Bleached Kraft Eucalyptus Fibers as Reinforcement of Poly(Lactic Acid) for the Development of High-Performance Biocomposites

Abstract

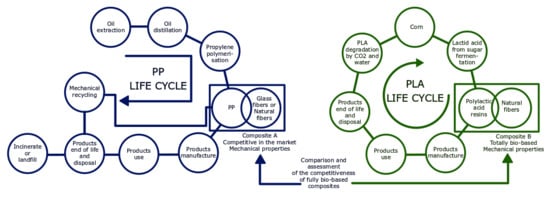

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composite and Sample Preparation

2.3. Mechanical Characterization

2.4. Fiber Extraction from the Composites

2.5. Morphologic Analysis of the Fibers

3. Micromechanics

3.1. Hirsch’s Model

3.2. Modified Rule of Mixtures for the Young’s Modulus

3.3. Cox and Krenchel’s Model

3.4. Modified Rule of Mixtures for the Tensile Strength

3.5. Modified Kelly and Tyson Equation

3.6. Bowyer and Bader Method

4. Results and Discussion

4.1. Bleached Kraft Hardwood Fiber Morphology

4.2. Tensile Properties of the Composites

4.3. Net Contribution of the Fibers to the Tensile Properties of the Composite

4.4. Micromechanics

4.4.1. Micromechanics of the Young’s Modulus

4.4.2. Micromechanics of the Tensile Strength

5. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- La Mantia, F.P.; Morreale, M. Green composites: A brief review. Compos. Part A 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Vilaseca, F.; Mendez, J.A.; Pèlach, A.; Llop, M.; Cañigueral, N.; Gironès, J.; Turon, X.; Mutjé, P. Composite materials derived from biodegradable starch polymer and jute strands. Process Biochem. 2007, 42, 329–334. [Google Scholar] [CrossRef]

- Saad, G.R.; Seliger, H. Biodegradable copolymers based on bacterial poly ((R)-3-hydroxybutyrate): Thermal and mechanical properties and biodegradation behaviour. Polym. Degrad. Stab. 2004, 83, 101–110. [Google Scholar] [CrossRef]

- Dufresne, A.; Vignon, M.R. Improvement of starch film performances using cellulose microfibrils. Macromolecules 1998, 31, 2693–2696. [Google Scholar] [CrossRef]

- Scott, G. ‘Green’polymers. Polym. Degrad. Stab. 2000, 68, 1–7. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Tarrés, Q.; Méndez, J.A.; Delgado-Aguilar, M.; Mutjé, P. Towards a good interphase between bleached kraft softwood fibers and poly(lactic) acid. Compos. Part B 2016, 99, 514–520. [Google Scholar] [CrossRef]

- Yusoff, R.B.; Takagi, H.; Nakagaito, A.N. Tensile and flexural properties of polylactic acid-based hybrid green composites reinforced by kenaf, bamboo and coir fibers. Ind. Crops Prod. 2016, 94, 562–573. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. Part A 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Netravali, A.N.; Chabba, S. Composites get greener. Mater. Today 2003, 6, 22–29. [Google Scholar] [CrossRef]

- Granda, L.; Tarres, Q.; Espinach, F.X.; Julian, F.; Mendes, A.; Delgado-Aguilar, M.; Mutje, P. Fully biodegradable polylactic composites reinforced with bleached softwood fibers. Cellul. Chem. Technol. 2016, in press. [Google Scholar]

- Lopez, J.P.; Mendez, J.A.; El Mansouri, N.E.; Mutje, P.; Vilaseca, F. Mean intrinsic tensile properties of stone groundwood fibers from softwood. BioResources 2011, 6, 5037–5049. [Google Scholar]

- Vallejos, M.E.; Espinach, F.X.; Julian, F.; Torres, L.; Vilaseca, F.; Mutje, P. Micromechanics of hemp strands in polypropylene composites. Compos. Sci. Technol. 2012, 72, 1209–1213. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Tresserras, J.; Pellicer, N.; Alcala, M.; Mutje, P. Study on the technical feasibility of replacing glass fibers by old newspaper recycled fibers as polypropylene reinforcement. J. Clean. Prod. 2014, 65, 489–496. [Google Scholar] [CrossRef]

- Bax, B.; Müssig, J. Impact and tensile properties of PLA/cordenka and PLA/flax composites. Compos. Sci. Technol. 2008, 68, 1601–1607. [Google Scholar] [CrossRef]

- Kovacevic, Z.; Bischof, S.; Fan, M. The influence of spartium junceum l. Fibres modified with montmorrilonite nanoclay on the thermal properties of PLA biocomposites. Compos. Part B 2015, 78, 122–130. [Google Scholar] [CrossRef]

- Shah, D.U.; Nag, R.K.; Clifford, M.J. Why do we observe significant differences between measured and ‘back-calculated’ properties of natural fibres? Cellulose 2016, 23, 1481–1490. [Google Scholar] [CrossRef] [Green Version]

- Serra, A.; Tarrés, Q.; Claramunt, J.; Mutjé, P.; Ardanuy, M.; Espinach, F. Behavior of the interphase of dyed cotton residue flocks reinforced polypropylene composites. Compos. Part B 2017, 128, 200–207. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Mendez, J.A.; Julian, F.; Mutjé, P. Tensile properties and micromechanical analysis of stone groundwood from softwood reinforced bio-based polyamide11 composites. Compos. Sci. Technol. 2016, 132, 123–130. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Tresserras, J.; del Rey, R.; Pellicer, N.; Mutje, P. Macro and micromechanics analysis of short fiber composites stiffness: The case of old newspaper fibers-polypropylene composites. Mater. Design 2014, 55, 319–324. [Google Scholar] [CrossRef]

- Wang, F.; Chen, Z.Q.; Wei, Y.Q.; Zeng, X.G. Numerical modeling of tensile behavior of fiber-reinforced polymer composites. J. Compos. Mater. 2010, 44, 2325–2340. [Google Scholar] [CrossRef]

- Zuccarello, B.; Scaffaro, R. Experimental analysis and micromechanical models of high performance renewable agave reinforced biocomposites. Compos. Part B 2017, 119, 141–152. [Google Scholar] [CrossRef]

- Hirsch, T. Modulus of elasticity of concrete affected by elastic moduli of cement paste matrix and aggregate. J. Am. Concr. Inst. 1962, 59, 427–451. [Google Scholar]

- Reixach, R.; Espinach, F.X.; Franco-Marquès, E.; Ramirez de Cartagena, F.; Pellicer, N.; Tresserras, J.; Mutjé, P. Modeling of the tensile moduli of mechanical, thermomechanical, and chemi-thermomechanical pulps from orange tree pruning. Polym. Compos. 2013, 34, 1840–1846. [Google Scholar] [CrossRef]

- Kalaprasad, G.; Joseph, K.; Thomas, S.; Pavithran, C. Theoretical modelling of tensile properties of short sisal fibre-reinforced low-density polyethylene composites. J. Mater. Sci. 1997, 32, 4261–4267. [Google Scholar] [CrossRef]

- Vilaseca, F.; Valadez-Gonzalez, A.; Herrera-Franco, P.J.; Pelach, M.A.; Lopez, J.P.; Mutje, P. Biocomposites from abaca strands and polypropylene. Part i: Evaluation of the tensile properties. Bioresour. Technol. 2010, 101, 387–395. [Google Scholar] [CrossRef] [PubMed]

- Thomason, J.L. Interfacial strength in thermoplastic composites—At last an industry friendly measurement method? Compos. Part A 2002, 33, 1283–1288. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Delgado-Aguilar, M.; Tarrés, Q.; Quintana, G.; Fullana-i-Palmer, P.; Mutjé, P.; Espinach, F.X. Sugarcane bagasse reinforced composites: Studies on the young’s modulus and macro and micro-mechanics. BioResources 2017, 12, 3618–3629. [Google Scholar] [CrossRef]

- Cox, H.L. The elasticity and strength of paper and other fibrous materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Krenchel, H. Fibre Reinforcement; Akademisk Forlag: Copenhagen, Denmark, 1964. [Google Scholar]

- Rezgui, F.; Swistek, M.; Hiver, J.; G’sell, C.; Sadoun, T. Deformation and damage upon stretching of degradable polymers (PLA and PCL). Polymer 2005, 46, 7370–7385. [Google Scholar] [CrossRef]

- Reixach, R.; Franco-Marquès, E.; El Mansouri, N.-E.; de Cartagena, F.R.; Arbat, G.; Espinach, F.X.; Mutjé, P. Micromechanics of mechanical, thermomechanical, and chemi-thermomechanical pulp from orange tree pruning as polypropylene reinforcement: A comparative study. BioResources 2013, 8, 3231–3246. [Google Scholar] [CrossRef]

- Thomason, J.L. The influence of fibre length and concentration on the properties of glass fibre reinforced polypropylene: 5. Injection moulded long and short fibre PP. Compos. Part A 2002, 33, 1641–1652. [Google Scholar] [CrossRef] [Green Version]

- Lopez, J.P.; Mendez, J.A.; Espinach, F.X.; Julian, F.; Mutje, P.; Vilaseca, F. Tensile strength characteristics of polypropylene composites reinforced with stone groundwood fibers from softwood. BioResources 2012, 7, 3188–3200. [Google Scholar] [CrossRef]

- Kelly, A.; Tyson, W. Tensile porperties of fibre-reinforced metals: Copper/tungsten and copper/molybdenum. J. Mech. Phys. Solids 1965, 13, 329–338. [Google Scholar] [CrossRef]

- Li, Y.; Pickering, K.L.; Farrell, R.L. Determination of interfacial shear strength of white rot fungi treated hemp fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1165–1171. [Google Scholar] [CrossRef]

- Granda, L.A.; Espinach, F.X.; Lopez, F.; Garcia, J.C.; Delgado-Aguilar, M.; Mutje, P. Semichemical fibres of leucaena collinsii reinforced polypropylene: Macromechanical and micromechanical analysis. Compos. Part B 2016, 91, 384–391. [Google Scholar] [CrossRef]

- Bowyer, W.H.; Bader, H.G. On the reinforcement of thermoplastics by imperfectly aligned discontinuous fibres. J. Mater. Sci. 1972, 7, 1315–1321. [Google Scholar] [CrossRef]

- Karmaker, A.C.; Youngquist, J.A. Injection molding of polypropylene reinforced with short jute fibers. J. Appl. Polym. Sci. 1996, 62, 1147–1151. [Google Scholar] [CrossRef]

- Valente Nabais, J.M.; Laginhas, C.; Ribeiro Carrott, M.M.L.; Carrott, P.J.M.; Crespo Amoros, J.E.; Nadal Gisbert, A.V. Surface and porous characterisation of activated carbons made from a novel biomass precursor, the esparto grass. Appl. Surf. Sci. 2013, 265, 919–924. [Google Scholar] [CrossRef] [Green Version]

- Granda, L.A.; Espinach, F.X.; Mendez, J.A.; Tresserras, J.; Delgado-Aguilar, M.; Mutje, P. Semichemical fibres of leucaena collinsii reinforced polypropylene composites: Young’s modulus analysis and fibre diameter effect on the stiffness. Compos. Part B 2016, 92, 332–337. [Google Scholar] [CrossRef]

- Reixach, R.; Espinach, F.X.; Arbat, G.; Julián, F.; Delgado-Aguilar, M.; Puig, J.; Mutjé, P. Tensile properties of polypropylene composites reinforced with mechanical, thermomechanical, and chemi-thermomechanical pulps from orange pruning. BioResources 2015, 10, 4544–4556. [Google Scholar] [CrossRef]

- Delgado-Aguilar, M.; Julián, F.; Tarrés, Q.; Méndez, J.A.; Mutjé, P.; Espinach, F.X. Bio composite from bleached pine fibers reinforced polylactic acid as a replacement of glass fiber reinforced polypropylene, macro and micro-mechanics of the young’s modulus. Compos. Part B 2017, 125, 203–210. [Google Scholar] [CrossRef]

- Lopez, J.P.; Mutje, P.; Pelach, M.A.; El Mansouri, N.E.; Boufi, S.; Vilaseca, F. Analysis of the tensile modulus of PP composites reinforced with stone grounwood fibers from softwood. BioResources 2012, 7, 1310–1323. [Google Scholar]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites. Compos. Part B 2013, 47, 339–343. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B 2017, 114, 15–22. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Chevali, V.S.; Ulven, C.A. Lignocellulosic byproducts as filler in polypropylene: Comprehensive study on the effects of compatibilization and loading. J. Appl. Polym. Sci. 2013, 127, 862–868. [Google Scholar] [CrossRef]

- Zabhizadeh, S.M.; Ebrahimi, G.; Enayati, A.A. Effect of compatibilizer on mechanical, morphological, and thermal properties of chemimechanical pulp-reinforced PP composites. J. Thermoplast. Compos. Mater. 2011, 24, 221–231. [Google Scholar] [CrossRef]

- Saha, P.; Manna, S.; Chowdhury, S.R.; Sen, R.; Roy, D.; Adhikari, B. Enhancement of tensile strength of lignocellulosic jute fibers by alkali-steam treatment. Bioresour. Technol. 2010, 101, 3182–3187. [Google Scholar] [CrossRef] [PubMed]

- Jiménez, A.M.; Espinach, F.X.; Granda, L.; Delgado-Aguilar, M.; Quintana, G.; Fullana-i-Palmer, P.; Mutje, P. Tensile strength assessment of injection-molded high yield sugarcane bagasse-reinforced polypropyene. BioResources 2016, 11, 6346–6361. [Google Scholar] [CrossRef]

- Jiménez, A.M.; Espinach, F.X.; Delgado-Aguilar, M.; Reixach, R.; Quintana, G.; Fullana-i-Palmer, P.; Mutjé, P. Starch-based biopolymer reinforced with high yield fibers from sugarcane bagasse as a technical and environmentally friendly alternative to high density polyethylene. BioResources 2016, 11, 9856–9868. [Google Scholar] [CrossRef]

- Fukuda, H.; Kawata, K. On young’s modulus of short fibre composites. Fibre Sci. Technol. 1974, 7, 207–222. [Google Scholar] [CrossRef]

- Sanomura, Y.; Kawamura, M. Fiber orientation control of short-fiber reinforced thermoplastics by ram extrusion. Polym. Compos. 2003, 24, 587–596. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.; Espinach, F.X.; Delgado-Aguilar, M.; Duran, J.; Mutjé, P. Stiffness of bio-based polyamide 11 reinforced with softwood stone ground-wood fibres as an alternative to polypropylene-glass fibre composites. Eur. Polym. J. 2016, 84, 481–489. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Canigueral, N.; Mendez, J.A.; Vilaseca, F.; Corrales, F.; Lopez, A.; Mutje, P. Benefit from hemp straw as filler/reinforcement for composite materials. Afinidad 2006, 63, 354–361. [Google Scholar]

- Espinach, F.X.; Granda, L.A.; Tarrés, Q.; Duran, J.; Fullana-i-Palmer, P.; Mutjé, P. Mechanical and micromechanical tensile strength of eucalyptus bleached fibers reinforced polyoxymethylene composites. Compos. Part B 2017, 116, 333–339. [Google Scholar] [CrossRef]

| BKHF (%) | VF | σtC (MPa) | εtC (MPa) | EtC (GPa) | σtM* (MPa) |

|---|---|---|---|---|---|

| 0 | - | 49.6 ± 0.23 | 3.3 + ± 0.18 | 3.4 ± 0.11 | - |

| 10 | 0.085 | 57.3 ± 0.48 | 2.9 ± 0.12 | 4.4 ± 0.18 | 48.4 |

| 20 | 0.172 | 68.7 ± 1.08 | 2.6 ± 0.15 | 5.7 ± 0.22 | 46.2 |

| 30 | 0.263 | 76.5 ± 1.31 | 2.3 ± 0.07 | 6.8 ± 0.26 | 44.2 |

| BKHF (%) | EtF (Gpa) | ηe | ηl | ηo | α |

|---|---|---|---|---|---|

| 10 | 28.09 | 0.541 | 0.905 | 0.598 | 46.6º |

| 20 | 31.41 | 0.533 | 0.917 | 0.581 | 47.9º |

| 30 | 29.84 | 0.547 | 0.931 | 0.587 | 47.5º |

| Mean | 28.78 | 0.541 | 0.918 | 0.589 | 47.3 |

| S.D. | 1.661 | 0.007 | 0.013 | 0.008 | 0.66 |

| BKHF (%) | σtF (Mpa) | fc | χ1 | χ2 | α |

|---|---|---|---|---|---|

| 10 | 768 | 0.20 | 0.284 | 0.704 | 61° |

| 20 | 768 | 0.23 | 0.284 | 0.810 | 61° |

| 30 | 768 | 0.22 | 0.284 | 0.774 | 61° |

| Mean | 768 | 0.22 | 0.284 | 0.763 | 61° |

| S.D. | - | 0.015 | - | 0.054 | - |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado-Aguilar, M.; Reixach, R.; Tarrés, Q.; Espinach, F.X.; Mutjé, P.; Méndez, J.A. Bleached Kraft Eucalyptus Fibers as Reinforcement of Poly(Lactic Acid) for the Development of High-Performance Biocomposites. Polymers 2018, 10, 699. https://doi.org/10.3390/polym10070699

Delgado-Aguilar M, Reixach R, Tarrés Q, Espinach FX, Mutjé P, Méndez JA. Bleached Kraft Eucalyptus Fibers as Reinforcement of Poly(Lactic Acid) for the Development of High-Performance Biocomposites. Polymers. 2018; 10(7):699. https://doi.org/10.3390/polym10070699

Chicago/Turabian StyleDelgado-Aguilar, Marc, Rafel Reixach, Quim Tarrés, Francesc X. Espinach, Pere Mutjé, and José A. Méndez. 2018. "Bleached Kraft Eucalyptus Fibers as Reinforcement of Poly(Lactic Acid) for the Development of High-Performance Biocomposites" Polymers 10, no. 7: 699. https://doi.org/10.3390/polym10070699

APA StyleDelgado-Aguilar, M., Reixach, R., Tarrés, Q., Espinach, F. X., Mutjé, P., & Méndez, J. A. (2018). Bleached Kraft Eucalyptus Fibers as Reinforcement of Poly(Lactic Acid) for the Development of High-Performance Biocomposites. Polymers, 10(7), 699. https://doi.org/10.3390/polym10070699