Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications

Abstract

:1. Introduction

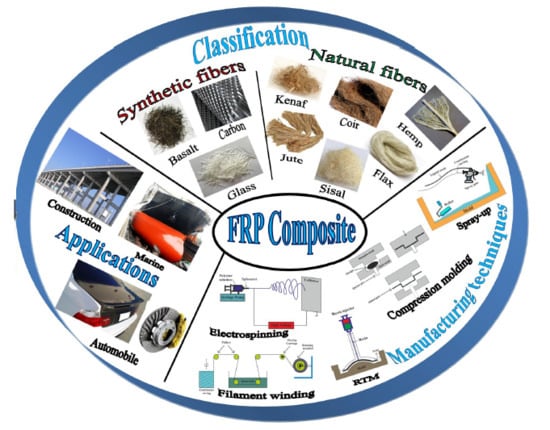

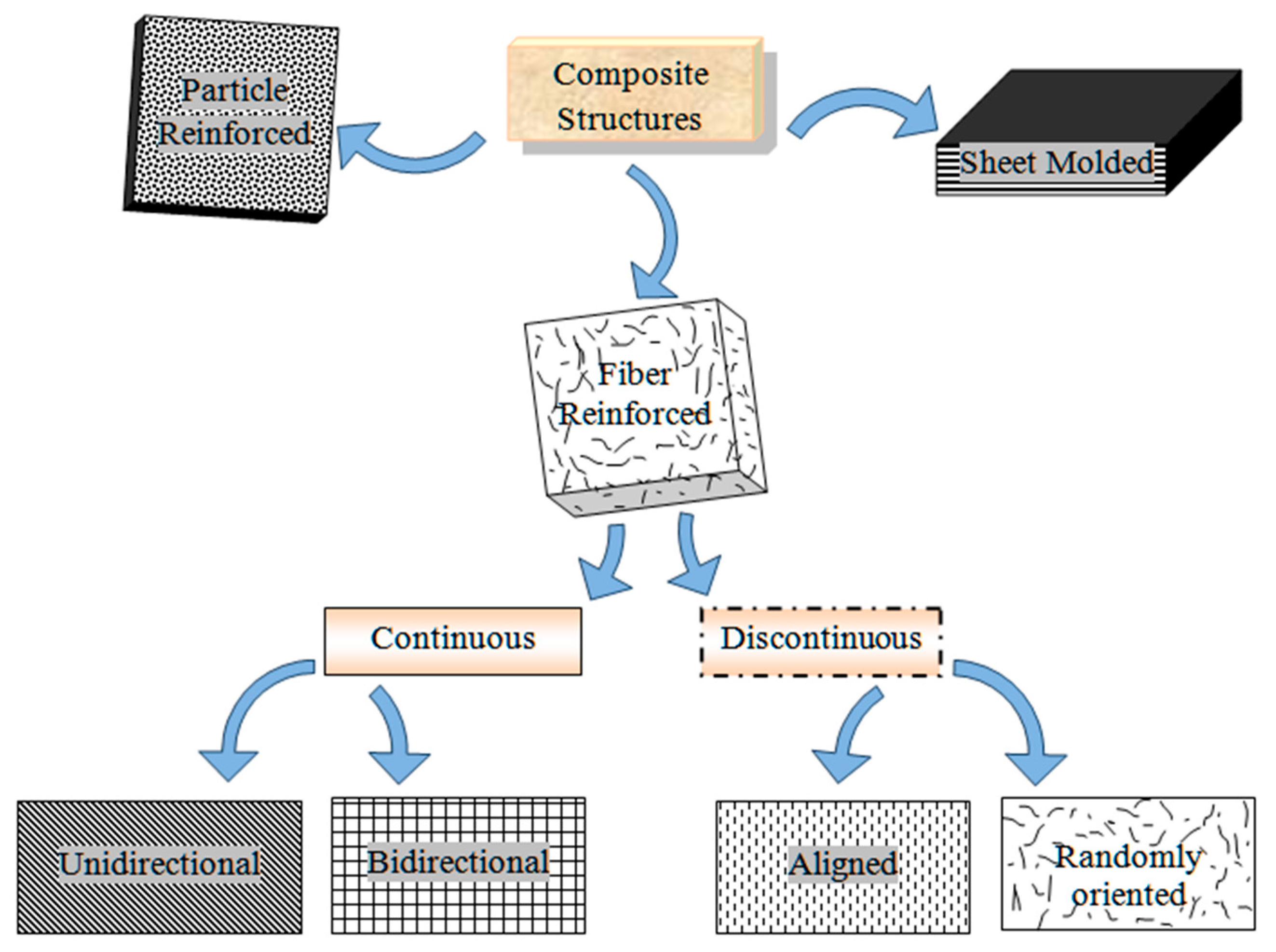

2. Classification

2.1. Fiber-Reinforced Composites

2.1.1. Synthetic Fibers

2.1.2. Natural Fibers

2.1.3. Hybrid Fibers

2.2. Particle-Reinforced Composite

2.3. Sheet-Molded Composites

3. Manufacturing Techniques

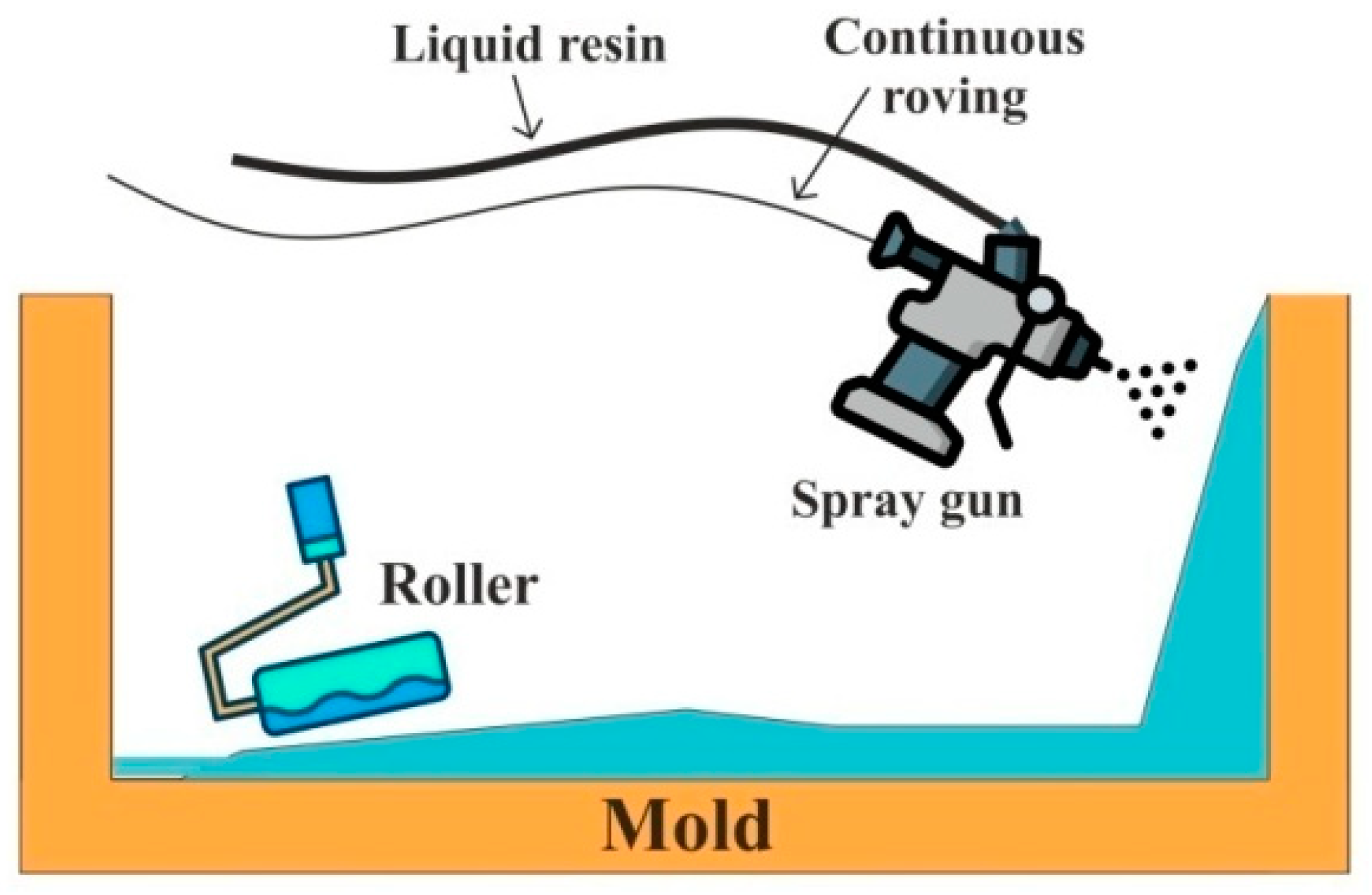

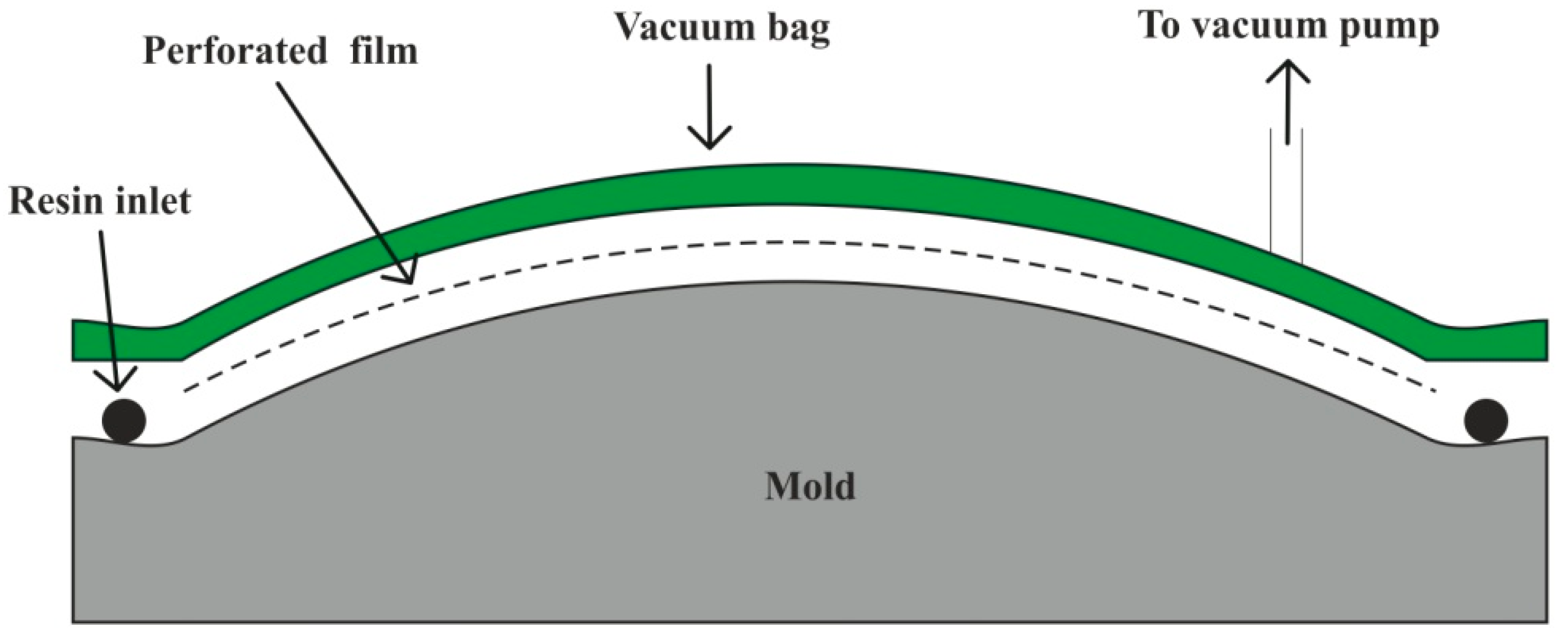

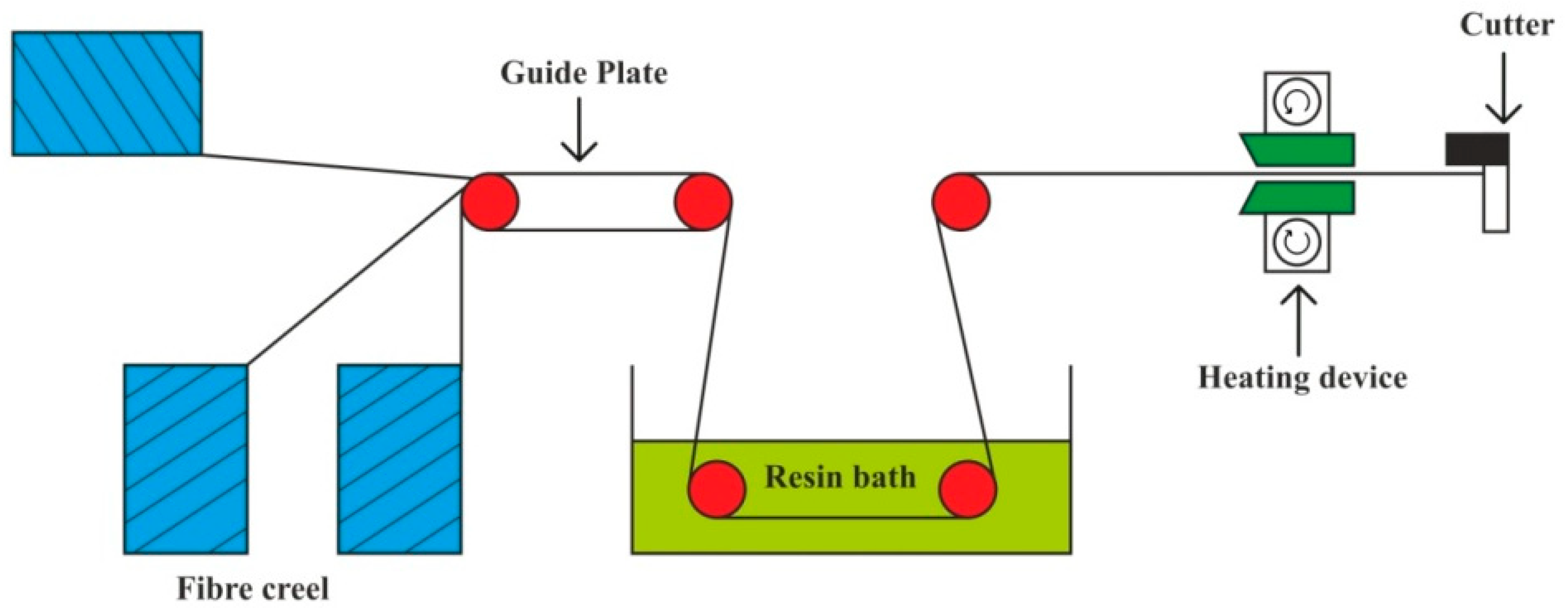

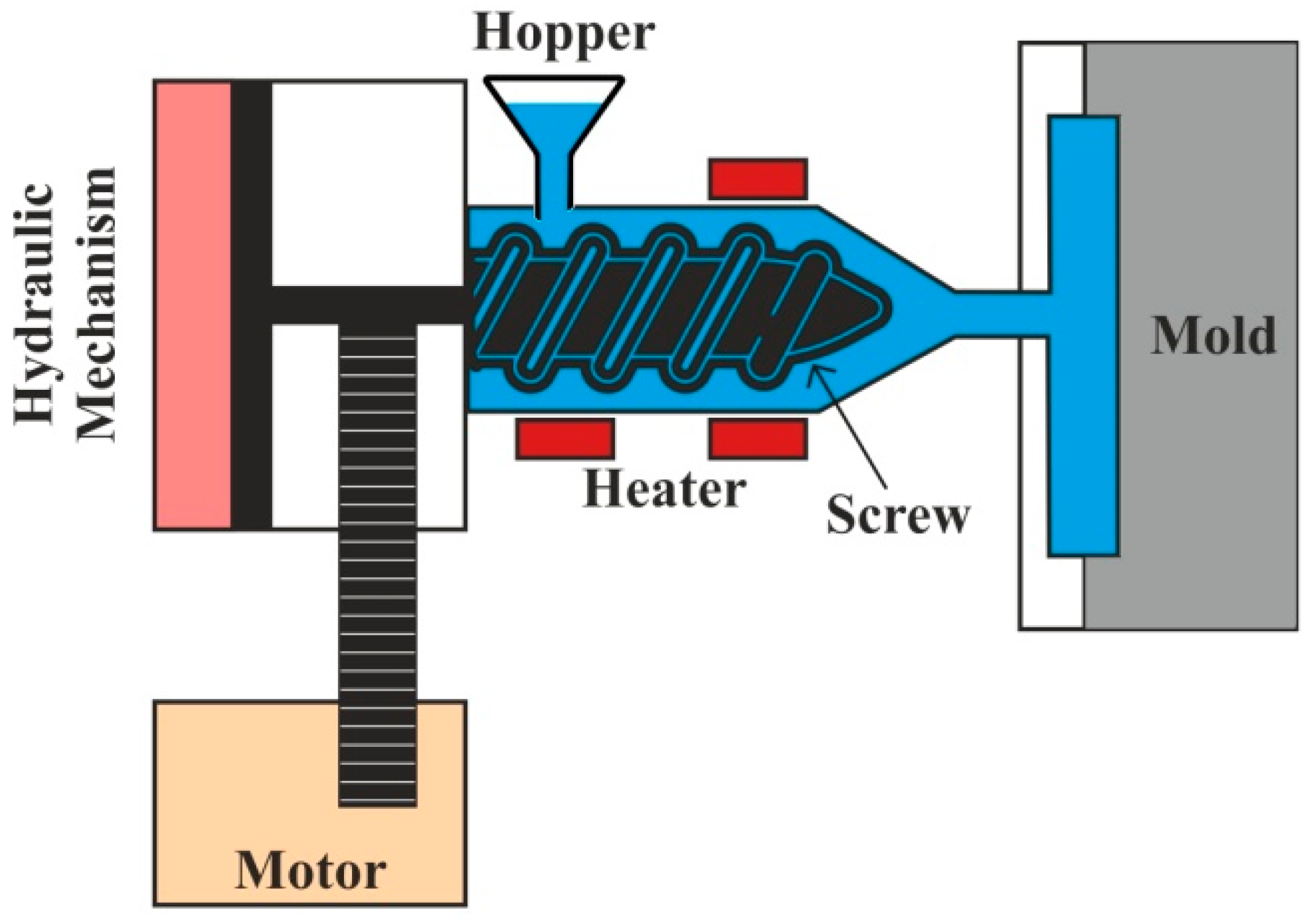

3.1. Conventional Manufacturing Processes

3.2. Advance Manufacturing Processes

3.3. Automated Manufacturing Techniques

4. Applications

4.1. Civil

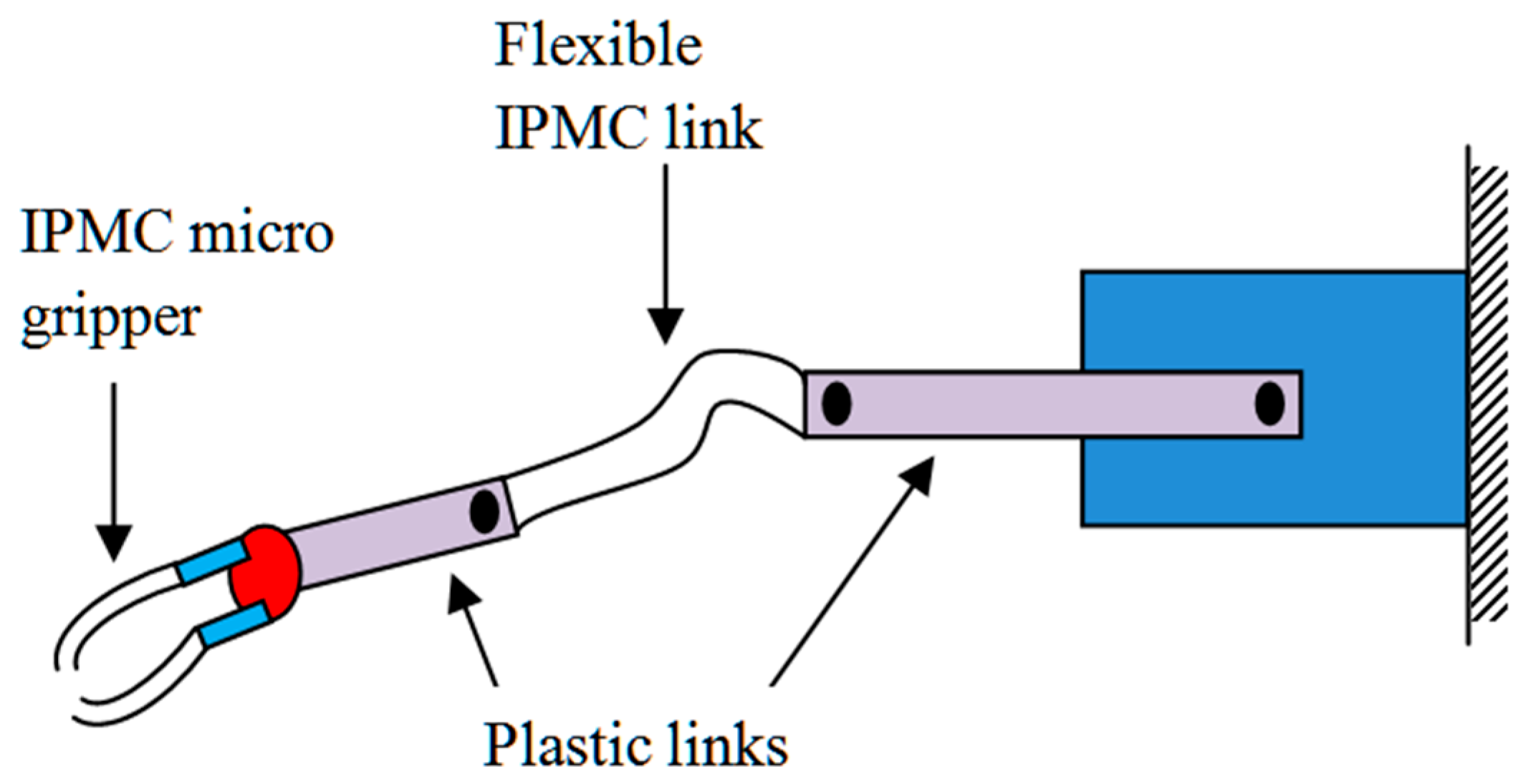

4.2. Mechanical

4.3. Automobile

4.4. Aerospace

4.5. Biomedical

4.6. Marine

5. FRP Replacing Conventional Material

6. Challenges

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yashas Gowda, T.G.; Sanjay, M.R.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. SSPolymer matrix-natural fiber composites: An overview. Cogent. Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Sherif, G.; Chukov, D.; Tcherdyntsev, V.; Torokhov, V. Effect of formation route on the mechanical properties of the polyethersulfone composites reinforced with glass fibers. Polymers 2019, 11, 1364. [Google Scholar] [CrossRef] [PubMed]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, mechanical and thermal properties of polyphenylene sulfide and polysulfone impregnated carbon fiber composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef] [PubMed]

- Linul, E.; Lell, D.; Movahedi, N.; Codrean, C.; Fiedler, T. Compressive properties of Zinc Syntactic Foams at elevated temperatures. Compos. Part B Eng. 2019, 167, 122–134. [Google Scholar] [CrossRef]

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials, 3rd ed.; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Zagho, M.M.; Hussein, E.A.; Elzatahry, A.A. Recent overviews in functional polymer composites for biomedical applications. Polymers 2018, 10, 739. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, S.N.; de Assis, F.S.; Ferreira, C.L.; Simonassi, N.T.; Weber, R.P.; Oliveira, M.S.; Colorado, H.A.; Pereira, A.C. Fique fabric: A promising reinforcement for polymer composites. Polymers 2018, 10, 246. [Google Scholar] [CrossRef] [PubMed]

- Movahedi, N.; Linul, E. Quasi-static compressive behavior of the ex-situ aluminum-alloy foam-filled tubes under elevated temperature conditions. Mater. Lett. 2017, 206, 182–184. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Torokhov, V.; Stepashkin, A.; Sherif, G.; Tcherdyntsev, V. Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results Phys. 2019, 15, 102634. [Google Scholar] [CrossRef]

- Linul, E.; Vălean, C.; Linul, P.A. Compressive behavior of aluminum microfibers reinforced semi-rigid polyurethane foams. Polymers 2018, 10, 1298. [Google Scholar] [CrossRef]

- Yongxu, D.; Dong, L.; Libin, L.; Guangjie, G. Recent achievements of self-healing graphene/polymer composites. Polymers 2018, 10, 114. [Google Scholar]

- Lebreton, L.C.M.; van der Zwet, J.; Damsteeg, J.W.; Slat, B.; Andrady, A.; Reisser, J. River plastic emissions to the world’s oceans. Nat. Commun. 2017, 8, 15611. [Google Scholar] [CrossRef] [PubMed]

- Scaffaro, R.; Maio, A.; Lopresti, F. Physical properties of green composites based on poly-lactic acid or Mater-Bi® filled with Posidonia Oceanica leaves. Compos. Part. A Appl. S. 2018, 112, 315–327. [Google Scholar] [CrossRef]

- Scaffaro, R.; Maio, A. A green method to prepare nanosilica modified graphene oxide to inhibit nanoparticles re-aggregation during melt processing. Chem. Eng. J. 2017, 308, 1034–1047. [Google Scholar] [CrossRef] [Green Version]

- Sun, M.; Sun, X.; Wang, Z.; Chang, M.; Li, H. The influence of shape memory alloy volume fraction on the impact behavior of polymer composites. Polymers 2018, 10, 1280. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M.F. An overview on properties and applications of poly (butylene adipate-co-terephthalate)-PBAT based composites. Polym. Eng. Sci. 2017, 59, E7–E15. [Google Scholar] [CrossRef]

- Dufresne, A. Nanocellulose processing properties and potential applications. Curr. For. Rep. 2019, 5, 76–89. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Ferreira, F.; Pinheiro, I.; de Souza, S.; Mei, L.; Lona, L. Polymer composites reinforced with natural fibers and nanocellulose in the automotive industry: A short review. J. Compos. Sci. 2019, 3, 51. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef] [Green Version]

- Ardanuy, M.; Claramunt, J.; García-Hortal, J.A.; Barra, M. Fiber-matrix interactions in cement mortar composites reinforced with cellulosic fibers. Cellulose 2011, 18, 281–289. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Blanco, A.; Negro, C. Nanocelluloses: Natural-based materials for fiber-reinforced cement composites. A critical review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef] [PubMed]

- Golewski, G.L. Determination of fracture toughness in concretes containing siliceous fly ash during mode III loading. Struct. Eng. Mech. 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of fly ash addition on the fracture toughness of plain concrete at third model of fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef] [Green Version]

- Pickering, K.L.; Efendy, M.G.A.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part. A-Appl. S. 2016, 83, 98–112. [Google Scholar] [CrossRef] [Green Version]

- Alves Fidelis, M.E.; Pereira, T.V.C.; Gomes, O.F.M.; de Andrade Silva, F.; Toledo Filho, R.D. The effect of fiber morphology on the tensile strength of natural fibers. J. Mater. Res. Technol. 2013, 2, 149–157. [Google Scholar] [CrossRef] [Green Version]

- Lotfi, A.; Li, H.; Dao, D.V.; Prusty, G. Natural fiber-reinforced composites: A review on material, manufacturing, and machinability. J. Compos. 2019. [Google Scholar] [CrossRef]

- Pegoretti, A.; Fabbri, E.; Migliaresi, C.; Pilati, F. Intraply and interply hybrid composites based on E-glass and poly (vinyl alcohol) woven fabrics: Tensile and impact properties. Polym. Int. 2004, 53, 1290–1297. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2018, 53, 1579–1669. [Google Scholar] [CrossRef]

- Dickson, A.N.; Ross, K.A.; Dowling, D.P. Additive manufacturing of woven carbon fibre polymer composites. Compos. Struct. 2018, 206, 637–643. [Google Scholar] [CrossRef]

- Altenbach, H.; Altenbach, J.; Kissing, W. Classification of Composite Materials. In Mechanics of composite Structural Elements; Springer: Singapore, 2004; pp. 1–14. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Raghunanan, L.; Sain, M.; Birat, K.C.; Tjong, J. Natural fiber and hybrid fiber thermoplastic composites. Green Compos. 2017. [Google Scholar] [CrossRef]

- Nair, A.B.; Joseph, R. Eco-friendly bio-composites using natural rubber (NR) matrices and natural fiber reinforcements. In Chemistry, Manufacture and Applications of Natural Rubber; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2014. [Google Scholar] [CrossRef]

- Agarwal, B.D.; Broutman, L.J.; Chandrashekhara, K. Analysis and Performance of Fiber Composites; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Dixit, S.; Goel, R.; Dubey, A.; Ahivhare, P.R.; Bhalavi, T. Natural fibre reinforced polymer composite materials- A review. Polym. Renew. Resour. 2017, 8, 71–78. [Google Scholar] [CrossRef]

- Arun Kumar, D.T.; Kaushik, V.P.; Raghavendra, R.P.S. Tensile and impact properties of jute/glass and jute/carbon fiber reinforced polypropylene. J. Polym. Compos. 2016, 4, 35–39. [Google Scholar]

- Hempalaya. The Difference between Hemp and Linen Fibers. 2019. Available online: https://hempalaya.com/blogs/news/der-unterschied-zwischen-hanf-und-leinen-fasern (accessed on 8 May 2019).

- Sunstrands. The Basics of Kenaf Fiber and Hurd. 2019. Available online: https://www.sunstrands.com/2019/the-uses-of-kenaf-fiber/ (accessed on 8 May 2019).

- Handloom Policies & Research. Indira Gandhi Krishi Vishvavidyalaya (IGKV) Achieves a Breakthrough in Getting Linen Yarn Using the Flax Plant. 2017. Available online: https://www.unnatisilks.com/blog/indira-gandhi-krishi-vishvavidyalaya-igkv-achieves-a-breakthrough-in-getting-linen-yarn-using-the-flax-plant/ (accessed on 10 May 2019).

- Textile School. Sampling from Cotton Bales. 2019. Available online: https://www.textileschool.com/469/sampling-from-cotton-bales/ (accessed on 12 May 2019).

- Lidija Grozdanic. Students Use Rice Husks to Build Affordable Homes in the Philippines. 2017. Available online: https://inhabitat.com/students-use-rice-husks-to-built-affordable-homes-in-the-philippines/ (accessed on 13 May 2019).

- Jute Geotextiles by Deyute, Geotextile Jute Fiber 732 gr/m2 122 cm. 2019. Available online: https://www.deyute.com/product/geotextiles-natural-fibers/91 (accessed on 13 May 2019).

- Backyard Poultry Contributor. Chicken Feather & Skin Development. 2019. Available online: https://backyardpoultry.iamcountryside.com/chickens-101/chicken-feather-skin-development/ (accessed on 13 May 2019).

- Tanmay Halaye. Ramie Fiber Market Competitive Research and Precise Outlook 2019 to 2025. 2019. Available online: https://themarketresearchnews.com/2019/04/02/ramie-fiber-market-competitive-research-and-precise-outlook-2019-to-2025/ (accessed on 17 May 2019).

- Textile Learner. Abaca Fiber (Manila Hemp) Uses/Application of Abaca Fiber. 2013. Available online: https://textilelearner.blogspot.com/2013/04/abaca-fiber-manila-hemp-usesapplication.html (accessed on 17 May 2019).

- Fertilefibre Admin. How We Make Our Peat-Free Coir Composts. 2008. Available online: https://www.fertilefibre.com/blog/peat-free-environment/coir-composts/ (accessed on 21 May 2019).

- Pond. Advantages of Using Natural Fibre Applications in Composites. 2017. Available online: https://pond.global/advantages-of-using-natural-fibre-applications-in-composites/ (accessed on 22 May 2019).

- Black and Beautiful. The Luffa/Loofah Skincare Benefits. 2015. Available online: https://blackandbeautiful.fr/blog/en/2015/04/08/the-luffa-skincare-benefits/ (accessed on 24 May 2019).

- BabaMu, Sisal Fibers. 2019. Available online: https://pixabay.com/photos/sisal-sisal-fibers-sisal-palm-4319997/ (accessed on 4 June 2019).

- Textile Learner. Properties of Banana Fiber, Manufacturing Process of Banana Fiber, Application of Banana Fiber. 2014. Available online: https://textilelearner.blogspot.com/2014/01/properties-of-banana-fiber.html (accessed on 4 June 2019).

- Beyond Materials, Basalt Fiber. Available online: https://beyondmaterials.com.au/2019/03/16/basalt-fiber/ (accessed on 11 June 2019).

- Carbon Black, Carbon. Available online: http://carbon-website.000webhostapp.com (accessed on 15 June 2019).

- Sanjay Impex. Fiberglass Scree. Available online: http://sanjayimpex.com/fiber-glass.html (accessed on 16 June 2019).

- Sathishkumar, T.; Naveen, J.; Satheeshkumar, S. Hybrid fiber reinforced polymer composites—A review. J. Reinf. Plast. Comp. 2014, 33, 454–471. [Google Scholar] [CrossRef]

- Rahman, R.; Zhafer Firdaus, S.P.S. Tensile properties of natural and synthetic fiber-reinforced polymer composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 81–102. [Google Scholar] [CrossRef]

- Jawaid, M.; Thariq, M.; Saba, N. Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Kumar, R.; Pruncu, C. Recent progress of reinforcement materials: A comprehensive overview of composite materials. J. Mater. Res. Technol. 2019. [Google Scholar] [CrossRef]

- Ghalia, M.A.; Abdelrasoul, A. Compressive and fracture toughness of natural and synthetic fiber-reinforced polymer. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 123–140. [Google Scholar] [CrossRef]

- Abdellaoui, H.; Raji, M.; Essabir, H.; Bouhfid, R.; Qaiss, A. Mechanical behavior of carbon/natural fiber-based hybrid composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 103–122. [Google Scholar] [CrossRef]

- Prakash, S. Experimental investigation of surface defects in low-power CO2 laser engraving of glass fiber-reinforced polymer composite. Polym. Compos. 2019. [Google Scholar] [CrossRef]

- Chalmers, D.W. Experience in design and production of FRP marine structures. Mar. Struct. 1991, 4, 93–115. [Google Scholar] [CrossRef]

- Unterweger, C.; Brüggemann, O.; Fürst, C. Synthetic fibers and thermoplastic short-fiber-reinforced polymers: Properties and characterization. Polym. Compos. 2013, 35, 227–236. [Google Scholar] [CrossRef]

- Yi, X.S. Development of multifunctional composites for aerospace application. In Multifunctionality of Polymer Composites; William Andrew Publishing: Oxford, UK, 2015; pp. 367–418. [Google Scholar] [CrossRef]

- Haim, A. Stability of composite stringer-stiffened panels. In Stability and Vibrations of Thin Walled Composite Structures; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2017; pp. 461–507. [Google Scholar] [CrossRef]

- Chung, D.D.L. Introduction to carbon composites. In Carbon Composites: Composites with Carbon Fibers, Nanofibers, and Nanotubes; Elsevier Science: Amsterdam, The Netherlands, 2017; pp. 88–160. [Google Scholar] [CrossRef]

- Nobe, R.; Qiu, J.; Kudo, M.; Ito, K.; Kaneko, M. Effects of SCF content, injection speed, and CF content on the morphology and tensile properties of microcellular injection-molded CF/PP composites. Polym. Eng. Sci. 2019, 59, 1371–1380. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. Graphene fiber: A new trend in carbon fibers. Mater. Today 2015, 18, 480–492. [Google Scholar] [CrossRef]

- Sreenivasulu, B.; Ramji, B.; Nagaral, M. A review on graphene reinforced polymer matrix composites. Mater. Today: Proc. 2018, 5, 2419–2428. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Wang, Q. A molecular dynamics simulation study on enhancement of mechanical and tribological properties of polymer composites by introduction of graphene. Carbon 2017, 111, 538–545. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Wu, Z.; Keller, T.; Vassilopoulos, A.P. Temperature effect on fatigue behavior of basalt fiber-reinforced polymer composites. Polym. Compos. 2018, 40, 2273–2283. [Google Scholar] [CrossRef]

- Singh, T.J.; Samanta, S. Characterization of Kevlar Fiber and its composites: A review. Mater. Today: Proc. 2015, 2, 1381–1387. [Google Scholar] [CrossRef]

- Omrani, E.; Menezes, P.L.; Rohatgi, P.K. State of the art on tribological behavior of polymer matrix composites reinforced with natural fibers in the green materials world. Eng. Sci. Technol. Int. J. 2016, 19, 717–736. [Google Scholar] [CrossRef] [Green Version]

- Ouarhim, W.; Zari, N.; Bouhfid, R.; Qaiss, A. Mechanical performance of natural fibers–based thermosetting composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 43–60. [Google Scholar] [CrossRef]

- Chand, N.; Fahim, M. Sisal reinforced polymer composites. Tribol. Nat. Fiber Polym. Compos. 2008. [Google Scholar] [CrossRef]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Saxena, M.; Pappu, A.; Haque, R.; Sharma, A. Sisal fiber based polymer composites and their applications. In Cellulose Fibers: Bio-and Nano-Polymer Composites; Springer: Berlin/Heidelberg, Germany, 2011; pp. 589–659. [Google Scholar] [CrossRef]

- Shahzad, A. Hemp fiber and its composites—A review. J. Compos. Mater. 2011, 46, 973–986. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part. B-Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef] [Green Version]

- Ochi, S. Mechanical properties of kenaf fibers and kenaf/PLA composites. Mech. Mater. 2008, 40, 446–452. [Google Scholar] [CrossRef]

- Chin, C.W.; Yousif, B.F. Potential of kenaf fibres as reinforcement for tribological applications. Wear 2009, 267, 1550–1557. [Google Scholar] [CrossRef]

- Abdi, B.; Azwan, S.; Abdullah, M.R.; Ayob, A. Flexural and tensile behaviour of kenaf fibre composite materials. Mater. Res. Innov. 2014, 18, S6–S184. [Google Scholar] [CrossRef]

- Ben Mlik, Y.; Jaouadi, M.; Rezig, S.; Khoffi, F.; Slah, M.; Durand, B. Kenaf fibre-reinforced polyester composites: Flexural characterization and statistical analysis. J. Text. Inst. 2017, 109, 713–722. [Google Scholar] [CrossRef]

- Huang, K.; Tran, L.Q.N.; Kureemun, U.; Teo, W.S.; Lee, H.P. Vibroacoustic behavior and noise control of flax fiber-reinforced polypropylene composites. J. Nat. Fibers 2019, 16, 729–743. [Google Scholar] [CrossRef]

- Goutianos, S.; Peijs, T.; Nystrom, B.; Skrifvars, M. Development of flax fibre based textile reinforcements for composite applications. Appl. Compos. Mater. 2006, 13, 199–215. [Google Scholar] [CrossRef]

- Habibi, M.; Laperrière, L.; Mahi Hassanabadi, H. Replacing stitching and weaving in natural fiber reinforcement manufacturing, part 2: Mechanical behavior of flax fiber composite laminates. J. Nat. Fibers 2018. [Google Scholar] [CrossRef]

- Chen, D.; Pi, C.; Chen, M.; He, L.; Xia, F.; Peng, S. Amplitude-dependent damping properties of ramie fiber-reinforced thermoplastic composites with varying fiber content. Polym. Compos. 2019, 40, 2681–2689. [Google Scholar] [CrossRef]

- Du, Y.; Yan, N.; Kortschot, M.T. The use of ramie fibers as reinforcements in composites. Biofiber Reinf. Compos. Mater. 2015. [Google Scholar] [CrossRef]

- Majeed, K.; Arjmandi, R.; Al-Maadeed, M.A.; Hassan, A.; Ali, Z.; Khan, A.U.; Khurram, M.S.; Inuwa, I.M.; Khanam, P.N. Structural properties of rice husk and its polymer matrix composites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2017; pp. 473–490. [Google Scholar] [CrossRef]

- Arjmandi, R.; Hassan, A.; Majeed, K.; Zakaria, Z. Rice husk filled polymer composites. Int. J. Polym. Sci. 2015, 2015, 1–32. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, H.; Zhang, C.; Ren, L.; Yu, H.; Galland, M.A.; Ichchou, M. Acoustic characteristics parameters of polyurethane/rice husk composites. Polym. Compos. 2018, 40, 2653–2661. [Google Scholar] [CrossRef]

- Verma, A.; Negi, P.; Singh, V.K. Experimental analysis on carbon residuum transformed epoxy resin: Chicken feather fiber hybrid composite. Polym. Compos. 2018, 40, 2690–2699. [Google Scholar] [CrossRef]

- Das, S.; Singha, A.K.; Chaudhuri, A.; Ganguly, P.K. Lengthwise jute fibre properties variation and its effect on jute–polyester composite. J. Text. Inst. 2019, 110, 1695–1702. [Google Scholar] [CrossRef]

- Khan, J.A.; Khan, M.A. The use of jute fibers as reinforcements in composites. In Biofiber Reinforcements in Composite Materials; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2015; pp. 3–34. [Google Scholar] [CrossRef]

- Munde, Y.S.; Ingle, R.B.; Siva, I. Investigation to appraise the vibration and damping characteristics of coir fibre reinforced polypropylene composites. Adv. Mater. Process. Technol. 2018, 4, 639–650. [Google Scholar] [CrossRef]

- Verma, D.; Shandilya, A.K.; Gupta, A. Coir fibre reinforcement and application in polymer composites: A Review. J. Mater. Env. Sci. 2013, 4, 263–276. [Google Scholar]

- Chollakup, R.; Smitthipong, W.; Kongtud, W.; Tantatherdtam, R. Polyethylene green composites reinforced with cellulose fibers (coir and palm fibers): Effect of fiber surface treatment and fiber content. J. Adhes. Sci. Technol. 2013, 27, 1290–1300. [Google Scholar] [CrossRef]

- Liu, Y.; Ma, Y.; Yu, J.; Zhuang, J.; Wu, S.; Tong, J. Development and characterization of alkali treated abaca fiber reinforced friction composites. Compos. Interface 2019, 26, 67–82. [Google Scholar] [CrossRef]

- Panneerdhass, R.; Gnanavelbabu, A.; Rajkumar, K. Mechanical properties of luffa fiber and ground nut reinforced epoxy polymer hybrid composites. Proced. Eng. 2014, 97, 2042–2051. [Google Scholar] [CrossRef]

- Bisen, H.B.; Hirwani, C.K.; Satankar, R.K.; Panda, S.K.; Mehar, K.; Patel, B. Numerical study of frequency and deflection responses of natural fiber (Luffa) reinforced polymer composite and experimental validation. J. Nat. Fibers 2018. [Google Scholar] [CrossRef]

- Laban, O.; Mahdi, E. Energy absorption capability of cotton fiber/epoxy composite square and rectangular tubes. J. Nat. Fibers 2016, 13, 726–736. [Google Scholar]

- Panthapulakkal, S.; Sain, M. Injection-molded short hemp fiber/glass fiber-reinforced polypropylene hybrid composites-Mechanical, water absorption and thermal properties. J. Appl. Polym. Sci. 2006, 103, 2432–2441. [Google Scholar] [CrossRef]

- Hanan, F.; Jawaid, M.; Md Tahir, P. Mechanical performance of oil palm/kenaf fiber-reinforced epoxy-based bilayer hybrid composites. J. Nat. Fibers 2018. [Google Scholar] [CrossRef]

- Ramesh, M.; Bhoopathi, R.; Deepa, C.; Sasikala, G. Experimental investigation on morphological, physical and shear properties of hybrid composite laminates reinforced with flax and carbon fibers. J. Chin. Adv. Mater. Soc. 2018, 6, 640–654. [Google Scholar] [CrossRef]

- Swolfs, Y.; Gorbatikh, L.; Verpoest, I. Fibre hybridisation in polymer composites: A review. Compos. Part. A-Appl. S. 2014, 67, 181–200. [Google Scholar] [CrossRef]

- Swolfs, Y.; Verpoest, I.; Gorbatikh, L. Recent advances in fibre-hybrid composites: Materials selection, opportunities and applications. Int. Mater. Rev. 2018, 64, 181–215. [Google Scholar] [CrossRef]

- Abhemanyu, P.C.; Prassanth, E.; Kumar, T.N.; Vidhyasagar, R.; Marimuthu, K.P.; Pramod, R. Characterization of natural fiber reinforced polymer composites. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2019; Volume 2080, p. 020005. [Google Scholar]

- Chawla, N.; Shen, Y.L. Mechanical behavior of particle reinforced metal matrix composites. Adv. Eng. Mater. 2001, 3, 357–370. [Google Scholar] [CrossRef]

- Mallick, P. Fiber-Reinforced Composites: Materials, Manufacturing, and Design, 3rd ed.; CRC Press: Boca Raton, FA, USA, 2007. [Google Scholar]

- Tanzi, M.C.; Farè, S. Foundations of Biomaterials Engineering; Matthew, D., Ed.; Elsevier: Amsterdam, The Netherlands; Academic Press: London, UK, 2019. [Google Scholar]

- Manickam, G.; Bharath, A.; Das, A.N.; Chandra, A.; Barua, P. Thermoelastic stability behavior of curvilinear fiber-reinforced composite laminates with different boundary conditions. Polym. Compos. 2018, 40, 2876–2890. [Google Scholar] [CrossRef]

- Fang, K. Encapsulation Technologies for Electronic Applications, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 123–181. [Google Scholar]

- Aditya Narayana, D.; Ganapathia, M.; Pradyumna, B. Investigation of thermo-elastic buckling of variable stiffness laminated composite shells using finite element approach based on higher-order theory. Compos. Struct. 2018, 211, 24–40. [Google Scholar] [CrossRef]

- Kelly, J.; Mohammadi, M. Uniaxial tensile behavior of sheet molded composite car hoods with different fibre contents under quasi-static strain rates. Mech. Res. Commun. 2018, 87, 42–52. [Google Scholar] [CrossRef]

- Balakrishnan, P.; John, M.J.; Pothen, L.; Sreekala, M.S.; Thomas, S. Natural fibre and polymer matrix composites and their applications in aerospace engineering. In Advanced Composite Materials for Aerospace Engineering; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2016; pp. 365–383. [Google Scholar] [CrossRef]

- Verma, D.; Senal, I. Natural fiber-reinforced polymer composites. BiomassBiopolym.-Based Mater. Bioenergy 2007, 44, 129. [Google Scholar] [CrossRef]

- Kumar, R.; Ul Haq, M.I.; Raina, A.; Anand, A. Industrial applications of natural fibre-reinforced polymer composites–challenges and opportunities. Int. J. Sustain. Eng. 2019, 12, 212–220. [Google Scholar] [CrossRef]

- Menezes, P.L.; Rohatgi, P.K.; Lovell, M.R. Studies on the tribological behavior of natural fiber reinforced polymer composite. In Green Tribology; Springer: Berlin/Heidelberg, Germany, 2012; pp. 329–345. [Google Scholar] [CrossRef]

- Venkatachalam, N.; Navaneethakrishnan, P.; Rajsekar, R.; Shankar, S. Effect of pretreatment methods on properties of natural fiber composites: A review. Polym. Polym. Compos. 2016, 24, 555–566. [Google Scholar] [CrossRef]

- Jamatia, R.; Deb, A. Size effect in FRP-confined concrete under axial compression. J. Compos. Constr. 2017, 21, 04017045. [Google Scholar] [CrossRef]

- Vincent, T.; Ozbakkaloglu, T. Influence of fiber orientation and specimen end condition on axial compressive behavior of FRP-confined concrete. Constr. Build. Mater. 2013, 47, 814–826. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T. Compressive behavior of concrete-filled FRP tube columns: Assessment of critical column parameters. Eng. Struct. 2013, 51, 188–199. [Google Scholar] [CrossRef] [Green Version]

- Ozbakkaloglu, T.; Vincent, T. Axial compressive behavior of circular high-strength concrete-filled frp tubes. J. Compos. Constr. 2014, 18, 04013037. [Google Scholar] [CrossRef]

- Chattopadhyay, S.K.; Khandal, R.K.; Uppaluri, R.; Ghoshal, A.K. Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J. Appl. Polym. Sci. 2010, 119, 1619–1626. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Zhou, Y.; Huang, Z.M.; Batra, R.C. Experimental and micromechanical investigation of T300/7901 unidirectional composite strength. Polym. Compos. 2018, 40, 2639–2652. [Google Scholar] [CrossRef]

- Chung, D.D.L. Polymer-matrix composites: Structure and processing. In Carbon Composites: Composites with Carbon Fibers, Nanofibers, and Nanotubes; Elsevier Science: Amsterdam, The Netherlands, 2017; pp. 161–217. [Google Scholar] [CrossRef]

- Boisse, P. (Ed.) Advances in Composites Manufacturing and Process Design; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2015. [Google Scholar]

- Balasubramanian, K.; Sultan, M.T.H.; Rajeswari, N. Manufacturing techniques of composites for aerospace applications. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2018; pp. 55–67. [Google Scholar] [CrossRef]

- Gascons, M.; Blanco, N.; Matthys, K. Evolution of manufacturing processes for fiber-reinforced thermoset tanks, vessels, and silos: A review. Iie Trans. 2012, 44, 476–489. [Google Scholar] [CrossRef]

- Holmes, M. High volume composites for the automotive challenge. Reinf. Plast. 2017, 61, 294–298. [Google Scholar] [CrossRef]

- Gunge, A.; Koppad, P.G.; Nagamadhu, M.; Kivade, S.; Murthy, K.V.S. Study on mechanical properties of alkali treated plain woven banana fabric reinforced biodegradable composites. Compos. Commun. 2019, 13, 47–51. [Google Scholar] [CrossRef]

- Elkington, M.; Bloom, D.; Ward, C.; Chatzimichali, A.; Potter, K. Hand layup: Understanding the manual process. Adv. Manuf. Polym. Compos. Sci. 2015, 1, 138–151. [Google Scholar]

- Jamir, M.R.M.; Majid, M.S.A.; Khasri, A. Natural lightweight hybrid composites for aircraft structural applications. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2018; pp. 155–170. [Google Scholar] [CrossRef]

- Perna, A.S.; Viscusi, A.; Astarita, A.; Boccarusso, L.; Carrino, L.; Durante, M.; Sansone, R. Manufacturing of a metal matrix composite coating on a polymer matrix composite through cold gas dynamic spray technique. J. Mater. Eng. Perform. 2019, 28, 3211–3219. [Google Scholar] [CrossRef]

- Marques, A.T. Fibrous materials reinforced composites production techniques. In Fibrous and Composite Materials for Civil Engineering Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2011; pp. 191–215. [Google Scholar] [CrossRef]

- Ervina, J.; Ghaleb, Z.A.; Hamdan, S.; Mariatti, M. Colloidal Stability of Water-based Carbon Nanotube Suspensions in Electrophoretic Deposition Process: Effect of Applied Voltage and Deposition Time. Compos. Part. A Appl. Sci. 2018, 117, 1–10. [Google Scholar] [CrossRef]

- Carruthers, J. Vacuum Bagging Process Overview, Coventive Composites. 2018. Available online: https://coventivecomposites.com/explainers/what-is-vacuum-bagging/ (accessed on 13 July 2019).

- Awan, F.S.; Fakhar, M.A.; Khan, L.A.; Zaheer, U.; Khan, A.F.; Subhani, T. Interfacial mechanical properties of carbon nanotube-deposited carbon fiber epoxy matrix hierarchical composites. Compos. Interface 2018, 25, 681–699. [Google Scholar] [CrossRef]

- Meola, C.; Boccardi, S.; Carlomagno, G. Composite Materials in the aeronautical industry. In Infrared Thermography in the Evaluation of Aerospace Composite Materials: Infrared Thermography to Composites; Elsevier Science: Amsterdam, The Netherlands, 2017; pp. 1–24. [Google Scholar] [CrossRef]

- Ahmad, N.; Bilal, I.; Khattak, S. Polyester usage in manufacturing of electrical and mechanical products and assemblies. Polyest.Prod. Charact. Innov. Appl. 2018. [Google Scholar] [CrossRef]

- Davis, D.C.; Mensah, T.O. Fabrication and fatigue of fiber-reinforced polymer nanocomposites—a tool for quality control. In Nanotechnology Commercialization: Manufacturing Processes and Products; Mensah, T.O., Wang, B., Bothun, G., Winter, J., Davis, V., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar] [CrossRef]

- Yalcinkaya, M.A.; Guloglu, G.E.; Pishvar, M.; Amirkhosravi, M.; Sozer, M.; Altan, M.C. Pressurized Infusion (PI): A new and improved liquid composite molding process. J. Manuf. Sci. Eng. 2018, 141, 011007. [Google Scholar] [CrossRef]

- Plummer, C.J.G.; Bourban, P.E.; Månson, J.A. Polymer matrix composites: Matrices and processing. Ref. Modul. Mater. Sci. Mater. Eng. 2016. [Google Scholar] [CrossRef]

- Ishikawa, H.; Takagi, H.; Nakagaito, A.N.; Yasuzawa, M.; Genta, H.; Saito, H. Effect of surface treatments on the mechanical properties of natural fiber textile composites made by VaRTM method. Compos. Interface 2014, 21, 329–336. [Google Scholar] [CrossRef]

- Mitschang, P.; Hildebrandt, K. Polymer and composite moulding technologies for automotive applications. In Advanced Materials in Automotive Engineering; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2012; pp. 210–229. [Google Scholar] [CrossRef]

- Park, C.H.; Lee, W.I. Compression molding in polymer matrix composites. In Manufacturing Techniques for Polymer Matrix Composites (PMCs); Woodhead Publishing: Sawston, UK; Cambridge, UK, 2012; pp. 47–94. [Google Scholar] [CrossRef]

- Matveenko, V.P.; Kosheleva, N.A.; Shardakov, I.N.; Voronkov, A.A. Temperature and strain registration by fibre-optic strain sensor in the polymer composite materials manufacturing. Int. J. Smart Nano Mater. 2018, 9, 99–110. [Google Scholar] [CrossRef] [Green Version]

- Biswas, B.; Hazra, B.; Sarkar, A.; Bandyopadhyay, N.R.; Mitra, B.C.; Sinha, A. Influence of ZrO2 incorporation on sisal fiber reinforced unsaturated polyester composites. Polym. Compos. 2018, 40, 2790–2801. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Singh, S.; Dhawan, V. Effect of curing temperature on mechanical properties of natural fiber reinforced polymer composites. J. Nat. Fibers 2017, 15, 687–696. [Google Scholar] [CrossRef]

- Ramôa Correia, J. Pultrusion of advanced fibre-reinforced polymer (FRP) composites. In Advanced Fibre-Reinforced Polymer (FRP) Composites for Structural Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2013; pp. 207–251. [Google Scholar] [CrossRef]

- Verma, D.; Joshi, G.; Dabral, R.; Lakhera, A. Processing and evaluation of mechanical properties of epoxy-filled E-glass fiber–fly ash hybrid composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 293–306. [Google Scholar] [CrossRef]

- Joshi, S.C. The pultrusion process for polymer matrix composites. In Manufacturing techniques for polymer matrix composites (PMCs); Woodhead Publishing: Sawston, UK; Cambridge, UK, 2012; pp. 381–413. [Google Scholar] [CrossRef]

- Leong, Y.W.; Thitithanasarn, S.; Yamada, K.; Hamada, H. Compression and injection molding techniques for natural fiber composites. In Natural Fibre Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2014; pp. 216–232. [Google Scholar] [CrossRef]

- Werner, V.M.K.; Krumpholz, R.; Rehekampff, C.; Scherzer, T.; Eblenkamp, M. Thermoplastic encapsulations of a sensor platform by high-temperature injection molding up to 360 °C. Polym. Eng. Sci. 2019. [Google Scholar] [CrossRef]

- González-López, M.E.; Pérez-Fonseca, A.A.; Manríquez-González, R.; Arellano, M.; Rodrigue, D.; Robledo-Ortíz, J.R. Effect of surface treatment on the physical and mechanical properties of injection molded poly(lactic acid)-coir fiber biocomposites. Polym. Compos. 2018, 40, 2132–2141. [Google Scholar] [CrossRef]

- Bhardwaj, N.; Kundu, S.C. Electrospinning: A fascinating fiber fabrication technique. Biotechnol. Adv. 2010, 28, 325–347. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Gonzalez-Henriquez, C.M.; Sarabia-Vallejos, M.A.; Rodriguez Hernandez, J. Polymers for additive manufacturing and 4D-printing: Materials, methodologies, and biomedical applications. Prog. Polym. Sci. 2019, 94, 57–116. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing: Principles and Applications. In Fifth Edition of Rapid Prototyping, 5th ed.; World Scientific Publishing Co., Inc.: Singapore, 2017. [Google Scholar]

- Goh, G.D.; Yap, Y.L.; Agarwala, S.; Yeong, W.Y. Recent progress in additive manufacturing of fiber reinforced polymer composite. Adv. Mater. Technol. 2018, 4, 1800271. [Google Scholar] [CrossRef]

- Hu, C.; Sun, Z.; Xiao, Y.; Qin, Q. Recent patents in additive manufacturing of continuous fiber reinforced composites. Recent Pat. Mech. Eng. 2019, 12, 25–36. [Google Scholar] [CrossRef]

- Parandoush, P.; Tucker, L.; Zhou, C.; Lin, D. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites. Mater. Des. 2017, 131, 186–195. [Google Scholar] [CrossRef]

- Shirvanimoghaddam, K.; Hamim, S.U.; Akbari, M.K.; Fakhrhoseini, S.M.; Khayyam, H.; Pakseresht, A.H.; Ghasali, E.; Zabet, M.; Munir, K.S.; Jia, S.; et al. Carbon fiber reinforced metal matrix composites: Fabrication processes and properties. Compos. Part. A-Appl. Sci. 2017, 92, 70–96. [Google Scholar] [CrossRef]

- Mantell, S.C.; Springer, G.S. Filament winding process models. Compos. Struct. 1994, 27, 141–147. [Google Scholar] [CrossRef]

- Minsch, N.; Herrmann, F.H.; Gereke, T.; Nocke, A.; Cherif, C. Analysis of filament winding processes and potential equipment technologies. Procedure Cirp 2017, 66, 125–130. [Google Scholar] [CrossRef]

- Hopmann, C.; Wruck, L.; Schneider, D.; Fischer, K. Automated winding of preforms directly from roving. Lightweight Des. Worldw. 2019, 12, 58–63. [Google Scholar] [CrossRef]

- Sorrentino, L.; Anamateros, E.; Bellini, C.; Carrino, L.; Corcione, G.; Leone, A.; Paris, G. Robotic filament winding: An innovative technology to manufacture complex shape structural parts. Compos. Struct. 2019, 220, 699–707. [Google Scholar] [CrossRef]

- Mouritz, A.P. Manufacturing of fibre–polymer composite materials. In Introduction to Aerospace Materials; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2012; Volume 10, pp. 303–337. [Google Scholar] [CrossRef]

- Frketic, J.; Dickens, T.; Ramakrishnan, S. Automated manufacturing and processing of fiber-reinforced polymer (FRP) composites: An additive review of contemporary and modern techniques for advanced materials manufacturing. Addit. Manuf. 2017, 14, 69–86. [Google Scholar] [CrossRef] [Green Version]

- Toutanji, H.; Deng, Y. Comparison between Organic and Inorganic Matrices for RC Beams Strengthened with Carbon Fiber Sheets. J. Compos. Constr. 2015, 11, 507–513. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part. B-Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Trapko, T. The effect of high temperature on the performance of CFRP and FRCM confined concrete elements. Compos. Part. B-Eng. 2013, 54, 138–145. [Google Scholar] [CrossRef]

- Wang, K.; Young, B.; Smith, S.T. Mechanical properties of pultruded carbon fibre-reinforced polymer (CFRP) plates at elevated temperatures. Eng. Struct. 2011, 33, 2154–2161. [Google Scholar] [CrossRef]

- Ding, Z.; Dai, J.G.; Munir, S. Study on an improved phosphate cement binder for the development of fiber-reinforced inorganic polymer composites. Polymers 2014, 6, 2819–2831. [Google Scholar] [CrossRef]

- Fang, Y.; Cui, P.; Ding, Z.; Zhu, J.X. Properties of a magnesium phosphate cement based fire-retardant coating containing glass fiber or glass fiber powder. Constr. Build. Mater. 2018, 162, 553–560. [Google Scholar] [CrossRef]

- Dai, J.G.; Munir, S.; Ding, Z. Comparative study of different cement-based inorganic pastes towards the development of FRIP strengthening technology. J. Compos. Constr. 2014, 18, A4013011. [Google Scholar] [CrossRef]

- Ding, Z.; Xu, M.R.; Dai, J.G.; Dong, B.Q.; Zhang, M.J.; Hong, S.X.; Xing, F. Strengthening concrete using phosphate cement-based fiber-reinforced inorganic composites for improved fire resistance. Constr. Build. Mater. 2019, 212, 755–764. [Google Scholar] [CrossRef]

- Manalo, A.; Aravinthan, T.; Fam, A.; Benmokrane, B. State-of-the-Art Review on FRP Sandwich Systems for Lightweight Civil Infrastructure. J. Compos. Constr. 2017, 21, 04016068. [Google Scholar] [CrossRef]

- Toutanji, H.A.; Gómez, W. Durability characteristics of concrete beams externally bonded with FRP composite sheets. Cem. Concr. Comp. 1997, 19, 351–358. [Google Scholar] [CrossRef]

- Kalfat, R.; Al-Mahaidi, R.; Smith, S.T. Anchorage devices used to improve the performance of reinforced concrete beams retrofitted with frp composites: State-of-the-Art Review. J. Compos. Constr. 2013, 17, 14–33. [Google Scholar] [CrossRef]

- Elgabbas, F.; Ahmed, E.A.; Benmokrane, B. Flexural behavior of concrete beams reinforced with ribbed basalt-FRP bars under static loads. J. Compos. Constr. 2016, 21, 195–230. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F. Concrete contribution to shear strength of beams reinforced with basalt fiber-reinforced bars. J. Compos. Constr. 2015, 20, 150–179. [Google Scholar] [CrossRef]

- Abed, F.; Alhafiz, A.R. Effect of basalt fibers on the flexural behavior of concrete beams reinforced with BFRP bars. Compos. Struct. 2019, 215, 23–34. [Google Scholar] [CrossRef]

- Zhang, H.W.; Smith, S.T. Influence of FRP anchor fan configuration and dowel angle on anchoring FRP plates. Compos. Part. B-Eng. 2012, 43, 3516–3527. [Google Scholar] [CrossRef]

- Available online: https://theconstructor.org/concrete/prestressed-concrete-principles-advantages/28/ (accessed on 12 October 2019).

- Scullybob. 2018. Available online: https://en.wikipedia.org/wiki/17th_Street_Bridge_(Vero_Beach,_Florida) (accessed on 20 June 2019).

- Huang, B.T.; Li, Q.H.; Xu, S.L.; Zhou, B. Strengthening of reinforced concrete structure using sprayable fiber-reinforced cementitious composites with high ductility. Compos. Struct. 2019, 220, 940–952. [Google Scholar] [CrossRef]

- Cheng, L.; Karbhari, V.M. New bridge systems using FRP composites and concrete: A state-of-the-art review. Progr. Struct. Eng. Mater. 2006, 8, 143–154. [Google Scholar] [CrossRef]

- Pham, T.M.; Hao, H. Review of concrete structures strengthened with FRP against impact loading. Structures 2016, 7, 59–70. [Google Scholar] [CrossRef]

- Alagusundaramoorthy, P.; Harik, I.E.; Choo, C.C. Structural behavior of FRP composite bridge deck panels. J. Bridge. Eng. 2006, 11, 384–393. [Google Scholar] [CrossRef]

- Gopinath, R.; Poopathi, R.; Saravanakumar, S.S. Characterization and structural performance of hybrid fiber-reinforced composite deck panels. Adv. Compos. Hybrid. Mater. 2019, 2, 115–124. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-confined concrete in circular sections: Review and assessment of stress-strain models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Guades, E.; Aravinthan, T.; Islam, M.; Manalo, A. A review on the driving performance of FRP composite piles. Compos. Struct. 2012, 94, 1932–1942. [Google Scholar] [CrossRef]

- Sen, R.; Mullins, G. Application of FRP composites for underwater piles repair. Compos. Part. B-Eng. 2007, 38, 751–758. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Mosalam, K.M. Strengthening of two-way concrete slabs with FRP composite laminates. Constr Build. Mater. 2003, 17, 43–54. [Google Scholar] [CrossRef]

- Ou, J.; Li, H. Structural health monitoring in mainland China: Review and future trends. Struct. Health Monit. Int. J. 2010, 9, 219–231. [Google Scholar]

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Mao, K.; Greenwood, D.; Ramakrishnan, R.; Goodship, V.; Shrouti, C.; Chetwynd, D.; Langlois, P. The wear resistance improvement of fibre reinforced polymer composite gears. Wear 2019, 426, 1033–1039. [Google Scholar] [CrossRef]

- Catera, P.G.; Mundo, D.; Treviso, A.; Gagliardi, F.; Visrolia, A. On the design and simulation of hybrid metal-composite gears. Springer Appl. Compos. Mater. 2019, 26, 817–833. [Google Scholar] [CrossRef]

- Bae, J.H.; Jung, K.C.; Yoo, S.H.; Chang, S.H.; Kim, M.; Lim, T. Design and fabrication of a metal composite hybrid wheel with a friction damping layer for enhancement of ride comfort. Compos. Struct. 2015, 133, 576–584. [Google Scholar] [CrossRef]

- Shweiki, S.; Palermo, A.; Mundo, D. A study on the dynamic behaviour of lightweight gears. Shock Vib. 2017, 2017, 7982170. [Google Scholar] [CrossRef]

- Rigaud, E.; Cornuault, P.H.; Bazin, B.; Grandais-Menant, E. Numerical and experimental analysis of the vibroacoustic behavior of an electric window-lift gear motor. Arch. Appl. Mech. 2018, 88, 1395–1410. [Google Scholar] [CrossRef] [Green Version]

- Schäkel, M.; Janssen, H.; Brecher, C. Increased reliability for the manufacturing of composite pressure vessels. Lightweight Des. Worldw. 2019, 12, 10–17. [Google Scholar] [CrossRef]

- Wilson, A. Vehicle weight is the key driver for automotive composites. Reinf. Plast. 2017, 61, 100–102. [Google Scholar] [CrossRef]

- Future Pipe Industries. Tanks. 2019. Available online: https://www.futurepipe.com/products/tanks (accessed on 11 July 2019).

- Solazzi, L.; Buffoli, A. Telescopic hydraulic cylinder made of composite material. Appl. Compos. Mater. 2019, 26, 1189–1206. [Google Scholar] [CrossRef]

- Chang, S.H.; Kim, P.J.; Lee, D.G.; Choi, J.K. Steel-composite hybrid headstock for high-precision grinding machines. Compos. Struct. 2001, 53, 1–8. [Google Scholar] [CrossRef]

- Jain, R.K.; Khan, A.; Inamuddin, I.; Asiri, A.M. Design and development of non-perfluorinated ionic polymer metal composite-based flexible link manipulator for robotics assembly. Polym. Compos. 2018, 40, 2582–2593. [Google Scholar] [CrossRef]

- Lu, Z.L.; Lu, F.; Cao, J.W.; Li, D.C. Manufacturing properties of turbine blades of carbon fiber-reinforced SiC Composite Based on Stereolithography. Mater. Manuf. Process. 2014, 29, 201–209. [Google Scholar] [CrossRef]

- Patel, M.; Saurabh, K.; Prasad, V.B.; Subrahmanyam, J. High temperature C/C–SiC composite by liquid silicon infiltration: A literature review. B. Mater. Sci. 2012, 35, 63–73. [Google Scholar] [CrossRef]

- Stenquist, P. Superbrakes for Civilians? The Cost Is the Obstacle 2010. Available online: https://www.nytimes.com/2010/08/01/automobiles/01BRAKES.html (accessed on 2 July 2019).

- Forintos, N.; Czigány, T. Multifunctional application of carbon fiber reinforced polymer composites: Electrical properties of the reinforcing carbon fibers—A short review. Compos. Part. B Eng. 2019, 162, 331–343. [Google Scholar] [CrossRef]

- Amiri, A.; Krosbakken, T.; Schoen, W.; Theisen, D.; Ulven, C.A. Design and manufacturing of a hybrid flax/carbon fiber composite bicycle frame. Proc. Inst. Mech. Eng. Part. P J. Sports Eng. Technol. 2017, 232, 28–38. [Google Scholar] [CrossRef] [Green Version]

- Kong, C.; Lee, H.; Park, H. Design and manufacturing of automobile hood using natural composite structure. Compos. Part. B-Eng. 2016, 91, 18–26. [Google Scholar] [CrossRef]

- Hassan, S.M.; Amir, N.; Rahmati, A.M. Pedestrian safety investigation of the new inner structure of the hood to mitigate the impact injury of the head. Thin Wall. Struct. 2014, 77, 77–85. [Google Scholar]

- Koronis, G.; Silva, A.; Fontul, M. Green composites: A review of adequate materials for automotive applications. Compos. Part. B-Eng. 2013, 44, 120–127. [Google Scholar] [CrossRef]

- Kong, C.; Park, H.; Lee, J. Study on structural design and analysis of flax natural fiber composite tank manufactured by vacuum assisted resin transfer molding. Mater. Lett. 2014, 130, 21–25. [Google Scholar] [CrossRef]

- Alves, C.; Ferrão, P.M.C.; Silva, A.J.; Reis, L.G.; Freitas, M.; Rodrigues, L.B. Ecodesign of automotive components making use of natural jute fiber composites. J. Clean. Prod. 2011, 18, 313–327. [Google Scholar] [CrossRef]

- Belauto. Available online: https://belauto.com.my/2014-volkswagen-xl1-carbon-fiber-body-parts/ (accessed on 3 July 2019).

- Ashworth, S.; Rongong, J.; Wilson, P.; Meredith, J. Mechanical and damping properties of resin transfer moulded jute-carbon hybrid composites. Compos. Part. B-Eng. 2016, 105, 60–66. [Google Scholar] [CrossRef] [Green Version]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Wagh, P.H.; Pagar, D.D. Investigation of mechanical and tribological behavior of composite material filled with black epoxy resin and aluminium tri-hydroxide using reinforcement of glass fiber. AIP Conf. Proc. 2018, 2018, 020025. [Google Scholar] [CrossRef]

- Zhang, J.; Khatibi, A.A.; Castanet, E.; Baum, T.; Komeily-Nia, Z.; Vroman, P.; Wang, X. Effect of natural fibre reinforcement on the sound and vibration damping properties of bio-composites compression moulded by nonwoven mats. Compos. Commun. 2019, 13, 12–17. [Google Scholar] [CrossRef]

- Farid, M.; Purniawan, A.; Rasyida, A.; Ramadhani, M.; Komariyah, S. Improvement of acoustical characteristics: Wideband bamboo based polymer composite. Iop Conf. Ser. Mater. Sci. Eng. 2017, 223, 012021. [Google Scholar] [CrossRef]

- Kelly, J. What Is the Ideal Interior Material for Cars? 2017. Available online: https://www.carconversation.com.au/opinions/what-is-the-ideal-interior-material-for-cars (accessed on 10 July 2019).

- Belingardi, G.; Koricho, E.G. Design of a composite engine support sub-frame to achieve lightweight vehicles. Int. J. Automot. Compos. 2014, 1, 90. [Google Scholar] [CrossRef]

- Hou, W.; Xu, X.; Han, X.; Wang, H.; Tong, L. Multi-objective and multi-constraint design optimization for hat-shaped composite T-joints in automobiles. Thin Wall Struct. 2019, 143, 106232. [Google Scholar] [CrossRef]

- Kim, D.-H.; Kim, H.-G.; Kim, H.-S. Design optimization and manufacture of hybrid glass/carbon fiber reinforced composite bumper beam for automobile vehicle. Compos. Struct. 2015, 131, 742–752. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C. Mechanical characterization of carbon fiber-reinforced plastic specimens for aerospace applications. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 387–407. [Google Scholar] [CrossRef]

- Alonso-Martin, P.P.; Gonzalez-Garcia, A.; Lapena-Rey, N.; Fita-Bravo, S.; Martinez-Sanz, V.; Marti-Ferrer, F. Green Aircraft Interior Panels and Method of Fabrication. European Patent EP2463083A2, 13 June 2012. [Google Scholar]

- Maryanka, Y.; Meidar, M.I.; Curless, R.A. Method of Signal Transmission Using Fiber Composite Sandwich Panel. US Patent 8903311, 2 December 2014. [Google Scholar]

- Rawal, S.P. Metal-matrix composites for space applications. JOM 2001, 53, 14–17. [Google Scholar] [CrossRef]

- Boegler, O.; Kling, U.; Empl, D.; Isikveren, A. Potential of sustainable materials in wing structural design. In Proceedings of the Deutscher Luft- und Raumfahrtkongress, München, Germany, 16–18 August 2014. [Google Scholar]

- Arockiam, N.J.; Jawaid, M.; Saba, N. Sustainable bio composites for aircraft components. In Sustainable Composites for Aerospace Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2018; pp. 109–123. [Google Scholar] [CrossRef]

- Fan, S.; Yang, C.; He, L.; Du, Y.; Krenkel, W.; Greil, P.; Travitzky, N. Progress of ceramic matrix composites brake materials for aircraft application. Rev. Adv. Mater. Sci. 2016, 44, 313–325. [Google Scholar]

- Zou, Z.; Qin, Y.; Tian, Q.; Huang, Z.; Zhao, Z. The influence of zirconia fibre on ablative composite materials. Plast. Rubber Compos. 2019, 48, 185–190. [Google Scholar] [CrossRef]

- Scholz, M.-S.; Blanchfield, J.P.; Bloom, L.D.; Coburn, B.H.; Elkington, M.; Fuller, J.D.; Bond, I.P. The use of composite materials in modern orthopaedic medicine and prosthetic devices: A review. Compos. Sci. Technol. 2011, 71, 1791–1803. [Google Scholar] [CrossRef]

- Lazar, M.A.; Rotaru, H.; Bâldea, I.; Boşca, A.B.; Berce, C.P.; Prejmerean, C.; Câmpian, R.S. Evaluation of the biocompatibility of new fiber-reinforced composite materials for craniofacial bone reconstruction. J. Craniofac Surg. 2016, 27, 1694–1699. [Google Scholar] [CrossRef] [PubMed]

- Kowsari, E.; Haddadi-Asl, V.; Ajdari, F.B.; Hemmat, J. Aramid fibers composites to innovative sustainable materials for biomedical applications. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 173–204. [Google Scholar] [CrossRef]

- Teo, A.J.T.; Mishra, A.; Park, I.; Kim, Y.-J.; Park, W.-T.; Yoon, Y.-J. Polymeric biomaterials for medical implants and devices. Acs Biomater. Sci. Eng. 2016, 2, 454–472. [Google Scholar] [CrossRef]

- Kim, S.S.; Lee, J. Antimicrobial polyacrylonitrile/m-aramid hybrid composite. Ind. Eng. Chem. Res. 2013, 52, 10297–10304. [Google Scholar] [CrossRef]

- Kim, S.S.; Lee, J. Miscibility and antimicrobial properties of m-aramid/chitosan hybrid composite. Ind. Eng. Chem. Res. 2013, 52, 12703–12709. [Google Scholar] [CrossRef]

- Vallittu, P.K.; Närhi, T.O.; Hupa, L. Fiber glass-bioactive glass composite for bone replacing and bone anchoring implants. Dent. Mater. 2015, 31, 371–381. [Google Scholar] [CrossRef]

- Zhu, B.; Li, W.; Lewis, R.V.; Segre, C.U.; Wang, R. E-Spun composite fibers of collagen and dragline silk protein: Fiber mechanics, biocompatibility, and application in stem cell differentiation. Biomacromolecules 2014, 16, 202–213. [Google Scholar] [CrossRef]

- Mengyan, L.; Mondrinos, M.J.; Xuesi, C.; Lelkes, P.I. Electrospun blends of natural and synthetic polymers as scaffolds for tissue engineering. In Proceedings of the 2005 IEEE Engineering in Medicine and Biology 27th Annual Conference, Shanghai, China, 17–18 January 2006. [Google Scholar] [CrossRef]

- Lelkes, P.I.; Mengyan, L.; Mondrinos, M.; Ko, F. U.S. Patent No. US8048446B2. Available online: https://patents.google.com/patent/US8048446B2/en (accessed on 12 October 2019).

- Jaganathan, S.K.; Mani, M.P. Enriched mechanical, thermal, and blood compatibility of single stage electrospun polyurethane nickel oxide nanocomposite for cardiac tissue engineering. Polym. Compos. 2018, 40, 2381–2390. [Google Scholar] [CrossRef]

- Kim, O.V.; Litvinov, R.I.; Chen, J.; Chen, D.Z.; Weisel, J.W.; Alber, M.S. Compression-induced structural and mechanical changes of fibrin-collagen composites. Matrix Biol. 2017, 60, 141–156. [Google Scholar] [CrossRef] [PubMed]

- Bensaıd, W.; Triffitt, J.; Blanchat, C.; Oudina, K.; Sedel, L.; Petite, H. A biodegradable fibrin scaffold for mesenchymal stem cell transplantation. Biomaterials 2003, 24, 2497–2502. [Google Scholar] [CrossRef]

- Shevchenko, R.V.; James, S.L.; James, S.E. A review of tissue-engineered skin bioconstructs available for skin reconstruction. J. R. Soc. Interface 2010, 7, 229–258. [Google Scholar] [CrossRef] [PubMed]

- Manvi, P.K.; Beckers, M.; Mohr, B.; Seide, G.; Gries, T.; Bunge, C.-A. Polymer fiber-based biocomposites for medical sensing applications. In Materials for Biomedical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 57–88. [Google Scholar] [CrossRef]

- Rebelo, R.; Fernandes, M.; Fangueiro, R. Biopolymers in medical implants: A brief review. Procedure Eng. 2017, 200, 236–243. [Google Scholar] [CrossRef]

- Azimi, B.; Nourpanah, P.; Rabiee, M.; Arbab, S. Poly (lactide-co-glycolide) Fiber: An Overview. J. Eng. Fiber Fabr. 2014, 9, 155892501400900. [Google Scholar] [CrossRef]

- Pivsa-Art, W.; Chaiyasat, A.; Pivsa-Art, S.; Yamane, H.; Ohara, H. Preparation of polymer blends between Poly(Lactic Acid) and Poly(Butylene adipate-co-terephthalate) and biodegradable polymers as compatibilizers. Energy Proced. 2013, 34, 549–554. [Google Scholar] [CrossRef]

- Shanks, R.; Kong, I. Thermoplastic Elastomers. In Applied Sciences, 1st ed.; RMIT University: Melbourne, Australia, 2012; pp. 95–116. [Google Scholar]

- Panwiriyarat, W.; Tanrattanakul, V.; Pilard, J.F.; Pasetto, P.; Khaokong, C. Preparation and Properties of Bio-based Polyurethane Containing Polycaprolactone and Natural Rubber. J. Polym. Env. 2013, 21, 807–815. [Google Scholar] [CrossRef]

- Nicolae, A.; Grumezescu, A.M. Polymer fibers in biomedical engineering. Mater. Biomed. Eng. 2019. [Google Scholar] [CrossRef]

- Nandi, S.K.; Mahato, A.; Kundu, B.; Mukherjee, P. Organic-inorganic micro/nanofiber composites for biomedical applications. Mater. Biomed. Eng. 2019. [Google Scholar] [CrossRef]

- Jesthi, D.K.; Nayak, R.K. Improvement of mechanical properties of hybrid composite through interply rearrangement of glass and carbon woven fabrics for marine applications. Compos. Part. B-Eng. 2019, 168, 467–475. [Google Scholar] [CrossRef]

- Dhakal, H.N.; MacMullen, J.; Zhang, Z.Y. Moisture measurement and effects on properties of marine composites. In Marine Applications of Advanced Fibre-Reinforced Composites; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2016; pp. 103–124. [Google Scholar] [CrossRef]

- Kootsookos, A.; Mouritz, A.P. Seawater durability of glass- and carbon-polymer composites. Compos. Sci. Technol. 2004, 64, 1503–1511. [Google Scholar] [CrossRef]

- Yu, Y.; Yang, X.; Wang, L.; Liu, H. Hygrothermal ageing on pultruded carbon fibre/vinyl ester resin composite for sucker rod application. J. Reinf. Plast. Compos. 2006, 25, 149–160. [Google Scholar] [CrossRef]

- Gellert, E.P.; Turley, D.M. Seawater immersion ageing of glass-fibre reinforced polymer laminates for marine applications. Compos.A Appl. Sci. Manuf. 1999, 30, 1259–1265. [Google Scholar] [CrossRef]

- Siriruk, A.; Jack Weitsman, Y.; Penumadu, D. Polymeric foams and sandwich composites: Material properties, environmental effects, and shear-lag modelling. Compos. Sci. Technol. 2009, 69, 814–820. [Google Scholar] [CrossRef]

- Siriruk, A.; Penumadu, D.; Weitsman, Y. Effect of sea environment on interfacial delamination behaviour of polymeric sandwich structures. Compos. Sci. Technol. 2009, 69, 821–828. [Google Scholar] [CrossRef]

- Akbar, S.; Zhang, T. Moisture diffusion in carbon/epoxy composite and the effect of cyclic hygrothermal fluctuations: Characterization by dynamic mechanical analysis (DMA) and interlaminar shear strength (ILSS). J. Adhes. 2008, 84, 585–600. [Google Scholar] [CrossRef]

- Kumar, A.; Lal, K.G.; Anantha, S.V. Design and Analysis of a Carbon Composite Propeller for Podded Propulsion. In Proceedings of the Fourth International Conference in Ocean. Engineering (ICOE2018), Lecture Notes in Civil. Engineering 22; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar] [CrossRef]

- Verma, D.; Goh, K.L. Natural fiber-reinforced polymer composites. In Biomass, Biopolymer-Based Materials, and Bioenergy: Construction, Biomedical, and Other Industrial Applications; Woodhead Publishing: Sawston, UK; Cambridge, UK, 2019; pp. 51–73. [Google Scholar] [CrossRef]

- Kovácik, J.; Jerz, J.; Mináriková, N.; Marsavina, L.; Linul, E. Scaling of compression strength in disordered solids: Metallic foams. Frat. Ed Integrita Strutt. 2016, 36, 55–62. [Google Scholar] [CrossRef]

- Movahedi, N.; Linul, E.; Marsavina, L. The Temperature effect on the compressive behavior of closed-cell aluminum-alloy foams. J. Mater. Eng. Perform. 2018, 27, 99–108. [Google Scholar] [CrossRef]

- Taherishargh, M.; Linul, E.; Broxtermann, S.; Fiedler, T. The mechanical properties of expanded perlite-aluminium syntactic foam at elevated temperatures. J. Alloy. Compd. 2018, 737, 590–596. [Google Scholar] [CrossRef]

- Park, H. A study on structural design and analysis of small wind turbine blade with natural fibre (flax) composite. Adv. Compos. Mater. 2015, 25, 125–142. [Google Scholar] [CrossRef]

- Tang, Q.; Wang, Y.; Ren, Y.; Zhang, W.; Guo, W. A novel strategy for the extraction and preparation of bamboo fiber-reinforced polypropylene composites. Polym. Compos. 2019, 40, 2178–2186. [Google Scholar] [CrossRef]

- Al-Mahaidi, R.; Kalfat, R. Fiber-reinforced polymers and their use in structural rehabilitation. In Rehabilitation of Concrete Structures with Fiber-Reinforced Polymer; Elsevier Science: Amsterdam, The Netherlands, 2018; pp. 15–20. [Google Scholar] [CrossRef]

- Linul, E.; Marsavina, L. Prediction of fracture toughness for open cell polyurethane foams by finite element micromechanical analysis. Iran. Polym. J. 2011, 20, 736–746. [Google Scholar]

- Linul, E.; Marsavina, L. Assesment of sandwich beams with rigid polyurethane foam core using failure-mode maps. P. Rom. Acad. A 2015, 16, 522–530. [Google Scholar]

- Rajak, D.K.; Mahajan, N.N.; Linul, E. Crashworthiness performance and microstructural characteristics of foam-filled thin-walled tubes under diverse strain rate. J. Alloy. Compd. 2019, 775, 675–689. [Google Scholar] [CrossRef]

- Marsavina, L.; Constantinescu, D.M.; Linul, E.; Voiconi, T.; Apostol, D.A.; Sadowski, T. Evaluation of mixed mode fracture for PUR foams. Procedure Mater. Sci. 2014, 3, 1342–1352. [Google Scholar] [CrossRef]

- Linul, E.; Serban, D.A.; Voiconi, T.; Marsavina, L.; Sadowski, T. Energy-absorption and efficiency diagrams of rigid PUR foams. Key Eng. Mater. 2014, 601, 246–249. [Google Scholar] [CrossRef]

- Pei, X.Q.; Friedrich, K. Friction and wear of polymer composites. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Habeeb, M.N.; Ashour, A.F. Flexural behavior of continuous GFRP reinforced concrete beams. J. Compos. Constr. 2008, 12, 115–124. [Google Scholar] [CrossRef]

- Abed, F.; El-Chabib, H.; AlHamaydeh, M. Shear characteristics of GFRP-reinforced concrete deep beams without web reinforcement. J. Reinf. Plast. Compos. 2012, 31, 1063–1073. [Google Scholar] [CrossRef]

- Rafi, M.M.; Nadjai, A.; Ali, F. Experimental testing of concrete beams reinforced with carbon FRP. J. Compos. Mater. 2007, 41, 2657–2673. [Google Scholar] [CrossRef]

- Rashid, M.A.; Mansur, M.A.; Paramasivam, P. Behavior of aramid fiber-reinforced polymer reinforced high strength concrete beams under bending. J. Compos. Constr. 2005, 9, 117–127. [Google Scholar] [CrossRef]

- Altalmas, A.; El Refai, A.; Abed, F. Bond degradation of basalt fiber-reinforced polymer (BFRP) bars exposed to accelerated aging conditions. Constr. Build. Mater. 2015, 81, 162–171. [Google Scholar] [CrossRef]

- Al-tamimi, A.; Abed, F.H.; Al-rahmani, A. Effects of harsh environmental exposures on the bond capacity between concrete and GFRP reinforcing bars. Adv. Concr. Constr. 2014, 2, 1–11. [Google Scholar] [CrossRef]

- El Refai, A.; Abed, F.; Altalmas, A. Bond durability of basalt fiber-reinforced polymer bars embedded in concrete under direct pullout conditions. J. Compos. Constr. 2014, 19, 1–11. [Google Scholar] [CrossRef]

| References | Materials Used | Application | Manufacturing Techniques | |

|---|---|---|---|---|

| Fiber Reinforcement | Matrix/Binder Material | |||

| [64,65] | Carbon | PP, metals, ceramics, epoxy resin, Polyether ether ketone (PEEK) | Lightweight automotive products, fuel cells, satellite components, armor, sports. | Injection molding, filament winding, resin transfer molding (RTM) |

| [68] | Graphene | Polystyrene (PS), epoxy, Polyaniline (PANI) | Wind turbines, Gas tanks, aircraft/automotive parts. | CVD, pultrusion, hand/spray up method |

| [76] | Sisal | PP, PS, epoxy resin | Automobile body parts, roofing sheets | Hand lay-up, compression molding |

| [77] | Hemp | PE, PP, PU | Furniture, automotive. | RTM, compression molding |

| [80] | Kenaf | PLA, PP, epoxy resin | Tooling, bearings, automotive parts. | Compression molding, pultrusion |

| [83,84] | Flax | PP, polyester, epoxy | Structural, textile. | Compression molding RTM, spray/hand lay-up, vacuum infusion |

| [86,87] | Ramie | PP, Polyolefin, PLA | Bulletproof vests, socket prosthesis, civil. | Extrusion with injection molding |

| [89] | Rice Husk | PU, PE | Window/door frames, automotive structure. | Compression/injection molding |

| [92,93] | Jute | Polyester, PP | Ropes, roofing, door panels. | Hand lay-up, compression/ injection molding |

| [94,95] | Coir | PP, epoxy resin, PE | Automobile structural components, building boards, roofing sheets, insulation boards. | Extrusion, injection molding |

| Fiber | Density (g/cm3) | Elongation (%) | Tensile Strength (MPa) | Young’s Modulus (GPa) |

|---|---|---|---|---|

| Aramid | 1.4 | 3.3–3.7 | 3000–3150 | 63–67 |

| E-glass | 2.5 | 2.5–3 | 2000–3500 | 70 |

| S-glass | 2.5 | 2.8 | 4570 | 86 |

| Cotton | 1.5–1.6 | 3–10 | 287–597 | 5.5–12.6 |

| Hemp | 1.48 | 1.6 | 550–900 | 70 |

| Jute | 1.3–1.46 | 1.5–1.8 | 393–800 | 10–30 |

| Flax | 1.4–1.5 | 1.2–3.2 | 345–1500 | 27.6–80 |

| Ramie | 1.5 | 2–3.8 | 220–938 | 44–128 |

| Sisal | 1.33–1.5 | 2–14 | 400–700 | 9–38 |

| Coir | 1.2 | 15–30 | 175–220 | 4–6 |

| Kenaf | 0.6–1.5 | 1.6–4.3 | 223–1191 | 11–60 |

| Bamboo | 1.2–1.5 | 1.9–3.2 | 500–575 | 27–40 |

| Oil palm | 0.7–1.6 | 4–8 | 50–400 | 0.6–9 |

| Betel nut | 0.2–0.4 | 22–24 | 120–166 | 1.3–2.6 |

| Sugarcane bagasse | 1.1–1.6 | 6.3–7.9 | 170–350 | 5.1–6.2 |

| References | Matrix Material | Properties | Applications |

|---|---|---|---|

| [2] | Polyethersulfone | Flame resistant | Automotive |

| [3] | Polyphenylene sulfide | Resistance to chemicals and high temperature | Electrical |

| [3, 9] | Polysulfone | Low moisture absorption, high strength, low creep | Marine, food packaging |

| [6] | Polyethylene (PE) | Resistance to corrosion | Piping |

| [6,36,54,66, 94,96,101] | Polypropylene (PP) | Resistance to chemicals | Packaging, automotive, construction |

| [6,13,79] | Polylactic acid (PLA) | Biodegradable, non-toxic | Food handling, bio-medical |

| [10,90] | Polyurethane (PU) | Wear resistance, low cost, sound and water-proof | Structural, acoustic |

| [16] | Poly(butylene adipate-co-terephthalate)-PBAT | Biodegradable, high stiffness | Coating, packaging |

| [19] | Cement | Durable | Structural |

| [28] | Poly(vinyl alcohol | High tensile strength | Bio-medical |

| [33] | Natural rubber | Low density, low cost, biodegradable | Structural, automobile |

| [54,91,98,100, 102] | Epoxy resin | High strength | Automotive, aerospace, marine |

| [82,92] | Polyester | Durable, resistance to water, chemicals | Structural |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers 2019, 11, 1667. https://doi.org/10.3390/polym11101667

Rajak DK, Pagar DD, Menezes PL, Linul E. Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers. 2019; 11(10):1667. https://doi.org/10.3390/polym11101667

Chicago/Turabian StyleRajak, Dipen Kumar, Durgesh D. Pagar, Pradeep L. Menezes, and Emanoil Linul. 2019. "Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications" Polymers 11, no. 10: 1667. https://doi.org/10.3390/polym11101667

APA StyleRajak, D. K., Pagar, D. D., Menezes, P. L., & Linul, E. (2019). Fiber-Reinforced Polymer Composites: Manufacturing, Properties, and Applications. Polymers, 11(10), 1667. https://doi.org/10.3390/polym11101667