Relationships between Thermoplastic Type and Properties of Polymer-Triticale Boards

Abstract

:1. Introduction

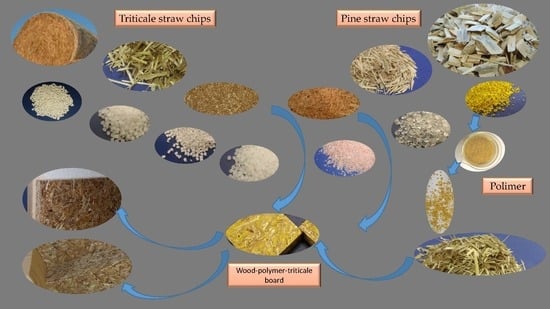

2. Materials and Methods

- ➢

- The face layers (1, 5) were made from straw with the moisture content of 2%;

- ➢

- The intermediate layers (2, 4) from straw with the moisture content of 25%;

- ➢

- The core layer (3) from chips with the moisture content of 7%.

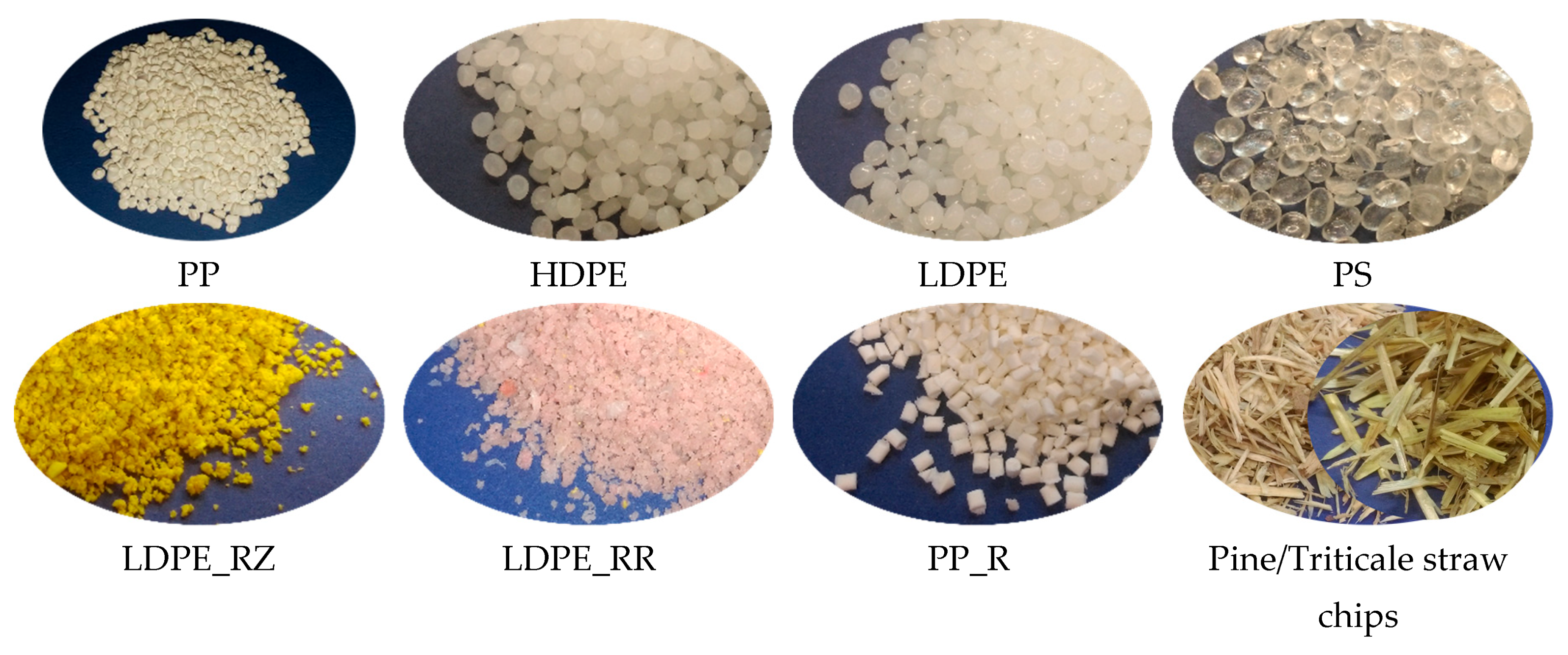

- PP—polypropylene impact copolymer (Zakład Przetwórstwa Tworzyw Sztucznych, Czapury, Poland);

- HDPE—high-density polyethylene (Basell Orlen Polyolefins Sp. z o.o., Płock, Poland);

- LDPE—low-density polyethylene (Basell Orlen Polyolefins Sp. z o.o., Płock, Poland);

- PS—polystyrene (Zakład Przetwórstwa Tworzyw Sztucznych, Czapury, Poland);

- LDPE rec. yellow—low-density polyethylene from recycled scraps of yellow plastic (Zakład Przetwórstwa Tworzyw Sztucznych, Czapury, Poland);

- LDPE rec. pink—low-density polyethylene from recycled scraps of pink plastic (Zakład Przetwórstwa Tworzyw Sztucznych, Czapury, Poland);

- PP recycled—polypropylene from reusable packaging (Zakład Przetwórstwa Tworzyw Sztucznych, Czapury, Poland).

3. Results

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Niska, K.; Sain, M. Wood-Polymer Composites; Woodhead publishing limited: Cambridge, UK, 2008. [Google Scholar]

- Wolcott, M.P. Formulation and process development of flat pressed wood-polyethylene composites. For. Prod. J. 2003, 53, 25–32. [Google Scholar]

- Ayrilmis, N.; Jarusombuti, S. Flat-pressed wood plastic composite as an alternative to conventional wood-based panels. J. Compos. Mater 2011, 45, 103–112. [Google Scholar] [CrossRef]

- Benthien, J.T.; Thoemen, H. Effects of raw materials and process parameters on the physical and mechanical properties of flat pressed WPC panels. Compos. Part A Appl. Sci. Manuf. 2012, 43, 570–576. [Google Scholar] [CrossRef]

- Schmidt, H.; Benthien, J.; Thoemen, H. Processing and flexural properties of surface reinforced flat pressed WPC panels. Eur. J. Wood Prod. 2013, 71, 591–597. [Google Scholar] [CrossRef]

- Lyutyy, P.; Bekhta, P.; Sedliačik, J.; Ortynska, G. Properties of flat-pressed wood-polymer composites made using secondary polyethylene. Acta Fac. Xylologiae Zvolen 2014, 56, 39–50. [Google Scholar]

- Bekhta, P.; Lyutyy, P.; Ortynska, G. Effects of different kinds of coating materials on flat pressed WPC panels. Drv. Ind. 2016, 67, 113–118. [Google Scholar] [CrossRef]

- Bekhta, P.; Lyutyy, P.; Ortynska, G. Properties of veneered flat pressed wood plastic composites by one-step process pressing. J. Polym. Environ. 2017, 25, 1288–1295. [Google Scholar] [CrossRef]

- Stark, N.M.; Berger, M. Effect of species and particle size on properties of wood-flour-filled polypropylene composites. In Proceedings of the Conference: Functional Fillers for Thermoplastics and Thermosets, San Diego, CA, USA, 8–10 December 1997. [Google Scholar]

- Falk, R.H.; Vos, D.; Cramer, S.M. The comparative performance of woodfiber-plastic and wood-based panels. In Proceedings of the 5th International Conference on Wood-Plastic Composites, Madison, WI, USA, 26–27 May 1999; pp. 269–274. [Google Scholar]

- Verhey, S.A.; Laks, P. Wood particle size affects the decay resistance of wood fiber/thermoplastic composites. For. Prod. J. 2002, 52, 78–81. [Google Scholar]

- Błędzki, A.K.; Faruk, O. Wood fiber reinforced polypropylene composites: Compression and injection molding process. Polym. Plast. Technol. 2004, 43, 871–888. [Google Scholar] [CrossRef]

- Chen, H.C.; Chen, T.Y.; Hsu, C.H. Effects of wood particle size and mixing Ratios of HDPE on the properties of the composites. Holz Roh Werkst. 2006, 64, 172–177. [Google Scholar] [CrossRef]

- Gozdecki, C.; Kociszewski, M.; Wilczyński, A.; Zajchowski, S. Mechanical properties of wood/polypropylene composite with coarse wood particles. Effect of specimen size. Ann. Wars. Univ. Life Sci. For. Wood Technol. 2009, 68, 283–287. [Google Scholar]

- Mirski, R.; Dziurka, D.; Banaszak, A. Using rape particles in the production of polymer and lignocellulose boards. BioResources 2019, 14, 6736–6746. [Google Scholar] [CrossRef]

- Synowiec, J. Sposób Wytwarzania Kompozytu z Polimerów Termoplastycznych i Cząstek Lignocelulozowych. Patent PL 183478 B1, 1996. [Google Scholar]

- Borysiuk, P.; Mamiński, M.; Zado, A. Some comments on the manufacturing of thermoplastic-bonded particleboards. Ann. Wars. Univ. Life Sci. For. Wood Technol. 2009, 68, 50–54. [Google Scholar]

- Hague, J.R.B.; Loxton, C.; Quinney, R.; Hobson, N. Assessment of the suitability of agri-based materials for panel products. In Proceedings of the First European Panel Products Symposium 1997, Llandudno, Wales, 9–10 October 1997; pp. 136–144. [Google Scholar]

- Papadopoulos, A.N.; Hague, J.B.B. The potential for using flax (Linum usitatissimum L.) shiv as a lignocellulosic raw material for particleboard. Ind. Crop. Prod. 2003, 17, 143–147. [Google Scholar] [CrossRef]

- Kurokochi, Y.; Sato, M. Properties of binderless board made from rice straw: The morphological effect of particles. Ind. Crop. Prod. 2015, 69, 55–59. [Google Scholar] [CrossRef]

- Kwon, J.H.; Ayrilmis, N.; Han, T.H. Combined effect of thermoplastic and thermosetting adhesives on properties of particleboard with rice husk core. Mater. Res. 2014, 17, 1309–1315. [Google Scholar] [CrossRef] [Green Version]

- Bekhta, P.; Korkut, S.; Hiziroglu, S. Effect of pretreatment of raw material on properties of particleboard panels made from wheat straw. BioResources 2013, 8, 4766–4774. [Google Scholar] [CrossRef]

- Dziurka, D.; Mirski, R. Lightweight boards from wood and rape straw particles. Drewno 2013, 56, 19–31. [Google Scholar]

- Mirski, R.; Dziurka, D.; Czarnecki, R. The possibility of replacing strands in the core layer of oriented strand board by particles from the stems of rape (Brassica napus L. var. napus). BioResources 2016, 11, 9273–9279. [Google Scholar] [CrossRef]

- Mirski, R.; Dziurka, D.; Banaszak, A. Properties of particleboards produced from various lignocellulosic particles. BioResources 2018, 13, 7758–7765. [Google Scholar] [CrossRef]

- Grigoriou, A.H. Straw-wood composites bonded with various adhesive systems. Wood Sci. Technol. 2000, 34, 355–365. [Google Scholar] [CrossRef]

- Pawlicki, J.; Nicewicz, D. Waste thermoplastic polymers in Technologies of wood-based panels. In Proceedings of the Third International Symposium “Wood Agglomeration”, Zvolen, Slovakia, 28–30 June 2000; pp. 81–84. [Google Scholar]

- Panthapulakkal, S.; Sain, M. Injection molded wheat straw and corn stem filled polypropylene composites. J. Polym. Environ. 2006, 14, 265–272. [Google Scholar] [CrossRef]

- Moresco, M.; Rosa, S.M.L.; Santos, E.F.; Nachtigall, S.M.B. Agrofillers in polypropylene composites: A relationship between the density and the mechanical properties. J. Appl. Polym. Sci. 2010, 117, 400–408. [Google Scholar] [CrossRef]

- Nourbakhsh, A.; Ashori, A. Wood plastic composites from agro-waste materials: Analysis of mechanical properties. Bioresour. Technol. 2010, 101, 2525–2528. [Google Scholar] [CrossRef]

- Hardinnawirda, K.; Aisha, I. Effect of rice husks as filler in polymer matrix composites. J. Mech. Eng. Sci. 2012, 2, 181–186. [Google Scholar] [CrossRef]

- He, С.; Hou, R.; Xue, J.; Zhu, D. The Performance of polypropylene wood–plastic composites with different rice straw contents using two methods of formation. For. Prod. J. 2013, 63, 61–66. [Google Scholar] [CrossRef]

- Haghdan, S.; Smith, G.D. Natural fiber reinforced polyester composites: A literature review. J. Reinf. Plast. Comp. 2015, 34, 1179–1190. [Google Scholar] [CrossRef]

- Dukarska, D.; Czarnecki, R.; Dziurka, D.; Mirski, R. Construction particleboards made from rapeseed straw glued with hybrid pMDI/PF resin. Eur. J. Wood Prod. 2017, 75, 175–184. [Google Scholar] [CrossRef]

- Abba, H.A.; Nur, I.Z.; Salit, S.M. Review of Agro Waste Plastic Composites Production. J. Min. Mater. Eng. 2013, 1, 271–279. [Google Scholar] [CrossRef] [Green Version]

- Panthapulakkal, S.; Law, S.; Sain, M. Enhancement of Processability of Rice Husk Filled High-density Polyethylene Composite Profiles. J. Compos. 2005, 18, 445–458. [Google Scholar] [CrossRef]

- Najafi, S.K.; Tajvidi, M.; Hamidina, E. Effect of temperature, plastic type and virginity on the water uptake of sawdust/plastic composites. Holz Roh Werkst. 2007, 65, 377–382. [Google Scholar] [CrossRef]

- Kelly, M.W. Critical Literature Review of Relationships Between Processing Parameters and Physical Properties of Particleboard. General Technical Report FPL-10; USDA Forest Service, Forest Products Laboratory: Madison, WI, USA, 1977.

- Park, B.D.; Riedl, B.; Hsu, E.W.; Shields, J. Hot-pressing process optimization by response surface methodology. For. Prod. J. 1999, 49, 62–68. [Google Scholar]

- Dziurka, D.; Mirski, R.; Łęcka, J. The effect of pine particle moisture content on properties of particleboards resinated with PMDI. EJPAU 2006, 9, 16. [Google Scholar]

- Borysiuk, P. Możliwości wytwarzania płyt wiórowo-polimerowych z wykorzystaniem poużytkowych termoplastycznych tworzyw sztucznych; Treatises and Monographs; Wydawnictwo SGGW: Warszawa, Poland, 2012; p. 393. [Google Scholar]

- Qi, C.; Yadama, V.; Guo, K.; Wolcott, M. Thermal conductivity of sorghum and sorghum–thermoplastic composite panels. Ind. Crop. Prod. 2013, 45, 455–460. [Google Scholar] [CrossRef]

- Research Report. Wood Plastic Composites Study-Technologies and UK Market Opportunities. The Waste and Resources; Action Programme (WRAP): Banbury, UK, 2003. [Google Scholar]

- EN 310. Wood-Based Panels—Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 1993.

- EN 319. Particleboards and fibreboards—Determination of Tensile Strength Perpendicular to the Plane of the Board; European Committee for Standardization: Brussels, Belgium, 1993.

- EN-1087-1. Particleboards—Determination of Moisture Resistance—Boil Test; European Committee for Standardization: Brussels, Belgium, 1995.

- EN 317. Particleboards and Fibreboards. Determination of Swelling in Thickness after Immersion in Water; European Committee for Standardization: Brussels, Belgium, 1993.

- Saechtling, H. Tworzywa Sztuczne; Wydawnictwa Naukowo-Techniczne: Warszawa, Poland, 2000. [Google Scholar]

- Zajchowski, S.; Ryszkowska, J. Kompozyty polimerowo-drzewne—Charakterystyka ogólna oraz ich otrzymywanie z materiałów odpadowych. Polimery 2009, 54, 674–682. [Google Scholar] [CrossRef]

- Kuciel, S.; Liber-Kneć, A.; Zajckowski, S. Kompozyty z włóknami naturalnymi na osnowie recyklatu polipropylenu. Polimery 2010, 55, 718–725. [Google Scholar] [CrossRef]

- EN 312. Particleboards—Specifications; European Committee for Standardization: Brussels, Belgium, 2010.

- Yasin, M.; Bhutto, A.W.; Bazmi, A.A.; Karim, S. Efficient Utilization of Rice-wheat Straw to Produce Value–added Composite Products. Int. J. Chem. Environ. Eng. 2010, 1, 136–143. [Google Scholar]

- Bengtsson, M.; Oksman, K. Silane crosslinked wood plastic composites: Processing and properties. Compos. Sci. Technol. 2006, 66, 2177–2186. [Google Scholar] [CrossRef]

- El-Kassas, A.M.; Mourad, A.-H.I. Novel fibers preparation technique for manufacturing of rice straw based fiberboards and their characterization. Mater. Des. 2013, 55, 757–765. [Google Scholar] [CrossRef]

- Li, X.J.; Cai, Z.Y.; Winandy, J.E.; Basta, A.H. Effect of oxalic acid and steam pretreatment on the primary properties of UF-bonded rice straw particleboards. Ind. Crop. Prod. 2011, 33, 665–669. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M.; Law, S. Effect of coupling agent on rice husk filled HDPE extruded profiles. Polym. Int. 2005, 54, 137–142. [Google Scholar] [CrossRef]

| Thermoplastic Type | Symbol | Thermoplastic Form | Density (g/cm3) | Softening Point (Vicata (A50)) | MFR (Melt Flow Index) |

|---|---|---|---|---|---|

| Polypropylene, impact copolymer | PP | Granulate | 0.9 | 150 °C | 4 g/10 min (230 °C/2.16 kg) |

| High-density polyethylene | HDPE | Granulate | 0.952 | 125 °C | 0.3 g/10 min (190 °C/2.16 kg) |

| Polystyrene | PS | Granulate | 1.5 | 90 °C | 6 g/min (200 °C/5 kg) |

| Low-density polyethylene | LDPE | Granulate | 0.923 | 91 °C | 1.5 g/10 min (190 °C/2.16 kg) |

| Polypropylene from reusable packaging | PP_R | Agglomerate | 0.54 * | nd | nd |

| Low-density polyethylene from yellow plastic | LDPE_RZ | Agglomerate | 0.37 * | nd | nd |

| Low-density polyethylene from pink plastic | LDPE_RR | Agglomerate | 0.38 * | nd | nd |

| Board Type (Thermoplastic) | Moisture Content | ||

|---|---|---|---|

| x, % * | SD, % | υ, % | |

| Reference Board | 3.70 | 0.06 | 1.69 |

| PP | 3.13 | 0.09 | 2.99 |

| HDPE | 3.29 | 0.22 | 6.81 |

| PS | 3.07 | 0.04 | 1.36 |

| LDPE | 2.92 | 0.13 | 4.51 |

| PP_R | 3.16 | 0.06 | 1.96 |

| LDPE_RZ | 2.90 | 0.16 | 5.59 |

| LDPE_RR | 3.00 | 0.11 | 3.56 |

| Board type (Thermoplastic) | MOR | MOE | ||||

|---|---|---|---|---|---|---|

| x, N/mm2 * | υ, % | HSD | x, N/mm2 | υ, % | HSD | |

| Reference board | 26.5 | 5.2 | e | 3880 | 4.3 | d |

| PP | 22.6 | 5.7 | a,b | 3020 | 4.6 | a,b |

| HDPE | 21.0 | 4.7 | a | 2930 | 3.4 | a |

| PS | 23.4 | 8.9 | b,c | 3490 | 3.4 | c |

| LDPE | 24.5 | 6.2 | c,d | 3150 | 5.6 | b |

| PP_R | 24.6 | 8.6 | c,d | 3180 | 4.3 | b |

| LDPE_RZ | 26.1 | 3.3 | d,e | 3030 | 4.2 | a,b |

| LDPE_RR | 25.9 | 2.7 | d,e | 3020 | 2.5 | a,b |

| ANOVA ** | F(7, 88) = 20.440, p = 0.00000 | F(7, 88) = 52.715, p = 0.0000 | ||||

| Board Type (Thermoplastic) | IB | V100 | |||||

|---|---|---|---|---|---|---|---|

| x, N/mm2 | υ, % | Max | HSD | x, N/mm2 | υ, % | HSD | |

| Reference board | 0.33 | 17.8 | 0.43 | A | 0.10 | 10.1 | A |

| PP | 0.33 | 14.4 | 0.40 | A | 0.12 | 10.5 | A,B |

| HDPE | 0.32 | 10.0 | 0.44 | A | 0.12 | 13.1 | B |

| PS | 0.42 | 9.53 | 0.49 | B | 0.13 | 15.7 | B |

| LDPE | 0.40 | 9.35 | 0.45 | B | 0.13 | 7.6 | B |

| PP_R | 0.40 | 9.44 | 0.44 | B | 0.12 | 13.6 | A,B |

| LDPE_RZ | 0.41 | 12.1 | 0.48 | B | 0.13 | 11.5 | B |

| LDPE_RR | 0.38 | 12.7 | 0.45 | A, B | 0.12 | 13.7 | A, B |

| ANOVA | F(7, 88) = 9.3263, p = 0.00000 | F(7, 88) = 5.5786, p = 0.00002 | |||||

| Board Type (Thermoplastic) | TS | TS-X | ||||

|---|---|---|---|---|---|---|

| x, % | υ, % | HSD | x, % | υ, % | HSD | |

| Reference board | 24.96 | 4.7 | A | 4.51 | 13.5 | A |

| PP | 21.99 | 3.7 | B,C | 2.36 | 20.0 | B |

| HDPE | 22.83 | 3.7 | B | 2.30 | 36.2 | B |

| PS | 19.51 | 4.4 | F | 1.64 | 32.0 | B |

| LDPE | 21.29 | 3.3 | C,D | 2.34 | 15.9 | B |

| PP_R | 20.41 | 5.2 | D,E | 1.99 | 35.0 | B |

| LDPE_RZ | 19.35 | 4.5 | F | 1.77 | 29.8 | B |

| LDPE_RR | 19.88 | 3.7 | F | 1.51 | 28.0 | B |

| ANOVA | F(7, 88) = 55.929, p = 0.0000 | F(7, 77) = 25.680, p = 0.0000 | ||||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mirski, R.; Bekhta, P.; Dziurka, D. Relationships between Thermoplastic Type and Properties of Polymer-Triticale Boards. Polymers 2019, 11, 1750. https://doi.org/10.3390/polym11111750

Mirski R, Bekhta P, Dziurka D. Relationships between Thermoplastic Type and Properties of Polymer-Triticale Boards. Polymers. 2019; 11(11):1750. https://doi.org/10.3390/polym11111750

Chicago/Turabian StyleMirski, Radosław, Pavlo Bekhta, and Dorota Dziurka. 2019. "Relationships between Thermoplastic Type and Properties of Polymer-Triticale Boards" Polymers 11, no. 11: 1750. https://doi.org/10.3390/polym11111750

APA StyleMirski, R., Bekhta, P., & Dziurka, D. (2019). Relationships between Thermoplastic Type and Properties of Polymer-Triticale Boards. Polymers, 11(11), 1750. https://doi.org/10.3390/polym11111750