRef]

| Diameter (mm) | 0.301–0.303 | 0.394–0.398 | 0.501–0.502 |

|---|---|---|---|

| for Delivery (℃) | 9.5 | 14.2 | 10 |

| Tensile Strength (MPa) | 1566.84 | 1536.27 | 1535.88 |

| Upper Plateau Stress (MPa) | 541.84 | 564.12 | 542.26 |

| Lower Plateau Stress (MPa) | 116.01 | 142.48 | 110.02 |

| Elongation (%) | 12.99 | 12.62 | 12.75 |

| Residual Elongation (%) | 0.05 | 0.01 | 0.15 |

| Codes | VF (%) | Codes | VF (%) | Codes | VF (%) |

|---|---|---|---|---|---|

| W | 0 | V1 | 1.14 | V2 | 0.65 |

| V3 | 0.49 | V4 | 0.41 | V5 | 0.37 |

| DA1 | 0.18 | DA2 | 0.31 | DA3 | 0.49 |

| DB1 | 0.23 | DB2 | 0.28 | DB3 | 0.33 |

| Codes | Resin Unit Price (¥/L) | Resin Dosage (L) | SMA Diameter (mm) | SMA Unit Price (¥/m) | SMA Dosage (m) | Total Price (¥) | Cost Increase Rate (%) |

|---|---|---|---|---|---|---|---|

| W | 50 | 0.125 | 0 | 0 | 0 | 6.25 | 0 |

| V1 | 50 | 0.125 | 0.3 | 1 | 5.0 | 11.25 | 80 |

| V2 | 50 | 0.125 | 0.3 | 1 | 2.5 | 8.75 | 40 |

| V3 | 50 | 0.125 | 0.3 | 1 | 1.7 | 7.95 | 27.2 |

| V4 | 50 | 0.125 | 0.3 | 1 | 1.3 | 7.55 | 20.8 |

| V5 | 50 | 0.125 | 0.3 | 1 | 1.1 | 7.35 | 17.6 |

| DA1 | 50 | 0.125 | 0.3 | 1 | 1.7 | 7.95 | 27.2 |

| DA2 | 50 | 0.125 | 0.4 | 1.5 | 1.7 | 8.8 | 40.8 |

| DA3 | 50 | 0.125 | 0.5 | 2 | 1.7 | 9.65 | 54.4 |

| DB1 | 50 | 0.125 | 0.3 | 1 | 2.5 | 8.75 | 40 |

| DB2 | 50 | 0.125 | 0.4 | 1.5 | 1.4 | 8.35 | 33.6 |

| DB3 | 50 | 0.125 | 0.5 | 2 | 0.9 | 8.05 | 28.8 |

| Parameters | Initial Energy | V1 | V2 | V3 | V4 | V5 | W |

|---|---|---|---|---|---|---|---|

| Max. contact force (kN) | 5 J | 3.51 | 3.61 | 3.75 | 3.56 | 3.47 | 3.23 |

| 14 J | 6.55 | 7.50 | 7.26 | 7.14 | 6.28 | 5.60 | |

| Avg. contact force (kN) | 5 J | 0.43 | 0.49 | 0.58 | 0.53 | 0.46 | 0.37 |

| 14 J | 0.65 | 0.91 | 1.01 | 0.78 | 0.69 | 0.46 | |

| Ultimate absorbed Energy (J) | 5 J | 4.6 | 4.26 | 3.11 | 4.22 | 4.50 | 4.71 |

| 14 J | 12.74 | 14.13 | 12.93 | 13.43 | 11.16 | 9.23 |

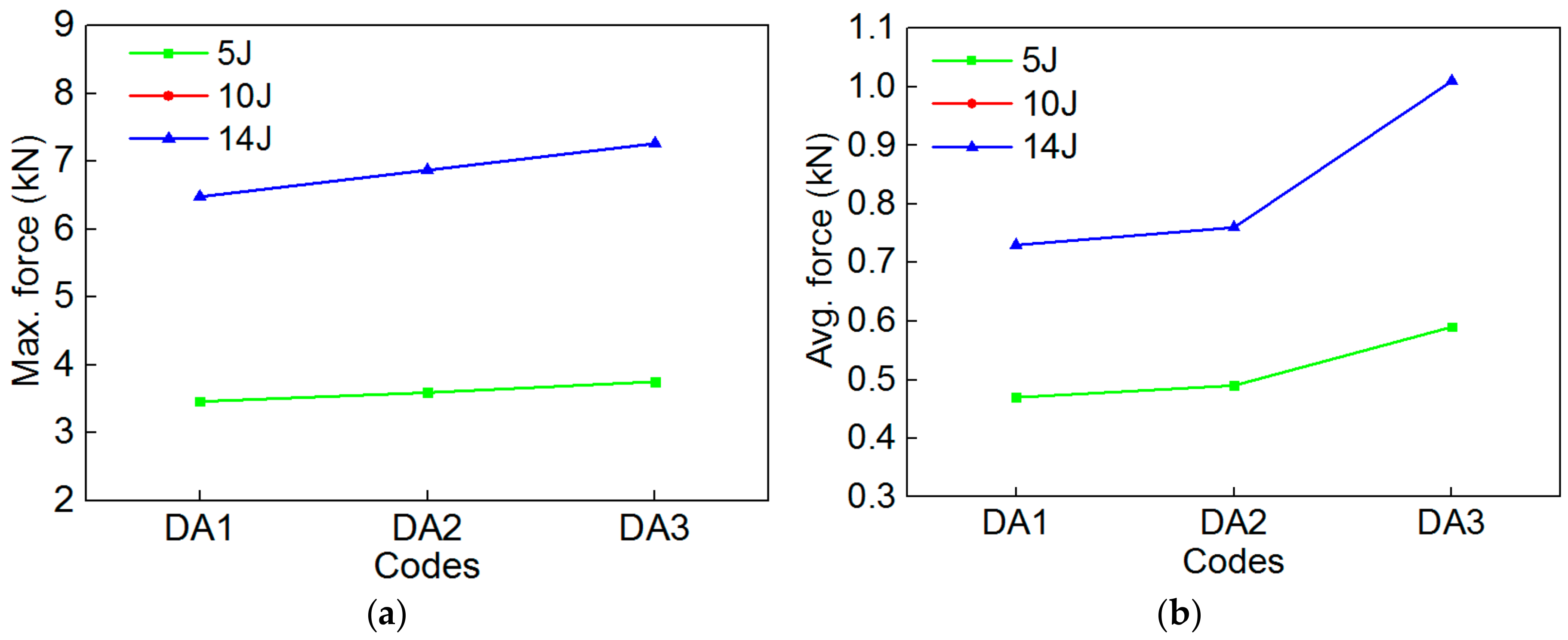

| Parameters | Initial Energy | DA1 | DA2 | DA3 |

|---|---|---|---|---|

| Max. contact force (kN) | 5 J | 3.46 | 3.59 | 3.75 |

| 14 J | 6.48 | 6.87 | 7.26 | |

| Avg. contact force (kN) | 5 J | 0.47 | 0.49 | 0.59 |

| 14 J | 0.73 | 0.76 | 1.01 | |

| Ultimate absorbed Energy (J) | 5 J | 4.22 | 3.75 | 3.11 |

| 14 J | 11.63 | 12.85 | 12.93 |

| Parameters | Initial Energy | DB1 | DB2 | DB3 |

|---|---|---|---|---|

| Max. contact force (kN) | 5 J | 3.4 | 3.52 | 3.3 |

| 14 J | 6.21 | 6.82 | 5.88 | |

| Avg. contact force (kN) | 5 J | 0.46 | 0.49 | 0.39 |

| 14 J | 0.54 | 0.75 | 0.51 | |

| Ultimate absorbed Energy (J) | 5 J | 4.21 | 3.50 | 4.29 |

| 14 J | 12.88 | 13.90 | 12.58 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Sun, X.; Wang, Z.; Chang, M.; Li, H. The Influence of Shape Memory Alloy Volume Fraction on the Impact Behavior of Polymer Composites. Polymers 2018, 10, 1280. https://doi.org/10.3390/polym10111280

Sun M, Sun X, Wang Z, Chang M, Li H. The Influence of Shape Memory Alloy Volume Fraction on the Impact Behavior of Polymer Composites. Polymers. 2018; 10(11):1280. https://doi.org/10.3390/polym10111280

Chicago/Turabian StyleSun, Min, Xiaokun Sun, Zhenqing Wang, Mengzhou Chang, and Hao Li. 2018. "The Influence of Shape Memory Alloy Volume Fraction on the Impact Behavior of Polymer Composites" Polymers 10, no. 11: 1280. https://doi.org/10.3390/polym10111280

APA StyleSun, M., Sun, X., Wang, Z., Chang, M., & Li, H. (2018). The Influence of Shape Memory Alloy Volume Fraction on the Impact Behavior of Polymer Composites. Polymers, 10(11), 1280. https://doi.org/10.3390/polym10111280