Application of Colloidal Dispersions of Bioshell Calcium Oxide (BiSCaO) for Disinfection

Abstract

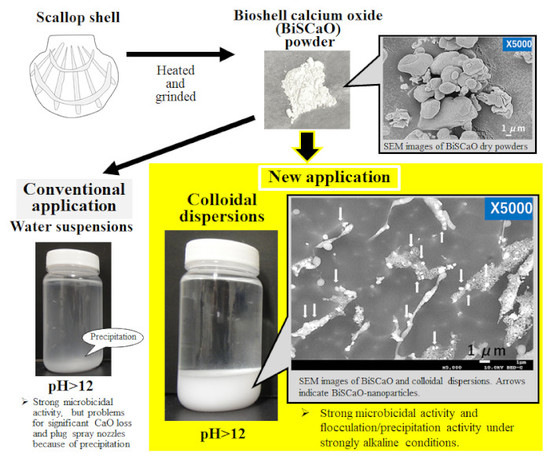

:1. Introduction

2. Materials and Methods

2.1. BiSCaO and BiSCa(OH)2 Powders and Chemicals

2.2. BiSCaO and BiSCa(OH)2 Colloidal Dispersions with Na-polyPO4 (PP) or Na-triPO4 (TP)

2.3. Scanning Electron Microscopy (SEM) and Cryo-images of BiSCaO Dry Powder and BiSCaO Colloidal Dispersions with PP

2.4. Flocculation and Precipitation of Trypan Blue with BiSCaO and BiSCa(OH)2 Colloidal Dispersions

2.5. Flocculation and Precipitations of Albumin with BiSCaO and BiSCa(OH)2 Colloidal Dispersions

2.6. Flocculation and Precipitation of Chondroitin Sulfate, Heparin, Non-Anticoagulant Heparin Carrying Polystyrene (NAC-HCPS) and Low-Molecular-Weight Heparin/Protamine Nanoparticles (LMWH/P NPs) with BiSCaO and BiSCa(OH)2 Colloidal Dispersions

2.7. Microbicidal Efficacies of BiSCaO and BiSCa(OH)2 Colloidal Dispersions

3. Results

3.1. BiSCaO and BiSCa(OH)2 Colloidal Dispersions with Na-polyPO4 (PP) and Na-triPO4 (TP)

3.2. Cryo-SEM Images of BiSCaO Dispersions Formed by Adding PP

3.3. Flocculation/Precipitation of Trypan Blue with BiSCaO and BiSCa(OH)2 Colloidal Dispersions

3.4. Flocculation/Precipitation of Albumin with BiSCaO and BiSCa(OH)2 Colloidal Dispersions

3.5. Flocculation/Precipitation of Chondroitin Sulfate, Heparin, NAC-HCPS, and LMWH/P NPs with BiSCaO and BiSCa(OH)2 Colloidal Dispersions

3.6. Antimicrobial Efficacy of BiSCaO and BiSCa(OH)2 Colloidal Dispersions

4. Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wiercinski, F.J. Calcium, an overview-1989. Biol. Bull. 1989, 176, 195–217. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.J.; Chou, K.S.; Huang, Y.K. A novel method to make regenerable core-shell lcalcium-based sorbants. J. Environ. Manag. 2006, 79, 51–56. [Google Scholar] [CrossRef] [PubMed]

- Sawai, J. Antimicrobial characteristics of heated scallop shell powder and its application. Biocontrol Sci. 2011, 16, 95–102. [Google Scholar] [CrossRef] [PubMed]

- Watanabe, T.; Fujimoto, R.; Sawai, J.; Kikuchi, M.; Yahata, S.; Satoh, S. Antibacterial characteristics of heated scallop-shell nano-particles. Biocontrol Sci. 2014, 19, 93–97. [Google Scholar] [CrossRef]

- Thammakarn, G.; Satoh, K.; Suguro, A.; Hakim, H.; Ruenphet, S.; Talehara, K. Inactivation of avian influenza virus, Newcastle disease virus and goose parvovirus using solution of nano-sized scallop shell powder. J. Vet. Med. Sci. 2014, 76, 1277–1280. [Google Scholar] [CrossRef]

- Sawai, J.; Miyoshi, H.; Kojima, H. Sporicidal kinetics of Baccillus subtilis spores by heated scallop shell powder. J. Food Prot. 2003, 66, 1482–1485. [Google Scholar] [CrossRef]

- Xing, R.; Qin, Y.; Guan, X.; Liu, S.; Yu, H.; Li, P. Comparison of antifungal activities of scallop shell, oyster shell and their pyrolyzed products. Egypt. J. Aquat. Res. 2013, 39, 83–90. [Google Scholar] [CrossRef]

- Sawai, J.; Nagasawa, K.; Kikuchi, M. Ability of heated scallop-shell powder to disinfect staphylococcus aureus biofilm. Food Sci. Technol. Res. 2013, 19, 561–568. [Google Scholar] [CrossRef]

- Kubo, M.; Ohshima, Y.; Irie, F.; Kikuchi, M.; Sawai, J. Disinfection treatment of heated scallop-shell powder on biofilm of Escherichia coli ATCC 25922 surrogated for E. coli O157:H7. J. Biomater. Nanobiotechnol. 2013, 4, 10–19. [Google Scholar] [CrossRef]

- Shimamura, N.; Irie, F.; Yamakawa, T.; Kikuchi, M.; Sawai, J. Heated scallop-shell powder treatment for deactivation and removal of Listeria sp. Biofilm formed at low temperature. Biocontrol Sci. 2015, 20, 153–157. [Google Scholar] [CrossRef]

- Sato, Y.; Ishihara, M.; Nakamura, S.; Fukuda, K.; Kuwabara, M.; Takayama, T.; Hiruma, S.; Murakami, K.; Fujita, M.; Yokoe, H. Comparison of various disinfectants on bactericidal activity under organic matter contaminated water. Biocontrol Sci. 2019, 24, 103–108. [Google Scholar] [CrossRef]

- Ishihara, M.; Murakami, K.; Fukuda, K.; Nakamura, S.; Kuwabara, M.; Hattori, H.; Fujita, M.; Kiyosawa, T.; Yokoe, H. Stability of weakly acidic hypochlorous acid solution with microbicidal activity. Biocontrol Sci. 2017, 22, 223–227. [Google Scholar] [CrossRef] [PubMed]

- Takada, T.; Furusaki, A.; Tanaka, Y. Formaldehyde reduction with scallop shell powders fired at high temperatures: Identification of the effective ingredient. Biomed. Mater. Eng. 2009, 19, 187–192. [Google Scholar] [CrossRef] [PubMed]

- Sato, Y.; Ishihara, M.; Nakamura, S.; Fukuda, K.; Takayama, T.; Hiruma, S.; Murakami, K.; Fujita, M.; Yokoe, H. Preparation and Application of Bioshell Calcium Oxide (BiSCaO) Nanoparticle-Dispersions with Bactericidal Activity. Molecules 2019, 24, 3415. [Google Scholar] [CrossRef]

- Fukuda, K.; Sato, Y.; Ishihara, M.; Nakamura, S.; Takayama, T.; Murakami, K.; Fujita, M.; Yokoe, H. Skin cleaning technique with high-velocity steam-air micromist jet spray. Biocontrol. Sci. In press. 2019.

- Grabow, W.O.K.; Middendorff, I.G.; Basson, N.C. Role of lime treatment in the removal of bacteria, enteric viruses, and coliphages in a wastewater reclamation plant. Appl. Environ. Microbiol. 1978, 35, 663–669. [Google Scholar]

- Leite, L.S.; Daniel, L.A.; Pivokonsky, M.; Branyikova, I.; Brannyik, T. Interference of model waster components with flocculation of Chlorella sorokiniana induced by calcium phosphate precipitates. Bioresour. Technol. 2019, 286, 121352. [Google Scholar] [CrossRef]

- Ishihara, M.; Saito, Y.; Yura, H.; Ono, K.; Ishikawa, K.; Hattori, H.; Akaike, T.; Kurita, A. Heparin-carrying polystyrene to mediate cellular attachment and growth via interaction with growth factors. J. Biomed. Mater. Res. A 2000, 50A, 144–152. [Google Scholar] [CrossRef]

- Ono, K.; Ishihara, M.; Ishikawa, K.; Ozeki, Y.; Deguchi, H.; Sato, M.; Hashimoto, H.; Saitoh, Y.; Yura, H.; Kurita, A.; et al. Periodate-treated, non-anticoagulant heparin carrying polystyrene (NAC-HCPS) affects angiogenesis and inhibits subcutaneous induced tumor growth and metastasis to the lung. Br. J. Cancer 2002, 86, 1803–1812. [Google Scholar] [CrossRef]

- Mori, Y.; Nakamura, S.; Kishimoto, S.; Kawakami, M.; Suzuki, S.; Matsui, T.; Ishihara, M. Preparation and characterization of low-molecular-weight heparin/protamine nanoparticles (LMW-H/P NPs) as FGF-2 carrier. Int. J. Nanomed. 2010, 5, 147–155. [Google Scholar] [CrossRef]

- Nakamura, S.; Kanatani, Y.; Kishimoto, S.; Nambu, M.; Ohno, C.; Hattori, H.; Fujita, M.; Hattori, H.; Tanaka, Y.; Kiyosawa, T.; et al. Controlled release of FGF-2 using fragmin/protamine microparticles and effect on neovascularization. J. Biomed. Mater. Res. A 2009, 91A, 814–823. [Google Scholar] [CrossRef] [PubMed]

- Reignier, J.; Alcouffe, P.; Mechin, F.; Fenouillot, F. The morphology of rigid polyurethane form matrix and its evolution with time furing foaming—New insight by cryogenic scanning electron microscopy. J. Colloid Interface Sci. 2019, 552, 153–165. [Google Scholar] [CrossRef] [PubMed]

- Hrubanova, K.; Nebesarova, J.; Ruzicka, F.; Krzyzanek, V. The innovation of cryo-SEM freeze-fracturing methodology demonstrated on high pressure frozen biofilm. Micron 2018, 110, 28–35. [Google Scholar] [CrossRef] [PubMed]

- Fukuda, K.; Ishihara, M.; Murakami, K.; Nakamura, S.; Sato, Y.; Kuwabara, M.; Fujita, M.; Kiyosawa, T.; Yokoe, H. Cleaning technique using high-velocity steam-air micromist jet spray. J. Med. Eng. Technol. 2017, 41, 522–528. [Google Scholar] [CrossRef] [PubMed]

- Sato, Y.; Ishihara, M.; Fukuda, K.; Nakamura, S.; Murakami, K.; Fujita, M.; Yokoe, H. Behavior of nitrate nitorogen and nitrite nitrogen in drinking waters. Biocontrol Sci. 2018, 23, 139–143. [Google Scholar] [CrossRef]

- Ishihara, M.; Ono, K.; Ishikawa, K.; Hattori, H.; Saitoh, Y.; Yura, H.; Akaike, T.; Ozeki, Y.; Tanaka, S.; Mochizuki, H.; et al. Enhanced ability of heparin-carrying polystyrene (HCPS) to bind to heparin-binding growth factors and to inhibit growth factor-induced endothelial cell growth. J. Biochem. 2000, 127, 797–803. [Google Scholar] [CrossRef]

- Hewitt, C.J.; Bellara, S.R.; Andreani, A.; Nebe-Von-Caron, G.; Mcfarlane, C.M. An evaluation of the anti-bacterial action of ceramic powder slurries using multi-parameter flow cytometry. Biotechnol. Lett. 2001, 23, 667–675. [Google Scholar] [CrossRef]

- Krishnamoorthy, K.; Manivannan, G.; Kim, S.J.; Jeya-Subramanian, K.; Premanathan, M. Antibacterial activity of MgO Nanoparticles Based on Lipid Peroxidation by Oxygen Vacancy. J. Nanopart. Res. 2012, 14, 1–10. [Google Scholar] [CrossRef]

- Berger, T.; Sterrer, M.; Stankic, S.; Bernardi, J.; Diwald, O.; Knozinger, E. Trapping of photogenerated charges in oxide nanoparticles. Mater. Sci. Eng. C 2005, 25, 664–668. [Google Scholar] [CrossRef]

- Sterrer, M.; Diwald, O.; Knozinger, E. Vacancies and electron deficient surface anions on the Surface of MgO Nanoparticles. J. Phys. Chem. B 2000, 104, 3601–3607. [Google Scholar] [CrossRef]

| BiSCaO | pH (Conc. of PP and TP) | 12.2 (0.05 %) | 12.2 (0.1 %) | 12.2 (0.15 %) | 12.2 (0.2 %) | 12.2 (0.25 %) | 12.2 (0.30 %) |

| Flocculants (vol.%) | 10 | 15 | 15 | 15 | 15 | 20 | |

| Appearance | Dispersion with flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | |

| BiSCa (OH)2 | pH (Conc. Of PP and TP) | 12.23 (0.05 %) | 12.22 (0.1 %) | 12.21 (0.15 %) | 12.2 (0.2 %) | 12.2 (0.25 %) | 12.2 (0.30 %) |

| Flocculants (vol.%) | 10 | 15 | 15 | 15 | 20 | 25 | |

| Appearance | Dispersion with flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates |

| BiSCaO | pH | 12.65 | 12.2 | 11.8 | 10.0 | 7.7 | 4.7 |

| Flocculants (vol.%) | 7 | 15 | 15 | 10 | 10 | 0 | |

| Appearance | Dispersion with flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Soluble | |

| Zeta potential (mV) | +5.1 ± 1.9 | +14.7 ± 1.6 | +11.2 ± 1.8 | −1.4 ± 0.2 | −5.6 ± 0.8 | Not measured | |

| BiSCa (OH)2 | pH | 12.23 | 11.5 | 10.6 | 9.6 | 7.2 | 5.6 |

| Flocculants (vol.%) | 15 | 15 | 15 | 10 | 10 | 0 | |

| Appearance | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Easy dispersible flocculants/ precipitates | Dissolution | |

| Zeta potential (mV) | +16.2 ± 2.0 | +10.8 ± 1.9 | −2.1 ± 0.6 | −4.3 ± 0.5 | −4.5 ± 0.6 | Not measured |

| BiSCaO | pH (Conc. of PP and TP) | 12.23 (0.05%) | 12.23 (0.1%) | 12.22 (0.15%) | 12.22 (0.2%) | 12.21 (0.25%) | 12.2 (0.30%) |

| OD650 (PP) | 0.25 ± 0.03 | 0.10 ± 0.02 | 0.03 ± 0.01 | 0.14 ± 0.02 | 0.22 ± 0.05 | 0.44 ± 0.11 | |

| OD650 (TP) | 0.2 ± 0.03 | 0.09 ± 0.02 | 0.05 ± 0.02 | 0.12 ± 0.03 | 0.2 ± 0.03 | 0.42 ± 0.10 | |

| BiSCaO with 0.15 wt.% PP and TP | pH | 12.65 | 12.2 | 11.8 | 10.0 | 7.7 | 4.7 |

| OD650 (PP) | 0.66 ± 0.22 | 0.03 ± 0.01 | 0.05 ± 0.02 | 0.38 ± 0.08 | 0.65 ± 0.11 | 0.92 ± 0.21 | |

| OD650 (TP) | 0.65 ± 0.18 | 0.11 ± 0.02 | 0.12 ± 0.02 | 0.60 ± 0.11 | 0.78 ± 0.16 | 1.19 ± 0.18 | |

| BiSCa(OH)2 | pH (Conc. of PP and TP) | 12.2 (0.05%) | 12.23 (0.1%) | 12.22 (0.15%) | 12.22 (0.2%) | 12.21 (0.25%) | 12.2 (0.30%) |

| OD650 (PP) | 0.28 ± 0.03 | 0.16 ± 0.02 | 0.15 ± 0.02 | 0.18 ± 0.02 | 0.22 ± 0.05 | 1.24 ± 0.21 | |

| OD650 (TP) | 0.3 ± 0.06 | 0.19 ± 0.04 | 0.17 ± 0.04 | 0.18 ± 0.03 | 0.33 ± 0.06 | 1.29 ± 0.2 | |

| BiSCa(OH)2 with 0.15 wt.% PP and TP | pH | 12.2 | 11.5 | 10.6 | 9.6 | 7.2 | 5.6 |

| OD650 (PP) | 0.15 ± 0.02 | 0.2 ± 0.05 | 0.43 ± 0.07 | 0.77 ± 0.14 | 0.79 ± 0.16 | 1.42 ± 0.33 | |

| OD650 (TP) | 0.2 ± 0.04 | 0.23 ± 0.06 | 0.47 ± 0.08 | 0.84 ± 0.2 | 0.88 ± 0.22 | 1.59 ± 0.38 |

| BiSCaO | pH (Conc. of PP and TP) | 12.2 (0.05%) | 12.19 (0.1%) | 12.2 (0.15%) | 12.19 (0.2%) | 12.2 (0.25%) | 12.2 (0.30%) |

| OD562 (PP) | 0.45 ± 0.12 | 0.22 ± 0.06 | 0.11 ± 0.01 | 0.18 ± 0.02 | 0.32 ± 0.08 | 0.74 ± 0.16 | |

| OD562 (TP) | 0.52 ± 0.14 | 0.29 ± 0.02 | 0.22 ± 0.04 | 0.24 ± 0.05 | 0.43 ± 0.12 | 0.84 ± 0.20 | |

| BiSCaO with 0.15 wt.% PP and TP | pH | 12.65 | 12.2 | 11.8 | 10.0 | 7.7 | 4.7 |

| OD562 (PP) | 0.73 ± 0.21 | 0.11 ± 0.01 | 0.14 ± 0.02 | 0.36 ± 0.08 | 0.75 ± 0.11 | 0.96 ± 0.21 | |

| OD562 (TP) | 0.75 ± 0.22 | 0.22 ± 0.04 | 0.18 ± 0.03 | 0.51 ± 0.11 | 0.88 ± 0.16 | 1.19 ± 0.18 | |

| BiSCa(OH)2 | pH (Conc. of PP and TP) | 12.2 (0.05%) | 12.21 (0.1%) | 12.21 (0.15%) | 12.19 (0.2%) | 12.21 (0.25%) | 12.2 (0.30%) |

| OD562 (PP) | 0.51 ± 0.11 | 0.36 ± 0.08 | 0.21 ± 0.04 | 0.42 ± 0.15 | 0.64 ± 0.19 | 1.12 ± 0.21 | |

| OD562 (TP) | 0.63 ± 0.16 | 0.48 ± 0.09 | 0.33 ± 0.06 | 0.48 ± 0.16 | 0.73 ± 0.21 | 1.29 ± 0.31 | |

| BiSCa(OH)2 with 0.15 wt.% PP and TP | pH | 12.21 | 11.2 | 10.4 | 9.6 | 7.2 | 4.6 |

| OD562 (PP) | 0.21 ± 0.04 | 0.27 ± 0.07 | 0.48 ± 0.08 | 0.67 ± 0.18 | 0.87 ± 0.19 | 1.34 ± 0.36 | |

| OD562 (TP) | 0.33 ± 0.06 | 0.38 ± 0.09 | 0.51 ± 0.11 | 0.64 ± 0.21 | 0.92 ± 0.22 | 1.43 ± 0.39 |

| Chondroitin sulfate | BiSCaO (PP; 0.15 wt.%) | pH | 12.63 | 12.1 | 11.5 | 10.2 | 7.8 | 5.6 |

| OD656 (PP) | 0.71 ± 0.25 | 0.17 ± 0.04 | 0.32 ± 0.12 | 0.66 ± 0.19 | 0.89 ± 0.21 | 1.44 ± 0.31 | ||

| BiSCa(OH)2 (PP; 0.15 wt.%) | pH | 12.2 | 11.4 | 10.5 | 9.8 | 7.5 | 5.5 | |

| OD656 (PP) | 0.23 ± 0.07 | 0.44 ± 0.11 | 0.63 ± 0.12 | 0.77 ± 0.21 | 0.95 ± 0.27 | 1.42 ± 0.33 | ||

| Heparin | BiSCaO (PP; 0.15 wt.%) | pH | 12.64 | 12.2 | 11.7 | 10.1 | 7.6 | 5.7 |

| OD656 (PP) | 0.77 ± 0.22 | 0.42 ± 0.12 | 0.58 ± 0.14 | 0.91 ± 0.26 | 0.13 ± 0.31 | 1.52 ± 0.33 | ||

| BiSCa(OH)2 (PP; 0.15 wt.%) | pH | 12.2 | 11.6 | 10.6 | 9.5 | 7.3 | 5.6 | |

| OD656 (PP) | 0.56 ± 0.18 | 0.72 ± 0.25 | 1.14 ± 0.27 | 1.27 ± 0.31 | 1.45 ± 0.41 | 1.55 ± 0.36 | ||

| NAC-HCPS | BiSCaO (PP; 0.15 wt.%) | pH | 12.65 | 12.2 | 11.5 | 10.0 | 7.8 | 5.7 |

| OD656 (PP) | 0.65 ± 0.2 | 0.03 ± 0.01 | 0.16 ± 0.04 | 0.42 ± 0.08 | 0.76 ± 0.17 | 1.22 ± 0.32 | ||

| BiSCa(OH)2 (PP; 0.15 wt.%) | pH | 12.2 | 11.6 | 10.4 | 9.9 | 7.3 | 5.3 | |

| OD656 (PP) | 0.26 ± 0.07 | 0.35 ± 0.12 | 0.57 ± 0.18 | 0.72 ± 0.24 | 0.88 ± 0.16 | 1.45 ± 0.32 | ||

| LMWH/P NPs | BiSCaO (PP; 0.15 wt.%) | pH | 12.65 | 12.2 | 11.5 | 10.0 | 7.8 | 5.7 |

| OD656 (PP) | 0.43 ± 0.1 | 0.04 ± 0.01 | 0.18 ± 0.0.4 | 0.46 ± 0.09 | 0.79 ± 0.24 | 1.28 ± 0.33 | ||

| BiSCa(OH)2 (PP; 0.15 wt.%) | pH | 12.2 | 11.6 | 10.4 | 9.9 | 7.3 | 5.3 | |

| OD656 (PP) | 0.23 ± 0.07 | 0.43 ± 0.14 | 0.82 ± 0.29 | 0.97 ± 0.28 | 1.29 ± 0.36 | 1.49 ± 0.33 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sato, Y.; Ohata, H.; Inoue, A.; Ishihara, M.; Nakamura, S.; Fukuda, K.; Takayama, T.; Murakami, K.; Hiruma, S.; Yokoe, H. Application of Colloidal Dispersions of Bioshell Calcium Oxide (BiSCaO) for Disinfection. Polymers 2019, 11, 1991. https://doi.org/10.3390/polym11121991

Sato Y, Ohata H, Inoue A, Ishihara M, Nakamura S, Fukuda K, Takayama T, Murakami K, Hiruma S, Yokoe H. Application of Colloidal Dispersions of Bioshell Calcium Oxide (BiSCaO) for Disinfection. Polymers. 2019; 11(12):1991. https://doi.org/10.3390/polym11121991

Chicago/Turabian StyleSato, Yoko, Heisuke Ohata, Akinori Inoue, Masayuki Ishihara, Shingo Nakamura, Koichi Fukuda, Tomohiro Takayama, Kaoru Murakami, Sumiyo Hiruma, and Hidetaka Yokoe. 2019. "Application of Colloidal Dispersions of Bioshell Calcium Oxide (BiSCaO) for Disinfection" Polymers 11, no. 12: 1991. https://doi.org/10.3390/polym11121991

APA StyleSato, Y., Ohata, H., Inoue, A., Ishihara, M., Nakamura, S., Fukuda, K., Takayama, T., Murakami, K., Hiruma, S., & Yokoe, H. (2019). Application of Colloidal Dispersions of Bioshell Calcium Oxide (BiSCaO) for Disinfection. Polymers, 11(12), 1991. https://doi.org/10.3390/polym11121991