In Situ Surface Modification of Paper-Based Relics with Atmospheric Pressure Plasma Treatment for Preservation Purposes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

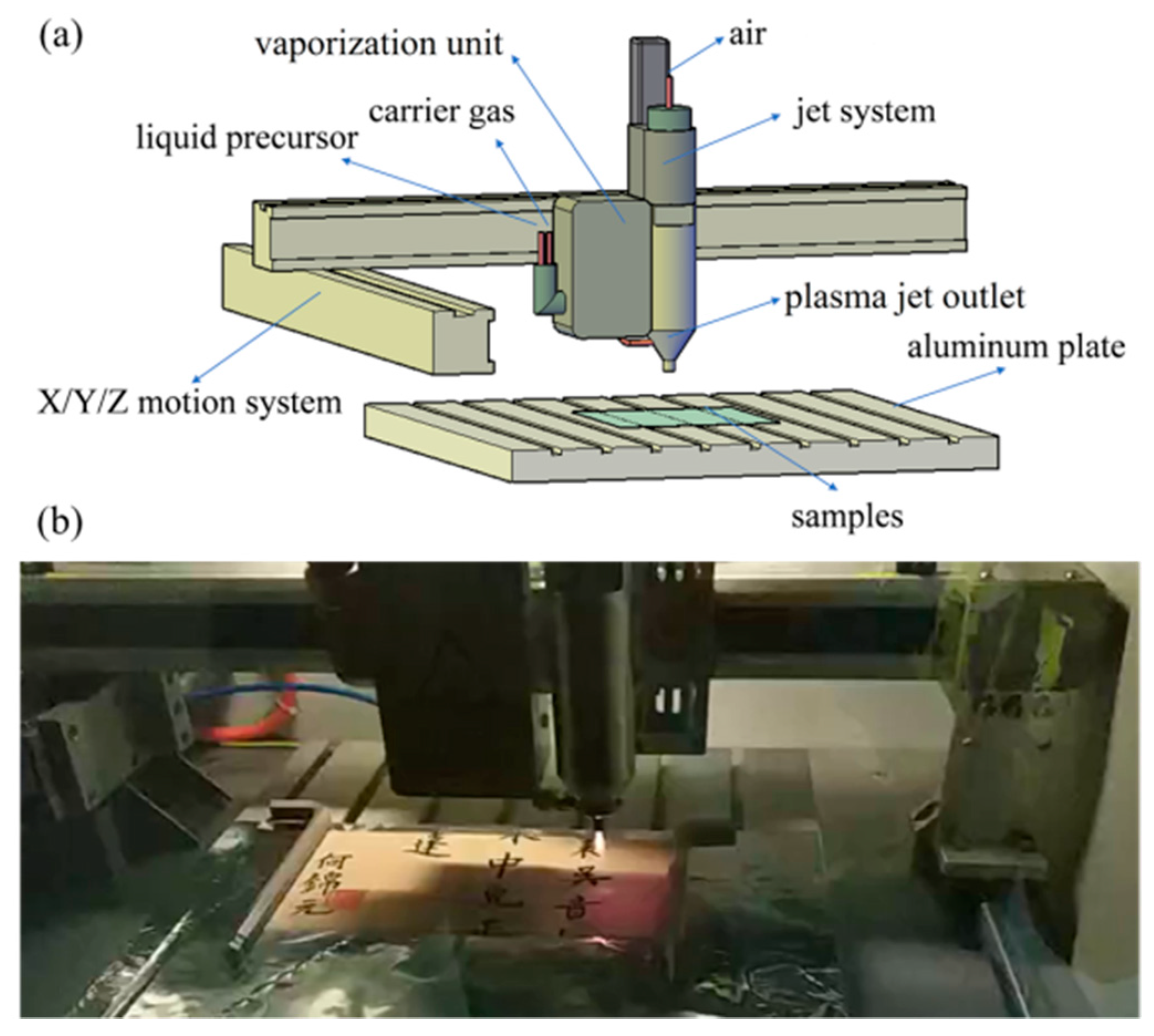

2.2. Plasma Polymerization

2.3. Characterization

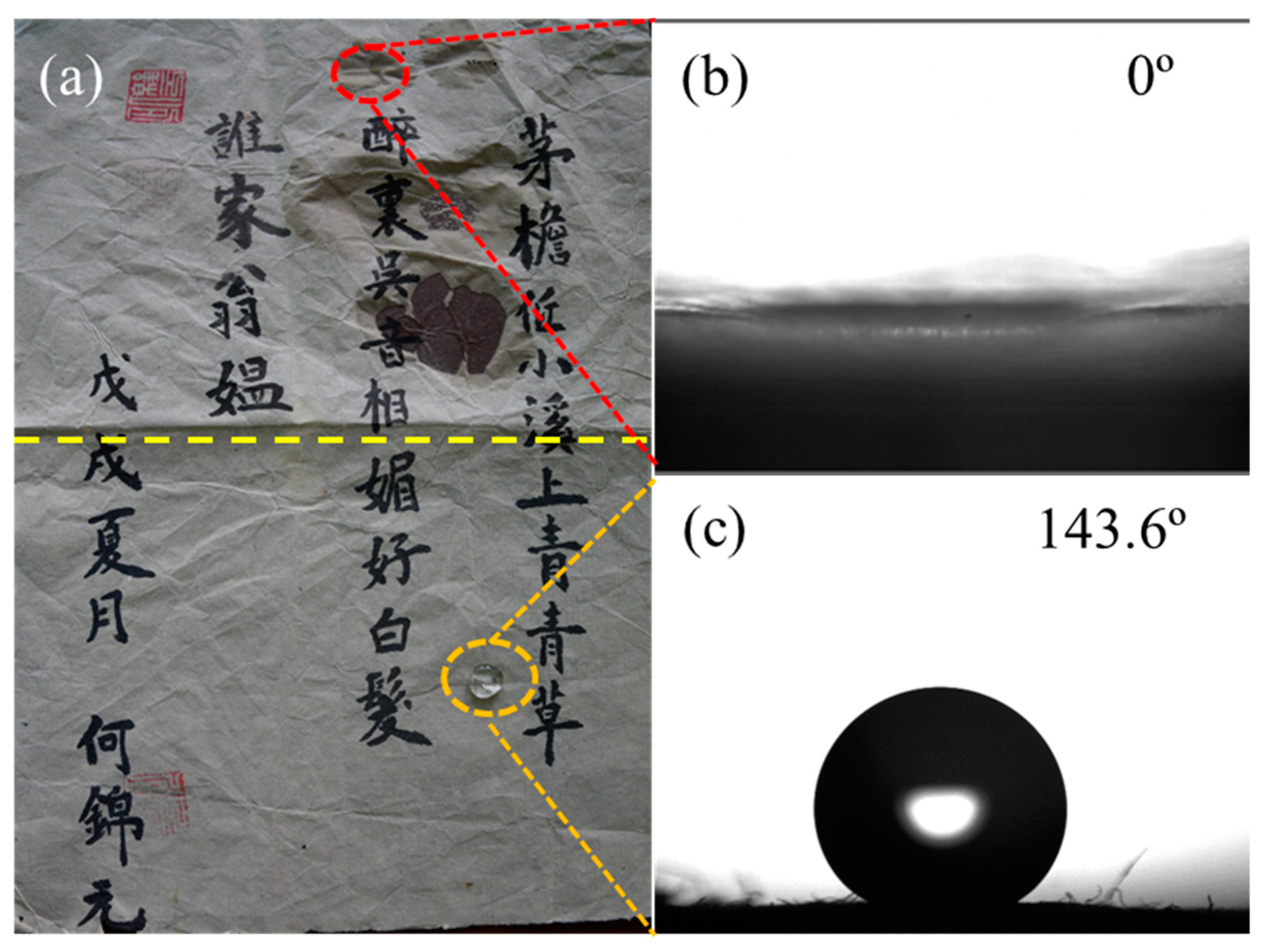

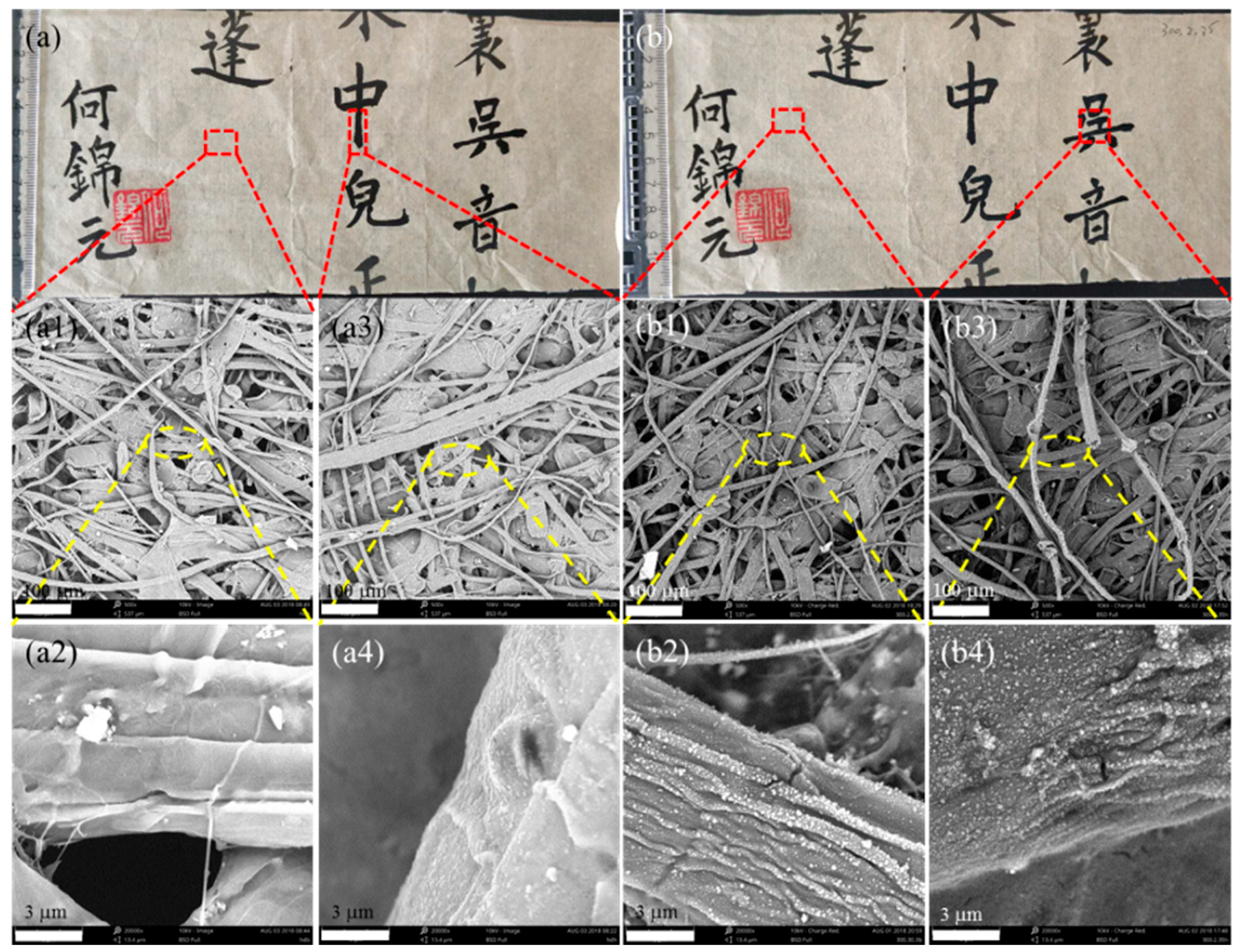

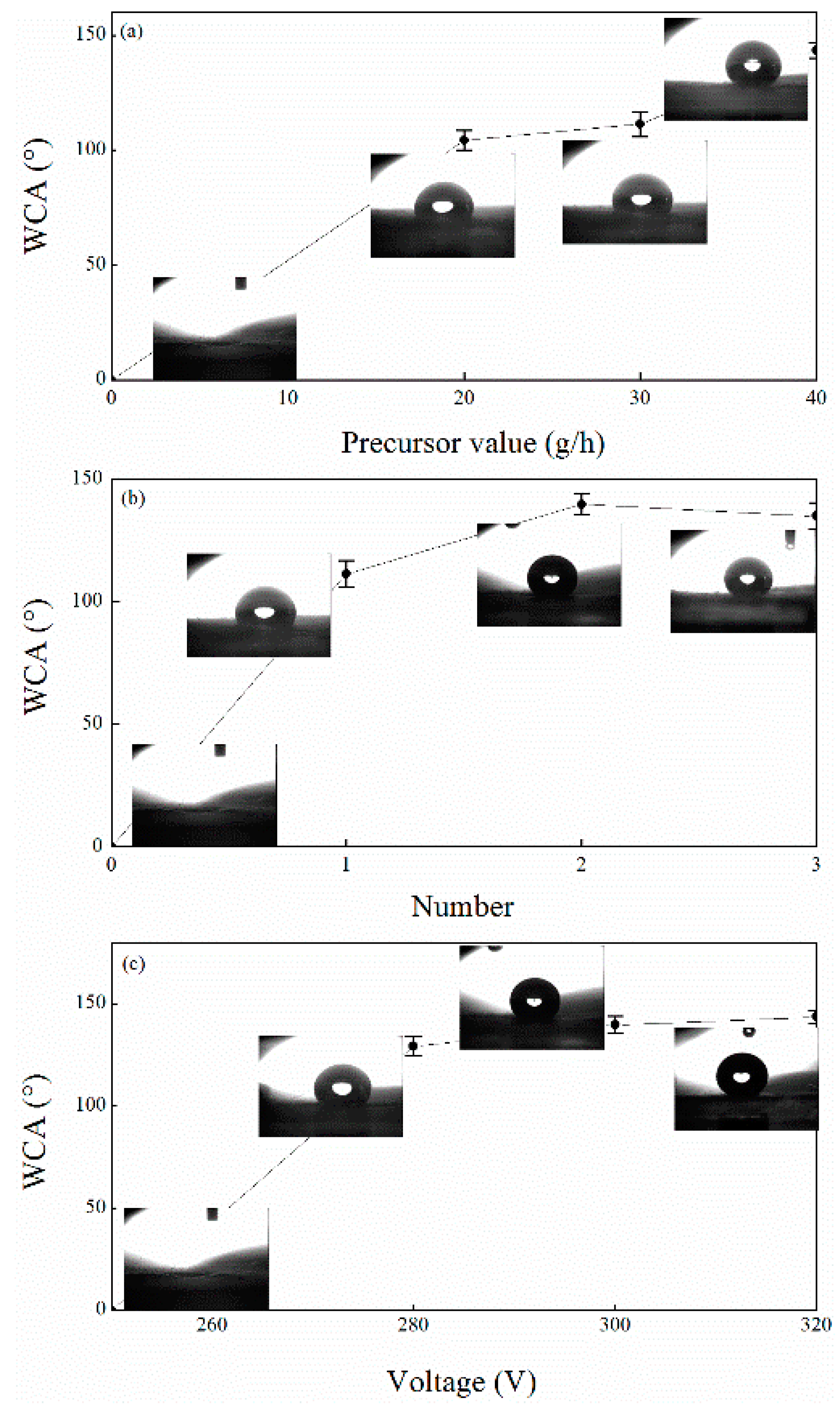

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Alexopoulou, I.; Zervos, S. Paper conservation methods: An international survey. J. Cult. Herit. 2016, 21, 922–930. [Google Scholar] [CrossRef]

- Zervos, S.; Alexopoulou, I. Paper conservation methods: A literature review. Cellulose 2015, 22, 2859–2897. [Google Scholar] [CrossRef]

- Chen, Q.; Wen, W.Y.; Qiu, F.X.; Xu, J.C.; Yu, H.Q.; Chen, M.L.; Yang, D.Y. Preparation and application of modified carboxymethyl cellulose Si/polyacrylate protective coating material for paper relics. Chem. Pap. 2016, 70, 946–959. [Google Scholar] [CrossRef]

- Liu, J.; Wang, J. Main factors affecting the preservation of Chinese paper documents: A review and recommendations. IFLA J. 2010, 36, 227–234. [Google Scholar]

- Daniels, V.D. The chemistry of paper conservation. Chem. Soc. Rev. 1996, 25, 179–186. [Google Scholar] [CrossRef]

- Carter, H.A. The chemistry of paper preservation: Part 1. the aging of paper and conservation techniques. J. Chem. Educ. 1996, 73, 417–420. [Google Scholar] [CrossRef]

- Carter, H.A. The chemistry of paper preservation: Part 2. The yellowing of paper and conservation bleaching. J. Chem. Educ. 1996, 73, 1068–1073. [Google Scholar] [CrossRef]

- Area, M.C.; Cheradame, H. Paper aging and degradation: Recent findings and research methods. BioResources 2011, 6, 5307–5337. [Google Scholar]

- Baty, J.W.; Maitland, C.L.; Minter, W.; Hubbe, M.; Jordan-Mowery, S.K. Deacidification for the conservationand preservation of paper-based works: A review. BioResources 2010, 5, 1955–2023. [Google Scholar]

- He, B.; Lin, Q.; Chang, M.; Liu, C.; Fan, H.; Ren, J. A new and highly efficient conservation treatment for deacidification and strengthening of aging paper by in-situ quaternization. Carbohydr. Polym. 2019, 209, 250–257. [Google Scholar] [CrossRef]

- Feng, W. Discussion on reason of ancient books’ moth-eaten and control measures. J. Libr. Inf. Sci. Agric. 2011, 5, 37. [Google Scholar]

- Princi, E.; Vicini, S.; Pedemonte, E.; Arrighi, V.; McEwen, I. New polymeric materialsfor paper and textile conservation. I. Synthesis and characterization of acryliccopolymers. J. Appl. Polym. Sci. 2005, 98, 1157–1164. [Google Scholar] [CrossRef]

- Princi, E.; Vicini, S.; Pedemonte, E.; Arrighi, V.; McEwen, I. New polymeric mate-rials for paper and textiles conservation. II. Grafting polymerization of ethylacrylate/methyl methacrylate copolymers onto linen and cotton. J. Appl. Polym. Sci. 2007, 103, 90–99. [Google Scholar] [CrossRef]

- Li, Q.; Xi, S.; Zhang, X. Conservation of paper relics by electrospun PVDF fiber membranes. J. Cult. Herit. 2014, 15, 359–364. [Google Scholar] [CrossRef]

- Robotti, E.; Bobba, M.; Panepinto, A.; Marengo, E. Monitoring of the surface of paper samples exposed to UV light by ATR-FT-IR spectroscopy and use of multivariatecontrol charts. Anal. Bioanal. Chem. 2007, 388, 1249–1263. [Google Scholar] [CrossRef]

- Liu, M.N.; Yan, X.; You, M.H.; Fu, J.; Nie, G.D.; Yu, M.; Ning, X.; Wan, Y.; Long, Y.Z. Reversible photochromic nanofibrous membranes with excellent water/windproof and breathable performance. J. Appl. Polym. Sci. 2018, 135, 46342. [Google Scholar] [CrossRef]

- Liu, G.S.; Yan, X.; Yan, F.F.; Chen, F.X.; Hao, L.Y.; Chen, S.J.; Lou, T.; Ning, X.; Long, Y.Z. In Situ electrospinning iodine-based fibrous meshes for antibacterial wound dressing. Nanoscale Res. Lett. 2018, 13, 309. [Google Scholar] [CrossRef]

- Cai, M.; He, H.; Zhang, X.; Yan, X.; Li, J.; Chen, F.; Yuan, D.; Ning, X. Efficient synthesis of PVDF/PI side-by-side bicomponent nanofiber membrane with enhanced mechanical strength and good thermal stability. Nanomaterials 2019, 9, 39. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.; Ju, D.D.; Li, X.; Zhang, J.C.; Yan, X.; Long, Y.Z.; Song, F. Flexible inorganic core-shell nanofibers endowed with tunable multicolor up conversion fluorescence for simultaneous monitoring dual drug delivery. Chem. Eng. J. 2018, 349, 554–561. [Google Scholar] [CrossRef]

- Chen, S.; Liu, G.S.; He, H.W.; Zhou, C.F.; Yan, X.; Zhang, J.C. Physical structure induced hydrophobicity analysed from electrospinning and coating Poly(vinyl butyral) (PVB) films. Adv. Condens. Matter Phys. 2019, 2019, 6179456. [Google Scholar] [CrossRef]

- Vohrer, U.; Tricka, I.; Bernhardt, J.; Oehr, C.; Brunner, H. Plasma treatment: An increasing technology for paper restoration? Surf. Coat. Technol. 2001, 142, 1069–1073. [Google Scholar] [CrossRef]

- Yuan, X.; Jayaraman, K.; Bhattacharyya, D. Effects of plasma treatment in enhancing the performance of woodfibre-polypropylene composites. Compos. Part A 2004, 35, 1363–1374. [Google Scholar] [CrossRef]

- Totolin, M.I.; Neamtu, I. Positive findings for plasma polymer (meth) acrylate thin films in heritage protective applications. J. Cult. Herit. 2011, 12, 392–398. [Google Scholar] [CrossRef]

- Yang, J.; Pu, Y.; Miao, D.; Ning, X. Fabrication of durably superhydrophobic cotton fabrics by atmospheric pressure plasma treatment with a siloxane precursor. Polymers 2018, 10, 460. [Google Scholar] [CrossRef]

- Ioanid, E.G.; Rusu, D.; Dunca, S. High-frequency plasma in heritage photo decontamination. Ann. Microbiol. 2010, 60, 355–361. [Google Scholar] [CrossRef]

- Li, Q.; Xi, S.; Zhang, X. Deacidification of paper relics by plasma technology. J. Cult. Herit. 2014, 15, 159–164. [Google Scholar] [CrossRef]

- Dong, Y.; Li, C.; Wang, Y.; Zhou, T. Anti-ultraviolet finish of cotton fabric by air low-temperature plasma. Prog. Text. Sci. Tech. 2007, 6, 20–22. (In Chinese) [Google Scholar]

- Cheng, C.; Fang, P.; Zhu, X.; Geng, S.; Zhan, R. Growth of SiOx films by dielectric barrier discharge (DBD) plasma enhanced chemical vapor deposition at atmospheric pressure. Chin. J. Vac. Sci. Tech. 2005, 25, 293–296. (In Chinese) [Google Scholar]

- Palaskar, S.; Kale, K.H.; Nadiger, G.S.; Desai, A.N. Dielectric barrier discharge plasma induced surface modification of polyester/cotton blended fabrics to impart water repellency using HMDSO. J. Appl. Polym. Sci. 2011, 122, 1092–1100. [Google Scholar] [CrossRef]

- Li, J.; Yan, L.; Zhao, Y.; Zha, F.; Wang, Q.; Lei, Z. One-step fabrication of robust fabrics with both-faced superhydrophobicity for the separation and capture of oil from water. Phys. Chem. Chem. Phys. 2015, 17, 6451–6457. [Google Scholar] [CrossRef]

| Operational Parameters | Unit | Values |

|---|---|---|

| Precursor feeding value | g/h | 20, 30, 40 |

| Plasma voltage | V | 280, 300, 320 |

| Treatment quantity | - | 1, 2, 3 |

| CIE Parameters | Blank Area | Inked Area | ||

|---|---|---|---|---|

| Untreated Sample | Treated Sample | Untreated Sample | Treated Sample | |

| L* | 75.96 | 76.19 | 26.17 | 25.25 |

| a* | 3.13 | 3.18 | 0.42 | 0.46 |

| b* | 20.51 | 20.97 | 2.03 | 2.16 |

| ∆E | 0.517 | 0.93 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Liu, G.-S.; Yang, J.; Pu, Y.; Chen, S.; He, H.-W.; Wang, C.; Long, Y.-Z.; Jiang, S. In Situ Surface Modification of Paper-Based Relics with Atmospheric Pressure Plasma Treatment for Preservation Purposes. Polymers 2019, 11, 786. https://doi.org/10.3390/polym11050786

Yan X, Liu G-S, Yang J, Pu Y, Chen S, He H-W, Wang C, Long Y-Z, Jiang S. In Situ Surface Modification of Paper-Based Relics with Atmospheric Pressure Plasma Treatment for Preservation Purposes. Polymers. 2019; 11(5):786. https://doi.org/10.3390/polym11050786

Chicago/Turabian StyleYan, Xu, Guo-Sai Liu, Jing Yang, Yi Pu, Shuo Chen, Hong-Wei He, Conger Wang, Yun-Ze Long, and Shouxiang Jiang. 2019. "In Situ Surface Modification of Paper-Based Relics with Atmospheric Pressure Plasma Treatment for Preservation Purposes" Polymers 11, no. 5: 786. https://doi.org/10.3390/polym11050786