Online Rheometry Investigation of Flow/Slip Behavior of Powder Injection Molding Feedstocks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of In-House Feedstocks

2.3. Rheological Investigation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- German, R.M.; Bose, A. Injection Molding of Metals and Ceramics, 1st ed.; Metal Powder Industry Federation: Princeton, NJ, USA, 1997. [Google Scholar]

- German, R.M. Powder Metallurgy and Particulate Materials Processing, 1st ed.; Metal Powder Industry Federation: Princeton, NJ, USA, 2005. [Google Scholar]

- Thavanayagam, G.; Pickering, K.L.; Swan, J.E.; Cao, P. Analysis of rheological behaviour of titanium feedstocks formulated with a water-soluble binder system for powder injection molding. Powder Technol. 2014, 269, 227–232. [Google Scholar] [CrossRef]

- Zauner, R.; Binet, C.; Heaney, D.F.; Piemme, J. Variability of feedstock viscosity and its correlation with dimensional variability of green powder injection moulded components. Powder Metall. 2004, 47, 151–156. [Google Scholar] [CrossRef]

- He, H.; Li, Y.; Lou, J.; Li, D.; Liu, C. Prediction of density variation in powder injection moulding-filling process by using granular modelling with interstitial power-law fluid. Powder Technol. 2016, 291, 52–59. [Google Scholar] [CrossRef]

- Denn, M.M. Extrusion instabilities and wall slip. Annu. Rev. Fluid. Mech. 2001, 33, 265–287. [Google Scholar] [CrossRef]

- Delime, A.; Moan, M. Lateral migrations of solid spheres in tube flow. Rheol. Acta 1991, 30, 131–139. [Google Scholar] [CrossRef]

- Barnes, H.A. A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: Its cause, character, and cure. J. Non-Newton. Fluid 1995, 56, 221–251. [Google Scholar] [CrossRef]

- Bryan, M.P.; Rough, S.L.; Wilson, D.I. Investigation of static zone and wall slip through sequential ram extrusion of contrasting micro-crystalline cellulose-based pastes. J. Non-Newton. Fluid 2015, 220, 57–68. [Google Scholar] [CrossRef]

- Kalyon, M.; Aktas, S. Factors Affecting the Rheology and Processability of Highly Filled Suspensions. Annu. Rev. Chem. Biomol. 2014, 5, 229–254. [Google Scholar] [CrossRef] [PubMed]

- Soltani, F.; Yilmazer, U. Slip velocity and slip layer thickness in flow of concentrated suspensions. J. Appl. Polym. Sci. 1998, 70, 515–522. [Google Scholar] [CrossRef]

- Lam, Y.C.; Wang, Z.Y.; Chen, X.; Joshi, S.C. Wall slip of concentrated suspension melts in capillary flows. Powder Technol. 2007, 77, 162–169. [Google Scholar] [CrossRef]

- Thornagel, M. MIM-Simulation: A virtual study on phase separation. Proc. EURO PM 2009 2009, 2, 135–140. [Google Scholar]

- Hausnerova, B.; Marcanikova, L.; Filip, P.; Saha, P. Wall-slip velocity as a quantitative measure of powder-binder separation during powder injection moulding. In Proceedings of the World Powder Metallurgy Congress and Exhibition, World PM 2010, Florence, Italy, 10–14 October 2010; pp. 557–562. [Google Scholar]

- Hausnerova, B.; Sanetrnik, D.; Ponizil, P. Surface structure analysis of injection molded highly filled polymer melts. Polym. Comp. 2013, 34, 1553–1558. [Google Scholar] [CrossRef]

- Gulmus, S.A.; Yilmazer, U. Effect of volume fraction and particle size on wall slip in flow of polymeric suspension. J. Appl. Polym. Sci. 2005, 98, 439–448. [Google Scholar] [CrossRef]

- Chen, Y.; Kalyon, D.M.; Bayramli, E. Effects of surface roughness and the chemical structure of materials of construction on wall slip behavior of linear low density polyethylene in capillary flow. J. Appl. Polym. Sci. 1993, 50, 1169–1177. [Google Scholar] [CrossRef]

- Aral, B.K.; Kalyon, D.M. Effects of temperature and surface roughness on time-dependent development of wall slip in steady torsional flow of concentrated suspension. J. Rheol. 1994, 38, 957–972. [Google Scholar] [CrossRef]

- Gulmus, S.A.; Yilmazer, U. Effect of the surface roughness and construction material on wall slip in the flow of concentrated suspensions. J. Appl. Polym. Sci. 2006, 103, 3341–3347. [Google Scholar] [CrossRef]

- Medhi, B.J.; Kumar, A.A.; Singh, A. Apparent wall slip velocity measurement in free surface flow of concentrated suspensions. Int. J. Multiph. Flow 2011, 37, 609–619. [Google Scholar] [CrossRef]

- Kalyon, D.M. Apparent slip and viscoplasticity of concentrated suspensions. J. Rheol. 2005, 49, 621–640. [Google Scholar] [CrossRef]

- Sanetrnik, D.; Hausnerova, B.; Filip, P.; Hnatkova, E. Influence of capillary die geometry on wall slip of highly filled powder injection molding compounds. Powder Technol. 2018, 325, 615–619. [Google Scholar] [CrossRef]

- Walter, B.L.; Pelteret, J.P.; Kaschta, J.; Schubert, D.W.; Steinmann, P. On the wall slip phenomenon of elastomers in oscillatory shear measurement using parallel-plate rotational rheometry: II. Influence of experimental conditions. Polym. Test. 2017, 61, 455–463. [Google Scholar] [CrossRef]

- Kwon, T.H.; Ahn, S.Y. Slip characterization of powder/binder mixtures and its significance in the filling process analysis of powder injection molding. Powder Technol. 1995, 85, 45–55. [Google Scholar] [CrossRef]

- Liu, L.; Ma, Y.H.; He, Z.Y. Rheological behavior of zirconia feedstock flowing through various channels considering wall-slip. Ceram. Int. 2018, 44, 22387–22392. [Google Scholar] [CrossRef]

- Liu, L.; Gao, Y.Y.; Qi, X.T.; Qi, M.X. Effect of wall slip on ZrO2 rheological behavior in micro powder injection molding. Ceram. Int. 2018, 44, 16282–16294. [Google Scholar] [CrossRef]

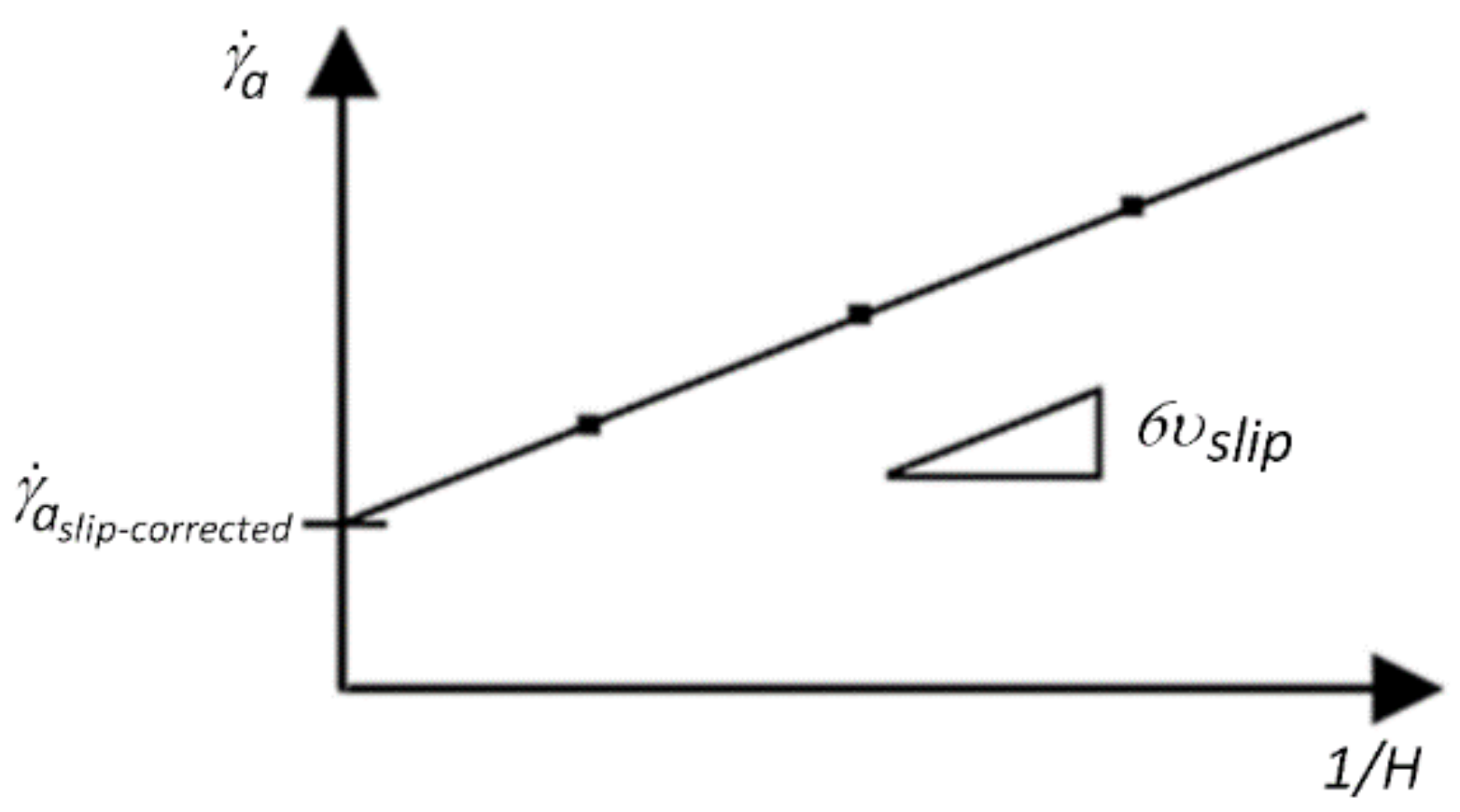

- Mooney, M. Explicit formulas for slip and fluidity. J. Rheol. 1931, 2, 210–222. [Google Scholar] [CrossRef]

- Kalyon, D.; Gevgilili, H.; Kowalczyk, J.E.; Prickett, S.; Murphy, C. Use of adjustable-gap on-line and off-line slit rheometers for the characterization of the wall slip and shear viscosity behavior of energetic formulations. J. Energ. Mater. 2006, 24, 175–193. [Google Scholar] [CrossRef]

- Papanikolaou, M.; Frank, M.; Drikakis, D. Effects of surface roughness on shear viscosity. Phys. Rev. E 2017, 95. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jeong, M.; Kim, Y.; Zhou, W.; Tao, W.Q.; Ha, M.Y. Effects of surface wettability, roughness and moving wall velocity on the Couette flow in nano-channel using multi-scale hybrid method. Comput. Fluids 2017, 147, 1–11. [Google Scholar] [CrossRef]

- Hausnerova, B.; Bleyan, D.; Kasparkova, V.; Pata, V. Surface adhesion between ceramic injection molding feedstocks and processing tools. Ceram. Int. 2016, 2016 42, 460–465. [Google Scholar] [CrossRef]

| Abbreviation of Feedstock | Type of Powder | Type of Binder | Commercial Name | Producer |

|---|---|---|---|---|

| P316L | Stainless steel 316L | Partly water soluble (PEG based) | PolyMIM 316L D 110 E | PolyMIM GmbH |

| P17-4PH | Stainless steel 17-4PH | Partly water soluble (PEG based) | PolyMIM 17-4PH D 110 E | PolyMIM GmbH |

| C316L | Stainless steel 316L | Catalytic (Poly-acetal based) | Catamold 316 L G | BASF |

| C17-4PH | Stainless steel 17-4PH | Catalytic (Poly-acetal based) | Catamold 17-4PH G | BASF |

| ZrO2 | Ceramic ZrO2 | LDPE 1 + EVA 2 + PW 3 | in-house | see bellow |

| Al2O3 | Ceramic Al2O3 | LDPE 1 + EVA 2 + PW 3 | in-house | see bellow |

| Metal Powder Feedstocks | Ceramic Powder Feedstocks | ||||

|---|---|---|---|---|---|

| Geometry (mm) | Surface | Roughness Sa (µm) | Geometry (mm) | Surface | Roughness Sa (µm) |

| 10 × 0.5 × 100 | smooth | 0.25 ± 0.03 | 10 × 1 × 100 | smooth | 0.81 ± 0.03 |

| roughened | 0.95 ± 0.02 | roughened | 9.65 ± 0.18 | ||

| 15 × 1 × 100 | smooth | 0.07 ± 0.00 | 10 × 2 × 100 | smooth | 0.82 ± 0.04 |

| roughened | 0.77 ± 0.03 | roughened | 7.87 ± 0.70 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sanetrnik, D.; Hausnerova, B.; Pata, V. Online Rheometry Investigation of Flow/Slip Behavior of Powder Injection Molding Feedstocks. Polymers 2019, 11, 432. https://doi.org/10.3390/polym11030432

Sanetrnik D, Hausnerova B, Pata V. Online Rheometry Investigation of Flow/Slip Behavior of Powder Injection Molding Feedstocks. Polymers. 2019; 11(3):432. https://doi.org/10.3390/polym11030432

Chicago/Turabian StyleSanetrnik, Daniel, Berenika Hausnerova, and Vladimir Pata. 2019. "Online Rheometry Investigation of Flow/Slip Behavior of Powder Injection Molding Feedstocks" Polymers 11, no. 3: 432. https://doi.org/10.3390/polym11030432

APA StyleSanetrnik, D., Hausnerova, B., & Pata, V. (2019). Online Rheometry Investigation of Flow/Slip Behavior of Powder Injection Molding Feedstocks. Polymers, 11(3), 432. https://doi.org/10.3390/polym11030432