Different Dependence of Tear Strength on Film Orientation of LLDPE Made with Different Co-Monomer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Film Preparation

2.3. Differential Scanning Calorimetry (DSC)

2.4. Small Angle X-ray Scattering (SAXS)

2.5. Elmendorf Tear Strength

3. Results and Discussion

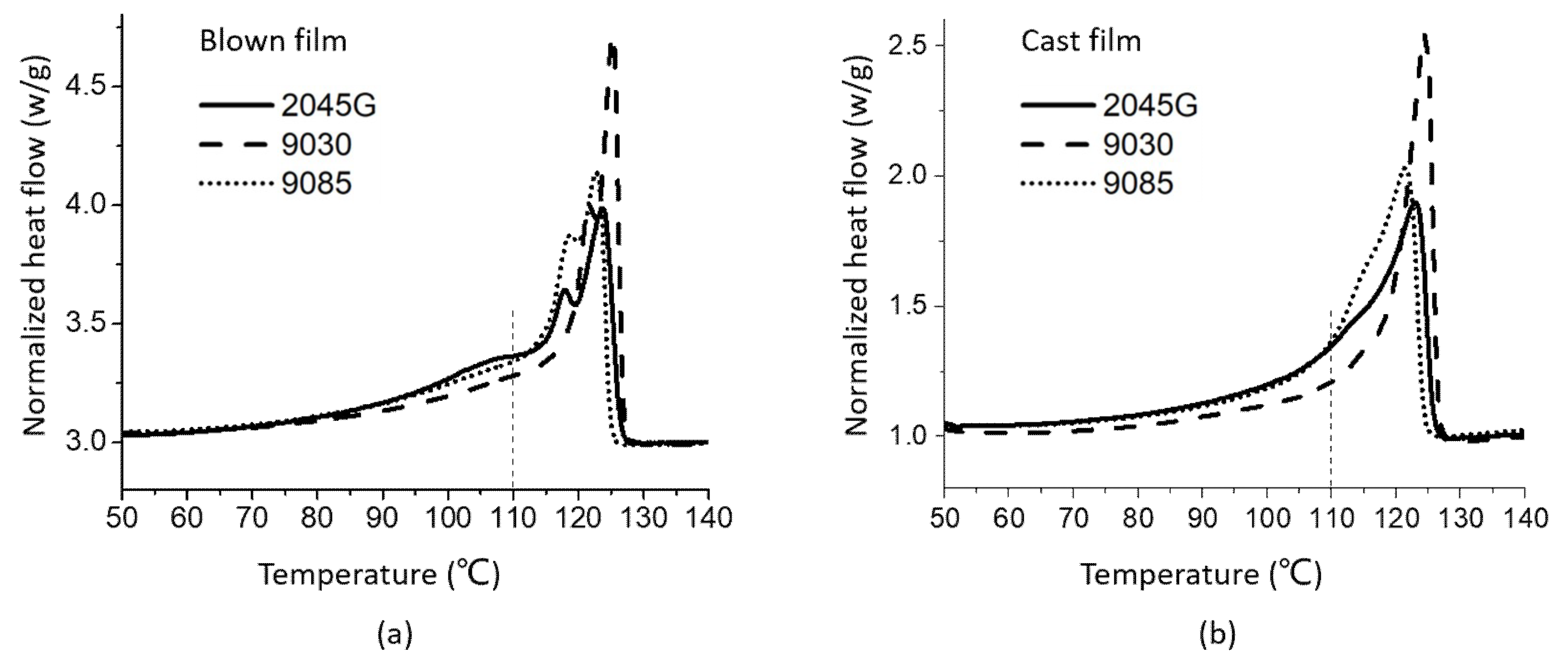

3.1. Non-Isothermal Crystallization of the LLDPE Resins and Thermal Property of the LLDPE Films Made of the Resins With Different Processes

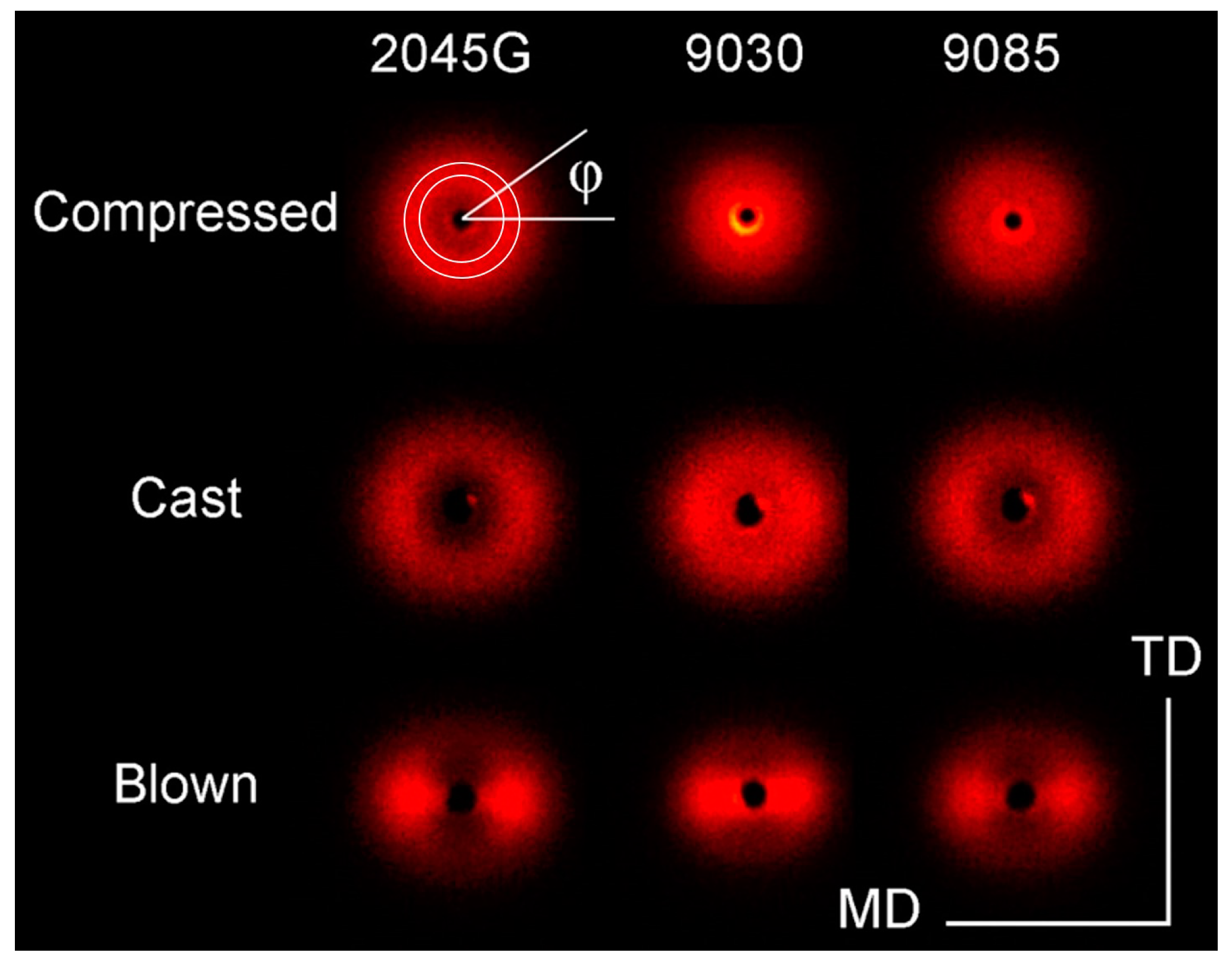

3.2. Structure and Orientation of LLDPE Films Made with Different Resins and Different Processes

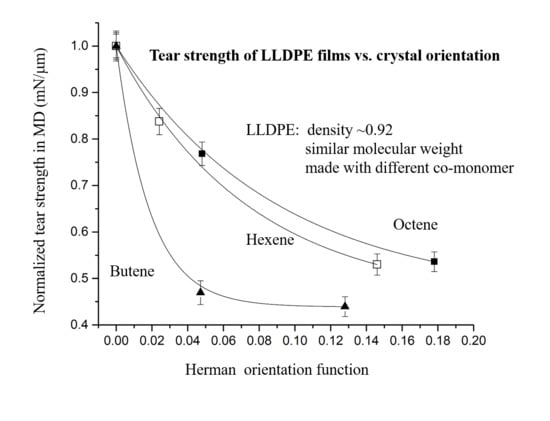

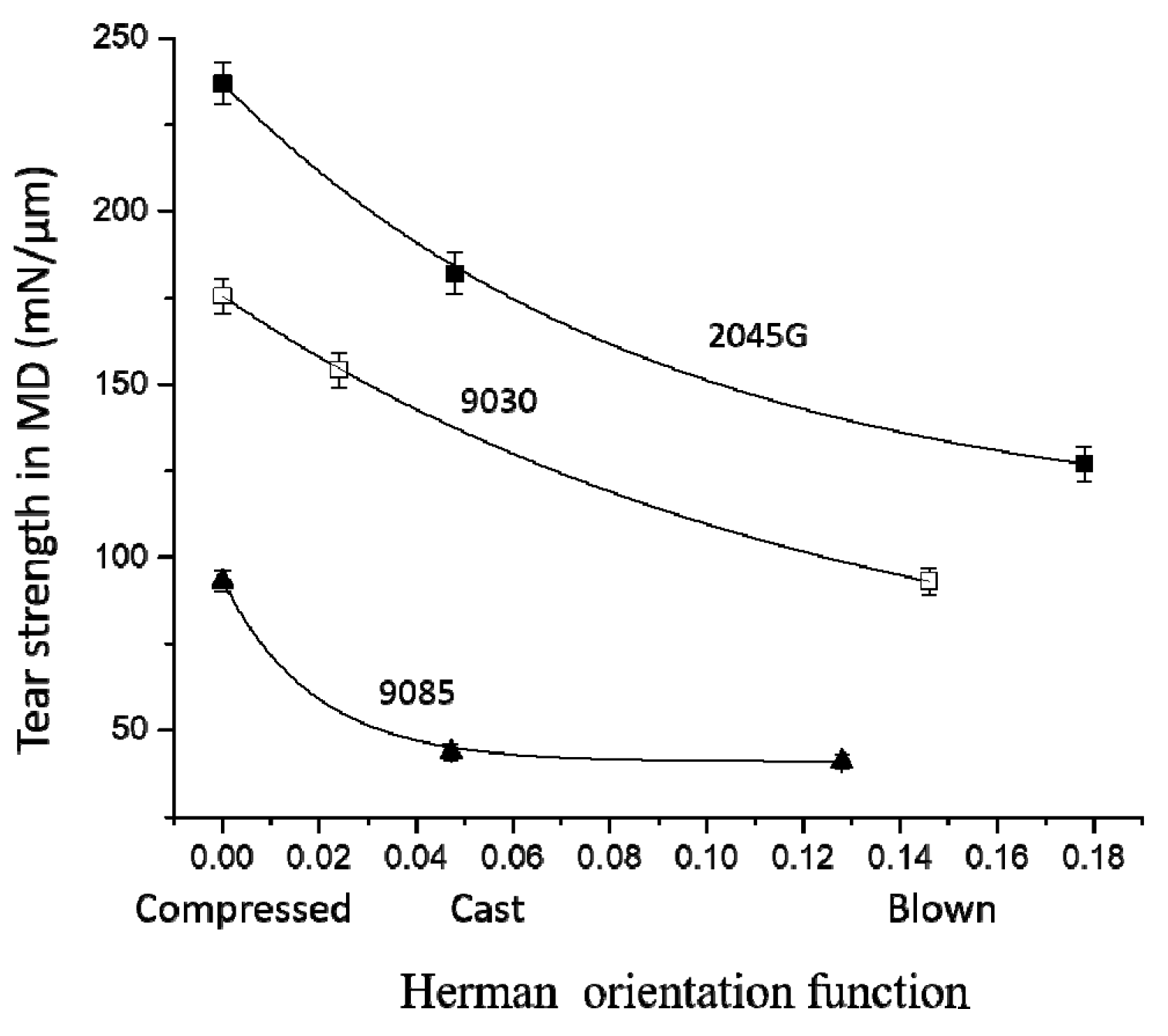

3.3. Intrinsic Tear Strength and MD Tear Strength for Oriented Films

3.4. MD Tear Strength Dependence on Crystal Orientation and Co-monomer Type of LLDPE

3.5. Shrinkage Property at High Temperature vs. Crystal Orientation and Melting Behavior

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Posch, W. Polyolefins. In Applied Plastics Engineering Handbook, 1st ed.; Kutz, M., Ed.; William Andrew: Norwich, NY, USA, 2011; pp. 23–48. ISBN 978-1-4377-3514-7. [Google Scholar]

- Starck, P. Dynamic mechanical thermal analysis on ziegler-natta and metallocene type ethylene copolymers. Eur. Polym. J. 1997, 33, 339–348. [Google Scholar] [CrossRef]

- Liu, T.M.; Baker, W.E. The effect of the length of the short chain branch on the impact properties of linear low density polyethylene. Polym. Eng. Sci. 1992, 32, 944–955. [Google Scholar] [CrossRef]

- Guichon, O.; Seguela, R.; David, L. Influence of the molecular architecture of low-density polyethylene on the texture and mechanical properties of blown films. Polym. Phys. 2003, 41, 327–340. [Google Scholar] [CrossRef]

- Gao, R.; He, X.; Shao, Y.; Zhang, H.; Liu, Z.; Liu, B. Effects of branch content and branch length on polyethylene crystallization: Molecular dynamics simulation. Macromol. Theory Simul. 2016, 25, 303–311. [Google Scholar] [CrossRef]

- Gupta, P.; Wilkes, G.L.; Sukhadia, A.M.; Krishnaswamy, R.K.; Wharry, S.M.; Tso, C.C.; Deslauriers, P.J.; Mansfield, T.; Beyer, F.L. Does the length of the short chain branch affect the mechanical properties of linear low density polyethylenes? An investigation based on films of copolymers of ethylene/1-butene, ethylene/1-hexene and ethylene/1-octene synthesized by a single site metallocene catalyst. Polymer 2005, 46, 8819–8837. [Google Scholar] [CrossRef]

- Campbell, G.A.; Kanai, T. Film Processing: Overview and Introductory Rheology. In Film Processing; Kanai, T., Campbell, G.A., Eds.; Hanser Publishers: Munich, Germany, 1999; pp. 2–6. ISBN 3-446-17882-1. [Google Scholar]

- Chen, H.Y.; Bishop, M.T.; Landes, B.G.; Chum, S.P. Orientation and property correlations for LLDPE blown films. J. Appl. Polym. Sci. 2006, 101, 898–907. [Google Scholar] [CrossRef]

- Zhang, X.M.; Elkoun, S.; Ajji, A.; Huneault, M.A. Oriented structure and anisotropy properties of polymer blown films: HDPE, LLDPE and LDPE. Polymer 2004, 45, 217–229. [Google Scholar] [CrossRef]

- Kim, Y.M.; Park, J.K. Effect of short chain branching on the blown film properties of linear low density polyethylene. J. Appl. Polym. Sci. 1996, 61, 2315–2324. [Google Scholar] [CrossRef]

- Du, W.J.; Ren, Y.; Tang, Y.J.; Yao, X.R.; Guo, M.F.; Zhang, S.J.; Liu, L.-Z. Structure and Tear Property Relationship of Linear Low Density Polyethylene Films. Acta Polym. Sinica 2016, 7, 895–902. [Google Scholar] [CrossRef]

- Du, W.J.; Ren, Y.; Tang, Y.J.; Shi, Y.; Yao, X.R.; Zheng, C.; Zhang, X.H.; Guo, M.F.; Zhang, S.J.; Liu, L.Z. Different structure transitions and tensile property of LLDPE film deformed at slow and very fast speeds. Eur. Polym. J. 2018, 103, 170–178. [Google Scholar] [CrossRef]

- Liu, L.-Z.; Chu, B.; Penning, J.P.; Manley, R.S.J. A Synchrotron SAXS Study of Miscible Blends of Semicrystalline Poly(vinylidene fluoride) and Semicrystalline Poly(1,4-butylene adipate). Macromolecules 1997, 30, 4398–4404. [Google Scholar] [CrossRef]

- Talibuddin, S.; Runt, J.; Liu, L.-Z.; Chu, B. Microstructure Development and Crystallization of Poly (ethylene oxide) and Melt-Miscible PEO Blends. Macromolecules 1998, 31, 1627–1634. [Google Scholar] [CrossRef]

- Roe, R.J. Methods of X-ray and Neutron Scattering in Polymer Science; Oxford Press: New York, NY, USA, 2000; pp. 123–132. ISBN 0-19-511321-7. [Google Scholar]

| Sample | Comonomer Type | Density (g/cm3) | MWD | MW | Comonomer Content (mol%) |

|---|---|---|---|---|---|

| 2045G | octene | 0.920 | 3.85 | 1.27 × 105 | 2.4 |

| 9030 | hexene | 0.919 | 4.74 | 1.10 × 105 | 3.8 |

| 9085 | butene | 0.920 | 4.21 | 1.33 × 105 | 3.9 |

| Sample Designation | Compressed | Cast | Blown |

|---|---|---|---|

| 2045G | 0 | 0.048 | 0.178 |

| 9030 | 0 | 0.024 | 0.146 |

| 9085 | 0 | 0.047 | 0.1328 |

| Sample Designation | Tear Strength (mN/μm) | Intrinsic Tear (mN/μm) | |||

|---|---|---|---|---|---|

| Blown | Cast | ||||

| MD | TD | MD | TD | ||

| 2045G | 127 | 411 | 182 | 198 | 237 |

| 9030 | 93 | 287 | 154 | 191 | 176 |

| 9085 | 41 | 219 | 44 | 105 | 93 |

| Sample | 2045G | 9030 | 9085 | |

|---|---|---|---|---|

| Comonomer type | Octene | Hexene | Butene | |

| Density (g/cm3) | 0.920 | 0.919 | 0.920 | |

| MW(×105) | 1.27 | 1.10 | 1.33 | |

| Long period (nm) | ||||

| Cast | 15.1 | 17.7 | 15.6 | |

| Blown | 13.6 | 14.9 | 13.9 | |

| Intrinsic tear (mN/μm) | 237 | 176 | 93 | |

| MD tear /intrinsic tear at the orientation of 0.05 | 77% | 75% | 47% | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, Y.; Shi, Y.; Yao, X.; Tang, Y.; Liu, L.-Z. Different Dependence of Tear Strength on Film Orientation of LLDPE Made with Different Co-Monomer. Polymers 2019, 11, 434. https://doi.org/10.3390/polym11030434

Ren Y, Shi Y, Yao X, Tang Y, Liu L-Z. Different Dependence of Tear Strength on Film Orientation of LLDPE Made with Different Co-Monomer. Polymers. 2019; 11(3):434. https://doi.org/10.3390/polym11030434

Chicago/Turabian StyleRen, Yi, Ying Shi, Xuerong Yao, Yujing Tang, and Li-Zhi Liu. 2019. "Different Dependence of Tear Strength on Film Orientation of LLDPE Made with Different Co-Monomer" Polymers 11, no. 3: 434. https://doi.org/10.3390/polym11030434

APA StyleRen, Y., Shi, Y., Yao, X., Tang, Y., & Liu, L.-Z. (2019). Different Dependence of Tear Strength on Film Orientation of LLDPE Made with Different Co-Monomer. Polymers, 11(3), 434. https://doi.org/10.3390/polym11030434