Tunable Tensile Properties of Polypropylene and Polyethylene Terephthalate Fibrillar Blends through Micro-/Nanolayered Extrusion Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

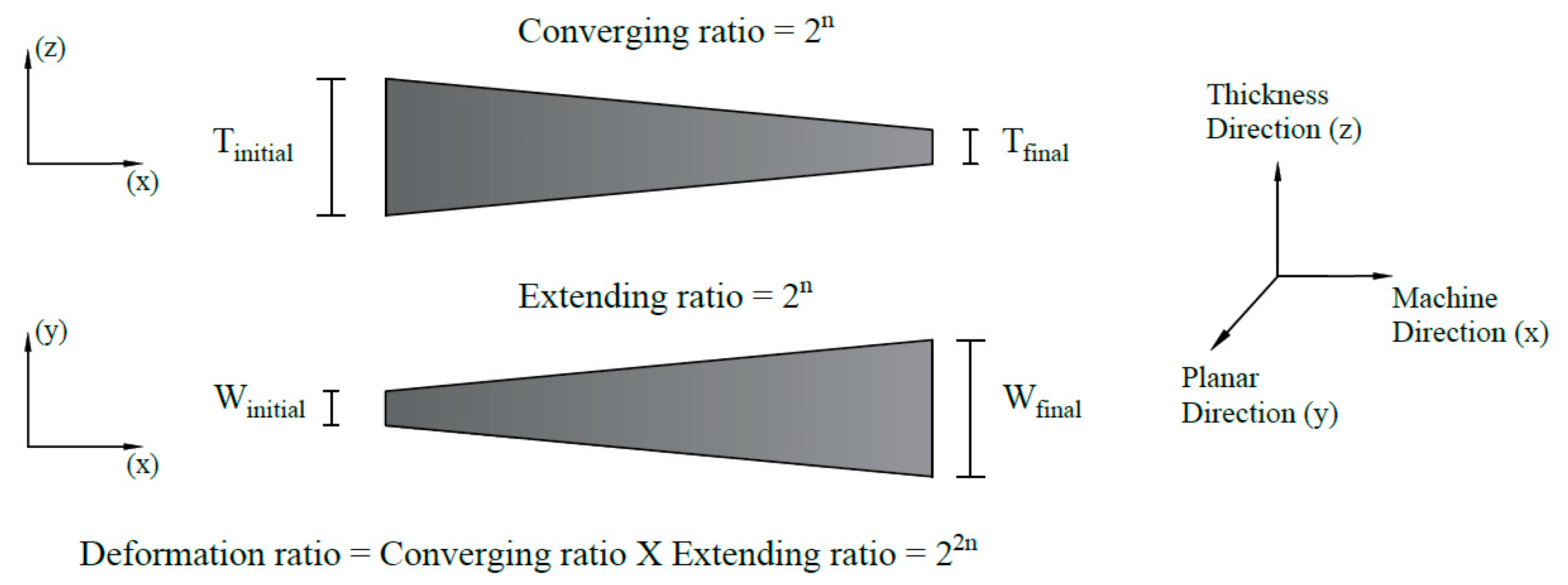

2.2. Fibrillation of PP/PET Blends

2.3. MNL Extrusion

2.4. Scanning Electron Microscopy (SEM)

2.5. Orientation Angle Measurements

2.6. Mechanical Test

3. Results

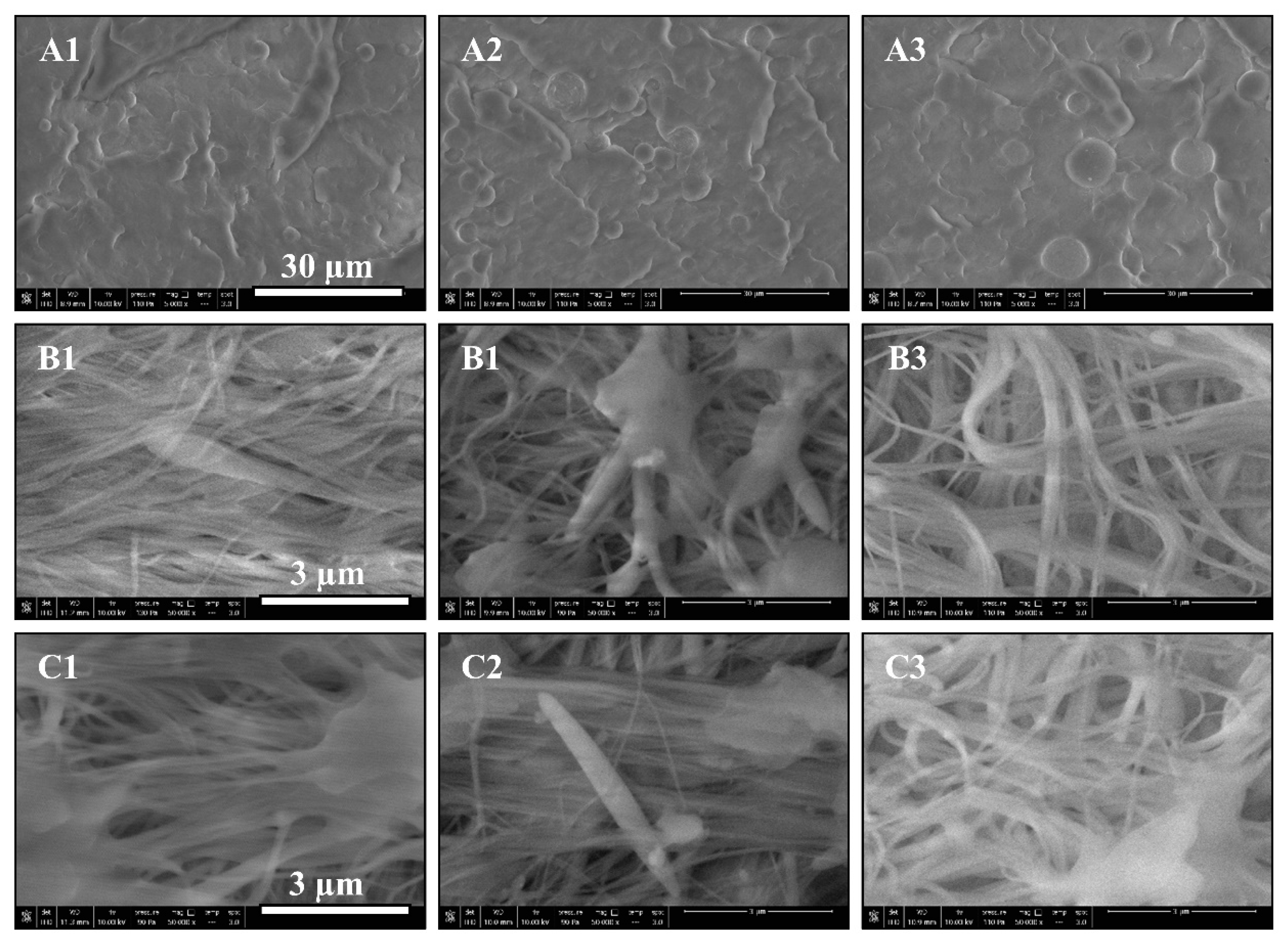

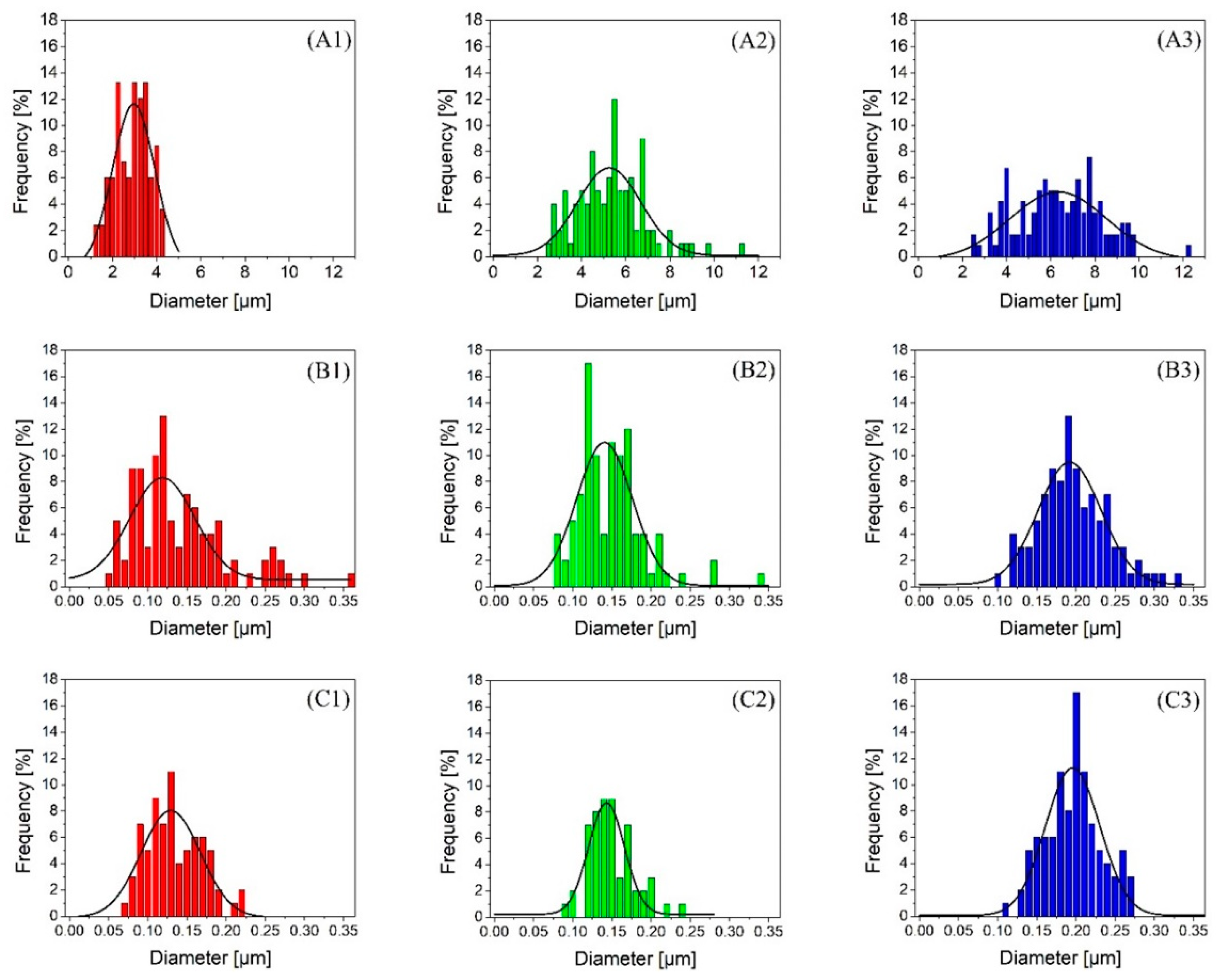

3.1. Size Distribution Analysis

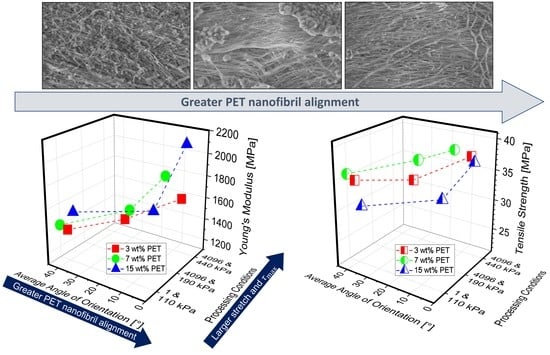

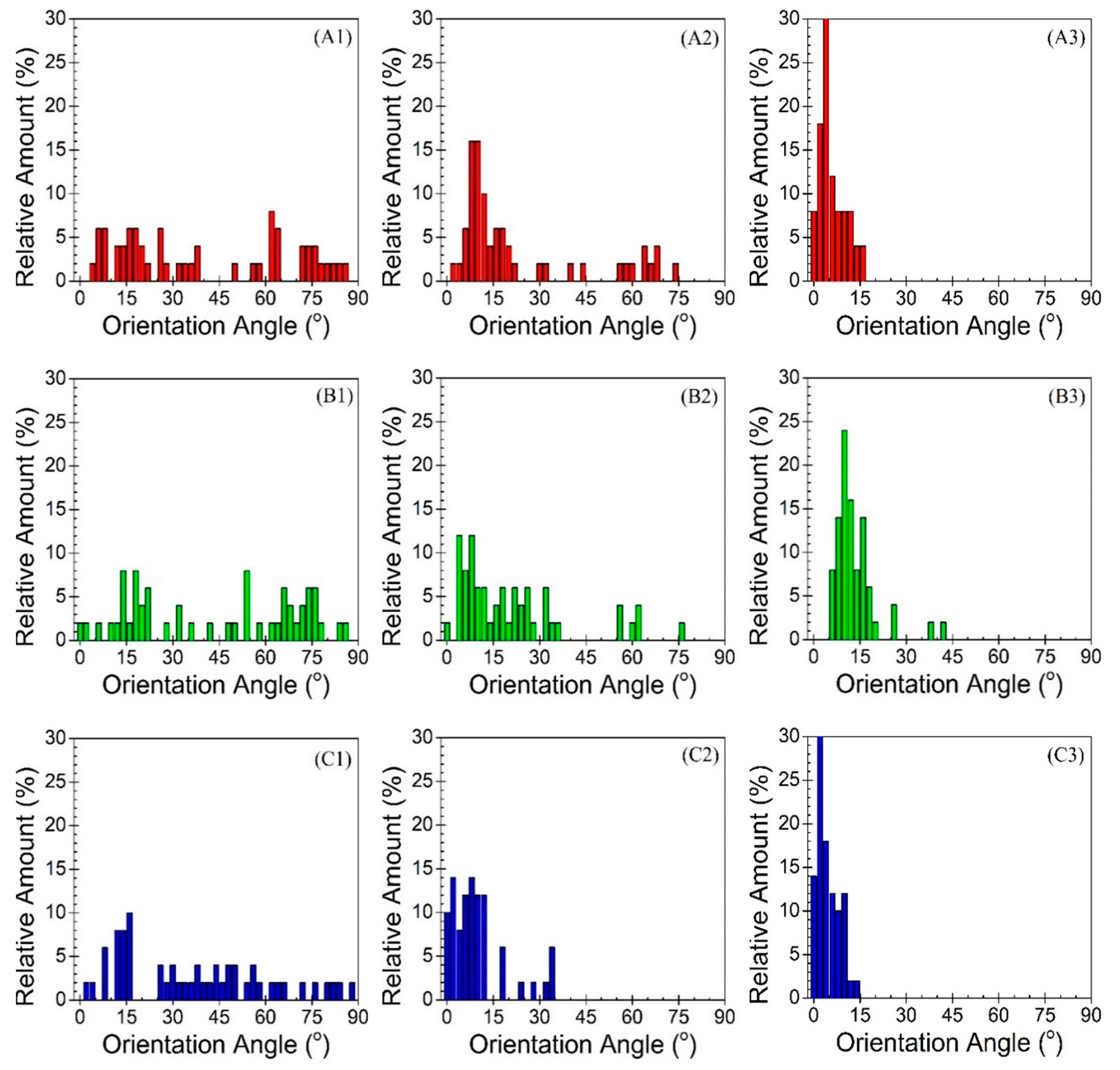

3.2. Orientation Angle Analysis

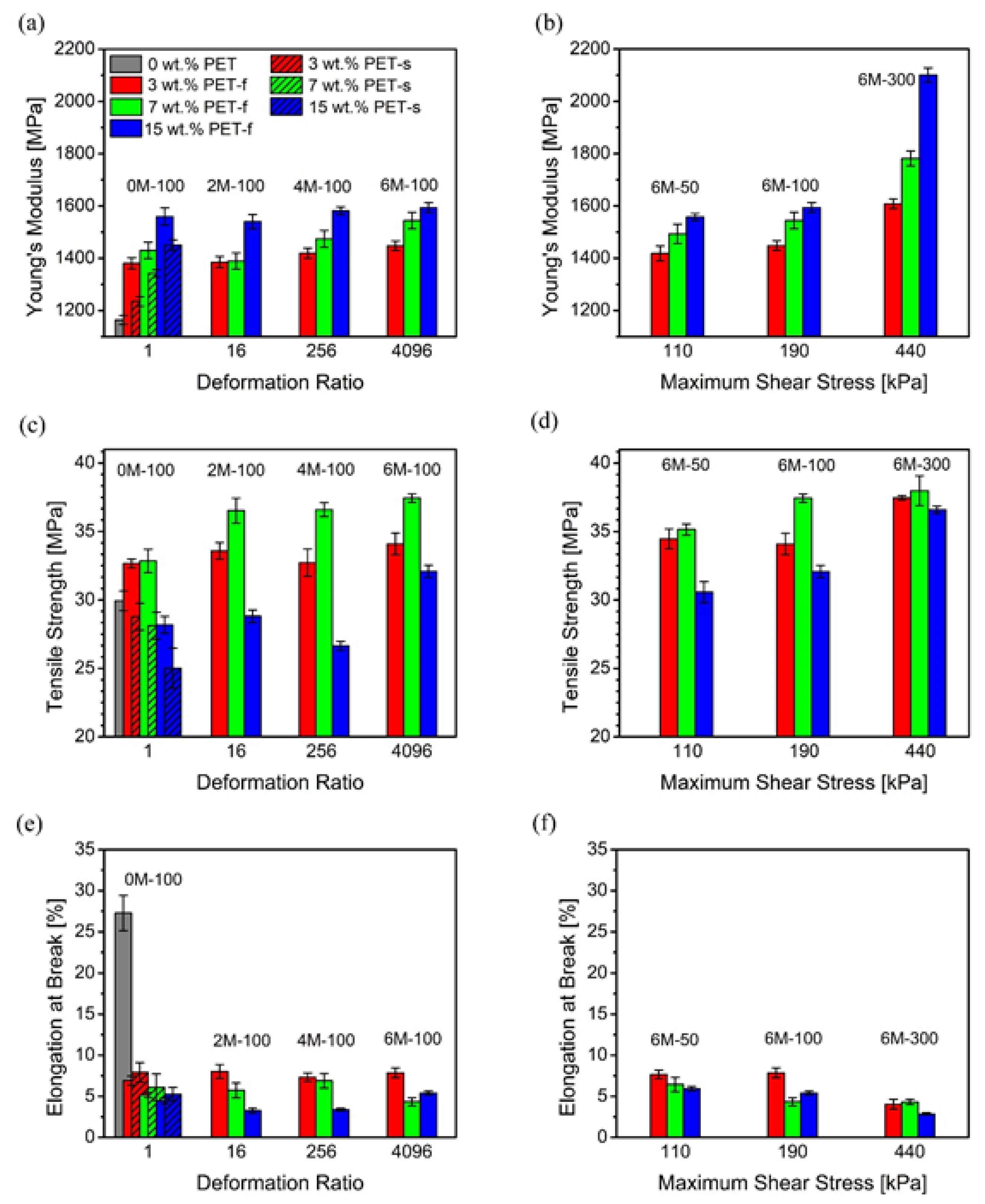

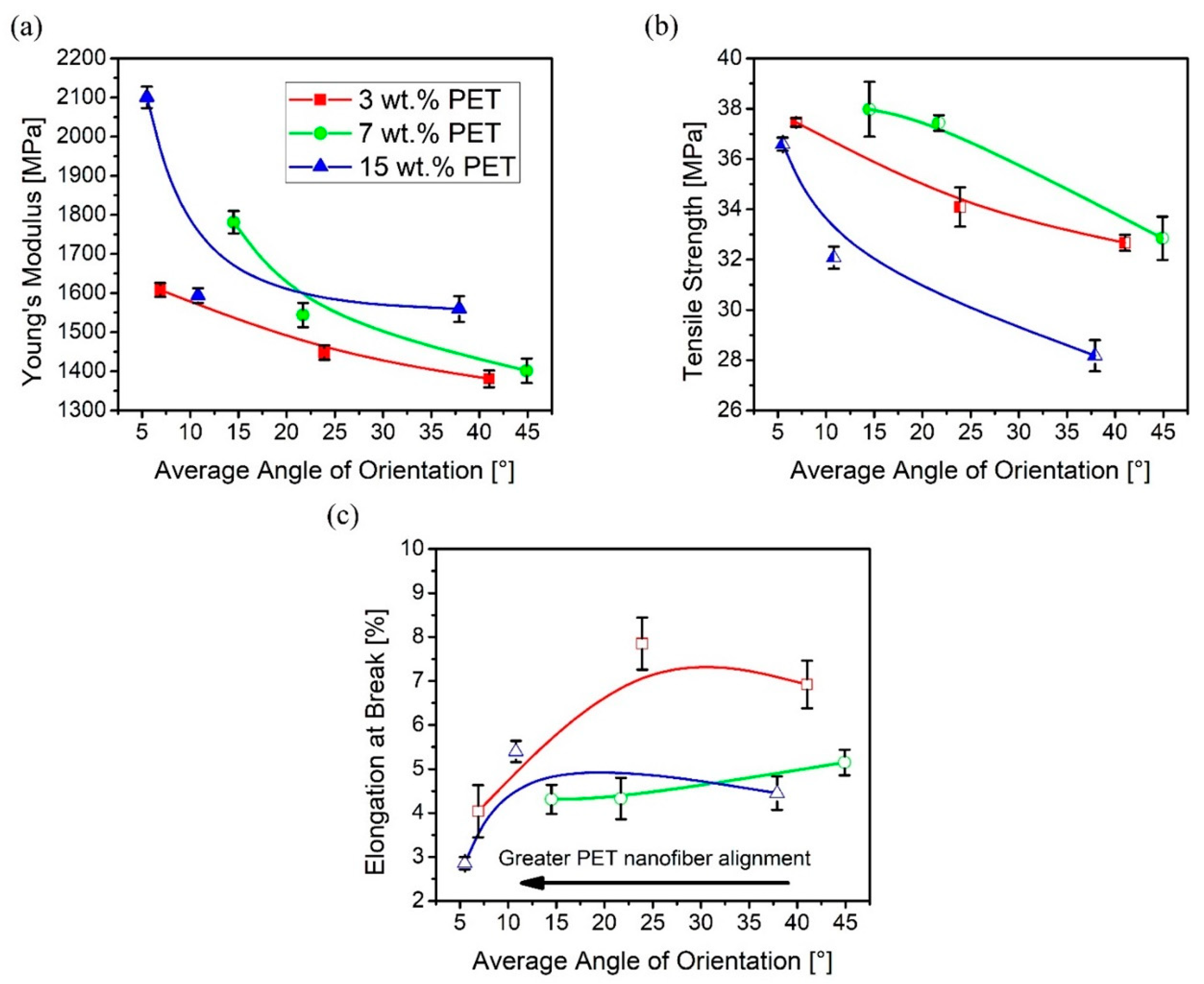

3.3. Tensile Testing

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tangirala, R.; Baer, E.; Hiltner, A.; Weder, C. Photopatternable reflective films produced by nanolayer extrusion. Adv. Funct. Mater. 2004, 14, 595–604. [Google Scholar] [CrossRef]

- Jin, Y.; Tai, H.; Hiltner, A.; Baer, E.; Shirk, J.S. New class of bioinspired lenses with a gradient refractive index. J. Appl. Polym. Sci. 2007, 103, 1834–1841. [Google Scholar] [CrossRef]

- Beadie, G.; Shirk, J.S.; Rosenburg, A.; Lane, P.A.; Fleet, E.; Kamdar, A.R.; Ponting, M.; Kazmierczak, T.; Yang, Y.; Hiltner, A.; et al. Optical properties of a bio-inspired gradient refractive index polymer lens. J. Opt. Soc. Am. 2008, 16, 11540–11547. [Google Scholar]

- Han, T.; Wang, T.; Xiong, Y.; Li, J.; Guo, S.; Chen, G. Light-weight poly (vinyl chloride)-based soundproofing composites with foam/film alternating multilayered structure. Compos. Part A Appl. Sci. Manuf. 2015, 78, 27–34. [Google Scholar] [CrossRef]

- Sun, X.; Liang, W. Cellular structure control and sound absorption of polyolefin microlayer sheets. Compos. Part B Eng. 2016, 87, 21–26. [Google Scholar] [CrossRef]

- Carr, J.M.; Langhe, D.S.; Ponting, M.T.; Hiltner, A.; Baer, E. Confined crystallization in polymer nanolayered films: A review. J. Mater. Res. 2012, 27, 1326–1350. [Google Scholar] [CrossRef] [Green Version]

- Thellen, C.; Schirmer, S.; Ratto, J.A.; Finnigan, B.; Schmidt, D. Co-extrusion of multilayer poly (m-xylylene adipimide) nanocomposite films for high oxygen barrier packaging applications. J. Membr. Sci. 2009, 340, 45–51. [Google Scholar] [CrossRef]

- Zhang, G.; Lee, P.C.; Jenkins, S.; Dooley, J.; Baer, E. The effect of confined crystallization on high-density poly (ethylene) lamellar morphology. Polymer 2014, 55, 663–672. [Google Scholar] [CrossRef]

- Zhang, G.; Lee, P.C.; Jenkins, S.; Dooley, J.; Baer, E. The effect of confined spherulite morphology of high-density polyethylene and polypropylene on their gas barrier properties in multilayered film systems. Polymer 2014, 55, 4521–4530. [Google Scholar] [CrossRef]

- Langhe, D.S.; Hiltner, A.; Baer, E. Melt crystallization of syndiotactic polypropylene in nanolayer confinement impacting structure. Polymer 2011, 52, 5879–5889. [Google Scholar] [CrossRef]

- Decker, J.J.; Meyers, K.P.; Paul, D.R.; Schiraldi, D.A.; Hiltner, A.; Nazarenko, S. Polyethylene-based nanocomposites containing organoclay: A new approach to enhance gas barrier via multilayer coextrusion and interdiffusion. Polymer 2015, 61, 42–54. [Google Scholar] [CrossRef]

- Wang, H.; Keum, J.K.; Hiltner, A.; Baer, E.; Freeman, B.; Rozanski, A.; Galeski, A. Confined crystallization of polyethylene oxide in nanolayer assemblies. AAAS 2009, 323, 757–760. [Google Scholar] [CrossRef] [PubMed]

- Levitt, L.; Macosko, C.W.; Schweizer, T.; Meissner, J. Extensional rheometry of polymer multilayers: A sensitive probe of interfaces. J. Rheol. 1997, 41, 671–685. [Google Scholar] [CrossRef]

- Lu, B.; Alcouffe, P.; Sudre, G.; Pruvost, S.; Serghei, A.; Liu, C.; Maazouz, A.; Lamnawar, K. Unveiling the Effects of in situ layer—Layer interfacial reaction in multilayer polymer films via multilayered assembly: From microlayers to nanolayers. Macromol. Mater. Eng. 2020, 105, 1–16. [Google Scholar] [CrossRef]

- Jordan, A.M.; Korley, L.T.J. Toward a tunable fibrous scaffold: Structural development during uniaxial drawing of coextruded poly(ε-caprolactone) fibers. Macromolecules 2015, 48, 2614–2627. [Google Scholar] [CrossRef]

- Wang, J.; Olah, A.; Baer, E. Continuous micro-/nano-fiber composites of polyamide 6/polyethylene oxide with tunable mechanical properties using a novel co-extrusion technique. Polymer 2016, 82, 166–171. [Google Scholar] [CrossRef]

- Wang, J.; Langhe, D.; Ponting, M.; Wnek, G.E.; Korley, L.T.J.; Baer, E. Manufacturing of polymer continuous nanofibers using a novel co-extrusion and multiplication technique. Polymer 2014, 55, 673–685. [Google Scholar] [CrossRef]

- Lenart, W.R.; Jang, K.; Jordan, A.M.; Baer, E.; Korley, L.T.J. Mechanically tunable dual-component polyolefin fiber mats via two-dimensional multilayer coextrusion. Polymer 2016, 103, 328–336. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Wu, H.; Guo, S. Realizing simultaneous reinforcement and toughening in polypropylene based on polypropylene/elastomer via control of the crystalline structure and dispersed phase morphology. R. Soc. Chem. 2016, 6, 1313–1323. [Google Scholar] [CrossRef]

- Zhang, X.; Wu, H.; Guo, S.; Wang, Y. Reinforced thermal conductivity and mechanical properties of in situ microfibrillar composites through multistage stretching extrusion. Polym. Compos. 2017, 38, 2663–2669. [Google Scholar] [CrossRef]

- Li, C.; Jiang, T.; Wang, J.; Wu, H.; Guo, S.; Zhang, X.; Li, J.; Shen, J.; Chen, R.; Xiong, Y. In situ formation of microfibrillar crystalline superstructure: Achieving high-performance polylactide. ACS Appl. Mater. Interfaces 2017, 9, 25818–25829. [Google Scholar] [CrossRef]

- Dong, J.; Huang, A.; Shun, J.; Wei, L.; Luo, S.; Qin, S. Effect of draw ratio on the morphologies and properties of in situ microfibrillar POE/PTT composites. Polym. Compos. 2019, 40, 629–637. [Google Scholar] [CrossRef]

- He, G.; Li, J.; Zhang, F.; Wang, C.; Guo, S. Effect of multistage tensile extrusion induced fiber orientation on fracture characteristics of high density polyethylene/short glass fiber composites. Compos. Sci. Technol. 2014, 100, 1–9. [Google Scholar] [CrossRef]

- Shen, J.; Wang, M.; Li, J.; Guo, S. In situ fibrillation of polyamide 6 in isotactic polypropylene occurring in the laminating-multiplying die. Polym. Adv. Technol. 2011, 22, 237–245. [Google Scholar] [CrossRef]

- Dong, J.; Qi, Y.; Sun, J.; Wei, L.; Qin, S. In situ fibrillation of poly (trimethylene terephthalate) in polyolefin elastomer through multistage stretching extrusion. J. Appl. Polym. Sci. 2016, 133, 1–9. [Google Scholar] [CrossRef]

- Luo, S.; Sun, J.; Huang, A.; Zhang, T.; Wei, L.; Qin, S. In situ fibrillation of isotactic polypropylene in ethylene-vinyl acetate: Toward enhanced rheological and mechanical properties. J. Appl. Polym. Sci 2019, 136, 1–8. [Google Scholar] [CrossRef]

- Sun, X.; Yu, Q.; Shen, J.; Gao, S.; Li, J.; Guo, S. In situ microfibrillar morphology and properties of polypropylene/polyamide/carbon black composites prepared through multistage stretching extrusion. J. Mater. Sci. 2013, 48, 1214–1224. [Google Scholar] [CrossRef]

- Wang, J.; Zhang, X.; Zhao, T.; Shen, L.; Wu, H.; Guo, S. Morphologies and properties of polycarbonate/polyethylene in situ microfibrillar composites prepared through multistage stretching extrusion. J. Appl. Polym. Sci. 2014, 131, 1–8. [Google Scholar]

- Fakirov, S.; Shields, R.J.; Bhattacharyya, D. Fibrillar polymer–polymer composites: Morphology, properties and applications. J. Mater. Sci. 2008, 43, 6758–6770. [Google Scholar]

- Kakroodi, A.R.; Kazemi, Y.; Ding, W.; Ameli, A.; Park, C.B. Poly(lactic acid)-based in situ microfibrillar composites with enhanced crystallization kinetics, mechanical properties, rheological behavior, and foaming ability. Biomacromolecules 2015, 16, 3925–3935. [Google Scholar] [CrossRef]

- Jurczuk, K.; Galeski, A.; Morawiec, J. Effect of poly (tetrafluoroethylene) nanofibers on foaming behavior of linear and branched polypropylenes. Eur. Polym. J. 2017, 88, 171–182. [Google Scholar] [CrossRef]

- Zhao, C.; Mark, L.H.; Chang, E.; Raymond, K.M.; Lee, P.C.; Park, C.B. Highly expanded, highly insulating polypropylene/polybutylene-terephthalate composite foams manufactured by nano- fibrillation technology. Mater. Des. 2020, 188, 1–11. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Wang, G.; Zhao, H.; Lin, J.; Zhao, G.; Park, C.B. Strong and super thermally insulating in-situ nanofibrillar PLA/PET composite foam fabricated by high-pressure microcellular injection molding. Chem. Eng. J. 2020, 390. [Google Scholar] [CrossRef]

- Leung, F.K.P.; Cheung, W.L.; Lin, X.D.; Jia, D.; Chung, C.Y. Poly (ethylene terephthalate)/polypropylene microfibrillar composites. III. Structural development of poly (ethylene terephthalate) microfibers. J. Appl. Polym. Sci. 2007, 104, 137–146. [Google Scholar] [CrossRef]

- Yi, X.; Xu, L.; Wang, Y.L.; Zhong, G.J.; Ji, X.; Li, Z.M. Morphology and properties of isotactic polypropylene / poly (ethylene terephthalate) in situ microfibrillar reinforced blends: Influence of viscosity ratio. Eur. Polym. J. 2010, 46, 719–730. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Lin, R.J.T.; Fuchs, C.; Friedrich, K. Contribution of coalescence to microfibril formation in polymer blends during cold drawing. J. Macromol. Sci. 2007, 46, 183–194. [Google Scholar] [CrossRef]

- Rizvi, A.; Park, C.B. Dispersed polypropylene fibrils improve the foaming ability of a polyethylene matrix. Polymer 2014, 55, 4199–4205. [Google Scholar] [CrossRef]

- Zhao, C.; Mark, L.H.; Alshrah, M.; Soltani, I.; Lee, P.C.; Park, C.B. Challenge in manufacturing nanofibril composites with low matrix viscosity: Effects of matrix viscosity and fibril content. Eur. Polym. J. 2019, 121. [Google Scholar] [CrossRef]

- Rizvi, A.; Andalib, Z.K.M.; Park, C.B. Fiber-spun polypropylene/polyethylene terephthalate microfibrillar composites with enhanced tensile and rheological properties and foaming ability. Polymer 2017, 110, 139–148. [Google Scholar] [CrossRef]

- Codou, A.; Anstey, A.; Misra, M.; Mohanty, A.K. Novel compatibilized nylon-based ternary blends with polypropylene and poly (lactic acid): Morphology evolution and rheological behaviour. R. Soc. Chem. 2018, 8, 15709–15724. [Google Scholar] [CrossRef] [Green Version]

- Zhang, J.; Lodge, T.P.; Macosko, C.W. Interfacial slip reduces polymer-polymer adhesion during coextrusion. J. Rheol. 2006, 50, 41–57. [Google Scholar] [CrossRef]

- Lee, P.C.; Park, H.E.; Morse, D.C.; Macosko, C.W. Polymer-polymer interfacial slip in multilayered films. J. Rheol. 2009, 53, 893–915. [Google Scholar] [CrossRef]

- Park, H.E.; Lee, P.C.; Macosko, C.W. Polymer-polymer interfacial slip by direct visualization and by stress reduction. J. Rheol. 2010, 54, 1207–1218. [Google Scholar]

- Ramezani, A.; Kazemi, Y.; Nofar, M.; Park, C.B. Tailoring poly (lactic acid) for packaging applications via the production of fully bio-based in situ microfibrillar composite films. Chem. Eng. J. 2017, 308, 772–782. [Google Scholar]

| RPM | 0 Multipliers | 2 Multipliers | 4 Multipliers | 6 Multipliers | |

|---|---|---|---|---|---|

| 3 wt.% PET | 50 | 3%-6M-50 | |||

| 100 | 3%-0M-100 | 3%-2M-100 | 3%-4M-100 | 3%-6M-100 | |

| 300 | 3%-6M-300 | ||||

| 7 wt.% PET | 50 | 7%-6M-50 | |||

| 100 | 7%-0M-100 | 7%-2M-100 | 7%-4M-100 | 7%-6M-100 | |

| 300 | 7%-6M-300 | ||||

| 15 wt.% PET | 50 | 15%-6M-50 | |||

| 100 | 15%-0M-100 | 15%-2M-100 | 15%-4M-100 | 15%-6M-100 | |

| 300 | 15%-6M-300 |

| PET Concentration | Average Diameter (µm) | Standard Deviation (µm) |

|---|---|---|

| 3 wt.%-sph | 2.78 | 0.77 |

| 3 wt.%-fib1 | 0.14 | 0.06 |

| 3 wt.%-fib2 | 0.13 | 0.04 |

| 7 wt.%-sph | 5.25 | 1.59 |

| 7 wt.%-fib1 | 0.14 | 0.03 |

| 7 wt.%-fib2 | 0.14 | 0.03 |

| 15 wt.%-sph | 6.21 | 1.87 |

| 15 wt.%-fib1 | 0.19 | 0.05 |

| 15 wt.%-fib2 | 0.19 | 0.04 |

| PET Concentration | Processing Condition | Label | Average Orientation Angle (°) | Standard Deviation |

|---|---|---|---|---|

| 3 wt.% | 0M-100 | A1 | 41.0 | 27.2 |

| 6M-100 | A2 | 23.9 | 21.4 | |

| 6M-300 | A3 | 6.9 | 4.3 | |

| 7 wt.% | 0M-100 | B1 | 44.9 | 26.4 |

| 6M-100 | B2 | 21.7 | 18.2 | |

| 6M-300 | B3 | 14.5 | 7.0 | |

| 15 wt.% | 0M-100 | C1 | 37.9 | 24.0 |

| 6M-100 | C2 | 10.8 | 9.1 | |

| 6M-300 | C3 | 5.5 | 3.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Embabi, M.; Kweon, M.S.; Chen, Z.; Lee, P.C. Tunable Tensile Properties of Polypropylene and Polyethylene Terephthalate Fibrillar Blends through Micro-/Nanolayered Extrusion Technology. Polymers 2020, 12, 2585. https://doi.org/10.3390/polym12112585

Embabi M, Kweon MS, Chen Z, Lee PC. Tunable Tensile Properties of Polypropylene and Polyethylene Terephthalate Fibrillar Blends through Micro-/Nanolayered Extrusion Technology. Polymers. 2020; 12(11):2585. https://doi.org/10.3390/polym12112585

Chicago/Turabian StyleEmbabi, Mahmoud, Mu Sung Kweon, Zuolong Chen, and Patrick C. Lee. 2020. "Tunable Tensile Properties of Polypropylene and Polyethylene Terephthalate Fibrillar Blends through Micro-/Nanolayered Extrusion Technology" Polymers 12, no. 11: 2585. https://doi.org/10.3390/polym12112585

APA StyleEmbabi, M., Kweon, M. S., Chen, Z., & Lee, P. C. (2020). Tunable Tensile Properties of Polypropylene and Polyethylene Terephthalate Fibrillar Blends through Micro-/Nanolayered Extrusion Technology. Polymers, 12(11), 2585. https://doi.org/10.3390/polym12112585