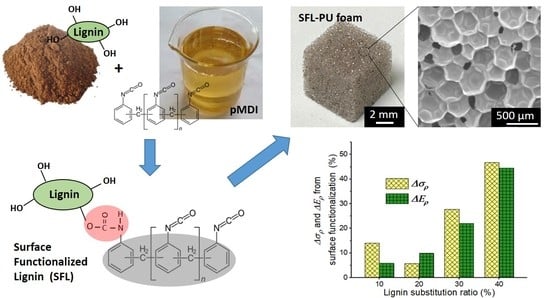

Effects of Surface Functionalization of Lignin on Synthesis and Properties of Rigid Bio-Based Polyurethanes Foams

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

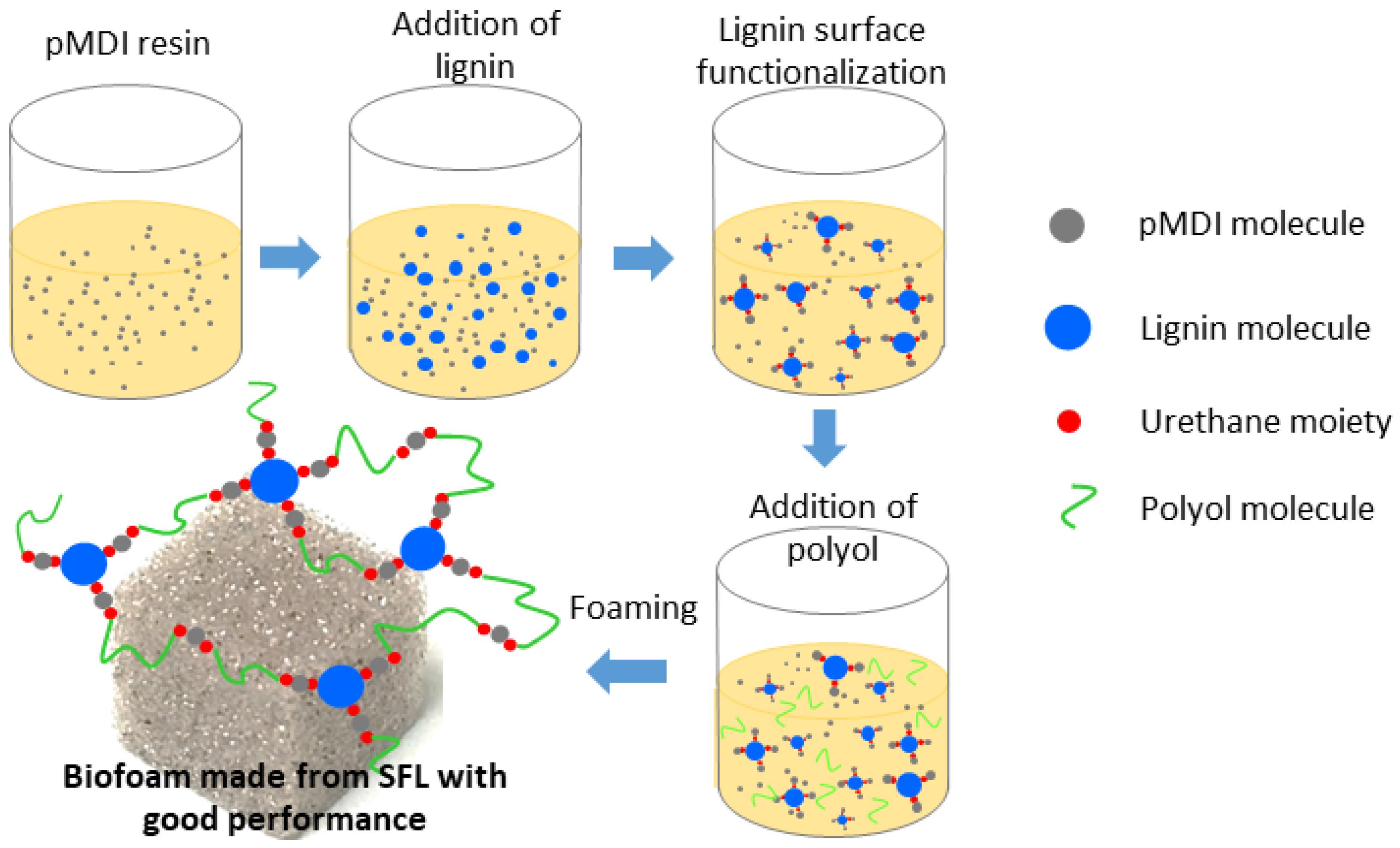

2.2. Surface Functionalization of Lignin

2.3. Preparation of RPU Foams

2.4. Lignin Structure Characterization

2.5. Characterization of SFL

2.6. Characterization of RPU Foams

2.7. Life Cycle Assessment

3. Results and Discussion

3.1. Lignin Properties

3.2. Rheological Behavior of Lignin-pMDI Premix and Prepolymer

3.3. Physical Properties of RPU Foams

3.4. Mechanical Properties of RPU Foams

3.5. FTIR Analysis of RPU Foams

3.6. Thermal Stability of RPU Foams

3.7. Life Cycle Assessment

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, Y.; Ragauskas, A.J. Kraft lignin-based rigid polyurethane foam. J. Wood Chem. Technol. 2012, 32, 210–224. [Google Scholar] [CrossRef]

- Li, H.; Mahmood, N.; Ma, Z.; Zhu, M.; Wang, J.; Zheng, J.; Yuan, Z.; Wei, Q.; Xu, C. (Chunbao) Preparation and characterization of bio-polyol and bio-based flexible polyurethane foams from fast pyrolysis of wheat straw. Ind. Crops Prod. 2017, 103, 64–72. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Q.; Leng, W.; Li, J.; Zhang, J.; Cai, Z.; Hassan, E.B. Carbon nanostructure of kraft lignin thermally treated at 500 to 1000 °C. Materials 2017, 10, 975. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Yan, Q.; Hassan, E.B.; Li, J.; Cai, Z.; Zhang, J. Temperature effects on formation of carbon-based nanomaterials from kraft lignin. Mater. Lett. 2017, 203, 42–45. [Google Scholar] [CrossRef]

- Zhang, X.; Yan, Q.; Li, J.; Chu, I.-W.; Toghiani, H.; Cai, Z.; Zhang, J. Carbon-based nanomaterials from biopolymer lignin via catalytic thermal treatment at 700 to 1000 °C. Polymers 2018, 10, 183. [Google Scholar] [CrossRef]

- Griffini, G.; Passoni, V.; Suriano, R.; Levi, M.; Turri, S. Polyurethane coatings based on chemically unmodified fractionated lignin. ACS Sustain. Chem. Eng. 2015, 3, 1145–1154. [Google Scholar] [CrossRef]

- Pan, X.; Saddler, J.N. Effect of replacing polyol by organosolv and kraft lignin on the property and structure of rigid polyurethane foam. Biotechnol. Biofuels 2013, 6, 12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lora, J.H.; Glasser, W.G. Recent industrial applications of lignin: A sustainable alternative to nonrenewable materials. J. Polym. Environ. 2002, 10, 39–48. [Google Scholar] [CrossRef]

- Xue, B.-L.; Wen, J.-L.; Sun, R.-C. Producing lignin-based polyols through microwave-assisted liquefaction for rigid polyurethane foam production. Materials 2015, 8, 586–599. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. Valorization of hydrolysis lignin for polyols/polyurethane foam. J. Sci. Technol. For. Prod. Process. 2014, 3, 26–31. [Google Scholar]

- Li, H.-Q.; Shao, Q.; Luo, H.; Xu, J. Polyurethane foams from alkaline lignin-based polyether polyol. J. Appl. Polym. Sci. 2016, 133. [Google Scholar] [CrossRef]

- Huang, X.; De Hoop, C.F.; Xie, J.; Hse, C.-Y.; Qi, J.; Hu, T. Characterization of biobased polyurethane foams employing lignin fractionated from microwave liquefied switchgrass. Int. J. Polym. Sci. 2017. [Google Scholar] [CrossRef]

- Cinelli, P.; Anguillesi, I.; Lazzeri, A. Green synthesis of flexible polyurethane foams from liquefied lignin. Eur. Polym. J. 2013, 49, 1174–1184. [Google Scholar] [CrossRef]

- Bernardini, J.; Cinelli, P.; Anguillesi, I.; Coltelli, M.-B.; Lazzeri, A. Flexible polyurethane foams green production employing lignin or oxypropylated lignin. Eur. Polym. J. 2015, 64, 147–156. [Google Scholar] [CrossRef]

- Cateto, C.A.; Barreiro, M.F.; Rodrigues, A.E.; Belgacem, M.N. Optimization study of lignin oxypropylation in view of the preparation of polyurethane rigid foams. Ind. Eng. Chem. Res. 2009, 48, 2583–2589. [Google Scholar] [CrossRef]

- Langlois, A.; Drouin, M. Process for the Preparation of Lignin Based Polyurethane Products. U.S. Patent 9,598,529 B2, 21 March 2017. [Google Scholar]

- Carriço, C.S.; Fraga, T.; Pasa, V.M.D. Production and characterization of polyurethane foams from a simple mixture of castor oil, crude glycerol and untreated lignin as bio-based polyols. Eur. Polym. J. 2016, 85, 53–61. [Google Scholar] [CrossRef]

- Huang, X.; De Hoop, C.F.; Xie, J.; Wu, Q.; Boldor, D.; Qi, J. High bio-content polyurethane (PU) foam made from bio-polyol and cellulose nanocrystals (CNCs) via microwave liquefaction. Mater. Des. 2018, 138, 11–20. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Hatakeyama, T. Environmentally compatible hybrid-type polyurethan foams containing saccharide and lignin components. Macromol. Symp. 2005, 224, 219–226. [Google Scholar] [CrossRef]

- Xue, B.-L.; Wen, J.-L.; Sun, R.-C. Lignin-based rigid polyurethane foam reinforced with pulp fiber: Synthesis and characterization. ACS Sustain. Chem. Eng. 2014, 2, 1474–1480. [Google Scholar] [CrossRef]

- Hatakeyama, H.; Kosugi, R.; Hatakeyama, T. Thermal properties of lignin-and molasses-based polyurethane foams. J. Therm. Anal. Calorim. 2008, 92, 419. [Google Scholar] [CrossRef]

- Mahmood, N.; Yuan, Z.; Schmidt, J.; Xu, C. (Charles) Preparation of bio-based rigid polyurethane foam using hydrolytically depolymerized Kraft lignin via direct replacement or oxypropylation. Eur. Polym. J. 2015, 68, 1–9. [Google Scholar] [CrossRef]

- Faruk, O.; Sain, M. Lignin in Polymer Composites; Elsevier: Kidlington, Oxford, UK; Waltham, MA, USA, 2016; ISBN 978-0-323-35565-0. [Google Scholar]

- Culbertson, C.; Treasure, T.; Venditti, R.; Jameel, H.; Gonzalez, R. Life Cycle Assessment of lignin extraction in a softwood kraft pulp mill. Nord. Pulp Pap. Res. J. 2016, 31, 30–40. [Google Scholar] [CrossRef]

- Bernier, E.; Lavigne, C.; Robidoux, P.Y. Life cycle assessment of kraft lignin for polymer applications. Int. J. Life Cycle Assess. 2013, 18, 520–528. [Google Scholar] [CrossRef]

- Chauhan, M.; Gupta, M.; Singh, B.; Singh, A.K.; Gupta, V.K. Effect of functionalized lignin on the properties of lignin–isocyanate prepolymer blends and composites. Eur. Polym. J. 2014, 52, 32–43. [Google Scholar] [CrossRef]

- Kourki, H.; Famili, M.H.N.; Mortezaei, M.; Malekipirbazari, M.; Disfani, M.N. Highly nanofilled polystyrene composite: Thermal and dynamic behavior. J. Elastomers Plast. 2016, 48, 404–425. [Google Scholar] [CrossRef]

- Ciobanu, C.; Ungureanu, M.; Ignat, L.; Ungureanu, D.; Popa, V.I. Properties of lignin–polyurethane films prepared by casting method. Ind. Crops Prod. 2004, 20, 231–241. [Google Scholar] [CrossRef]

- Luo, X.; Mohanty, A.; Misra, M. Lignin as a reactive reinforcing filler for water-blown rigid biofoam composites from soy oil-based polyurethane. Ind. Crops Prod. 2013, 47, 13–19. [Google Scholar] [CrossRef]

- Cateto, C.A.; Barreiro, M.F.; Ottati, C.; Lopretti, M.; Rodrigues, A.E.; Belgacem, M.N. Lignin-based rigid polyurethane foams with improved biodegradation. J. Cell. Plast. 2014, 50, 81–95. [Google Scholar] [CrossRef]

- Paruzel, A.; Michałowski, S.; Hodan, J.; Horák, P.; Prociak, A.; Beneš, H. Rigid polyurethane foam fabrication using medium chain glycerides of coconut oil and plastics from end-of-life vehicles. ACS Sustain. Chem. Eng. 2017, 5, 6237–6246. [Google Scholar] [CrossRef]

- Cateto, C.A.; Barreiro, M.F.; Rodrigues, A.E. Monitoring of lignin-based polyurethane synthesis by FTIR-ATR. Ind. Crops Prod. 2008, 27, 168–174. [Google Scholar] [CrossRef] [Green Version]

| Lignin Substitution Ratio (%) | Lignin-pMDI Premix (g) | Polyol Premix (g) | NCO Index | ||||

|---|---|---|---|---|---|---|---|

| Lignin | pMDI | Silicone Oil * | Polyol R-23-015 | Dabco 33-LV * | 1,1,1,3,3-Pentafluorobutane * | ||

| 0 | 0 | 51.5 | 0 | 50 | 0 | 0 | 157 |

| 10 | 5 | 51.5 | 0.25 | 45 | 0.025 | 0.45 | 156 |

| 20 | 10 | 51.5 | 0.50 | 40 | 0.050 | 0.90 | 154 |

| 30 | 15 | 51.5 | 0.75 | 35 | 0.075 | 1.35 | 153 |

| 40 | 20 | 51.5 | 1.00 | 30 | 0.100 | 1.80 | 152 |

| Samples | Ash (wt. %) | Mn (g/mol) | Mw (g/mol) | Mw/Mn | Al-OH (mmol/g) | Ph-OH (mmol/g) | COOH (mmol/g) | Total OH (mmol/g) |

|---|---|---|---|---|---|---|---|---|

| Lignin | 1.65 ± 0.04 | 816 | 3374 | 4.13 | 1.91 ± 0.12 | 3.04 ± 0.21 | 0.29 ± 0.02 | 5.24 ± 0.35 |

| Polyol | 0 | - | - | - | 5.21 ± 0.25 | 0.11 ± 0.01 | 0.02 ± 0.00 | 5.34 ± 0.25 |

| Samples | Cell Diameter (μm) | Density (kg/m3) | Thermal Conductivity (mW·m−1·K−1) |

|---|---|---|---|

| RPU0 | 588 ± 85 | 34.6 ± 1.8 | 24.1 ± 0.5 |

| L-RPU10 | 548 ± 154 | 33.9 ± 2.3 | 23.8 ± 0.4 |

| L-RPU20 | 448 ± 135 | 36.2 ± 1.9 | 24.0 ± 0.4 |

| L-RPU30 | 393 ± 93 | 41.7 ± 1.7 | 23.9 ± 0.3 |

| L-RPU40 | 255 ± 67 | 53.3 ± 3.3 | 25.0 ± 0.7 |

| SFL-RPU10 | 419 ± 98 | 35.5 ± 1.3 | 24.0 ± 0.6 |

| SFL-RPU20 | 347 ± 132 | 38.5 ± 1.8 | 23.6 ± 0.5 |

| SFL-RPU30 | 305 ± 135 | 41.6 ± 1.8 | 23.3 ± 0.5 |

| SFL-RPU40 | 304 ± 99 | 42.2 ± 1.6 | 24.2 ± 0.4 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Jeremic, D.; Kim, Y.; Street, J.; Shmulsky, R. Effects of Surface Functionalization of Lignin on Synthesis and Properties of Rigid Bio-Based Polyurethanes Foams. Polymers 2018, 10, 706. https://doi.org/10.3390/polym10070706

Zhang X, Jeremic D, Kim Y, Street J, Shmulsky R. Effects of Surface Functionalization of Lignin on Synthesis and Properties of Rigid Bio-Based Polyurethanes Foams. Polymers. 2018; 10(7):706. https://doi.org/10.3390/polym10070706

Chicago/Turabian StyleZhang, Xuefeng, Dragica Jeremic, Yunsang Kim, Jason Street, and Rubin Shmulsky. 2018. "Effects of Surface Functionalization of Lignin on Synthesis and Properties of Rigid Bio-Based Polyurethanes Foams" Polymers 10, no. 7: 706. https://doi.org/10.3390/polym10070706

APA StyleZhang, X., Jeremic, D., Kim, Y., Street, J., & Shmulsky, R. (2018). Effects of Surface Functionalization of Lignin on Synthesis and Properties of Rigid Bio-Based Polyurethanes Foams. Polymers, 10(7), 706. https://doi.org/10.3390/polym10070706