Hierarchical Structured Polyimide–Silica Hybrid Nano/Microfiber Filters Welded by Solvent Vapor for Air Filtration

Abstract

:1. Introduction

2. Experiments

2.1. Materials

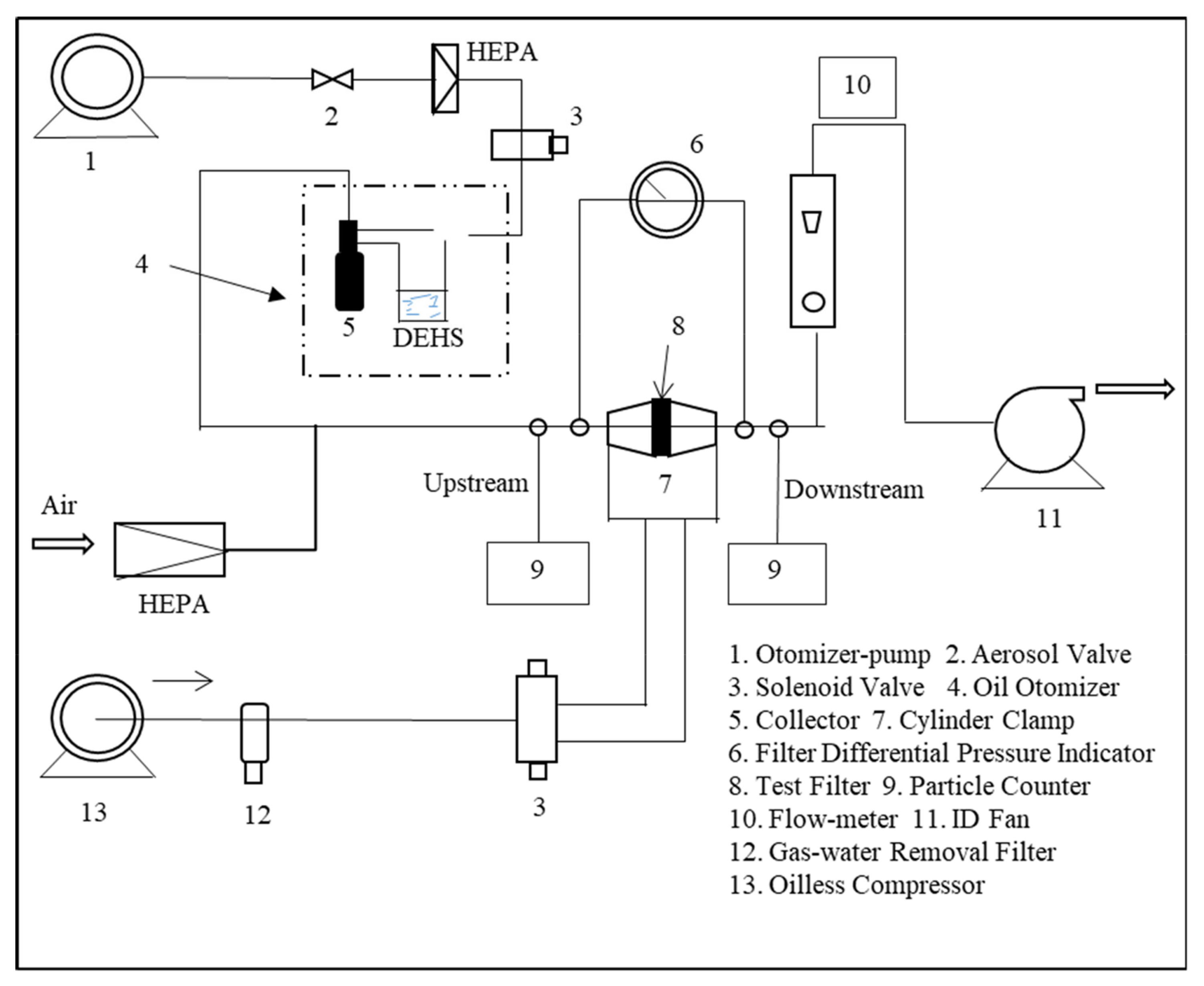

2.2. Methods

2.2.1. Preparation of SiO2@PI Hybrid Membranes

2.2.2. Preparation of PPS–SiO2@PI Composite Filters

2.3. Characterizations

3. Results and Discussion

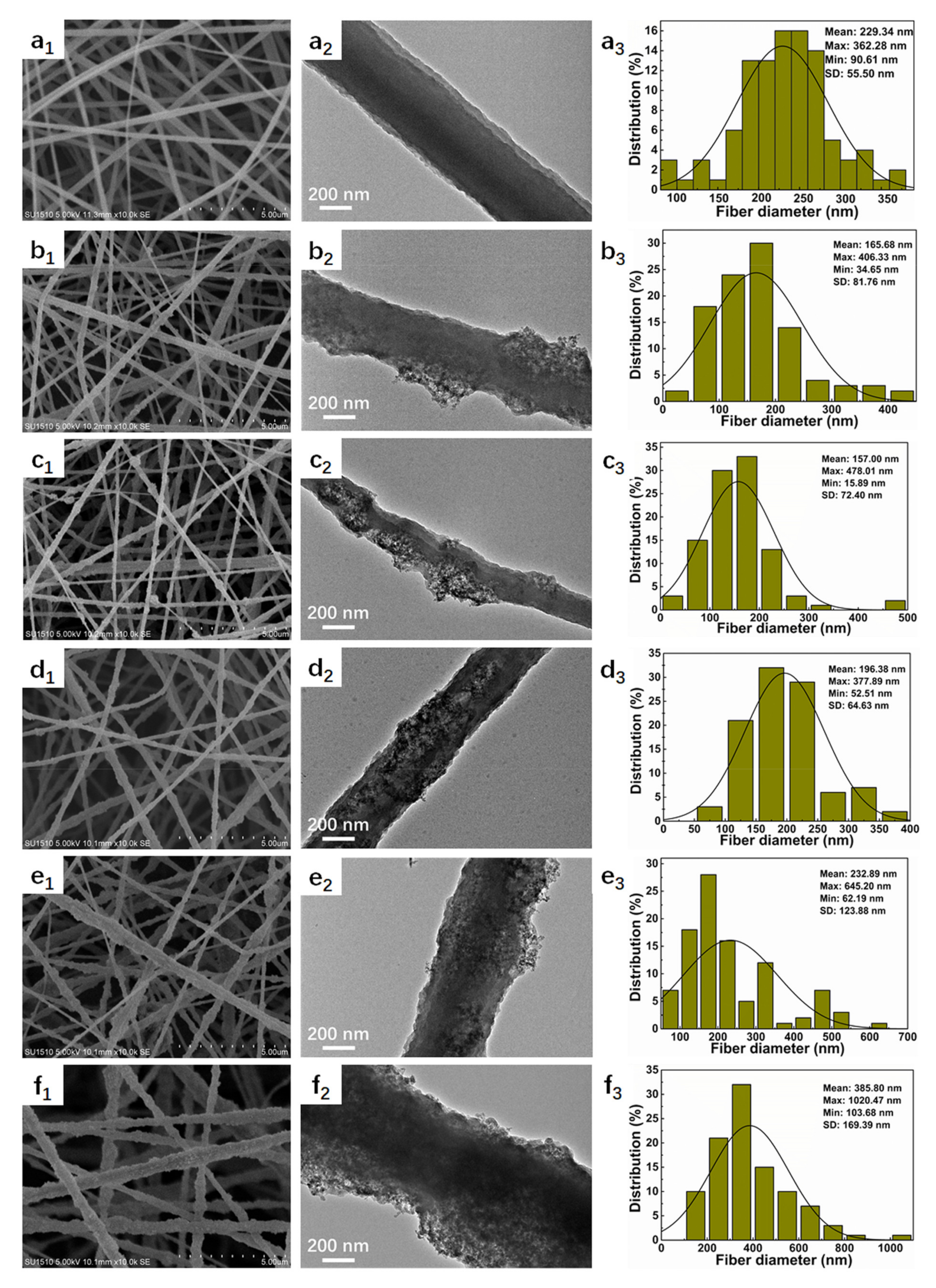

3.1. Morphology of Hybrid Membranes

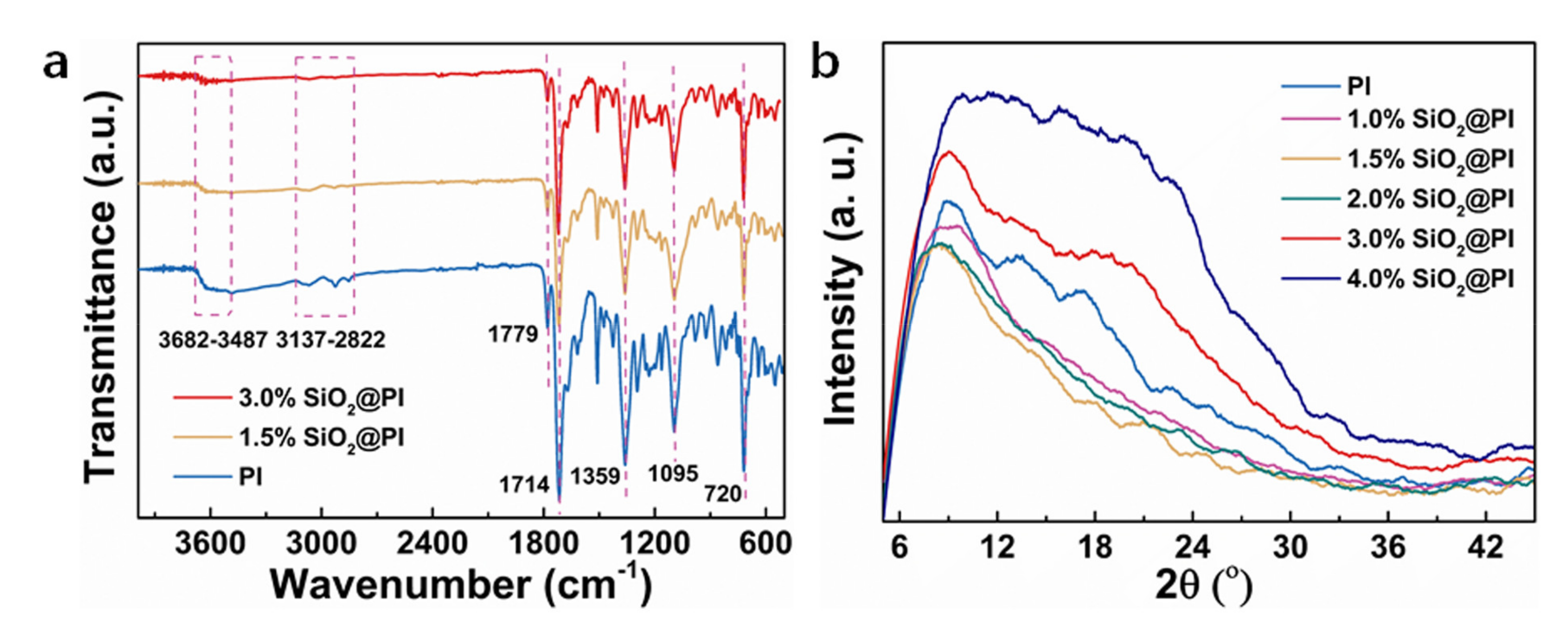

3.2. Chemical Structure

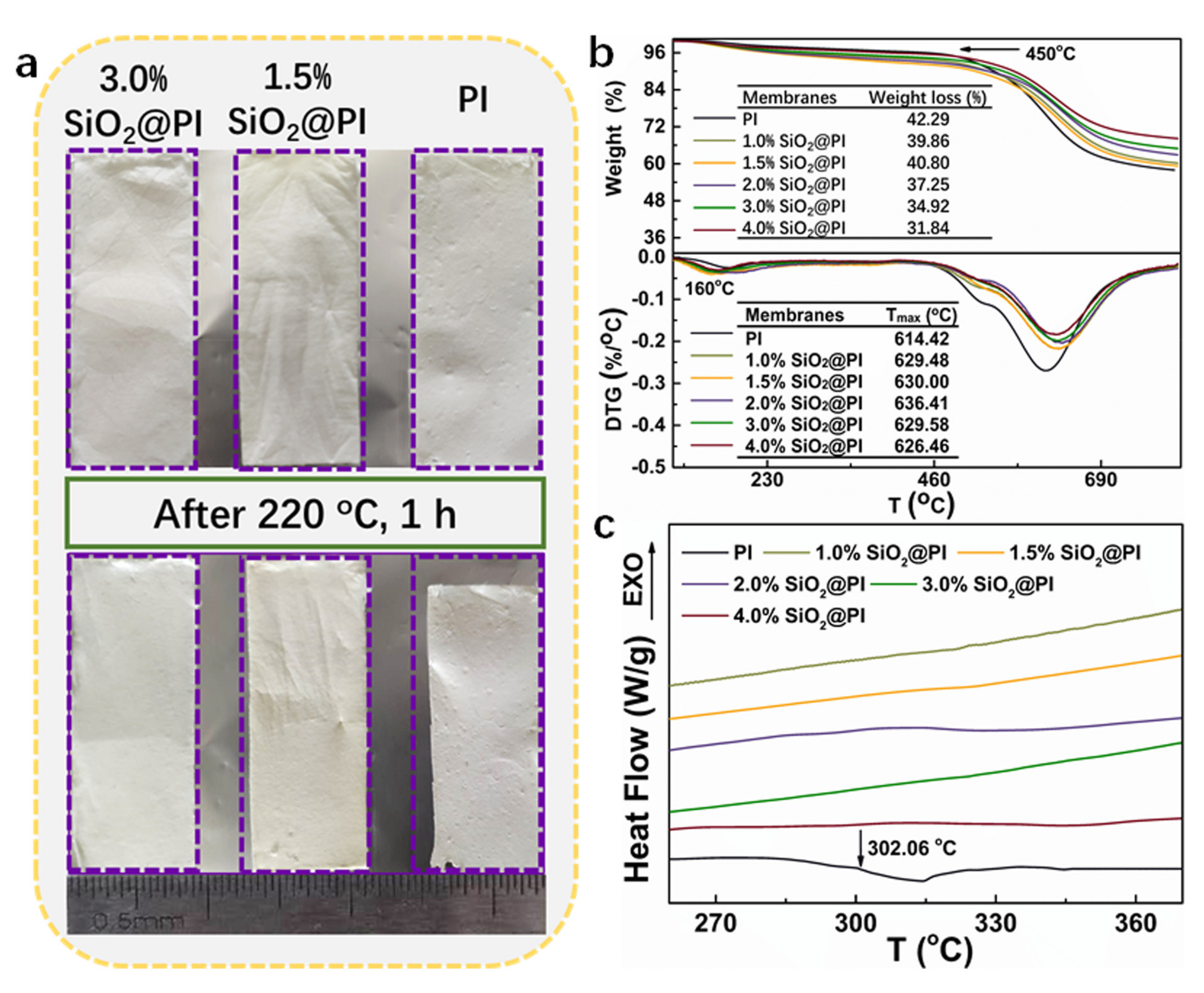

3.3. Thermal Performance

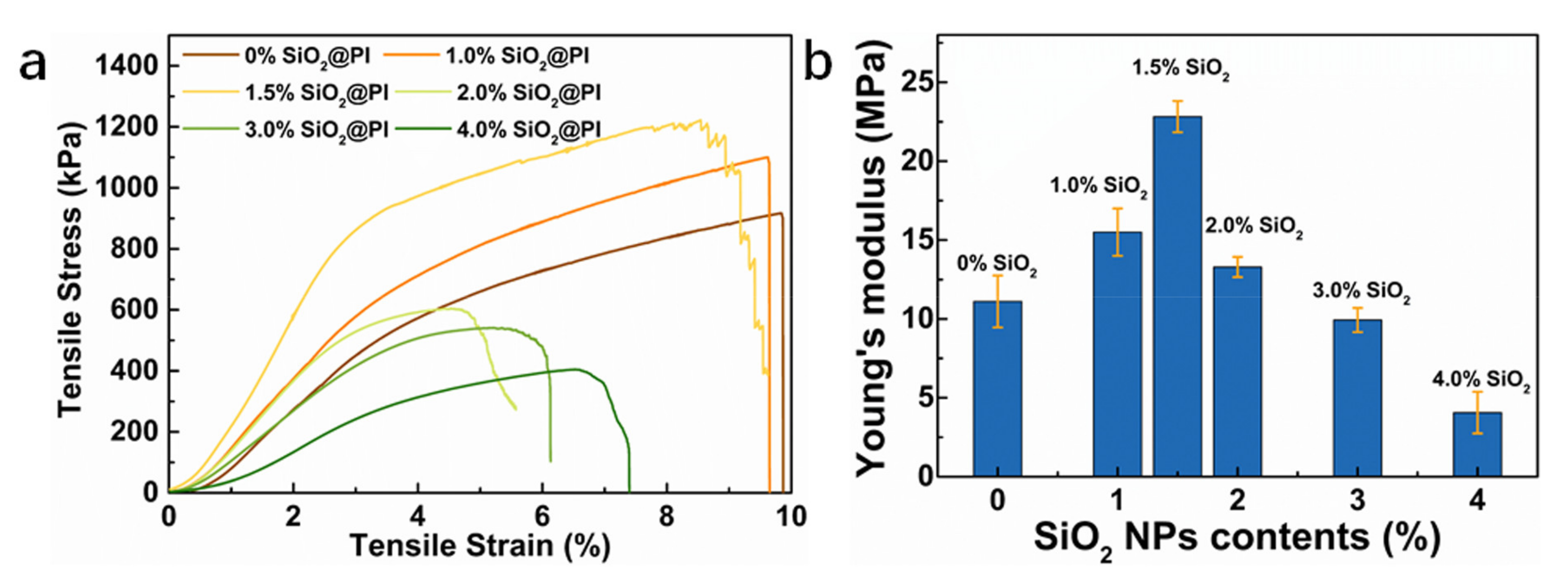

3.4. Mechanical Property

3.5. Porous Structure

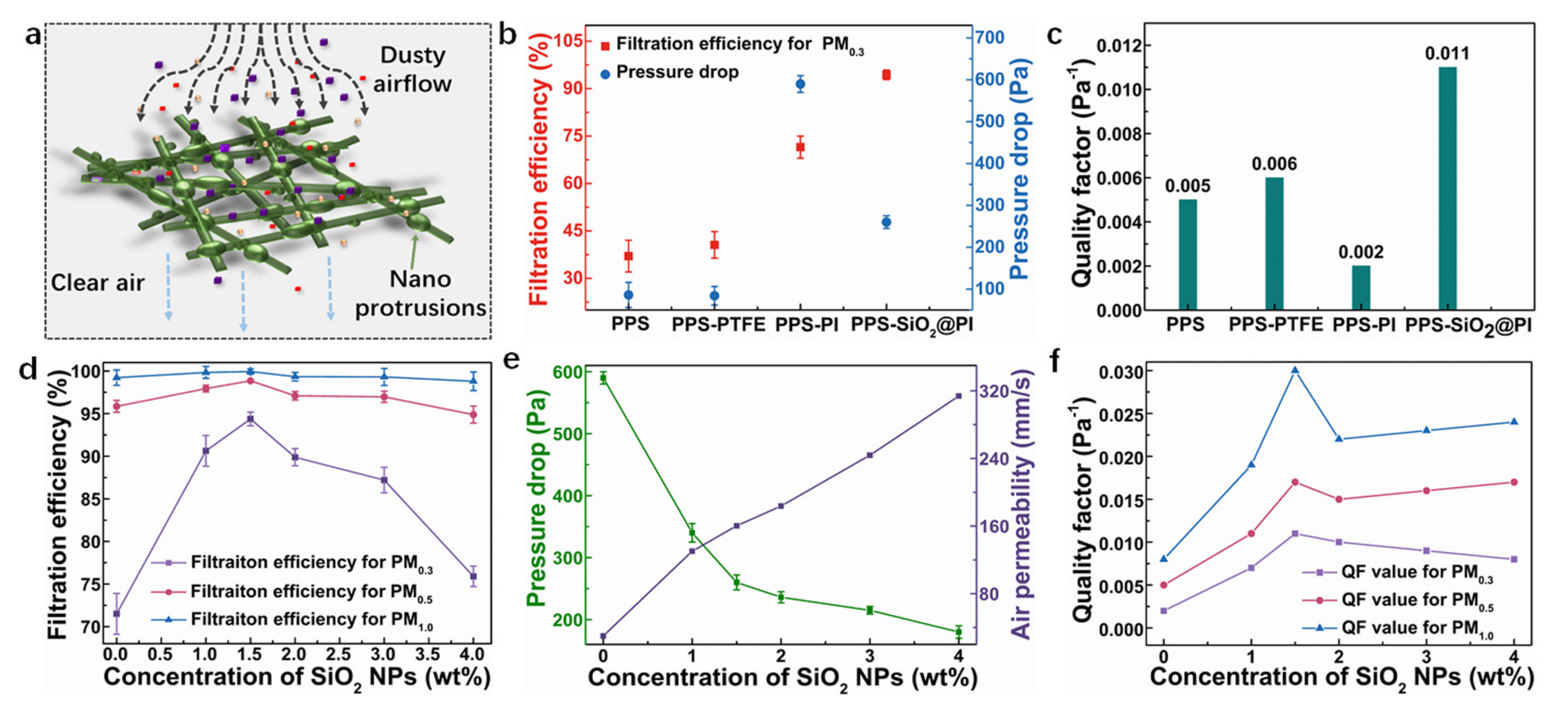

3.6. Filtration Performance

3.7. Filtration Efficiency and Reusability of Welded Composite Filters

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Xie, Y.; Zhao, B.; Zhang, L.; Luo, R. Spatiotemporal variations of PM2.5 and PM10 concentrations between 31 Chinese cities and their relationships with SO2, NO2, CO and O3. Particuology 2015, 20, 141–149. [Google Scholar] [CrossRef]

- Miao, H.; Takamichi, I.; Makoto, K. Differences in allergic inflammatory responses between urban PM2.5 and fine particle derived from desert-dust in murine lungs. Toxicol. Appl. Pharmacol. 2016, 297, 41–55. [Google Scholar]

- Afghan, F.R.; Patidar, S.K. Health impacts assessment due to PM2.5, PM10 and NO2 exposure in national capital territory (NCT) delhi. Pollution 2020, 6, 115–126. [Google Scholar]

- Xu, Y.; Yang, L.; Wang, X.; Zheng, M.; Li, C.; Zhang, A.; Fu, J.; Yang, Y.; Qin, L.; Liu, X.; et al. Risk evaluation of environmentally persistent free radicals in airborne particulate matter and influence of atmospheric factors. Ecotox. Environ. Safe 2020, 196, 110571. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Liang, J.; Zhang, C.; Tao, Y.; Ling, G.; Yang, Q. Advanced materials for capturing particulate matter: Progress and perspectives. Small Methods 2018, 2, 1800012. [Google Scholar] [CrossRef]

- Kadam, V.V.; Wang, L.; Padhye, R. Electrospun nanofiber materials to filter air pollutants—A review. J. Ind. Text. 2018, 47, 2253–2280. [Google Scholar] [CrossRef]

- Liu, J.; David, Y.; Pui, H.; Wang, J. Removal of airborne nanoparticles by membranes coated filters. Sci. Total. Environ. 2011, 409, 4868–4874. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Zhang, S.; Zhao, X.; Yu, J.; Ding, B. Sandwich structured polyamide-6/polyacrylonitrile nanonets/bead-on-string composite membrane for effective air filtration. Sep. Purif. Technol. 2015, 152, 14–22. [Google Scholar] [CrossRef]

- Das, D.; Das, S.; Ishtiaque, S.M. Optimal design of nonwoven air filter media: Effect of fiber shape. Fiber. Polym. 2014, 15, 1456–1461. [Google Scholar] [CrossRef]

- Lee, Y.; Wadsworth, L.C. Structure and filtration properties of melt blown polypropylene webs. Polym. Eng. Sci. 1990, 30, 1413–1419. [Google Scholar] [CrossRef]

- Yu, Y.; Xiong, S.; Huang, H.; Zhao, L.; Nie, K.; Chen, S.; Xu, J.; Yin, X.; Wang, H.; Wang, L. Fabrication and application of poly (phenylene sulfide) ultrafine fiber. React. Funct. Polym. 2020, 150, 104539. [Google Scholar] [CrossRef]

- Yu, B.; Han, J.; He, X.; Xu, G.; Ding, X. Effects of tourmaline particles on structure and properties of polypropylene filtration melt-blown nonwoven electrets. J. Macromol. Sci. B. 2012, 51, 619–629. [Google Scholar] [CrossRef]

- Zhu, X.; Dai, Z.; Xu, K.; Zhao, Y.; Ke, Q. Fabrication of multifunctional filters via online incorporation nano-TiO2 into spun-bonded/melt-blown nonwovens for air filtration and toluene degradation. Macromol. Mater. Eng. 2019, 304, 1900350. [Google Scholar] [CrossRef]

- Katarzyna, M.; Malgorzata, O.; Anita, J.; Justyna, S.; Beata, G. Microbial growth on dust-loaded filtering materials used for the protection of respiratory tract as a factor affecting filtration efficiency. Int. J. Environ. Res. Public Health 2018, 15, 1902–1920. [Google Scholar]

- Dixit, P.; Ishtiaque, S.M.; Roy, R. Influence of sequential punching in layered structure of needle punched nonwoven on the filtration behavior. Compos. Part B Eng. 2020, 182, 107564. [Google Scholar] [CrossRef]

- Wang, Y.X.; Xu, Y.K.; Wang, D.; Zhang, Y.J.; Zhang, X.; Liu, J.C.; Zhao, Y.; Huang, C.; Jin, X.Y. Polytetrafluoroethylene/polyphenylene sulfide needle-punched triboelectric air filter for efficient particulate matter removal. ACS Appl. Mater. Interfaces 2019, 11, 48437–48449. [Google Scholar] [CrossRef]

- Thakur, R.; Das, D.; Das, A. Electret air filters. Sep. Purif. Rev. 2013, 42, 87–129. [Google Scholar] [CrossRef]

- Xiao, H.M.; Song, Y.P.; Chen, G.J. Correlation between charge decay and solvent effect for melt-blown polypropylene electret filter fabrics. J. Electrost. 2014, 72, 311–314. [Google Scholar] [CrossRef]

- Li, Y.Y.; Yin, X.; Yu, J.Y.; Ding, B. Electrospun nanofibers for high-performance air filtration. Compos. Commun. 2019, 15, 6–19. [Google Scholar] [CrossRef]

- Ye, B.; Wang, S.; Zhang, L.; Chen, C. Influence of fiber diameter, filter thickness, and packing density on PM2.5 removal efficiency of electrospun nanofiber air filters for indoor applications. Build. Environ. 2020, 170, 106628. [Google Scholar]

- Li, P.; Wang, C.Y.; Zhang, Y.Y.; Wei, F. Air filtration in the free molecular flow regime: A review of high-efficiency particulate air filters based on carbon nanotubes. Small 2014, 10, 4543–4561. [Google Scholar] [CrossRef] [PubMed]

- Pafal, P.; Leon, G. Deposition and filtration of nanoparticles in the composites of nano- and microsized fibers. Aerosol. Sci. Tech. 2008, 42, 483–493. [Google Scholar]

- Zhao, X.L.; Wang, S.; Yin, X.; Yu, J.; Ding, B. Slip-effect functional air filter for efficient purification of PM2.5. Sci. Rep. UK 2016, 6, 35472–35483. [Google Scholar] [CrossRef]

- Maze, B.; Tafreshi, H.V.; Wang, Q.; Pourdeyhimi, B. A simulation of unsteady-state filtration via nanofiber media at reduced operating. J. Aerosol. Sci. 2007, 38, 550–571. [Google Scholar] [CrossRef]

- Thenmozhi, S.; Dharmaraj, N.; Kadirvelu, K.; Kim, H.Y. Electrospun nanofibers: New generation materials for advanced applications. Mat. Sci. Eng. B 2017, 217, 36–48. [Google Scholar] [CrossRef]

- Nam, C.; Lee, S.; Ryu, M.; Lee, J.; Lee, H. Electrospun nanofiber filters for highly efficient PM2.5 capture. Korean J. Chem. Eng. 2019, 36, 1565–1574. [Google Scholar] [CrossRef]

- Su, J.F.; Yang, G.H.; Cheng, C.L.; Huang, C.; Xu, H.; Ke, Q.F. Hierarchically structured TiO2/PAN nanfibrous membranes for high-efficiency air filtration and toluene degradation. J. Colloid Interface Sci. 2017, 507, 386–396. [Google Scholar] [CrossRef] [PubMed]

- Yanilmaz, M.; Lu, Y.; Dirican, M.; Fu, K.; Zhang, X. Nanoparticle-on-nanofiber hybrid membrane separators for lithium-ion batteries via combining electrospraying and electrospinning techniques. J. Mater. Sci. 2014, 456, 57–65. [Google Scholar] [CrossRef]

- Benykhlef, S.; Bekhoukh, A.; Berenguer, R.; Benyoucef, A.; Morallon, E. PANI-derived polymer/Al2O3 nanocomposites: Synthesis, characterization, and electrochemical studies. Colloid Polym. Sci. 2016, 294, 1877–1885. [Google Scholar] [CrossRef] [Green Version]

- Mescheder, U.; Müller, B.; Baborie, S.; Urbanovic, P. Properties of SiO2 electret films charged by ion implantation for MEMs-based energy harvesting systems. J. Micromech. Microeng. 2009, 19, 094003. [Google Scholar] [CrossRef]

- Liu, F.; Li, M.; Shao, W.; Yue, W.; Hu, B.; Weng, K.; Chen, Y.; Liao, X.; He, J. Preparation of a polyurethane electret nanofiber membrane and its air-filtration performance. J. Colloid Interface Sci. 2019, 557, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Yu, Y.; Tan, Z.; Zhang, J.; Liu, G. Microstructural evolution and mechanical investigation of hot stretched graphene oxide reinforced polyacrylonitrile nanofiber yarns. Polym. Adv. Technol. 2020, 31, 1935–1945. [Google Scholar] [CrossRef]

- Korkmaz, M.N.; Gizem, K.; Demet, Y. Development of a novel hybrid yarn production process for functional textile products. J. Ind. Text. 2019, 48, 1462–1488. [Google Scholar] [CrossRef]

- Homocianu, M.; Pascariu, P. Electrospun polymer-inorganic nanostructured materials and their applications. Polym. Rev. 2020, 60, 493–541. [Google Scholar] [CrossRef]

- Garnett, E.C.; Cai, W.; Cha, J.J.; Mahmood, F.; Connor, S.T.; Christoforo, M.G.; Cui, Y.; McGehee, M.D.; Brongersma, M.L. Self-linited plasmonic welding of silver nanowire junctions. Nat. Mater. 2012, 11, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Parnian, K.; Alessandra, V.; Dalle, V.S.; Roberta, B. Photo-crosslinking of chitosan/poly(ethylene oxide) electrospun nanofibers. Carbohyd. Polym. 2019, 217, 144–151. [Google Scholar]

- Cai, J.; Zhang, Q.; Lei, M.; He, J.; Liu, G. The use of solvent-soaking treatment to enhance the anisotropic mechanical properties of electrospun nanofiber membranes for water filtration. RSC Adv. 2016, 6, 66807–66813. [Google Scholar] [CrossRef]

- Li, H.X.; Zhu, C.L.; Xue, J.J.; Ke, Q.F.; Xia, Y.N. Enhancing the mechanical properties of electrospun nanofiber mats through controllable welding at the cross points. Macromol. Rapid. Comm. 2017, 38, 1600723. [Google Scholar] [CrossRef] [Green Version]

- Huang, L.W.; Manickam, S.S.; McCutcheon, J.R. Increasing strength of electrospun nanofiber membranes for water filtration using solvent vapor. J. Membrane. Sci. 2013, 436, 213–220. [Google Scholar] [CrossRef]

- Ding, M.X. Isomeric Polyimide. Prog. Polym. Sci. 2007, 32, 623–668. [Google Scholar] [CrossRef]

- Ding, Y.C.; Hou, H.Q.; Zhao, Y.; Zhu, Z.T.; Fong, H. Electrospun polyimide nanofibers and their application. Prog. Polym. Sci. 2016, 61, 67–103. [Google Scholar] [CrossRef]

- Shen, Y.; Li, D.; Deng, B.; Liu, Q.; Liu, H.; Wu, T. Robust polyimide nano/microfibre aerogels welded by solvent-vapour for environmental applications. R Soc. Open Sci. 2019, 6, 190596. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wenzel, R.N. Resistance of solid surfaces to wetting by water. Ind. Eng. Chem. 1936, 28, 988–994. [Google Scholar] [CrossRef]

- Ghaffari, S.; Aliofkhazraei, M.; Darband, G.; Zakeri, A.; Ahmadi, E. Review of superoleophobic surfaces: Evaluation, fabrication methods, and industrial applications. Surf. Interfaces 2019, 17, 1000340. [Google Scholar] [CrossRef]

- Xu, W.; Ding, Y.; Huang, R.; Zhu, Z.; Fong, H.; Hou, H. High-performance polyimide nanofibers reinforced polyimide nanocomposite films fabricated by co-electrospinning followed by hot-pressing. J. Appl. Polym. Sci. 2018, 135, 46849. [Google Scholar] [CrossRef]

- Tripp, C.P.; Hair, M.L. Reaction of methylsilanols with hydrated silica surfaces: The hydrolysis of trichloro-, dichloro-, and monochloromethylsilanes and the effects of curing. Langmuir 1995, 11, 149–155. [Google Scholar] [CrossRef]

- Jung, H.; Ju, D.; Lee, W.; Zhang, X.; Kotek, R. Electrospun hydrophilic fumed silica/polyacrylonitrile nanofiber-based composite electrolyte membranes. Electrochim. Acta 2009, 54, 3630–3637. [Google Scholar] [CrossRef]

- Leo, C.J.; Thakur, A.K.; Subba Rao, G.V.; Chowdari, B.V.R. Effect of glass-ceramic filler on properties of polyethylene oxide-LiCF3SO3 complex. J. Power Sources 2003, 115, 295–304. [Google Scholar] [CrossRef]

- Kim, Y.J.; Ahn, C.H.; Lee, M.B.; Choi, M. Characteristics of electrospun PVDF/SiO2 composite nanofiber membranes as polymer electrolyte. Mater. Chem. Phys. 2011, 127, 137–142. [Google Scholar] [CrossRef]

- Gobi, N.; Vijayalakshmi, E.; Robert, B.; Srinivasan, N.R. Development of PAN nano fibrous filter hybridized by SiO2 nanoparticles electret for high efficiency air filtration. J. Polym. Mater. 2018, 35, 317–328. [Google Scholar] [CrossRef]

- Li, X.; Wang, N.; Fan, G.; Yu, J.; Gao, J.; Sun, G.; Ding, B. Electreted polyetherimide-silica fibrous membranes for enhanced filtration of fine particles. J. Colloid Interface Sci. 2015, 439, 12–20. [Google Scholar] [CrossRef] [PubMed]

- Wan, H.; Wang, N.; Yang, J.; Si, Y.; Chen, K.; Ding, B.; Sun, G.; EI-Newehy, M.; Al-Swyab, S.S.; Yu, J. Hierarchically structured polusulfone/titania fibrous membranes with enhanced air filtration performance. J. Colloid Interface Sci. 2014, 417, 18–26. [Google Scholar] [CrossRef] [PubMed]

| Filters | Mean Pore Size (μm) | Maximum Pore Size (μm) | Bubble Point Pressure (psi) | Pressure Drop (Pa) |

|---|---|---|---|---|

| PPS–1.5%SiO2@PI | 1.70 | 3.68 | 2.479 | 260 |

| Welded PPS–1.5%SiO2@PI | 1.77 | 7.98 | 0.930 | 243 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Shen, Y.; Wang, L.; Liu, F.; Deng, B.; Liu, Q. Hierarchical Structured Polyimide–Silica Hybrid Nano/Microfiber Filters Welded by Solvent Vapor for Air Filtration. Polymers 2020, 12, 2494. https://doi.org/10.3390/polym12112494

Li D, Shen Y, Wang L, Liu F, Deng B, Liu Q. Hierarchical Structured Polyimide–Silica Hybrid Nano/Microfiber Filters Welded by Solvent Vapor for Air Filtration. Polymers. 2020; 12(11):2494. https://doi.org/10.3390/polym12112494

Chicago/Turabian StyleLi, Dawei, Ying Shen, Lanlan Wang, Feng Liu, Bingyao Deng, and Qingsheng Liu. 2020. "Hierarchical Structured Polyimide–Silica Hybrid Nano/Microfiber Filters Welded by Solvent Vapor for Air Filtration" Polymers 12, no. 11: 2494. https://doi.org/10.3390/polym12112494

APA StyleLi, D., Shen, Y., Wang, L., Liu, F., Deng, B., & Liu, Q. (2020). Hierarchical Structured Polyimide–Silica Hybrid Nano/Microfiber Filters Welded by Solvent Vapor for Air Filtration. Polymers, 12(11), 2494. https://doi.org/10.3390/polym12112494