Fine-Structure Analysis of Perhydropolysilazane-Derived Nano Layers in Deep-Buried Condition Using Polarized Neutron Reflectometry

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of PDS Thin-Layer Samples

2.3. Fourier-Transform Infrared (FT-IR) Measurements

2.4. Neutron Reflectivity Measurements and Data Analysis

3. Results

3.1. FT-IR Analysis of PDS Thin-Layer Samples

3.2. Structural Study of PDS Thin-Layer Samples by NR Analyses

3.3. Structural Study of PP/PDS/Si Substrate Sample by PNR Analyses

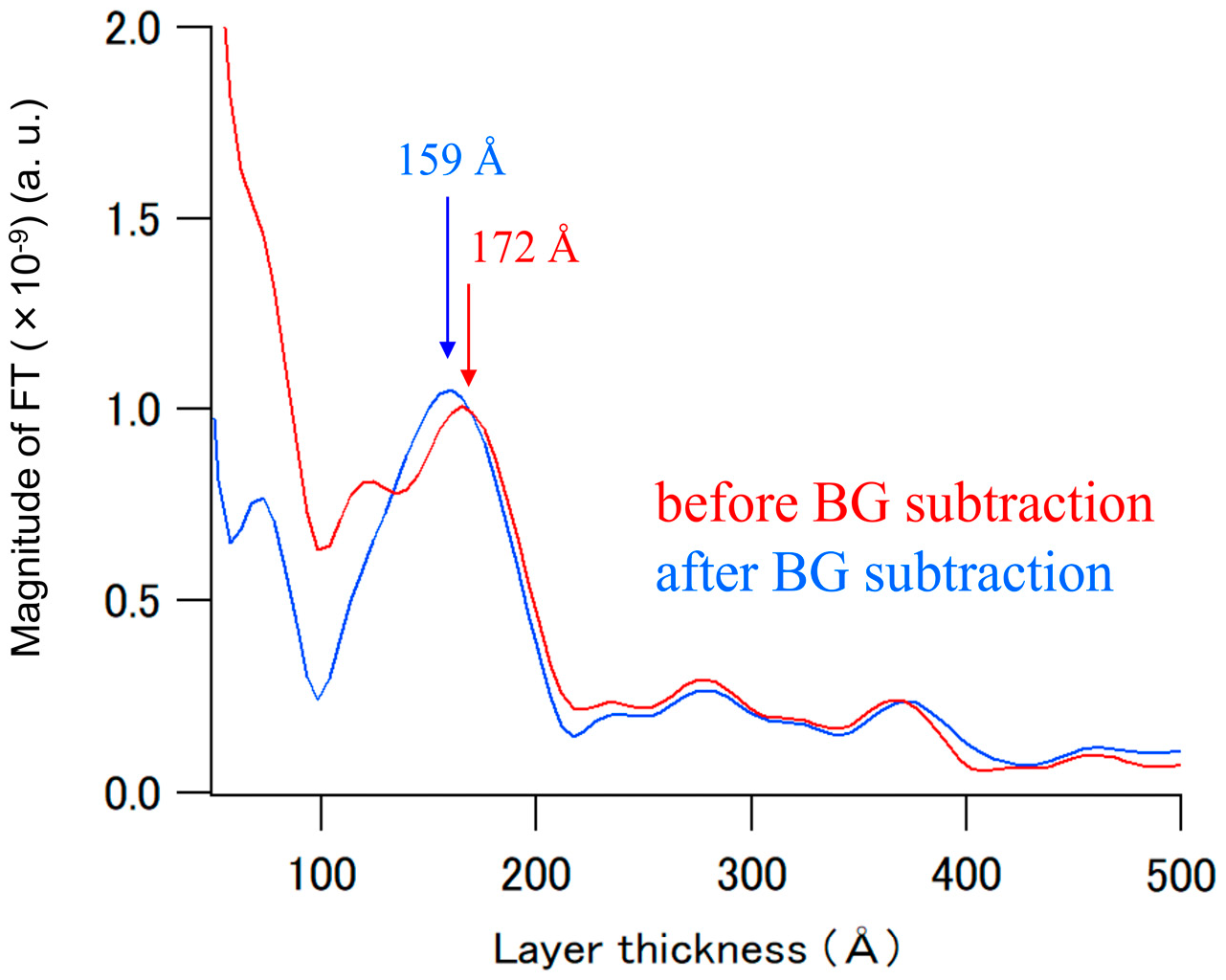

3.4. Fourier Transform (FT) Analysis Using Background-Subtracted Reflectivity Profiles

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Morlier, A.; Cros, S.; Garandet, J.P.; Alberola, N. Structural properties of ultraviolet cured polysilazane gas barrier layers on polymer substrates. Thin Solid Film. 2014, 550, 85–89. [Google Scholar] [CrossRef]

- Akutsu, K.; Niizeki, T.; Nagayama, S.; Miyata, N.; Sahara, M.; Shimomura, A.; Yoshii, M.; Hasegawa, Y. Investigation of structure of a thin SiO2 layer as an antifouling and corrosion-resistant coating. J. Ceram. Soc. Jpn. 2016, 124, 172–176. [Google Scholar] [CrossRef] [Green Version]

- Smokovych, I.; Krüger, M.; Sche, M. Journal of the European Ceramic Society Polymer derived ceramic materials from Si, B and MoSiB fi ller-loaded perhydropolysilazane precursor for oxidation protection. J. Eur. Ceram. Soc. 2019, 39, 3634–3642. [Google Scholar] [CrossRef]

- Smokovych, I.; Bolbut, V.; Krüger, M.; Scheffler, M. Tailored Oxidation Barrier Coatings for Mo-Hf-B and Mo-Zr-B Alloys. Materials 2019, 12, 2215. [Google Scholar] [CrossRef] [Green Version]

- Niizeki, T.; Nagayama, S.; Hasegawa, Y.; Miyata, N.; Sahara, M.; Akutsu, K. Structural Study of Silica Coating Thin Layers Prepared from Perhydropolysilazane: Substrate Dependence and Water Penetration Structure. Coatings 2016, 6, 64. [Google Scholar] [CrossRef] [Green Version]

- Sato, K.; Kaya, H.; Funayama, O.; Isoda, T. Evaluation of Polysilazanes-Perhydropolysilazane, Matrix Precursors Polyborosilazane of Ceramic-Matrix and Takeshi and Composites Kiyoshi (PHS), polyborosilazane (PBS) and methyl hydropolysilazane (MHS), were synthesized by a pyridine-adduct method. J. Ceram. Soc. Jpn. 2001, 109, 440–446. [Google Scholar] [CrossRef] [Green Version]

- Ma, R.; Xiao, B.; Ma, N.; Du, P. Low-loss insulating-conductive ceramic composite with giant permittivity and high permeability using glass phase as separating layer. Ceram. Int. 2016, 42, 4126–4135. [Google Scholar] [CrossRef]

- Lu, Z.; Hu, J.H.; Chen, C.; Peng, W.F.; Liu, Z.Z.; Liu, Y.; Zeng, K.; Yang, G. Preparation and characterization of adenine-based polyimide/nano-silica hybrid films. Eur. Polym. J. 2018, 102, 209–218. [Google Scholar] [CrossRef]

- Vassilakopoulou, A.; Georgakilas, V.; Vainos, N.; Koutselas, I. Successful entrapment of carbon dots within flexible free-standing transparent mesoporous organic-inorganic silica hybrid films for photonic applications. J. Phys. Chem. Solids 2017, 103, 190–196. [Google Scholar] [CrossRef] [Green Version]

- Altinpinar, S.; Ali, W.; Schuchardt, P.; Yildiz, P.; Zhao, H.; Theato, P.; Gutmann, J.S. Porous ultra-thin films from photocleavable block copolymers: In-situ degradation kinetics study of pore material. Polymers 2020, 12, 781. [Google Scholar] [CrossRef] [Green Version]

- Sudre, G.; Siband, E.; Gallas, B.; Cousin, F.; Hourdet, D.; Tran, Y. Responsive adsorption of N-isopropylacrylamide based copolymers on polymer brushes. Polymers 2020, 12, 153. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Akutsu-Suyama, K.; Cagnes, M.; Tamura, K.; Kanaya, T.; Darwish, T.A. Controlled deuterium labelling of imidazolium ionic liquids to probe the fine structure of the electrical double layer using neutron reflectometry. Phys. Chem. Chem. Phys. 2019, 21, 17512–17516. [Google Scholar] [CrossRef] [PubMed]

- Darwish, T.A.; Luks, E.; Moraes, G.; Yepuri, N.R.; Holden, P.J.; James, M. Synthesis of deuterated [D32]oleic acid and its phospholipid derivative [D64]dioleoyl-sn-glycero-3-phosphocholine. J. Label. Compd. Radiopharm. 2013, 56, 520–529. [Google Scholar] [CrossRef] [PubMed]

- Rosi-Schwartz, B.; Mitchell, G.R.; Soper, A.K. A new approach to neutron scattering for non-crystalline hydrogenous polymers. Polymer 1992, 33, 3744–3747. [Google Scholar] [CrossRef]

- Moon, R.M.; Riste, T.; Koehler, W.C. Polarization analysis of thermal-neutron scattering. Phys. Rev. 1969, 181, 920–931. [Google Scholar] [CrossRef]

- Motokawa, R.; Endo, H.; Nagao, M.; Heller, W.T. Neutron Polarization Analysis for Biphasic Solvent Extraction Systems. Solvent Extr. Ion Exch. 2016, 34, 399–406. [Google Scholar] [CrossRef]

- Wolff, M.; Devishvili, A.; Dura, J.A.; Adlmann, F.A.; Kitchen, B.; Pálsson, G.K.; Palonen, H.; Maranville, B.B.; Majkrzak, C.F.; Toperverg, B.P. Nuclear Spin Incoherent Neutron Scattering from Quantum Well Resonators. Phys. Rev. Lett. 2019, 123, 16101. [Google Scholar] [CrossRef]

- Takeda, M.; Arai, M.; Suzuki, J.; Yamazaki, D.; Soyama, K.; Maruyama, R.; Hayashida, H.; Asaoka, H.; Yamazaki, T.; Kubota, M.; et al. Current Status of a New Polarized Neutron Reflectometer at the Intense Pulsed Neutron Source of the Materials and Life Science Experimental Facility (MLF) of J-PARC. Chin. J. Phys. 2012, 50, 161. [Google Scholar]

- Sakasai, K.; Satoh, S.; Seya, T.; Nakamura, T.; Toh, K.; Yamagishi, H.; Soyama, K.; Yamazaki, D.; Maruyama, R.; Oku, T.; et al. Materials and Life Science Experimental Facility at the Japan Proton Accelerator Research Complex III: Neutron Devices and Computational and Sample Environments. Quantum Beam Sci. 2017, 1, 10. [Google Scholar] [CrossRef] [Green Version]

- Nelson, A. Co-refinement of multiple-contrast neutron/X-ray reflectivity data using MOTOFIT. J. Appl. Crystallogr. 2006, 39, 273–276. [Google Scholar] [CrossRef]

- Kira, H.; Hayashida, H.; Iwase, H.; Ohishi, K.; Suzuki, J.; Oku, T.; Sakai, K.; Hiroi, K.; Takata, S.; Ino, T.; et al. Demonstration Study of Small-Angle Polarized Neutron Scattering Using Polarized 3He Neutron Spin Filter. In Proceedings of the 2nd International Symposium on Science at J-PARC: Unlocking the Mysteries of Life, Matter and the Universe, Tsukuba, Japan, 25 September 2015; p. 036008. [Google Scholar]

- Kozuka, H.; Nakajima, K.; Uchiyama, H. Superior properties of silica thin films prepared from perhydropolysilazane solutions at room temperature in comparison with conventional alkoxide-derived silica gel films. ACS Appl. Mater. Interfaces 2013, 5, 8329–8336. [Google Scholar] [CrossRef] [PubMed]

- Yamano, A.; Kozuka, H. Preparation of silica coatings heavily doped with spiropyran using perhydropolysilazane as the silica source and their photochromic properties. J. Phys. Chem. B 2009, 113, 10548. [Google Scholar] [CrossRef] [Green Version]

- Shimomura, J.; Ogihara, T.; Ogata, N.; Kozuka, H.; Kato, K.; Suzuki, H. Preparation and Characterization of Silica/Polymethylmethacrylate Hybirid Thin Films on Polybutyleneterephthalate Substrates by Sol-Gel Method. J. Ceram. Soc. Jpn. 2007, 115, 556–561. [Google Scholar] [CrossRef] [Green Version]

- Akutsu, K.; Cagnes, M.; Niizeki, T.; Hasegawa, Y.; Darwish, T.A. Penetration behavior of an ionic liquid in thin-layer silica coating: Ionic liquid deuteration and neutron reflectivity analysis. Phys. B Condens. Matter 2018, 551, 262–265. [Google Scholar] [CrossRef]

- Schneider, S. Determination of Protein Molecular Weight and Size Using the Agilent 1260 Infi nity Multi-Detector Bio-SEC Solution with Advanced Light Scattering Detection. Agil. Technol. Appl. Note 2014. Available online: https://www.agilent.com/cs/library/applications/5991-3955EN.pdf (accessed on 30 August 2020).

- Sakurai, K.; Mizusawa, M.; Ishii, M. Significance of Frequency Analysis in X-ray Rflectivity: Towards analysis which does not depend too much on models. Trans. Mater. Res. Soc. Jpn. 2008, 33, 523–528. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Sakurai, K. Slow dynamics in thermal expansion of polyvinyl acetate thin film with interface layer. Polym. J. 2019, 51, 1073–1079. [Google Scholar] [CrossRef]

- Sakaguchi, Y.; Asaoka, H.; Mitkova, M. Silver photodiffusion into Ge-rich amorphous germanium sulfide—Neutron reflectivity study. J. Appl. Phys. 2017, 122, 235105. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akutsu-Suyama, K.; Kira, H.; Miyata, N.; Hanashima, T.; Miyazaki, T.; Kasai, S.; Yamazaki, D.; Soyama, K.; Aoki, H. Fine-Structure Analysis of Perhydropolysilazane-Derived Nano Layers in Deep-Buried Condition Using Polarized Neutron Reflectometry. Polymers 2020, 12, 2180. https://doi.org/10.3390/polym12102180

Akutsu-Suyama K, Kira H, Miyata N, Hanashima T, Miyazaki T, Kasai S, Yamazaki D, Soyama K, Aoki H. Fine-Structure Analysis of Perhydropolysilazane-Derived Nano Layers in Deep-Buried Condition Using Polarized Neutron Reflectometry. Polymers. 2020; 12(10):2180. https://doi.org/10.3390/polym12102180

Chicago/Turabian StyleAkutsu-Suyama, Kazuhiro, Hiroshi Kira, Noboru Miyata, Takayasu Hanashima, Tsukasa Miyazaki, Satoshi Kasai, Dai Yamazaki, Kazuhiko Soyama, and Hiroyuki Aoki. 2020. "Fine-Structure Analysis of Perhydropolysilazane-Derived Nano Layers in Deep-Buried Condition Using Polarized Neutron Reflectometry" Polymers 12, no. 10: 2180. https://doi.org/10.3390/polym12102180

APA StyleAkutsu-Suyama, K., Kira, H., Miyata, N., Hanashima, T., Miyazaki, T., Kasai, S., Yamazaki, D., Soyama, K., & Aoki, H. (2020). Fine-Structure Analysis of Perhydropolysilazane-Derived Nano Layers in Deep-Buried Condition Using Polarized Neutron Reflectometry. Polymers, 12(10), 2180. https://doi.org/10.3390/polym12102180